ARMY

TM 11-5820-553-10

NAVY EE150-SN-OPl-010/E110-PRC 70

OPERATOR’S MANUAL

RADIO SET AN/PRC-70

(NSN 5820-01-062-8246)

This copy is a reprint which includes current

pages from Changes 1 and 2.

DEPARTMENTS OF THE ARMY AND THE NAVY

19 FEBRUARY 1982

TM 11-5820-553-10/EE150-SN-OPl-010/E110-PRC 70

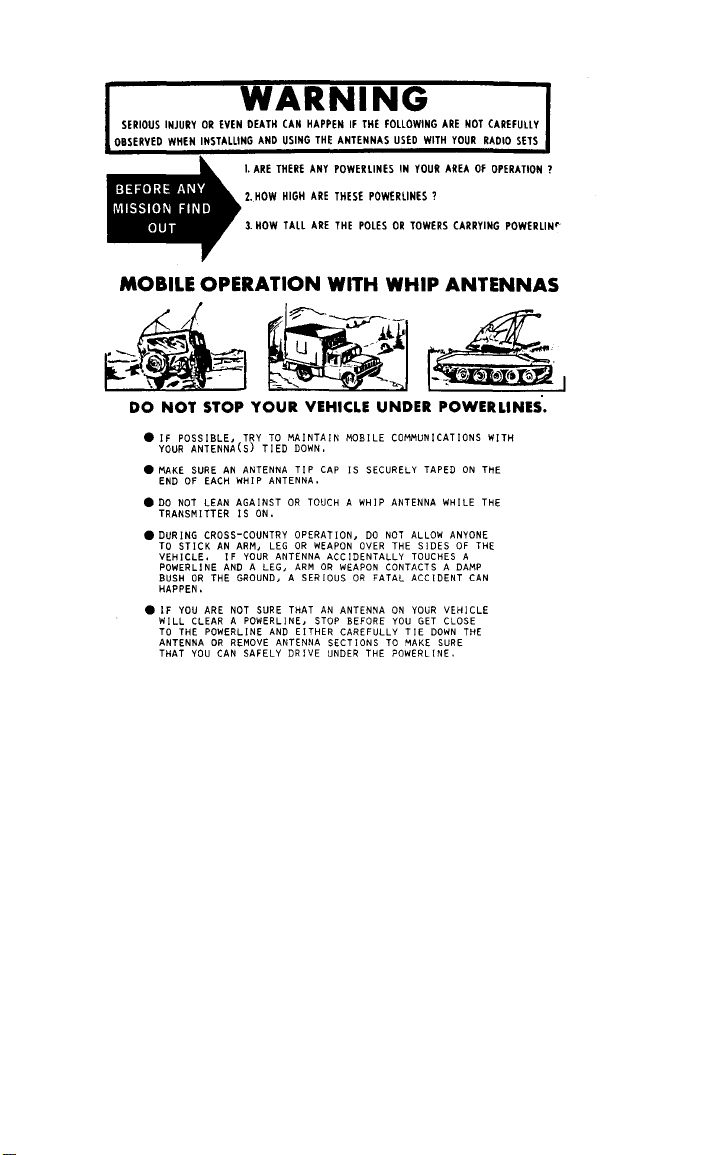

WARNING

Serious injury or death could result to personnel if the

whip antenna comes in contact with power lines.

When operating in HI PWR with the whip antenna, DO

NOT TOUCH the antenna when in transmit mode—an

RF burn can result.

This decal is located near the WIRE terminal and WHIP

antenna on the front panel of the radio set. It is applicable to BOTH long wire and whip antenna usage.

WARNING

Adequate ventilation should be provided while using

TRICHLOROTRIFLUOROETHANE. Prolonged

breathing of vapor should be avoided. The solvent

should not be used near heat or open flame; the products of decomposition are toxic and irritating. Since

TRICHLOROTRIFLUOROETHANE dissolves

natural oils, prolonged contact with skin should be

avoided. When necessary, use gloves which the solvent

cannot penetrate. If the solvent is taken internally, consult a physician immediately.

TM 11-5820-553-10/EE150-SN-OPl-010/E110-PRC 70

WARNING

A potential RF radiation hazard exists when Radio Set

AN/PRC-70 is operated in HI PWR, with the whip

antenna, either 6 or 9 foot (2 or 3 meters). This hazard is

increased when the radio is operated in the portable

(backpack) mode. For protection against these hazards,

observe the following safeguards:

a. Use a dummy load when operating the radio, if

possible, such as when performing Preventive Maintenance Checks and Services (PMCS) to determine

equipment readiness/availability.

b. Operate the radio in the off-the-back (fieldemplaced) mode, if possible, using either the doublet or

the long-wire antenna.

c. If a whip antenna must be used for transmissions

in the field-emplaced mode, use a microphone cable

long enough to maintain a distance of at least 1.7 feet

(50 centimeters) from the antenna.

d. If the radio must be operated in the portable (onthe-back) mode, use LO PWR or do not transmit for

longer than 30 seconds out of any 6-minute interval.

CAUTION

Do not attach antenna to this unit if high power

transmitters in the range 2-76 MHz are being operated

within 200 feet.

Change 1

A

TM 11-5820-553-10/EE150-SN-OPl-010/E110-PRC 70

CAUTION

FREQUENCY STABILITY CHECK

The AN/PRC-70 radio requires a radio frequency

stability check annually. Refer to your organizational

maintenance schedule to ensure your radio does not

become due for this check during a mission.

CAUTION

Handcrank Generator G-76/G must be producing

power BEFORE the AN/PRC-70 is turned on. Failure

to do this may damage the radio.

B

Change 1

TM 11-5820-553-10

TM 11-5820-553-10

D

TM 11-5820-553-10

SAFETY STEPS TO FOLLOW IF SOMEONE

IS THE VICTIM OF ELECTRICAL SHOCK

DO NOT TRY TO PULL OR GRAB THE INDIVIDUAL

IF POSSIBLE

, TURN OFF THE ELECTRICAL POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL

POWER, PULL, PUSH, OR LIFT THE PERSON TO

SAFETY USING A WOODEN POLE OR A ROPE OR

SOME OTHER INSULATING MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF

CONTACT WITH THE SOURCE OF ELECTRICAL

SHOCK, MOVE THE PERSON A SHORT DISTANCE

AWAY AND IMMEDIATELY START ARTIFICIAL

RESUSCITATION

TM 11-5820-553-10

F

TM 11-5820-553-10

EE150-SN-OPI-01B/E110-PRC 70

C2

CHANGE

DEPARTMENTS OF THE ARMY

AND THE NAVY

NO. 2

Washington, DC, 1 August 1987

OPERATOR’S MANUAL

RADIO SET AN/PRC-70

(NSN 5820-01-062-8246)

TM 1l-5820-533-10/EE150-SN-OPI-010/E110-PRC 70,

19 February 1982 is changed as follows:

1. Remove old pages and insert new pages as indicated

below. New or changed material is indicated by a vertical bar in the margin of the page. Added or revised

illustrations are indicated by a vertical bar adjacent to

the identification number.

Remove pages

i through iv . . . . . . . . . . . . . . . . . .

1-1 and 1-2 . . . . . . . . . . . . . . . . . . . .

1-5 through 1-10 . . . . . . . . . . . . . . .

2-3 AND 2-4 . . . . . . . . . . . . . . . . . . .

2-11 and 2-12 . . . . . . . . . . . . . . . . . .

2-15 through 2-26 . . . . . . . . . . . . . .

4-3 and 4-4 . . . . . . . . . . . . . . . . . . . .

4-7 through 4-10 . . . . . . . . . . . . . . .

4-17/(4-18 blank) . . . . . . . . . . . . . . .

A1 and A2 . . . . . . . . . . . . . . . . . .

Insert pages

i through iv

1-1 and 1-2

1-5 through 1-10

2-3 and 2-4

2-11 and 2-12

2-15 through 2-26

4-3 and 4-4

4-7 through 4-10

4-17/(4-18 blank)

A1 and A2

2. File this change sheet in front of the publication for

reference purposes.

Distribution authorized to the Department of Defense and DOD contractors only

for official use or for administration or operational purposes. This determination

was made on 26 March 1987. Other requests for this document will be referred

Commander, US Army Communications-Electronics Command and Fort

Monmouth, ATTN: AMSEL-ME-P, Fort Monmouth, NJ 07703-5000.

DESTRUCTION NOTICE–Destroy by any method that will

prevent disclosure of contents or reconstruction of the

document.

TM 11-5820-553-10

EE150-SN-OPl-010/E110-PRC 70

TECHNICAL MANUAL

NO. 11-5820-553-10

TECHNICAL MANUAL NO.

EE150-SN-OPI-010/E110-PRC 70

DEPARTMENTS OF THE

ARMY AND THE NAVY

Washington, DC, 19 Feb 82

OPERATOR’S MANUAL

RADIO SET AN/PRC-70

(NSN 5820-01-062-8246)

REPORTING ERRORS AND

RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any

mistakes or if you know of a way to improve the procedures, please let us know. Mail your letter, DA Form 2028

(Recommended Changes to Publications and Blank

Forms), or DA Form 2028-2 located in back of this

manual direct to: Commander

Electronics Command and Fort Monmouth, ATTN:

AMSEL-ME-MP, Fort Monmouth, New Jersey 07702-5000.

, US Army Communications-

For Navy, mail comments to the Commander

Naval Warfare Systems Command,

Washington, DC 20363-5100.

In either case, a reply will be furnished direct to you.

Chapter

Section I. General

1. INTRODUCTION

Scope . . . . . . . . . . . . . . . . . . . 1-1

Consolidated Index of Army

Publications and Blank

Forms . . . . . . . . . . . . . . . . . . . .1-2

Maintenance Forms,

Records, and Reports . . . . . . . .1-3

Reporting Equipment Im-

provement Recommendations

(EIR) . . . . . . . . . . . . . . . . .... . . . . . . . . . . 1-4

Warranty Information . . . . . . . .1-5

II. Description and Data

Equipment Characteristics,

Capabilities, and Features . . . . .1-6

EE150-SN-OPI-01B/E110-PRC 70/Change 2

ATTN: SPAWAR8122,

, Space and

Paragraph

Page

1-1

1-1

1-1

1-2

1-2

1-2

i

TM 11-5820-553-10

Chapter 2

Section I.

Section II.

III.

IV.

Paragraph

Location and Description

of Major Components.

System Application. . . . .

Tabulated Data . . . . . . .

OPERATING

INSTRUCTIONS

Controls and Indicators

Damage From Improper

Settings . . . . . . . . . . . . .

Operator/Crew Controls

Operation Under Usual

Conditions

Types of Operation . . . . .

Preliminary Starting

Procedures . . . . . . . . . .

Portable Configuration.

Fixed Configuration. . . . .

Initial Adjustments. . . . .

Operating Procedures . . .

Operation Under Unusual

Conditions

Operation Under Emer-

gency Conditions . . . . .

Recognition and Identi-

fication of Jamming . . .

Antijamming Procedures . . . . . . . . 2-11

Preparation for Movement

Portable Configuration

Movement . . . . . . . . . . . . . . . . . . . . .2-12

Fixed Congifuration

Movement . . . . . . . . . . . . . . . . . . . . 2-13

Fixed Voice Configura-

tion Movement . . . . . . . . . . . .2-14

CW or FSK Configuration

Movement . . . . . . . . . . . . . . . . . . . . . 2-15

Retransmit Configuration

Movement . . . . . . . . . . . . . . . . . . . . . . 2-16

. . . . 1-7

1-8

. . . .

1-9

. . . .

2-1

2-2

2-3

2-4

. . .

. . . . 2-5

. . . . 2-6

. . . . 2-7

. . . 2-8

. . . 2-9

2-10

Page

1-3

1-7

1-7

2-1

2-1

2-5

2-5

2-5

2-7

2-15

2-15

2-21

2-23

2-24

2-26

2-26

2-27

2-27

2-28

Chapter 3.

Section I.

ii

MAINTENANCE

INSTRUCTIONS

Tools and Equipment

General. . . . . . . . . . . . . . . . . . . . . .3-1

II.

Lubrication Instructions

General . . . . . . . . . . . . . . . . . . .. . . . . . .3-2

3-1

3-1

TM 11-5820-553-10

III.

IV.

Chapter 4.

Section I.

II.

Preventive Maintenance

Checks and Services

(PMCS)

General . . . . . . . . . . . . . . . . . . . .3-3

Preventive Maintenance

Checks and Services. . . . . . . .3-4

Maintenance of the Radio

Set . . . . . . . . . . . . . . . . . . . . ..3-5

Troubleshooting

General . . . . . . . . . . . . . . . . . . .3-6

V.

Maintenance of Radio Set

General . . . . . . . . . . . . . . . . . . .3-7

MATERIEL USED IN

CONJUNCTION WITH

MAJOR ITEM

General

List of Auxiliary Equip-

merit . . . . . . . . . . . . . . . . . . . . 4-1

Installation Instruc-

tions for Auxiliary

Equipment

Voice Security Equip-

ment Configuration . . . . . . . .4-2

Code Burst and CW

Configuration . . . . . . . . . . . . .4-3

Digital Message Device Group

OA-8990 Configuration . . . . . . . . 4-4

Handcrank Generator

Configuration . . . . . . . . . . . . . . . . .4-5

Power Supply Configuration . . . . . 4-6

Paragraph

Page

3-1

3-2

3-2

3-3

3-3

4-1

4-1

4-4

4-8

4-10

4-14

Appendix A.

Section I.

II.

Section I.

REFERENCES . . . . . . . . . . . . .

B.

COMPONENTS OF END

ITEM LIST . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . .

Integral Components of

End Item . . . . . . . . . . . . . . . . .

ADDITIONAL AUTHORI-

C.

ZATION LIST

Introduction . . . . . . . . . . . . . . . .

Additional Authorization

II.

List . . . . . . . . . . . . . . . . . . . . .

A-1

B-1

B-3

C-1

C-2

Change 2 iii

TM 11-5820-553-10

Section

Number

1-1

1-2

2-1

2-2

2-3

2-4

2-5

4-1

4-2

4-3

4-4

4-5

4-6

D. EXPENDABLE SUPPLIES

AND MATERIALS LIST

I. Introduction . . . . . . . . . . . . . . . .

II. Expendable Supplies and

Material List . . . . . . . . .

. . . . .

Paragraph

Page

D-1

D-2

LIST OF ILLUSTRATIONS

Title

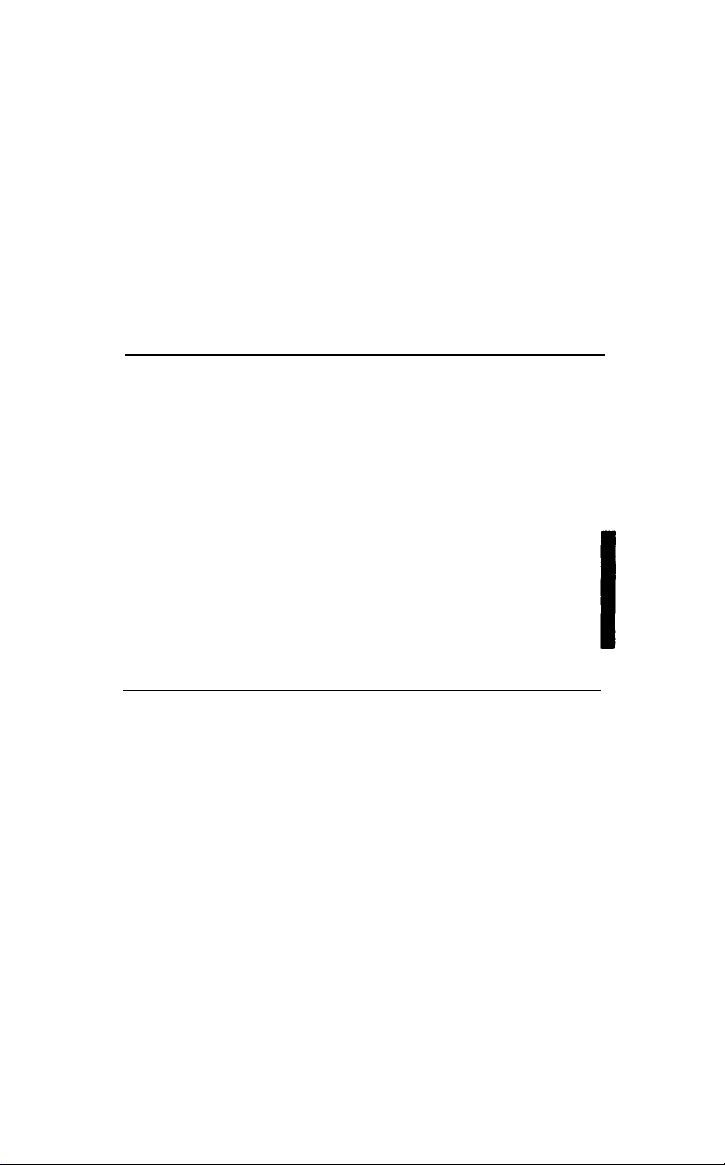

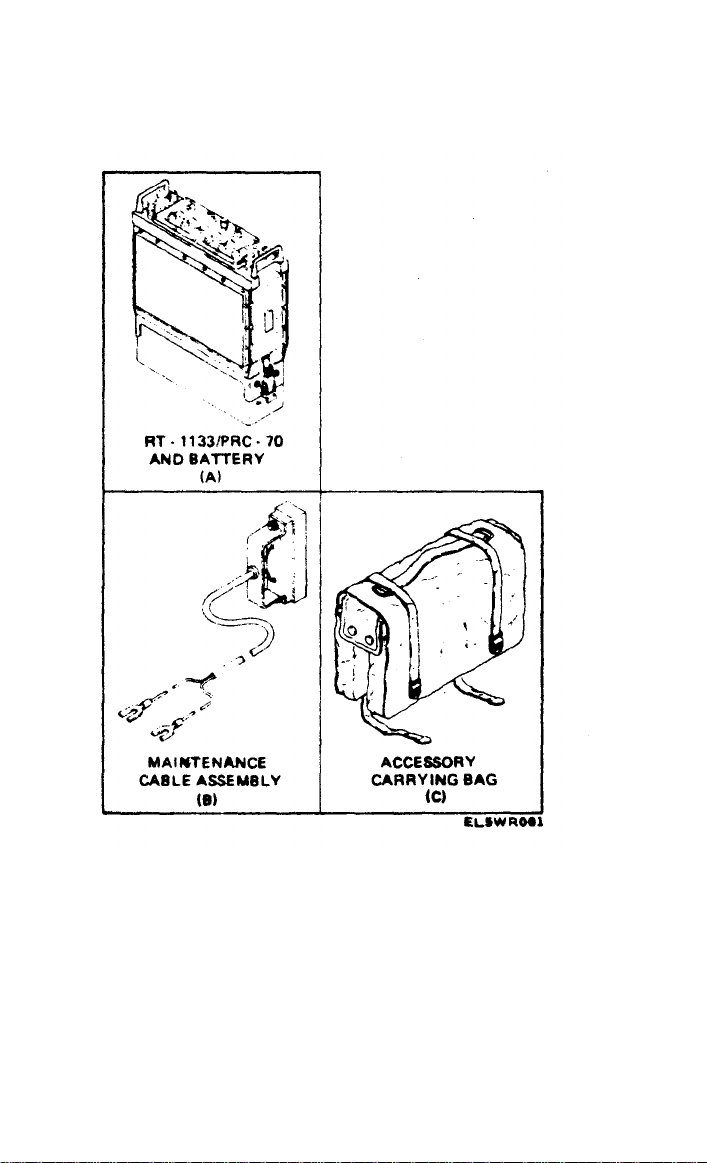

Radio Set AN/PRC-70 . . . . . . . . . . .

Contents of Accessory Carrying Bag . .

RT-1133/PRC-70 Controls.

Radio Set AN/PRC-70 Portable Con-

figuration . . . . . . . . . . . . . . . . . . . 2-6

Doublet Antenna AS-2975/PRC-70 . . . . . . . . . . . . 2-8

Long Wire Antenna Configuration . . . . . . . 2-11

Retransmit Configuration . . . . . . . . . . . . . . . . 2-13

Voice Security Equipment Configuration 4-2

CW Configuration . . . . . . . . . . . . 4-5

Digital Message Device Group (DMDG),

OA-8990/P Configuration . . . . 4-8

Handcrank Generator, G-76/G Con-

figuration, . . . . . . . . . . . . . . . . 4-10

Battery Charging with

Generator G-76/G . . . . . . . . . . . . . . . . . . 4-12

Power Supply, PP-6148/U Configuration 4-16

Handcrank

Page

1-4

1-5

2-2

iv

TM 11-5820-553-10/EE150-SN-OPl-010/E110-PRC 70

CHAPTER 1

INTRODUCTION

Section I. GENERAL

1-1. Scope

This manual contains operator instructions for Radio

Set AN/PRC-70. Equipment description, installation

instructions, and maintenance duties for the operator

are included in the manual. Operating and maintenance

instructions for the auxiliary equipment used with the

AN/PRC-70 are contained in separate technical

manuals. Refer to appendix A for a listing of these

manuals.

1-2. Consolidated Index of Army Publications and

Blank Forms

Refer to the latest issue of DA Pam 310-1 to determine

whether there are new editions, changes or additional

publications pertaining to the equipment.

1-3. Maintenance Forms, Records, and Reports

a. Reports of Maintenance and Unsatisfactory

Equipment. Department of the Army forms and pro-

cedures used for equipment maintenance will be those

prescribed by DA Pam 738-750, as contained in

Maintenance Management Update. Navy personnel will

report maintenance performed utilizing the

Maintenance Data Collection Subsystem (MDCS) IAW

OPNAVINST 4790.2, Vol 3 and unsatisfactory

material/conditions (UR submissions) IAW OP-

NAVINST 4790.2, Vol 2, chapter 17.

b. Report of Packaging and Handling Deficiencies.

Fill out and forward SF 364 (Report of Discrepancy

ROD)) as prescribed in AR 735-11-2/DLAR 4140.55/

NAVMATINST 4355.73B/AFR 400-54/MCO 4430.3H.

Change 2

1-1

TM 11-5820-553-10/EE150-SN-OPl-010/E110-PRC 70

c.

Discrepancy in Shipment Report (DISREP) (SF

361). Fill out and forward Discrepancy in Shipment

Report (DISREP) (SF 361) as prescribed in AR 55-38/

NAVSUPINST 4610.33C/AFR 75-18/MCO P4610

.19D/DLAR 4500.15.

1-4. Reporting Equipment Improvement

Recommendations (EIR)

a. Army. If your Radio Set AN/PRC-70 needs

improvement, let us know. Send us an EIR. You, the

user, are the only one who can tell us what you don’t

like about the design. Put it on an SF 368 (Quality

Deficiency Report). Mail it to Commander, US Army

Communications—Electronics Command and Fort

Monmouth, ATTN: AMSEL—PA—MA—D, Fort

Monmouth, New Jersey 07703—5000. We’ll send you

a reply.

b. Navy. Navy personnel are encouraged to submit

EIR's through their local Beneficial Suggestion Pro-

gram.

1-5. Warranty Information

Radio Set AN/PRC-70 is warranted by the contractor

for a period of 12 months. It starts on the date of

Government acceptance indicated on the appropriate

DD Form 2408-9. Report all defects in material or

workmanship to your supervisor who will take appropriate action through your Organization's maintenance shop.

Section II.

1-6. Equipment Characteristics, Capabilities and

Features (fig. 1-1)

Radio Set AN/PRC-70, referred to hereafter as the

radio set, is a medium-to-long-range communications

set which operates in the 2 to 76 MHz frequency band.

Various configurations of this equipment are possible so

that it may be transported by one or two persons or installed at fixed sites such as field headquarters, command

posts, etc. The radio set may be operated in all kinds of

1-2

Change 2

DESCRIPTION AND DATA

TM 11-5820-553-10

weather and terrain. Operating modes include

amplitude modulation (AM), single sideband (SSB),

continuous wave (CW), frequency modulation (FM),

and frequency-shift keying (FSK). Provisions are

included for the connection of separate security

devices to allow secure communications in selected

modes. Two radio sets may be connected together

for retransmission purposes.

1-7. Location and Description of Major

Components

The radio set consists of the items shown in figures

1-1 and 1-2. The items not described in separate

technical manuals are described in the following

subparagraphs.

1-3

TM 11-5820-553-10

1-4

Figure 1-1. Radio Set AN/PRC- 70.

Change 2

1-5

Figure 1-2.

TM 11-5820-553-10

Figure 1-2.

TM 11-5820-553-10

a. Receiver-Transmitter RT-1133/PRC-70. The

Receiver-Transmitter RT-1133/PRC-70 (A, fig.

1-1) is the major assembly of the radio set. Receiver-

Transmitter RT-1133/PRC-70 is referred to

hereafter as the RT unit. The RT unit is housed in a

metal case and contains the receive and transmit

circuits. Controls for the operator and cable connectors are located on the front panel of the RT unit.

b. Accessory Carrying Bag. The accessory

carrying bag (C, fig.1-1) is used for carrying the

following items (fig. 1-2):

(1) Handset H-250/U.

(2) Headset H-251/U.

(3) CW

CX-13101/PRC-70.

(4) Doublet Antenna AS-2975 PRC-70 con-

sisting of:

(a) 5-foot measuring tape.

(b) Ground rod.

(c) Balun assembly with RG-58 Cable

Assembly.

(d) 25-foot RG-25 Cable Assembly with BNC

adapter.

(e) Halyard assembly (2 each).

(f) Wire rope assembly (2 each).

(5) Whip Antenna AS-2974/PRC-70 consisting

of:

(a) 6-foot whip (4 sections).

(b) 9-foot whip (6 sections).

(c) Swivel antenna base.

c. Maintenance Cable Assembly. This assembly

(B, fig. 1-1) connects the RT unit to a power supply

for operating, testing, and troubleshooting the RT

unit without a battery.

d. Doublet Antenna AS-2975/PRC-70. This

assembly is a half-wave portable antenna that is

adjustable for an operating frequency between 2 and

30 MHz and is only used in fixed configurations.

Key KY-116/U

with Cable

1-6

TM 11-5820-553-10/EE150-SN-OPl-010/E110-PRC 70

e. Whip

assembly consists of a foldable 6-foot antenna, a

foldable 9-foot antenna, and a swivel antenna base.

The 6-foot antenna is used for the 4 to 76 MHz

range and the 9-foot antenna is used for the 3 to 76

MHz range. The whip antenna assembly is required

for portable configurations.

1-8. System Application

The radio set is a lightweight transceiver designed

for manpack use. It operates in the frequency range

of 2 to 76 MHz in AM, CW, SSB, and FSK modes

and from 30 to 76 MHz in FM mode. The radio set

has a long-range communications capability up to

2500 miles (4000 km). The 30 to 76 MHz SSB mode

offers flexibility for setting up communication nets

and links. The built-in antenna coupler is automatic,

and provides the best match with whip, long wire,

and doublet antenna assemblies.

1-9. Tabulated Data

The following subparagraphs describe the technical

data for the radio set. Table 1-1 lists the physical

data of the items of the radio set. The relationship

between the various modes, frequencies, antenna

assemblies and distances are shown in tables 1-2

and 1-3.

a. Receiver-Transmitter RT-1133/PRC-70

Input Voltage . . . . . . . . . . . . . . .+20 to +32 vdc

Power Consumption:

Receive Mode .. . . . . . . . . . . . 7 watts maximum

Low-Power Transmit Mode. . . .50 watts maximum

High-Power Transmit Mode

FSK, CW, FM, AM . . . . . . . . . . 160 watts maximum

SSB . . . . . . . . . . . . . 115 watts maximum

Power Output:

Duty Cycle . . . . . . . . . . . . . .9 to 1 receive-to-transmit

Antenna AS-2974/PRC-70. This

ratio.

Change 2

1-7

TM 11-5820-553-10

High-Power Mode

CW, FM*, FSK. . . . . . . . . . . 21-42 watts average

SSB . . . . . . . . . . . . . . . . . . . . . . .

AM . . . . . . . . . . . . . . . . . . . . . . . 7.5 watts carrier, 7.5

Low-Power Mode . . . . . . . . . .3 watts, +2dB, -2.5 dB

Frequency Range. . . . . . . . . . .2.000 to 75.9999 MHz in

* FM transmit enabled only in 30.0000 to 75.9999 MHz range.

NOTE

A temperature-sensing switch is located

in the power amplifier module. If continuous transmission at HI PWR is

required during high temperatures the

RT unit may switch to lower power

(approximately

proximately

operation. When the temperature is

sufficiently reduced the RT unit will

automatically return to the higher power

level.

Receiver Sensitivity:

FM . . . . . . . . . . . . . . . . . . . 0.60µV

SSB, FSK, CW . . . . . . . . . . . . . 0.375 to

AM . . . . . . . . . . . . . . . . . . . . . .2.50

Receiver Signal-to-Noise

Ratio . . . . . . . . . . . . . . . . . . . .10 dB at referenced

Receiver Selectivity:

FM . . . . . . . . . . . . . . . . . . . . . . . . . .32 kHz at 6dB

SSB, CW, FSK . . . . . . . . . . . . .2.8 kHz at 6 dB

AM. . . . . . . . . . . . . . . . . . . . 6.0 kHz at 6 dB

3 watts) after ap-

10 minutes of such

21-42 watts peak en-

velope power

watts upper sideband.

30 watts PEP at

85%

minimum

100 Hz steps

(varies with frequency)

modulation

0.50

µV

sensitivity

70 kHz at 60 dB

4.0 kHz at 26 dB

6.0 kHz at 60 dB

14.0 kHz at 60 dB

µV

1-8

TM 11-5820-553-10

Doublet Antenna AS-2975/PRC-70

b.

Frequency Range . . . . . . . . . . . . 2 to 30 MHz

(normal range)

Input Impedance. . . . . . . . . . . . 50 ohms

Whip Antenna AS-2974/PRC-70

c.

6- foot section . . . . . . . . . . . . . . 4 to 76 MHz

9-foot section . . . . . . . . . . . . . . .3 to 76 MHz

Table 1-1. Items Comprising an Operable Equipment

Dimensions

Length Depth Width Weight

NSN

Item

5820-01-062-8246 Radio Set

AN/PRC-70

Consisting

of:

5820-01-073-9114 Receiver-

Transmitter

RT-1133/

PRC-70

5995-01-092-5943 Maintenance

Cable

Assembly 1 60 –

Accessory

Carrying

Bag

5985-01-073-5602 Doublet

Antenna

AS-2975/

PRC-70

5985-01-073-5601 Whip An-

tenna

AS-2974/

PRC-70

(6 ft)

(9 ft)

5965-01-017-0549 Headset

H-251/U 1 8 4

5965-00-043-3463 Handset

H-250/U 1 8 2

5805-00-503-3395 CW Key KY-

116/U

with

(in.) (in.) (in.) (lb.)

Qty

4 11.9 13.25 21.0

1

1 11 17.5

1 2808 –

1

72 –

1 108 –

153

–

6.5

—

– 0.75

—

1.00

4

2

3

0.45

2.0

5.25

0.7

0.5

0.4

Change 2

1-9

TM 11-5820-553-10

Table 1-1. Items Comprising an Operable

NSN

5995-01-073-6123

Equipment- Continued

Length Depth Width Weight

(in.) (in.)

Item

Qty

Cable CX-

Dimensions

13101/

PRC-70

Ground Rod

SMC

746768/800-

45 NOTE 1 18 –

The following equipment is required but not supplied as part of the AN/PRC-70.

6140-01-089-7636 Battery

BB-542/U 1 12.2 2.56 4.0

Table 1-2. Operating Modes, Antennas, and Frequencies

Operating Mode

FM

Antenna Frequency

6-foot whip

30 to 76 MHz

9-foot whip 30 to 76 MHz

CW, FSK, AM, SSB

6-foot whip

9-foot whip

Doublet

4 to 76 MHz

3 to 76 MHz

2 to 30 MHz

(normal)

Table 1-3. Operating Modes, Antennas, and Distances

(in.) (lb.)

0.75

0.8

7.0

Mode

CW

Antenna

AS-2975/PRC-70

Distance Range

up to 2,500

miles*

SSB Voice, AM AS-2975/PRC-70 0–500 miles

SSB Voice, FM

AM

FM

AS-2974/PRC-70

AS-2974/PRC-70 0–15 miles

AS-2974/PRC-70

0–25 miles

0–15 miles

*Long wire antenna may be used (para 2-6b).

1-10

TM 11-5820-553-10

CHAPTER 2

OPERATING INSTRUCTIONS

Section I. CONTROLS

AND INDICATORS

2-1. Damage From Improper Settings

No damage will result to the equipment from improper control settings at turn-on. Battery life will

be shortened by some control settings. Maximum

battery drain occurs when the POWER switch is set

to HI PWR and the SQUELCH switch is held in the

DIAL LIGHT position. For best battery life use

other settings of the controls when possible.

2-2. Operator/Crew Controls

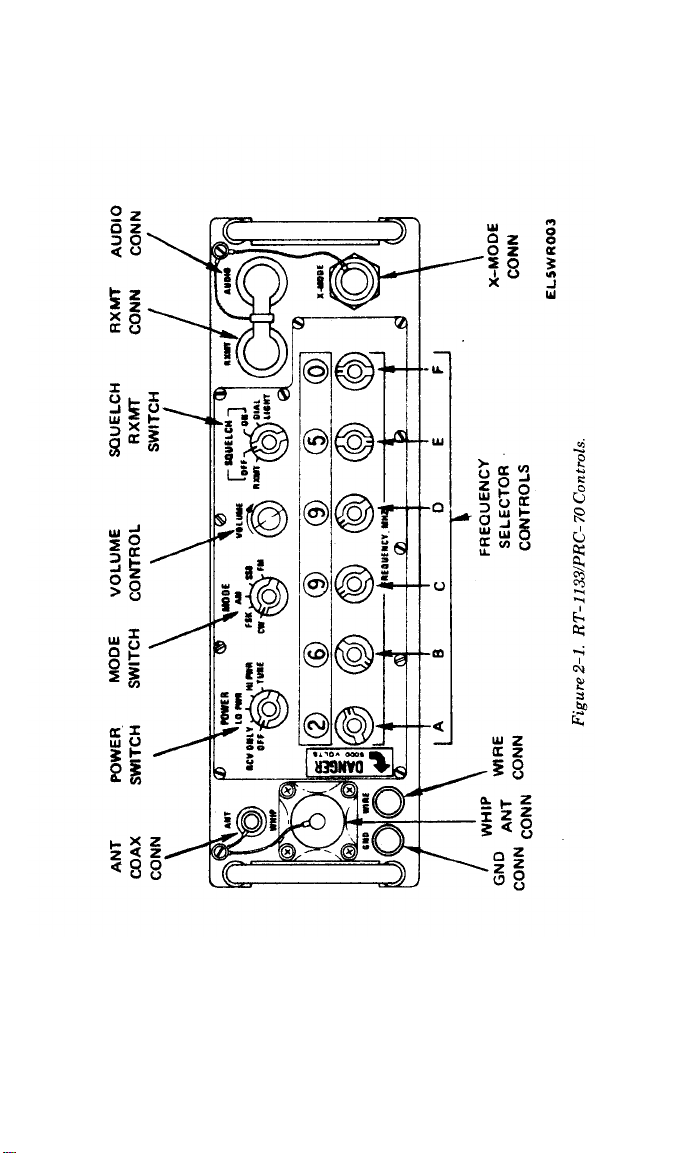

Figure 2-1 shows the RT unit front panel controls.

Table 2-1 lists the operator controls, indicators, and

connectors and describes their functions.

CAUTION

Do not change front panel controls while

RT unit is transmitting.

2-1

TM 11-5820-553-10

Figure 2-1.

2-2

Figure 2-1.

TM 11-5820-553-10

Table 2-1. Controls, Indicators and Connectors

Control, indicator,

or connector

Function

POWER switch Sets major functions of RT-l133/PRC-

70 as follows:

Positions:

OFF

RCV ONLY

LO PWR

Removes all power from RT unit.

Applies power to receive circuits only,

Allows transmission in low-power mode

when transmitter is keyed. Output is

approximately 3 watts,

HI PWR

Allows transmission in high-power mode

when transmitter is keyed. Output is

approximately 30 watts.

TUNE Starts automatic tuning sequence in unit

to tune antenna coupler. Switch is

spring loaded in this position and

returns to HI PWR position when

released.

MODE switch

Selects operating mode of unit. Modes

are CW, FSK, AM, SSB, and FM*.

* Transmit enables only in 30.0000 to 75.9999 MHz range.

VOLUME control

SQUELCH switch

Sets volume of received audio.

Controls operation of receiver squelch

and unit dial lights as follows:

Positions:

RXMT

Actuates switching circuit which con-

trols second RT-1133/PRC-70 in

retransmit mode.

OFF

ON

Disables squelch circuit.

Enables receiver squelch in voice modes.

Squelch is disabled if MODE switch is

set to CW or FSK.

DIAL LIGHT

Momentary switch position; applies

power to dial lights. Switch returns to

ON position when released.

RXMT connector

Connects

unit to second RT unit

RT-1133/PRC-70 in retransmit mode.

Connects CW Key KY-116/U for CW or

FSK operation.

AUDIO connector

Connects Handset H-250/U to RT unit

for normal voice operation and Headset

H-251/U during CW or FSK operation.

X-MODE

connector

Connects voice security applique to unit

for secure voice operation.

2-3

TM 11-5820-553-10

Table 2-1. Controls, Indicators and Connectors–Continued

Control. indicator

or connector

CAUTION

Dummy shorting caps for AN/PRC-70 and

AN/PRC-77 are not interchangeable.

NOTE

Shorting cap must be connected to connector at all

times when voice security applique is not being

used or power to RT unit will be interrupted.

ANT connector

Installing the coax connector of the doublet antenna to the antenna connector removes all R.F.

power from the wire connector post.

WHIP connector

Installing the antenna swivel base to the whip connector removes all R.F. power from the antenna and

wire connectors.

WIRE connector

GND connector

FREQUENCY

selector controls

and indicators:

A

B

C

D

E

F

Connects feedline for Doublet Antenna

AS-2975/PRC-70 to RT unit.

NOTE

Connects whip Antenna AS-2974/PRC-70 to

RT unit.

NOTE

Connects random wire length antennas to

RT unit.

Connects ground wire to RT unit.

Operating frequency is changed by rotat-

ing frequency selector controls while

observing frequency readout numerals.

FM transmit is disabled by these

controls below 30.0000 MHz setting.

Megahertz tens selector

Megahertz unit selector

Kilohertz hundreds selector

Kilohertz tens selector

Kilohertz units selector

Hertz hundreds selector

Function

2-4

Change 2

TM 11-5820-553-10

Section II. OPERATION UNDER

USUAL CONDITIONS

2-3. Types of Operation

Two types of operation are possible using the radio

set: portable and fixed configurations. Refer to

Chapter 4, Section II, for the installation and

operation

of configurations

using

auxiliary

equipment.

2-4. Preliminary Starting Procedures

Before operating the radio set, set controls as

follows:

Control

POWER switch

MODE switch

VOLUME control

SQUELCH switch

FREQUENCY selector

controls

OFF

Operating mode desired

Midrange

OFF

Operating frequency desired

Setting

2-5. Portable Configuration

Figure 2-2 shows the portable configuration. For

operation in this configuration, assemble equipment

as follows:

CAUTION

The antenna base must be screwed down

all the way until the antenna base meets

with the connector. If a gap is left between the antenna base and the connector,

the antenna base screw may break.

2-5

TM 11-5820-553-10

Figure 2-2. Radio Set AN/PRC- 70 Portable Configuration.

a. Install the antenna swivel base in RT unit

WHIP connector.

2-6

TM 11-5820-553-10

b.

Assemble the whip antenna by unfolding either

the 6-foot or the 9-foot section, and pressing

ferrules together.

c. Screw whip antenna into the antenna swivel

base.

d. For voice operation, connect Handset H-250/U

to the AUDIO connector on the RT unit.

e. For CW operation, connect Headset H-251/U

to the AUDIO connector and CW Key KY-116/U

with cable CX- 13101/PRC-70 to the RXMT connector on the RT unit.

2-6. Fixed Configuration

This paragraph contains setup and assembly for

operable equipment in fixed configurations. Nonportable equipment use is determined by the local

commander.

NOTE

When using the doublet antenna, the

direction of the antenna wire should be at

right angles to the desired direction of

transmission.

a.

Installation of Doublet Antenna. Figure 2-3

shows the equipment setup for this configuration.

The halyard assemblies may be attached to any

suitable structure, manmade or natural, that will

provide maximum height, correct antenna length,

and antenna orientation at a right angle to the

direction of desired transmission.

2-7

TM 11-5820-553-10

Figure 2-3.

2-8

Figure 2-3.

TM 11-5820-553-10

(1) Select a good location for the installation of

the doublet antenna.

(2) Calculate antenna length of each leg by the

following formula:

234

Operating Frequency in MHz

NOTE

Total antenna length is the length of both

antenna pieces added together.

EXAMPLE

Operating Frequency is 2 MHz,

117 (ft) each antenna leg.

Total antenna length for 2 MHz = 2 x 117

ft or 234 ft.

NOTE

Due to corrosive effects of weather on the

antenna wire the radio may not tune to

this length. To compensate for this effect,

the length of each leg of the

AS-2975/PRC-70 including bobbins,

should be shortened by one foot below the

length calculated from the standard

formula 234 ft. (MHz).

(3) Remove Doublet Antenna Assembly

AS-2975/PRC-70 from accessory carrying bag (fig.

1-2).

(4) Connect the two wire rope assemblies to the

balun assembly as shown in figure 2-3.

(5) Unwind the desired antenna wire length as

determined by (2) above on both wire rope assemblies.

(6) Unwind the nylon rope from the two halyard

assemblies.

(7) Connect the end of the rope of the halyard

assemblies to the reel of the two-wire rope assemblies.

(8) Secure the halyard assemblies to the

= (ft) of one leg

234

=

2 MHz

2-9

TM 11-5820-553-10

selected structures.

(9) Place the RT unit under the balun assembly

near the RG-58 Cable Assembly.

(10) Place ground rod in the ground near the RT

unit. Connect the ground wire to the GND terminal

on the RT unit.

(11) Connect the RG-58 Cable Assembly to the

ANT connector on the RT unit. If necessary, use the

extra 25-foot RG-58 Cable Assembly with Adapter

UG-914/U.

b. Operation With Long Wire Antenna. The radio

set may be operated by using the two wire rope

assemblies and the two halyard assemblies of the

doublet antenna. The two guy hooks of the wire rope

assembly are overlayed and bolted together. This

will provide an antenna wire length of 234 feet. The

arrangement of equipment is shown in figure 2-4.

This long wire antenna arrangement can be used at

any operating frequency from 6 to 30 MHz.

2-10

Figure 2-4.

TM 11-5820-553-10

Figure 2-4.

2-11

TM 11-5820-553-10

c. Retransmit Configuration.

(1) Equipment setup. Two radio sets can be

operated together to establish retransmission of

voice signals on AM, FM, and SSB. Figure 2-5 shows

this configuration which includes the following items:

(a) Two Receiver-Transmitters RT-1133/

PRC-70.

(b) Two Batteries BB-542/U.

(c) Transmission Cable Kit MK-456 or

MK-456A/GRC.

(d) One Doublet Antenna AS-2975/PRC-70.

(e) One 6-foot or 9-foot Whip Antenna

AS-2974/PRC-70.

(f) Handset H-250/U.

2-12

Change 2

TM 11-5820-553-10

Figure 2-5. Retransmit Configuration.

2-13

TM 11-5820-553-10

(2) Assembly. Assemble the doublet antenna as

described in paragraph 2-6. Perform the following

steps:

(3) Operating Instructions.

(a) Set controls on RT unit as follows:

Control

POWER switch

MODE switch

VOLUME control

SQUELCH switch

FREQUENCY SELECTOR

switch

OFF

Operating mode desired

Midrange

OFF

To assigned operating

frequencies

Setting

(b) Initial tune up.

1. Turn RT unit

B POWER switch

to HI

PWR.

2. Set VOLUME control to a level

which

permits monitoring of any radio traffic on the

specified frequencies.

If undesired traffic exists,

turn squelch switch to RMXT and observe if the

unit stays squelched. If the squelch breaks, even

marginally, do not use that frequency. A good link

check can be made at this point using the received

desired frequency to assure that it will break the

squelch.

3. Perform the coupler tune sequence by

momentarily setting the POWER switch to TUNE.

This switch is spring loaded and will return to the

HI PWR position.

4. Set the POWER switch to HI PWR or

LO PWR as desired.

5. Tune unit C in a similar manner and set

both units’ SQUELCH switch to RXMT position.

6. Connect RXMT Cable CX-4656/GRC.

7. Set RT units A and B to FM mode on the

specified VHF frequency.

8. Set RT units C and D to the SSB mode

on the specified VHF frequency.

9. Communication link can be established

by voice transmission from unit A to reception at

2-14

TM 11-5820-553-10

unit D. Proper relay operation can be determined by

monitoring communications at CX-4656/GRC

audio connector. To prevent a loss of message, the

operator at the transmitting end should wait until

his unit squelches (noise is muted) before responding

to the received message. This will take approximately 2 seconds.

10. To shut down the equipment, set both

RT unit POWER switches to OFF.

2-7. Initial Adjustments

No adjustments of the radio set are necessary.

2-8. Operating Procedures

a. Equipment Starting. Start the equipment in

accordance with the following procedures:

WARNING

Serious injury or death could result to

personnel if the whip antenna comes in

contact with power lines.

(1) Set RT unit to desired frequency.

(2) Set RT unit POWER switch to RCV ONLY.

(3) Adjust RT unit VOLUME control for

suitable audio output level.

NOTE

The POWER switch is spring loaded in

the TUNE position and will return to HI

PWR when released. When RT unit is in

the coupler tuning mode, radio silence is

broken.

When the POWER switch is placed in the

TUNE (momentary spring loaded)

coupler unit will

position,

automatically tune to match the power

amplifier to the antenna being used. If a

good match is made, the tune cycle will

stop and the RT will be ready for use. If a

the

2-15

TM 11-5820-553-10

good match cannot be made within 15

seconds, the coupler will stop the tune

cycle. A no-tune condition will exist and

is indicated by a series of 2000 Hz beeps

when the RT is keyed. In SSB mode, the

operator must talk into the handset to

detect a no-tune condition.

(4) Momentarily set RT unit POWER switch to

TUNE and release. Allow 15 seconds for tuning to

be completed (when TUNE tone disappears from

handset). Once coupler tuning is completed, the

MODE switch can be changed without having to

retune.

(5) A beeper (no-tune) tone will result if the

antenna coupler does not provide a proper match.

Some power may be available and communication

should be attempted even though the antenna is not

optimum matched. Several corrective actions may

be taken to improve the match and are listed below:

(a) Move POWER switch to RCV ONLY and try

tuning again.

(b) Change frequency and try tuning again.

(c) Check antenna for damage.

(d) Check doublet antenna for proper length.

(e) Move to different location if near some large

object (tree, rock building, etc.).

(f) Check battery. Hold dial lamp switch on and

key transmitter. Dial lamps should not go out.

WARNING

When operating in HI PWR with the

whip antenna, do not touch the antenna

when in transmit mode—an RF burn can

result.

A potential RF radiation hazard exists

when Radio Set AN/PRC-70 is operated

with the whip antenna, either 2 or 3

meters. This hazard is increased when the

radio is operated in the portable (backpack) mode. For protection against these

2-16

Change 2

TM 11-5820-553-10/EE150-SN-OPl-010/E110-PRC 70

hazards,

observe

the

following

safeguards:

a. Use a dummy load when operating

the radio, if possible, such as when

performing

Preventive Maintenance

Cheeks and Services (PMCS) to determine

equipment readiness/availability.

b. Operate the radio in the off-the-back

(field-emplaced) mode, if possible, using

either the doublet or the long-wire antenna.

c. If a whip antenna must be used for

transmissions in the field-emplaced mode,

use a microphone cable long enough to

maintain a distance of at least 50 centimeters

from the antenna.

d. If the radio must be operated in the

portable (on-the-back) mode, do not transmit for longer than 30 seconds out of any

6-minute interval.

(6) Set RT unit POWER switch to LO PWR.

(7) Set RT unit SQUELCH switch to ON (if

desired).

NOTE

If RT unit FREQUENCY selectors are

reset, momentarily set POWER switch to

TUNE and release. After retuning is

completed (within 15 seeonds), LO PWR

position of POWER switch may be

selected.

b. Voice Mode Operation. Transmit in any of the

voice modes by pressing the H-250/U Handset

push-to-talk button and speaking into the

microphone.

c. Standard CW Operation. Use Headset

H-251/U for CW operation. To transmit in the

standard CW mode, key the RT unit with CW Key

KY-116/U.

Change 2

2-17

TM 11-5820-553-10

WARNING

Serious injury or death could

personnel if the whip antenna

result to

comes in

contact with power lines.

d. Miscellaneous Operating Notes.

(1) Changing settings of RT

unit controls

should not be done while transmitter is keyed.

(2) To read FREQUENCY selector dials in poor

light, set SQUELCH switch to DIAL LIGHT. The

switch is spring-loaded in this position and will

return to ON when released.

(3) The radio set will not operate well with FM

sets having 25-kHz channelization unless the RT

unit has been modified for this mode. Such

modification can be performed by depot support

maintenance personnel.

e. Equipment Shutdown. To shut down the

equipment set the RT unit POWER switch to OFF.

f. Special Tuning Procedures. Certain frequencies

and loading conditions may affect tuning. If several

attempts at tuning fail, the operator should try the

following steps:

(1) Change the location of the antenna. Objects

near the antenna (including the operator, other

people, and the handset cable) affect the impedance

of the antenna. The operator can try to tune the

radio set after doing one or more of the following:

(a) Change his position relative to the an-

tenna.

(b) Move the handset cable away from the

antenna.

(c) Move the radio position if it is sitting close

to a tree, post, or some other conductor.

(2) Change frequency.

(a) Change the frequency of the radio set in

100 kHz steps to a frequency at which it will tune.

(b) Change frequency as in (2)(a) then, change

2-18

TM 11-5820-553-10

back to the desired frequency. This will often solve

the problem.

g. Field Checkout. There may be times when the

operator wants to know the operational condition of

the unit without breaking radio silence. The

following steps will provide a partial check and may

lead to the corrective action required:

(1) With POWER switch OFF, attach battery.

(2) Set FREQUENCY to 10.997 MHz, MODE

switch to SSB, and SQUELCH switch to OFF. Do

not connect any antenna to the radio.

(3) Turn POWER switch to RCV ONLY and

adjust VOLUME control to obtain a suitable level

of tone which should have a frequency of approximately 3000 Hz.

(4) Change the FREQUENCY to 10.998 MHz

and observe that tone changes to a frequency of

approximately 2000 Hz. This test indicates that

power supplies,

audio, and IF circuits, volume

control, and handset or headset are operable. If no

audio is heard, turn VOLUME control fully

clockwise. If audio is still not heard, try a new

handset and/or new battery.

(5) To check squelch operation, set

FREQUENCY to 10.898 MHz and turn SQUELCH

switch to ON. The radio should mute (no audio or

noise unless strong traffic exists on that frequency).

Set FREQUENCY to 10.998 MHz and observe that

squelch breaks and 2000 Hz tone is heard.

(6) A battery check can be accomplished by

setting controls as given below:

(a) FREQUENCY at 10.998 MHz.

(b) Turn SQUELCH switch to DIAL LIGHT

and observe light level. While holding switch in

DIAL LIGHT position, change FREQUENCY to

14.998 MHz. The bandswitch motor will run and

lights should not dim (motor drains about 200 mA

from battery).

2-19

TM 11-5820-553-10

(7) Transmitter (hot tune) check can be accomp-

lished into an antenna as given below.

NOTE

Radio silence will be broken.

(a) Set FREQUENCY to assigned frequency.

(b) Turn POWER switch to TUNE and note

presence of a tone in handset while coupler is tuning

(Radio silence is broken.)

(c) Note that tune sequence finishes in less

than 15 seconds and that tone shuts off.

(d) Key transmitter and observe that voice

sidetone is heard.

(e)

If a series of beeps (a 2000 Hz tone coming

on at an interval of approximately 1 second) is heard,

try the following procedure:

1.

Move POWER switch to RCV ONLY and try

tuning again.

2.

Change frequency and try tuning again.

3. Check antenna for damage or doublet

antenna for correct length.

4.

Move to a different location if near some

large object (tree, building, etc.).

5.

Change battery if available.

2-20

Change 2

TM 11-5820-553-10

(8) Changing batteries.

(a) Battery removal.

1. Position RT-1133/PRC-70 (RT unit)

with battery assembly attached on a flat surface.

Insure POWER switch on RT unit is in OFF

position.

2. Unfasten battery side latches.

3. Lift RT unit away from battery.

(b) Battery installation.

1. Place a fully charged battery on a flat

surface with latches pulled out and down.

2. Ensure POWER switch on RT unit is in

OFF position. Place RT unit over battery and

carefully mate battery connector with RT unit

connector.

3. Press two units together and lock side

latches.

Section III. OPERATION UNDER

UNUSUAL CONDITIONS

2-9.

Operation Under Emergency Conditions

a.

Operation Under Extreme Climatic Conditions.

AN/PRC-70 is designed to operate in a wide

The

variety of climates. Some of the extreme climatic

conditions that may be encountered are moist heat,

dry heat, cold, rain, freezing rain, and snow. These

conditions are discussed, and information for

equipment operation and maintenance during their

occurrence is provided in the following subparagraphs:

(1) Extreme moist heat. In warm damp climates

or swampy regions, the equipment is subject to

damage from moisture and fungus. Observe the

Change 2

2-21

TM 11-5820-553-10

following precautions:

(a) Check the equipment frequently for

condensed moisture and fungus growth. Clean

equipment surfaces using a mild detergent solution.

Thoroughly wipe moisture from the exterior of the

equipment with a lint-free cloth; remove fungus

immediately.

(b) Warm damp climate promotes rust. Inspect facilities and equipment for signs of loose

paint and corrosion. Refer to TM 11-5820-553-23

section I of chapter 2 for refinishing and repainting

information.

(2) Extreme rainfall. During periods of extreme

rainfall, site facilities and equipment are subject to

damage from water seepage around weather seals.

Inspect weather seals on electrical equipment for

aging and resultant water seepage.

(3) Extreme dry heat. In hot, dry climates,

exposed electrical connectors, receptacles, and

terminals are subject to damage from blown dirt

and dust. Lubricants used on moving parts may

become contaminated with sand and grit and accelerate parts wear by the resulting abrasive action.

Minimize the effects of extreme dry heat by ob-

serving that electrical connectors and receptacles

have protective covers installed when not in use.

(4) Extreme cold. Subzero temperatures and

climatic conditions associated with cold weather

affect the operating efficiency of equipment. Extreme cold causes cables and wires to become hard,

brittle, and difficult to handle. Ice formation can

cause damage to facilities and equipment. Under

certain conditions it may be advisable to discontinue terminal operations. The following

precautionary measures apply:

(a) Be careful when handling power and signal

cables.

(b) Ensure that external connectors and

2-22

TM 11-5820-553-10

receptacles are kept free of frost, snow, and ice.

Keep protective covers installed on unused electrical receptacles.

protected cable connector in the snow.

(c) Keep batteries fully charged.

(5) Freezing rain. A freezing rain condition,

commonly known as sleeting, can occur when the

ambient temperature drops to between +27°F and

+32°F(-2.8°C and 0°C) during precipitation conditions.

On these occasions, the ice levels on the antenna may

accumulate to a level that can result in excessive

loads being placed on the antenna drive mechanism. A

sleeting condition is apparent by an accumulative

level of ice building up on exposed surfaces.

(6) Salt air and sea spray. Operation of

AN/PRC-70 equipment in an area where salt air and

sea spray are prevalant requires the following

preventive and protective maintenance procedures.

With fresh water, wash down antenna and support

equipment to prevent salt accumulation.

b. Operation on Low Batteries. Any or all of the

following procedures may be used to save the

batteries in RT unit in an emergency.

(1) Set POWER switch to LO PWR for trans-

mitting if good communications can be established

using this mode.

(2) If possible, use SSB voice or standard CW

mode.

(3) Use an external light source to check

frequency and controls.

Never drag or place an un-

2-10. Recognition and Identification

of Jamming

It is likely that under real or simulated tactical

conditions the receiver will be jammed by the

enemy. Enemy jamming is done by transmitting a

strong signal on the same frequency as that used for

Change 2

2-23

TM 11-5820-553-10

communication, thereby making it difficult or

impossible to receive the desired signal. Unusual

noises or interference heard on the receiver may be

caused by enemy jamming, noise from a local source

or a bad receiver. To determine whether or not the

interference is in the receiver, disconnect and

remove the antenna leads, and/or temporarily

connect the WIRE post to the chassis. If the in-

terference continues, the receiver is bad. Enemy

jamming signals may be a continuous wave or

modulated. A jamming signal may be intended to

block a single frequency. This is called spot jam-

ming. The enemy may use one or several trans-

mitters to jam a block or band of frequencies. This

method is called barrage jamming.

a. Continuous-Wave (CW) Jamming. CW jamming is transmitted as a steady carrier. This signal

beats with another signal and produces a steady

tone. CW jamming signals may also be keyed by

using a random on-and-off signal or using actual

code characters keyed to the same rate or a little

faster than the signal being received.

b. Modulated Jamming. Modulated jamming

signals may be noise,

various tones, or almost any unusual sound, or it

may be a number of these sounds. Various types of

modulated jamming signals are explained below.

(1) Spark. This is one of the simplest, most

effective, and easily produced jamming signals. This

type of signal sounds very rough, raspy, and

sometimes like an operating electric motor with

sparking brushes. The signal is very broad;

therefore, it will interfere with a larger number of

communication channels.

(2) Sweep-through. This signal is the result of

sweeping or moving a carrier back and forth at a

slow or rapid rate, The numerous signals of varying

amplitude and frequency produce a sound like that

laughter, singing, music,

2-24

Change 2

TM 11-5820-553-10

of a low-flying airplane passing overhead. This type

of jamming is effective over a broad range or

frequencies. When it is varied rapidly, it is effective

against all types of voice signals.

(3) Stepped tones or

usually consists of several separate tones. The tones

are transmitted in the order of first increasing and

then decreasing pitch, repeated over and over. The

audible effect is like the sound of a Scottish bagpipe.

(4) Noise. Noise is random both in amplitude

and frequency. It produces a sound similar to that

heard when a receiver is not tuned to a station and

the VOLUME control is turned to maximum.

(5) Gulls. This signal consists of a quick rise

and slow fall of a variable audio frequency. The

sound is similar to the cry of the sea gull.

(6) Tone. This signal consists of a single audio

frequency of unvarying tone, It produces a steady

howl. Another method of tone jamming.is to very it

slowly. This produces a howling sound of varying

pitch.

2-11. Antijamming Procedures

When it is determined that the incoming signal is

being jammed, notify your immediate supervisor

and continue to operate the equipment. To provide

maximum understanding of jammed signals, follow

one or more of the procedures in the following steps.

If these procedures do not provide satisfactory

operation, change to an alternate frequency.

a. Operate RT unit as outlined in paragraph 2-8.

b. Tune FREQUENCY, using 100 Hz dial on

either side of received signal. This may separate the

received signal and jamming signal.

Do not transmit on

frequencies.

c. Vary VOLUME control.

bagpipes. This signal

NOTE

unauthorized

This may reduce

2-25

TM 11-5820-553-10

jamming signals enough to permit weak signals to

be heard.

d. Use either SSB or standard CW mode. These

modes are less affected by jamming.

Section IV. PREPARATION

FOR MOVEMENT

2-12. Portable Configuration Movement

The portable configuration of the radio set may be

carried while assembled if continued use is needed.

The whip antenna may be folded if the radio set will

be transported in a vehicle. However, if the radio set

will not be used right away at the new location, the

equipment should be taken apart as follows:

a. Set POWER switch to OFF.

b. Unscrew whip antenna from the antenna

swivel base.

c. Fold the whip antenna by pulling ferrules

apart. (Start with top section first.)

d. Unscrew the antenna swivel base from WHIP

terminal on RT unit.

e. For voice operation, remove Handset H-250/U

from the AUDIO connector on the RT unit.

f. For CW operation, remove Headset H-251/U

from AUDIO connector and CW Key KY-116/U

with cable CX-13101/PRC-70 from RXMT con-

nector on RT unit.

g. Put whip antenna, antenna swivel base, Handset

H-250/U, Headset H-251/U, CW Key KY-116/U and all

other loose items in accessory bag.

2-13. Fixed Configuration Movement

When the doublet antenna configuration is being

used, proceed as follows:

2-26

Change 2

TM 11-5820-553-10

a. Set POWER switch to OFF.

b. Remove RF cable assembly from ANT con-

nector on RT unit.

c. Loosen and remove halyard assemblies from

supporting structures.

d. Remove halyard assembly from wire rope

assembly and rewind cord.

e. Disconnect wire rope assembly and terminals

from terminals on balun assembly.

f. Rewind antenna wire on reel of rope assembly

and secure.

g. Put all doublet antenna assembly items in

accessory carrying bag.

h. Remove ground wire from GND terminal on

RT unit.

i. Pull ground rod assembly out of the ground.

j. If Handset H-250/U was used, remove it from

AUDIO connector on RT unit.

k. If headset H-251/U was used, remove it from

the AUDIO connector and disconnect CW Key

KY-116/U from RXMT connector on RT unit.

l. Put all assemblies in accessory carrying bag.

2-14. Fixed Voice Configuration Movement

a. Set POWER switch to OFF.

b. Disassemble doublet antenna configuration as

described in paragraph 2-13.

c. Remove Handset H-250/U from voice security

applique.

d. If applicable, remove security applique from

X-MODE connector. Replace shorting cap on

X-MODE connector.

2-15. CW or FSK Configuration Movement

To prepare the fixed CW or FSK configuration for

movement, proceed as follows:

a. Set POWER switch to OFF.

b. Separate doublet antenna configuration as

2-27

TM 11-5820-553-10

described in paragraph 2-13.

c. Remove ground wire from RT unit GND

connector.

d. Remove KY-468/GRA-71(KE-8B) from

RXMT connector.

e. Put

AS-2975/PRC-70, and other loose items in carrying

bags.

2-16. Retransmit Configuration Movement

To prepare the retransmit configuration for

movement, proceed a:

a. Set POWER switch on each RT unit to OFF.

b. Separate doublet antenna configurations as

described in paragraph 2-13.

c. Remove ground wires from GND connectors.

d. Remove MK-456/GRC from both RXMT

connectors.

e. Put

AS-2975/PRC-70, and other loose items in carrying

bags.

Doublet Antenna Assembly

Doublet Antenna Assembly

2-28

TM 11-5820-553-10

CHAPTER 3

MAINTENANCE INSTRUCTIONS

Section I. TOOLS AND EQUIPMENT

3-1. General

There are no tools or test equipment issued at this

level of maintenance.

Section II. LUBRICATION

INSTRUCTIONS

3-2. General

No lubrication is required for the radio set.

Section III. PREVENTIVE MAINTENANCE

CHECKS AND SERVICES (PMCS)

3-3. General

Always keep the radio set ready for operation, It

must be inspected routinely so that defects may be

discovered and corrected before serious damage or

failure results. The preventive maintenance checks

and services to be done are listed and described in

table 3-1. The item numbers show the order of

minimum

discovered during operation of the unit will be noted

for correction when operation has ceased. Stop

operation immediately if a failure is found during

operation which would damage the equipment.

a. Before you Operate. Always keep in mind the

CAUTIONS and WARNINGS. Perform your before

(B) PMCS.

b. While you Operate. Always keep in mind the

CAUTIONS and WARNINGS. Perform your

inspection

requirements.

Defects

3-1

TM 11-5820-553-10

during (D) PMCS.

c. After you Operate. Be sure to perform your

after (A) PMCS.

d. If Your Equipment Fails to Operate. Refer to

troubleshooting, Section IV. Report any deficiencies

using the proper form, see TM 38-750.

3-4. Preventive Maintenance Checks and

Services (PMCS)

Refer to table 3-1. Checks and services are numbered in order. The item number column will be used

as a source of item numbers for the TM Number

column on DA Form 2404, Equipment Inspection

and Maintenance Work Sheet, in recording results

of PMCS.

3-5. Maintenance of the Radio Set

a. Cleaning.

(1) Remove dust and loose dirt from the surface

of equipment with a clean, soft cloth, item 1, appendix D.

WARNING

Adequate ventilation should be provided

while using

ROETHANE. Prolonged breathing of

vapor, should be avoided. The solvent

should not be used near heat or open

flame; the products of decomposition are

toxic and irritating. Since TRICHLORO-

TRIFLUOROETHANE

natural oils, prolonged contact with skin

should be avoided. When necessary, use

gloves which the solvent

penetrate. If the solvent is taken in-

ternally,

mediately.

(2) Remove grease, fungus, and ground-in dirt

with a cloth dampened (not wet) with TRI-

TRICHLOROTRIFLUO-

dissolves

cannot

consult a physician im-

3-2

TM 11-5820-553-10

CHLOROTRIFLUOROETHANE,

pendix D.

(3) Clean control knobs, switches, and indicators with a cloth dampened with mild soap and

water.

b. Inspection.

(1) Inspect interconnecting cables, doublet

antenna, and cords for fraying, cuts, kinks and

broken insulation.

(2) Inspect canvas items for mildew, torn and

corroded, broken, or loose buckles and snaps.

(3) Inspect antennas for damage, loose fit, and

corrosion.

(4) Inspect RT unit and battery assembly for

damage, loose fitting latches, knobs, and switches,

and corrosion.

Section IV. TROUBLESHOOTING

3-6. General

An equipment malfunction under field conditions

necessitates the operator to isolate the trouble to an

operator-replaceable unit and, if possible, return the

unit to an operating condition. Perform field

checkout procedures of paragraph 2–8g and refer to

table 3-2 to determine failed operator-replaceable

unit. Any repair that is beyond the scope of the

operator shall be referred to organizational main-

tenance.

item 2, ap-

Section V. MAINTENANCE OF

RADIO SET

3-7. General

There are no maintenance procedures which are the

responsibility of the operator/crew as allocated by

the maintenance allocation chart, except for visual

inspection.

3-3

TM 11-5820-553-10

Table 3-1. Operator/Crew Preventive Maintenance Checks

and Services (PMCS)

NOTE

If the equipment must be kept in continuous operation, check and service only

those items that can be checked and

serviced without disturbing operation.

Make the complete checks and services

when the equipment can be shut down.

Within the designated interval, these

checks are to be performed in the order

listed.

D–During Operation

C–Combat Ready

Procedure available if

Check that equipment manuals are

available.

Check that equipment is complete.

Check that

equipment

clean.

Check that

painted surfaces

are free of bare

spots, rust, and

corrosion.

Check that

connectors

free of corrosion,

foreign materials,

and damage.

Check that

canvas items are

not worn or torn

and buckles and

snaps work good.

is

are

Item

no.

B–Before Operation

A–After Operation

Interval

BDAC inspected

1

2

3

4

5

6

Item to be

AN/PRC-70

Radio Set

AN/PRC-70

Radio Set

AN/PRC-70

RT Unit

RT Unit

Carrying

Bags

For readiness

reporting,

equipment is

not ready/

3-4

TM 11-5820-553-10/EE150-SN-OPI/E110-PRC 70

Table 3-1. Operator/Crew Preventive Maintenance Checks and

Interval

Item

no. BDAC

7

Services (PMCS) — Continued

Item to be

inspected Procedure

RT Unit

Check that connectors

For readiness

reporting.

equipment is

not ready/

available if

not in use are securely

covered.

8

RT Unit

Check that controls

and switches are free

of corrosion, are not

loose or damaged,

and operate smoothly.

9

Handset

and Cables

Check that cables and

cords are not worn,

cut, kinked, or have

broken insulation.

10

Antennas

Check that antennas

are free of damage

and can be properly

installed.

11

12

RT Unit

Radio Set

AN/PRC-

70

Check that connectors

in use are tight.

Check equipment for AN/PRC-70

proper operation fails to

(para 2-8).

operate

correctly.

13

NOTE

See DD 314 Preventative Maintenance

Schedule and record to see if Frequency

Stability Check is due.

RT Unit

Check that equipment

does not overheat.

14

RT Unit

Check that POWER

switch is turned off.

Change 1

3-5

TM 11-5820-553-10

Table 3-2. Operator Troubleshooting

Malfunction

1. No Transmit

or Receive.

Probable Cause

a. Antenna

Whip.

b. Antenna Doublet.

c. Handset.

d. RT-1133/

PRC-70.

e. Battery.

Corrective Action

(1) Make sure antenna is

fully screwed into

whip

antenna

nector.

(2) Try both 6 ft. and 9 ft.

whip sections.

(3) Use doublet antenna.

(1) Check all connections

for proper fit.

(2) If coax is suspected,

substitute with extra

25 ft. coax section.

(3) Use long wire or whip

setup if necessary.

(1) Check connector for

proper fit.

(2) Replace handset with

headset and telegraph

key if possible.

(3) Substitute with

another handset if

available.

(1) Check all switch

positions for proper

settings.

(2) Substitute another

RT-1133/PRC-70 if

available.

(1) Make sure battery is

properly seated into

rear connector of RT

unit.

(2) Remove battery and

replace with good battery if available.

(3) Remove battery and

recharge using G-76/

G, Handcrank Generator or PP-6148/U,

Power Supply, Battery Charger if

con-

3-6

TM 11-5820-553-10

Table 3-2. Operator Troubleshooting–Continued

Malfunction

2. No Transmit/ a. Handset.

Receive OK.

3. Transmit OK/ a. Handset.

No Receive.

Probable Cause Corrective Action

b. RT-1133/ (1) Check

PRC-70.

c. Battery. (1) Remove battery and

available.

(4) Use

(1) Remove handset con-

(2) Replace handset with

(3) Substitute another

(2) Substitute another

(2) Remove battery and

(3) Use

(1) Remove handset con-

(2) Replace handset with

G-76/G or

PP-6148/U as power

source.

nector and clean connector and radio contacts with pencil

eraser.

headset and telegraph

key if possible.

handset if available.

POWER switch for

proper setting.

RT-1133/PRC-70 if

available.

replace with good battery if available.

recharge using

G-76/G,

Generator or

PP-6148/U, Power

Supply,

Charger if available.

PP-6148/U as power

source.

nector and clean connector and radio contacts

eraser.

headset and telegraph

key if possible.

RT unit

Handcrank

Battery

G-76/G or

with pencil

3-7

TM 11-5820-553-10

Table 3-2. Operator Troubleshooting– Continued

Malfunction

4. No Transmit

or Receive

in one or

more Modes.

5. No Transmit

in HI

PWR/LO

PWR and

Receive OK.

6. No Transmit

in LO

PWR/HI

PWR and

Receive OK.

Probable Cause

b. RT-1133/

PRC-70.

RT-1133/

PRC-70.

RT-1133/

PRC-70.

RT-1133/

PRC-70.

Corrective Action

(3) Substitute another

handset if available.

(1) Check all switch

positions for proper

settings.

(2) Substitute another

RT-1133/PRC-70 if

available.

(1) Try to communicate in

another operating

mode.

(2) Substitute another

RT-1133/PRC-70 if

available.

(1) Transmit in LO PWR

setting using whip or

doublet or long wire

antenna if possible.

(2) Substitute another

RT-1133/PRC-70 if

available.

(1) Transmit in HI PWR

setting using doublet,

long wire or whip an-

tenna if possible.

(2) Substitute another

RT-1133/PRC-70 if

available.

3-8

TM 11-5820-553-10

CHAPTER 4

MATERIEL USED IN

CONJUNCTION WITH

MAJOR ITEM

Section I. GENERAL

4-1. List of Auxiliary Equipment

a. Voice Security Equipment.

b. Code Burst Transmission Group AN/GRA-71

(Cable Assembly SM-C-746195).

c. Digital Message Device Group OA-8990/P.

d. Handcrank Generator G-76/G.

e. Power Supply Battery Charger PP-6148/U.

f. Battery BB-542/U.

Section II. INSTALLATION

INSTRUCTIONS FOR AUXILIARY

EQUIPMENT

4-2. Voice Security Equipment Configuration

a. Equipment Setup.

operated in secure or nonsecure voice modes from

fixed locations. Figure 4-1 shows this configuration

which includes the following items:

The radio set can be

4-1

TM 11-5820-553-10/EE150-SN-OPl-010/E1 10-PRC 70

Figure 4-1. Voice Security Equipment Configuration

(1) Receiver Transmitter RT-1133/PRC-70.

(2) Handset H-250/U.

(3) Doublet

Antenna Assembly AS-2975/

PRC-70 or Whip Antenna AS-2974/PRC-70.

(4) Voice Security Applique (optional).

b. Assembly. Proceed as follows:

(1) Assemble whip antenna and connect to RT

unit WHIP connector, or assemble doublet antenna

on structures as directed in paragraph 2-6a.

(2) Remove shorting cap from X-MODE

connector on RT unit.

(3) Connect voice security applique to

X-MODE connector.

(4) Connect Handset H-250/U to voice security

applique.

c. Operating Instructions.

4-2

TM 11-5820-553-10

(1) Preliminary Control Settings.

POWER switch

Control

MODE switch

VOLUME control

SQUELCH switch

FREQUENCY selector

controls

OFF

AM or SSB

Midrange

OFF

Operating frequency desired

Setting

(2) Start the equipment in accordance with the

following steps:

(a) Set RT unit POWER switch to RCV

ONLY.

(b) Adjust RT unit VOLUME control for

proper audio output level.

(c) Set RT unit POWER switch to TUNE and

release. Allow 15 seconds for tuning to be completed.

(d) Set RT unit POWER switch to HI PWR

or LO PWR, as required.

NOTE

The POWER switch is spring loaded in

the TUNE position and will return to HI

PWR when released.

(e) Set RT unit SQUELCH switch to ON (if

desired).

(f) Start voice security equipment as directed

in applicable technical manuals.

WARNING

When operating in HI PWR with the

whip or long wire wire antenna, DO NOT

TOUCH the antenna when in transmit

mode—an RF burn can result.

NOTE

If RT unit FREQUENCY selector

controls are reset, momentarily set

POWER switch to TUNE and release.

The set should retune within 15 seconds.

Change 2

4-3

TM 11-5820-553-10

LO PWR position of POWER switch may

be selected after this time.

(3) Transmit in any of the voice modes by

pressing the H-250/U Handset push-to-talk button

and speaking into the microphone. With voice

security equipment connected, wait until the

security tone is heard before speaking.

(4) To shut down the equipment, proceed as

follows:

(a) Set RT unit POWER switch to OFF.

(b) Shut down voice security equipment as

directed in applicable technical manuals.

4-3. Code Burst and CW Configuration

a. Equipment Setup.

operated in standard CW modes from fixed

locations. Figure 4-2 shows this configuration

which includes the following items:

The radio set can be

4-4

TM 11-5820-553-10

Figure 4-2. CW Configuration.

4-5

TM 11-5820-553-10

(1) Receiver-Transmitter RT-1133/PRC-70.

(2) CW Key KY-116/U with cable

CX-13101/PRC-70.

(3) Headset H-251/U.

(4)

Code

Burst

Transmission Group

AN/GRA-71.

(5) Doublet Antenna AS-2975/PRC-70 or

Whip Antenna AS-2974/PRC-70.

b. Assembly. Proceed as follows:

(1) Assemble whip antenna and connect to RT

unit WHIP connector, or assemble doublet antenna

on structures as directed in paragraph 2–6a.

(2) Automatic mode.

(a) Connect in accordance with figure 4-2(A)

automatic setup.

(b) Prepare message as required in accordance

with instructions for Code Burst Transmission

Group AN/GRA-71.

(3) Manual Mode.

(a) Connect in accordance with figure 4-2(B)

manual setup.

(b) Connect CW Key KY-116/U with cable to

RXMT connector of RT unit.

(c) Connect Headset H-251/U to AUDIO

connector of RT unit.

c. Operating Instructions.

(1) Preliminary settings.

(a) Set controls on RT unit as follows:

POWER switch

Control

MODE switch

VOLUME control

SQUELCH switch

FREQUENCY selector

controls

(b) Set controls on

OFF

CW or FSK

Midrange

OFF

Operating frequency desired

all ancillary equipment to

Setting

preliminary settings listed in applicable technical

manuals.

(2) Equipment starting. Start the equipment

4-6

TM 11-5820-553-10

using the following procedures:

(a) Set RT unit POWER switch to RCV

ONLY.

(b) Adjust RT unit VOLUME control for

proper audio output level.

WARNING

When operating in HI PWR with the

whip or long wire antenna, DO NOT

TOUCH the antenna when in transmit

mode—an RF bum can result.

(c) Set RT unit POWER switch to TUNE and

release. Allow 15 seconds for tuning to be com-

pleted.

NOTE

The POWER switch is spring loaded in

the TUNE position and will return to HI

PWR when released.

(d) Set RT unit POWER switch to HI PWR

LO PWR, as required.

(e) Set RT unit SQUELCH switch to ON (if

desired).

(3) Standard (manual mode) CW operation. To

transmit in the standard CW mode, key the RT unit

with CW Key KY-116/U.

NOTE

The RT unit remains in a keyed condition

but produces no RF output during the

pauses between characters. With the key

open the RT unit returns to the receive

mode after a pause of about 1.2 seconds.

(4) Burst CW Transmission. To transmit in the

burst CW mode, proceed as follows:

(a) Wind drive motor and load tape cartridge

in KY-468/GRA-7 (KE-8B).

(b) To transmit identity tone (optional), press

KY-468/GRA-71(KE-8B) IDY switch up and hold

Change 2

4-7

TM 11-5820-553-10

for at least five seconds.

(c) Turn IDY switch OFF and immediately

set KY-468/GRA-71(KE-8B) motor ON-OFF

switch to ON.

(d) When transmission is complete,

KY-468/GRA-71(KE-8B) ON-OFF switch to

OFF.

(e) Remove tape cartridge

KY-468/GRA-71(KE-8B).

O shut down the equipment, set RT unit

(5) T

POWER switch to OFF.

4-4. Digital Message Device Group OA-8990

Configuration

a. Equipment Setup.

The radio set can be

operated with a DMDG unit from fixed or portable

locations. Figure 4-3 shows this configuration

which includes the following items:

set

from

Figure 4-3, Digital Message Device Group (DMDG),

OA-8990/P configuration

Receiver-Transmitter RT-1133/PRC-70.

(1)

Digital Message Device Group OA-8990/P.

(2)

4-8

TM 11-5820-553-10

(3) Doublet Antenna AS-2975/PRC-70 or

Whip Antenna AS-2974/PRC-70.

b. Assembly. Proceed as follows:

(1) Assemble whip antenna and connect to RT

unit WHIP connector, or assemble doublet antenna

on structures as directed in paragraph 2-6a.

(2) Connect OA-8990 DMDG, HF connector

(A2J4) to RXMT connector of RT unit using Cable,

CX-13156/GR.

c. Operating Instructions.

(1) Preliminary Settings.

(a) Set controls on RT unit as follows:

Control Setting

POWER switch OFF

MODE switch SSB

VOLUME control Midrange

SQUELCH switch

FREQUENCY selector Operating frequency desired

controls

(b) Set controls on ancillary equipment to