Ultrasonic milk analyser

Milkotronic Ltd

LACTOSCAN SA

MILK ANALYZER

LCD display – 4 lines x 16 characters

Operation manual

Operation manual 11.04.19 1/110

Ultrasonic milk analyser

Switching Adapter

• Input: 100 - 240 V ~1.6 A max.

50-60 Hz

• Output: +12 V

3 А min.

• Output power: 36 - 42 W

Measurement modes

• cow milk

• sheep milk

• UHT milk

• goat milk

• buffalo milk

• cream

• whey

• recovered milk

• other /pasteurized milk/

CAUTION!

Keep the switching adapter dry!

Please, read and follow strictly all the instructions in the manual.

Due to continuous improvement in the device, information contained in this

manual is subject to change without notice. Contact the company-producer

for revisions and corrections

4, Narodni Buditeli Str.

8900 Nova Zagora

BULGARIA

Phone/Fax: + 359 457 67082

e-mail: office@lactoscan.com

www.lactoscan.com

www.milkotronic.com

Operation manual 11.04.19 2/110

Ultrasonic milk analyser

SAFETY INSTRUCTIONS

1. Read this manual carefully and make sure that you understand all the

instructions.

2. For safety purposes the device is equipped with grounded power

cable. If there is no grounded electrical outlet where the device will

be used, please, install suc h be f ore using the device.

3. Place the device on leveled and stable plate. In case it falls or is

severely shocked it may be damaged.

4. Connect to the electri cal network in such a wa y that the power cable

to stay away from the side for accessing the device and not to be

stepped on.

5. Every time before cleani ng the device swit ch it off and unplug it from

the electrical outlet. The device has to remain unplugged till the

cleaning completion.

6. Do not disassemble the unit in order to avoid possible electrical

shock. In case of malfunct ion contact your local dealer.

7. Handle the liquids the device works with carefully, following all the

instructions for their preparation.

8. Place the switching adaptor in such a way as to be protected from

overflow and spillage of liquids.

Operation manual 11.04.19 3/110

Ultrasonic milk analyser

№

Description

Item №

pcs

1.

Ultrasonic portable milk analyzer

LSSA001

1

50 sec

30 sec

Operation

manual

LSSA00

2.

Plastic sample holder

LSSA003

1

3.

Spare Pipes

LSSA004

2

4.

12 V DC Power Supply Cable

LSSA005

2

5.

Alkaline cleaning solution Lactodaily

100 g

1

6.

Acidic cleaning solution Lactoweekly

100 g

1

№

Description

not included in the set (may be

Item №

pcs

7.

RS232 Interface Cable - Analyser-IBM PC

LSSA006

8.

Service Pack - CD

LSSA007

9.

pH measuring system

LSSA009

1

10.

pH probe with cable and holder

1

11.

Buffer solution Ph 60 ml

(pH7.00±0.01/20˚C)

LSSA011

1

12.

Buffer solution pH 60 ml

(pH4.00±0.01/20˚C)

LSSA012

1

13.

Milk conductivity measuring system

LSSA013

1

14.

Buffer solution conductivity 50 ml (5.02

(±5%) mS/cm (18±0.1˚C)

LSSA014

1

15.

Real time clock

LSSA015

1

16.

High-fat measuring function

LSSA016

1

17.

ECS POS Serial Printer

LSSA017

1

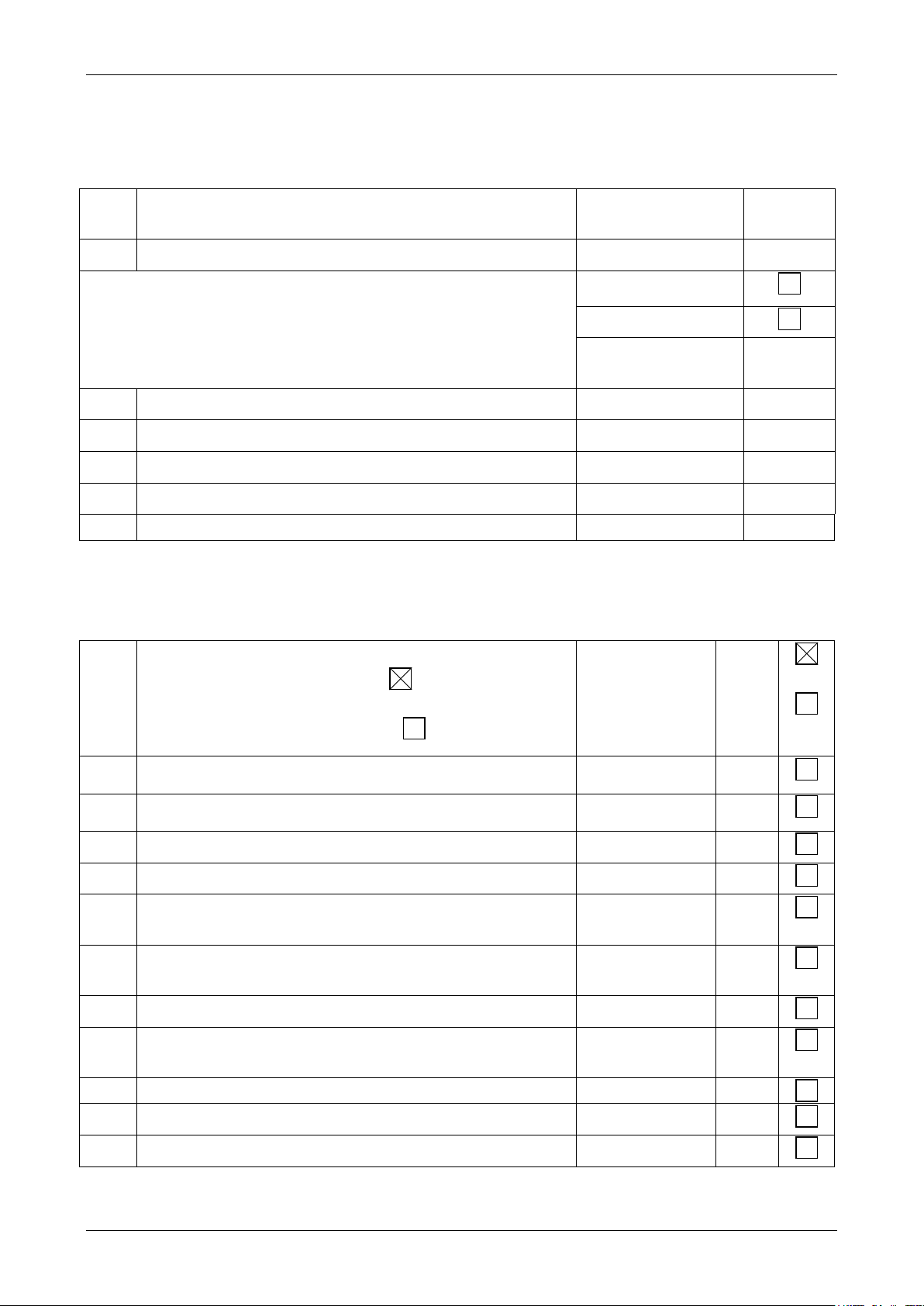

PARTS AND ACCESSORIES

In the table below the standard delivery configuration of the milk analyzer is

listed:

1 sample measurement time

2

In the table below the milk analyzer spares and accessories, which are

delivered on customers request are listed:

a) included in the set:

b)

additionally bought):

LSSA010

/

Operation manual 11.04.19 4/110

Ultrasonic milk analyser

18.

12 V Serial Printer Power Supply Cable

LSSA018

1

19.

RS232 Interface Cable - Milk Analyser –

Serial Printer

LSSA019

1

20.

Carrying case

LSSA020

1

21.

Plug type

1

1

22.

Spare O-ring for the pH probe

1

23.

USB flash drive (slot)

1

Operation manual 11.04.19 5/110

Ultrasonic milk analyser

1. FUNCTION

The function of the milk a na lyzer is to make quick analysis of mil k on f a t

(FAT), non-fat solids (SNF), proteins, lactose and water content

percentages, temperature (

conductivity as well as density of one and the same sample directly

after milking, at collecting and during processing.

o

С), pH, freezing point, salts, total solids,

Operation manual 11.04.19 6/110

Ultrasonic milk analyser

2. TECHNICAL PARAMETERS

2.1. Working modes characteristics:

The program of the milk analyzer has four working modes.

2.1.1. Measurement mode milk / dairy product – first type

2.1.2. Measurement mode milk / dairy product – second type

2.1.3. Measurement mode UHT milk / dairy product – third type

These modes have been calibrated on customers’ request for 3 milk types

from the following: cow, sheep, UHT, buffalo, goat, camel milk, cream, ice

cream mixtures, whey, recovered milk, etc. before leaving the production

facilities and the text on the display will be for the corresponding types, as is

indicated on page 2 Measurement modes.

2.1.4. Cleaning

2.1.4.1. Current

2.1.4.2. Final

Note:

For devices with a 5 button keypad on the front panel by pressing the extra

buttons, you can run the following commands:

Pressing the button labeled A - start re-printing the results

Pressing the button labeled B - start of flushing (2.1.4.)

These commands are possible when the unit is in Idle mode, i.e. expecting

command for measuring sample.

Operation manual 11.04.19 7/110

Ultrasonic milk analyser

Fat ………………........... .. ........

…………..from 0.01% to 25% (45%*)

SNF ………………………………

...…………………....from 3% to 40%

Density ** ……………………….

……...…….from 1000 to 1150 kg/m3

Proteins ………………………….

………………………..from 2% to 7%

Lactose ………………………...

…………………from 0.01 % to 20 %

Water content …………………

……………...……..from 0 % to 70 %

Temperature of milk ……………

from 1oC to 40oC (if measurement is

30 sec, then t° is from 15 to 40°)

Freezing point ***.………………

…………..from – 0,400 to – 0,700oC

Salts …………………………….

…...…………...………from 0,4 to 4%

PH*..……………………………...

…………………..………from 0 to 14

Conductivity* ** …………………

……………...…from 3 to 14 [mS/cm]

Total Solids* …………………….

………………………...from 0 to 50 %

Fat …..………………………………..

…...………………….…...± 0.06%

SNF …………………………………..

…………...………….…...± 0.15%

Density ………………………………

………………………..± 0.3 kg/m3

Proteins ……………………………...

……...……………….…...± 0.15%

Lactose ………………………………

.…………………………...± 0.20%

Water content ……………………….

.…………………………….± 3.0%

Temperature of milk ………………..

.………………………………± 1oC

Freezing point………………………..

..……...…………………± 0.005oC

Salts ………………………………...

…..…………...…………...± 0.05%

2.2. Measuring range:

* Option, on customers’ request

** Density data are shown in an abbreviated form. For example 27.3 have to

be understood as 1027.3 kg/m

3

. To determine the milk density, write down

the result from the display and add 1000.

Example: result 21,20; density = 1000 + 21,20 = 1021,2 kg/m

3

The abbreviated form of the density is used also when entering data for

samples in working mode Recalibrate, for example:

If the measured sample density is 1034.5 kg/m3, then in the menu for

entering the samples parameters used for calibration, across the parameter

Den = , you have to enter 34.5.

*** pH and conductivity measurements are optional and are embedded in the

device on customers' request.

**** Please, carefully read Appendix Freezing Point.

2.3. Accuracy:

Operation manual 11.04.19 8/110

Ultrasonic milk analyser

PH…………………………………….

………………………………±0.05

Conductivity....……………………….

……………………………...±0.05

Total solids ………………………….

……………………………± 0.17%

Air temperature…………………………

….…from 10oC to 40oC (43 oC)

Relative humidity ………………………

……………...from 30% to 80%

Power supply …………………………

…………………...220V (110V)

extent of contamination at normal

environmental conditions

…………………….…………..2

2.4 Correct ambient condit ions:

Accuracy is guaranteed in case of normal ambient conditions:

Accuracy values in point 2.3 are in dependence on the correctness of the

corresponding chemical method, used for component content determination.

In point 2.3. are used the following reference methods: Gerber – for fat,

gravimetric – for SNF, Kjeldahl – for protein. The boundary for maximum

variation of repeatability when the power supply voltage is from +10 to – 15%

from the nominal voltage values (220V) have to be no more than 0.8

accuracy according point 2.3. The analyser is used in conditions free of outer

electrical and magnetic fields (except the magnetic field of the Earth) and

vibrations.

2.5. Dimensions: ……………… ……………..240/220/100 mm, mass 3,0 kg

2.6. Continuous working ti m e : ………………………………………non-stop

2.7 Milk sample volume per one measurement: ………..15 cm3 (= 25 ml)

Operation manual 11.04.19 9/110

Ultrasonic milk analyser

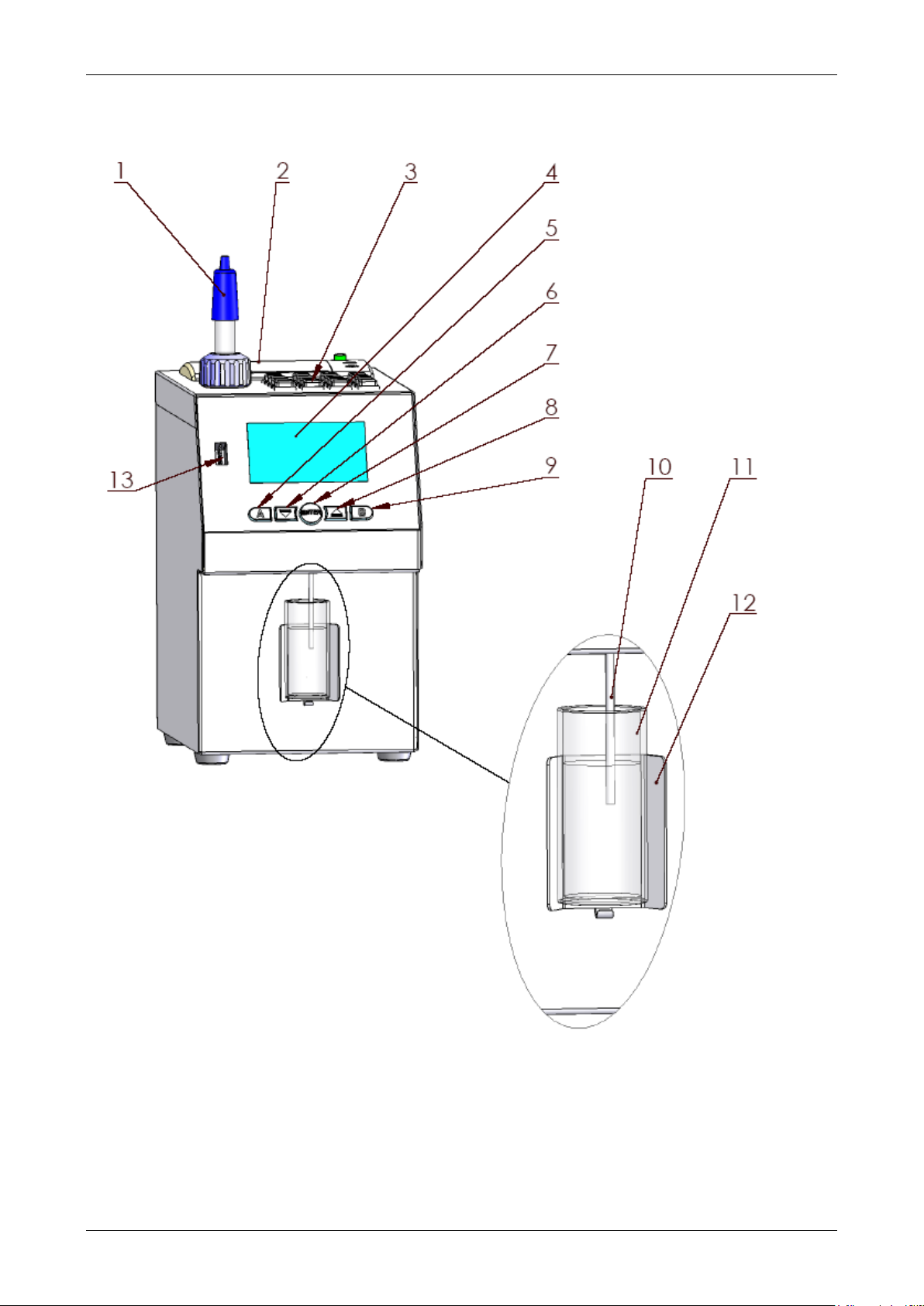

1. pH probe(option)

10. Sample holder

2. printer (option)

11 Input pipe

3. keypad (option)

12. Hanger

4. Display

13. USB f lash drive (slot)

5-9. Buttons

Fig.1 Front panel

Operation manual 11.04.19 10/110

Ultrasonic milk analyser

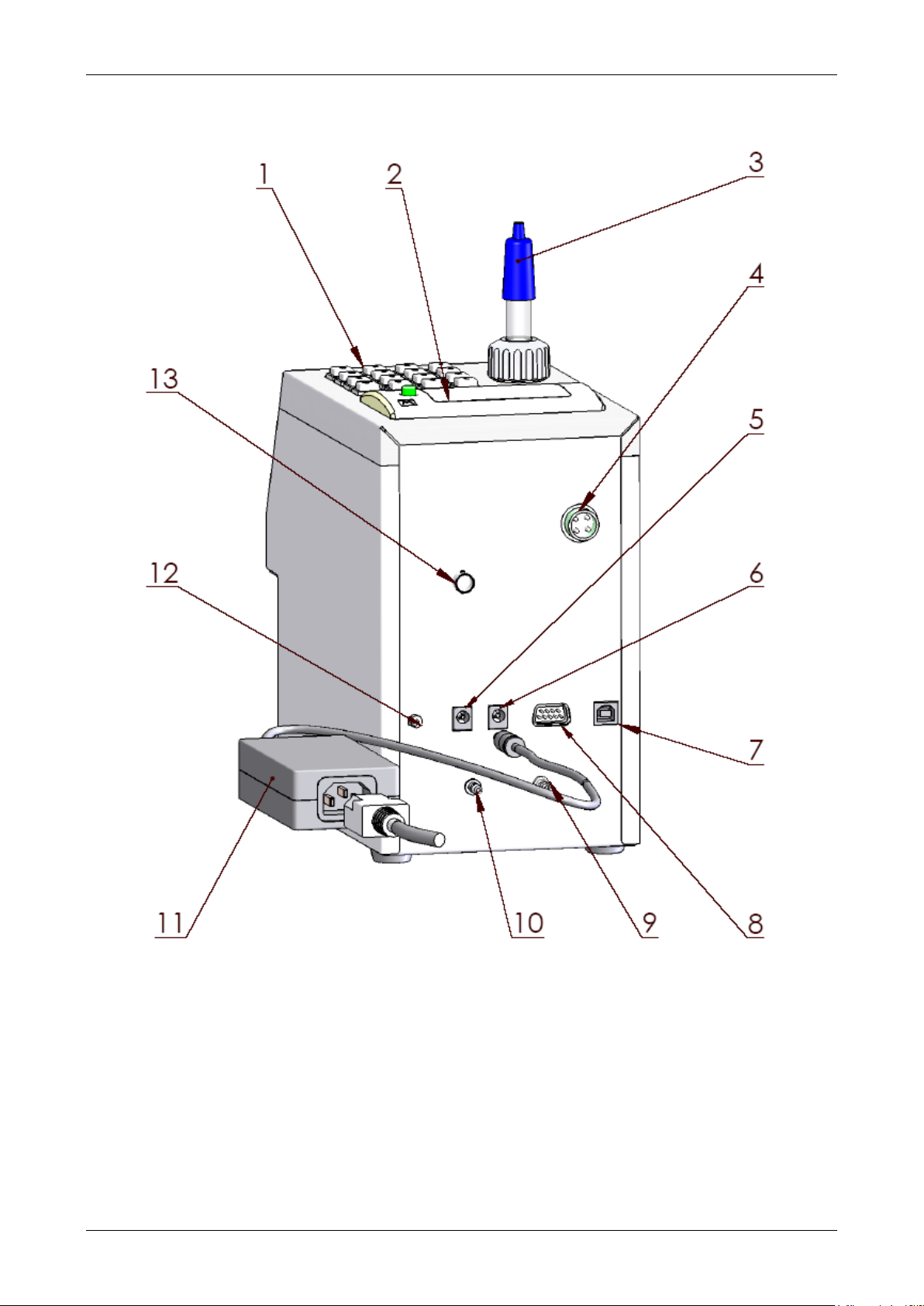

1. keypad (option)

8. Serial printer interface/RS232

2. Printer (option)

9. Waste solution output pipe orifice

3. pH-probe (option)

10. Cleaning solution input pipe orifice

4. Weigh Scale input (option)

11. Switching adapter

5. AC adaptor input

12. Power switch

6. DC Power Supply output

13. pH-meter input (option)

7. USB (option)

fig. 2 Back panel

Operation manual 11.04.19 11/110

Ultrasonic milk analyser

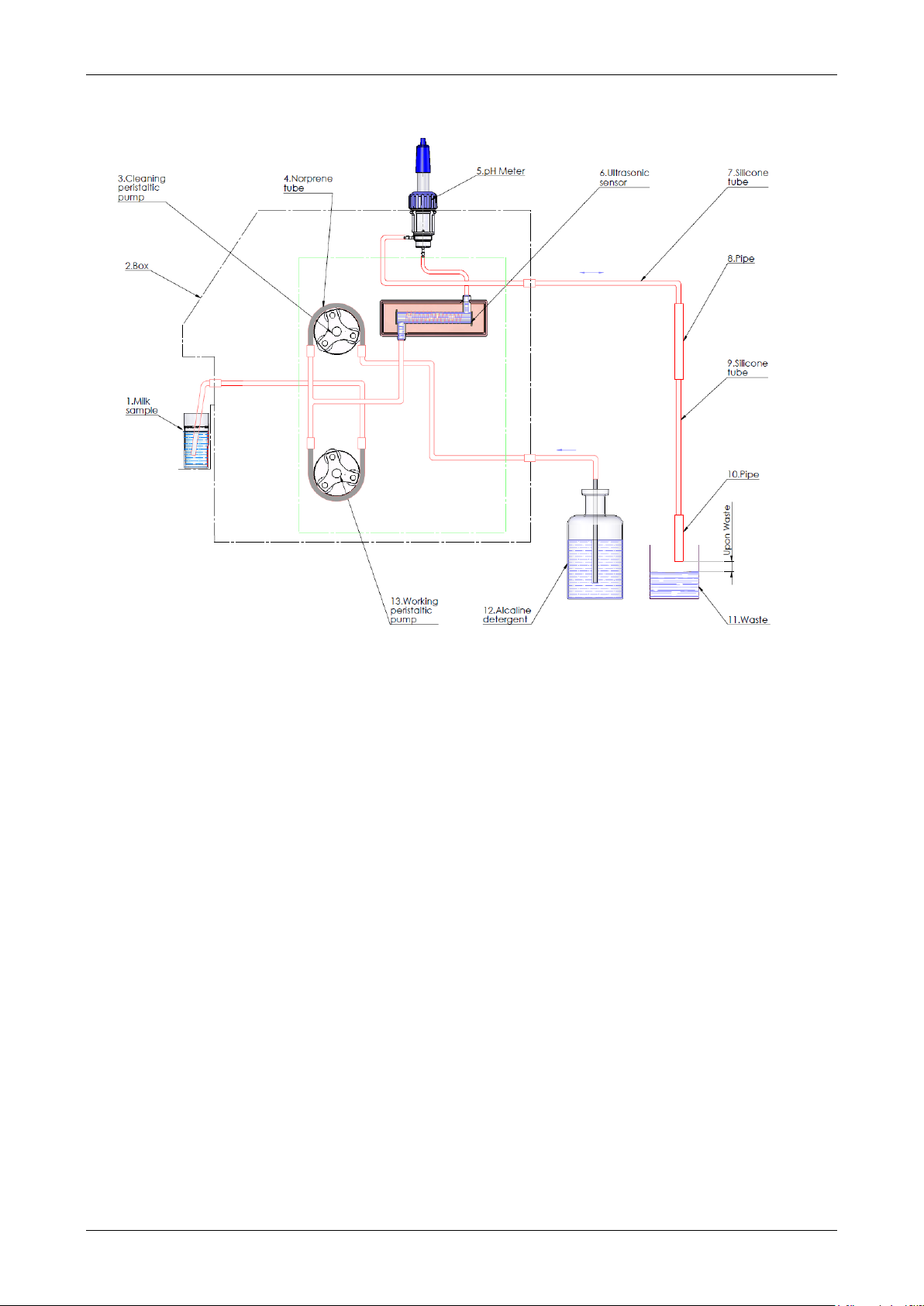

Fig 3 Principle working schem e

Operation manual 11.04.19 12/110

Ultrasonic milk analyser

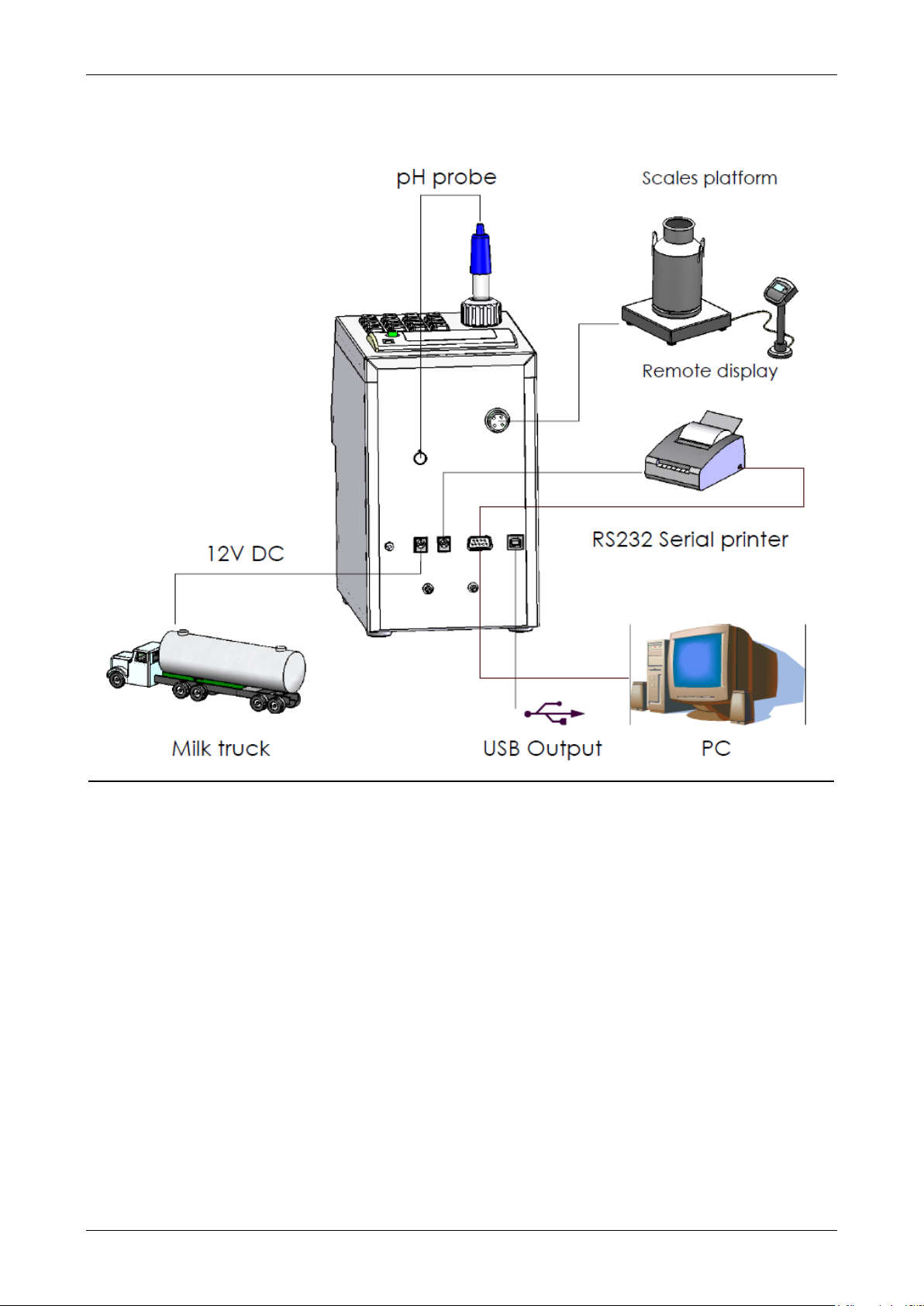

Fig. 4 Connecting peripheral de vi ce s

Operation manual 11.04.19 13/110

Ultrasonic milk analyser

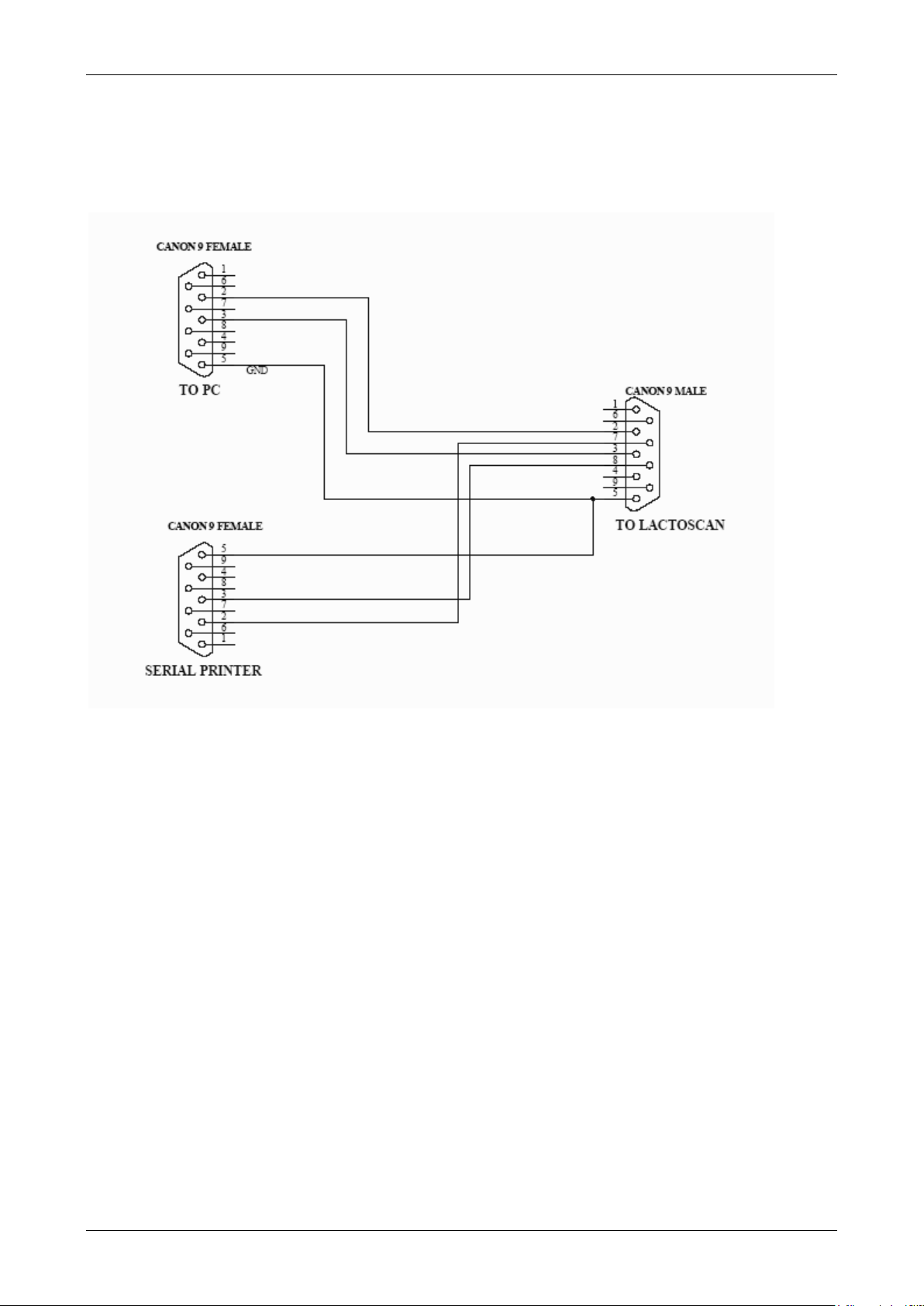

Fig. 5 Cables description

90-1801-0008

RS232 Interface Cable - Milk Analyser – Serial Printer/ IBM PC

The connection of the analyser with other devices via RS232 Interface is

made through the coupling DB9 on the back panel of the device. In it can be

plugged only the cable, supplied by the producer with the analyser (or

produced by the customer as per above scheme). The coupling from the

cable, marked on the scheme with „TO LACTOSCAN” must be plugged in the

computer. If due to some reason is used an external cable USB to RS232

Converter (usually when working with a laptop the customers buy such

cables from the market), it must be plugged in the coupling “TO PC” of the

original cable, not directly in the device.

90-1801-0009

DC 12V Power Supply Milk Analyzer Cable

1. GND

2. No connection

3. No connection

4. 12V DC

There’s an option in the analyser – embedded USB interface (USB to

RS232 Serial Converter) for connection with computer type IBM PC. It is

Operation manual 11.04.19 14/110

Ultrasonic milk analyser

intended for connecting computers from laptop type, which have no RS 232

interface (COM Ports – DB9 Connector). This option may be available

together with the standard RS232 – connector DB9, which always exists in

the analyzers. At one and the same time, connection analyzer – computer,

can be established only through one of the couplings – either only DB9, or

only USB, i.e. analyzer could not be connected at one and the same time,

using one of the interfaces with one and using the other interface to another,

second computer. The coupling for this option (Printer Type) is at the back of

the analyzer, next to the standard RS232 DB9 connector. Ot her USB devices

like

printers, keypads etc COULD NOT be connected to this coupling.

USB interface is based on the element MCP2200 of the company

Microchip Technology Inc. – site:

http://www.microchip.com. For establishing

a connection through this interface a driver has to be installed for MCP2200

in the correspondent computer, which will be connected with the analyzer.

Please, follow the procedure, from the Internet site of the producer:

http://www.microchip.com/wwwproducts/devices.aspx?ddocname=en546923,

by choosing the suitable for your operation system driver.

After installing the driver, choose the СОМ port, which will be used for

the real communication. For Win XP it is done by executing the following

commands: Start -> Settings -> Control panel -> System -> Hardware ->

Device Manager -> Ports (COM and LPT) – Right Click -> Properties -> Port

Settings -> Advanced -> COM Port Number. Choose Number 1 or if another

number is chosen, for example 3, then, when working with the software tools,

in the field COM Port (upper right corner), you have to set the new number of

the port, in this case 3.

Operation manual 11.04.19 15/110

Ultrasonic milk analyser

3. QUALIFICATION OF RAW MILK, THERMALLY TREATED MILK, OTHER DAIRY PRODUCTS AND DERIVATIVES

3.1. Taking samples and preparation for analysis

In order to receive reliable results in qualification of milk, dairy products and

derivatives are needed: precise samples taking; correct samples storing (in

need to be preserved); correct preparation before making measurement. The

rules and requirements for this are described in details in Appendix Milk

sampling.

3.2. Making the measurement.

3.2.1. Preparing the a na lyzer for working mode

3.2.1.1. Put the analyzer on the working place, providing good ventilation and

not in the vicinity of heat providing devices or sources. The temperature in the

premises has to be in the boundaries 10-30

3.2.1.2. Check if the power switch is in "0" position and that the outlet voltage

complies with the voltage indicated on the rating plate of the analyzer.

Connect the switching adapter.

3.2.1.3. Switch on the “POWER” button, which starts the identification

procedure. For a short time the display shows the number of the software

versions, for example:

o

C.

Milkanalyzer xxx

LCD vers xx

MA vers yy

MA ser. N. xxxx

where:

Milkanalyzer xxx is the time for measurement.

LCD vers XX is display control software version.

MA vers YY is the motherboard software version.

MA ser. N. xxxx is the serial number – written on the rear panel of the

analyzer.

Operation manual 11.04.19 16/110

Ultrasonic milk analyser

If in the process of exploitation there is a need to ask a question the

company-producer, you have to send the data, written on the display during

the above described initialization procedure.

3.2.1.4.Till the analyzer is prepared for work (at about 5 minutes) the

following message is written on the display: “Getting ready”. Above pointed

time is in dependence of the environmental temperature and increases with

decreasing the temperature.

3.2.1.5. When the device is ready for work the display shows: “Ready to

start”.

The analyzer is ready to make analysis in mode 1 (normally Cow)

3.2.1.6. If you want to pass to another mode press the button Enter and hold

it pressed. The following message appears on the display:

Release button to

start menu

Release the button Enter. The display shows the possible working modes:

Milk selector

Cal1 – Cow

Cal2 – Sheep

Cal3 – UHT

-----------------------------Cleaning

Final cleaning

Using “up”▲and ”down”▼buttons, choose the working mode and press Enter

in order to start it.

3.2.2. Making analysis

To start measurement:

- pour the preliminary prepared sample in the sample holder of the

analyzer;

- put the sample holder in the recess of the analyzer;

- press the button Enter.

Operation manual 11.04.19 17/110

Ultrasonic milk analyser

The analyzer sucks the milk, makes the measurement and returns the milk in

the waste liquid reservoir. During the measurement the temperature of the

sample is shown on the display.

Ignore the results received immediately after switching on the analyzer and

after measuring distilled water. Make a second measurement with new

portion of the same sample.

3.2.3. Displaying the r e s ult s

3.2.3.1. When the measurement is finished, the sample returns in the

sample-holder and the display shows the results. For example:

Results:

F=ff.ff S=ss.ss

D=dd.dd P=pp.pp

L=ll.ll W=ww.ww

Where:

F= ff.ff - measured FAT in percentage;

S= ss.ss - measured SNF in percentage;

D= dd.dd - measured density in percentage;

P= pp.pp - measured protein in percentage;

L= ll.ll - measured lactose in percentage;

W= ww.ww - measured sample’s added water in percentage;

By pressing the button” Down” ▼ the display shows the second page,

containing the results:

Page 2 Results:

T=tt.tC pH=pp.pp

FP=-0.fff

s=0.sss A=aa.aa

Where:

tt.tC - sample’s temperature;

pp.pp - sample’s pH result – if there is a pH probe connected;

-0.fff - measured sample’s freezing point;

0.sss - measured salts values;

aa.aa - measured total solids

Operation manual 11.04.19 18/110

Ultrasonic milk analyser

By pressing the button”Up” ▲ display shows the third page with results:

Page 3 Results:

L=l.ll

Where:

L= ll.ll - measured Lactose in %;

By pressing the buttons “up”▲ and ”down”▼, the operator has the possibility

to pass from one page result to another.

If the device has an embedded option “Conductivity” and "conductivity

measurement" started, the result is shown on the display, showing the basic

results replacing lactose results in the following way:

C=xx.xx

In this case the Lactose result is shown on a new page - Page 3 Results.

xx.xx is the measured milk sample’s conductivity in [mS/cm]. If the results are

outside the limits for this type of sample (see table from the Appendix

Conductivity measurement), the cursor flashes after the letter С, reminding

that the sample is not correct. On the printout it is printed as !!!.

If the conductiity value is outside measuring range (2-14 mS/cm), the

following message appears on the display:

C=OutRg (Out of Range), and on the printout there isn’t any line with

conductivity value.

3.2.3.2. Write down the results in the form. The results remain on the display

till a new measurement is started. If the analyzer is connected to a computer

or a printer, it sends the data to the computer or prints them.

Operation manual 11.04.19 19/110

Ultrasonic milk analyser

Time: xx:xx:xx

Conduct.(mS/sm)…………..xx.xx

Fig. 6 Printing the results

For more information for the printer see 8.2. Working with Printer.

SCHEME:

PRINTOUT OF THE RESULTS-EXAMPLE

Date: xx:xx:xxxx

Milk analyser 60 SN: xxxxx

Calibration 1 – UHT

Results:

Temp.Sample………………..˚C

Fat………………………..xx.xx%

SNF………………………xx.xx%

Density…………………….xx.xx

Protein…………………...xx.xx%

Lactose…………………..xx.xx%

Added water…………….xx.xx%

pH……………………………..xx

Salts…………………….xx.xx%

Freezing point…………-x.xxx˚C

Deliverer No……………….xxxx

Liters…………………………xx.x

Operation manual 11.04.19 20/110

Ultrasonic milk analyser

94

connected towards

4. CLEANING THE ANALYZER

This procedure prevents gathering milk fat residues and milk stone on the

sensor. The milk stone consists of milk solids, calcium, iron, sulphates,

magnesium, etc. All these substances form layer on the pipe and sensor’s

walls, which leads to deviations in the measurement results and blocking up

the piping.

The company-producer recommends usage of the chemicals, supplied with

the analyser – alkaline and acidic (Lactodaily and Lactoweekly). You may

order them separately or together with the analyser. Try to use only these

chemicals for cleaning the analyser.

In case you missed to order these chemicals, the alternative is to use alkaline

and acidic cleaning solutions for dairy equipment by one the companies,

producing such chemi ca l s , as for example:

http://www.diversey.com

http://www.ecolab.com

http://www.calvatis.com

4.1. Automatic cleaning the analyzer

Analyzer's contamination as a result of the irregular cleaning is the basic

reason for inexactness during measurement. In order to be avoid this, in the

milk analyzers with peristaltic pump is embedded automatic cleaning. For this

purpose the analyzer has to be prepared on the following way:

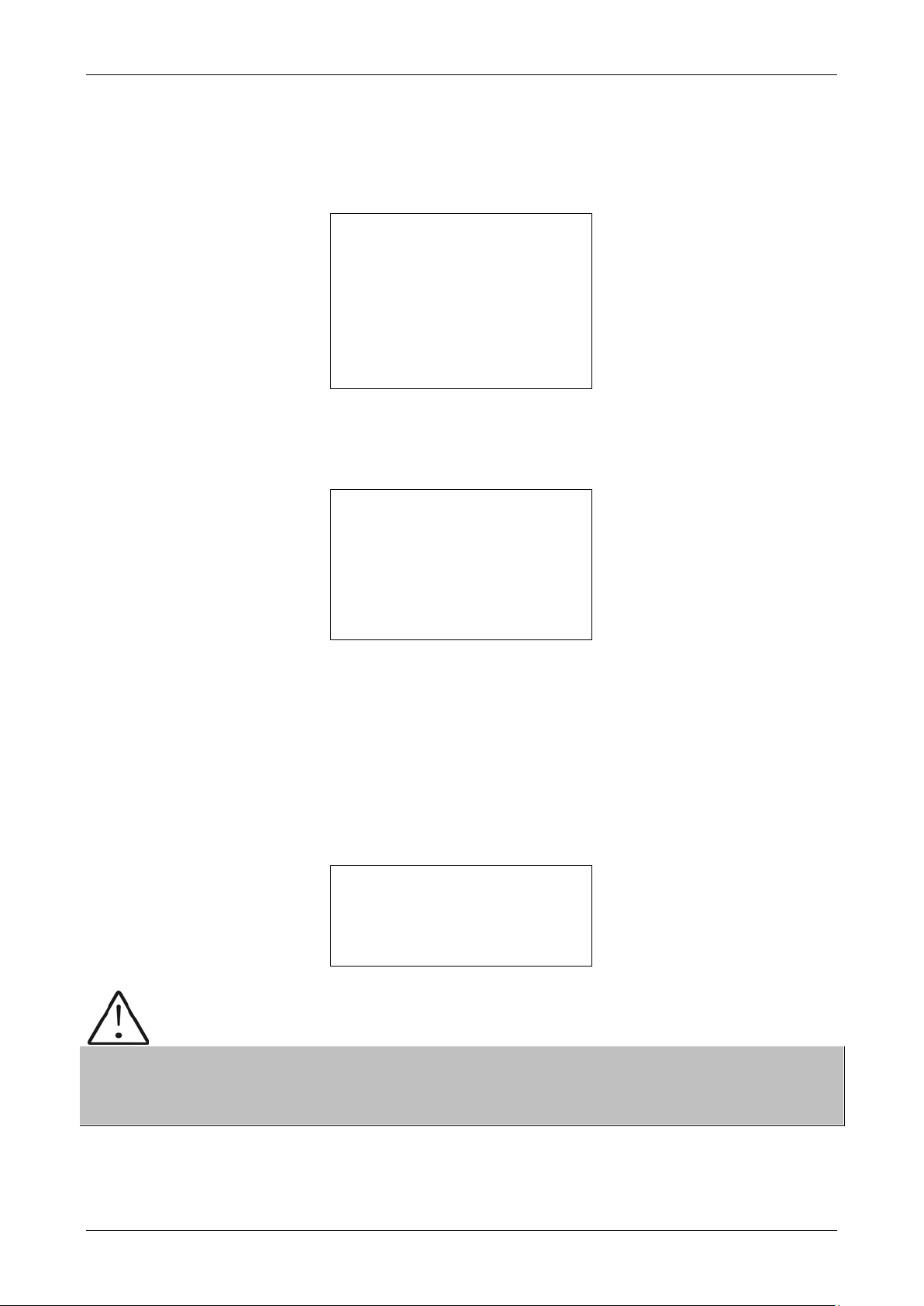

Fig.7 Additional pipe to the input pipe for

automatic cleaning

94 - additional pipe,

input pipe

Please, pay attention to the additional pipe, connected towards the input pipe.

It has to be long enough to suck all the content in the glass, but to be bent in

order not to impede the pump function.

Operation manual 11.04.19 21/110

Ultrasonic milk analyser

Pay attention to the

ith the

cleaning solution has to be

well dipped in the cleaning

solution while the pipe in the

reservoir with the already

used samples and cleaning

solution MUST NOT be

Pay attention to the level of

the cleaning solution in the

reservoir. Add solution when

used samples and used

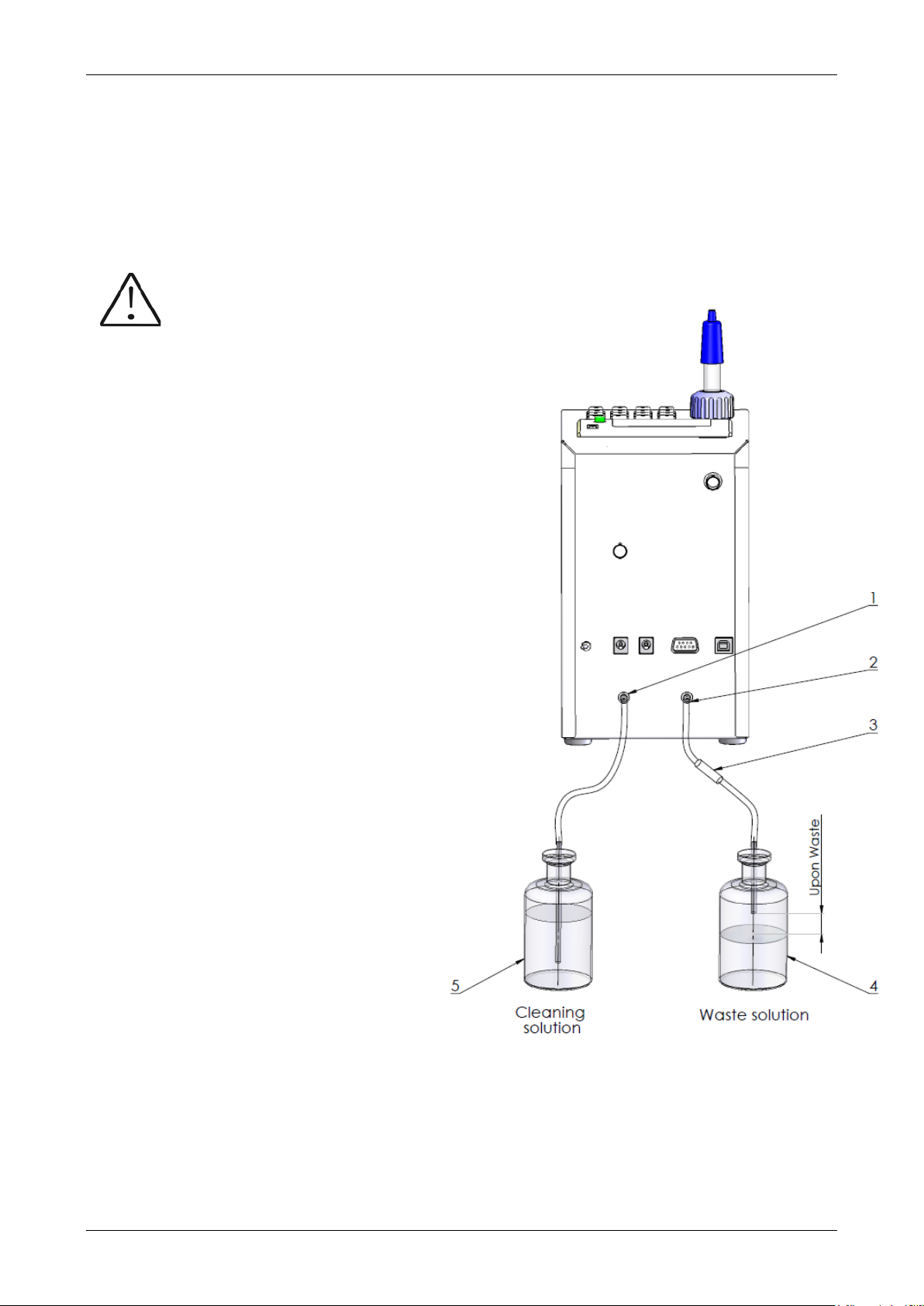

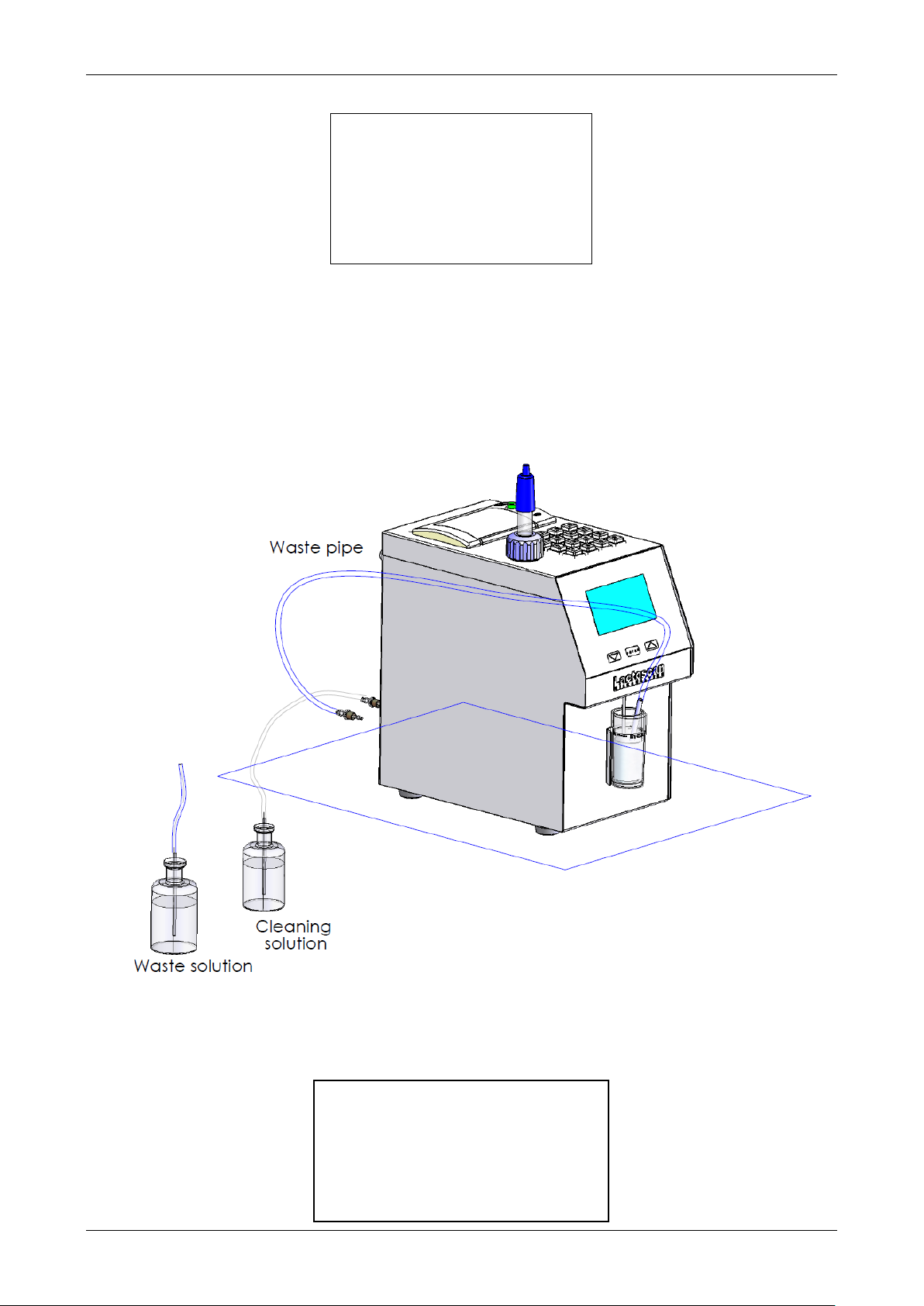

The reservoir with the cleaning solution have to be connected towards the

analyser and outgoing pipe towards reservoir for collecting the measured

samples and used cleaning solution, as is shown on the scheme:

Fig.8 Connecting the re s er voi rs towards the milk analyzer

pipes in both reservoirs. The

pipe in the reservoir w

dipped in the liquid.

the level is below 2/3!

1 - cleaning solution input

2 cleaning solution output

Description of the cleaning procedures

There are two ways of cleaning the analyzer embedded in it – current and

end (final) cleaning.

Operation manual 11.04.19 22/110

:

Ultrasonic milk analyser

4.1.1. Current cleaning.

4.1.1.1. Auto matic start

The current cleaning is made with 3% alkaline solution (for working solution

preparation see 4.2.1.), with which the reservoir for the cleaning solution is

filled in.

It is automatically started, without operator's interference after the set time

intevals elapse

1. 55 min. after switching on the power supply of the analyser,

but idle* work;

2. 15 min. after the last measurement of real milk sample.

*Idle Mode is that part of the standard working mode, when the analyser is

not making measurements. There’s embedded in the analyser system for

measurement of the idle time. The idle time is measured starting from the last

action of the operator. In dependence of it (what the operator last did), are

taken decisions regarding the cleaning.

There are 2 options:

Option A: If the analyser:

1. Was only switched on but was not started in measurement mode,

2. Or the last action was cleaning,

3. Or the last action was measuring sample with very low Fat (similar to

water)

Then the automatic cleaning is started after 55 min.

Option B: If the last thing done with the analyser was measurement of normal

milk sample, the automatic cleaning is started after 15 min.

The display shows the following message and a sound signal is emitted:

Auto clean

started!

Put empty glass

After this the cleaning i s started. The display shows:

Operation manual 11.04.19 23/110

Ultrasonic milk analyser

Cow

Cleaning

Please wait

If there is a glass with sample it is completely emptied and then the analyser

automatically fulfills procedure for sucking the cleaning solution and c rinsing

the analyzer's inner system. In order the input metal pipe to be cleaned out

for a short time a cleaning solution is pumped out for a short time in the

already empty glass. It is filled to the middle and then is sucked back and

poured in the reservoir with the used liquids. If there wasn't glass before the

start of the automatic cleaning and if you do not replace it or put an empty

glass then the cleaning solution will be poured in front of the device.

After the cleaning is finished the displays shows the following:

End of cleaning

After 2 seconds the display shows:

Analyzer ready

Then the analyser is ready for normal measurement.

4.1.1.2. Manual start

The current cleaning may be completed by manual start of the menu

Cleaning. It is used before starting the menu Final Clean. It serves for

cleaning the fats from the measuring tract with alkaline cleaning solution. It is

started using the menu for choosing the working mode of the analyzer. After

the measurement is completes, by continuous pressing the button Enter, the

possible analyser operation modes are shown on the display.

Sheep

UHT

Cleaning

Final Clean

Operation manual 11.04.19 24/110

Ultrasonic milk analyser

By choosing Cleaning the current cleaning is started. The display shows the

following:

Auto clean

started!

Put empty glass

In this way the current cleaning is started. The procedure and operator’s

actions are described above.

Do not switch off the device at the end of the working day before the

automatic cleaning procedure is completed. If it is not automatically cleaned

and there is not a possibility to wait starting the automatic cleaning, then start

manually the cleaning procedure with alkaline cleaning solution and if it is

necessary with acidic cleaning solution as it is described below.

4.1.2. End (final) cleaning.

4.1.2.1. Final cleaning.

It is done with 3% acidic cleaning detergent (for working solution preparation

see 4.2.2.). It is done daily. Serves for cleaning the protein deposits from the

measuring system of the analyser, which were not removed during work with

the alkaline cleaning solution and removing milk stone layers.

Do not use chemicals, which are not intended for milking equipment and

vessels in dairy industry. Pay particular attention to the acidic cleaning

solution concentration. The higher concentration may damage the measuring

sensor.

Always before the final acidic cleaning rinse the device with alkaline cleaning

solution by manual starting if it was not already automatically cleaned. It is

necessary to be done in order to remove the milk residues which could react

with the acidic cleaning solution.

Do not forget to rinse with clean water!

Operation manual 11.04.19 25/110

Ultrasonic milk analyser

It is started using the working modes menu. After the measurement is

completed, by pressing and holding pressed the button Enter, the display

shows the possible working modes of the analyser.

Cow

Sheep

UHT

Cleaning

Final Clean

1. Choose Final Clean. After choosing the final cleaning, the following

message appears on the display:

Put filled with

Water glass

and press Enter

to Continue

2. Put a glass filled with water.

3. The hose from the Waste pipe has to be placed in the vessel for waste

liquids.

4. Press the button Enter in order to continue the procedure. Then the

following message appears on the display:

Cleaning

Please wait

Do not miss to clean with water because the residues from the alkaline

cleaning solution could react with the acidic solution, which will lead to gas

and sediment formation.

After rinsing with water

, the display shows the following:

Operation manual 11.04.19 26/110

Ultrasonic milk analyser

Cleaning: X

Glass Alcal Detrg

Waste pipe

Glass

press Enter

5. Place glass filled with alkaline cleaning solution.

6. The pipe, coming from the orifice with inscription Waste Pipe has to be

placed in the glass.

Fig 9. Cleaning

7. Pressing button Enter starts the procedure for cleaning with alkaline

solution.

The following appears on the display:

Operation manual 11.04.19 27/110

Ultrasonic milk analyser

Glass Acid Detrg

End of Cleaning

Cleaning: X

Where, X is changing number showing number of cycles done by the pump.

8. After the cleaning procedure is finished, the following message appears,

reminding the analyzer needs rinsing.

9. Rinsing procedure is executed, described in p. 2. After it is finished, the

display shows:

Waste pipe Glass

press Enter

10. Place glass filled with acidic cleaning solution.

11. The pipe, coming from the orifice with inscriptionс Waste Pipe has to be

placed in the glass.

12. Pressing button Enter starts the procedure for cleaning with acidic

solution.

The following appears on the display:

Where, X is changing number showing number of cycles done by the pump.

13. After the c leaning procedure is finished, the following message appears,

reminding the analyzer needs rinsing.

14. Rinsing procedure is executed, described in p. 2. After it is finished, the

display shows:

Ready to Start

15. Procedure Final Clean is finished.

3. Pour warm alkaline solution in the glass and press the button Enter, in

order to continue the cleaning.

Then the following message appears on the display:

Operation manual 11.04.19 28/110

Ultrasonic milk analyser

Cleaning

Please wait

Follow repeatedly sucking/pouring out the cleaning solution and heating it up.

After the cleaning is finished, the cleaning solution is emitted in the reservoir

with the waste liquids.

For maximum cleaning effect it is recommended the cleaning solution to be

preliminary heated up to 40-50 degrees centigrade.

Follows rinsing with water:

4. Put a glass with water for rinsing the device

.

Put filled with

Water glass

and press Enter

to Continue

After rinsing the display shows the following:

End of cleaning

After 2 seconds the following appears on the display:

Analyser ready

After this the analyser is ready for normal measurement or to be switched off

from the power supply.

Operation manual 11.04.19 29/110

Ultrasonic milk analyser

4.2. Preparation of cleaning s olution

For a single cleaning cycle you need only 25 ml cleaning solution. We

recommend you to prepare working solutions of cleaning chemicals, enough

for normal work for 1 week, because, during their stay unused, the working

solutions loose their strength and also is difficult to store them.

Preparation of 3 % alkaline solution of Lactodaily for circulation cleaning in

the milk analyser:

1. Take the package concentrated chemical Lactodaily

2. In appropriate vessel (for example bucket) pour 1 l water.

3. Add the chemical and then again water up to 3 l.

Then follow the instruction for milk analyser cleaning.

4.2.2. Preparation of acidic cleaning solution

Preparation of 3 % acidic solution of Lactoweekly for circulation cleaning in

the milk analyser:

1. Take the package concentrated chemical Lactoweekly

2. In appropriate vessel (for example bucket) pour 1 l water.

3. Add the chemical and then again water up to 3 l.

Then follow the instruction for milk analyser cleaning.

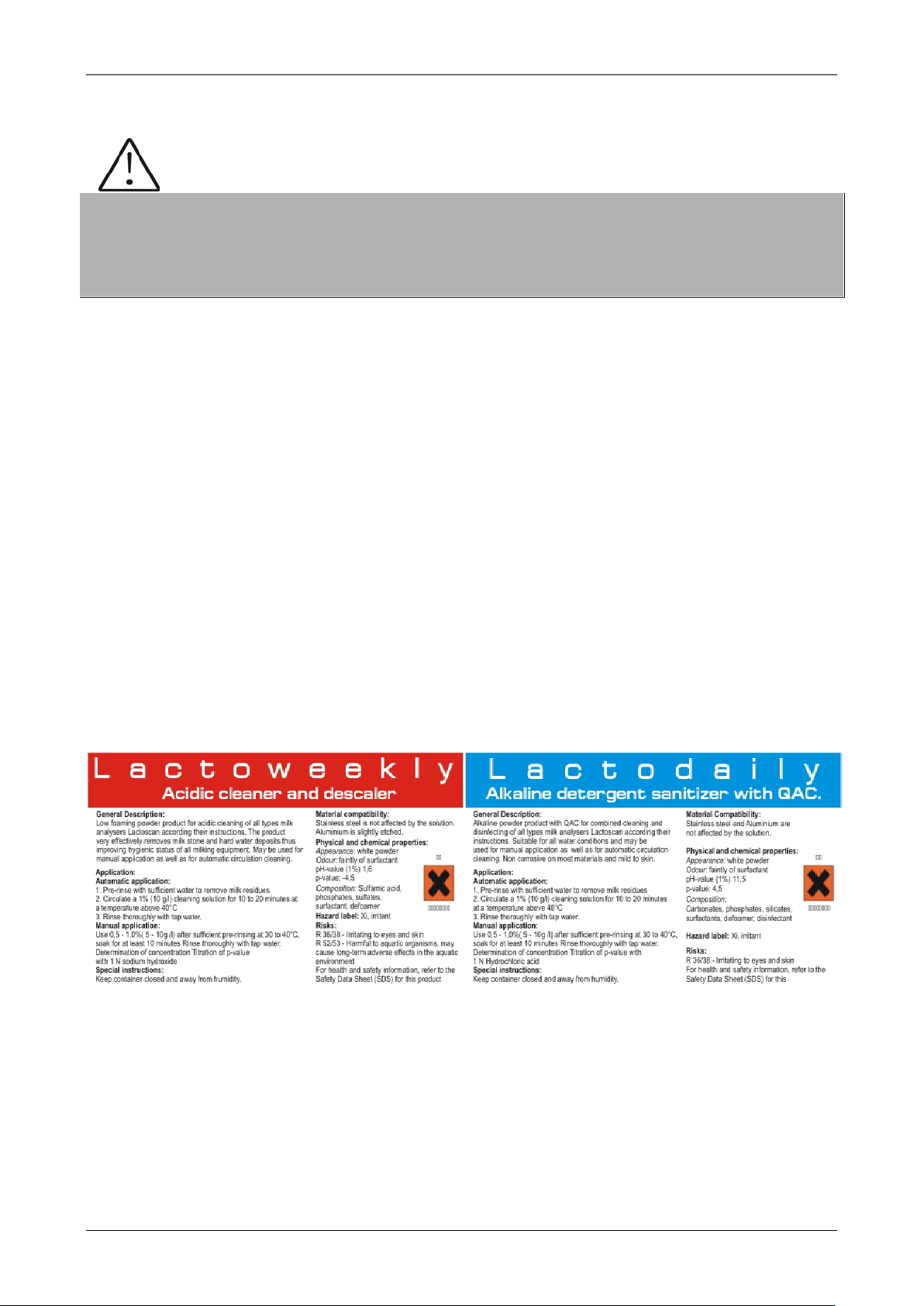

Fig. 10 Labels for acidic cleaning chemical Lactoweekly and alkaline

cleaning chemical Lactodaily

The following procedure is executed:

1. Rinsing the milk residues:

Fill in the glass with water. Put it in the recess of the analyser and start

command Cleaning from the main menu. After finishing it pour out the

contaminated water.

Operation manual 11.04.19 30/110

Ultrasonic milk analyser

repair has to be paid.

2. Cleaning with acidic solution

Fill in the glass with warm (50-60 С) acidic cleaning solution. Put it in the

recess of the analyser and start the command Cleaning from the main menu.

After finishing it, pour out the contaminated liquid.

3. Rinsing with water

Fill in the glass with water. Put it in the recess of the analyser and start

command “Cleaning” from the main menu. After finishing it pour out the

contaminated water. Now the device is ready for work.

Please, pay attention that, when the analysers gives a signal for need of

cleaning 15 min after the last measurement of real milk samples or 55 min.

after being powered and not used, cleaning is made ONLY with alkaline

solution in concentration 1-3%.

During the basic/final cleaning sequence is: alkaline solution – water – acidic

solution - water

IMPORTANT

THE MAIN REASON FOR MALFUNCTIONING OF THE

DEVICE IS THE BAD CLEANING OF THE SYSTEM AFTER

MAKING ANALYSIS.

In case of malfunction due to the bad cl e a ning of t he

analyser your guarantee is not valid anymore and any

Operation manual 11.04.19 31/110

Ultrasonic milk analyser

4.3. Working with the peris t al t ic pumps

There are two peristaltic pumps in the analyser – 1 for the s ample and 1 for

the cleaning.

Fig.11 Peristaltic pumps

Operation manual 11.04.19 32/110

Ultrasonic milk analyser

Fig. 12 Peristaltic pump SL 16

Operation manual 11.04.19 33/110

Ultrasonic milk analyser

Error

message

Possible

problem /cause

Repair/remedy

2. MA

sound signal

Immediately swi tc h off the analy z er .

again.

The analyzer is ready to measure the next sample.

The sample is prepared according the

milk sample in the sample holder

there is damage in

Avoid the end of the suction pipe to be above

Avoid curdling of the milk sample. Clean

a sample curdled in the

In mode Measurement, after starting the

measurement, remove the sample holder and

k in the

sample holder.

The analyzer is ready to measure the next sample.

5. POSSIBLE MALFUNCTIONS AND ERROR MESSAGES, TROUBLESHOOTING

In the table below are described the possible malfunctions during the milk

analyzer’s exploitation and ways for their repair/remedy. If the problem

persists after all recommended measures are taken, please, connect the

nearest service center.

overheated

Accompanied

by a

continuous

3. Empty

Camera

Overheated milk

analyzer

Insufficient

quantity of the

milk sample

sucked in the

system or air in

the sample

Pay attention the analyzer to be situated away from

direct sunlight or heating devices.

Wait 5-10 minutes the device to cool down or to be

normalized the ambient temperature and switch it on

In order to avoid the future appearance of the same

error message, please, check the following:

instructions and there aren’t air bubbles in it.

- There is a real suction of the sample after

starting measurement, i.e. it is obvious that the

level of the

decreases. In other case –

the suction system.

the surface of the liquid (not dipped enough).

immediately if there is

system.

- Check the pipe, connecting orifices for cleaning

solution and waste liquid (on the analyzer’s rear

panel.

-

Sucked

4. Sample

Overheat

Operation manual 11.04.19 34/110

overheated

sample

see if there is no milk poured bac

In order to avoid the future appearance of the same

error message, please, check the following:

-The sample is prepared according the instructions

and its temperature does not exceed the maximum

permissible sample’s temperature.

-Complete the procedure for checking the analyzer

in case of error message Empty Camera.

Ultrasonic milk analyser

6. MAKING CORRECTIONS AND RECALLIBRATION OF THE DEVICE

In the process of work with the analyser there is a possibility the results to

start differing between the data for some of the measuring parameters when

measured with the milk analyzer and the corresponding reference method of

analysis (Gerber for fat, Kjeldhal for proteins etc). In order to establish the

possible discrepancy and to correct the readings of the milk analyser do the

following:

6.1. Taking samples and pr e par a ti on of s a m ples for checking the accurracy of the milk analyser, making corrections and recalibration

This is a basic moment for the correct checking the accuracy of the analyser

and for making correct and precise correction and calibration. It is

accomplished according Appendix Sampling and preparation of samples for

verification the accuracy of the milk analyzer, making corrections and

recalibration.

6.2. Determination the type of the discrepancy:

6.2.1. Making measurements

Make measurements with different samples (not less than 3) with known

values of a separate parameter (for example fat content), determined by the

known reference methods of analysis (for example Gerber's method for

determination of fat content). For more accuracy it is recommended among

these samples to be also such with values, close to the lowest and highest

bounds for the measured parameters.

Make 5-time measurement for each of the samples. Calculate the average

value for each sample parameter, without taking into consideration the first

measurement for each sample.

6.2.2. Analysing the measurement results

Make comparison between the values of the parameter from the reference

sample and measured with the analyser. Make analysis of the difference

received.

6.2.2.1. If the received differences are relatively constant value for samples

with different content of the analysed parameter, it is necessary to make

correction.

Operation manual 11.04.19 35/110

Ultrasonic milk analyser

Parameter

Increasing

Decreasing

Step

FAT

0.95%

0.95%

0.01%

SNF

4.75%

4.75%

0.05%

Density

4.75%

4.75%

0.05%

Lactose

0.95%

0.95%

0.01%

Salts

0.95%

0.95%

0.01%

Proteins

0.95%

0.95%

0.01%

Added water

9.00%

9.00%

1.00%

Sample’s temperature

9.90oС

9.90oС

0.1oС

For example

М% of the reference samples: 2,20 3,00 3,80 4,60 5,20

М%average when measuring

with the analyser:

2,38 3,17 4,01 4,79 5,42

Difference: 0,18 0,17 0,21 0,19 0,22

Conclusion: the difference is relatively constant value and correction is

possible to be done with – 0,2 % (see Corrections, p6.3.3)

6.2.2.2. If the differences are not a constant value it is necessary recalibration

to be done.

For example.

М% of the reference samples: 2,20 3,00 3,80 4,60 5,20

М% when measured with the

analyser:

2,02 2,93 3,76 4,75 5,44

Difference: -0,18 -0,07 -0,04 0,15 0,24

Conclusion: It is obvious that the difference is variable value and

recalibration have to be done (See Recalib ration, p.6.4).

6.3. Making corrections

6.3.1. Possible corrections, limits and changing steps

Every parameter from each calibration may be separately corrected. Below is

the table with possible corrections, limits and changing steps:

Operation manual 11.04.19 36/110

Ultrasonic milk analyser

Corrections:

6.3.2. Preparing the a na lyzer for mode Corrections

6.3.2.1. Press the button Enter and without releasing it switch on the power

supply of the device, wait for the starting identification messages and release

the button after the following message appears on the display:

Release button

to start setup

After releasing the button on the display is shown:

Setup Menu

followed by possible to be entered by the operator menus:

6.3.2.2. By using buttons “up” ▲ and “down” ▼position on Corrections and

press Enter.

6.3.3. Making correction

6.3.3.1 Determining t he c orrection mode

When starting Corrections, the following appears on the display:

Special modes

Corrections

Setting

s

-----------------------------Tests

pH & Co Meter

Accessories

Exit

Measurement

Temperature

Cond measure

Exit

Operation manual 11.04.19 37/110

Ultrasonic milk analyser

Cal1 Cow

Position on Measurement and press Enter. By using buttons “up”▲ and

”down”▼position on the corresponding calibration (for example Correction 1

– cow) and press Enter.

6.3.3.2. Choosing correction parameter

After choosing calibration mode the display shows the following:

Param:Fat

Correct=00.00

Edit OK Next

Using the buttons “up”▲ and ”down”▼position on the action you want to take

(for example Edit) and press the button Enter.

6.3.3.3. Making correc t ion

After choosing parameter (for example fat) the display shows the following:

Using the buttons “up”▲ and ”down”▼is possible to increase or decrease the

value of the measured parameter in the above pointed limits. Leaving this

mode means saving the correction value and activating it.

6.3.3.4. Making verifica tion

After the corrections are made put the milk analyser in working mode and

make several times measurement of reference samples with known values of

the corrected parameter. If the difference between the values of the

parameter from the reference methods and milkanalyser are in the limits for

the parameter it may be considered that the correction is successfully made.

If the discrepancy between the measurements from the milk analyser and

classical methods is bigger than is necessary to make second correction

according above described way.

If after the second correction the results are unsatisfactory we recommend

making a calibration of the analyser. In dependence of the conditions and

Cal:….

Param:….

Correct= 00,00

- OK +

Operation manual 11.04.19 38/110

Ultrasonic milk analyser

your requirements you may make the calibration using a personal computer

type IBM PC and the company's calibration program or autonomous - by

recalibration.

When making corrections or calibrations be 100% sure in the accuracy of the

reference methods result.

6.4. Recalibrating the milk analyser

6.4.1. Running the analyser in mode Recalibrate

6.4.1.1. Press the button Enter and without releasing it switch on the power

supply of the device, wait for the starting identification messages and release

the button after the following message appears on the display:

Release button

to start setup

After releasing the button on the display is shown:

Setup menu

Followed by the possible to be entered by the operator menus:

Special modes

Corrections

Setting

s

-----------------------------Tests

pH & Co Meter

Accessories

Exit

6.4.1.3. In the newly opened menu, position on Recalibrate and press the

button Enter.

Operation manual 11.04.19 39/110

Ultrasonic milk analyser

Cal: 1 Cow

Prev OK Next

Cal1 Cow

Edit OK Next

Cal1 Cow

- OK +

Cal1 Cow

Edit OK Next

6.4.2. Making recalibration

6.4.2.1. Choosing the calibration mode

After starting Recalibrate, the display shows the following:

You can choose the type of milk to be calibrated. By pressing

▼ (Next) you can

switch between Cal: 1, Cal: 2 or Cal: 3.

By pressing the button ОК you are choosin g t he type of calibration.

6.4.2.2. Entering values for the separate sample parameters

The following menu is displayed:

High

FAT=f.ff

In this display the results, received by using the corresponding reference

methods from Appendix Methods for

high-fat milk analysis must be

entered.

In this menu, with button ▼ (Edit) must be entered the values of the high fat

milk sample

For example:

FAT=05.29

High

FAT=f.ff

With buttons ▼(-),▲(+) set the needed value. With next pressing of Enter the

cursor is moved to the next number. After needed value entering completion for

FAT, press Enter (ОК) and you are going back to t he previous menu:

Operation manual 11.04.19 40/110

High

FAT=05.29

Ultrasonic milk analyser

Cal1 Cow

Edit OK Next

You Must Enter

Cal1 Cow

Edit OK Next

With the button ▲(Next), choose SNF and in the same as above

described procedure, enter the value for SNF. After it is finished, press

“Enter” (OK) and you are going back to the previous menu. With button

▲ (Next), choose DEN (density) and enter the value for density; the rest

of the parameters are entered in the same manner – LAC (lactose), SOL

(salts), PRO (protein)

High

PRO=f.ff

If you miss to enter some of the parameters of milk, the following warning

message will appea r:

Values > 00.00

Try Again

Then you must pres s the button Enter (ОК) and enter the missed parameters.

After all the paramet ers are entered, press Enter (ОК).

You must enter values for all the measured milk parameters!!!

The screen for entering the results, received with the corresponding

reference methods (See Appendix Methods) for the

low-fat milk is displayed:

Low

FAT=f.ff

In the same way the val ues of milk with low fat sample are entered.

You must enter values for all the measured milk parameters!!!

Operation manual 11.04.19 41/110

Ultrasonic milk analyser

Cal: Cow

Cow

In other case the cali brat ion will not be corre ct.

6.4.2.3. Making recalibration with the available samples

After entering the values for the separate parameters of the sample, pressing

Enter (OK) will display the following menu:

Cal: Cow

Put sample High

5 times

which reminds us to put 5 times the sample with high FAT.

The sample has to be with temperature in the boundaries 15-25°С.

Before each milk measurement stir 2-3 times the milk sample by pouring it

from one vessel to another. The needed quantity is poured in the sampleholder and it is put in the recess of the analyser. Start the measurement by

pressing the button Enter. The sample is sucked. Appears the following

menu:

Put sample: High

5 times

Temp=….

After the samp l e is measured, appears the following menu:

High

1=….. 2=…….

N

Cal meas=1/5

which reminds us to make the next measurement. Before each measurement

the milk is stirred by pouring it 2-3 times from vessel to vessel. Continue the

procedure till the 5th measurement.

Operation manual 11.04.19 42/110

Ultrasonic milk analyser

5 times

Cal: Cow

After 5th measurement completion automatically appears the menu, which

reminds us to place the

Low fa t milk sample:

Cal: Cow

Put Sampl: Low

Stir 2-3 times the milk sample before each measurement by pouring it from

one vessel to another. The needed quantity is poured in the sample-holder

and it is put in the recess of the analyser. Start the measurement by pressing

the button Enter. The sample is sucked. Appears the following menu:

Make 5 times measurement of the low FAT sample.

After 5th measurement completion automatically appears the menu:

Put sample: Water

5 times

Which reminds for 5-times water measurement.

After the 5

th

measurement appears the menu:

Recalibrated

Power Off-On

This means that the calibration was completed successfully and the analyzer

is recalibrated for cow milk, marked as “Cal: Cow”.

Switch off the power supply of the device and switch it on again.

The device is ready to work with the new calibration.

Next time when the analyser is switched on, it will be ready for work with

those milk types it was just calibrated with.

If calibration with another milk type is needed, do not forget to change the

calibration number for the new type of milk.

Calibration for Sheep milk will be saved as second calibration, UHT – as

third. This sequence may not be followed and calibrations can be saved in

whichever order is needed. Calibration can be done with different liquid dairy

products using 2 representative samples.

Checking the calibration

1. Switch on the calibrated device.

Operation manual 11.04.19 43/110

Ultrasonic milk analyser

2. Make sure it shows the same serial number as this already calibrated.

For checking, use the third sample with medium FAT content.

3. Measure the milk 5 times in the mode you’ve calibrated it.

In case that the device is not connected towards printer write down the

results.

4. Ignore the first two results.

The rest three could not differ more than 0,05% FAT, 0,07% SNF, 0,7%

Density one from another

Operation manual 11.04.19 44/110

Ultrasonic milk analyser

7. STARTING THE DEVICE IN A SERVICE TEST/SETUP OPERATIONAL MODE. MENUS DESIGNATION

7.1. Starting the device in a service Test/Setup operational mode. In order to start the Setup of the device the operator has to press the button

Enter and without releas ing it to switch on the power supply of the device, to

wait for the starting identification messages and to release the button after

the following message appears on the display:

Release button

to start setup

After releasing the button on the display is shown:

MA Setup

Followed by possible to be entered by the operator menus:

Special modes

Corrections

Setting

s

-----------------------------Tests

pH & Co Meter

Exit

You may move in the menus by using buttons “up” ▲ and “down” ▼.

If by pressing the button Enter you choose a menu, each menu offers new

points/submenus. When Exit is chosen the device leaves the Setup mode

and returns to normal work.

7.2. Menus Function:

7.2.1. Special modes.

Operation manual 11.04.19 45/110

Ultrasonic milk analyser

Serve for choosing special (technological) working modes. After starting it the

following appears on the display:

Special modes

Calibration

Cycle

Fast cycle

Exit

This mode is normally used in production conditions.

7.2.1.2. Calibration mode

In mode Calibration the analyzer is ready to make measurement and to send

the received results towards the technological milk analyzers calibration

system. For this purpose you need personal computer type IBM PC,

company’s calibration system LSC.EXE and methods for calibration of milk

analyzers (see the corresponding documents). To start measurement in this

mode, the operator has to put a sample-holder containing milk sample in the

recess of the analyzer and to press the button Enter.

7.2.1.2. Cycle mode / Fast cycle mode

Mode Cycle serves for training the analyzers. When you start this mode, the

analyzer, without additional commands, sucks the sample, makes the

measurement, pours the sample out in the sample-holder and displays the

received results cyclically.

7.2.2. Corrections

Serves for entering corrections in the measured data. Detailed description in

point 6.3.2 and 6.3.3.

7.2.3. Settings.

Serve for assigning different working parameters (modes).

7.2.3.1. Net number.

Serves for assigning the device network number when connecting it in the

production network. The possible numbers are from 0 to 15 including.

After starting this function the display shows the following:

Operation manual 11.04.19 46/110

Ultrasonic milk analyser

Save

Restore

Net number

0

- OK +

By using the button “up”▲ the operator has the possibility to increase the

number, showing the channel’s number, and by button “down”▼, to decrease

it. Pressing the button Enter saves the chosen channel and exits the function.

When connected in the production network each device has to have a unique

number.

7.2.3.2.Recalibrate.

Serves for changing definite calibration. Methods are described in point 6.4.

7.2.3.3. Save/Rest Cal.

Through this menu you may save the new calibration in the device or to

restore the old one (factory) calibration. This is necessary in case that you’ve

calibrated the device for cow milk, but after that the device is not measuring

correctly and you decide to restore the factory calibration settings. Position

the cursor across “Restore calibration” an d press “Enter”

Possibilities:

Save calibration – saves the chosen calibration in an internal buffer.

Restore calibration – restores the chosen calibration from the internal

buffer.

The procedure Save/Restore is done for each calibration separately.

Current working

calibration (1,2 or 3)

Internal storing

buffer

Current calibration content is not changed, the analyzer continues using it,

but there is a reserve copy in an internal buffer.

Current working

calibration (1,2 or 3)

Internal storing

buffer

Operation manual 11.04.19 47/110

Ultrasonic milk analyser

Exit

Large Results

The current calibration is replaced with the calibration from the internal buffer

and the analyzer starts working with it. The content of the internal buffer is not

changed.

If after recalibration “Save calibration” is pressed the new calibration

settings will be saved over the factory settings. After that is impossible

to restore the factory settings of the calibration. Save the newly made

calibration only if you are sure about its correctness.

7.2.3.4. Settings Page 2.

After this menu is started the display shows the f ollowing:

Settings Page2

Set Calibr Name

Select High Fat

HFSpeed for Cal

Result Precision

PCB Main Identi

Larg Res En/Dis

Now there is a possibility one of the follow ing opt i ons to be set:

7.2.3.4.1. Larg Res En/Dis.

The format of the measurement data send towards the c omputer is set.

If the option Large Disable, is chosen, then only the main results are send to

the computer – Fat, SNF, Density, Lac, Proteins, Added Water, sample

temperature, devi ce serial number and calibration num ber.

If the option Enable, is chosen, except the above mentioned parameters also

data for Salts, Freez ing Point, pH, Conductivity will be send to the computer. In

this case is necessary the software in the computer to be conformable to the

format of the sent dat a. After starting the menu, the display shows (for example):

Operation manual 11.04.19 48/110

Ultrasonic milk analyser

No

No OK Yes

7.2.3.4.2. Select High Fat

If the analyzer has embedded function for measurement of high fat products, by

this menu the calibration, with which this measurement to be made is chosen.

What is seen when this option is turned on is an obvious slowdown of the

sample’s suction speed.

7.2.3.4.3. HFSpeed for Cal

If the analyzer has embedded function for measurement of high fat products,

and a new calibration for high fat measurement is needed, before starting the

new calibration the operator has to start this menu. What is seen when this

option is turned on is an obvious slowdown of the sample’s suction speed during

calibration.

Please, pay attention to the fact that switching off the power supply cancels this

command action.

7.2.3.4.4. Reslt Precision

Serves for setting the precision of the measured results shown on the display. It

is set separately for every parameter, the precision could be 0.01 (standard) or

0.1.

7.2.3.4.5. PCB Main Identi

Gives information a bout the type and the version of the analy ser (LS I dentity).

7.2.3.4.6. Set Calibr Name.

Sets the names of the separate calibrations. The name could be chosen from

the group of predefined calibrations names or to edit a new one. When editing

the new name there is a possibility all ASCII codes to be used, as letters (caps

and normal), numbers and punctuation marks and popular symbols. The

calibration name consists of 8 symbols.

After starting this menu the display show s:

Select Calibr

Cal1: Sheep

Exit Yes Next

Operation manual 11.04.19 49/110

Ultrasonic milk analyser

There are the following possibilities:

With button Exit – to leave the menu.

With button Yes – to confirm the chosen for editing calib rat i on name.

With button Next – to choose the next calibration nam e for editing.

If a calibration for change or edit of name is chosen, the display shows

(example):

Cal:Sheep

PreDef Exit Edit

There are the following possibilities:

With button PreDef – to choose a calibration name from the list of preliminary

given names.

With button Exit – to leave the menu.

With button Edit – to edit the new calibration name.

If a name from the preliminary given names list is chosen, the display shows:

Cal1: Sheep

UHT

Exit Yes Next

There are the following possibilities:

With button Exit – to leave the menu.

With button Yes – to confirm the chosen from the list calibration name.Now the

program returns to the beginning of the menu for setting calibrati on names.

With button Next – to show the next calibration name from the li st.

If it is decided a new calibration name to be edited, the display shows:

Cal1: Sheep

User Edited

Name:

Prev Set Next

There are the following possibilities:

With button Prev – to display the previous ASCII symbol.

Operation manual 11.04.19 50/110

Ultrasonic milk analyser

With button Set – to confirm the ASCII symbol, shown on the display and

passes to editing th e next symbol from the cali bration name.

With button Next – to show the next ASCII symbol.

After editing the last (eighth) name symbol, the display shows:

Cal1: Sheep

User Edited

Name:MilkShp

Exit Save

There are the following possibilities:

With button Exit – to leave the menu.

With button Save – to confirm already edited calibration name and to save it in

the device. The program returns to the beginning of the menu for setting

calibration names.

7.2.3.5. Set Base FrPnt

Through this menu you have the possibility to enter the basic freezing point

separately for each calibration. For more information, see Appendix Freezing

point. After choosing the menu the following is displayed:

Edit FrPoints

FrPoint Calibr1

FrPoint Calibr2

FrPoint Calibr3

---------------------------- Exit

After choosing freezing point for the calibration, the following is displayed:

FrPoint Calibrx

-0.fff

- OK +

Where:

Calibrx - basic freezing point to be edited for chosen calibration;

-0.fff - basic freezing point current value;

Operation manual 11.04.19 51/110

Ultrasonic milk analyser

By pressing the buttons:

“up”▲ - you may increase the absolute value of the freezing point;

”down”▼ - you may decrease the absolute value of the freezing point;

“Enter” - saves the edited value and exits the menu;

7.2.4. Tests.

Start different tests. Possibilities:

7.2.4.1. Test pump.

Starts pump’s test. The number of the completed suction/display cycles is

indicated.

7.2.4.2. Ultrasound.

Test for the ultrasonic system. Used in production conditions.

7.2.4.3. Set Amplitude.

Serves for ultrasound amplitude adjustment. It is used under production

conditions or by the customer (after sensor change) according the

instructions in the document SetCell.pdf.

7.2.4.4. RS232 COMPort

7.2.4.5. Keypad

7.2.4.6. USB Flash

Please, use this menu only after reading the above pointed document

SetCell.pdf

7.2.5. pH meter & Co meter

Ph and conductivity measuring are additional possibilities for the analyser

and are optional. Their usage is described in Appendices PH Measurement

and Conductivity Measurement.

Operation manual 11.04.19 52/110

Ultrasonic milk analyser

Special

modes

Calibration

Shut Down

Corrections

Calibration 1

Fat

Water

Calibration 2

Fat

Water

Calibration 3

Fat

Water

Temperature

Cond

measure

Settings

Net number

LCD Setup

Contrast fast

B.Light fine

Recalibrate

7.2.6. Exit

By pressing the button you may leave the program and pass towards another

menu.

7.2.7. Setup menu structure

Analyzer Setup

Cycle

Reports

SNF

Density

Lactose

Salts

Proteins

COM1 mode

SNF

Density

Lactose

Salts

Proteins

SNF

Density

Lactose

Salts

Proteins

Operation manual 11.04.19 53/110

Contrast fine

B.Light fast

Ultrasonic milk analyser

Calibration 1

Edit samp's 3

Edit FrPoints

FrPoint Calibr1

FrPoint Calibr3

Save/Rest

Cal

Save Calibr 1

Rest Calibr 3

Fan Temp

Page2

Final clean cnt

Option Select

Sel Pump Speed

Speed for Cal 1

OutSample Delay

Reslt

Fat - Precision

AdW - Precision

Properties

PCB Main Identi

PCB LCD Identi

Tests

Test pump

Serial Prnter

Calibration 2

Calibration 3

Edit samp's 1

Edit samp's 2

FrPoint Calibr2

Save Calibr 2

Save Calibr 3

Rest Calibr 1

Rest Calibr 2

Offs

Settings

Auto Print Res

Larg Res En/Dis

Set Calibr Name

Speed for Cal 2

Speed for Cal 3

HFSpeed for Cal

Precision

SNF - Precision

Den - Precision

Lac - Precision

Sol - Precision

Pro - Precision

Operation manual 11.04.19 54/110

Ultrasound

Ultrasonic milk analyser

KeyPad

Parallel Prn

pH & Co

Meter

pH

En/Dis

Accessories

Weight scale

Raw Test

On Line En/Dis

Battery

Measure Bat U

Ctrl Enabl/Dis

RT Clock

Display Time

Adjust Date

Displays

Calibration

pH

Measuring

pH

En/Disable

pH U Display

pH Test U[V]

Co Meter

Calibr

Co Meter

Test

Co Meter

Calibration

Measure

Adjust Time

Operation manual 11.04.19 55/110

Ultrasonic milk analyser

8. ENTERING DATA WITH THE KEYPAD AND PRINTING OUT THE RESULTS

8.1. Working with the keypad

To make the operation easier there is embedded keypad in the device.

Via it one may enter 4 digit number of the milk supplier (from 1 up to 9999)

and the delivered by this milk supplier liters of milk (from 0.1 up to 9999.9

liters) with accuracy up to 0.1 l.

Entering these data is done before starting the measurement. For that

purpose:

1. Pr ess the button # (Enter) on the keyboard and the display will show the

following:

Enter Data

Del N:

2. Now enter the number of the supplier.

3. By pressing # Enter on the keyboard, the display shows:

Enter Data

Del N:xxxx

Liters =

4. Now enter the liters and press the button # (Enter) on the keyboard. The

display shows:

Del N:xxxx

Liters=yyyy.y

Are you sure?

0-No Yes

Where:

хxxx - entered by the operator number of the supplier

Operation manual 11.04.19 56/110

Ultrasonic milk analyser

Loading way

easy

Cutting way

divulsion(dentiform)

Direct thermal print and auto

paper feed

384 dots/line

8 dots/mm

Printing width

48 mm

Max Printer Speed

85 mm/s(max.)

dot distance

0.125 mm

word size(WⅹH

mm)

ASCⅡ

dots)

8×16; 24

ASCⅡ Size(WⅹH

mm)

16 lattice:2×4; 24

lattice:1.5×3

drawing/bar code

suitable

Testing Method

lacking paper testing

photoelectricity sensor

printer interface

TTL/RS232

buffer

32k

ESC printer command/WH

printing command

DC3.5V--9V (from7.2-5v,with

highest speeed and excellent

effect)

Average electricity

less than 1.5A

Max electricity

less than 3A

Printer

Mechanism

yyyy.y - entered by the operator liters

The operator has the following two possibilities:

1. To cancel the entered data by pressing the button 0 on the keyboard and

to start entering them again.

2. To confirm the entered data by pressing the button # (Enter) on the

keyboard, and then the display will show currently chosen calibration. Now

the device is ready to start measurement. After finishing the measurement,

data, entered for the supplier are printed out.

8.2. Working with the pri nt er

8.2.1. Printer characteristics

Paper Working

Printer

performance

Drawing/Bar

code

Control System

Print method

Printing density

Character(WⅹH

Command System

0.75×1

16 lattice:

lattice:12×24

Woking Voltage

Power

printing head lifespan 50km

Operation manual 11.04.19 57/110

Ultrasonic milk analyser

paper item

thermal paper

paper width

58mm

papaer thickness

65±5um

diameter of paper roll

30mm

0~55℃;-20~55℃

10~90%RH

–25~70℃

10~90%RH

Dimension (WⅹHⅹD

mm)

4

2

3

1

Paper

Environment

adaptability

Physics

Specification

Storage temperature

Fig. 12 Printer control pane l

103mm×57mm×57mm

1. Printout

2. Paper roll compartment

3. Printout button

4. Cover opening button

Changing the roll

To change the paper rolls proceed as follows:

Operation manual 11.04.19 58/110

Ultrasonic milk analyser

1. Press the button as it is shown on the figure.

2. Position the paper roll making sure it unrolls in the proper direction.

3. Tear off the paper and close the cover.

8.2.2. Sequence of actions when printing

The embedded printer is automatically switched on with switching on the

device. After finishing the measuring procedure the results are automatically

printed out. If there is a need of repeated printing of the same results the

operator has to press the button 1 on the embedded keyboard (each

pressing the button 1 on the keyboard the results will be printed out).

Moreover, a copy of the printout can be made by pressing the button A or by

choosing a command Printing from the main menu for operation of the

device (selection of modes for operation).

Operation manual 11.04.19 59/110

Ultrasonic milk analyser

9. ADDITIONAL POSSIBILITIES OF THE ANALYSER

9.1. Connecting to 12 V DC power supply.

If there is a need the analyser to work on place without electrical supply

available, then it could be powered by car battery or other 12 V DC external

power supply. Use the 12 V power supply cable (art. number 30030).

9.2. Connecting to IBM PC

The analyser can be connected to IBM PC using the RS232 interface cable

(art. number 30012, Parts and Accessories, point 16). In order to make the

connection: switch off both the milk analyser and PC. Connect the RS 232

cable towards Com. Port 1 and towards the computer. Turn on both analyser

and PC. Now the device is ready to communicate with IBM PC. For more

detailed information regarding milk collection data program see the file resLS.

9.3. Connecting additi ona l s e rial printer (option).

The interface connector for the printer is on the rear panel of the device

(Com. Port 2). The printer should be connected towards it. Connect it via

cables, delivered by the company-producer. If the printer is connected directly

to the electrical network, then the analyser and the printer should be

connected to one and the same electrical phase.

Communication parameters: 9600 bps, No parity, 8 bits, 1 stop bit. It’s oneway communication (uses one line) – the analyser only sends and the printer

only accepts dat a.

9.4. Connecting matrix pri nter (option).

If the device is working n milk collection center, where work load is heavy,

and there are a lot of results to be printed out, we suggest an option

connecting standard matrix printer (paper expenses would be less, the

reliability better).

Interface connection with the printer is at the rear panel of the analyser

“Parallel printer interface”.

9.5. Measuring high fat sample s (opti on) .

The standard device measures samples up to 25% fat.

On customer’s request, the device could be produced with possibility to

measure samples up to 50% fat. The customer can choose which calibration

to have this possibility and which not, as well as during the process of

exploitation to change the measuring mode i.e. to pass from measuring

normal fat percentage towards high and vice versa.

Operation manual 11.04.19 60/110

Ultrasonic milk analyser

Calibr x

Normal OK HiFat

What the operator sees during these passes is the difference in the speed of

sucking the sample. For that purpose, the high-fat sample has to be

preliminary heated up to 30С +- 3С.

To choose the mode, follow the sequence below:

Setup->Settings->Settings

Page2->Option

Select->SelPumpSpeed->Speed for Cal x

After which the display shows:

Pump Speed

By pressing the correspondent buttons the operator can choose the type of

measurement and to exit the menu.

When changing the type of measurement on a calibration is necessary a new

calibration of the device on the new speed to be done. When calibrating

measuring high fat sample, before starting the calibration procedure, the

operator has to choose from the menu:

Setup->Settings->Settings

Page2->Option

Select->SelPumpSpeed-> HFSpeed for Cal

By which the device passes in a mode of measuring high fat samples.

This calibration mode is active till the power supply of the device is switched

off i.e. it has to be always set if the device will be calibrated for high fat

measurement.

9.6. Working with embedded accumulator (option).

On customers’ request accumulator could be embedded in the milk analyser.

In this way it could work independently on the electrical network. In this case

the Power switch on the rear panel of the analyser serves for close / open the

electric circuit of the outer power supply. After closing the circuit, in order to

start the analyser, the operator has to press the Start button on the front

panel of the analyser.

Switching off the analyser could be done on one of the following ways:

Through the analyser – by switching the Power button on the rear panel of

the analyser.

Through the software – by using the option Shut Down from the Calibration

and Working mode menus.

Operation manual 11.04.19 61/110

Ultrasonic milk analyser

After pressing and holding pressed the button Enter (when choosing

calibration), the following is displayed:

Milk selector

Cal1 – Cow

Cal2 – Sheep

Cal3 – UHT

----------------------------Cleaning

Final clean

Shut Down

By choosing the option Shut Down the operator may switch off the power

supply of the analysers.

In case that the external power supply from the electrical network, the

analyzer automatically starts working with power supply from the battery.

Possible working modes with battery:

1. The analyser is powered by the battery, works normally; the display shows

the following message

Battery Powered

2. The analyser is in mode Sleep – do not accept any commands, expects

change in the power (supply from switching adapter for starting the battery),

display shows the following

Low Battery

3. The battery power is under the allowed minimum, milk analyser is

automatically switched off. Before switching off, for a short time, the display

shows

Out of Battery

Operation manual 11.04.19 62/110

Ultrasonic milk analyser

9.7. Automatic weighting the milk with scales (option).

Scales could be connected towards the milk analyser, which to be used for

weighting the delivered milk before measuring its parameters. For using the

scale the operator has to follow up the two procedures:

- Preparation for work and checking the scales

- Wei ghting delivered milk

9.7.1. Preparation for work a nd checki ng t he sca les

Put the scales on round and solid surface and level it, using its helical legs.

Checking the scales is done by using 2 standards of weight – light and heavy,

for example 5 and 50 kg, in mode:

Setup ->Accessories->Weigh Scale->Measure

(this is OFF Line measuring mode). I n case there is discrepancy noticed, you

need to make scales calibration, as is described below.

9.7.2. Weighting delivered milk.

The procedure is analogous to work when entering data for the deliverer

using additional keypad. The difference is that weight of milk is automatically

send from the scales.

Sequence of work is as follows: switch on the analyser for normal work. Place

the vessel where the milk from different deliverers will be collected, for

example with 80 l volume. W hen the analyser is ready for work, the operator

has to press “#” (Enter) on the digital keyboard. Display shows the following:

Enter Data

Del N:

Now enter the deliverer’s number and press the button “#” (Enter) on the

digital keyboard. Display shows the following:

Net =xx.xxx [kg]

Tare

=yy.yyy[kg]

Totl

=zz.zzz[kg]

0-Tare #OK

where:

xx.xxx – weight of the poured milk of the current deliverer.

Operation manual 11.04.19 63/110

Ultrasonic milk analyser

yy.yyy – tarе’s weight (weight of the milk collecting vessel plus milk,

collected from the previous deliverers, if there is such in the vessel)

zz.zzz – sum of Net + Tare

After the first measurement, across Net will be shown the weight of the milk

collecting vessel, and Tare will show 0. Now press the button Tare, and now

the scales is ready to weight the milk of the deliverer, i.e. Net shows 0. Fill the

glass for sample measuring and the rest of the milk pour in the milk-collecting

vessel, placed on the weighting scales. Now the value on the display across

Net is changing. The operator has to wait the scales to be set at rest and

press the button “#”. The display shows the following:

Net =xx.xxx [kg]