Military surplus Use_and_care_of_hand_tools_and_measuring_tools_TM9-243_2022.pdf Use_and_care_of_hand_tools_and_measuring_tools_TM9-243_2022.pdf

AIR FORCE AIR FORCE TO 32-1-101

BASIC AND ALL UPDATES HAVE BEEN MERGED TO MAKE THIS A COMPLETE PUBLICATION.

ARMY ARMY TM 9-243

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

MARINE CORPS MARINE CORP TM

10209-10/1

TECHNICAL MANUAL

USE AND CARE OF HAND TOOLS AND MEASURING

TOOLS

DISTRIBUTION STATEMENT A - Approved for public release; distribution is unlimited. PA Case Number 05-07153. Other requests for this

document shall be referred to 406 SCMS/GUEE, Robins AFB, GA 31098. Questions concerning technical content shall be referred to

AFLCMC/EZPT.

Published UnderAuthority of the Secretary of the Air Force

19 AUGUST 2020 CHANGE 2 - 8 APRIL 2022

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

LIST OF EFFECTIVE PAGES

Dates of issue for original and changed pages are:

NOTE

Original........0.....19August 2020

Change ........1.....5October 2020

TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 518, CONSISTING OF THE FOLLOWING:

Page *Change

No. No.

Page *Change

No. No.

INSERT LATEST CHANGED PAGES. DESTROY SUPERSEDED PAGES.

The portion of the text affected by the changes is indicated by a vertical line in the outer margins of

the page. Changes to illustrations are indicated by shaded or screened areas, or by miniature

pointing hands.

Change ........2.......8April 2022

Page *Change

No. No.

Title......................2

A........................2

i - xvii....................0

xviii Blank..................0

xix-xx...................0

xxi.......................2

xxii - xxiii .................0

xxiv Blank..................0

1-1.......................0

1-2 Blank ..................0

2-1.......................0

2-2.......................1

2-3.......................0

2-4.......................2

2-5-2-6...................0

3-1-3-3...................0

3-4 Blank ..................0

4-1-4-2...................0

5-1-5-3...................0

5-4 Blank ..................0

6-1-6-8...................0

7-1-7-7...................0

7-8 Blank ..................0

8-1-8-5...................0

8-6 Blank ..................0

9-1-9-4...................0

10-1 - 10-4.................0

11-1-11-9.................0

11-10 Blank.................0

12-1 - 12-4.................0

13-1 - 13-13 ................0

13-14 Blank.................0

14-1 - 14-5.................0

14-6 Blank..................0

15-1 - 15-15 ................0

15-16 Blank.................0

16-1 - 16-13 ................0

16-14 Blank.................0

17-1 ......................2

17-2 - 17-3.................0

17-4 - 17-5.................1

17-6 - 17-10 ................0

18-1 - 18-7.................0

18-8 ......................2

19-1 - 19-5.................0

19-6 Blank..................0

20-1 - 20-9.................0

20-10 Blank.................0

21-1 - 21-26 ................0

22-1 - 22-12 ................0

23-1 - 23-7.................0

23-8 Blank..................0

24-1 - 24-3.................0

24-4 ......................1

24-5 Added .................1

24-6 Blank..................1

25-1 - 25-12 ................0

25-13 .....................1

25-14 - 25-27 ...............0

25-28 Blank.................0

26-1 - 26-9.................0

26-10 Blank.................0

27-1 - 27-11................0

27-12 Blank.................0

28-1 - 28-9.................0

28-10 Blank.................0

29-1 - 29-11................0

29-12 Blank

.................0

30-1 - 30-4.................0

31-1 - 31-3.................0

31-4 Blank..................0

32-1 - 32-6.................0

33-1 - 33-6.................0

34-1 - 34-6.................0

35-1 - 35-13 ................0

35-14 Blank.................0

36-1 - 36-6.................0

37-1 - 37-6.................0

38-1 - 38-12 ................0

39-1 - 39-6.................0

40-1 - 40-6.................0

41-1 - 41-8.................0

42-1 - 42-4.................0

43-1 - 43-3.................0

43-4 Blank..................0

44-1 - 44-4.................0

45-1 - 45-10 ................0

46-1 - 46-11................0

46-12 Blank.................0

47-1 - 47-4.................0

* Zero in this column indicates an original page.

48-1 - 48-3.................0

48-4 Blank..................0

49-1 - 49-8.................0

50-1 - 50-5.................0

50-6 Blank..................0

51-1 - 51-7.................0

51-8 Blank..................0

52-1 - 52-28 ................0

53-1 - 53-6.................0

54-1 - 54-2.................0

55-1 - 55-21 ................0

55-22 Blank.................0

56-1 - 56-2.................0

Index 1 - Index 14............0

A Change 2 USAF

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

TABLE OF CONTENTS

Chapter Page

LIST OF ILLUSTRATIONS ..................................................... xvii

LIST OF TABLES ............................................................ xvii

INTRODUCTION ............................................................ xix

SAFETY SUMMARY ......................................................... xxiii

1 INTRODUCTION ........................................................... 1-1

1.1 HOW TO USE THIS MANUAL .......................................... 1-1

2 SAFETY.................................................................. 2-1

SECTION I ................................................................ 2-1

2.1 GENERAL SAFETY RULES ............................................ 2-1

2.2 TOOL HABITS ...................................................... 2-2

2.2.1 Keep Each Tool in its Proper Storage Place ................................... 2-2

2.2.2 Keep Your Tools in Good Condition ........................................ 2-3

2.2.3 Keep Your Tool Set Complete ............................................ 2-3

2.2.4 Use Each Tool Only on the Job for Which it was Designed ........................ 2-3

2.2.5 Keep Your Tools Within Easy Reach and Where They Cannot Fall on the Floor or on

Machinery........................................................ 2-3

2.2.6 Never Use Damaged Tools .............................................. 2-4

SECTION II ............................................................... 2-4

2.3 POWER TOOL SAFETY ............................................... 2-4

SECTION III ............................................................... 2-5

2.4 PERSONAL PROTECTIVE EQUIPMENT (PPE) ............................... 2-5

2.4.1 SAFETY SHOES ..................................................... 2-5

2.4.2 EYE PROTECTION................................................... 2-5

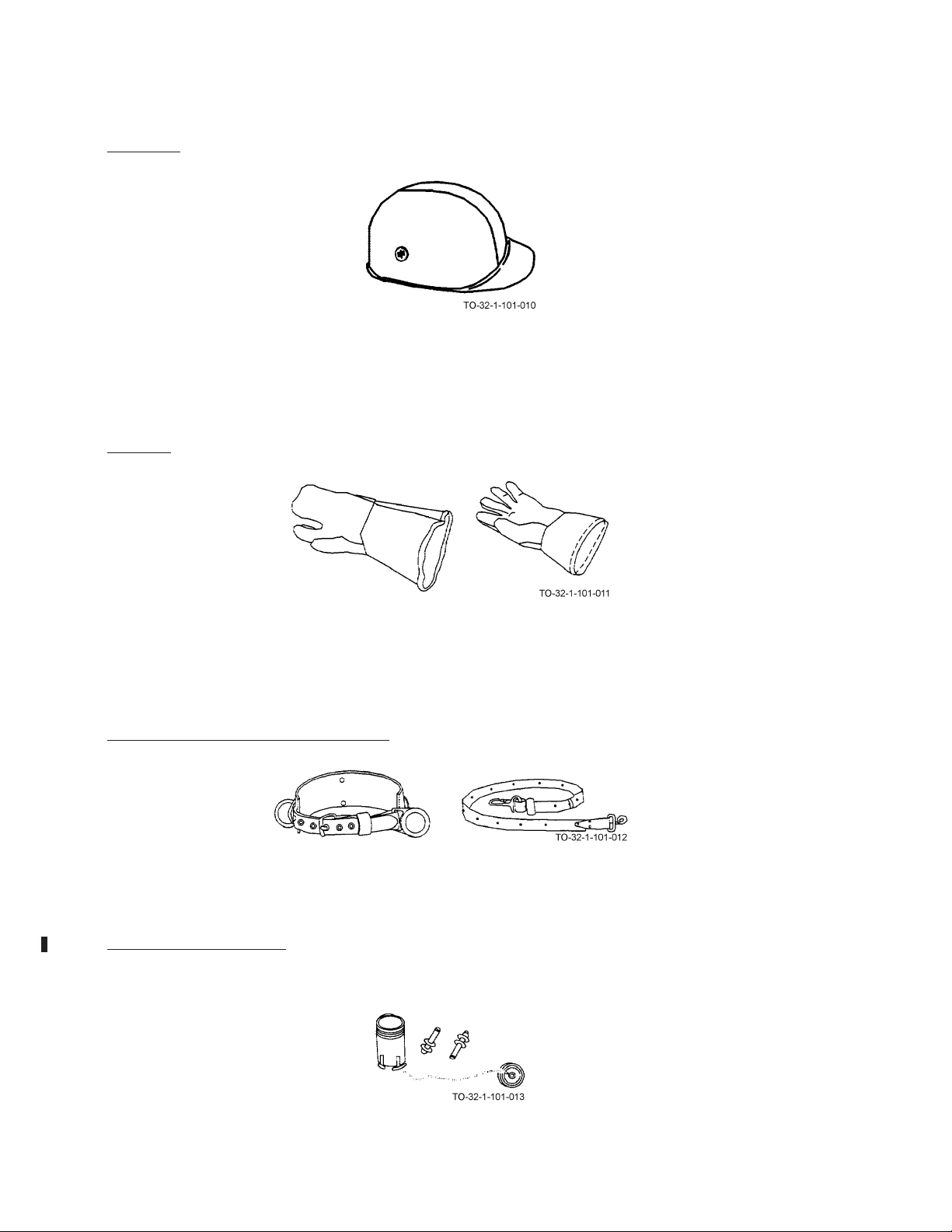

2.4.3 HELMETS ......................................................... 2-6

2.4.4 GLOVES .......................................................... 2-6

2.4.5 SAFETY BELTS AND SAFETY STRAPS.................................... 2-6

2.4.6 HEARING PROTECTION .............................................. 2-6

3 READING MEASURING SCALES ............................................... 3-1

3.1 READING MEASURING SCALES INTRODUCTION ........................... 3-1

3.2 READING THE SCALE OF A RULE OR TAPE ............................... 3-1

3.3 READING A METRIC RULE ............................................ 3-3

4 TOOL BOXES.............................................................. 4-1

4.1 HOW TO CHOOSE AND USE TOOL BOXES ................................ 4-1

4.2 TOOL BOXES TYPES AND USES ........................................ 4-1

i

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

TABLE OF CONTENTS - CONTINUED

Chapter Page

5 DIVIDERS ................................................................ 5-1

5.1 HOW TO CHOOSE AND USE DIVIDERS ................................... 5-1

5.2 DIVIDERS TYPES AND USES ........................................... 5-1

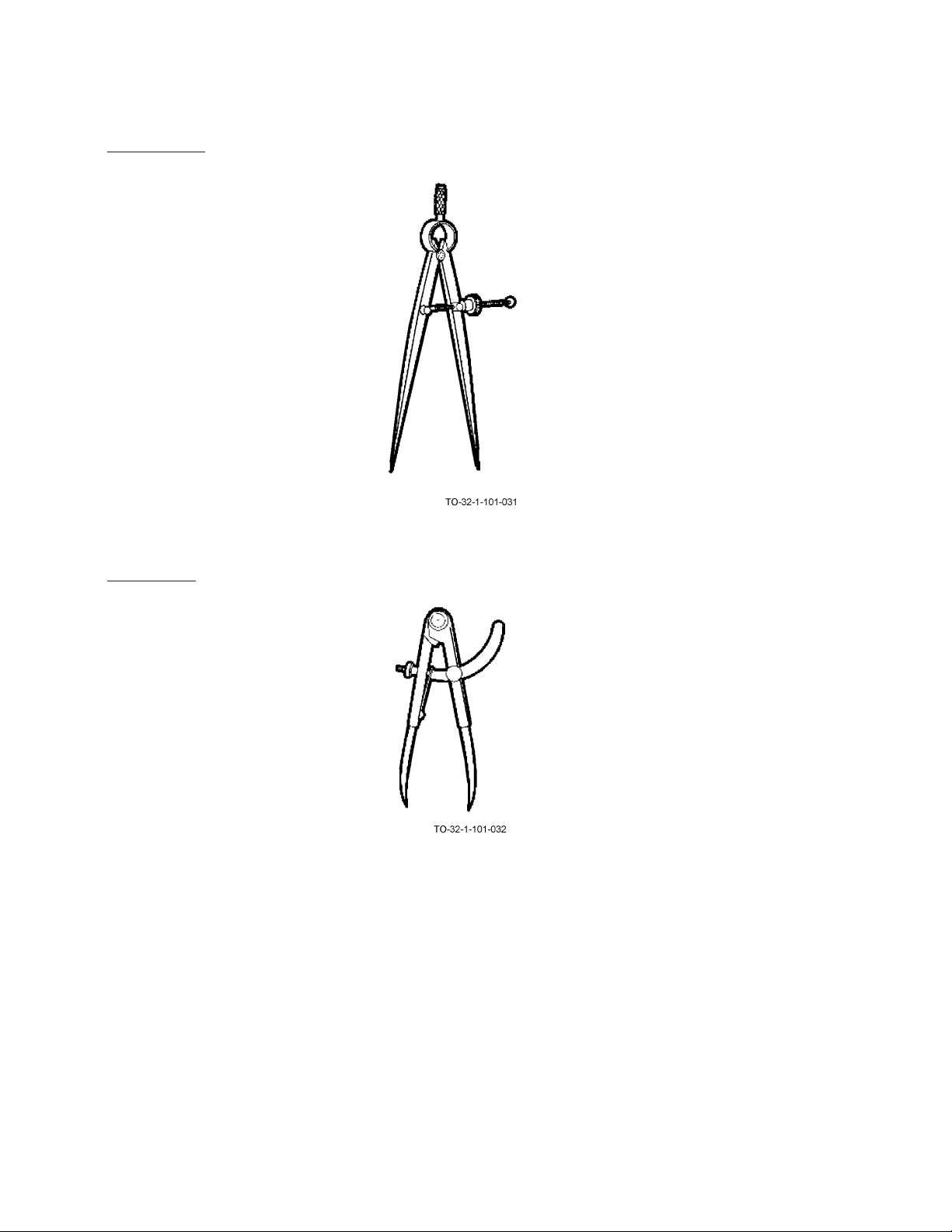

5.2.1 Spring Divider....................................................... 5-2

5.2.2 Wing Divider........................................................ 5-2

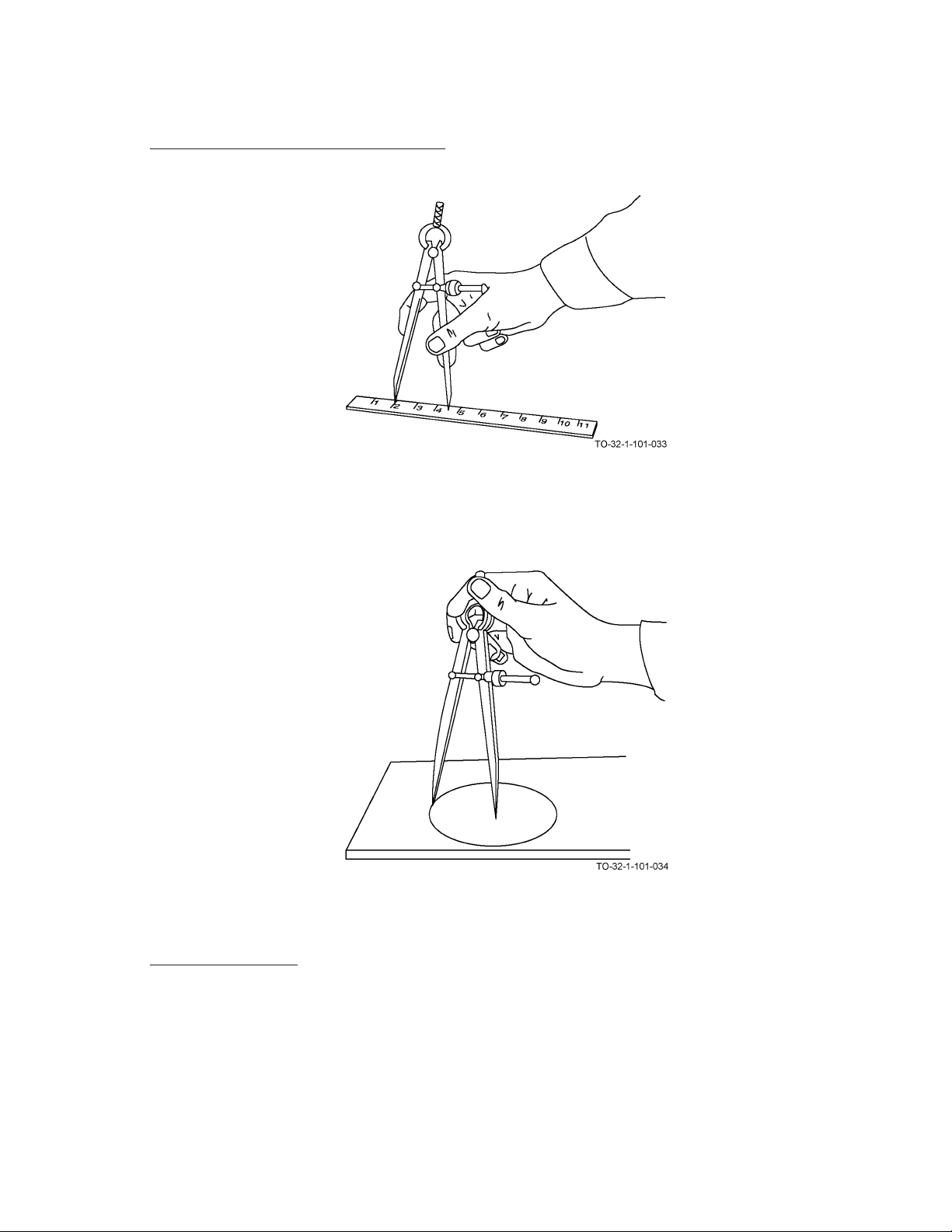

5.3 USING A DIVIDER TO SCRIBE A CIRCLE.................................. 5-3

5.4 CARE OF DIVIDERS ................................................. 5-3

6 CALIPERS ................................................................ 6-1

6.1 HOW TO CHOOSE AND USE CALIPERS ................................... 6-1

6.2 CALIPERS TYPES AND USES........................................... 6-1

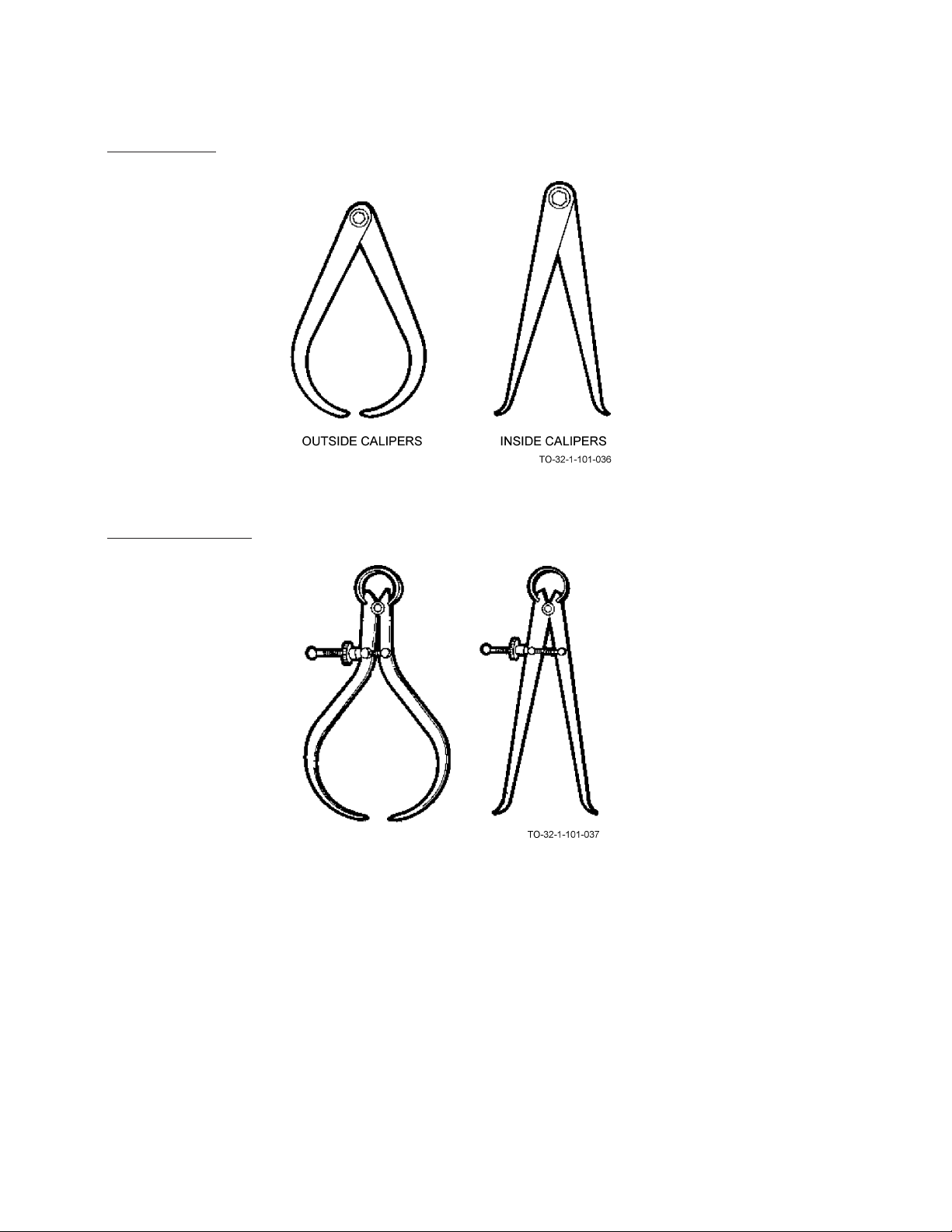

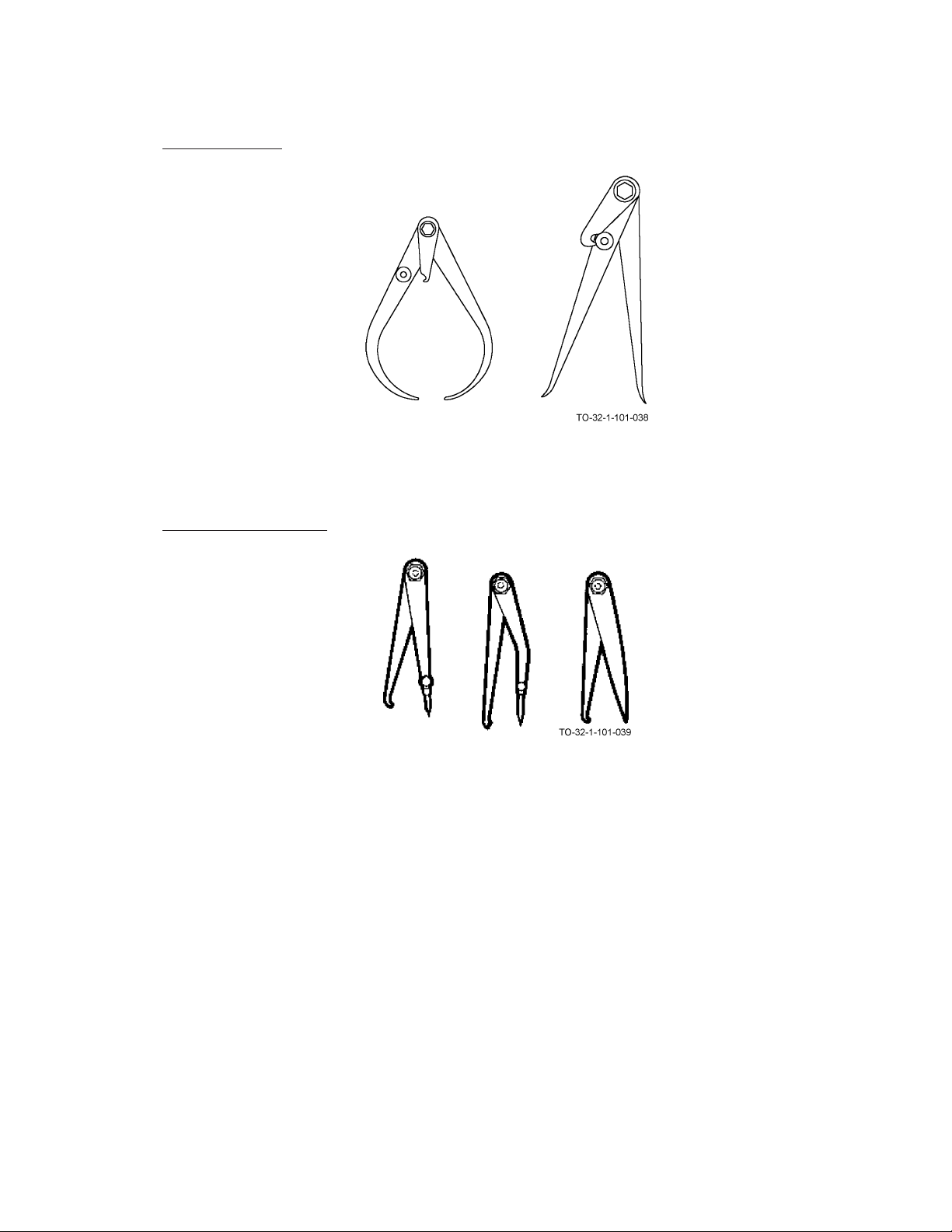

6.2.1 Simple Calipers ...................................................... 6-2

6.2.2 Spring-Joint Calipers .................................................. 6-2

6.2.3 Transfer Calipers ..................................................... 6-3

6.2.4 Hermaphrodite Calipers................................................. 6-3

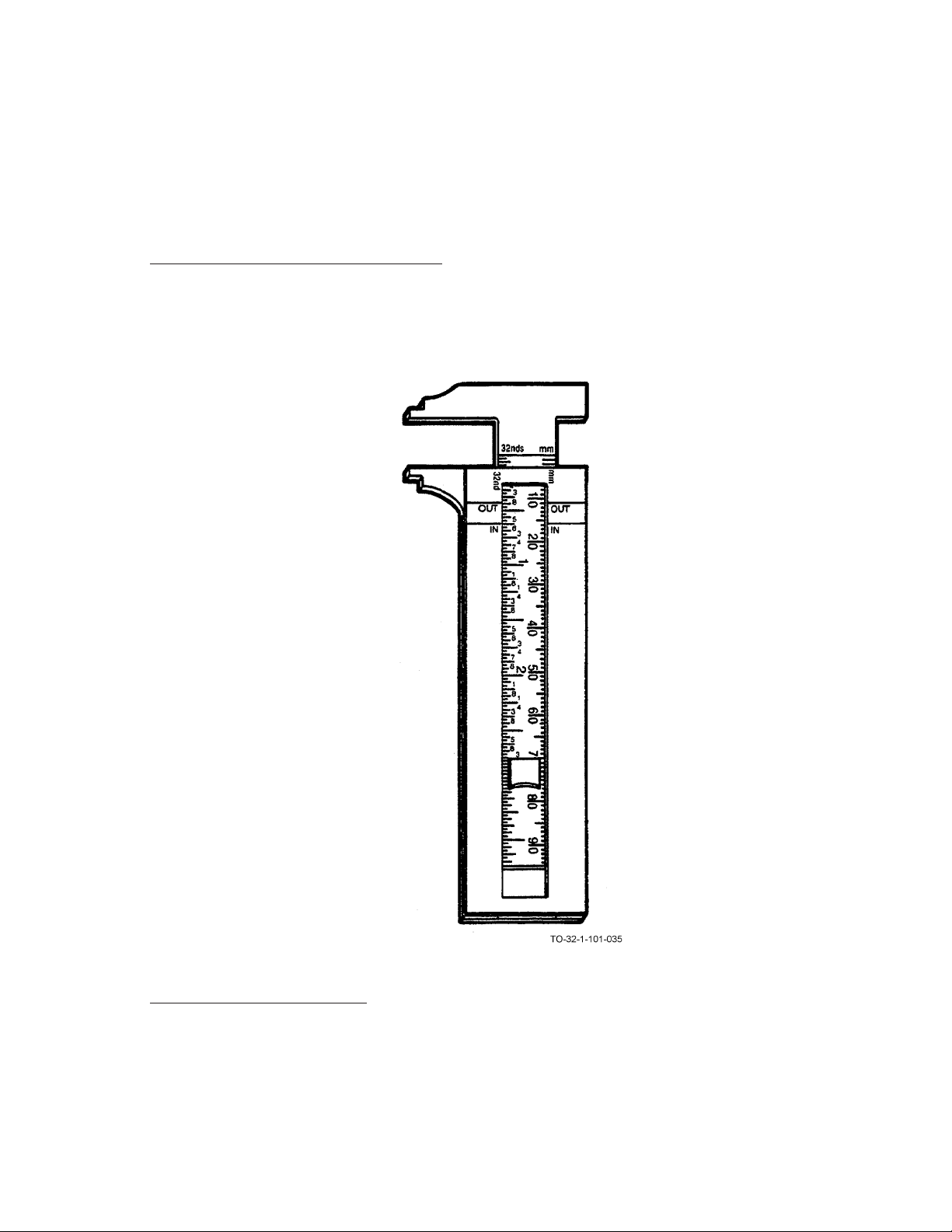

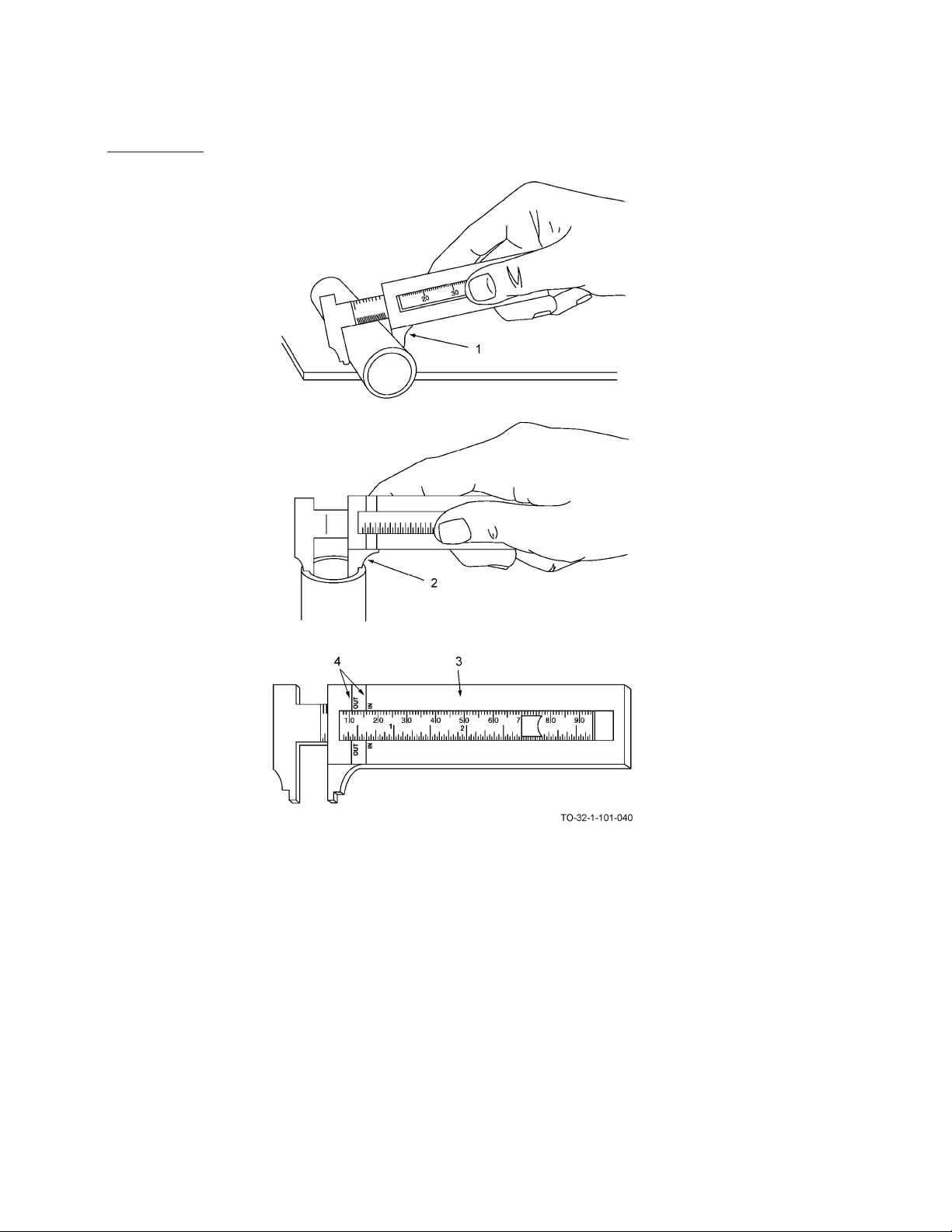

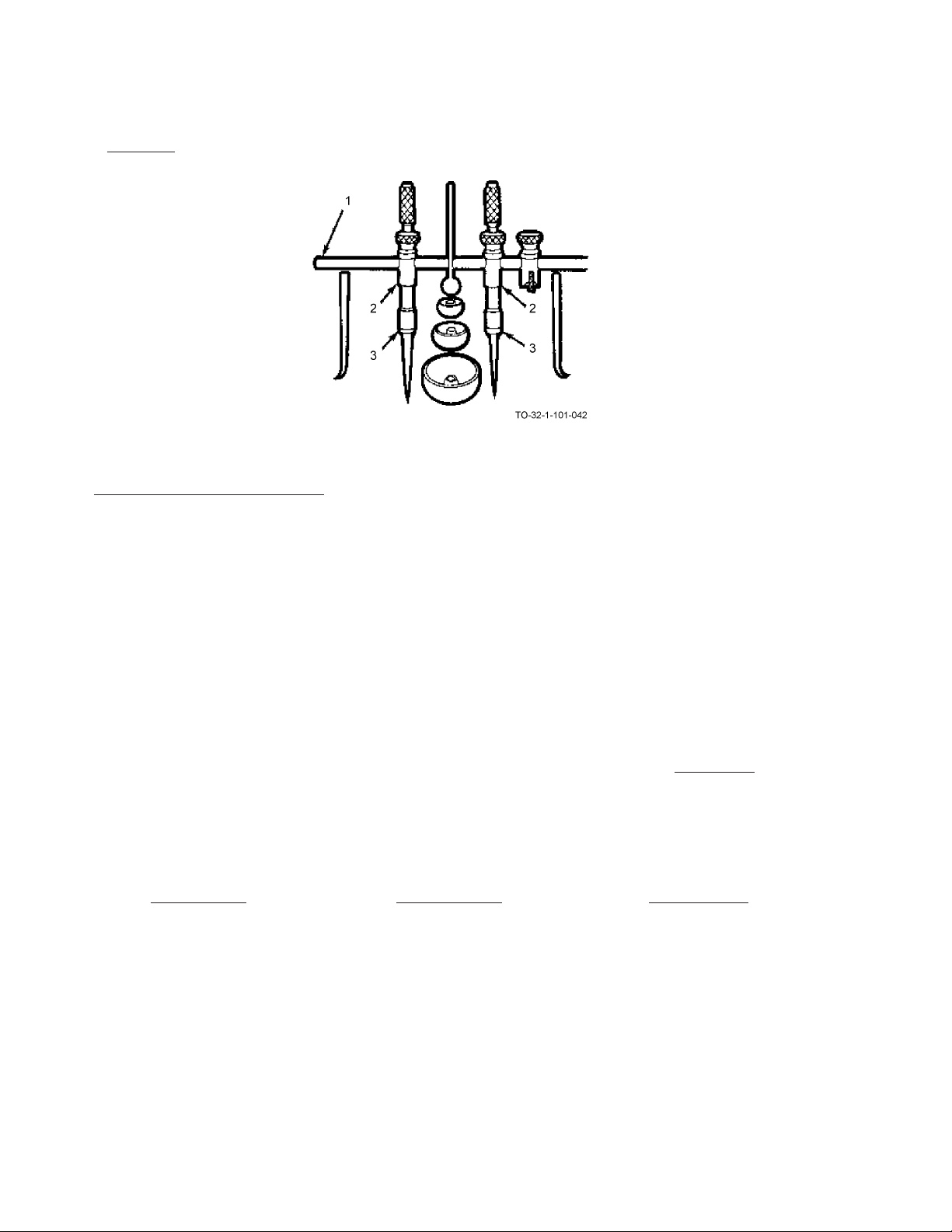

6.2.5 Slide Calipers ....................................................... 6-4

6.2.6 Vernier Calipers ...................................................... 6-5

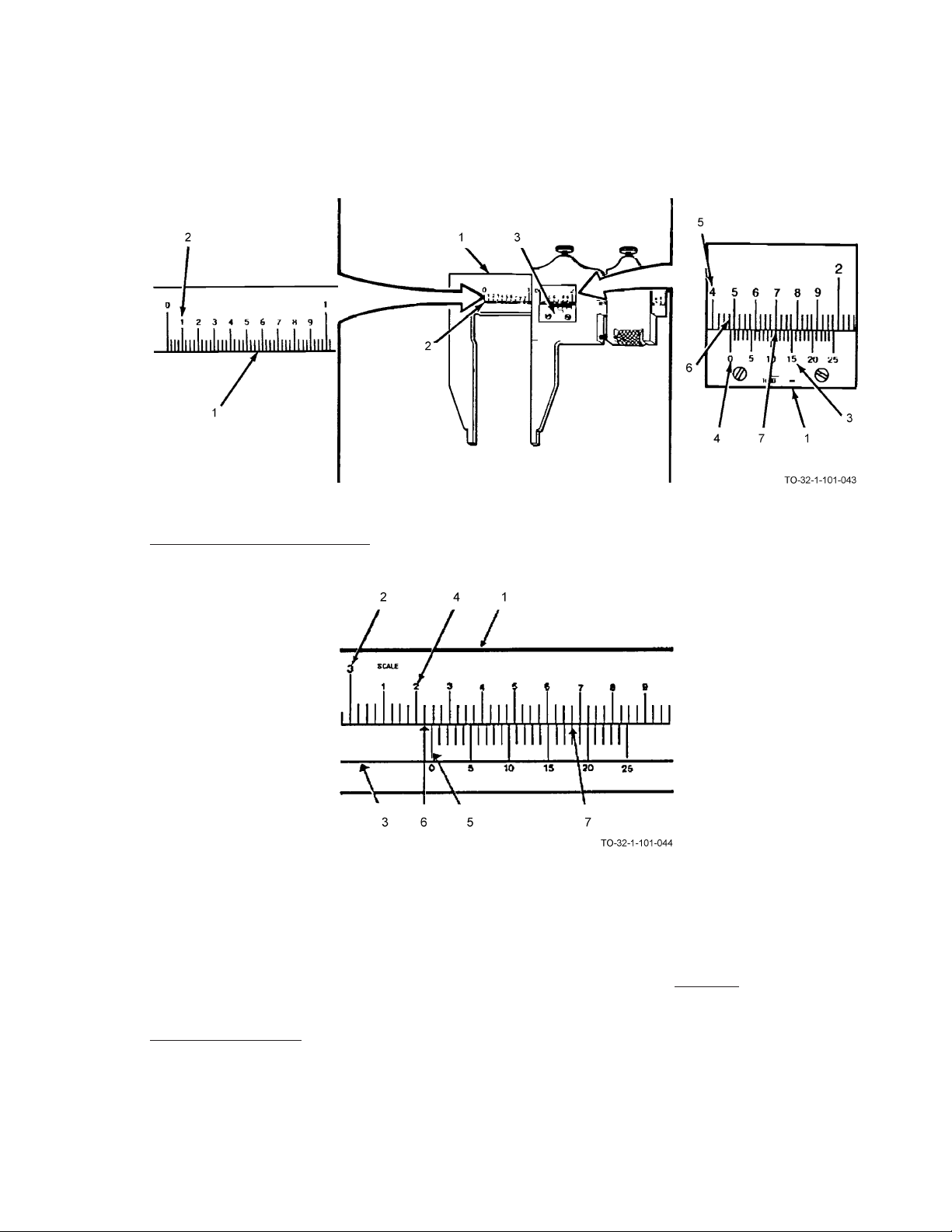

6.2.7 Trammels .......................................................... 6-6

6.3 READING A VERNIER CALIPER......................................... 6-6

6.4 READING A METRIC CALIPER ......................................... 6-7

6.5 CARE OF CALIPERS ................................................. 6-7

7 MICROMETERS ............................................................ 7-1

7.1 HOW TO CHOOSE AND USE MICROMETERS............................... 7-1

7.2 MICROMETERS TYPES AND USES ...................................... 7-1

7.2.1 Outside Micrometers................................................... 7-1

7.2.2 Inside Micrometers.................................................... 7-2

7.2.3 Depth Micrometers.................................................... 7-2

7.3 SELECTING THE PROPER MICROMETER ................................. 7-3

7.4 READING A STANDARD MICROMETER................................... 7-5

7.4.1 To Read a Measurement as Shown in the Paragraph Above: ........................ 7-5

7.5 READING A VERNIER MICROMETER .................................... 7-6

7.5.1 To Read a Measurement as Shown Above:.................................... 7-6

7.6 READING A METRIC MICROMETER ..................................... 7-7

7.6.1 To Read a Measurement as Shown Above .................................... 7-7

7.7 CARE OF MICROMETERS ............................................. 7-7

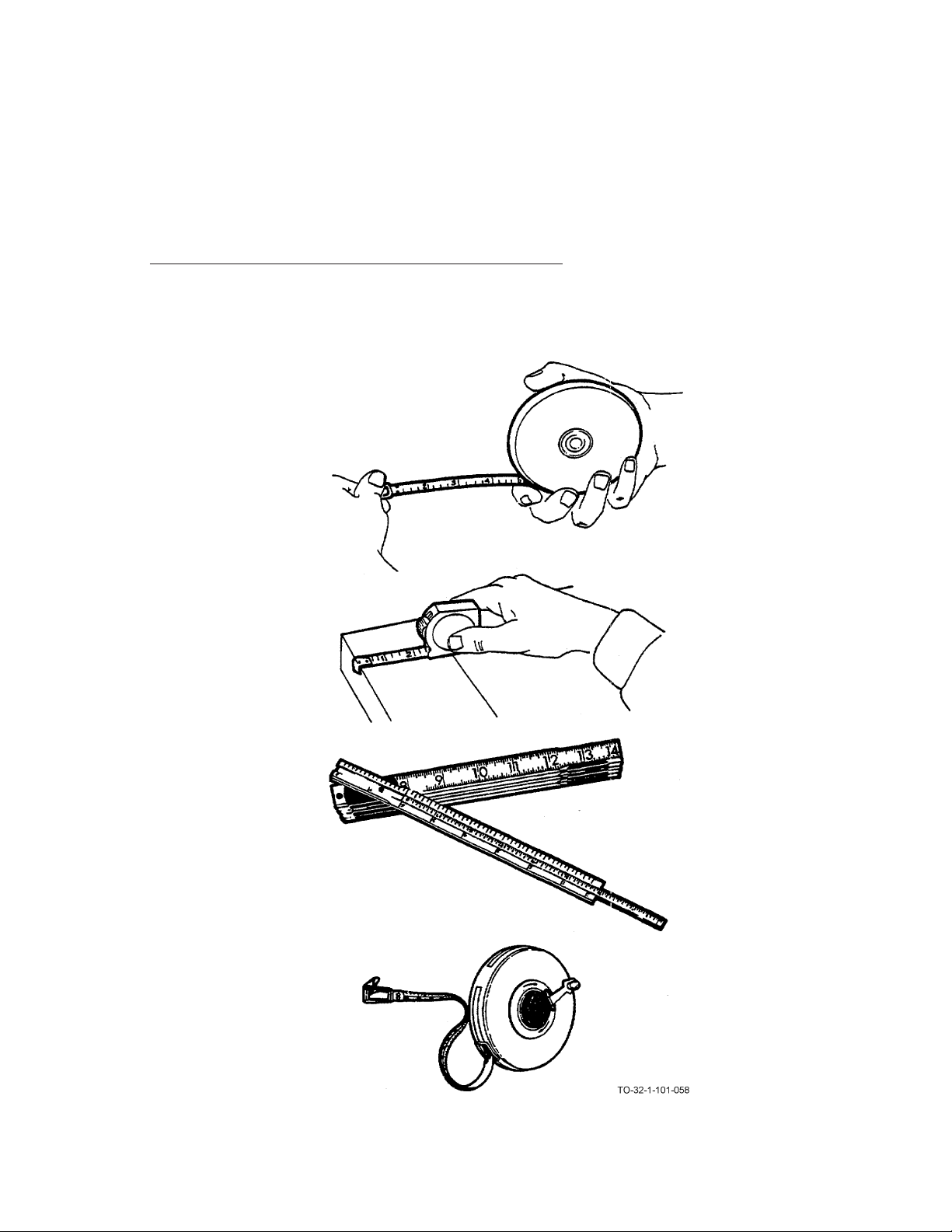

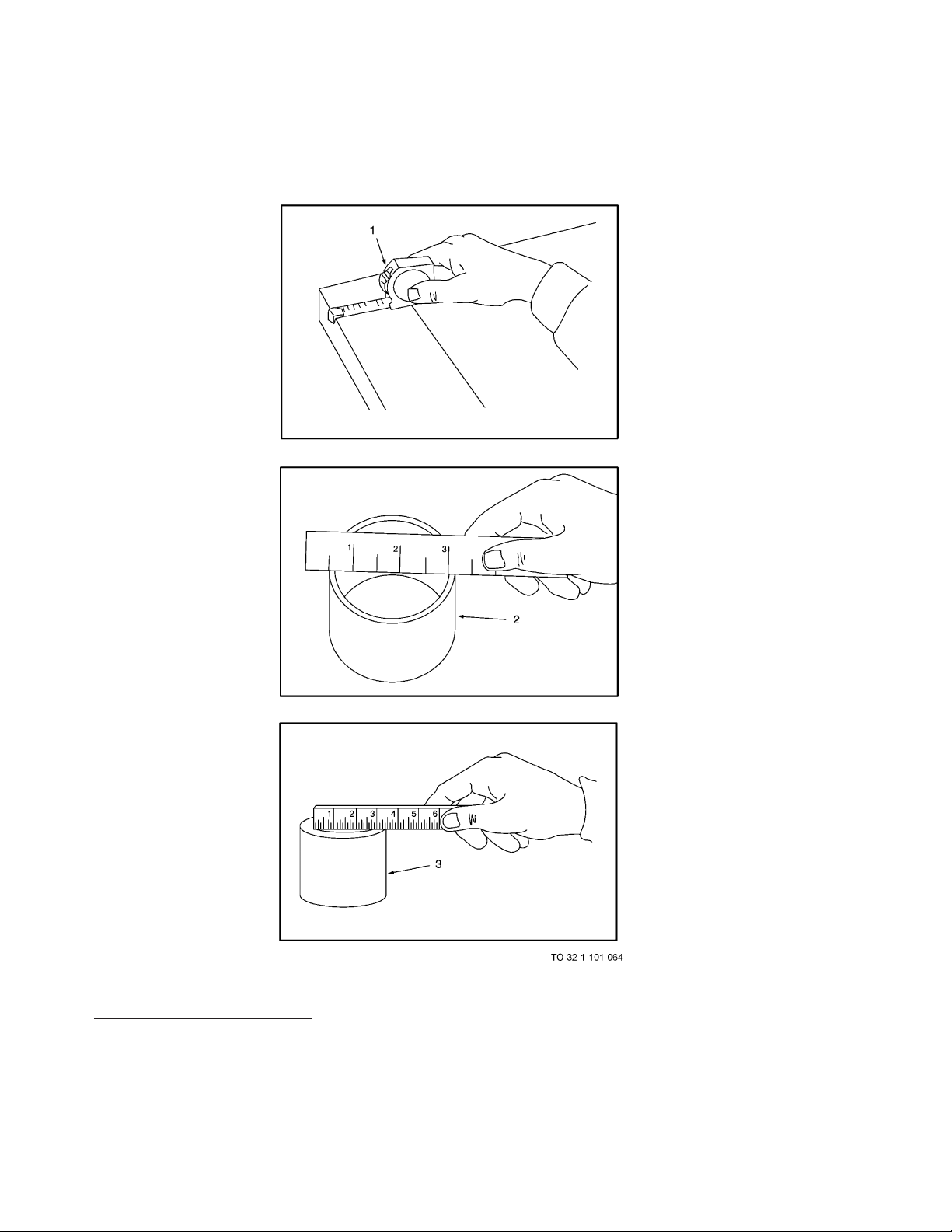

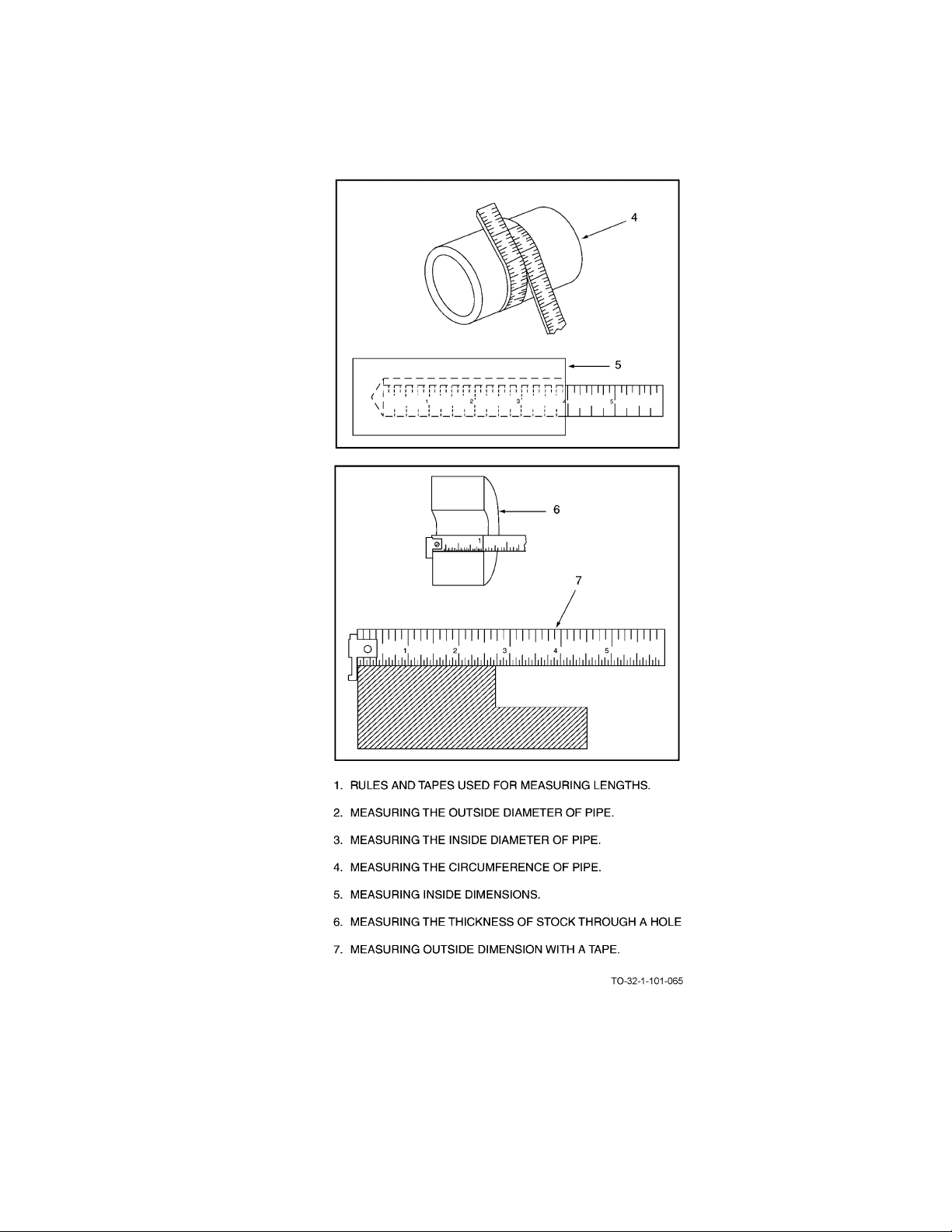

8 RULES AND STEEL TAPES.................................................... 8-1

8.1 HOW TO CHOOSE AND USE RULES AND STEEL TAPES ...................... 8-1

8.2 RULES AND STEEL TAPES TYPES AND USES .............................. 8-2

8.2.1 Rules ............................................................. 8-2

8.2.2 Folding Rules ....................................................... 8-3

8.2.3 Steel Tapes ......................................................... 8-3

8.3 USING RULERS AND TAPES EXAMPLES .................................. 8-4

8.4 CARE OF RULES AND TAPES .......................................... 8-4

9 MISCELLANEOUS MEASURING TOOLS.......................................... 9-1

ii

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

TABLE OF CONTENTS - CONTINUED

Chapter Page

9.1 HOW TO CHOOSE AND USE MISCELLANEOUS MEASURING TOOLS ............ 9-1

9.2 MISCELLANEOUS MEASURING TOOLS TYPES AND USES .................... 9-1

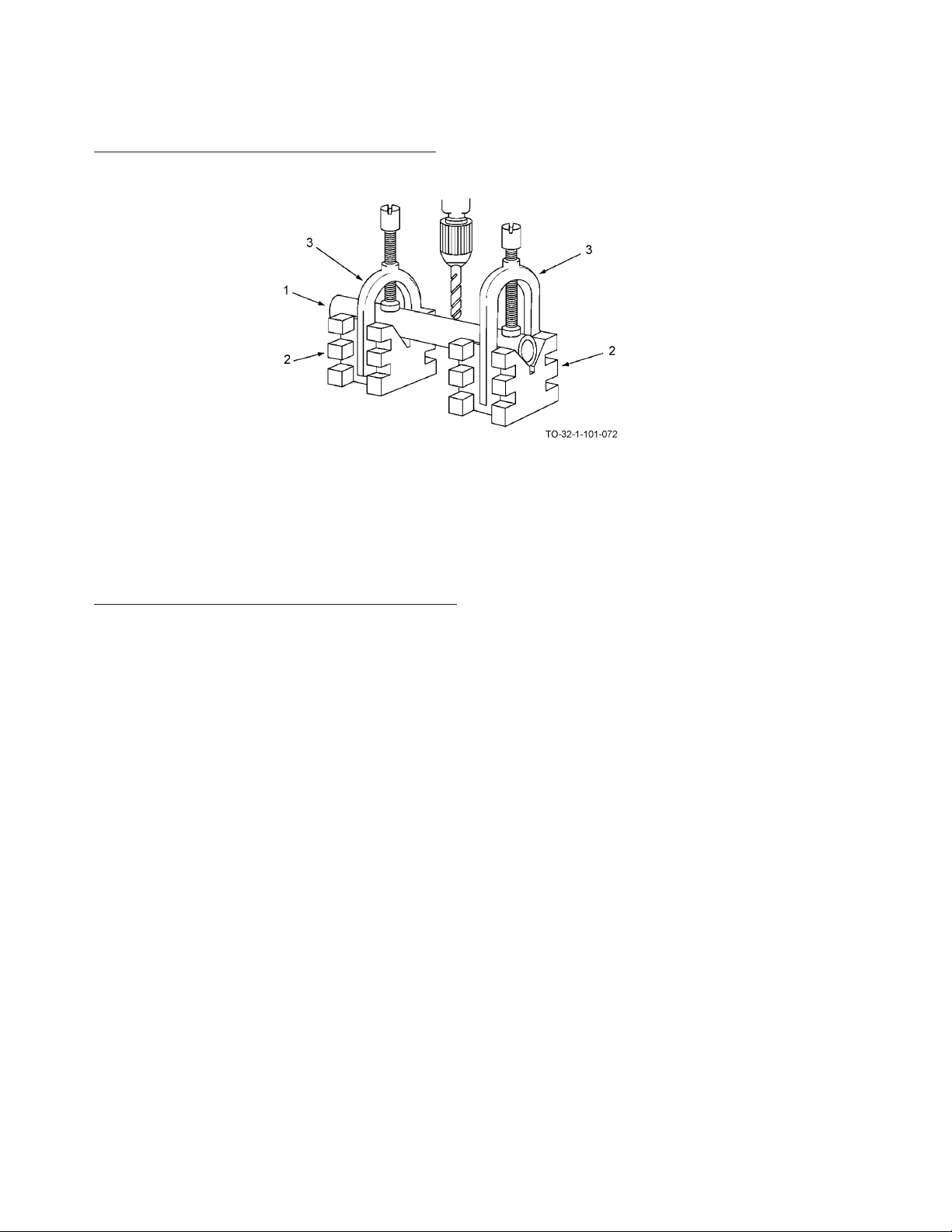

9.2.1 Adjustable Parallel .................................................... 9-1

9.2.2 V-Block and Clamp ................................................... 9-2

9.2.3 Angle Plates ........................................................ 9-2

9.2.4 Magnetic Base Indicator Holder ........................................... 9-3

9.2.5 Registering Speed Indicators ............................................. 9-3

9.3 USING MISCELLANEOUS MEASURING TOOLS ............................. 9-4

9.4 CARE OF MISCELLANEOUS MEASURING TOOLS ........................... 9-4

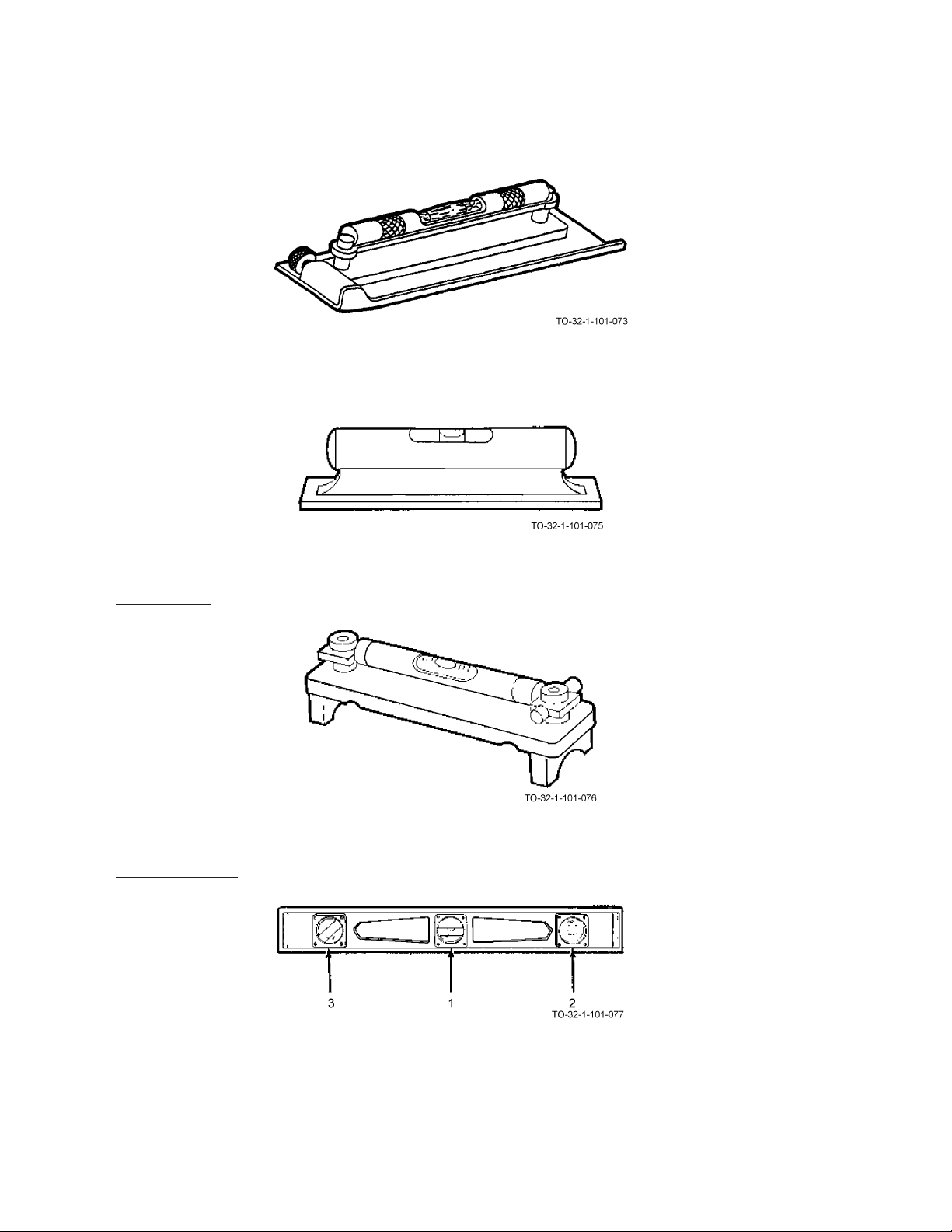

10 LEVELS .................................................................. 10-1

10.1 HOW TO CHOOSE AND USE LEVELS .................................... 10-1

10.2 LEVELS TYPES AND USES ............................................ 10-1

10.2.1 Master Precision Level ................................................. 10-1

10.2.2 Machinist’s Level..................................................... 10-2

10.2.3 Iron Bench Level ..................................................... 10-2

10.2.4 Striding Level ....................................................... 10-2

10.2.5 Carpenter’s Level ..................................................... 10-2

10.2.6 Line Level ......................................................... 10-3

10.3 USING A LEVEL .................................................... 10-3

10.3.1 Horizontal Surface .................................................... 10-3

10.3.2 Angled Surface ...................................................... 10-4

10.3.3 Vertical Surface ...................................................... 10-4

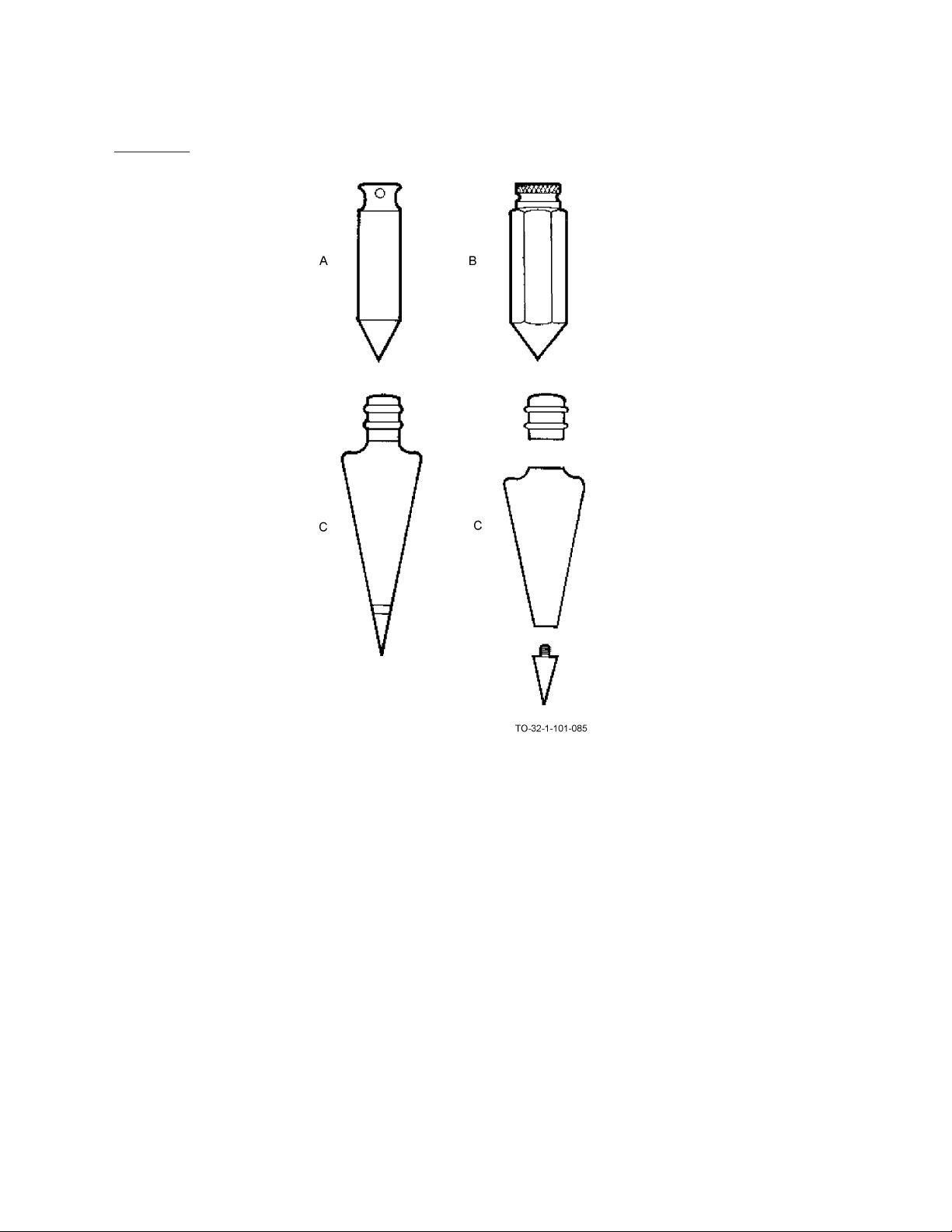

11 PLUMB BOBS ............................................................. 11-1

11.1 HOW TO CHOOSE AND USE PLUMB BOBS ................................ 11-1

11.2 PLUMB BOBS TYPES AND USES ........................................ 11-1

11.2.1 Plumb Bobs......................................................... 11-1

11.2.2 Surveyor’s Polished Brass ............................................... 11-1

11.2.3 Solid Steel ......................................................... 11-2

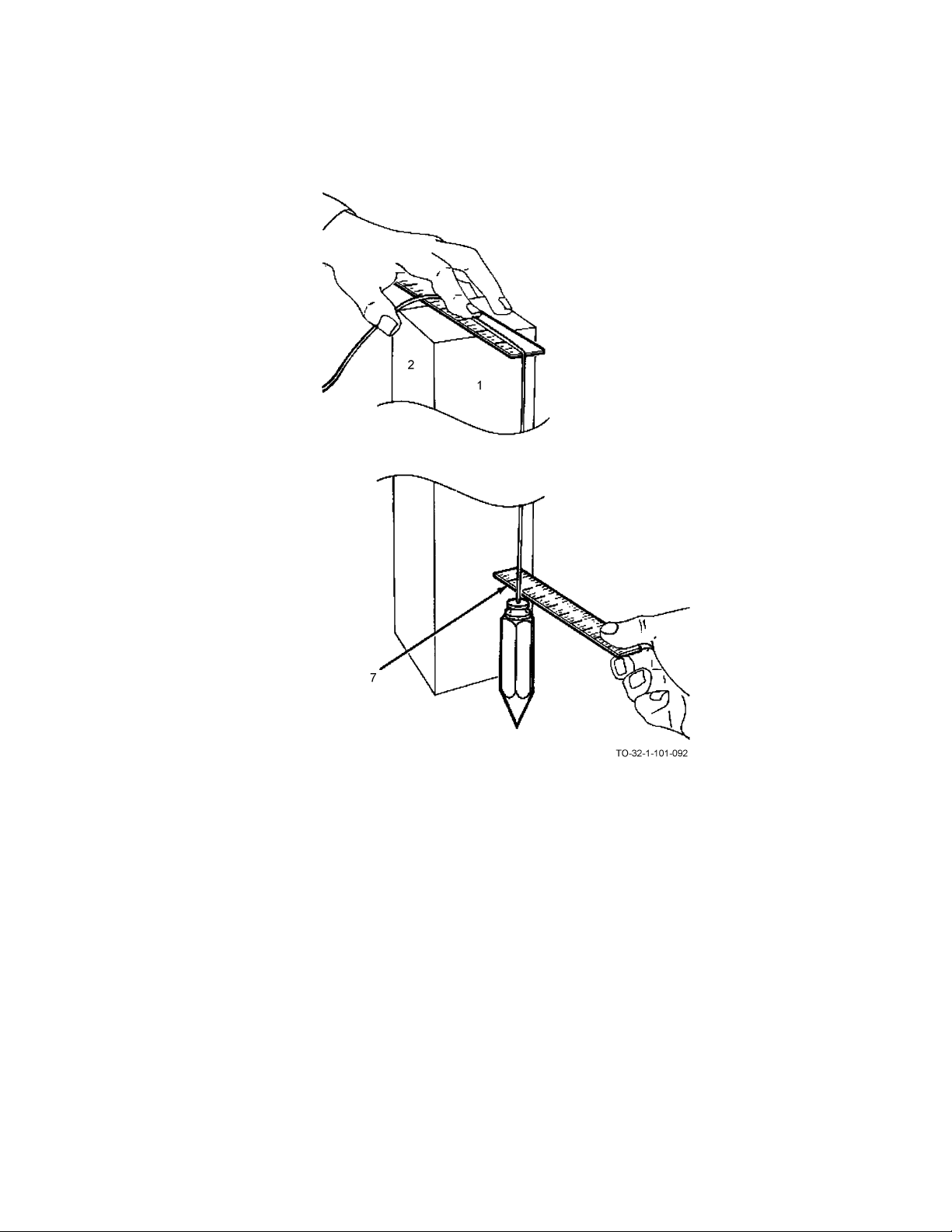

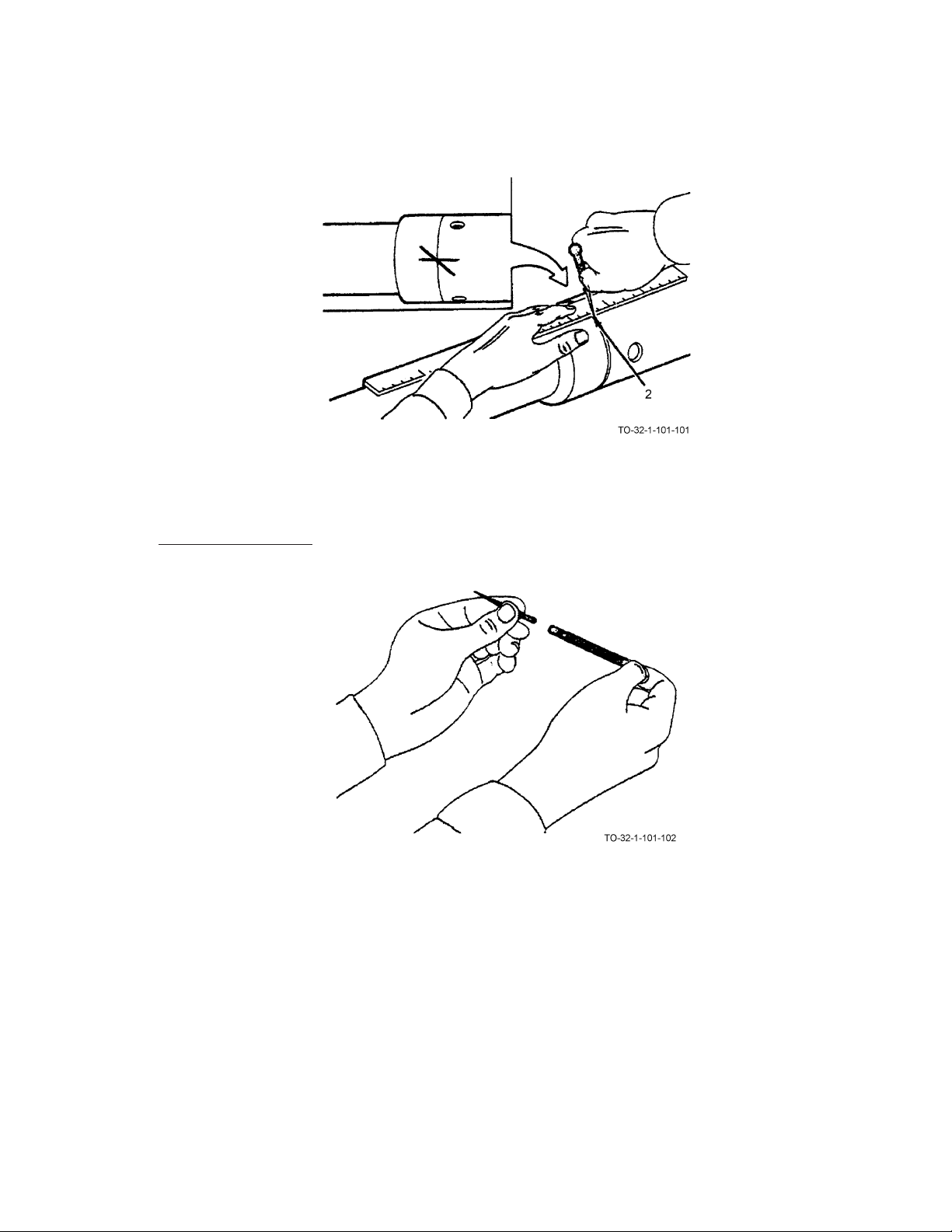

11.3 USING A PLUMB BOB ................................................ 11-3

11.4 CARE OF PLUMB BOBS............................................... 11-9

12 SCRIBERS ................................................................ 12-1

12.1 HOW TO CHOOSE AND USE SCRIBERS ................................... 12-1

12.2 SCRIBERS TYPES AND USES........................................... 12-1

12.2.1 Machinist’s Scribers ................................................... 12-1

12.3 USING A MACHINIST’S SCRIBER ....................................... 12-2

12.4 CARE OF SCRIBERS ................................................. 12-3

13 SQUARES ................................................................ 13-1

13.1 HOW TO CHOOSE AND USE SQUARES ................................... 13-1

13.2 SQUARES TYPES AND USES ...........................................

13.2.1 Carpenter’s Square .................................................... 13-2

13.2.2 Try Square ......................................................... 13-4

13.2.3 Combination Square ................................................... 13-4

13.2.4 Sliding T-Bevel ...................................................... 13-5

13.2.5 Bevel Protractor...................................................... 13-5

13-2

iii

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

TABLE OF CONTENTS - CONTINUED

Chapter Page

13.3 USING A CARPENTER’S SQUARE TO MARK A SQUARE LINE.................. 13-5

13.4 USING A CARPENTER’S SQUARE TO LAY OUT STEPS ....................... 13-6

13.5 USING A TRY SQUARE ............................................... 13-6

13.6 USING A SLIDING T-BEVEL SQUARE .................................... 13-7

13.7 USING A COMBINATION SQUARE....................................... 13-8

13.7.1 Using as a Center Head to Find the Diameter of a Cylinder ........................ 13-8

13.7.2 Using as a Protractor Head to Determine an Angle .............................. 13-9

13.7.3 Using a Combination Square to Determine Depth ............................... 13-11

13.8 CARE OF SQUARES.................................................. 13-13

14 SURFACE, DEPTH, AND HEIGHT GAGES ......................................... 14-1

14.1 HOW TO CHOOSE AND USE SURFACE, DEPTH, AND HEIGHT GAGES............ 14-1

14.2 SURFACE, DEPTH, AND HEIGHT GAGES TYPES AND USES ................... 14-1

14.2.1 Surface Gage........................................................ 14-1

14.2.2 Rule Depth Gage ..................................................... 14-2

14.2.3 Micrometer Depth Gage ................................................ 14-2

14.2.4 Vernier Depth Gage ................................................... 14-3

14.2.5 Height Gage ........................................................ 14-3

14.2.6 Surface Plate ........................................................ 14-4

14.3 USING THE SURFACE, DEPTH, AND HEIGHT GAGES ........................ 14-4

14.3.1 Using a Surface Gage .................................................. 14-4

14.3.2 Using a Rule Depth Gage ............................................... 14-4

14.3.3 Using a Micrometer Depth Gage .......................................... 14-5

14.3.4 Using a Vernier Depth Gage ............................................. 14-5

14.3.5 Using a Height Gage .................................................. 14-5

14.4 CARE OF SURFACE, HEIGHT, AND DEPTH GAGES .......................... 14-5

15 RING AND SNAP GAGES AND GAGE BLOCKS..................................... 15-1

15.1 HOW TO CHOOSE AND USE RING AND SNAP GAGES AND GAGE BLOCKS ....... 15-1

15.2 RING AND SNAP GAGES AND GAGE BLOCKS TYPES AND USES ............... 15-1

15.2.1 Ring Gages ......................................................... 15-3

15.2.2 Snap Gages......................................................... 15-4

15.2.3 Gage Blocks ........................................................ 15-5

15.3 USING A RING GAGE ................................................ 15-5

15.4 USING AN ADJUSTABLE SNAP GAGE .................................... 15-7

15.5 GAGING FLAT PARTS ................................................ 15-9

15.6 GAGING CYLINDRICAL PARTS ......................................... 15-10

15.7 HOW TO USE PRECISION GAGE BLOCKS ................................. 15-11

15.8 FACTORS TO CONSIDER WHEN USING GAGE BLOCKS ...................... 15-13

15.9 CARE OF RING AND SNAP GAGES ...................................... 15-14

15.10 CARE OF GAGE BLOCKS ............................................. 15-14

16 MISCELLANEOUS MEASURING GAGES.......................................... 16-1

16.1 HOW TO CHOOSE AND USE MISCELLANEOUS MEASURING GAGES ............ 16-1

16.2 MISCELLANEOUS MEASURING GAGES TYPES AND USES .................... 16-2

16.2.1 Thickness (Feeler) Gages................................................ 16-2

16.2.2 Center Gage ........................................................ 16-3

16.2.3 Screw Pitch Gages .................................................... 16-4

16.2.4 Small Hole Gage Set .................................................. 16-4

16.2.5 Telescoping Gages .................................................... 16-5

iv

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

TABLE OF CONTENTS - CONTINUED

Chapter Page

16.2.6 Threaded Cutting Tool Gages............................................. 16-5

16.2.7 Fillet and Radius Gages ................................................ 16-6

16.2.8 Drill Point Gage...................................................... 16-6

16.2.9 Wire Gages ......................................................... 16-6

16.2.10 Drill Gages ......................................................... 16-7

16.2.11 Marking Gages ...................................................... 16-7

16.3 USING A THICKNESS GAGE ........................................... 16-8

16.4 USING A CENTER GAGE .............................................. 16-8

16.5 USING A SCREW PITCH GAGE ......................................... 16-8

16.6 USING A SMALL HOLE GAGE .......................................... 16-9

16.7 USING A TELESCOPING GAGE ......................................... 16-9

16.8 USING A THREAD CUTTING TOOL GAGE ................................. 16-10

16.9 USING A FILLET AND RADIUS GAGE .................................... 16-11

16.10 USING A DRILL POINT GAGE .......................................... 16-11

16.11 USING A WIRE GAGE ................................................ 16-12

16.12 USING A DRILL GAGE................................................ 16-12

16.13 USING MARKING GAGES ............................................. 16-13

16.14 CARE OF GAGES.................................................... 16-13

17 PLIERS AND TONGS ........................................................ 17-1

17.1 HOW TO CHOOSE AND USE PLIERS AND TONGS ........................... 17-1

17.2 PLIERS AND TONGS TYPES AND USES ................................... 17-2

17.2.1 Slip-joint Pliers ...................................................... 17-2

17.2.2 Diagonal Cutting Pliers ................................................. 17-2

17.2.3 Lineman’s Side Cutting Pliers ............................................ 17-2

17.2.4 Parallel Jaw Pliers .................................................... 17-3

17.2.5 Flat-nose Pliers ...................................................... 17-3

17.2.6 Round-nose Pliers .................................................... 17-3

17.2.7 Straight-lip Flat-jaw Tongs............................................... 17-3

17.2.8 End Cutting Pliers .................................................... 17-4

17.2.9 Wire Strippers (Multipurpose) ............................................ 17-4

17.2.10 Crimping Tools ...................................................... 17-4

17.2.11 Wire Twister ........................................................ 17-5

17.3 USING SLIP-JOINT PLIERS ............................................ 17-5

17.4 USING DIAGONAL CUTTING PLIERS .................................... 17-7

17.5 USING LINEMAN’S SIDE CUTTING PLIERS ................................ 17-8

17.6 CARE OF PLIERS AND TONGS ......................................... 17-10

18 VISES ................................................................... 18-1

18.1 HOW TO CHOOSE AND USE VISES ...................................... 18-1

18.2 VISES TYPES AND USES .............................................. 18-1

18.2.1 Machinist’s Bench Vise................................................. 18-1

18.2.2 Bench and Pipe Vise................................................... 18-2

18.2.3 Clamp Base Bench Vise ................................................ 18-2

18.2.4 Pipe Vise .......................................................... 18-3

18.2.5 Machine Table Vise ................................................... 18-3

18.2.6 Pin Vise ........................................................... 18-3

18.2.7 Piston Holding Vise ................................................... 18-4

18.2.8 Handsaw Filing Vise................................................... 18-4

18.3 USING A MACHINIST’S BENCH VISE .................................... 18-5

18.4 USING A PIPE VISE .................................................. 18-7

v

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

TABLE OF CONTENTS - CONTINUED

Chapter Page

18.5 CARE OF VISES..................................................... 18-8

19 CLAMPS ................................................................. 19-1

19.1 HOW TO CHOOSE AND USE CLAMPS .................................... 19-1

19.2 CLAMPS TYPES AND USES ............................................ 19-1

19.2.1 C-Clamps .......................................................... 19-1

19.2.2 Hand Screw Clamps ................................................... 19-2

19.3 USING A C-CLAMP .................................................. 19-2

19.4 USING A HAND SCREW CLAMP ........................................ 19-4

19.5 CARE OF C-CLAMPS................................................. 19-5

19.6 CARE OF HAND SCREW CLAMPS ....................................... 19-5

20 JACKS ................................................................... 20-1

20.1 HOW TO CHOOSE AND USE JACKS...................................... 20-1

20.2 JACK TYPES AND USES .............................................. 20-1

20.2.1 Screw Jacks......................................................... 20-1

20.2.2 Ratchet Lever Jacks ................................................... 20-2

20.2.3 Hydraulic Jacks ...................................................... 20-3

20.3 SAFETY........................................................... 20-4

20.4 USING A BELL BASE SCREW JACK...................................... 20-5

20.5 USING A RATCHET LEVER JACK ....................................... 20-7

20.6 CARE OF JACKS .................................................... 20-9

21 HAMMERS, MALLETS AND MAULS ............................................ 21-1

21.1 HOW TO CHOOSE AND USE HAMMERS, MALLETS AND MAULS ............... 21-1

21.2 HAMMERS, MALLETS AND MAULS TYPES AND USES ....................... 21-2

21.2.1 Carpenter’s Hammer ................................................... 21-2

21.2.2 Machinist’s Peen Hammer ............................................... 21-3

21.2.3 Bumping Body Hammer ................................................ 21-3

21.2.4 Blacksmith’s or Sledge Hammers .......................................... 21-4

21.2.5 Jeweler’s Hammer .................................................... 21-5

21.2.6 Mason’s Hammer ..................................................... 21-5

21.2.7 Napping Hammer..................................................... 21-5

21.2.8 Riveting Hammer..................................................... 21-5

21.2.9 Sawmaker’s Hammer .................................................. 21-6

21.2.10 Setting Hammer...................................................... 21-6

21.2.11 Soft-Faced Hammer ................................................... 21-6

21.2.12 Lead or Copper Hammer................................................ 21-7

21.2.13 Inserted Soft-Faced Hammer ............................................. 21-7

21.2.14 Trimmer’s Hammer ................................................... 21-8

21.2.15 Welder’s Hammer..................................................... 21-8

21.2.16 Dead Blow Hammers .................................................. 21-9

21.2.17 Mallets ............................................................ 21-9

21.2.18 Mauls............................................................. 21-10

21.3 HAMMERS, MALLETS AND MAULS SAFETY .............................. 21-11

21.3.1 Specific Steps to Take.................................................. 21-12

21.4 USING HAMMERS ................................................... 21-13

21.4.1 Using a Carpenter’s Hammer ............................................. 21-14

21.4.2 Using a Mechinist’s Ball Peen Hammer ...................................... 21-18

21.5 CARE OF HAMMERS................................................. 21-19

vi

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

TABLE OF CONTENTS - CONTINUED

Chapter Page

21.5.1 Care of Inserted Face Hammers ........................................... 21-20

21.6 REPLACING THE HANDLE ............................................ 21-21

21.6.1 Removing Old Hammer Handle ........................................... 21-21

21.6.2 Installation of New Handle .............................................. 21-23

22 SCREWDRIVERS ........................................................... 22-1

22.1 HOW TO CHOOSE AND USE SCREWDRIVERS .............................. 22-1

22.2 SCREWDRIVERS TYPES AND USES...................................... 22-1

22.2.1 Common Screwdrivers ................................................. 22-1

22.2.2 Cross-Tip Screwdrivers ................................................. 22-3

22.2.3 Cross-Point Screwdrivers................................................ 22-3

22.2.4 Clutch Head Screwdrivers ............................................... 22-4

22.2.5 Offset Screwdrivers ................................................... 22-4

22.2.6 Ratchet Screwdrivers .................................................. 22-5

22.2.7 Screwdriver Bits ..................................................... 22-5

22.2.8 Jeweler’s Screwdriver .................................................. 22-6

22.2.9 Flexible Screwdrivers .................................................. 22-6

22.2.10 Radio and Pocket Screwdrivers ........................................... 22-6

22.2.11 Screw Starter or Gimlet................................................. 22-7

22.3 SCREWDRIVERS SAFETY ............................................. 22-7

22.4 USING SCREWDRIVERS .............................................. 22-7

22.4.1 Preparing the Work Surface .............................................. 22-8

22.4.2 Using a Screwdriver ................................................... 22-8

22.4.3 Using an Offset Screwdriver ............................................. 22-9

22.4.4 Using an Offset Ratchet Screwdriver ........................................ 22-9

22.4.5 Using a Spiral Ratchet Screwdriver......................................... 22-10

22.4.6 Using a Jeweler’s Screwdriver ............................................ 22-11

22.5 CARE OF SCREWDRIVERS ............................................ 22-11

23 MANUAL DRILLS .......................................................... 23-1

23.1 HOW TO CHOOSE AND USE MANUAL DRILLS ............................. 23-1

23.2 MANUAL DRILLS TYPE AND USES ...................................... 23-2

23.2.1 Brace Drill ......................................................... 23-2

23.2.2 Breast Drill ......................................................... 23-2

23.2.3 Hand Drill.......................................................... 23-3

23.3 USING A BRACE DRILL............................................... 23-3

23.4 USING AN EXPANSIVE BIT ............................................ 23-5

23.5 CARE OF MANUAL DRILLS............................................ 23-7

24 SCREW AND TAP EXTRACTORS ............................................... 24-1

24.1 HOW TO CHOOSE AND USE CREW AND TAP EXTRACTORS ................... 24-1

24.2 SCREW AND TAP EXTRACTORS TYPES AND USES .......................... 24-2

24.2.1 Screw Extractors ..................................................... 24-2

24.2.2 Tap Extractor........................................................ 24-2

24.3 USING A SPIRAL TAPERED SCREW EXTRACTOR ........................... 24-3

24.4 CARE OF EXTRACTORS .............................................. 24-4

25 WRENCHES ............................................................... 25-1

vii

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

TABLE OF CONTENTS - CONTINUED

Chapter Page

25.1 HOW TO CHOOSE AND USE WRENCHES ................................. 25-1

25.2 WRENCHES TYPES AND USES ......................................... 25-1

25.2.1 Open-End Wrenches ................................................... 25-1

25.2.2 Box Wrenches ....................................................... 25-3

25.2.3 Combination Wrenches ................................................. 25-5

25.2.4 Socket Wrenches ..................................................... 25-6

25.2.5 Socket Wrench Handles, Extensions and Adapters ............................... 25-7

25.2.6 Special Purpose Socket Wrenches.......................................... 25-9

25.2.7 Crowfoot Wrench..................................................... 25-11

25.2.8 Hexagon Key Wrench (Shorter Section)...................................... 25-11

25.2.9 Plug Wrenches....................................................... 25-11

25.2.10 Adjustable Open-End Wrench ............................................ 25-12

25.2.11 Clamp Pliers ........................................................ 25-13

25.2.12 Monkey and Auto Wrenches ............................................. 25-14

25.2.13 Pipe Wrenches....................................................... 25-14

25.2.14 Torque Wrenches ..................................................... 25-15

25.2.15 Power Torque Wrench.................................................. 25-16

25.2.16 Spanner Wrenches .................................................... 25-17

25.3 WRENCH SAFETY ................................................... 25-18

25.4 HOW TO USE A BOX WRENCH ......................................... 25-18

25.5 USING A SOCKET WRENCH ........................................... 25-19

25.6 USING AN ADJUSTABLE OPEN-END WRENCH ............................. 25-20

25.7 USING AN ADJUSTABLE STRAP PIPE WRENCH............................. 25-21

25.8 USING THE TORQUE WRENCH ......................................... 25-22

25.9 USING THE POWER TORQUE WRENCH................................... 25-23

25.10 USING A SPANNER WRENCH .......................................... 25-27

25.11 CARE ............................................................ 25-27

26 CHISELS ................................................................. 26-1

26.1 HOW TO CHOOSE AND USE CHISELS .................................... 26-1

26.2 CHISELS TYPES AND USES............................................ 26-1

26.2.1 Woodworker’s Chisels.................................................. 26-1

26.2.2 Machinist’s Chisels.................................................... 26-2

26.2.3 Track Chisel ........................................................ 26-2

26.2.4 Rivet Buster Chisel.................................................... 26-2

26.3 USING A WOODWORKER’S CHISEL ..................................... 26-3

26.4 USING A MACHINIST’S COLD CHISEL ................................... 26-5

26.5 USING A RIVET BUSTER CHISEL ....................................... 26-8

26.6 CARE OF CHISELS .................................................. 26-9

27 PUNCHES ................................................................ 27-1

27.1 HOW TO CHOOSE AND USE PUNCHES ................................... 27-1

27.2 PUNCHES TYPES AND USES ........................................... 27-1

27.2.1 Center Punches ...................................................... 27-1

27.2.2 Drift Punch ......................................................... 27-2

27.2.3 Alignment Punch ..................................................... 27-2

27.2.4 Drive Pin Punch...................................................... 27-2

27.2.5 Prick Punch......................................................... 27-2

27.2.6 Starting Punch ....................................................... 27-3

27.2.7 Grommet-Inserting Punch ............................................... 27-3

27.2.8 Catapunch.......................................................... 27-3

viii

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

TABLE OF CONTENTS - CONTINUED

Chapter Page

27.2.9 Metal Cutting Punch................................................... 27-3

27.2.10 Tinmen’s Hollow Punch ................................................ 27-4

27.2.11 Sheet Metal Punch .................................................... 27-4

27.2.12 Lever Punch ........................................................ 27-4

27.2.13 Screw Punch ........................................................ 27-4

27.3 USING A CENTER PUNCH ............................................. 27-5

27.4 USING A DRIFT PUNCH............................................... 27-7

27.5 USING AN ALIGNMENT PUNCH ........................................ 27-9

27.6 CARE OF PUNCHES.................................................. 27-11

27.7 SCREW PUNCH USAGE ............................................... 27-11

28 FILES.................................................................... 28-1

28.1 HOW TO CHOOSE AND USE FILES ...................................... 28-1

28.2 FILES TYPES AND USES .............................................. 28-1

28.2.1 American Pattern File .................................................. 28-2

28.2.2 Mill File ........................................................... 28-2

28.2.3 Pillar File .......................................................... 28-2

28.2.4 Round File ......................................................... 28-2

28.2.5 Square File ......................................................... 28-2

28.2.6 Taper File .......................................................... 28-3

28.2.7 Three-Square File..................................................... 28-3

28.2.8 Warding File ........................................................ 28-3

28.2.9 Curved-Tooth File .................................................... 28-3

28.2.10 Swiss Pattern File..................................................... 28-4

28.3 FILE SAFETY ...................................................... 28-4

28.4 USING A FILE ...................................................... 28-4

28.4.1 Selecting Proper File .................................................. 28-4

28.4.2 Method of Filing ..................................................... 28-5

28.4.3 Draw Filing......................................................... 28-5

28.5 CARE OF FILES..................................................... 28-6

28.6 REPLACING THE HANDLE ............................................ 28-8

29 GRINDERS AND SHARPENING STONES.......................................... 29-1

29.1 HOW TO CHOOSE AND USE GRINDERS AND SHARPENING STONES ............ 29-1

29.2 GRINDERS AND SHARPENING STONES TYPES AND USES .................... 29-1

29.2.1 Bench Grinder ....................................................... 29-2

29.2.2 Valve Grinder ....................................................... 29-3

29.2.3 Sharpening Stones .................................................... 29-4

29.3 USING A BENCH GRINDER ............................................ 29-4

29.4 USING A SHARPENING STONE ......................................... 29-8

29.5 CARE OF BENCH GRINDERS........................................... 29-10

29.6 CARE OF SHARPENING STONES ........................................ 29-11

30 SCRAPERS................................................................ 30-1

30.1 HOW TO CHOOSE AND USE SCRAPERS .................................. 30-1

30.2 SCRAPERS TYPES AND USES .......................................... 30-1

30.2.1 Carbon Scraper ...................................................... 30-1

30.2.2 Bearing Scraper ...................................................... 30-2

30.2.3 Box Scraper ........................................................ 30-2

30.2.4 Flat Blade Scraper .................................................... 30-2

ix

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

TABLE OF CONTENTS - CONTINUED

Chapter Page

30.2.5 Triangular Blade Scraper ................................................ 30-2

30.3 SCRAPER SAFETY................................................... 30-2

30.4 USING A BEARING SCRAPER .......................................... 30-3

30.5 CARE OF SCRAPERS................................................. 30-4

31 AWLS................................................................... 31-1

31.1 HOW TO CHOOSE AND USE AWLS ...................................... 31-1

31.2 AWLS TYPES AND USES .............................................. 31-1

31.2.1 Saddler’s Awl ....................................................... 31-1

31.2.2 Scratch Awl......................................................... 31-1

31.3 USING A SCRATCH AWL .............................................. 31-2

31.4 CARE OF AWLS..................................................... 31-3

32 BOLT AND CABLE CUTTERS .................................................. 32-1

32.1 HOW TO CHOOSE AND USE BOLT AND CABLE CUTTERS .................... 32-1

32.2 BOLT AND CABLE CUTTERS TYPE AND USES ............................. 32-1

32.2.1 Center Cut Cutter..................................................... 32-2

32.2.2 Clipper Cut Cutter .................................................... 32-2

32.2.3 Shear Cut, Flat Bar, and Strip Cutter........................................ 32-3

32.2.4 Side Nut Splitter Cutter................................................. 32-3

32.2.5 Angular Cut Cutter.................................................... 32-4

32.2.6 Shear Cut Cable Cutter ................................................. 32-4

32.3 CUTTER SAFETY.................................................... 32-4

32.4 USING CENTER CUT CUTTERS ......................................... 32-5

32.5 CARE OF BOLT AND CABLE CUTTERS ................................... 32-6

33 GLASS CUTTERS ........................................................... 33-1

33.1 HOW TO CHOOSE AND USE GLASS CUTTERS ............................. 33-1

33.2 GLASS CUTTERS TYPES AND USES ..................................... 33-1

33.2.1 Wheel Type Glass Cutter................................................ 33-1

33.2.2 Circle Glass Cutter .................................................... 33-1

33.3 USING A WHEEL-TYPE GLASS CUTTER .................................. 33-2

33.4 CARE OF CUTTERS.................................................. 33-6

34 KNIVES .................................................................. 34-1

34.1 HOW TO CHOOSE AND USE KNIVES..................................... 34-1

34.2 KNIVES TYPES AND USES ............................................ 34-1

34.2.1 Rubber Cutting Knives

34.2.2 Saddler’s Knives ..................................................... 34-2

34.2.3 Shop Knife ......................................................... 34-3

34.2.4 Pocket Knife ........................................................ 34-3

34.2.5 Draw Knife......................................................... 34-4

34.2.6 Putty Knife ......................................................... 34-4

34.3 KNIFE SAFETY ..................................................... 34-4

34.4 USING A PUTTY KNIFE ............................................... 34-5

34.5 CARE OF KNIVES ................................................... 34-6

35 PIPE CUTTING AND THREADING TOOLS......................................... 35-1

................................................. 34-2

x

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

TABLE OF CONTENTS - CONTINUED

Chapter Page

35.1 HOW TO CHOOSE AND USE PIPE CUTTING AND THREADING TOOLS ........... 35-1

35.2 PIPE CUTTING AND THREADING TOOLS TYPES AND USES ................... 35-1

35.2.1 Pipe Cutters......................................................... 35-1

35.2.2 Pipe Threading Set.................................................... 35-2

35.3 USING A PIPE CUTTER ............................................... 35-2

35.4 USING A PIPE THREADING SET ........................................ 35-6

35.5 CARE OF PIPE CUTTERS AND THREADING SETS ........................... 35-13

35.5.1 Pipe Cutters......................................................... 35-13

35.5.2 Threading Sets....................................................... 35-13

36 TUBE CUTTING AND FLARING TOOLS .......................................... 36-1

36.1 HOW TO CHOOSE AND USE TUBE CUTTING AND FLARING TOOLS............. 36-1

36.2 TUBE CUTTING AND FLARING TOOLS TYPES AND USES..................... 36-1

36.2.1 Tube Cutters ........................................................ 36-1

36.2.2 Flaring Tool ........................................................ 36-2

36.3 USING A FLARING TOOL ............................................. 36-2

36.4 CARE OF TUBE CUTTERS AND FLARING TOOLS ........................... 36-6

36.4.1 Tube Cutters ........................................................ 36-6

36.4.2 Flaring Tool ........................................................ 36-6

37 SHEARS AND NIPPERS ...................................................... 37-1

37.1 HOW TO CHOOSE AND USE SHEARS AND NIPPERS ......................... 37-1

37.2 SHEARS AND NIPPERS TYPES AND USES ................................. 37-1

37.2.1 Hand Shears ........................................................ 37-2

37.2.2 Tinner’s Bench Shears ................................................. 37-2

37.2.3 Metal Shearing Machine ................................................ 37-2

37.2.4 Nippers............................................................ 37-3

37.2.5 Cutting Nippers ...................................................... 37-3

37.3 SHEARS AND NIPPERS SAFETY ........................................ 37-3

37.4 USING CUTTING NIPPERS............................................. 37-4

37.4.1 Wire Cutting ........................................................ 37-4

37.4.2 Flush Cutting........................................................ 37-5

37.5 CARE OF SHEARS AND NIPPERS ....................................... 37-5

38 TAPS AND DIES............................................................ 38-1

38.1 HOW TO CHOOSE AND USE TAPS AND DIES .............................. 38-1

38.2 TAPS AND DIES TYPES AND USES ...................................... 38-1

38.2.1 Taps.............................................................. 38-2

38.2.2 Dies.............................................................. 38-3

38.3 USING A HAND TAP ................................................. 38-5

38.4 USING A DIE AND DIESTOCK .......................................... 38-8

38.5 CARE OF TAPS ..................................................... 38-11

38.6 CARE OF DIES ..................................................... 38-12

39 REAMERS ................................................................ 39-1

39.1 HOW TO CHOOSE AND USE REAMERS ................................... 39-1

39.2 REAMERS TYPES AND USES........................................... 39-1

39.2.1 Solid Straight-Hole Reamer .............................................. 39-2

xi

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

TABLE OF CONTENTS - CONTINUED

Chapter Page

39.2.2 Solid Taper-Pin Reamer................................................. 39-3

39.2.3 Expansion Reamer .................................................... 39-3

39.2.4 Adjustable-Blade Reamer ............................................... 39-3

39.3 USING A SOLID STRAIGHT-HOLE REAMER................................ 39-4

39.4 CARE OF REAMERS ................................................. 39-5

40 BENDERS ................................................................ 40-1

40.1 HOW TO CHOOSE AND USE BENDERS ................................... 40-1

40.2 BENDERS TYPES AND USES ........................................... 40-2

40.2.1 Spring Tube Benders .................................................. 40-2

40.2.2 Electrical Conduit Hand Bender ........................................... 40-2

40.3 USING A TUBING BENDER ............................................ 40-3

40.4 USING AN ELECTRICAL CONDUIT HAND BENDER.......................... 40-5

40.5 CARE OF BENDERS.................................................. 40-6

41 PULLERS ................................................................. 41-1

41.1 HOW TO CHOOSE AND USE PULLERS ................................... 41-1

41.2 PULLERS TYPES AND USES ........................................... 41-2

41.2.1 Universal Gear Puller .................................................. 41-2

41.2.2 Gear and Bearing Puller ................................................ 41-2

41.2.3 Universal Bearing and Bushing Puller ....................................... 41-2

41.2.4 Electrical Unit Bearing Puller............................................. 41-3

41.2.5 Battery Terminal and Small Gear Puller...................................... 41-3

41.2.6 Steering Gear Arm Puller ............................................... 41-3

41.2.7 Push and Pull Puller Set ................................................ 41-4

41.2.8 Steering Wheel Puller Set ............................................... 41-4

41.2.9 Wheel Puller Set ..................................................... 41-5

41.2.10 Cylinder Sleeve Puller ................................................. 41-5

41.2.11 Slide Hammer Puller .................................................. 41-6

41.2.12 Cotter Pin Puller ..................................................... 41-6

41.3 USING A GEAR AND BEARING PULLER .................................. 41-6

41.4 USING A SLIDE HAMMER PULLER SET .................................. 41-7

41.5 CARE OF PULLERS .................................................. 41-8

42 BARS.................................................................... 42-1

42.1 HOW TO CHOOSE AND USE BARS ...................................... 42-1

42.2 BARS TYPES AND USES .............................................. 42-1

42.2.1 Wrecking Bar ....................................................... 42-1

42.2.2 Crowbar ........................................................... 42-1

42.2.3 Pinch Bar .......................................................... 42-2

42.2.4 Combination Bar ..................................................... 42-2

42.3 BAR SAFETY....................................................... 42-2

42.4 USING THE COMBINATION BAR ........................................ 42-2

42.5 CARE OF BARS..................................................... 42-4

43 MATTOCKS ............................................................... 43-1

43.1 HOW TO CHOOSE AND USE MATTOCKS.................................. 43-1

43.2 MATTOCKS TYPES AND USES.......................................... 43-1

xii

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

TABLE OF CONTENTS - CONTINUED

Chapter Page

43.2.1 Single-Bevel and Double-Bevel ........................................... 43-1

43.3 MATTOCKS SAFETY ................................................. 43-2

43.4 USING THE MATTOCK ............................................... 43-2

43.5 CARE OF MATTOCKS ................................................ 43-3

44 GASKET CUTTERS ......................................................... 44-1

44.1 HOW TO CHOOSE AND USE GASKET CUTTERS ............................ 44-1

44.2 GASKET CUTTERS TYPES AND USES .................................... 44-1

44.2.1 Circle Gasket Cutter ................................................... 44-1

44.2.2 Bit Brace Circle Gasket Cutter ............................................ 44-2

44.2.3 Hollow Gasket Cutter .................................................. 44-2

44.2.4 Heavy Duty Bench Mount Gasket Cutter ..................................... 44-2

44.3 USING THE GASKET CUTTER .......................................... 44-3

44.3.1 Using a Circle Gasket Cutter ............................................. 44-3

44.3.2 Using a Bit Brace Circle Gasket Cutter ...................................... 44-3

44.3.3 Using a Hollow Gasket Cutter ............................................ 44-4

44.4 CARE OF GASKET CUTTERS........................................... 44-4

45 CHOPPING TOOLS .......................................................... 45-1

45.1 HOW TO CHOOSE AND USE CHOPPING TOOLS ............................ 45-1

45.2 CHOPPING TOOLS TYPES AND USES .................................... 45-1

45.2.1 Axes ............................................................. 45-1

45.2.2 Hatchets ........................................................... 45-2

45.2.3 Adz .............................................................. 45-3

45.2.4 Timber Wedges ...................................................... 45-3

45.3 SAFETY........................................................... 45-3

45.4 USING THE SINGLE-BIT AX ........................................... 45-4

45.5 USING THE ADZ .................................................... 45-6

45.6 USING THE TIMBER WEDGE........................................... 45-7

45.7 CARE OF CHOPPING TOOLS ........................................... 45-10

46 SAWS.................................................................... 46-1

46.1 HOW TO CHOOSE AND USE SAWS ...................................... 46-1

46.2 SAWS TYPES AND USES .............................................. 46-1

46.2.1 Handsaw........................................................... 46-1

46.2.2 One-Man Crosscut Saw................................................. 46-2

46.2.3 Two-Man Crosscut Saw

46.2.4 Backsaw ........................................................... 46-3

46.2.5 Nested Saws ........................................................ 46-3

46.3 SAW SAFETY ...................................................... 46-5

46.4 USING THE CROSSCUT SAW........................................... 46-6

46.5 USING THE KEYHOLE SAW ........................................... 46-8

46.6 USING THE HACKSAW ............................................... 46-10

46.7 CARE OF SAWS..................................................... 46-11

................................................ 46-2

47 BRUSH-CUTTING TOOLS..................................................... 47-1

47.1 HOW TO CHOOSE AND USE BRUSH-CUTTING TOOLS ....................... 47-1

47.2 BRUSH-CUTTING TOOLS TYPES AND USES ............................... 47-1

xiii

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

TABLE OF CONTENTS - CONTINUED

Chapter Page

47.2.1 Brush Hook......................................................... 47-2

47.2.2 Machete ........................................................... 47-2

47.3 BRUSH-CUTTING TOOLS SAFETY....................................... 47-2

47.4 USING THE BRUSH HOOK............................................. 47-3

47.5 CARE OF BRUSH-CUTTING TOOLS ...................................... 47-3

48 TIMBER HANDLING TOOLS .................................................. 48-1

48.1 HOW TO CHOOSE AND USE TIMBER HANDLING TOOLS ..................... 48-1

48.2 TIMBER HANDLING TOOLS TYPES AND USES ............................. 48-1

48.2.1 Timber Carrier....................................................... 48-1

48.2.2 Peavy............................................................. 48-1

48.3 TOOL SAFETY...................................................... 48-1

48.4 USING TIMBER HANDLING TOOLS...................................... 48-2

48.4.1 Using a Timber Carrier ................................................. 48-2

48.4.2 Using A Peavy....................................................... 48-2

48.5 CARE OF TIMBER HANDLING TOOLS.................................... 48-2

49 CLIMBING TOOLS .......................................................... 49-1

49.1 HOW TO CHOOSE AND USE CLIMBING TOOLS............................. 49-1

49.2 CLIMBING TOOLS TYPES AND USES .................................... 49-2

49.2.1 Safety Belt ......................................................... 49-2

49.2.2 Safety Strap......................................................... 49-3

49.2.3 Leg Irons .......................................................... 49-3

49.3 CLIMBING TOOLS SAFETY ............................................ 49-3

49.4 USING CLIMBING TOOLS ............................................. 49-4

49.5 CARE OF CLIMBING TOOLS ........................................... 49-8

50 PLANES.................................................................. 50-1

50.1 HOW TO CHOOSE AND USE PLANES .................................... 50-1

50.2 PLANES TYPES AND USES ............................................ 50-1

50.2.1 Block Plane......................................................... 50-1

50.2.2 Bench Plane ........................................................ 50-2

50.3 CUTTING TOOLS SAFETY ............................................. 50-2

50.4 USING THE BLOCK PLANE ............................................ 50-2

50.5 USING THE BENCH PLANE ............................................ 50-4

50.6 CARE OF PLANES................................................... 50-5

51 DIGGING TOOLS ........................................................... 51-1

51.1 HOW TO CHOOSE AND USE DIGGING TOOLS.............................. 51-1

51.2 DIGGING TOOLS TYPES AND USES...................................... 51-1

51.2.1 Long-Handled Shovel .................................................. 51-1

51.2.2 D-Handled Shovel .................................................... 51-2

51.2.3 Spade............................................................. 51-2

51.2.4 Posthole Auger ...................................................... 51-2

51.2.5 Posthole Digger ...................................................... 51-3

51.3 PROPER TOOL SAFETY............................................... 51-3

51.4 USING THE LONG-HANDLED SHOVEL ................................... 51-3

51.5 USING THE SPADE .................................................. 51-5

xiv

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

TABLE OF CONTENTS - CONTINUED

Chapter Page

51.6 USING THE POSTHOLE DIGGER ........................................ 51-6

51.7 CARE AND CLEANING OF DIGGING TOOLS ............................... 51-7

52 ELECTRICAL POWER TOOLS.................................................. 52-1

52.1 HOW TO CHOOSE AND USE ELECTRICAL POWER TOOLS .................... 52-1

52.2 ELECTRICAL POWER TOOLS TYPES AND USES ............................ 52-1

52.2.1 Portable Electric Drill .................................................. 52-3

52.2.2 Portable Electric Hammer ............................................... 52-4

52.2.3 Portable Electric Impact Wrench........................................... 52-4

52.2.4 Portable Electric Circular Saw ............................................ 52-5

52.2.5 Portable Electric Chain Saw.............................................. 52-5

52.2.6 Portable Electric Disk Sander............................................. 52-6

52.2.7 Bench Grinders and Oilstones ............................................ 52-6

52.3 ELECTRICAL POWER TOOL SAFETY..................................... 52-8

52.4 USING THE PORTABLE ELECTRIC DRILL ................................. 52-9

52.5 DRILLS, REAMERS, TAPS, AND COUNTERSINKS............................ 52-11

52.5.1 Drills, Reamers, Taps, and Countersinks Introduction............................. 52-11

52.5.2 Twist Drills ......................................................... 52-11

52.5.3 Drill Terminology..................................................... 52-11

52.5.4 Drill Sizes.......................................................... 52-11

52.5.5 Using the Drill....................................................... 52-12

52.5.6 Countersinks ........................................................ 52-13

52.6 USING THE PORTABLE ELECTRIC HAMMER .............................. 52-14

52.7 USING THE PORTABLE ELECTRIC IMPACT WRENCH ........................ 52-17

52.8 USING THE PORTABLE ELECTRIC CIRCULAR SAW ......................... 52-19

52.9 USING THE ELECTRIC CHAIN SAW...................................... 52-23

52.10 CARE OF ELECTRIC POWER TOOLS ..................................... 52-27

53 SOLDERING............................................................... 53-1

53.1 SOLDERING INTRODUCTION .......................................... 53-1

53.2 SOLDERING TOOLS.................................................. 53-1

53.3 BASIC SOLDERING TECHNIQUES ....................................... 53-1

53.3.1 Temperatures ........................................................ 53-1

53.3.2 Heating............................................................ 53-5

53.3.3 Cooling ........................................................... 53-5

53.3.4 Copper Bit Soldering Irons .............................................. 53-5

53.3.5 Flux Residue Removal ................................................. 53-6

53.4 SOLDERING SAFETY PRACTICES ....................................... 53-6

54 PAINT APPLICATION ........................................................ 54-1

54.1 PAINT APPLICATION INTRODUCTION.................................... 54-1

54.2 PRE-TREATMENT ................................................... 54-1

54.3 BRUSH PAINTING ................................................... 54-1

54.3.1 Care of Paintbrushes................................................... 54-1

54.4 SPRAY PAINTING ................................................... 54-1

54.4.1 Aerosol Can Operation ................................................. 54-2

54.4.2 Using Aerosol Paint ................................................... 54-2

55 MISCELLANEOUS TOOLS .................................................... 55-1

xv

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

TABLE OF CONTENTS - CONTINUED

Chapter Page

55.1 HOW TO CHOOSE AND USE MISCELLANEOUS TOOLS ....................... 55-1

55.2 MISCELLANEOUS TOOLS TYPES AND USES ............................... 55-1

55.2.1 Cement Trowel ...................................................... 55-1

55.2.2 Brick Trowel ........................................................ 55-1

55.2.3 Miner’s Spoon ....................................................... 55-2

55.2.4 Blocks ............................................................ 55-2

55.2.5 Trip Wire Grapnel .................................................... 55-2

55.2.6 Chain Assembly...................................................... 55-3

55.2.7 Cable Jaw Grip ...................................................... 55-3

55.2.8 Tension Puller ....................................................... 55-3

55.3 MISCELLANEOUS TOOL SAFETY ....................................... 55-4

55.4 USING THE BRICK TROWEL ........................................... 55-4

55.5 USING THE BLOCK .................................................. 55-8

55.6 USING THE CABLE JAW GRIP AND TENSION PULLER ....................... 55-8

55.7 CARE OF MISCELLANEOUS TOOLS ..................................... 55-9

56 PNEUMATIC RATCHETS ..................................................... 56-1

56.1 AIR RATCHETS MODEL NUMBERS FAR70C AND 72B ........................ 56-1

INDEX .................................................................... Index 1

xvi

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

LIST OF ILLUSTRATIONS

Number PageTitle

52-1 Drill Terminology......................................................... 52-11

52-2 Countersink Angles........................................................ 52-13

52-3 Countersink Tool ......................................................... 52-14

53-1 Soldering Tools and Accessories ............................................... 53-2

53-2 Using the Soldering Iron .................................................... 53-6

54-1 Aerosol Spray Can ........................................................ 54-2

55-1 Open End Wrenches ....................................................... 55-14

56-1 Snap-On Air Ratchets ...................................................... 56-2

LIST OF TABLES

Number PageTitle

55-1 Decimal Equivalent Chart ................................................... 55-10

55-2 A.S.M.E. Standard Screws and American Wire Gauge ................................ 55-10

55-3 Numbered Twist Drills ..................................................... 55-11

55-4 Fractional Twist Drill Sizes .................................................. 55-12

55-5 Tap, Tap Drill, and Clearance Drill Sizes ......................................... 55-12

55-6 Screw Extractors ......................................................... 55-13

55-7 Taper Reamers ........................................................... 55-13

55-8 Extension Taper Reamers.................................................... 55-13

55-9 Open End Wrenches F. E. Tool Kit ............................................. 55-13

55-10 Adjustable and Ratchet Wrenches .............................................. 55-14

55-11 Box Wrenches F. E. Tool Kit ................................................. 55-14

55-12 Sockets................................................................ 55-15

55-13 Socket Handles and Extensions F. E. Tool Kit...................................... 55-15

55-14 Hexagon and Fluted Wrenches ................................................ 55-17

55-15 Chassis Punches .......................................................... 55-18

55-16 Lug and Crimping Tools .................................................... 55-18

xvii/(xviii blank)

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

INTRODUCTION

1 PURPOSE.

This manual provides information on the functional use and care of selected hand and measuring tools. It explain the types

and uses of a large number of tools, a practical application of a selected group of tools, safety requirements, general care,

and limited reconditioning. The user must have, choose, and use the correct tools in order to accomplish the work quickly,

accurately, and safely. Without the proper tools and knowledge of how to use them, the user wastes time, reduces efficiency,

and may face injury.

2 SCOPE.

This manual consist of the following chapters:

Chapter 1 Introduction

Chapter 2 Safety

Chapter 3 Reading Measuring Scales

Chapter 4 Tool Boxes

Chapter 5 Dividers

Chapter 6 Calipers

Chapter 7 Micrometers

Chapter 8 Rules And Steel Tapes

Chapter 9 Miscellaneous Measuring Tools

Chapter 10 Levels

Chapter 11 Plumb Bobs

Chapter 12 Scribers

Chapter 13 Squares

Chapter 14 Surface, Depth, And Height Gages

Chapter 15 Ring And Snap Gages And Gage Blocks

Chapter 16 Miscellaneous Measuring Gages

Chapter 17 Pliers And Tongs

Chapter 18 Vises

Chapter 19 Clamps

Chapter 20 Jacks

Chapter 21 Hammers, Mallets And Mauls

Chapter 22 Screwdrivers

Chapter 23 Manual Drills

Chapter 24 Screw And Tap Extractors

Chapter 25 Wrenches

Chapter 26 Chisels

Chapter 27 Punches

Chapter 28 Files

Chapter 29 Grinders And Sharpening Stones

Chapter 30 Scrapers

Chapter 31 Awls

Chapter 32 Bolt And Cable Cutters

Chapter 33 Glass Cutters

Chapter 34 Knives

Chapter 35 Pipe Cutting And Threading Tools

xix

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

Chapter 36 Tube Cutting And Flaring Tools

Chapter 37 Shears And Nippers

Chapter 38 Taps And Dies

Chapter 39 Reamers

Chapter 40 Benders

Chapter 41 Pullers

Chapter 42 Bars

Chapter 43 Mattocks

Chapter 44 Gasket Cutters

Chapter 45 Chopping Tools

Chapter 46 Saws

Chapter 47 Brush-Cutting Tools

Chapter 48 Timber Handling Tools

Chapter 49 Climbing Tools

Chapter 50 Planes

Chapter 51 Digging Tools

Chapter 52 Electrical Power Tools

Chapter 53 Soldering

Chapter 54 Paint Application

Chapter 55 Miscellaneous Tools

Chapter 56 Pneumatic Ratchets

3 ABBREVIATIONS.

All abbreviations used in this manual are shown in the list of abbreviations below. Standard abbreviations are in accordance

with ASME Y14.38, Abbreviations and Acronyms for Use on Drawings and Related Documents.

°F degrees Fahrenheit

AF Air Force

AFTO Air Force Technical Order

CD Compact Disk

cm centimeter

DLA Defense Logistics Agency

DoD Department of Defense

ERRC Expendability, Recoverability, and Repairability Category

ESDS Electrostatic Discharge Sensitive

ETIMS Enhanced Technical Information Management System

HAZMAT Hazardous Material

HCI Hardness Critical Items

mm millimeter

No. Number

OSHA Occupational Safety and Health Administration

PN Part Number

PSI Pound-force per Square Inch

TAMMS The Army Maintenance Management System

TCTO Time Compliance Technical Order

TO Technical Order

TOMA Technical Order Management Agency

VAC Volts Alternating Current

xx

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

4 RELATED PUBLICATIONS.

NOTE

When searching Technical Order (TO) numbers in the Enhanced Technical Information Management System

(ETIMS) catalog, please use the wildcard (*) after typing in the TO number. Many TOs are not available in paper

format, (i.e., digital (WA-1) or Compact Disk (CD-1)). This ensures TOs in all media formats will populate the

search.

The following publications contain information in support of this technical manual.

List of Related Publications

Number Title

ADP 1-02 Terms and Military Symbols

AFMAN 91-203 Air Force Occupational Safety, Fire and Health Standards Checklist

AR 25-30 Army Publishing Program

AR 385-10 The Army Safety Program

AR 385-40 Accident Reporting and Records

ASME Y14.38 Abbreviations and Acronyms for Use on Drawings and Related Documents

DA Form 2028 Recommended changes to Publications and Blank Forms

DODI 5330.03 Defense Logistics Agency (DLA) Document Services

FED 256 Effect of chronic hypovitaminosis A on water metabolism in the weanling rat

TC 9-515 Shop Mathematics

TC 9-524 Fundamentals of Machine Tools

TM 36-750 The Army Maintenance Management System (TAMMS)

TO 00-5-1 AF Technical Order System

TO 00-25-234 General Shop Practice Requirements for the Repair, Maintenance, and Test of Electri-

cal Equipment

TO 32-1-2 Use of Hand Tools

5 RECORD OF APPLICABLE TIME COMPLIANCE TECHNICAL ORDERS (TCTOS).

List of Time Compliance Technical Orders

TCTO

Number

TCTO

Title

None

6

HARDNESS CRITICAL ITEMS (HCI).

The HCI symbol (

) establishes special requirements limiting changes and substitutions and that the specific

parts listed must be used to ensure hardness is not degraded.

If included, items with nuclear survivability requirements are marked with the HCI symbol (

proposed substitutions of, HCIs must be approved by the acquiring activity.

TCTO

Date

). All changes to, or

Change 2 xxi

AIR FORCE AIR FORCE TO 32-1-101

ARMY ARMY TM 9-243

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

7 ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) ITEMS.

All ESDS parts shall be handled in accordance with the ESDS device handling procedures in TO 00-25-234.

If included, items containing ESDS parts are marked with the ESDS symbol (

8 IMPROVEMENT REPORTS.

Recommended changes to this manual shall be submitted in accordance with TO 00-5-1.

).

xxii

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

SAFETY SUMMARY

1 GENERAL SAFETY INSTRUCTIONS.

This manual describes physical and/or chemical processes which may cause injury or death to personnel, or damage to

equipment, if not properly followed. This safety summary includes general safety precautions and instructions that must be

understood and applied during operation and maintenance to ensure personnel safety and protection of equipment. Prior to

performing any specific task, the WARNINGs, CAUTIONs, and NOTEs included in that task shall be reviewed and understood.

2 WARNINGS, CAUTIONS, AND NOTES.

WARNINGs and CAUTIONs are used in this manual to highlight operating or maintenance procedures, practices, conditions, or statements which are considered essential to protection of personnel (WARNING) or equipment (CAUTION).

WARNINGs and CAUTIONs immediately precede the step or procedure to which they apply. WARNINGs and CAUTIONs

consist of four parts: heading (WARNING, CAUTION, or icon), a statement of the hazard, minimum precautions, and

possible results if disregarded. NOTEs are used in this manual to highlight operating or maintenance procedures, practices,

conditions, or statements which are not essential to protection of personnel or equipment. NOTEs may precede or follow the

step or procedure, depending upon the information to be highlighted. The headings used and their definitions are as follows:

Highlights an essential operating or maintenance procedure, practice, condition, statement, etc. Failure to comply

could result in injury to, or death of, personnel or long term health hazards.

Highlights an essential operating or maintenance procedure, practice, condition, statement, etc. Failure to comply

could result in damage to, or destruction of, equipment or loss of mission effectiveness.

NOTE

Highlights an essential operating or maintenance procedure, condition, or statement.

xxiii/(xxiv blank)

AIR FORCE AIR FORCE TO 32-1-101

MARINE CORPS MARINE CORP TM 10209-10/1

NAVY (NAVAIR) NAVY M6290-AJ-MAN-1010

ARMY ARMY TM 9-243

CHAPTER 1

INTRODUCTION

NOTE

Reconditioning of Expendability, Recoverability, and Repairability Category (ERRC) “XB3” type items. Reconditioning includes virtually any minor, common sense maintenance action and is discretionary. Common sense

acts of reconditioning are normally within the capability of any level of maintenance and are not to be construed

as a repair (AFI 23-101).

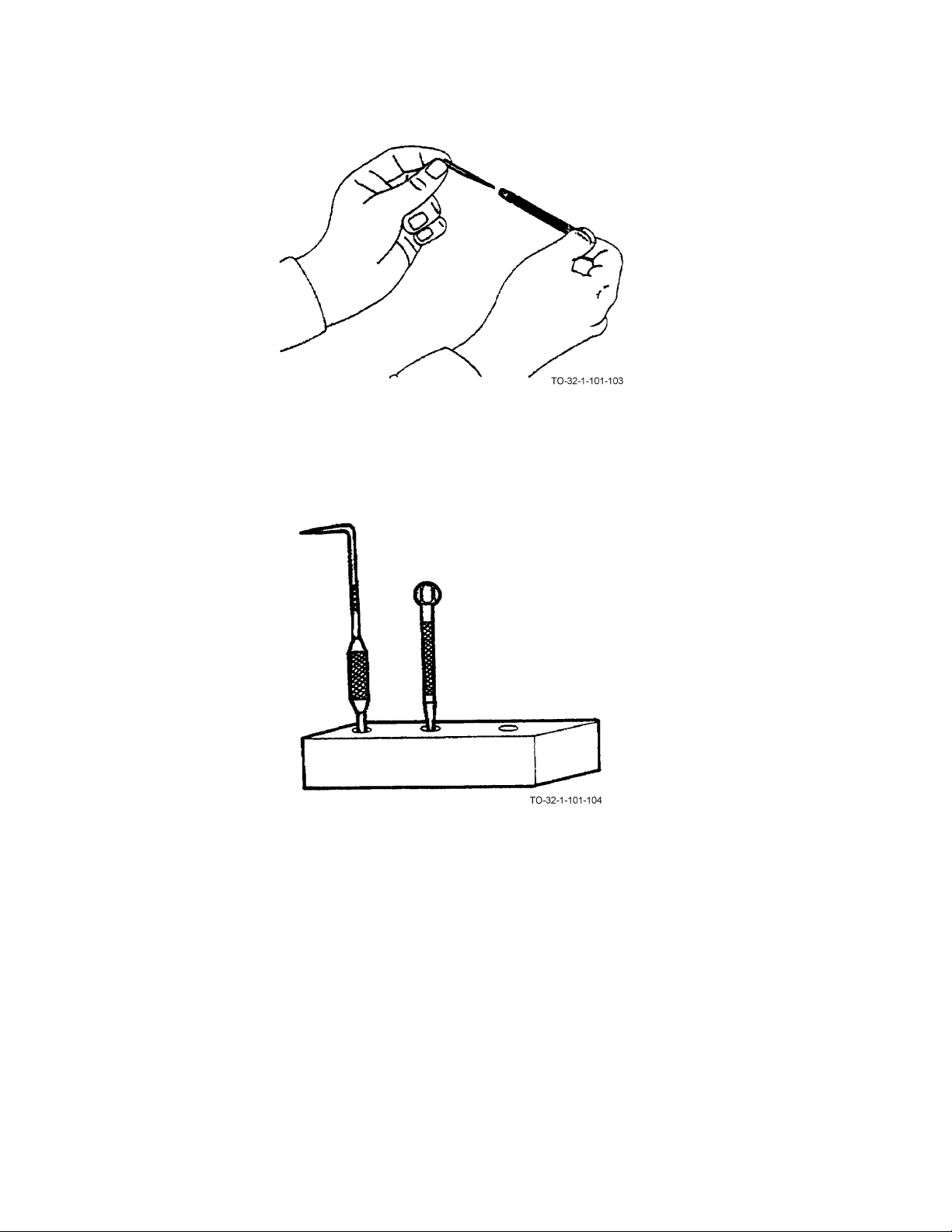

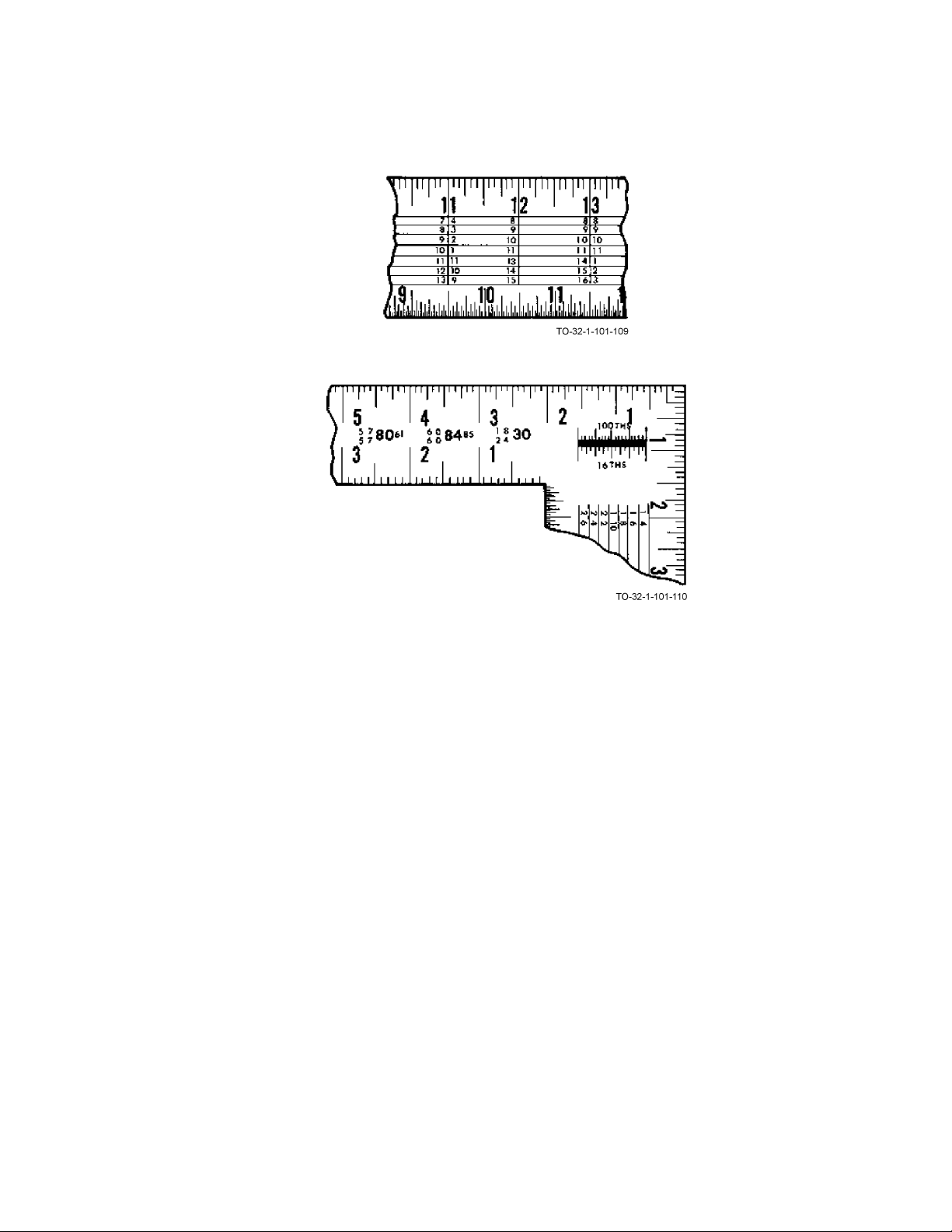

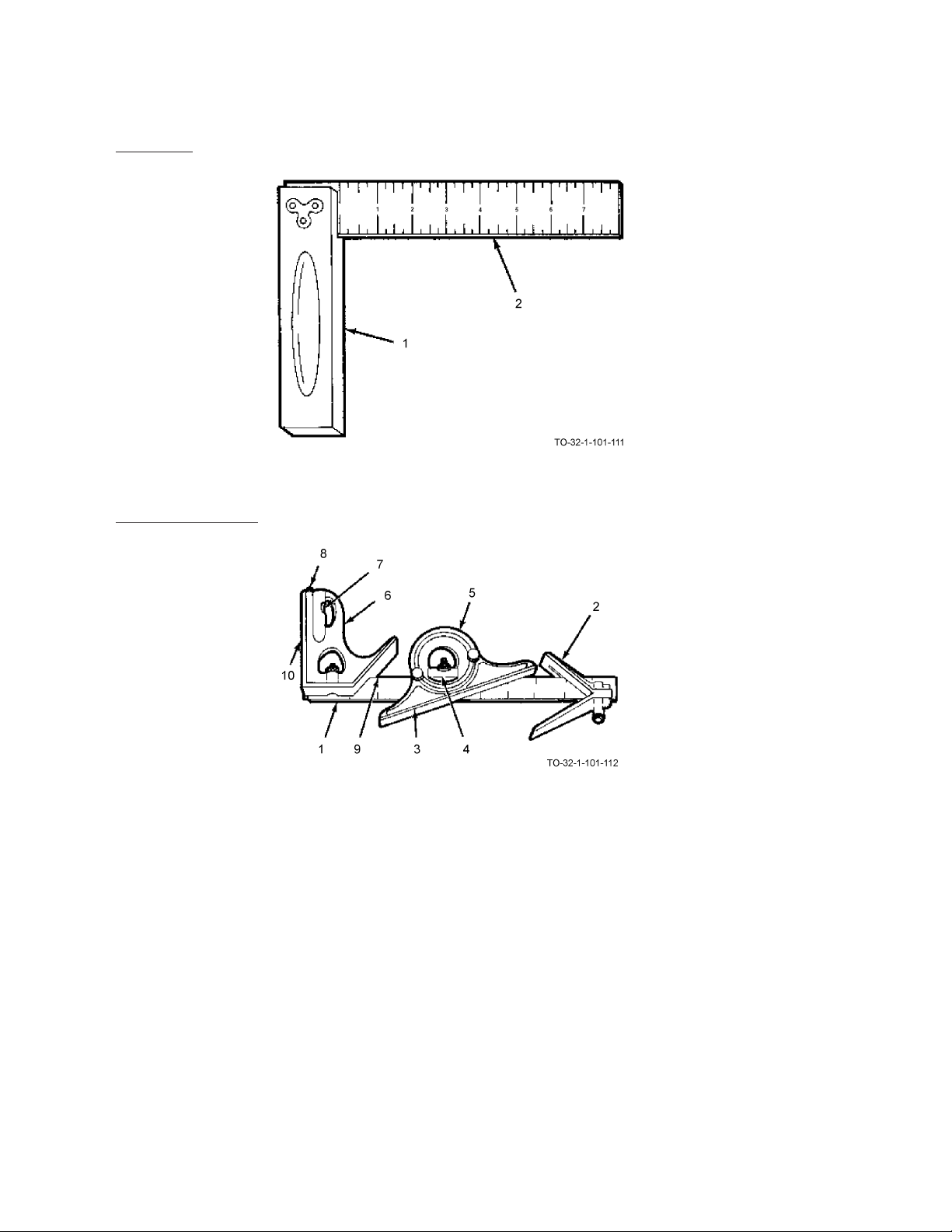

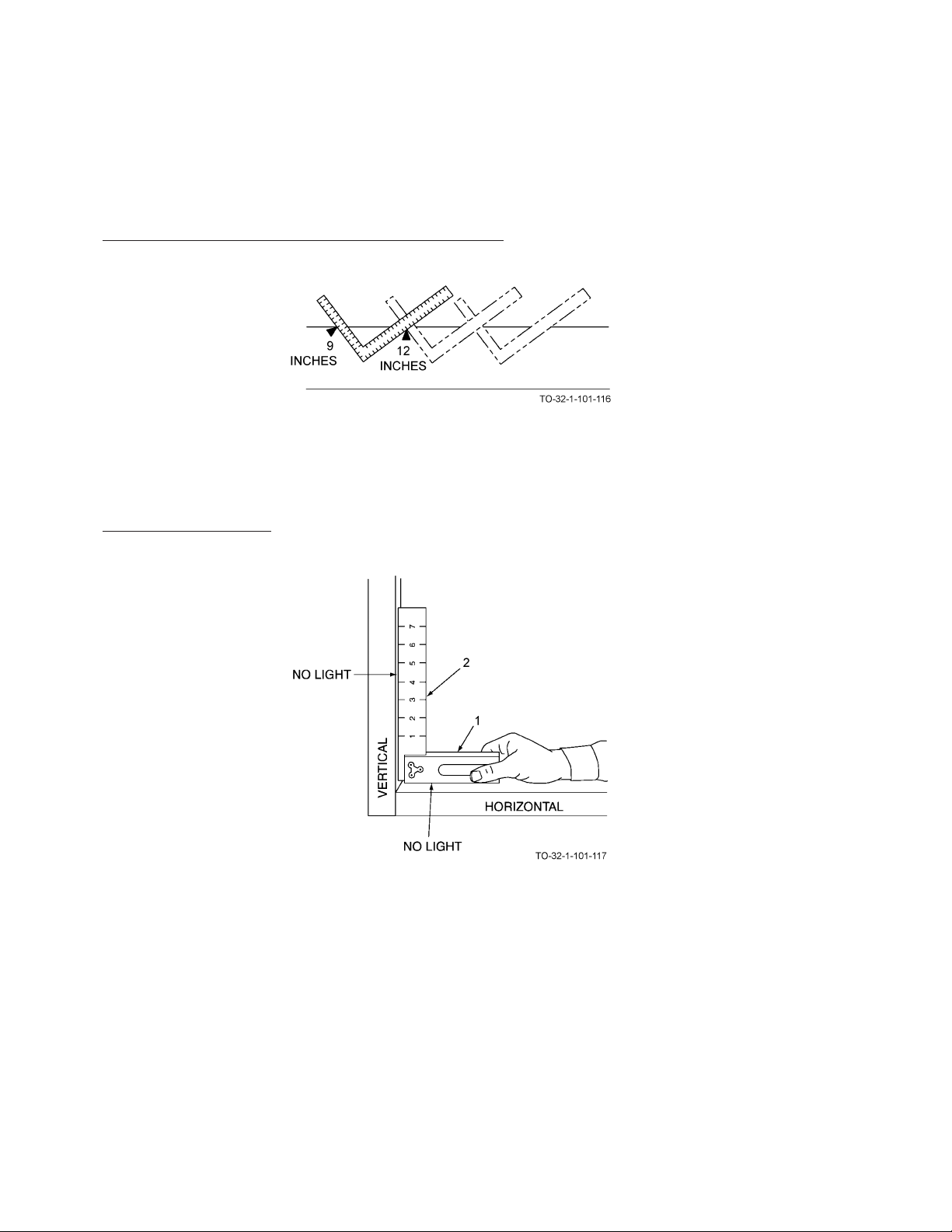

1.1 HOW TO USE THIS MANUAL.