TM 11-5835-224-12

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

OPERATOR AND ORGANIZATIONAL

MAINTENANCE MANUAL

CODER-BURST

TRANSMISSION

GROUP AN/GRA-71

This copy is a reprint which includes

current pages from Changes 2 and 5.

HEADQUARTERS, DEPARTMENT OF THE ARMY

MAY 1964

Changes in force: C 2

*TM 11-5835-224-12

C 2

CHANGE DEPARTMENT OF THE ARMY

No. 2 Washington, D.C., 8 July 1969

Operator and Organizational Maintenance

Manual

CODER-BURST TRANSMISSION GROUP

AN/GRA-71

TM 11-5835-224-12, 27 May 1964, is changed as follows:

Title is changed as shown above (as changed by C 1, 24 Jun 66).

The parenthetical reference to previous changes (example: page 1 of C 2) indicates

that pertinent material was published in that change.

Page 4, preface, paragraph A. Delete paragraph A (as changed by C 1, 24 Jun 66),

and substitute:

A. Indexes of Equipment Publications

1. DA Pam 310-4. Refer to the latest issue of DA Pam 3104 to determine

whether there are new editions, changes, or additional publications pertaining to the

equipment.

2. DA Pam 310-7. Refer to the latest issue of DA Pam 310-7 to determine

whether there are modification work orders (MWO's) pertaining to the equipment.

*This change supersedes C 1, 24 June 1966.

HEADQUARTERS

1

Paragraph B. Designate the -first subparagraph as:

1. (As changed by C1, 24 Jun 66) Delete the following subparagraphs and-

substitute:

2. Report of Packaging and Handling Deficiencies. Fill out and forward DD

Form 6 (Report of Packaging and Handling Deficiencies) as prescribed in AR 70058 (Army), NAVSU7P Publication 378 (Navy), AFR 714 (Air Force), and MCO

P4610-5 (Marine Corps).

3. Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and forward

Discrepancy in Shipment Report (DISREP) (SF 361) as prescribed in AR 55-38

(Army), NAVSUP Pub 459 (Navy), AFM 75-34 (Air Force), and MCO P4610.19

(Marine Corps).

4. Reporting of Equipment Manual Improvements. Reporting of errors,

omissions, and recommendations for improving this publication by the individual

user is encouraged. Reports should be submitted on DA Form 2028

(Recommended Changes to Publications) and forwarded direct to Commanding

General, U.S. Army Electronics Command, ATTN: AMSEL-ME-NMP-AD, Fort

Monmouth, N.J. 07703.

Page 28. Add paragraphs 2.6 and 2.7 after paragraph 2.5:

2.6 Premission Operational Check

a. Procedure. The equipment operator should perform a premission

operational check on the AN/GRA-71 before going on an assigned mission. Locate

the AN/GRA-71 and the associated radio set (para 2.7) a few hundred yards from

the base station. Set -p the equipment for communication with the base station, and

then record 20-word messages

2

on the magnetic tape in the two CA-3B cartridges. Record one message on one

magnetic tape with the CO/B-8 Coder and a message on the remaining tape with the

COMB Coder. Before performing this premission check, arrange with the base

station for receiving the test messages. Figure 2-7 illustrates a typical example.

Perform the test transmission by following the steps given in the chart below:

b. Premission Operational Chart.

Step

No.

1---------

2---------

3---------

Performance procedure

Remove the cover from the KA-3 Keyer Adapter

(fig. 2-3). Remove the components from the

storage compartments and remove or open the

covers of those compartments that have covers.

Refer to the technical manual for the authorized

transmitter operating instructions. Tune the

transmitter for operation with the base station.

Turn the transmitter off. Some configurations do

not need the KA-3 Keyer Adapter. A typical

example is shown on figure 2-6. Attach the

TRANS cable on the KA-3 Keyer Adapter to the

transmitter.

Attach one CA-3B Cartridge (fig. 1-5) to the

CO/B-8 Coder (fig. 1-2) locking pins. Press down

on the CO/B-8 Coder word space button gently

and slowly (fig. 3-4), and observe the following:

a. Tape moves forward as evidenced by the

movement of the white lines on the storage

spool (fig. 1-5) in two steps.

b. Two distinct clicks are heard when the button

is pushed downward, gently, slowly, and

completely. Two distinct clicks are heard

when the button is released gently and

slowly. The procedure should be repeated

five or six times.

3

Step

No.

Performance procedure

4---------

5---------

6---------

7---------

8---------

c. Premission Test Message Reception.

Record the test message on the CA-3B Cartridge

with the CO/B-8 Coder by following the message

recording instructions in paragraph 2.2, steps

1 through 9.

Record a test message o-i the remaining CA-3B

Cartridge with the CO-3B Coder by following

the message recording instructions given in

paragraph 2.2.2, steps 1 through 8.

To transmit the messages recorded with the CO/B-8

Codera. Attach the appropriate CA-3B Cartridge on

the KE-8B Keyer locking pins. Wind the

KE-8B Keyer spring with the windup

crank (fig. 1-4).

b. Attach the KA-3 Keyer Adapter KEYER

cable to the KE-8B Keyer connector receptacle, and then turn the transmitter to ON.

c. Refer to paragraph 2.3, steps 4, and 5 for

instructions on transmitting the message.

Repeat step 6 above to send the message recorded

by the CO-3B Coder on the other CA-3B

Cartridge.

Disassemble all equipment, and return to the base

station to check the quality of the recorded

messages. If incorrect messages are received and

the defect cannot be remedied by the operator,

return the AN/GRA-71 to maintenance for

adjustment, or repair and adjustment.

(1) A typical setup for premission test message reception is shown in figure

2-7.

(2) Follow the operating instructions in TM 11-5820-357-10, to operate

Radio Receiver R-390/URR, and TM 11-5895-373-12, TM 11-5835-228-12, TM 115835-229-12, and TM 11-5835-227-12 to op-

4

erate Recorder-Reproducer Set, Sound AN/GSH-17 for premission test message

reception.

2.7 Operation With Radio Set AN/PRC-74A or AN/PRC-74B

a. The AN/GRA-71 may be used with several radio sets to transmit pretaped

messages. A typical example of a radio set configuration for transmission without

the KA-3 Keyer Adapter is shown on figure 2-6.

b. To operate the AN/PRC-74A or AN/PRC-74B in coder-burst transmission,

Cable Assembly, Special Purpose, Electrical CX-10239/PRC-74 or Cable

Assembly, Power Electrical CX-11468/U can be used. This cable is connected

between J1 on KE-8B Keyer and an AUDIO connector on the front panel of AN/

PRC-74A or AN/PRC-74B. The KW8B Keyer output is applied directly to AN/PRC74A or AN/PRC, 74B through either a CX-10239/PRC-74 or a CX-11468/U.

NOTE

The encoded messages must be prerecorded on the CA-3B

Cartridges recording tapes and be ready for use prior to turning

on the AN/PRC-74A or AN/PRC74B for transmission to minimize

the transmitter on-air time during the coder-burst transmission.

c. Connect the CA-B Cartridge containing the message to be burst-transmitted

to the KR4B Keyer locking pins.

d. Turn on and tune the AN/PR-74A as instructed in TM 11-582059s12, or the

AN/PRC-74B as instructed in TM 11-5820590-12-1.

5

Figure 2-6. Keying transmitter without KA-3 Keyer Adapter.

6

Figure 2-7. Setup for receiving coder-burst transmission for a premission equipment check.

7

e. Set the KE-8B Keyer IDY switch to on. Local operating procedures

establish the length of time that the IDY switch is left on.

f. Turn the IDY switch off, and set the OFF-ON switch on the KE-8B Keyer to

ON. The encoded message will be transmitted automatically.

g. Turn the AN/PRC-74A or AN/PRC-74B off immediately after the message

has been transmitted.

Page 52, paragraph 4.2.6. Delete and substitute:

4.2.6 Cleaning. Clean the exterior surfaces only. The exterior surfaces should be

clean and free of dirt, grease, and fungus. The interior of the adapter, the coders,

the keyer, and the magazines will be cleaned by a higher category of maintenance

personnel.

Paragraph 4.3.1. Delete subparagraphs b, c, and d, and substitute:

b. Repeat the daily and weekly preventive maintenance checks and services as

part of the organizational maintenance (para 4.2.4 through 4.2.6).

Page 53, paragraph 4.3.2. Delete and substitute the following:

4.3.2 Tools and Material Required. No tools are required for organizational

maintenance of the AN/GRA-71. The materials required are listed below.

a. Cleaning Compound (FSN 7930-395-9542).

b. Cleaning cloth (soft, lintfree).

Page 55, paragraph 4.3.5. Make the following changes:

Delete sequence No. 1 in the chart in its entirety, and substitute the following note:

NOTE: IF THE AN/GRA-71 COMPONENTS HAVE BEEN CLOSED IN THE

CASE FOR SOME TIME, THE ELECTRICAL SWITCH CONTACTS COULD

HAVE FORMED A DARK SULPHIDE, CAUSED BY THE SUL-

8

PHUR IN THE RUBBER CASE LINER. THIS COULD CAUSE POOR

ELECTRICAL CONTACT AND THE RESULTANT DROPPING OF DASH OR

DOT SIGNALS. THE ORGANIZATIONAL MAINTENANCE MAN SHOULD

TURN THE AN/GRA-71 IN TO DIRECT SUPPORT PERIODICALLY TO HAVE

THESE ELECTRICAL CONTACTS CLEANED.

Change chart sequence numbers 2, 3, and 4 to read:

1, 2, and 3, respectively.

9

Page 73, appendix I (as changed by C 1, 24 Jun 66). Delete and substitute:

APPENDIX A

REFERENCES

Following is a list of applicable references that should be available to the operator

and organizational maintenance personnel of Coder-Burst Transmission Group

AN/GRA-71:

DA Pam 310-4 Index of Technical Manu-

DA Pam 310-7 U.S. Army Equipment In-

SB 38-100 Preservation, Packaging,

SM 11-4-5180-R09 Tool Kit, Radio Repair

TB 746-10 Field Instructions for

TM 11-5820-357-10 Operator's Manual: Radio

als, Technical Bulletins,

Supply Manuals (types

7, 8, and 9), Supply Bulletins, and Lubrication

Orders.

dex of Modification Work

Orders.

Packing and Marking

Materials, Supplies, and

Equipment Used By the

Army.

TK-115/G.

Painting and Preserving

Electronics Command

Equipment.

Receiver R-390/URR.

A-1

TM 11-5820-474-14 Organizational, DS, and

TM 11-5820-590-12 Operator and Organiza-

TM 11-5820-590-12-1 Operator and Organiza-

TM 11-5835-227-12 Organizational Mainte-

TM 11-5835-228-12 Organizational Mainte-

TM 11-5835-229-12 Organizational Mainte-

GS Maintenance Manual: Radio Set AN/GRC-

109.

tional Maintenance Man-

ual Including Repair

Parts and Special Tool

Lists: Radio Sets AN/

PRC-74 and AN/PRC74A and Power Supply

PP-4514/PRC-74.

tional Maintenance Manual Including Repair

Parts and Special Tool

Lists: Radio Set AN/

PRC-74B and Power

Supply PP-4514/PRC-

74.

nance Manual: Recorder-

Reproducer Set, Sound

AN/GSH-17.

nance Manual: RecorderReproducer, Sound RD265/GR.

nance Manual: Reproducer, Sound RP-138/

GR.

A-2

TM 11-5895-373-12 Operator and Organiza-

TM 38-750 Army Equipment Record

tional Maintenance Manual: Converter, Frequency, Electronic CV-1716/

GR.

Procedures.

A-3

APPENDIX B

BASIC ISSUE ITEMS

Section I. INTRODUCTION

B-1. Scope

This appendix lists items comprising an operable equipment and those required for

installation, operation, or operator's maintenance for Coder-Burst Transmission

Group AN/GRA-71.

B-2. Explanation of Columns

The following is a list of explanations of columns in section II.

a. Source, Maintenance, and Recoverability Codes (SMR) Column. Not used.

b. Federal Stock Number Column. This column indicates the Federal stock

number for the item.

c. Description Column. This column includes the Federal item name and any

additional description of the item which may be required. A part number or the

reference number is followed by the applicable five-digit Federal supply code for

manufacturers. Usable on code column is not used.

d. Unit of Measure Column The unit used as a basis of measure (e.g., ea, pr,

ft, yd, etc.) is given in this column

e. Quantity Incorporated in Unit Column. The total quantity of the item used in

the equipment is given in this column.

B-1

f. Quantity Furnished With Equipment Column. This column lists the quantity

of the item supplied for initial operation of the equipment and/or the quantities

authorized to be kept on hand by the operator for maintenance of the equipment.

g. Illustration Column. Not used.

D-3. Federal Supply Code.

This paragraph lists the Federal supply code with the associated manufacturer's

name.

Code number Manufacturers name

80063-------------------------------- Army Electronics Command.

B-2

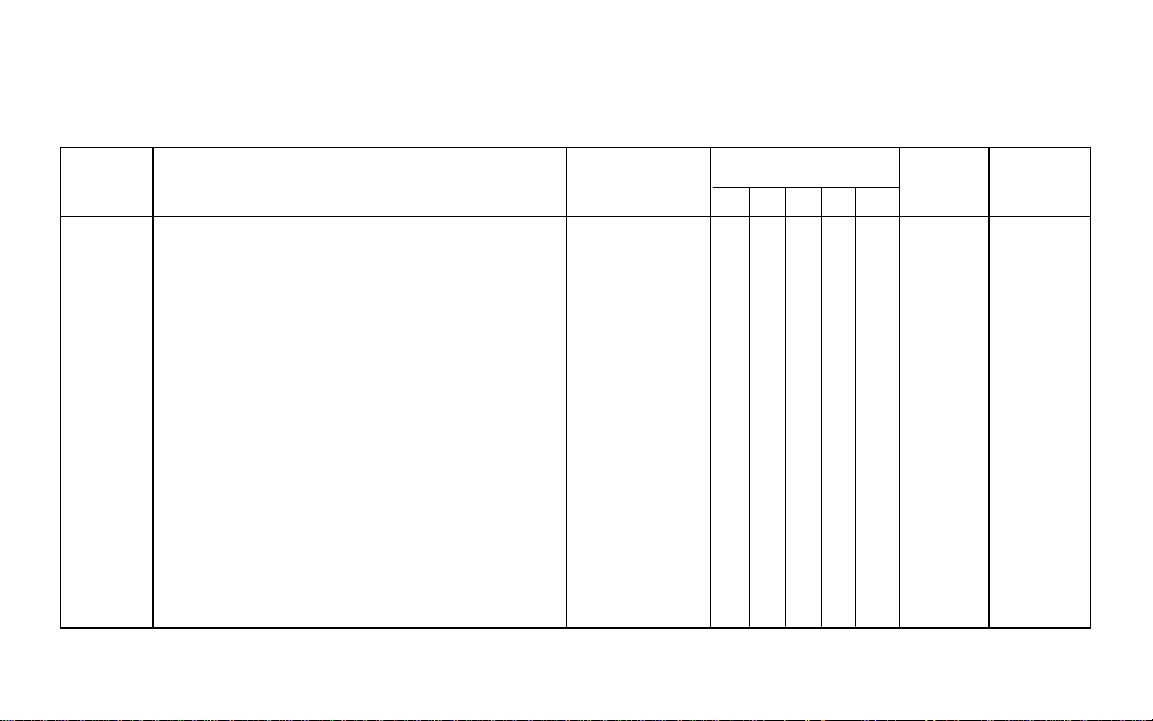

SECTION II. BASIC ISSUE ITEMS

OR REFERENCE

(1)

SMR

CODE

(2)

FEDERAL

STOCK

NUMBER

Reference Number & Mfr Code CODE

5820-056-6856 CODER-BURST TRANSIMISSION GROUP AN/GRA 71:

SC-DL-556000; 80063 (This item is nonexpendable)

TECHNICAL MANUAL TM 11-5835-224-12

Requisition through pinpoint account number if assigned;

otherwise through nearest Adjutant General facility.

A quantity of one technical manual is packed with each

equipment. Where a valid need exists, additional copies may

be requisitioned and kept on hand.

NO PART AUTHORIZED OPERATOR/CREW

NO ACCESSORIES, TOOLS OR TEST EQUIPMENT ARE TO BE ISSUED

WITH THIS EQUIPMENT

NO BASIC ISSUE ITEMS ARE MOUNTED IN OR ON THE EQUIPMENT

(3)

DESCRIPTION

B-3

USABLE ON

(4)

UNIT

MEAS

(5)

QTY

OF

INC

IN

UNIT

ea 1 1

(6)

QTY

FURN

WITH

EQUIP

(7)

ILLUSTRATIONS

(a) (b)

FIG. ITEM NO.

NO.

DESIGNATION

APPENDIX C

MAINTENANCE ALLOCATION

Section I. INTRODUCTION

C-1. General

This appendix provides a summary of the maintenance operations covered in the

equipment literature for Coder-Burst Transmission Group AN/GRA-71. It authorizes

categories of maintenance for specific maintenance functions on repairable items

and components and the tools and equipment required to perform each function.

This appendix may be used as an aid in planning maintenance operations.

C-2. Explanation of Format for Maintenance Allocation Chart

a. Group Number. Group numbers correspond to the reference designation

prefix assigned in accordance with ASA Y32.16, Electrical and Electronics

Reference Designations. They indicate the relation of listed items to the next higher

assembly.

b. Component Assembly Nomenclature. This column lists the item names of

component units, assemblies, subassemblies, and modules on which maintenance

is authorized.

c. Maintenance Function. This column indicates the maintenance category at

which performance of the specific maintenance function is authorized. Authorization

to perform a function at any category

C-1

also includes authorization to perform that function at higher categories. The codes

used represent the various maintenance categories as follows:

Code Maintenance category

C ------------------------------------------ Operator/crew.

O ------------------------------------------ Organizational maintenance.

F ------------------------------------------ Direct support maintenance.

H ------------------------------------------ General support maintenance.

D ------------------------------------------ Depot maintenance.

d. Tools and Equipment. The numbers appearing in this column refer to

specific tools and equipment which are identified by these numbers in section III.

e. Remarks. Self-explanatory.

C-3. Explanation of Format for Tool and Test Equipment Requirements

The columns in the tool and test equipment requirements chart are as follows:

a. Tools and Equipment. The numbers in this column coincide with the

numbers used in the tools and equipment column of the MAC. The numbers

indicate the applicable tool for the maintenance function.

b. Maintenance Category. The codes in this column indicate the maintenance

category normally allocated the facility.

c. Nomenclature. This column lists tools, test, and maintenance equipment

required to perform the maintenance functions.

d. Federal Stock Number. This column lists the Federal stock number.

e. Tool Number. Not used.

C-2

GROUP

NUMBER

COMPONENT ASSEMBLY

NOMENCLATURE

CODER-BURST TRANSMISSION

GROUP AN/GRA-71

SECTION II. MAINTENANCE ALLOCATION CHART

MAINTENANCE FUNCTIONS

I T S A A C I R R O R

N E E D L A N E E V E

S S R J I L S P P E B

P T V U G I T L A R U

E I S N B A A I H I

C C T R L C R A L

T E A E U D

T L

E

O

O

F

F

F

F

F

TOOLS AND

EQUIPMENT

9

3, 5, 6

9

8

REMARKS

Exterior mechanical and visual

inspection.

Exterior cleaning.

Interior mechanical and visual

inspection.

Mechanical and electrical

troubleshooting.

Interior cleaning and

lubrication.

Repair by replacement of:

MX-4496/GRA-71;

MX-4495/GRA-71;

KY-468/GRA-71;

MA-9/GRA-71 AND

MX-4498/GRA-71.

C-3

GROUP

C-4

NUMBER

1A

COMPONENT ASSEMBLY

NOMENCLATURE

AN/GRA-71 (continued)

CODER-BURST TRANSMISSION

GROUP AN/GRA-71.

ADAPTER, KEYER MX-4498/GRA-71

(KA-3 KEYER ADAPTER)

MAINTENANCE ALLOCATION CHART

MAINTENANCE FUNCTIONS

I T S A A C I R R O R

N E E D L A N E E V E

S S R J I L S P P E B

P T V U G I T L A R U

E I S N B A A I H I

C C T R L C R A L

T E A E U D

T L

E

D

D

D

D

O

O

F

F

F

D

D

TOOLS AND

EQUIPMENT

1, 2, 3, 4,

5, 6, 7

8

8

8

9

3, 5, 6

9

8

8

REMARKS

Exterior mechanical and visual

inspection.

Exterior cleaning

Interior mechanical and visual

inspection.

Mechanical and electrical

troubleshooting.

Interior cleaning and

lubrication.

Repair by replacement of:

MX-4496

GROUP

NUMBER

2A

COMPONENT ASSEMBLY

NOMENCLATURE

AN/GRA-71 (continued)

MAGAZINE, RECORDING TAPE

MA-9/GRA-71

(CA-3B CARTRIDGE)

MAINTENANCE ALLOCATION CHART

MAINTENANCE FUNCTIONS

I T S A A C I R R O R

N E E D L A N E E V E

S S R J I L S P P E B

P T V U G I T L A R U

E I S N B A A I H I

C C T R L C R A L

T E A E U D

T L

E

O

O

F

F

F

D

D

C-5

TOOLS AND

EQUIPMENT

9

9

8

8

REMARKS

Exterior mechanical and visual

inspection.

Exterior cleaning.

Interior mechanical and visual

inspection.

Mechanical troubleshooting.

Interior cleaning and

lubrication.

Replace magnetic tape.

GROUP

NUMBER

3A

COMPONENT ASSEMBLY

NOMENCLATURE

AR/GR71 (continued)

CODER, TAPE MX-4496/GRA-71

(CO/B-8 CODER)

MAINTENANCE ALLOCATION CHART

MAINTENANCE FUNCTIONS

I T S A A C I R R O R

N E E D L A N E E V E

S S R J I L S P P E B

P T V U G I T L A R U

E I S N B A A I H I

C C T R L C R A L

T E A E U D

T L

E

O

O

F

F

F

F

D

D

D

C-6

TOOLS AND

EQUIPMENT

9

3

9

8

8

8

8

REMARKS

Exterior mechanical and visual

inspection.

Exterior cleaning.

Interior mechanical and visual

inspection.

Mechanical troubleshooting.

Interior cleaning and

lubrication.

Replace magnetic tape.

GROUP

NUMBER

4A

COMPONENT ASSEMBLY

NOMENCLATURE

AN/GRA-71 (continued)

KEYER KY-468/GRA-71

(KE-8B KEYER)

MAINTENANCE ALLOCATION CHART

MAINTENANCE FUNCTIONS

I T S A A C I R R O R

N E E D L A N E E V E

S S R J I L S P P E B

P T V U G I T L A R U

E I S N B A A I H I

C C T R L C R A L

T E A E U D

T L

E

O

O

F

F

F

F

D

D

D

D

TOOLS AND

EQUIPMENT

9

3

9

8

2, 3, 4, 6, 7

8

8

8

REMARKS

Exterior mechanical and visual

inspection.

Exterior cleaning.

Interior mechanical and visual

inspection.

Mechanical and electrical

troubleshooting.

Interior cleaning and

lubrication.

IDY frequency and waveshape;

dot, dash and space duration;

dot frequency; erase function.

C-7

GROUP

NUMBER

5A

COMPONENT ASSEMBLY

NOMENCLATURE

AR/GRA-71 (continued)

CODER, TAPE MX-4495/GRA-71

(CO-3B CODER)

MAINTENANCE ALLOCATION CHART

MAINTENANCE FUNCTIONS

I T S A A C I R R O R

N E E D L A N E E V E

S S R J I L S P P E B

P T V U G I T L A R U

E I S N B A A I H I

C C T R L C R A L

T E A E U D

T L

E

O

O

F

F

F

F

D

D

D

TOOLS AND

EQUIPMENT

9

3

9

8

8

8

8

REMARKS

Exterior mechanical and visual

inspection.

Exterior cleaning.

Interior mechanical and visual

inspection.

Mechanical and electrical

troubleshooting.

Interior cleaning and

lubrication.

C-8

SECTION III. TOOL AND TEST EQUIPMENT REQUIREMENTS

TOOLS AND

EQUIPMENT

1

2

3

4

5

6

7

8

9

MAINTENANCE

CATEGORY

D

D

F, D

D

F, D

F, D

D

F, D

F

NOMENCLATURE

AN/GRA-71 (continued)

CODE RECORDER RD-60/U

FREQUENCY METER AN/USM-26

MULTIMETER TS-352B/U

OSCILLOSCOPE AN/USM-140A

TEST SET, ELECTRON TUBE TV-7/U

TEST SET, TRANSISTOR TS-1836

TIME WORK GENERATOR AN/USM-108

TOOL KIT TK-100/G

TOOL KIT TK-115/G

C-9

FEDERAL

STOCK

NUMBER

5805-164-7323

6625-543-1356

6625-242-5023

6625-987-6603

6625-376-4939

6625-893-2628

6625-987-9564

5180-605-0079

5180-856-1578

TOOL NUMBER

By Order of the Secretary of the Army:

W. C. WESTMORELAND,

General, United States Army,

Official: Chief of Staff.

KENNETH G. WICKHAM,

Major General, United States Army

The Adjutant General.

Distribution:

Active Army:

USASA (2) Army Pic Cen (2)

CNGB (1) USACDCEC (10)

ACSC-E (2) USAJFKCENSPWAR

Dir of Trans (1) (25)

Cof Engrs (1) Instl (21 except

TSG (1) Fort Gordon (10)

Cot Spt S (1) Fort Huachuca (10)

USAARENBD (2) WSMR (5)

USAAESWBD (5) Fort Carson (25)

USACDC Agcy (1) Fort Knox (12)

USAMC (5) Army Dep (2) except

USCONARC (5) LBAD (14)

ARADCOM (5) SAAD (30)

ARADCOM Rgn (2) TOAD (14)

OS Maj Comd (4) LEAD (7)

USARYIS (25) SHAD (3)

LOGCOMD (2) except NAAD (5)

1st LOGCOMD (10) SVAD (5)

9th LOGCOMD (10) CHAD (3)

USAMICOM (4) ATAD (10)

USATECOM (2) GENDEPS (2)

USASTRATCOM (4) Sig Sec GENDEPS (5)

USAESC (70) Sig Dep (12)

MDW(1) Sig FLDMS (2)

Armies (2) except TOPOCOM

Seventh USA (5) USAERDAA (2)

Mil Intel Bn (4) USAERDAW (13)

Corrs (2) USACRREL (2)

1st av Div (5) MAAG (2)

Inf Div (10) USARMIS (2)

Armor Div (10) USARMS (2)

Airborne Div (9) USMACV (50)

Inf Bde (2) Units organized under

Armor Bde (4) following TOE's (2

Mechanized Bde (2) copies each)

Airborne Bde (2) 7 (AA-AC)

Svce Colleges (2) 7-4 11-587

USASFESS (20) 7-157 11-592

USAADS7(2) 11-57 11-597

USAAMS (2) 11-97 17'

USAARMS (5) 11-98 30-25

USAIS (10) 11-117 M1-105

USAES (2) 11-127 31-106

USAINTS (3) 11-155 31-10

USATC Armor (2) 11-157 37

USATC Inf (2) 11-158 57

USASTC (2) 11-500 57-4

WRAMC (1)

NG: State AG (3).

USAR: None.

For explanation of abbreviations used see AR 320-50

Changes in force: C 2 and C 5

*TM 11-5835-224-12

CHANGE HEADQUARTERS, No. 5 WASHINGTON DC, 5 September 1978

TM 11 5835-224-12, 27 May 1964, is changed as follows:

Title is changed as shown above.

Paragraphs B, C, and D are superseded as follows:

B. Forms and Records

forms, records, and re-

}

Operator's and Organizational

Maintenance Manual

CODER-BURST TRANSMISSION

GROUP AN/GRA-71

(NSN 5820-00-056-6860)

Page 2. Table of contents. Delete the second line.

Page 4. Paragraph A, change title to read: "Indexes of Publications."

a. Reports of Maintenance and Unsatisfactory Equipment. Maintenance

DEPARTMENT OF THE ARMY

C5

* This change supersedes C 3, 2 June 1970 and C 4, 31 August 1973.

1

ports which are to be used by maintenance personnel at all maintenance levels are

listed in and prescribed by TM 38-750.

b. Report of Packaging and Handling Deficiencies. Fill out and forward DD

Form 6 (Packaging Improvement Report) as prescribed in AR 70058/NAVSUPINST 4030.29/AFR 71-13/MCO P4030.29A, and DLAR 4145.8.

c. Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and forward

Discrepancy in Shipment Report (DISREP) (SF 361) as prescribed in AR 5538/NAVSUPINST 4610.33B/AFR 75-18/MCO P4610.19C and DLAR 4500.15.

C. Reporting of Errors

The reporting of errors, omissions, and recommendations for improving this

publication by the individual user is encouraged. Reports should be submitted on

DA Form 2028 (Recommended Changes to Publications and Blank Forms) and

forwarded direct to Commander, US Army Communications and Electronics Materiel

Readiness Command, ATTN: DRSEL-ME-MQ, Fort Monmouth, NJ 07703.

C.1. Reporting Equipment Improvement Recommendations (EIR)

EIR's will be prepared using SF 368 (Quality Deficiency Report). Instructions for

preparing EIR's are provided in TM 38750, The Army Maintenance management

System. EIR's should be mailed direct to Commander, US Army Communications

and Elec-

2

tronics Materiel Readiness Command, ATTN: DRSEL-ME-MQ, Fort Monmouth, NJ

07703. A reply will be furnished direct to you.

D. Items Comprising an Operable Coder-Burst Transmission Group

AN/GRA-71 (NSN 5820-00-056-6856)

NSN Qty Item Fig.No.

5820-00-056-6860 1 Adapter, Keyer MX-4498/

GRA-71(KA-3)............................. 1-6

1 Coder, Tape MX-4495/

GRA-71 (CO-3B)......................... 1-3

1 Coder, Tape MX-4496/

GRA-71 (CO/B-8)a....................... 1-2

1 Keyer KY-468/GRA-71

(KE-8B)........................................ 1-4

5820-00-056-6857 2 Magazine, Recording Tape

MA-9/GRA-71 (CA-3B)................ 1-5

a

lncludes Dial Character (NSN 5820-00-920-5429), and Dial Character (NSN

5820-00-920-5430).

Page 9, paragraph 1.2.2. The last four lines are superseded as follows: "There

must be one space between each character and three spaces between each word.

Therefore, after each character depress the SPACE key once. If the character is

the last letter in a word, depress the SPACE key three times."

Page 20, paragraph 2.2.2, Step 6. The last line is changed to read: "the

SPACE key three times."

Page 22, paragraph 2.3. Add the following CAUTION after Step 1.

3

CAUTION

When the AN/GRA-71 components are stowed in the carrying

case and the cables have been secured by the retainer clamps,

place the cover on the carrying case so that the rubber pad on

the inside of the cover is over the component area and not over

the cables and retainer clamps. This will prevent the clamps

from being broken by placing the cover on incorrectly.

Page 26, paragraph 2.5 is deleted in its entirety.

Page 28. Delete figure 25.

Page 42, paragraph 3.2. The last sentence is superseded as follows: "With the

CO-3B Coder, there must be one space between each character and three spaces

between each word. Therefore, after each character depress the SPACE key once.

If the character is the last letter in a word, depress the SPACE key three times.

Page 73, appendix A. TM 38-750 is changed to read: "The Army Maintenance

Management System (TAMMS)."

Appendix B is deleted in its entirety.

Appendix C is superseded as follows:

4

MAINTENANCE ALLOCATION

C-1. General

This appendix provides a summary of the maintenance operations for AN/GRA-71.

It authorizes categories of maintenance for specific maintenance functions on

repairable items and components and the tools and equipment required to perform

each function. This appendix may be used as an aid in planning maintenance

operations.

C-2. Maintenance Function.

Maintenance functions will be limited to and defined as follows:

a. Inspect. To determine the serviceability of an item by comparing its

physical, mechanical, and/or electrical characteristics with established standards

through examination.

b. Test. To verify serviceability and to detect incipient failure by measuring the

mechanical or electrical characteristics of an item and comparing those

characteristics with prescribed standards.

c. Service. Operations required periodically to keep an item in proper operating

condition, i.e., to clean (decontaminate), to preserve, to drain, to

APPENDIX C

Section I. INTRODUCTION

5

paint, or to replenish fuel, lubricants, hydraulic fluids, or compressed air supplies.

d. Adjust. To maintain, within prescribed limits, by bringing into proper or exact

position, or by setting the operating characteristics to the specified parameters.

e. Align. To adjust specified variable elements of an item to bring about

optimum or desired performance.

f. Calibrate. To determine and cause corrections to be made or to be adjusted

on instruments or test measuring and diagnostic equipments used in precision

measurement. Consists of comparisons of two instruments, one of which is a

certified standard of known accuracy, to detect and adjust any discrepancy in the

accuracy of the instrument being compared.

g. Install. The act of emplacing, seating, or fixing into position an item, part,

module (component or assembly) in a manner to allow the proper functioning of the

equipment or system.

h. Replace. The act of substituting a serviceable like type part, subassembly,

or module (component or assembly) for an unserviceable counterpart.

i. Repair. The application of maintenance services (inspect, test, service,

adjust, align, calibrate, replace) or other maintenance actions (welding, grinding,

riveting, straightening, facing, re-machining, or resurfacing) to restore serviceability

to an item by correcting specific damage, fault, malfunction, or failure in a part,

subassembly,

6

module (component or assembly), end item, or system.

j. Overhaul. That maintenance effort (service/action) necessary to restore an

item to a completely serviceable/operational condition as prescribed by maintenance

standards (i.e., DMWR) in appropriate technical publications. Overhaul is normally

the highest degree of maintenance performed by the Army. Overhaul does not

normally return an item to like new condition.

k. Rebuild. Consists of those services/actions necessary for the restoration of

unserviceable equipment to a like new condition in accordance with original

manufacturing standards. Rebuild is the highest degree of materiel maintenance

applied to Army equipment. The rebuild operation includes the act of returning to

zero those age measurements (hours, miles, etc.) considered in classifying Army

equipments/components.

C-3. Column Entries.

a. Column 1, Group Number. Column 1 lists group numbers, the purpose of

which is to identify components, assemblies, subassemblies, and modules with the

next higher assembly.

b. Column 2, Component/Assembly. Column 2 contains the noun names of

components, assemblies, subassemblies, and modules for which maintenance is

authorized.

c. Column 3, Maintenance Functions. Column 3 lists the functions to be

performed on the item

7

listed in column 2. When items are listed without maintenance functions, it is solely

for purpose of having the group numbers in the MAC and RPSTL coincide.

d. Column 4, Maintenance Category. Column 4 specifies, by the listing of a

"worktime" figure in the appropriate subcolumn(s), the lowest level of maintenance

authorized to perform the function listed in column 3. This figure represents the

active time required to perform that maintenance function at the indicated category of

maintenance. If the number or complexity of the tasks within the listed maintenance

function vary at different maintenance categories, appropriate "worktime" figures will

be shown for each category. The number of task-hours specified by the "worktime"

figure represents the average time required to restore an item (assembly,

subassembly, component, module, end item or system) to a serviceable condition

under typical field operating conditions. This time includes preparation time,

troubleshooting time, and quality assurance/quality control time in addition to the

time required- to perform the specific tasks identified for the maintenance functions

authorized in the maintenance allocation chart. Subcolumns of column, 4 are as

follows:

C - Operator/Crew

O - Organizational

F - Direct Support

H - General Support

D - Depot

8

e. Column 5, Tools and Equipment. Column 5 specifies by code, those

common tool sets (not individual tools) and special tools, test, and support

equipment required to perform the designated function.

f. Column 6, Remarks. Column 6 contains an alphabetic code which leads to

the remark in section IV, Remarks, which is pertinent- to the item opposite the

particular code.

C-4. Tool and Test Equipment Requirements (Sec III).

a. Tool or Test Equipment Reference Code. The numbers in this column

coincide with the numbers used in the tools and equipment column of the MAC.

The numbers indicate the applicable tool or test equipment for the maintenance

functions.

b. Maintenance Category. The codes in this column indicate maintenance

category allocated the tool or test equipment.

c. Nomenclature. This column lists the noun name and nomenclature of the

tools and test equipment required to perform the maintenance functions.

d. National/NATO Stock Number. This column lists the National/NATO stock

number of the specific tool or test equipment.

e. Tool Number. This column lists the manufacturer's part number of the tool

followed by the Federal Supply Code for manufacturers (5-digit) in Parentheses.

9

C-5. Remarks (Sec IV).

a. Reference Code. This code refers to the appropriate item in section II,

column 6.

b. Remarks. This column provides the required explanatory information

necessary to clarify items appearing in section II.

10

(1)

GROUP

NUMBER

00

01

02

SECTION II. MAINTENANCE ALLOCATION CHART

CODER-BURST TRANSMISSION GROUP AN/GRA-71

COMPONENT ASSEMBLY

CODER-BURST TRANSMISSION GROUP AN/GRA-71

ADAPTER, KEYER MX-4498/GRA-71 (KA-3 KEYER)

MAGAZINE, RECORDING TAPE MA-9/GRA-71

(CA-3B CARTRIDGE)

(2)

FOR

(Continued)

MAINTENANCE

(3)

FUNCTION

Inspect

Inspect

Service

Service

Test

Test

Test

Adjust

Align

Repair

Repair

Overhaul

Inspect

Inspect

Service

Service

Test

Repair

Repair

Inspect

Inspect

Service

Service

Test

Repair

Repair

0.5

0.5

0.1

0.1

0.1

0.1

1.0

1.0

1.0

1.0

1.5

0.5

0.2

0.2

1.0

0.5

0.2

0.2

0.5

0.5

(4)

MAINTENANCE CATEGORY

C O F H D

4.0

0.6

2.0

4.5

1.5

1.5

(5)

TOOLS

AND

EQUIPT.

9

9

3, 9

8

9

8

9

9

3, 9

9

2, 3, 4, 6

7, 8

8

8

8

9

9

3, 9

8

8

(6)

REMARKS

A

B

C

D

E

J

A

B

C

D

E

J

I

A

B

C

D

E

11

(1)

GROUP

NUMBER

03

04

05

SECTION II. MAINTENANCE ALLOCATION CHART

CODER-BURST TRANSMISSION GROUP AN/GRA-71

COMPONENT ASSEMBLY

CODER, TAPE MX-4496/GRA-71 (CO-B8 CODER)

KEYER KY-468/GRA-71 (KE-8B KEYER)

CODER, TAPE MX-4495/GRA-71 (CO-3B)

(2)

FOR

(Continued)

MAINTENANCE

12

(3)

FUNCTION

Inspect

Inspect

Service

Service

Test

Adjust

Repair

Repair

Inspect

Inspect

Service

Service

Test

Repair

Test

Adjust

Align

Repair

Inspect

Inspect

Service

Service

Test

Adjust

Repair

0.1

0.1

0.1

0.1

0.1

0.1

0.2

0.2

1.2

2.0

0.5

0.2

0.2

1.5

0.5

1.2

0.2

0.2

1.0

1.2

(4)

MAINTENANCE CATEGORY

C O F H D

2.5

2.0

0.6

3.0

2.5

(5)

TOOLS

AND

EQUIPT.

9

9

3, 9

8

9

8

9

9

3, 9

9

2, 3, 4, 6

7, 8

8

8

8

9

9

3, 9

8

8

(6)

REMARKS

A

B

C

D

E

J

A

B

C

D

E

J

I

A

B

C

D

E

SECTION III. TOOL AND TEST EQUIPMENT REQUIREMENTS

CODER-BURST TRANSMISSION GROUP AN/GRA-71

FOR

TOOL OR TEST

EQUIPMENT

REF CODE

1

2

3

4

5

6

7

8

9

MAINTENANCE

CATEGORY

F, H, D

D

F, D

D

F, D

F, D

D

F, D

F

NOMENCLATURE

CODE RECORDER RD-60/U

TEST SET, RADIO AN/USM-26/A

MULTIMETER TS-352B/U

OSCILLOSCOPE AN/USM-140A

TEST SET, ELECTRON TUBE TV-7/U

TEST SET, TRANSISTOR TS-1836

TIME-MARK GENERATOR AN/USM-108

TOOL KIT, ELECTRONIC EQUIPENT TK-100/G

TOOL KIT, ELECTRONIC EQUIPMENT TK-105/G

13

NATIONAL NATO

STOCK NUMBER

5805-00-164-7323

6625-00-543-1356

6625-00-242-5023

6625-00-987-6603

6625-00-376-4939

6625-00-893-2628

6625-00-987-9564

5180-00-605-0079

5180-00-610-8177

TOOL NUMBER

SECTION IV. REMARKS

REFERENCE

CODE

A

B

C

D

E

F

G

H

I

J

K

REMARKS

Exterior mechanical and visual inspection,

Interior mechanical and visual inspection.

Exterior cleaning.

Interior cleaning and lubrication.

Mechanical and electrical troubleshooting.

Repair by replacement of components: MX-4496/GRA-71, MX-4495/GRA-71, KY-468/GRA-71, MA-9/GRA-71,

and MX-4498/GRA-71.

Mechanical troubleshooting.

Repair by replacement of magnetic tape and authorized parts.

IDY frequency and waveshape, dot, dash, and space duration; dot frequency; erase function.

Repair by authorized parts replacement.

Check for tape reproduction exactness after tape replacement.

14

By Order of the Secretary of the Army:

BERNARD W. ROGERS

General, United States Army

Official: Chief of Staff

J. C. PENNINGTON

Brigadier General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with DA Form 12-51, operator maintenance

requirements for AN/GRA-71.

This manual contains information copyrighted and owned by Stenographic

Machines, Inc., 8040 North Ridgewas Avenue, Skokie, ILL.

TM 11-5835-224-12

TECHNICAL MANUAL HEADQUARTERS

No. 11-5835-224-12 WASHINCTON, D.C., 27 May 1984

Preface........................................................................................................................4

1.0 GENERAL INFORMATION

1.1 Introduction.....................................................................................................6

1.2 Purpose and Description ................................................................................6

1.2.1 CO/B-8 Coder..........................................................................................6

1.2.2 CO-3B Coder...........................................................................................8

1.2.3 KE-8B Keyer............................................................................................9

1.2.4 CA-3B Cartridge....................................................................................12

1.2.5 KA-3 Keyer Adapter...............................................................................13

2.0 OPERATING INSTRUCTIONS

2.1 General Instructions......................................................................................14

2.1.1 CO/B-8 Coder........................................................................................14

2.1.2 CO-3B Coder.........................................................................................15

2.1.3 KE-8B Coder..........................................................................................15

2.1.4 CA-3B Cartridge....................................................................................15

2.2 Message Recording......................................................................................16

2.2.1 CO/B-8 Coder message recording.........................................................16

2.2.2 CO-3B Coder message recording..........................................................19

2.3 Message Transmission.................................................................................20

}

Operator and Organizational Maintenance

CODER-BURST TRANSMISSION GROUP

DEPARTMENT OF THE ARMY

Manual

AN/GRA-71

Page

1

2.4 Message Erasing.........................................................................................26

Page

2.5 Tape Replacement.......................................................................................26

3.0 THEORY OF OPERATION

3.1 General Theory............................................................................................29

3.1.1 CO/B-8 Coder.......................................................................................29

3.1.2 CO-3B Coder........................................................................................29

3.1.3 KE-8B Keyer ........................................................................................30

3.1.4 CA-3B Cartridge...................................................................................30

3.1.5 KA-3 Keyer Adapter..............................................................................30

3.2 Morse Code structure...................................................................................31

4.0 MAINTENANCE

4.1 Introduction..................................................................................................43

4.2 Operator's Maintenance...............................................................................43

4.2.1 Scope of operator's Maintenance...........................................................43

4.2.2 Preventive maintenance.........................................................................43

4.2.3 Preventive maintenance checks and

services...........................................................................................................44

4.2.4 Daily preventive maintenance checks

and services chart...........................................................................................46

4.2.5 Weekly preventive maintenance checks

and services chart...........................................................................................49

4.2.6 Cleaning.................................................................................................52

4.3 Organizational Maintenance

4.3.1 Scope of organizational maintenance.....................................................52

4.3.2 Tools and materials required..................................................................53

4.3.3 Organizational preventive maintenance..................................................53

4.3.4 Quarterly maintenance...........................................................................54

4.3.5 Quarterly preventive maintenance checks

and services chart...........................................................................................55

4.3.6 Cleaning and touchup painting

instructions .....................................................................................................60

APPENDIX. REFERENCES.................................................................................73

2

Note. For reading convenience, the following short form equipment nomenclatures

are used throughout this manual.

1. Coder, Tape MX-4496/GRA-71 is termed CO/ B-8 Coder.

2. Coder, Tape MX-4495/GRA-71 is termed CO- 3B Coder.

3. Keyer KY-468/GRA-71 is termed KE-8B Keyer.

4. Magazine, Recording Tape MA-9/GRA-71 is termed CA-3B Cartridge.

5. Adapter, Keyer MX-4498/GRA-71 is termed KA-3 Keyer Adapter.

Figure 1-1. AN/GRA-71 Coder-Burst transmission group components.

3

A. Index of Publications

PREFACE

Refer to the latest issue of DA Pam 310 4 to determine whether there are new

editions, changes, or additional publications pertaining to the equipment. DA Pam

3104 is an index of current technical manuals, technical bulletins, supply manuals

(types 4, 6, 7, 8, and 9), supply bulletins, lubrication orders, and modification work

orders which are available through publications supply channels. The index lists the

individual parts (-10, -20, -5, etc.) and the latest changes to and revisions of each

equipment publication.

Forms and Records

Reports of Maintenance- and Unsatisfactory Equipment. Use equipment forms

and records in accordance with instructions in TM 38750.

Report of Damaged or Improper Shipment. Fill out and forward DD Form 6 (Report

of Damaged or Improper Shipment) as prescribed in AR 700-58 (Army),

NAVSANDA Publication 378 (Navy), and AFR 71-4 (Air Force).

Reporting of Equipment Manual Improvements. The direct reporting by the

individual user of errors, omissions, and recommendations for improving this manual

is authorized and encouraged. DA Form 2028 (Recommended changes to DA

technical manual parts lists or supply manual 7, 8, or 9) will be used for reporting

these

4

improvements. This form will be completed in triplicate using pencil, pen, or

typewriter. The original and one copy will be forwarded direct to Commanding

Officer, U.S. Army Electronics Materiel Support Agency, ATTN: SELMS-MP, Fort

Monmouth, N. J. 07703. One information copy will be furnished to the individual's

immediate supervisor (officer, noncommissioned officer, supervisor, etc).

5

1.0 GENERAL INFORMATION

1.1 Introduction

This manual is supplied as supporting literature for the AN/GRA-71 CoderBurst Transmission Group components shown in Figure 1-1. Instructions for

operating and maintaining these components are included in the manual. Preventive

maintenance and limited corrective maintenance required of the operator to keep the

equipment in dependable operating condition are provided in the maintenance

section. Mechanical and electrical principles of operation are presented in the theory

of operation section to assist the operator in understanding the equipment and as a

prerequisite to basic troubleshooting.

1.2 Purpose and Description

1.2.1 CO/B-8 Coder (MX-4496/GRA-71). Essentially, the CO/B-8 Coder

(fig. 1-2) is an electromechanical Morse code generator that enables an operator to

record messages in a CA-3B Cartridge. The purpose of the CO/B-8 Coder is to

generate magnetic impulse trains, corresponding to Morse code patterns, for

subsequent recording on magnetic recording tape.

In this capacity, a mechanical coding system and an electrical impulse

generating system are employed in conjunction with each other to generate a Morse

code structure. Briefly, the mechanical coding system drives the electrical impulse

6

Figure 1-2. CO/B-8 Coder.

generating system to form a Morse-encoded magnetic impulse train for each

character on the coder character dial. This mechanical coding system automatically

generates each impulse to form either a dot or dash, and automatically produces

The correct number of dots and dashes in proper sequence to form a Morse code

pattern of magnetic impulses for each character.

Word spacing is also a function of the mechanical coding system. Spaces

between one word and the next are created by depressing the WORD-SPACE

button on the coder housing.

7

Figure 1-3. CO/3B Coder.

1.2.2 CO-3B Coder (MX-4495/GRA-71). The CO-3B Coder (fig. 1-3), like the

CO/B8, is also an electromechanical Morse code generator that enables an operator

to record coded messages in a CA-3B Cartridge. Essentially, the purpose of the

CO-3B Coder is the same as the CO/B8: to generate magnetic impulses for

subsequent recording on magnetic recording tape.

The CO-3B Coder, however, is somewhat less

8

automatic than the CO/B-8 in that each dot and dash element of a character is

generated and recorded individually by way of the keyboard. Briefly, the DOT and

DASH keys drive an electrical impulse generating system which automatically

generates an impulse to form either a dot or dash element. The DOT and DASH

keys also drive a spacing mechanism which automatically provides the correct

amount of space after each dot and dash element.

Spaces between characters are created by depressing the SPACE key once.

Spaces between two-s are created by depressing the SPACE key twice.

1.2.3 KE8B Keyer (KY-468/GRA-71). The purpose of the KE-8B Keyer (fig.

1-4) is to convert tape-recorded, Morse-encoded characters into equivalent electrical

impulses for "keying" an associated transmitter. Also associated with the KE-8B is

the CA-3B Cartridge. The CA-B Cartridge, containing magnetic impulses recorded

in it by either the CO/B-8 or CO-3B Coder, locks onto the KE-8B Keyer- to enable

tape reading for subsequent keying of 'the associated transmitter by way of the KA-3

Keyer Adapter component.

Internally, the KE-8B Keyer contains a spring motor to drive the CA-3B

Cartridge and pull the magnetic tape across the reading head. Also included is

electronic circuitry for converting the prerecorded impulses on the tape into properly

9

Figure 1-4. KE-8B Keyer

spaced Morse signals for transmitter keying. The KE-8B Keyer includes an IDY

function for sending a continuous train of impulses at the rate of 300 wmp (words

per minute), and a provision for erasing CA-3B Cartridges. Required operating

power is obtained from the KA-3 Keyer Adapter cable which is plugged into the KE8B connector.

10

Figure 1-5. CA-3B Cartridge.

11

Figure 1-6. KA-3 Keyer Adapter.

1.2.4 CA-B Cartridge (MA-9/GRA-71). Essentially, the CA-B Cartridge (fig.

1-5) is a mechanical device consisting of a miniature tape transport and magnetic

recording tape.

The purpose of the CA-B Cartridge is to supply magnetic tape to the CO/B8

and CO-3B Coders so that magnetic impulses can be recorded on the tape for

subsequent transmission by way of the KE-8B Keyer, KA-3 Keyer Adapter, and T784/GRC-109 Transmitter. After transmission, messages in the CA-3B Cartridge

can be erased with the KE-8B Keyer component. The

12

CA45B Cartridge can then be reused for recording another message. A special

feature of the CA-3B is an automatic rewind function which returns the tape to its

starting point whenever the cartridge is detached from either of the coders or the

keyer.

1.2.5 KA-3 Keyer Adapter (MX-4498/GRA-71). The KA-3 Keyer Adapter (fig.

1-6) is a water-tight carrying case for the CO/B-8, CO3B, KE-8B, and CA-3B

components. Within the KA-3 are rubber cushioned compartments for two (2) CA3B Cartridges, one (1) KE-78B Keyer, one (1) COTB Coder, one (1) CO/B-8 Coder,

one (1) extra character dial, and one (1) camel-hair cleaning brush. Rubber padding

on the inside of the KA-3 lid protects the components against possible abrasion and

damage during transit.

Also contained in the KA-3 is electronic circuitry for supplying power to the KE8B Keyer and for adapting the KE-8B to a T-784/GRC-109 Transmitter. The T784/GRC-109 Transmitter is not supplied as part of the AN/GRA-71 System.

Cables for interconnecting the KE-8B with the KA-3 Keyer Adapter are mounted on

the KA-3 panel. They are equipped with combination pin straighteners and protective

caps.

13

2.0 OPERATING INSTRUCTIONS

2.1 General Instructions

Although the AN/GRA-71 components are simple to operate, these instructions

should be thoroughly understood by the operator before using the equipment so that

accidental damage and improper use may be avoided.

2.1.1 CO/B-8 Coder. In general, the CO/B8 Coder is operated by rotating the

CHARACTER DIAL until the desired character is positioned opposite the index mark

and then pulling the OPERATING HANDLE down. The operating handle must be

pulled down smoothly and evenly. It must not be snapped or jerked quickly, and

must always be pulled to the stop at the end of its travel. To become accustomed to

the "feel" of the operating handle, operate the CO/B-8 Coder several times without a

CA-3B Cartridge attached. Open the extension handle as shown in Figure 2-1.

A new character may be selected either before the operating handle is pulled,

or after its travel has been completed. The character dial moves easily from one

position to the next, but must not be rotated during the downstroke of the operating

handle. If the dial becomes jammed, DO NOT FORCE IT. Operate the handle

again, more slowly. When the jam clears, insert two word spaces and repeat the

entire group in which

14

the jam occurred. Forcing a jammed dial can seriously damage the CO/B-8 Coder

mechanism. If the difficulty persists, consult the maintenance section of this manual.

2.1.2 COMB Coder. In general, the C0-SB Coder is operated by depressing

the DOT, DASH, and SPACE keys in various combinations to arrive at a recorded

message. Each dot or dash element must be recorded individually. After the correct

sequence of dots and dashes have been recorded to form a character, then the

SPACE key is depressed. To become accustomed to the "feel" of the keyboard,

operate the keys several times without a CA-3B Cartridge attached.

2.1.3 KE-8B Keyer. Essentially, KE-8B Keyer operation consists of attaching a

prerecorded CA3B Cartridge to the keyer and then allowing the recorded message to

be read by the KE-8B and sent into the KA-3 Keyer Adapter to trigger the T784/GRC-109 Transmitter.

Erasing a CA-3B Cartridge on the KE-8B is also a simple operation and

consists of attaching a CA-3B to the KE-8B and then allowing the message to be

erased. Erasing must be performed with the KE-8B, KA-3, and T-784/GRC-109

interconnected with power applied.

2.1.4 CA-SB Cartridge. The CA-3B is operated in conjunction with a CO/B-8

Coder, CO4B Coder, or KE-8B Keyer. Messages are recorded in the CA-3B by

either the CO/B-8 or CO-3B

15

Coder. After a message is recorded in the CA-3B, it is attached to the KE-8B to be

read and transmitted.

2.2 Message Recording

2.2.1 CO/B-8 Coder Message Recording. The CA-3B Cartridge will hold at

least 125 five-letter words plus word spaces. The maximum word capacity varies,

depending upon the number of characters per word and the message length.

Because of the automatic rewind feature, the CA-3B must not be removed from the

CO/B-8 until the entire message has been recorded. If it is accidentally

disconnected from the CO/B-8 before message completion, erase the tape and start

over.

The following procedure describes the steps necessary to record a message in the

CA-3B Cartridge with a co/B-8 Coder.

by sliding them off their hinge pins. Attach a fully erased CA- 8B Cartridge onto the

Step 1. Open and remove the CO/B-8 Coder and CA-3B Cartridge LIDS

CO/B-8 Coder by lining up the locking pins and cartridge drive gear on the coder

with the sockets (in locking plates) and tape drive gear on the CA-3B Cartridge.

Gently snap the two units together.

Step 2. Place the CO/B8 Coder on a smooth, flat surface. Depress the

WORD-SPACE BUTTON about 10 times to move exposed tape past the recording

head.

Step 3. Rotate the CHARACTER DIAL until

16

Figure 2-1. Using CO/B-8 Coder.

the first character of the message clicks into position opposite the index mark. The

character dial may be rotated in either direction before or after the operating handle

is pulled down.

17

Step 4. Depress the EXTENSION HANDLE RELEASE BUTTON and lift up

the handle. Raise the HANDLE to the "starting" position shown in Figure 2-1.

Step 5. Using the thumb and three fingers as shown in Figure 2-1, grasp the

HANDLE and pull it down with a firm, even stroke until it snaps against the stop at

the end of its travel. DO NOT HESITATE DURING THE DOWNSTROKE. The

character has now been recorded in the CA43B Cartridge.

Step 6. Select the next character of the word and repeat step 5.

Step 7. After the word has been recorded, insert a word space by firmly

depressing the WORD-SPACE BUTTON once and releasing it, allowing it to return

to normal position.

Step 8. Continue the procedure of steps 5, 6, and 7 until the entire message

has been recorded.

Step 9. After the entire message has been recorded, detach the CA-3B

Cartridge from the CO/B-8 Coder by pressing the CARTRIDGE RELEASE

BUTTON inward. Lift the cartridge away from the Coder. As soon as the cartridge

drive and coder drive gears separate, the cartridge begins rewinding the tape. Upon

completion of rewind (about 5 seconds), the message recorded in the cartridge may

be transmitted. Replace the coder LID immediately and fold the EXTENSION

HANDLE

18

back down by depressing the release button. Replace the cartridge LID as soon as

possible.

2.2.2 CO-3B Coder Message Recording. The CA-3B Cartridge will hold at

least 125 five-letter words plus word spaces. The maximum word capacity varies,

depending upon the number of characters per word and the message length.

Because of the automatic rewind feature, the CA-3B must not be removed from the

CO-3B until the entire message has been recorded. If it is accidentally disconnected

from the CO-3B before message completion, erase the tape and start over.

The following procedure describes the steps necessary to record a message in

the CA-3B Cartridge with a CO-3B Coder.

Step 1. Depress the LID RELEASE BUTTON and open the CO-3B Coder LID.

Open and remove CA-3B Cartridge LID by sliding it off the hinge pins. Attach a fully

erased CA-3B Cartridge onto the CO-3B Coder by lining up the locking pins and

cartridge drive gear on the CO-3B Coder with the sockets (in locking plates) and

tape drive gear on the CA-3B Cartridge. Gently snap the two units together.

Step 2. Place the CO-3B Coder on a smooth, flat surface. Place fingers on the

keyboard a shown in Figure 2-2. Depress the SPACE key about 10 times to move

exposed tape past the recording head.

Step 3. Depress the DOT (s) and DASH (-) keys accordingly to record a

character. For ex-

19

ample to 'record the letter Q (- - -), depress the DASH key twice, depress the DOT

key once, and depress the DASH key again once. The letter Q is now recorded on

the tape as DASH DOT DASH.

Step 4. Depress the SPACE key once to create a space at the end of the

character.

Step 5. Record the next character in the word by repeating steps 3 and 4.

Step 6. After a complete word has been recorded, insert a word space by

depressing the SPACE key twice.

Step 7. Continue the procedure of steps 3, 4, 5, and 6 until the entire message

has been recorded.

Step 8. After the entire message has been recorded, detach the CA-3B from

the CO-3B by pressing the CARTRIDGE RELEASE BUTTON inward. Lift the

cartridge away from the coder. As soon as the cartridge drive and coder gears

separate, the CA-3B Cartridge begins rewinding the tape. Upon completion of

rewind (about 5 seconds), the message recorded in the CA-3B Cartridge may be

transmitted. Close the CO-3B Coder LID immediately. Replace the CA-3B Cartridge

LID as soon as possible.

2.3 Message Transmission

The following procedure describes the steps necessary to transmit a recorded

message with the KE-8B Keyer.

20

Figure 2-2. Using CO-3B Coder.

Step 1. Remove the KA-3 Keyer Adapter LID as shown in Figure 2-3. Grasp the

trunk latches at opposite corners of the KA-3 and lift them up. (When replacing the

LID, close the trunk latches at opposite corners. This prevents the rubber gasket

front becoming distorted, maintaining the water-tight sea).) Open and remove the

KE8B and CA4B LIDS by

21

Figure 2-3. Removing KA-3 Keyer Adapter cover.

sliding them off their hinge pins. Insert the plug (P2) at the end of the keyer

connector cable on the KA-3 into the CONNECTOR RECEPTACLE on the KE-8B

control panel. Figure 2-4 shows the KE-8B connected to the KA4. Insert the plug

(P1) at the end of the transmitter connector cable into the appropriate receptacle on

the T-784/GRC-109 Transmitter.

22

Figure 2-4. KE-3B Keyer connection to KA-3 Keyer Adapter.

23

Step 2. The KE-4B Keyer drive motor must be fully wound before attaching the

CA-3B Cartridge and Keyer connector cable. With the MOTOR ONOFF switch in

OFF position, fold out the WIND-UP CRANK and wind it clock-wise until the TAPE

DRIVE GEAR begins to rotate. A definite increase in winding resistance occurs

when the motor is fully wound. About 30 turns of the crank will wind a fully run down

motor.

Step 3. Attach the CA-3B Cartridge to the KE-8B by lining up the locking pins

with their respective sockets on the CA-3B so that the CA-8B -and the KE-8B gears

will mesh. Gently snap the two units together. The KE-8B is now ready for

operation. Be sure that the T-784/GRC-109 Transmitter is switched ON and is

properly adjusted.

Step 4. To transmit IDY, press the spring-loaded IDY SWITCH upward and hold

it all the way up for-the required IDY interval. The transmitter output, indicator will be

activated during IDY transmission.

Step 5. To transmit the recorded message, slide the MOTOR ON-OFF switch to

ON position. The output indicator on the transmitter should show that the message

is being transmitted. When message transmission is completed, slide the MOTOR

ON-OFF switch back to OFF and immediately disconnect the keyer connector cable.

When the CA-3B is detached, the tape will rewind automatically. The CA-3B

24

may now be reattached and the message transmitted again, if necessary.

2.4 Message Erasing

The following procedure describes the steps necessary to erase a CA-3B

Cartridge with the KE-8B Keyer.

Step 1. Be certain that the KE-8B Keyer drive motor is fully wound. With the

MOTOR ON-OFF switch in OFF position, fold out the WIND-UP CRANK and wind

it clockwise until the TAPE DRIVE GEAR begins to rotate.

Step 2. Connect the KE-8B Keyer to the KA-3 Keyer Adapter. Connect the KA-3

Keyer Adapter to the T-784/GRC-109 Transmitter and be certain that the transmitter

is in operating condition.

Step 3. Attach the CA-3B to the KE-8B by lining up the locking pins with their

respective sockets on the CA-3B so that the CA-3B and KE-8B gears will mesh.

Gently snap the two units together. The CA-3B is now ready to be erased.

Step 4. Slide the ERASE switch up, in the direction of the arrow, and hold it in

the up-ward position. Then slide the MOTOR ON-OFF to full ON position. This will

lock the ERASE switch in position. Hold the MOTOR ON-OFF switch firmly against

its stop until the tape has run completely through and stops.

25

Step 5. Return the MOTOR ON-OFF switch to OFF position, allowing the

ERASE switch to return automatically to its original position.

Step 6. Disconnect the keyer adapter connector cable and then detach the CA3B Cartridge to allow automatic rewinding. The tape is now ready for another

recording.

2.5 Tape Replacement

When necessary to replace the recording tape in the CA-3B cartridge, refer to

figures 1-5, 2-5, and 3-8 and proceed as follows:

Step 1. Remove the hinge pin and remove the lid of the cartridge.

Step 2. Remove the three spool cover attaching screws and remove the spool

cover.

Step 3. Remove the end of the old tape from, the core of the takeup spool and

allow it to dangle free.

Step 4. Remove (pull) the tape from the storage spool. Apply finger pressure to

the spool to prevent automatic rewind action, then disconnect the end of the tape

from the storage spool. Discard the old tape. Allow the storage spool to rewind

slowly.

Step 5. Inspect the cores of both spools. Remove any residue remaining from

the old tape with the camel's-hair brush provided.

Step 6. Rotate the storage spool clockwise (to increase spring pressure) until it

encounters the takeup auto-stops, and hold it in this position.

26

Step 7. Place the shiny side of the new tape towards the core of the storage

spool. Firmly attach one end of the tape to the backside of the storage spool core

with a small piece of pressure-sensitive adhesive tape.

Step 8. Allow the storage spool to rewind (the tape) slowly. Control the rewind

speed with finger pressure on the storage spool while maintaining sufficient tension

on the tape to prevent it from wrinkling or winding up loosely. There should be about

1 inch of loose tape remaining after a complete rewind.

Step 9. Rotate the takeup spool counterclock-wise until it encounters the rewind

auto-stops.

Step 10. Thread the free end of the tape over the tension idler, and over the tape

guides. Be sure that the dull surface of the tape is on the outside.

Step 11. Pull out enough tape to make a complete extra turn around the core of

the takeup spool (fig. 2-5). Attach the tape to the core with a short length of

pressure-sensitive tape. The purpose of this extra turn is to provide a full turn of

tape completely around the core of the spool when it is at rest. This insures a lasting

attachment and prevents the adhesive tape from contaminating or touching the

overlying layers of recording tape.

Step 12. Check the rewind action by rotating the takeup spool fully clockwise and

then allowing the storage spool to rewind completely.

27

Figure 2-5. CA-3B Cartridge tape replacement.

There should be no slack during or after rewind. Replace the spool cover.

Step 13. Reassemble the cartridge and condition (polarize) the tape before using

it by erasing it on the KE-8B Keyer.

28

3.0 THEORY OF OPERATION

3.1 General Theory

This section is presented to familiarize the operator with the operating principles

of the equipment and as a prerequisite to preventive maintenance and basic

troubleshooting. It consists of a summary of general theory, including Morse code

structure, followed by detailed explanations of the CO/B-8 Coder, CO-3B Coder, KE8B Keyer, CA-3B Cartridge, and the KA-3 Keyer Adapter operating principles.

3.1.1 CO/B-8 Coder. As mentioned, the CO/B-8 Coder enables an operator to

record Morse-encoded messages on a magnetic tape contained in the CA-3B

Cartridge. Actually the message is stored in two tracks on the tape in the form of

precisely spaced, magnetic impulses representing Morse-encoded characters.

Magnetic impulses representing dots are recorded in one track; magnetic impulses

representing dashes are recorded in the other track.

3.1.2 CO-3B Coder. The CO-3B Coder like the CO/B-8 records in two channels

in the form of precisely spaced, magnetic impulses representing Morse-encoded

characters. Magnetic impulses representing dots are recorded in one track;

magnetic impulses representing dashes are recorded in the other track.

29

3.1.3 KE-8B Keyer. The function of the KE-8B is to read the CA-3B Cartridge

magnetic tape and to generate a perfectly spaced Morse code dot whenever a dot

impulse occurs, and a perfectly spaced dash whenever a dash impulse occurs.

The KE-8B Keyer contains a spring motor to drive the CA-3B Cartridge, and

electronic circuitry for converting the tape-recorded impulses into properly spaced

Morse code keying signals. In addition, an IDY function for sending a continuous

train of dots at 300 wpm, and an erasing function for erasing CA-3B Cartridges, are

included. Required input power is 12-volts dc at a maximum current drain of 40

milliamperes. This power is supplied to the Keyer by the KA-3 Keyer Adapter. All

electrical connections to the KE-8B Keyer are made through the 7-pin Amphenol

connector receptacle located on the control panel.

3.1.4 CA-3B Cartridge. The sole function of the CA-3B Cartridge is to carry and

store the magnetic tape used for recording Morse-encoded messages. The CA-3B

Cartridge has a capacity of 12 1/2 feet of Minnesota Mining & Manufacturing Co.,

Type 428 Instrument Grade magnetic recording tape, including the "lead" portion (at

the beginning) and the "residual" portion (at the end).

3.1.5 KA-3 Keyer Adapter. Essentially, the KA-3 Keyer Adapter connects the KE8B Keyer output to the input of a T-784/GRC-109 Transmitter. In this capacity, the

KA-3 converts the

30

KE-8B output keying impulses into transmitter modulation signals. Also, the KA-3

supplies 12 vdc at 50 ma to the KE-8B Keyer.

3.2 Morse Code Structure

The basic unit of measure in Morse code structure is the dot. By definition the

dot is one baud long; the dash is defined as three bauds long. Spaces within

characters are one baud, spaces between characters are three bauds, and spaces

between words are seven bauds.

Figure 3-1 shows the relationship between impulse spacing on the tape and the

corresponding Morse code message. Notice that the impulses in the dot and dash

tracks are identical in width-only the amount of tape advance after each impulse

differs. The code pattern for each character on CO/B-8 Coder character dial no. 1 is

shown in Figure 3-2A. Figure 3-2B shows codes for character dial no. 2. These

codes are shown as they appear on the magnetic tape when the tape is "developed"

in Magna-See. The Magna-See "developing" procedure is described in Figure 4-12.

In a 300 word-per-minute system, such as the AN/GRA-71, the time duration of a

dot is 3.3 milliseconds, and that of a dash is 10 milliseconds. Accordingly, the

distance between impulses and the speed of the tape are directly related to the

signaling rate. From the speed of the tape during transmission (4.5 inches per

seconds) it may be

31

Figure 3-1. Magnified example of recorded tape.

32

Figure 3-2A. Code chart for CO/B-8 Coder character dial No. 1.

33

Figure 3-2B. Code chart for CO/B-8 Coder character dial No. 2.

34

Figure 3-3. CO/B-8 Coder functional block diagram.

35

Figure 3-4. CO/B-8 Coder internal mechanism.

36

Figure 3-5. CO-3B Coder functional block diagram.

37

Figure 3-6. CO-3B Coder internal mechanism.

calculated that the baud length on the tape is 0.015 inches.

When a dot is to be recorded, the CO/B-8 or CO-3B Coder must place an impulse in

the dot track and then advance the tape 0.030 inches or 2 baud lengths: one baud

for the dot itself and one baud for the space that always follows a dot. When a dash

is to be recorded, the CO/B-8 or CO-3B must place an impulse in the dash track

and then advance the tape 0.060 inches or four baud lengths: three bauds for the

dash itself and

38

Figure 3-7. KE-8B Keyer electronics section functional block diagram.

39

Figure 3-8. CA-3B Cartridge internal mechanism.

40

Figure 3-9. KA-3 Keyer Adapter functional block diagram

41

one baud for the space that always follows a dash.

At the end of each character the CO/B-8 or CO-3B Coder must insert an

additional two bauds, which when added to the single baud following the last dot or

dash in the character, equals the three-baud character space. Between words,

depressing the CO/B8 Coder WORD-S PACE BUTTON once advances the tape

an additional four bauds for a total of seven bauds between words. The CO3B

Coder SPACE KEY must be depressed twice for the additional four-baud advance.

42

4.0 MAINTENANCE

4.1 Introduction

The AN/GRA-71 components are precision assemblies, carefully assembled

and adjusted to very close tolerances at the factory. The complexities of these

assemblies preclude extensive repairs in the field; accordingly no service or repairs

should be attempted beyond the preventive and corrective maintenance outlined in

this manual. When any procedures described in this manual fail to correct a

malfunction condition, the faulty component should be returned to the factory for

repairs.

4.2 Operator's Maintenance

4.2.1 Scope of Operator's Maintenance. The maintenance duties

assigned to the operator of the AN/GRA-71 are listed below together with a

reference to the paragraphs covering the specific maintenance functions. No tools

or test equipment are required for performing operator's maintenance.

a. Daily preventive maintenance checks and services (para. 4.2.4).

b. Weekly preventive maintenance checks and services (para. 4.2.5).

c. Cleaning (para. 4.2.6).

4.2.2 Preventive Maintenance. Preventive maintenance is the systematic

care, servicing, and inspection of equipment to prevent the occurrence

43

of trouble, to reduce downtime, and to assure that the equipment is serviceable.

4.2.6 cover routine systematic care and cleaning essential to proper upkeep and