TO 31R4-2GRA6-31

TM 11-5820-489-10

NSN 5820-00-644-4554

TM 11-5820-489-10

TO 31R4-2GRA6-31

HIGH VOLTAGE

is used in the operation of this equipment.

DEATH ON CONTACT

may occur if person operating this equipment fails

to obey safety precautions.

Do not be mislead by The Term LOW VOLTAGE. Voltage as low as

90 volts may cause DEATH under certain conditions.

TRICHLOROTRIFLUOROETHANE

Adequate ventilation should be provided while

using TRICHLOROTRIFLUOROETHANE. Prolonged

breathing of vapor should be avoided. The solvent should not be used near heat or open flame;

the products of decomposition are toxic and irritating.

dissolves natural oils, prolonged contact with

skin should be avoided. When necessary, use

gloves which the solvent cannot penetrate. If the

solvent is taken internally, consult a physician

immediately.

Since TRICHLOROTRIFLUOROETHANE

A/(B BLANK

TECHNICAL MANUAL

NO. 11-5820-489-10

TECHNICAL ORDER

TO 31R4-2GRA6-31

OPERATOR’S MANUAL

CONTROL GROUP AN/GRA-6

(NSN 5820-00-644-4554)

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes or if you

know of a way to improve the procedures, please let us know. Mail your

letter or DA Form 2028 (Recommended Changes to Publications and

Blank Forms), direct to: Commander, US Army CommunicationsElectronics Command and Fort Monmouth, ATTN: DRSEL-ME-MP, Fort

Monmouth, New Jersey 07703.

For Air Force, submit AFTO Form 22 (Technical Order System Publication

Improvement Report and Reply) in accordance with paragraph 6-5, Section VI, TO 00-5-1. Forward direct to prime ALC/MST.

In either case, a reply will be furnished direct to you.

TABLE OF CONTENTS

Washington, DC, 23 November 1983

DEPARTMENTS OF THE ARMY

AND THE AIR FORCE

HOW TO USE THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

CHAPTER 1

Section I

II

Ill

*This manual supersedes so much of TM 11-5038, 18 April 1951, including all

changes as pertains to operator maintenance.

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-0

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Maintenance Forms, Records and Reports. . . . . . . . . . . . . . . 1-1

Reporting Equipment Improvement

Recommendations (EIR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Nomenclature Cross-Reference List . . . . . . . . . . . . . . . . . . . . 1-1

List of Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Hand Receipt . . . . . . . . . .. . . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose, Capabilities and Features . . . . . . . . . . . . . . . . . . . . 1-2

Description of Major Components . . . . . . . . . . . . . . . . . . . . . . 1-3

Differences Between Models

Performance Data

Technical Principles of Operation. . . . . . . . . . . . . . . . . . . . . . 1-8

Arrangement of Local Control to Remote Control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .. . . . . . . . . . . . . . ....

. . . . . . ..

PAGE

1-2

1-6

1-6

1-8

i

TM 11-5820-489-10

To 31R4-2GRA6-31

TABLE OF CONTENTS - Continued

PAGE

CHAPTER 2

Section I

Section II

Section III

Section IV

CHAPER 3

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . .

Description and use of Operator’s

Controls and Indicators

Panel Controls and Facilities . . . . . . . . . . . . . . . . .

Preventive Maintenance Checks and

Services

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance Checks and Services

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly and Preparation for Use . . . . . . . . . . . .

Initial Adjustments, Daily Checks and Self-

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . .

Operation Under Unusual Conditions

General . . . . . . . . . . . . . .......... . . . . . . . . . . . . . . . . . . . ..... . . .

Operation in Arctic Climates . . . . . . . . . . . . . . . . .

Operation in Tropical Climates . . . . . . . . . . . . . . .

Operation in Desert Climates. . . . . . . . . . . . . . . . .

MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . .

2-0

2-1

2-1

2-8

2-8

2-8

2-13

2-13

2-24

2-27

2-38

2-38

2-38

2-38

2-38

3-0

Section I

Section II

APPENDIX A

Section l

APPENDIX C

Section I

APPENDIX D

Section l

ii

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Information . . . . . . . . . . . . . . . . .

Maintenance Procedures . . . . . . . . . . . . . . . . . . . .

Introduction . .

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement. . . . . . . . . . . . . . . . . . .

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPONENTS OF END ITEM AND BASIC

B

ISSUE ITEMS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II

IlI

II

II

Componentsof End Item . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Issue Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADDITIONAL AUTHORIZATION LIST . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Authorization List . . . . . . . . . . . . . . . . . . . . .

EXPENDABLE SUPPLIES AND MATERIALS LIST . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expendable Supplies and Materials List . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3-1

3-1

3-1

3-1

3-3

3-4

A-1

B-1

B-1

B-2

B-3

C-1

C-1

C-1

D-1

D-1

D-2

TM 11-5820-489-10

TO 31R4-2GRA6-31

HOW TO USE THIS MANUAL

●

THIS MANUAL TELLS ABOUT THE TYPICAL ARRANGEMENTS OF

CONTROL GROUP AN/GRA-6.

●

ALL THE PROCEDURES IN THIS MANUAL MUST BE EXAMINED BEFORE

YOU BEGIN ANY TASK.

●

THROUGHOUT THIS MANUAL COLOR CODED MARGIN TABS WILL

GUIDE YOU TO THE SECTION THAT CONTAINS THE SPECIFIC

INFORMATION YOU NEED.

●

THIS MANUAL IS ORGANIZED INTO CHAPTERS, SECTIONS,

PARAGRAPHS AND ILLUSTRATIONS, WHICH ARE NUMBERED TO HELP

YOU FIND INFORMATION ABOUT YOUR EQUIPMENT QUICKLY AND

EASILY.

●

COLOR IS USED TO EMPHASIZE KEY POINTS.

●

UNFAMILIAR WORDS WILL BE EXPLAINED AT THE BEGINNING OF

EACH CHAPTER.

●

THE SUBJECT INDEX IN THE BACK OF THE MANUAL WILL HELP YOU

FIND INFORMATION QUICKLY.

iii

TM 11-5820-489-10

TO 31R4-2GRA6-31

CHAPTER 1

INTRODUCTION

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....... . . . . . . . . . . . . . . .1-2

Arrangement of Local Control to RemoteControl . . . . . . . . . . . . . . . . . . . . . . . 1-8

Differences between Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-6

Hand Receipt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-2

Maintenance Forms, Records and Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

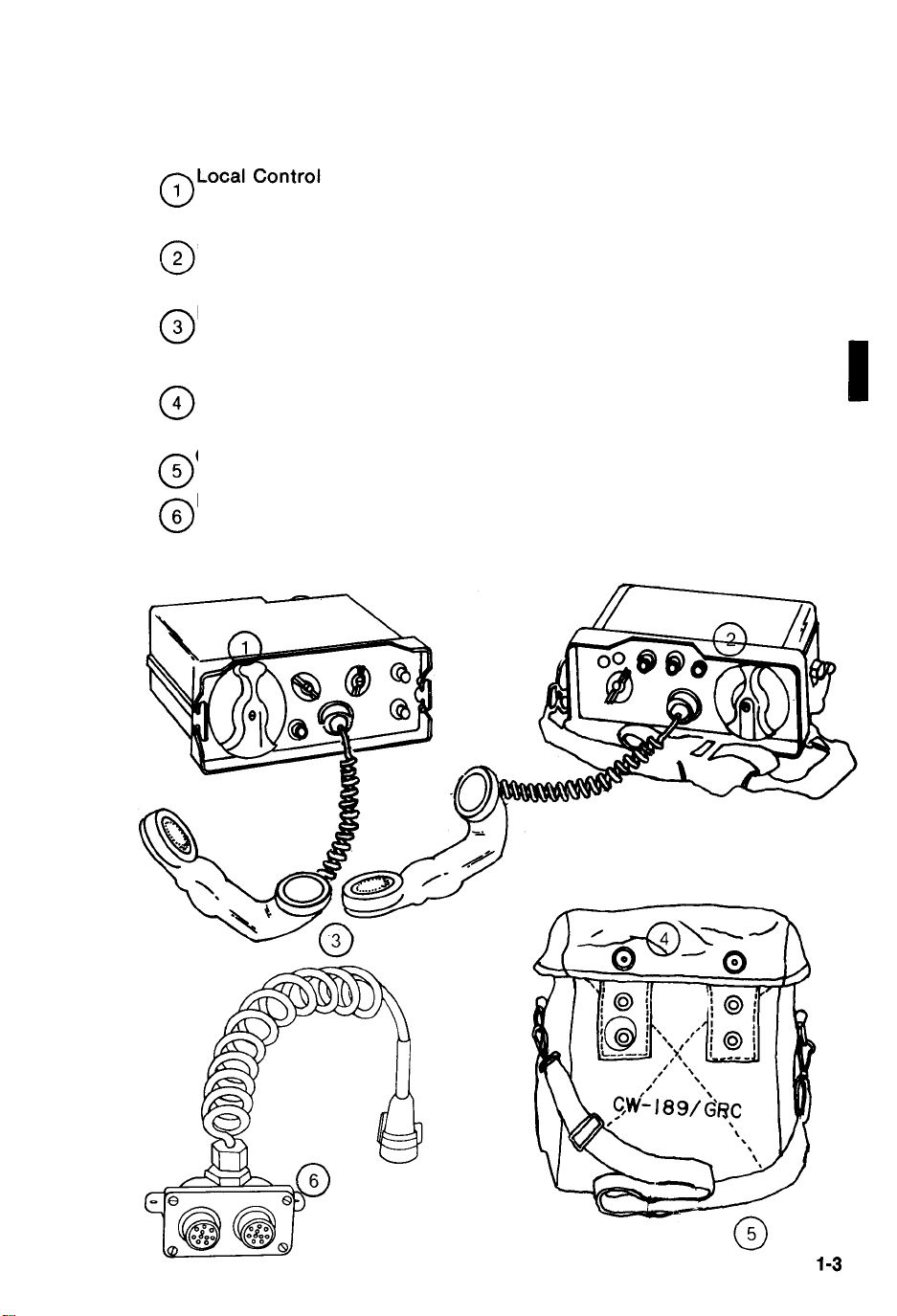

MajorComponents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-3

Nomenclature Cross-Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-1

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-6

Purpose, Capabilities, and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-2

Reporting Equipment Improvement Recommendations . . . . . . . . . . . . . . . . . 1-1

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-1

REMOTE CONTROL C-433/GRC

BAG CW-189/GRC

LOCAL CONTROL C-434/GRC

1-0

TM 11-5820-489-10

CHAPTER 1 TO 31R4-2GRA6-31

INTRODUCTION

Section I. GENERAL INFORMATION

1-1. SCOPE

This manual describes Control Group AN/GRA-6. The manual covers the

operation and Operator’s maintenance procedures.

1-2. MAINTENANCE FORMS AND RECORDS

Department of the Army forms and procedures used for equipment maintenance

will be those prescribed by TM 38-750, The Army Maintenance Management System

(TAMMS).

1-3. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR)

a. Army. If your AN/GRA-6 needs improvement, let us know. Send us an EIR.

You, the user are the only one who can tell us what you don’t like about your equipment. Let us know why you don’t like the design. Put it on an SF 368 (Quality Deficiency Report). Mail it to Commander, US Army Communications-Electronics Command and Fort Monmouth, ATTN: DRSEL-ME-MP, Fort Monmouth, New Jersey 07703.

We’ll send you a reply.

b. Air Force. Air Force personnel are encouraged to submit ElR’s in accordance

with AFR 900-4.

1-4. NOMENCLATURE CROSS-REFERENCE LIST

Common names will be used when the major components of the Control Group

are mentioned in this manual.

COMMON NAME

Control Group . . . . . . . . . . . . . . . . . . . . . .

Local Control . . . . . . . . . . . . . . . . . . . . . .

Remote Control . . . . . . . . . . . . . . . . . . . .

Handset . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . .

NOMENCLATURE

Control Group AN/GRA-6

Local Control C-434/GRC

Remote Control C-433/GRC

Handset H-33/PT

Bag CW-189/GRC

Wire WD-1/TT

Mounting MT-297/GR or

Mounting MT-298/GR

Interconnecting Box . . . . . . . . . . . . . . . .

Loudspeaker . . . . . . . . . . . . . . . . . . . . . . .

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interconnecting Box J-654/G

Loudspeaker, Dynamic LS-166/U

Battery, Dry BA-30 or

Battery, Dry BA-414/U

Container . . . . . . . . . . . . . . . . . . . . . . . . . .

Container for Interconnecting

B0X J-654/G

Generator . . . . . . . . . . . . . . . . . . . . . . . . .

Multimeter. . . . . . . . . . . . . . . . . . . . . . . . .

Generator G-25/PT

Multimeter AN/URM-105

1-1

TM 11-5820-489-10

TO 31R4-2GRA6-31

Nomenclature MUST be used when filling out report

forms or looking up Technical Manuals.

1-5. LIST OF ABBREVIATIONS

NOTE

Abbreviations are spelled out the first time they appear in this

manual. A com-

plete list of abbreviations used in this manual is given below.

AAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Authorization List

alternating current

BII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Basic lssue ltems

COEI . . . . . . . . . . . . . . . . . . . . . . . . . . .

Components of End Item

dc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . direct current

FSCM . . . . . . . . . . . . . . . . . . . . . . . . . . .

Federal Supply Code of Manufacturer

Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hertz

o/a . . . . . . . . . . . . . . . . .

PMCS . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overall

Preventive Maintenance Checks

and Services

rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

u/m . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

revolutions per minute

unit of measure

1-6. HAND RECEIPT

This manual has a companion document with aTM number followed by ’’-HR”

(which stands for Hand Receipt). TM 11-5820-489-10-HR consists of preprinted hand

receipts (DA Form 2062) that list end item related equipment (i.e., COEI, Bll, and

AAL) you must account for. As an aid to property accountability, additional -HR

manuals may be requisitioned from The US Army Adjutant General Publications

Center, Baltimore, MD, in accordance with the procedures in Chapter 3, AR 310-2,

and DA PAM 310-10-2.

Section Il. EQUIPMENT DESCRIPTION

1-7. PURPOSE, CAPABILITIES AND FEATURES

●

Used to control and operate a radio set

●

For listening and talking, can use one or two receiver-transmitters,

amplifiers or similar push-to-talk types of equipment

●

Transmission range about 2 miles (300 to 4000 Hz frequency)

●

Small, portable, lightweight, fungi proof

●

Continuous dc circuit

●

Two-way telephone communication with ringing

●

Uses two-wire telephone line

●

Can be used under bad weather conditions

●

Auxiliary components:

● Push-to-talk type handset ● 1 set running spares

● Interconnecting Box

1-2

● large waterproof carrying bag

1-8. DESCRIPTION OF MAJOR COMPONENTS

a. Control Group AN/GRA-6

Permits local selection of telephone operation or push-to-talk operation.

TM 11-5820-489-10

TO 31R4-2GRA6-31

Remote Control

Handsets

Bag

Carrying strap

Interconnecting

Box

Permits field telephone operation connec-

tions with local control up to a 2 mile range

Used for transmitting and receiving voice

signals.

Used to contain Control Units, Handset, and

running spare parts when not in use.

For use in carrying Remote Control Unit.

Used when Handset and Loudspeaker are

needed at the same time.

1-3

TM 11-5820-489-10

TO 31R4-2GRA6-31

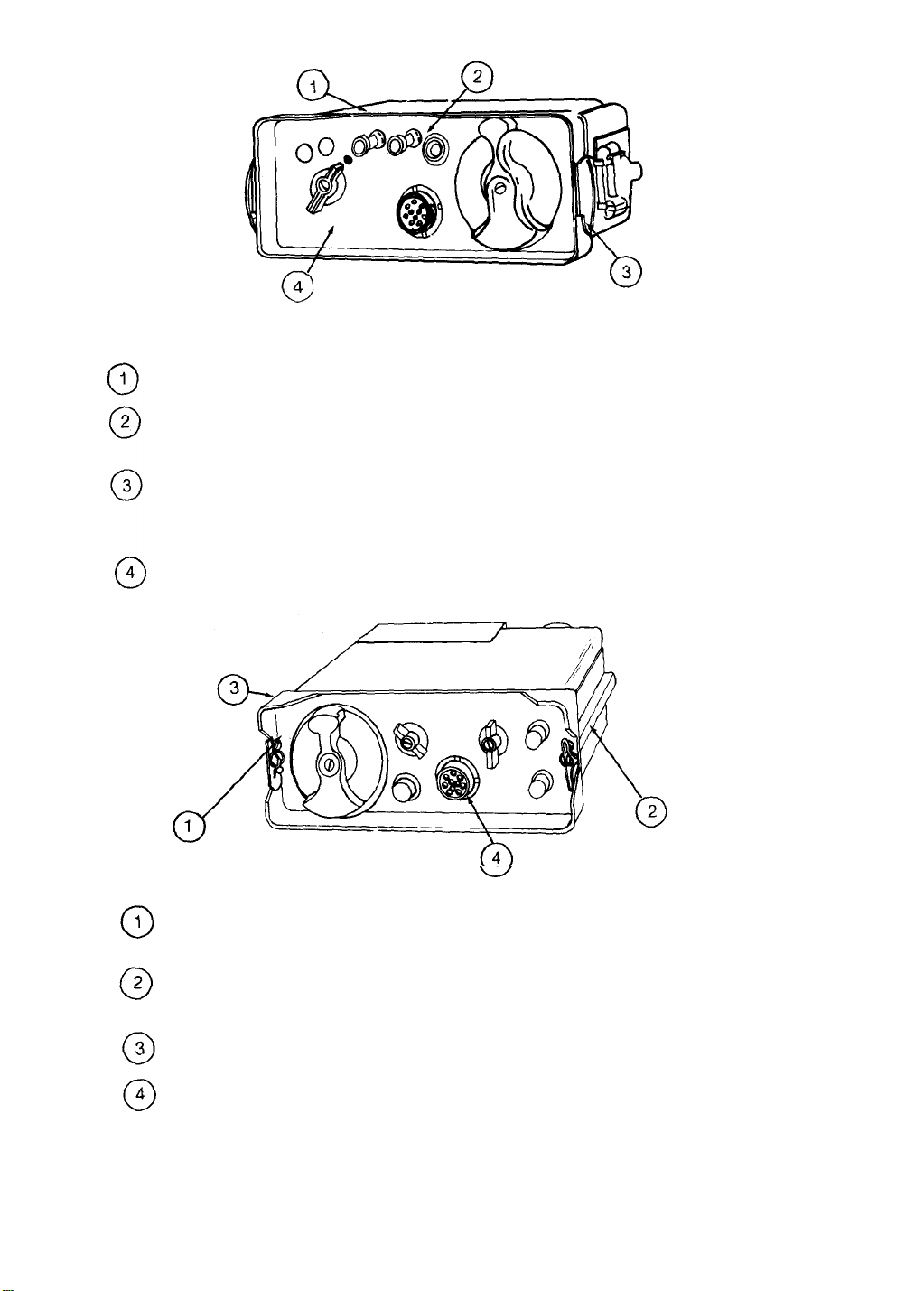

b. Remote Control

Outer Case

Battery Compartment

Cover (under case)

“D” rings

Front Panel

c. Local Control

Waterproof, houses panel and chassis.

Provides access to area that contains bat-

teries.

These hold shoulder strap for carrying posi-

tion. In carrying position, operating controls

of front panel face upward.

Contains controls and instruments for opera-

tion.

1-4

Front Panel

Channel or Mounting

runners

Outer Case

Connector

Contains controls and instruments for operation.

Allows Local Control to be mounted for plugin connection to radio sets using mounting.

Waterproof, houses panel and chassis.

Plugs into a mating connector on a mounting

radio set to establish an electrical connection between Control Unit and radio set (see

rear view).

TM 11-5820-489-10

TO 31R4-2GRA6-31

Cable Compartment

5

o

o

o

o

o

o

Cover Latch

Cable Assembly

6

Cable Compartment

7

Cover

Cap Retainer Chain

8

Cap

9

Cap Retaining

10

Bracket

d. Handset

A means to control opening and

closing of cable compartment cover.

Means for establishing electrical connections

between Control Unit and radio sets.

Provides access to area that contains cable

assembly.

An aid to preventing loss of cap.

Used for the protection of connector plug

when not in use.

Used to hold the cap when the connector is

being used.

Push-to-talk switch

is used to provide

voice communication.

Push switch to talk

and release switch

to listen.

e. Interconnecting box

Plug Connector

Receptacle Connectors

When plugged into Remote Control, provides

extra electrical power to extension.

Needed when Loudspeaker and Handset are

used at the same time.

1-5

TM 11-5820-489-10

TO 31R4-2GRA6-31

1-9. DIFFERENCES BETWEEN MODELS

Generators

G-25/PT (used in this manual)

rotates at 155 rpm.

1-10. PERFORMANCE DATA

ITEMS USED IN AN OPERABLE CONTROL GROUP

Item

No.

Qty.

1 1

Component Requirements

Remote Control

C-433/GRC

2

Local Control

1

C-434/GRC

3

Handset H-33/PT

2

Power

80 to 100v ac, 20 Hz

single ph battery 3v

+ 45v dc.

80 to 100v ac, 20 Hz

single ph dc battery

power, 3v.

300 ohms impedance,

100 Hz, carbon type

xmtr 40 ohms dc

resistance, 60 ma 300 to

4000 Hz freq. range.

G-25A/PT (others)

rotates at 208 rpm

Technical

Characteristics

manual control,

alumn, 7lbs, (3.15

kg) 9-3/8” I X :

3½” h X 7“ w

manual control,

alumn, 10½ lbs.,

(5.6 kg) 8-9/16” I

X 10½" w X 3½” h

battery powered,

black plastic

handle, magnetic

receiver 1-1/81bs.

(.51 kg)

4

5

6

7 4

8

1-6

1

Interconnecting

Box J-654/G

Container for

1

Interconnecting

B

OX

J-654/G

1

Loudspeaker,

Dynamic LS-166/U

Battery, dry BA-30

1

Battery, dry

BA-414/U

8 ohms voice call

impedance, 2W normal

and 3W peak input

1.5V

45v tapped at 22v

3/8” dia. cable

accom, alumn

w/cover, 1 lb. (.45

kg ) 4-5/8” lg X

2-1/8” w X 1¼” h

(incl. 3 ft. interconnection cord)

2lbs. (.9 kg) X 0.2

cu ft.

5-21/32 “ l X

3-3/16” w X 7-1/32 "

h

(2 ea. local control)

(2 ea. remote

control)

used with remote

control

TM 11-5820-489-10

TO 31R4-2GRA6-31

ITEMS USED IN AN OPERABLE CONTROL GROUP - Continued

Item

No.

10

Qty. Component

9

1

Lamp, glow

1

Lamp, glow

Dry batteries shown are used with the equipment, but

are not considered part of the equipment. They will not

be preshipped automatically, but are to be requisitioned in quantities necessary for the particular organization in accordance with SB 11-6.

Power

Requirements

1/25w, 65v, ac, 90v dc

1/25w, 65v, ac, 90v dc

NOTE

Technical

Characteristics

neon gas, GE type

NE51 (used with

local control) 1-1/8”

h o/a

neon gas GE NE-51

(used with remote

control) 1-1/8”h o/a

1-7

Section Ill.

1-11.

ARRANGEMENT OF LOCAL CONTROL TO REMOTE CONTROL

Up to 2 miles of Ii

TECHNICAL PRINCIPLES OF OPERATION

1-8

Remote Control

TM 11-5820-489-10

TO 31R4-2GRA6-31

CHAPTER 2

OPERATING INSTRUCTIONS

Controls and lndicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Telephone circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Telephone lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write-in blanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly and Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Break-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local push-to-talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote push-to-talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ringing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation - Unusual conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arctic Climates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Desert Climates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tropical Climates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-1

2-5

2-24

2-24

2-23

2-25

2-13

2-23

2-17

2-13

2-27

2-34

2-33

2-33

2-31

2-28

2-37

2-38

2-38

2-38

2-38

2-8

(1-9 blank)/2-0

TM 11-5820-489-10

TO 31R4-2GRA6-31

Section I. DESCRIPTION AND USE OF OPERATOR’S CONTROLS AND

INDICATORS

2-1. PANEL CONTROLS AND FACILITIES

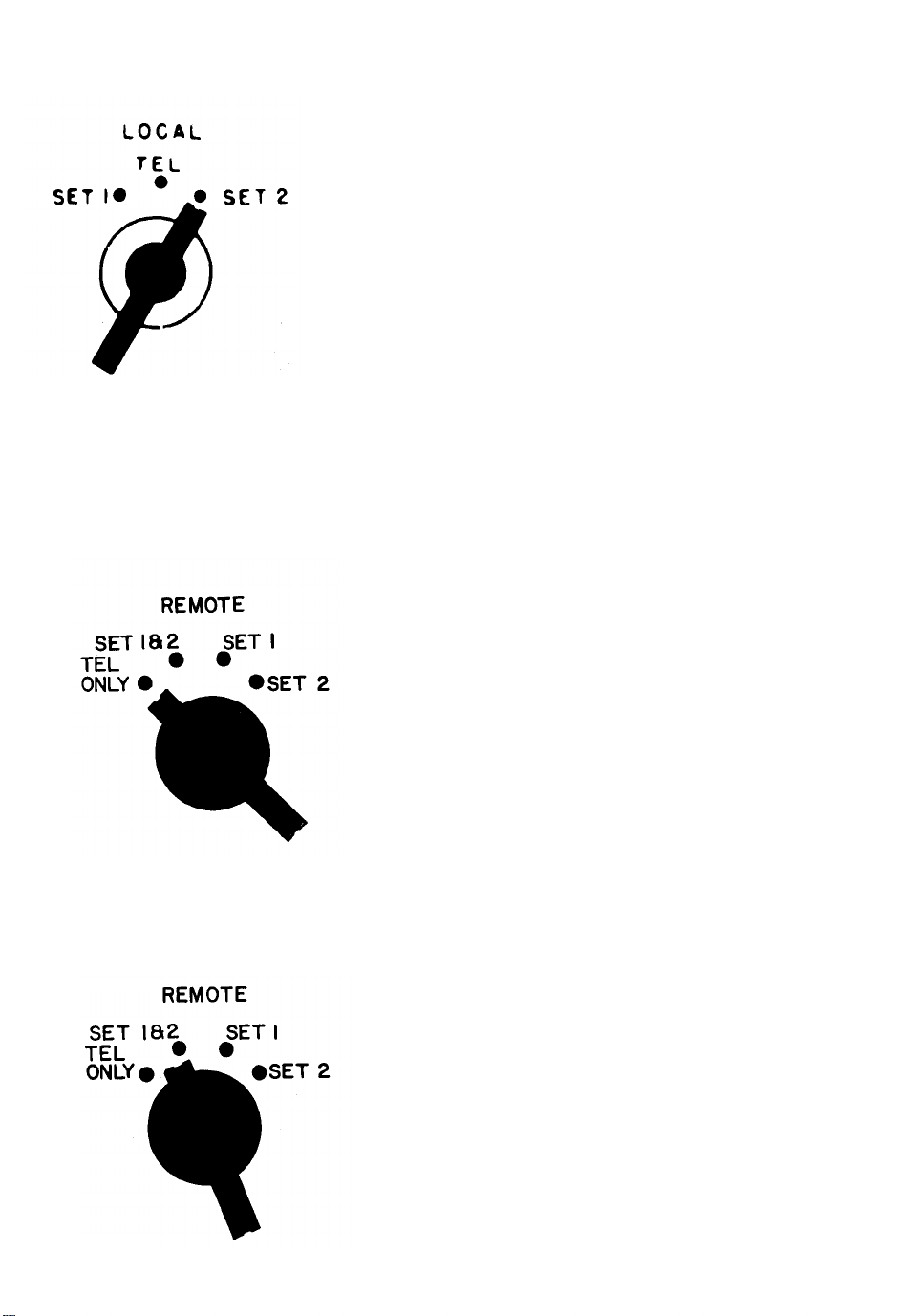

a. Local Control Panel controls and indicators.

Local Switch

POSITION

of Control or

Indicators

FUNCTION

when used with Local

Control Unit

● Allows push-to-talk operation of

Set 1 (using spring action).

● Allows Telephone operation with

Remote Control.

2-1

TM 11-5820-489-10

TO 31R4-2GRA6-31

POSITION

Remote Switch

FUNCTION

● Allows push-to-talk operation of

Set 2 (using spring action).

● Allows Telephone communication

between Local and Remote Control

Units.

● May also be used to turn power

OFF in TEL ONLY position.

● For push-to-talk operation of either

Set 1 or Set 2 move REMOTE knob

to Set 1 and Set 2 setting. Local

Control is now ON.

2-2

TM 11-5820-489-10

TO 31R4-2GRA6-31

POSITION

FUNCTION

● Provides for Remote Control of

power for a radio set and pushto-talk operation of Set 1.

● Monitors Set 1 and Set 2.

● Provides for Remote Control of

power for a radio set and push-to-

talk operation of Set 2.

Wire Binding Posts

● Monitors Set 1 and Set 2.

● Allows connection of lines for

remote control.

2-3

TM 11-5820-489-10

TO 31R4-2GRA6-31

To prevent accidental operation of the radio set

transmitters, the REMOTE switch of Local Control

MUST be in the TEL ONLY position when ringing

generator is operated.

Ringing Generator

NOTE

POSITION

Call Light

FUNCTION

handle and turning

vides the means of

ycle ringing signal

Control Unit.

●

When lit, shows that a ringing signal

is being received from the Remote Control

Unit.

● Using dimmer, call light can be adjusted

to desired brightness.

●

Turn clockwise to dim,

counterclockwise to brighten.

Audio Connector

2-4

●

Connection point for a Handset or similar

accessory for telephone communication

and push-to-talk operation of the radio

set.

NOTE

Use audio cover when

not in operation.

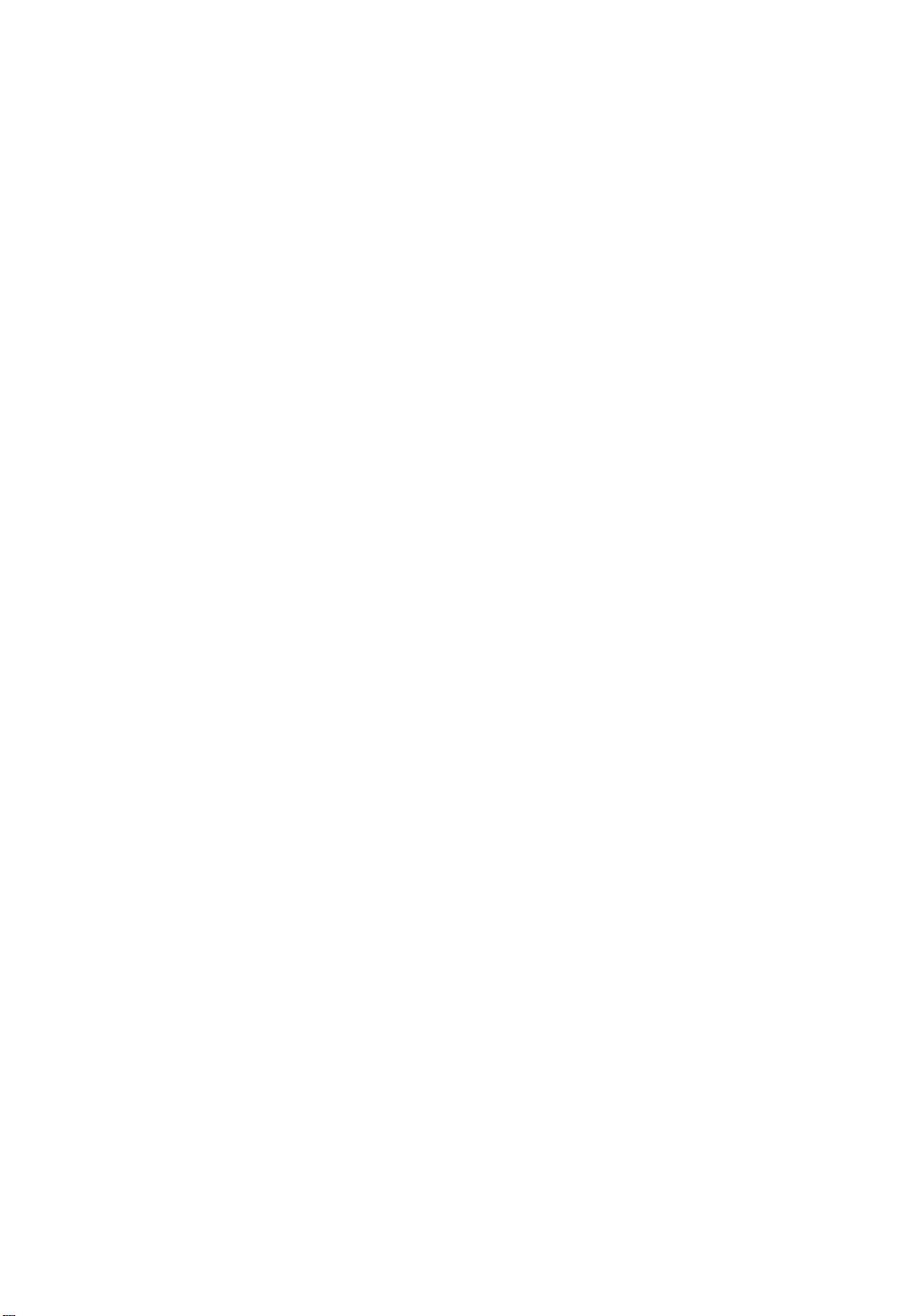

b. Remote Control Panel controls and indicators.

Selector Switch

TM 11-5820-489-10

TO 31R4-2GRA6-31

POSITION

of Control or

Indicators

FUNCTION

when used with Local Control

Unit

● Provides power ON position for a

radio set and/or Set 1 or Set 2

depending on indicator setting at

Local Control Unit.

Write-in positions (spaces) for operator

to record functions of switch positions.

●

Provides power OFF position for

a radio set and/or Set 1 or Set 2

depending on indicator setting at

Local Control Unit.

NOTE

The functions of the write-in positions will be reversed if the telephone line

connections are reversed at either Local or Control units.

2-5

TM 11-5820-489-10

TO 31R4-2GRA6-31

POSITION

of Control or

Indicator

Wire Bind Posts

FUNCTION

when used with Local Control

Unit

● For telephone communications with

Local Control Unit.

● Allows connection of Remote

Control Unit.

NOTE

To prevent accidental operation of the radio set

transmitters, the REMOTE switch of Local Control

MUST be in the TEL ONLY position when ringing

generator is operated.

Ringing Generator

●

Using spinner handle and turning

clockwise provides the means of

sending a 20-cycle ringing signal

to the Local Control Unit.

Fold-out handle

2-6

TM 11-5820-489-10

TO 31R4-2GRA6-31

POSITION

of Control or

Indicator

Call Light

Audio Connector

FUNCTION

when used with Local Control

Unit

When lit, shows that a ringing

signal is being received at the

Local Control Unit.

Using dimmer, call light can be

adjusted to desired brightness.

●

Turn clockwise to dim,

counterclockwise to brighten.

● This is where a Handset or similar

accessory for telephone communication and push-to-talk operation of the

radio set is connected.

● Use audio cover when

not in operation.

2-7

TM 11-5820-489-10

TO 31R4-2GRA6-31

Section Il. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

2-2. GENERAL

Operator’s Preventive Maintenance Checks and Services (PMCS) are the required daily and weekly inspections and care of your equipment necessary to

keep it in good operating condition.

Tools and Materials

No tools or equipment are required for operator maintenance. The following

cleaning materials will be useful to you:

● Lint-free cloths

● Soft bristle brush

● Dishwashing compound or detergent

● Cleaning compound

2-3. PREVENTIVE MAINTENANCE CHECKS AND SERVICES PROCEDURES

NOTE

If your Control Group AN/GRA-6 must be in USE ALL

THE TIME, check and service those items that can be

checked and serviced without stopping its operation.

Make COMPLETE checks and services ONLY when the

Control Group is finally SHUT DOWN.

2-8

TM 11-5820-489-10

TO 31R4-2GRA6-31

a. Routine Services

Routine services are not listed in the PMCS table. They are, however,

important and should be done on a routine basis. Here are the routine

steps to be performed by you as necessary:

●

● Clean

● Dust

● Wash

● Check for cut or frayed

cables

● Check for dented, bent, or

broken components

Check to see that items not

in use are properly stored

●

Check for rusting

●

Check controls for smooth

operation

●

Cover unused receptacles

●

Check for loose nuts, bolts,

and connectors

●

Check for completeness and

current changes to publications

b. Explanation of INTERVAL column of PMCS chart

NOTE

Always keep in mind all CAUTIONS and WARNINGS

when PMCS are performed.

WEEKLY - Do your Weekly (W) PMCS to ensure that the

Control Group is functioning properly.

2-9

TM 11-5820-489-10

TO 31R4-2GRA6-31

NOTE

ALL PMCS must be done as regularly scheduled and

also under the following conditions:

● Before the Control Group is used on a mission.

● When the Control Group is first installed.

●

When the Control Group is reinstalled after being

removed for any reason.

●

When you are operating the Control Group for the

first time.

c. Explanation of EQUIPMENT IS NOT READY/AVAILABLE IF

column of PMCS chart.

l This column tells the conditions under which the equipment can not

perform the assigned mission requirements.

NOTE

The procedures column in your PMCS chart tells you

how to perform the required checks and services.

Carefully follow these instructions. If tools are needed

or the chart instructions tell you, get organizational

maintenance to do the necessary work.

NOTE

If any portion of your Control Group fails to operate, refer to Chapter 3

under Troubleshooting for possible corrective action. Report any

malfunctions or failures on the proper DA Form 2404 or refer to TM

38-750.

2-10

Loading...

Loading...