Page 1

MILESTONE

HELPING

PATIENTS

PRESTO PRO

Automatic processor/stainer

for next generation frozen sections

Operator Manual - MM136

Page 2

Page 3

PRESTO PRO MM136-002 – Operator Manual

Thank you for choosing one of our systems and welcome to the ever more crowded club of Milestone laboratory

instrumentation users.

We feel confident that you will be fully satisfied adding this new device to your laboratory.

We recommend to ready carefully this operator manual and to always keep it within reach for convenient and

quick referencing.

For any clarification or request for assistance, please contact our representative in your country:

Or contact:

Milestone s.r.l.

Via Fatebenefratelli, 1/5

24010 Sorisole (BG) Italy

Tel. +39.035.412 8264

Fax +39.035.575498

web site www.milestonemed.com

e-mail marketing@milestonemedsrl.com

Read carefully this manual before using the instrument.

MM136-002 – PRESTO PRO – Operator Manual

2018-11

3

Page 4

PRESTO PRO MM136-002 – Operator Manual

CONTENTS

CONTENTS ....................................................................................................................................................... 4

1. INTRODUCTION ........................................................................................................................................ 6

1.1. Symbols used .................................................................................................................................... 6

1.2. Designated uses ................................................................................................................................ 7

1.3. Technical specifications ..................................................................................................................... 7

1.3.1.

Touch control terminal ............................................................................................................... 7

1.4. Transport and storage conditions ...................................................................................................... 8

1.5. Warning information ........................................................................................................................... 9

1.6. Label ................................................................................................................................................ 10

1.7. Compatible reagents ........................................................................................................................ 10

1.8. Waste disposal ................................................................................................................................ 11

2. INSTALLATION ........................................................................................................................................ 12

2.1. Space requirements ......................................................................................................................... 12

2.2. Unpacking and check list ................................................................................................................. 13

2.3. Fume extraction system ................................................................................................................... 16

2.4. Water fitting ...................................................................................................................................... 17

2.4.1.

Water drain .............................................................................................................................. 18

2.5. Electrical installation ........................................................................................................................ 19

2.5.1.

Power supply ........................................................................................................................... 19

2.6. Final placement ............................................................................................................................... 20

2.7. General description .......................................................................................................................... 20

2.7.1.

Remove or place the reagent cover disc ................................................................................. 21

2.7.2.

Add protection labels to the disc covering the reagents .......................................................... 22

2.7.3.

Cover of the second loading position ...................................................................................... 22

2.7.4.

Loading positions of the racks on the arm of the PRESTO PRO ............................................ 23

2.7.5.

Remove or replace the caps to the reagent vessels ............................................................... 23

2.7.6.

Remove or place the tray of reagent vessels .......................................................................... 24

2.7.7.

Reagent positions inside PRESTO PRO ................................................................................. 25

2.7.8.

Connect the barcode reader .................................................................................................... 26

2.7.9.

Rear panel ............................................................................................................................... 27

2.8. Remote alarm connection ................................................................................................................ 28

2.9. Reagents.......................................................................................................................................... 28

2.10. Accessing and exiting the system ................................................................................................... 29

2.11. Create a new user ........................................................................................................................... 30

2.12. Changing the language .................................................................................................................... 32

2.13. Set Date and Time ........................................................................................................................... 33

2.14. Fill the FineFIX reagent in the PRESTO PRO ................................................................................. 33

2.14.1. Load the consumable changes ................................................................................................ 33

2.14.2. Sequence of software activation .............................................................................................. 34

2.15. Load the reagents in the PRESTO PRO vessels ............................................................................ 35

2.15.1. Labels ...................................................................................................................................... 35

2.15.2. Load fixation, staining and cleaning reagents in the PRESTO PRO ....................................... 36

2.15.3. FineFIX heating settings .......................................................................................................... 40

2.16. Most used programs ........................................................................................................................ 42

2.17. Owner Settings ................................................................................................................................ 44

3. USE PRESTO PRO.................................................................................................................................. 46

3.1. Loading slides in the rack ................................................................................................................ 46

3.2. Run a program ................................................................................................................................. 46

3.2.1.

Run a favourite standard protocol............................................................................................ 48

3.2.2.

Run a favourite “Continuous” protocol ..................................................................................... 51

3.2.3.

Press the start button to run a standard protocol .................................................................... 57

3.2.4.

Press the start button to run a “Continuous” protocol .............................................................. 59

3.3. Editing a program ............................................................................................................................ 60

3.3.1.

Modify a standard protocol ...................................................................................................... 60

3.3.2.

Modify a “Continuous” protocol ................................................................................................ 62

3.3.3.

Modify the temperature of the fixation reagent ........................................................................ 63

4. REAGENT MANAGEMENT ..................................................................................................................... 64

4.1. Use of FineFIX ................................................................................................................................. 64

4.2. Reuse of reagents ........................................................................................................................... 66

4

Page 5

PRESTO PRO MM136-002 – Operator Manual

4.3. Setting the configuration of reagents ............................................................................................... 68

4.4. Edit reagents list .............................................................................................................................. 69

5. SAFETY PROCEDURE ........................................................................................................................... 70

5.1. Water error ....................................................................................................................................... 70

5.2. Arm position lost error ...................................................................................................................... 73

6. MAINTENANCE ....................................................................................................................................... 76

6.1. Introduction ...................................................................................................................................... 76

6.2. Before/after every process ............................................................................................................... 76

6.3. Daily ................................................................................................................................................. 77

6.4. Weekly ............................................................................................................................................. 77

6.5. Yearly ............................................................................................................................................... 77

7. DECONTAMINATION AND CLEANING .................................................................................................. 78

7.1. Safety precautions ........................................................................................................................... 78

7.2. Procedure for PRESTO PRO decontamination and cleaning ......................................................... 78

7.2.1.

Detergents ............................................................................................................................... 78

7.2.2.

Procedure ................................................................................................................................ 79

8. REPORTING ............................................................................................................................................ 81

8.1. Exporting saved process data ......................................................................................................... 81

8.1.1.

How to delete a saved process................................................................................................ 82

8.2. Exporting the events log .................................................................................................................. 83

9. OPTIONALS ............................................................................................................................................. 84

9.1. External exhaust fume filter kit (Code 61550/F) .............................................................................. 84

9.2. FineFIX tanks ................................................................................................................................... 84

A.

Appendix – Hints and tips .................................................................................................................... 85

A.1. Fatty tissues ..................................................................................................................................... 85

A.2. Tips to modify the staining protocol ................................................................................................. 85

B.

Appendix – Alarm management .......................................................................................................... 86

B.1. Alarm management ......................................................................................................................... 86

5

Page 6

PRESTO PRO MM136-002 – Operator Manual

1. INTRODUCTION

1.1. Symbols used

The instructions marked with this symbol are important and must be read carefully.

An instruction accompanied by this WARNING symbol means you need to proceed with

caution. Failure to follow the instruction may endanger the user or cause damage to the

device.

When an instruction features this symbol, great care is required as there is the risk of

an electric shock. Carefully follow the instruction in order to avoid this kind of accident.

Biohazard: pay attention when performing a procedure marked with this symbol, as

there is a biological contamination hazard.

Pay attention: parts identified with this symbol are areas at risk of crushing hand and

or fingers.

Surfaces identified by this symbol feature a high temperature hazard.

Inflammable material.

CE Logo: this instrument complies with European Community directives.

IVD medical device according to directive 98/79/EC.

Symbol of the European WEEE directive (2002/96/EC):

electric/electronic material – do not disperse in the environment.

Fragile

Manufacturer.

6

Page 7

PRESTO PRO MM136-002 – Operator Manual

1.2. Designated uses

Milestone PRESTO PRO and its optional parts have been designed for laboratory use and are therefore able

to withstand the harshest lab conditions. They have been developed for continuous use in procedures for

fixation, processing and staining of specimens for extemporaneous diagnoses in a quick, reliable and

standardized manner.

Milestone PRESTO PRO must solely be used with the reagents listed in the “Compatible reagents” chapter,

refer to chapter 1.7.

Any other use of the instrument should be deemed as misuse and voids the manufacturer's

warranty.

1.3. Technical specifications

REF 100300: PRESTO PRO 230V~ 50/60Hz 180W

REF 100301: PRESTO PRO 115V~ 60Hz 180W

Productivity: 120 slides per hour

194 slides per hour with loading “Continuous”

Rack capacity: 6 slides

Number of stations: 10

Reagent vessel volume: 200ml

Operating Temperature: 18°C – 30°C (64.4°F – 86°F)

Humidity (relative): up to 80% non-condensing

Maximum altitude: 2000m (6561ft)

Air intake flow interval: 35-45m3/h (cubic meters per hour).

Weight: 42Kg (92lb)

The instrument is intended for laboratory use (indoor use) only.

1.3.1. Touch control terminal

The following picture shows the Touch Control Terminal of the PRESTO PRO unit. It is possible to operate the

unit simply by touching the icons on the screen.

7

Page 8

PRESTO PRO MM136-002 – Operator Manual

Two USB ports are at the sides of the Touch Terminal.

When the USB ports are not used, it is required to leave the port protection on, as shown

in the picture above.

Characteristics: TFT-LCD 7” widescreen color display

Resolution 800X480,

Resistive Touchscreen

Mass storage 4GB

CPU 1GHz

Windows™ Embedded Compact 7

Programs: Pre-stored and customizable user defined programs.

I/O-Interface: 2x USB ports 2.0, 1x LAN Ethernet 10/100 Mbps RJ-45.

The manufacturer reserves the right to change and/or improve the specifications with no

prior notice and without incurring any obligation.

1.4. Transport and storage conditions

Temperature: –20°C up to +60°C (-4°F up to 140°F)

Humidity: up to 80% (up to 50% at 40°C) (104°F) non-condensing.

Before switching on PRESTO PRO (when coming from a storage chamber), allow the

instrument to reach operating environment conditions (at least half an hour).

8

Page 9

PRESTO PRO MM136-002 – Operator Manual

It is important that normal standards for safety and good laboratory practices are

1.5. Warning information

Any use of the instrument other than specified forfeits the warranty provided by the manufacturer.

PERSONAL DATA

The Device described herein is not intended for managing personal data of natural persons. Personal data of

natural persons shall not be inserted into the Device during the use of the Device. The organization that uses

the Device shall implement appropriate measures to ensure that no personal data of natural persons are

inserted into the Device. All the data referred to a person and inserted into the device shall use, at least, the

pseudonymization, in such a manner that the personal data can no longer be attributed to a specific data

subject without the use of additional information, provided that such additional information is kept separately

and is subject to technical and organizational measures to ensure that the personal data are not attributed to

an identified or identifiable natural person.

The main power supply plug is to be considered as disconnect device. Disconnect all plugs from the power

outlet before assembling the system, before connecting optional parts (if any) and before cleaning it.

The equipment must be connected to well visible sockets and accessible by the operator.

The instrument is supplied with replaceable fuses, but their replacement must be effected by trained and

authorized SERVICE personnel. If the system is still not properly working, please contact the local authorized

and trained SERVICE representative or the manufacturer.

All parts of the equipment and its optional parts shall be supplied only by the manufacturer.

DO NOT OPEN THE UNIT'S BODY. Failure to comply with the instructions in the

documentation might lead to a reduction in the device's safety. Should the equipment

not work correctly you are kindly requested to contact the supplier or manufacturer.

Do not remove the instrument, optional parts, panels or cover. Only authorized and

qualified personnel may repair and access the instrument's internal components.

applied. Always use common sense and the best-known laboratory practice when

operating the instrument.

The Competent Authority who owns the instrument has the primary responsibility for

incidents due to operations on the instrument without attending personnel in charge

of use or repairs.

Only use the reagents listed in chapter 1.7 “Compatible reagents”, to avoid damage

to the instrument. Failure to follow the instructions might lead to decreased device

safety.

9

Page 10

PRESTO PRO MM136-002 – Operator Manual

Fixative

Staining

Cleaning

1.6. Label

MILESTONE SRL

Via Fatebenefratelli, 1/5 – 24010 Sorisole (BG) – ITALY

Tel. +39.035.4128264

Fax. +39.035.575498

PRESTO PRO

REF 100300

SERIAL NUMBER (SN)

INPUT

MANUFACTURED:

For an explanation of symbols see chapter 1.1.

1.7. Compatible reagents

reagents

Milestone

FineFIX

Limonene

Reagents

Haematoxylin

Eosin

Reagents

Ethanol >99.9%

(Ethanol)

Acetic Acid 2% in

water

(Acetic Acid 2%)

Xylene

(Xylene)

Isoparaffin

(Isoparaffin,

MileGREEN)

Isopropanol

(Isopropanol)

DO NOT USE REAGENTS OTHER THAN THOSE LISTED ABOVE.

In case of doubts please contact: application@milestonemedsrl.com.

DO NOT USE HYDROCHLORIC ACID in any concentration.

10

Page 11

PRESTO PRO MM136-002 – Operator Manual

Handle with care and st

ore in a cool dry space using a tightly closed container.

1.8. Waste disposal

This instrument is a medical in-vitro device and is usually installed in a laboratory where are specimens and

other biological tissue. For your safety, it is therefore required to clean and disinfect the instrument prior to

coming into contact with it. It is also required to wear gloves when operating the system.

In the event this instrument should be returned to Milestone S.r.l., it is required to clean and disinfect the unit

before shipping it. Non-disinfected devices shall not be accepted and you will be contacted to pay the relative

disinfection costs.

International health standards require shipments of biological hazard material to be effected in standard

containers (risk of sanctions).

Do not remove the frame panels of the unit during cleaning operations.

Disconnect the power supply before any operation.

Do not use direct or high-pressure water to clean the unit.

For safety reason, any operation without the personal protective equipment must be

avoided.

It is recommended to use polyphenolic based disinfectants to clean and disinfect the instrument.

For further information, please contact the manufacturer: application@milestonemedsrl.com.

Complying with directive 2012/19/EC of the European Parliament and of the Council of 4 July 2012 on waste

electrical and electronic equipment (WEEE), the separate collection environmental managed of equipment is

mandatory.

It is necessary to return the used equipment to the distributor or to inquire about the presence of a local

empowered system for collection and disposal of WEEE.

The in-observance of Directive 2012/19/EC or of the local law which acknowledge it can have potential effects

on the environment and human health.

This symbol indicates separate collection

for electrical and electronic materials

If additional requirements on accident prevention and environmental protection exist in the country of

operation, this instruction manual must be supplemented by appropriate instructions to ensure compliance to

such requirements.

Waste disposal of the reagents

Vapours may collect in empty containers. We therefore recommend treating empty

containers as hazardous waste.

Waste material should be disposed of in an approved incinerator or in a designated landfill

site, in compliance with all provincial and local government regulation.

Certain reagents may have effects on health and cause environmental pollution.

For further information please refer to the SDS (Safety Data Sheet) provided by your supplier.

11

Page 12

PRESTO PRO MM136-002 – Operator Manual

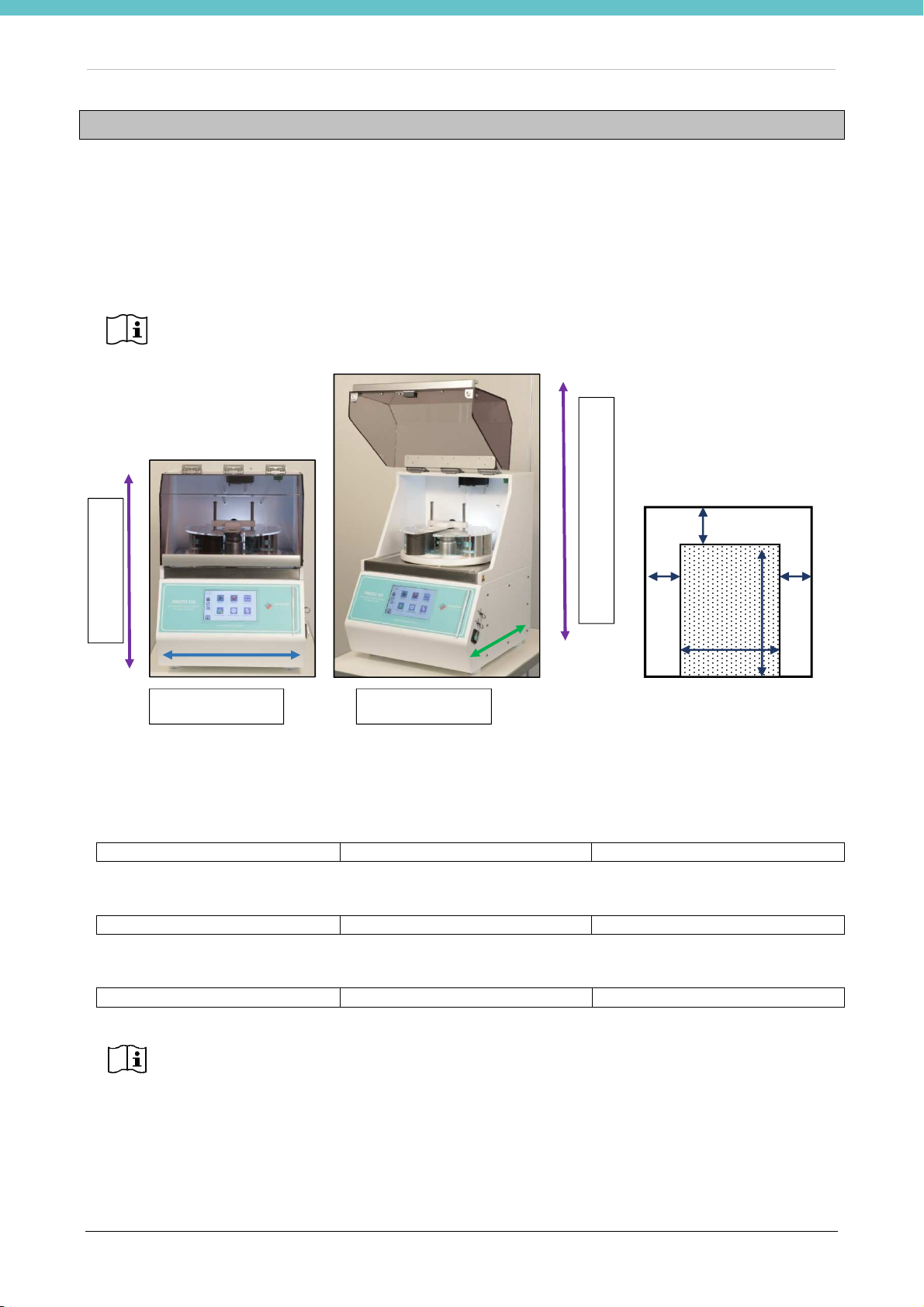

20cm

20cm

20cm

44cm

50cm

2. INSTALLATION

Milestone PRESTO PRO is an instrument that requires the utmost attention when unpacked and installed.

Arrange a bench at least 84cm (33in) wide and 70cm (27.5in) deep able to withstand the weight of PRESTO

PRO which is 42Kg (92.5 lbs).

Then place PRESTO PRO on the bench, ensuring the unit is level and the table is not flammable and vibration

proof. Ensure the instrument is positioned away from heat sources or from direct sunlight. Finally, ensure the

box collecting excess reagents is in the proper position.

Ensure the unit is not placed against any side surface thus restricting intake/outlet cooling

air: leave at least a 20cm (7.9in) distance on each side.

Maximum height 860 mm

Height 610 mm

Width 440mm Depth 525mm

2.1. Space requirements

PRESTO PRO is shipped in a wooden case with the following dimensions:

Width: 580mm (23in) Height: 1000mm (39.4in) Depth: 1050mm (41.3in)

Unit dimensions:

Width: 440mm (17.3in) Height: 610mm (24in) Depth 525mm (20.7in)

Dimensions of the space required to place the unit

Width: 840mm (33in) Height: 900mm (35.4in) Depth: 725mm (28.5in)

The MINIMUM depth required for the bench is 725mm (28.5in).

PRESTO PRO is a heavy instrument. Ensure the bench can withstand it.

At least two people are necessary to move and unpack the instrument.

12

Page 13

PRESTO PRO MM136-002 – Operator Manual

2.2. Unpacking and check list

On opening the package ensure all parts are present by checking the list attached with the shipment. The

utmost attention must be paid during PRESTO PRO unpacking to prevent scratches or damage to the body.

The PRESTO PRO system (REF 100300 and REF 100301) includes the following components:

• Qty.1 Main power supply cable (Code 50036 for 230V version)

• Q.ty. 1 Exhaust tube with 2 metal clamps (Code 61410)

• Qty. 1 20µm water filter (Code 100180L) with two G 1/2’’ connectors (Code 68278)

• Qty. 2 Water pipe 2m (Code 68309)

• Qty. 3 Electro-polished steel rack for 6 slides (Code 100177)

13

Page 14

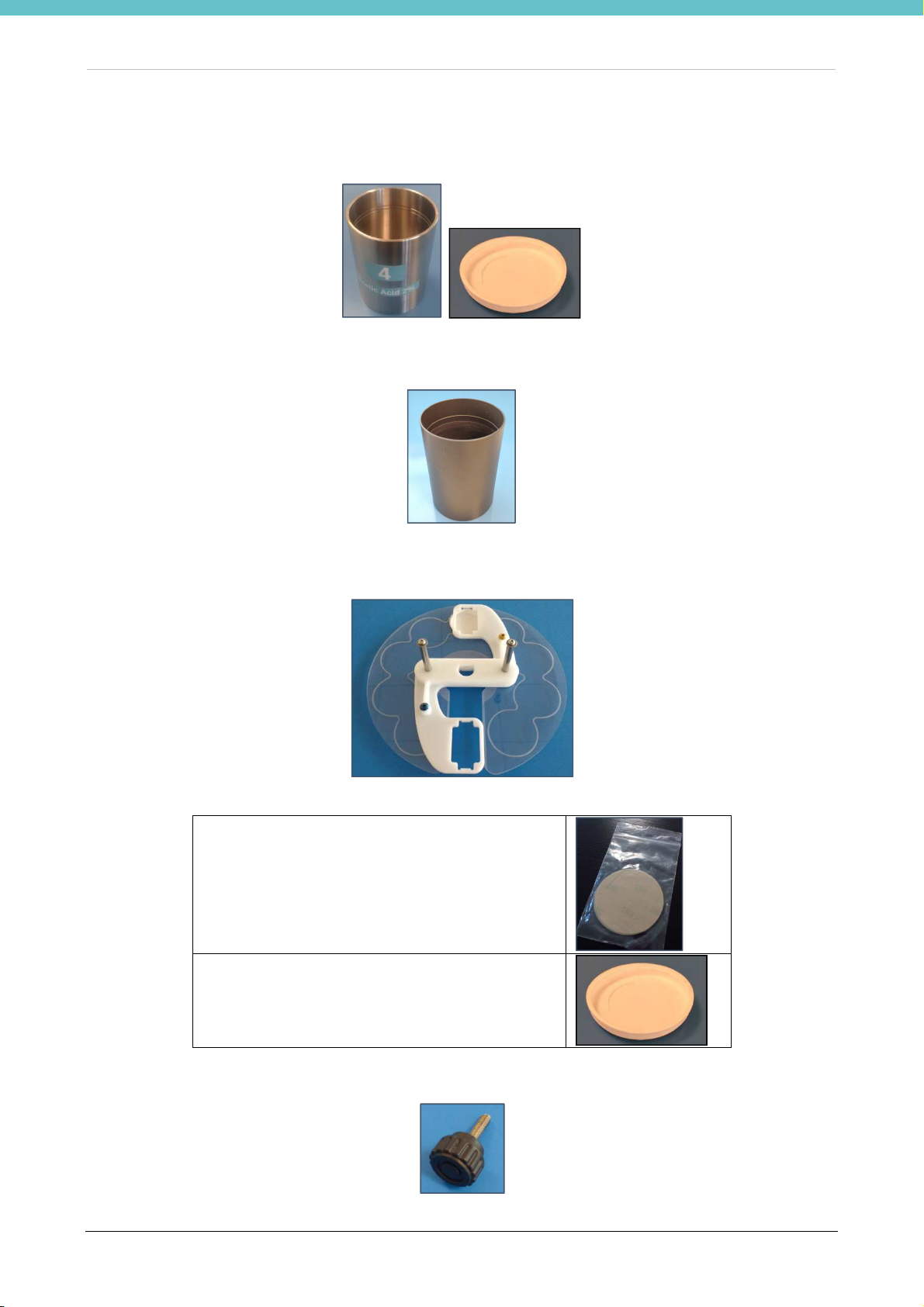

PRESTO PRO MM136-002 – Operator Manual

Code

100323

Code 100212

• Qty. 10 Steel reagent container (Code 100197). Eight containers are labelled and designated for the

positions in the PRESTO PRO. The other two are for transporting the slides from the cryostat and the

stained ones to their place of assembly.

• Qty. 1 Aluminum vessel for heated reagents (Code 100344)

• Qty. 1 Reagent container cover disc (Code 100375)

Consisting of:

10 protective polyester discs (

Cover of the second position (

)

)

• Qty. 1 Safety screw of the reagent container cover disc (Code 100348)

14

Page 15

PRESTO PRO MM136-002 – Operator Manual

• Qty. 1 Tray for vessels (Code 100367)

• Qty. 1 Kit reagent labels (Code 100356)

White labels

for customization

of reagents

• Qty.1 Magnetic pen to work with the touch screen terminal (Code 50597/M)

• Qty.1 Operation manual in electronic form

• Q.ty 1 Linear barcode reader (Code 370059)

15

Page 16

PRESTO PRO MM136-002 – Operator Manual

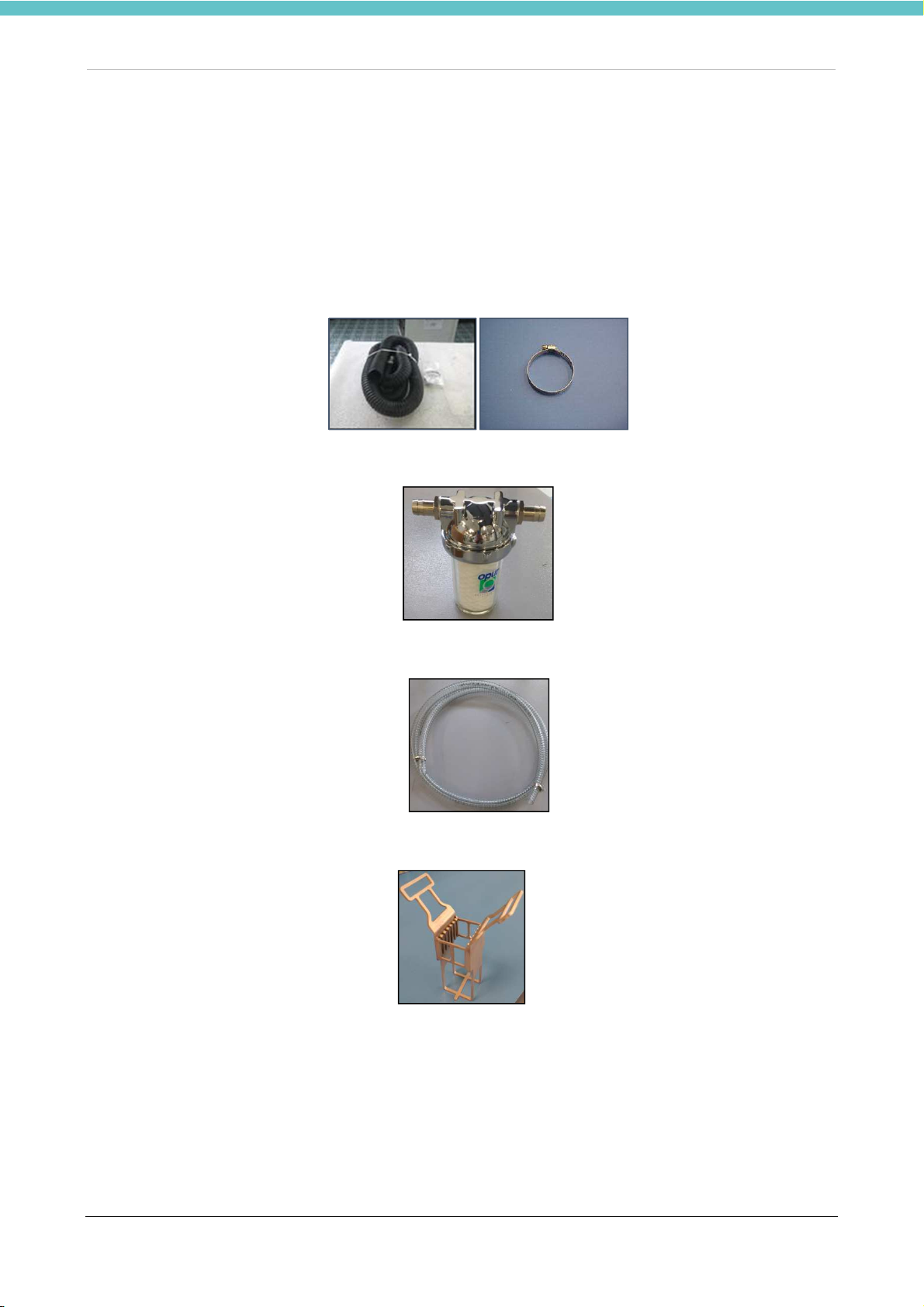

2.3. Fume extraction system

PRESTO PRO is ventilated through the external exhaust outlet located at the rear of the instrument, with a

pipe connected to the fume extraction system (if any).

The external fume extraction system must be properly installed at all times, according to

local regulations in force on laboratory safety.

The customer is required to adapt the hose connector. The plastic hose supplied has these specifications:

• Length: 3m

• Outer diameter: 69mm

• Inner diameter: 60mm

The external fume extraction system must assure an air flow of 40m3/h

(cubic meter per hour).

There is no filter on the fume extraction system of the unit.

it is possible to connect an external exhaust fume extraction kit (Code 61550/F), please refer

to chapter 9.1.

Connect the exhaust tube (Code 61377) to the appropriate outlet on the back panel.

Use the metal strap to fasten the pipe to the fume exhaust duct. (Code 50051).

Now connect the other end of tube to the fume extractor of the laboratory.

16

Page 17

PRESTO PRO MM136-002 – Operator Manual

It is mandatory to install the water filter between the tap and the

water inlet in the PRESTO

2.4. Water fitting

The PRESTO PRO unit is to be connected to the water system in order to work properly. On the back of the

unit are the ports for water inlet (left) and drain (right), pictured below.

Connect the (cold) water pipe to the water inlet at the rear of the unit. Gradually open the water "supply".

Connect the drain pipe to the water outlet at the rear of the unit.

PRO. The filter prevents the formation of limestone and dirt in the water system of

PRESTO PRO.

The filter fittings are G 1/2’’.

In order to simplify the replacement of the filter cartridges, it is important to have a tap

upstream of the filter, as pictured below.

Milestone recommends working in cooperation with the hospital’s clinical engineering

department when installing the water system of PRESTO PRO.

Water connections:

Water inlet: connection for a 17mm pipe (with G 1/2’’ fitting)

Water outlet: connection for a 17mm pipe (with G 1/2’’ fitting)

The minimum difference in height between the water outlet and the water system is at

least 50cm (19.7in), otherwise the system does not drain water properly.

Ensure the drain pipe has a slope of approximately 10cm (4in) for every meter.

Incoming water pressure: maximum 2bar, minimum 1bar

Milestone recommends using a water softener.

17

Page 18

PRESTO PRO MM136-002 – Operator Manual

2.4.1. Water drain

The drain water is polluted with the reagents in which the rack is dipped before rinsing.

The amount of reagent that a fully loaded rack (6 slides) takes in is about 1 – 1.5ml. Therefore, the drain water

of a standard process, with water flow duration 30 seconds, contains about 1.5ml FineFIX, haematoxylin and

2% acetic acid. In other words, the concentration of these substances in the drain water is about 0.075%

FineFIX and haematoxylin and 0.0015% of acetic acid.

The waste water may contain pathogens and must be connected according to local

regulations.

In the interest of safety, the operator must be present throughout the entire process.

18

Page 19

PRESTO PRO MM136-002 – Operator Manual

Before connecting the plug to the laboratory’s socket, check that the power supply voltage

2.5. Electrical installation

2.5.1. Power supply

The power supply line needs to be grounded. The earthing connection of the

power supply socket must be designated and come directly from the electrical distribution board of the

laboratory.

Carefully ascertain that:

• There is an earthed connection in the laboratory. Do not connect Milestone units without earthing

connection.

• The power cords (size and distance from the electric board) are compliant with the label on the back

of the unit.

• The socket is visible and accessible.

The power supply line needs to be grounded (Class I device).

Power line protection:

115V version: Miniature circuit breaker curve C, 15A, residual current device: 30mA.

230V version: Miniature circuit breaker curve C, 10A, residual current device: 30mA.

A power cord is supplied with Schuko plug.

of the unit matches the power supply line of the laboratory.

Damage occurs if the instrument is supplied with incorrect power supply.

19

Page 20

PRESTO PRO MM136-002 – Operator Manual

3

1

2

4

5

6

7

8

9

1

2

3

4

5

6

7

2.6. Final placement

The PRESTO PRO unit may now be placed in its final position of use. Ensure the unit is level.

Then connect:

The main power supply cable to the power plug located at the rear of the unit, then plug the power supply

cable into the socket.

Now it is possible to switch PRESTO PRO on.

2.7. General description

1. Work area cover

2. Intake

3. Disc covering the reagents

4. Reagent vessels

5. Tray of the reagent vessels

6. Touch screen terminal

7. USB ports

8. Main power switch

9. Collecting tray (Code 100360) BEA

1. Arm with rack supports

2. Standard rack position (BLUE)

3. Secondary rack position (YELLOW)

4. Reagent containers

5. Water container

6. FineFIX Container

7. Tray of the reagent containers

20

Page 21

PRESTO PRO MM136-002 – Operator Manual

2.7.1. Remove or place the reagent cover disc

Removal of the reagent cover disc is required for reagent change operations and for PRESTO PRO cleaning

and maintenance.

To remove the disc, move the safety screw of the covering disc to the front, moving the arm of the standard

position (BLUE) back (see section 2.7.7).

In case of filling or changing the reagents or for cleaning PRESTO PRO press the icon of the reagent

management page: the software automatically moves the arm in that position (see chapter 2.15).

At this point, loosen the screw and lift the rack support, which allows the covering disc to be extracted as it is

connected to it. Pay attention not to hit the reagent vessels.

Upon completing the operations that required disc removal, always place it back in position.

Always place the disc back in position to prevent excessive evaporation of the reagents

and preserve their cleanliness.

To put the covering disc back in position, place it on the central piston so that the standard position (BLUE) is

at the back; the hole for the safety screw is visible and the hole engages to the base of the arm. The hole in

fact has a semicircular shape with one straight side, which must be positioned in front of the operator. Place

the safety screw and tighten it, while holding the rack support steady.

Always tighten the safety screw completely.

21

Page 22

PRESTO PRO MM136-002 – Operator Manual

2.7.2. Add protection labels to the disc covering the reagents

The cover disc is in direct contact with the reagents and in some cases, it needs greater protection. Some vinyl

labels are supplied together with the reagent cover disc, which make the disc more resistant once they are

applied.

Milestone recommends to reinforce the protection disc in the positions where the following reagents are:

• acids

• alcohol solvents (ethanol, isopropanol)

• xylene and xylene substitutes (isoparaffin, limonene)

For further information, please contact: application@milestonemedsrl.com.

Underneath the disc there are slots to indicate the position for the protection labels. Turn the cover disc over

and apply the label in the appropriate position, following the guide markings.

2.7.3. Cover of the second loading position

The reagent covering disc has a hole at the secondary loading position (marked in yellow) so that it can be

used. This hole can be closed when the protocols are not used continuously, in order to reduce evaporation

of the reagents.

Remove the reagent covering disc and, while holding the arm raised, place the cover on the hole and push it

downwards until the hole is completely covered.

Remove the cap to use the second loading position (yellow).

22

Page 23

PRESTO PRO MM136-002 – Operator Manual

Secondary

Standard

2.7.4. Loading positions of the racks on the arm of the PRESTO PRO

The arm of the PRESTO PRO has two loading positions for racks:

The standard loading position: it is the position used for all the standard protocols and for all the odd

numbered cycles of the “Continuous” protocols, and is marked in blue

The secondary loading position: it is the position used only for even numbered cycles (from the second

cycle onwards) of the “Continuous” protocols, and is marked in yellow.

This manual refers to the standard loading position, in blue, unless specified otherwise.

loading

position

loading

position

2.7.5. Remove or replace the caps to the reagent vessels

The reagent vessels are fitted with a cap that prevents evaporation and oxidation of the reagents. The caps

must be removed before any process and it is suggested to place them back after using PRESTO PRO if it is

not going to be used for a long time (more than 24 hours).

Remove the cap while holding the vessel steady and with a slow and gentle movement to prevent the vessel

from moving and spilling the reagent. After removing the cap clean it from any trace of reagent and set it aside

(for instance, in the space behind the reagent vessel tray).

Place the cap back while holding the container and with a slow and gentle motion paying attention not to spill

out the reagent in the vessel.

It is possible to apply a label with the number on the cap, so as to always use the same cap for each vessel.

Use the Kit of reagent labels (Code 100356).

23

Page 24

PRESTO PRO MM136-002 – Operator Manual

2.7.6. Remove or place the tray of reagent vessels

The support disc of the vessels is required for correct positioning of the reagent vessels.

To remove the support disc (for the purpose of cleaning), remove the reagent protection disc (refer to chapter

2.7.1) and all the reagent containers (do not remove the container in position 3 which is for water).

It is required to bring the PRESTO PRO arm to lower position, preferably in the 5DOWN position with arm

turned backwards (see section 2.7.7). Press the icon of the reagent management page: the software

automatically moves the arm in that position (see chapter 2.15).

Lift the support disc and extract it from the water container and the housing for the fixative container.

Remove the support disc without fitted vessels.

To replace the support disc, insert its central hole in the arm shaft, turn the disc so that the number 10 on the

disc label is in front of the operator and the metal water glass and support for the FineFIX container go through

the side holes.

24

Page 25

PRESTO PRO MM136-002 – Operator Manual

2.7.7. Reagent positions inside PRESTO PRO

The slide rack support may make two movements:

• circular motion to move the rack in one of the 10 reagent positions

• vertical motion to lift the rack for moving from one reagent and lower it for dipping in another. In every

position, the vertical movement also allows to perform:

- dripping to move the rack up and down in the reagent, so as to stir the reagent and achieve

better contact between specimen and reagent.

- dipping to shake the rack in order to remove excess reagent from the slide (this function is

recommended after staining reagents).

There are 10 positions inside the PRESTO PRO and they are numbered clockwise:

• Position 10: position immediately in front of the operator. It may be:

- 10UP, PRESTO PRO reset position

- 10DOWN, standby position where the cover disc closes the reagent vessels to prevent

evaporation.

• Position 1 In this position the reagent vessel is designated for FineFIX for specimen processing. This

is the only heated position of PRESTO PRO.

Position 1DOWN with arm lowered is the loading position of the rack at the start of a process.

25

Page 26

PRESTO PRO MM136-002 – Operator Manual

• Position 3: This position is fixed and designated for the rinse water reagent, the flow of which is

regulated automatically.

• Position 5DOWN Position taken for reagent change that assures simple removal of the cover disc.

• Positions 2, 4, 5, 6, 7, 8, 9 and 10: these positions are designated for the staining and cleaning

reagents. The reagents set by default in these positions are those used in the default HIGH QUALITY

program recommended by Milestone (refer to chapter 3.2). The reagents in these positions are not

fixed and may be set by the user, refer to chapter 4.3 Setting the configuration of reagents .

2.7.8. Connect the barcode reader

Connect the reader’s USB to one of the USB ports on the right side of PRESTO PRO.

26

Page 27

PRESTO PRO MM136-002 – Operator Manual

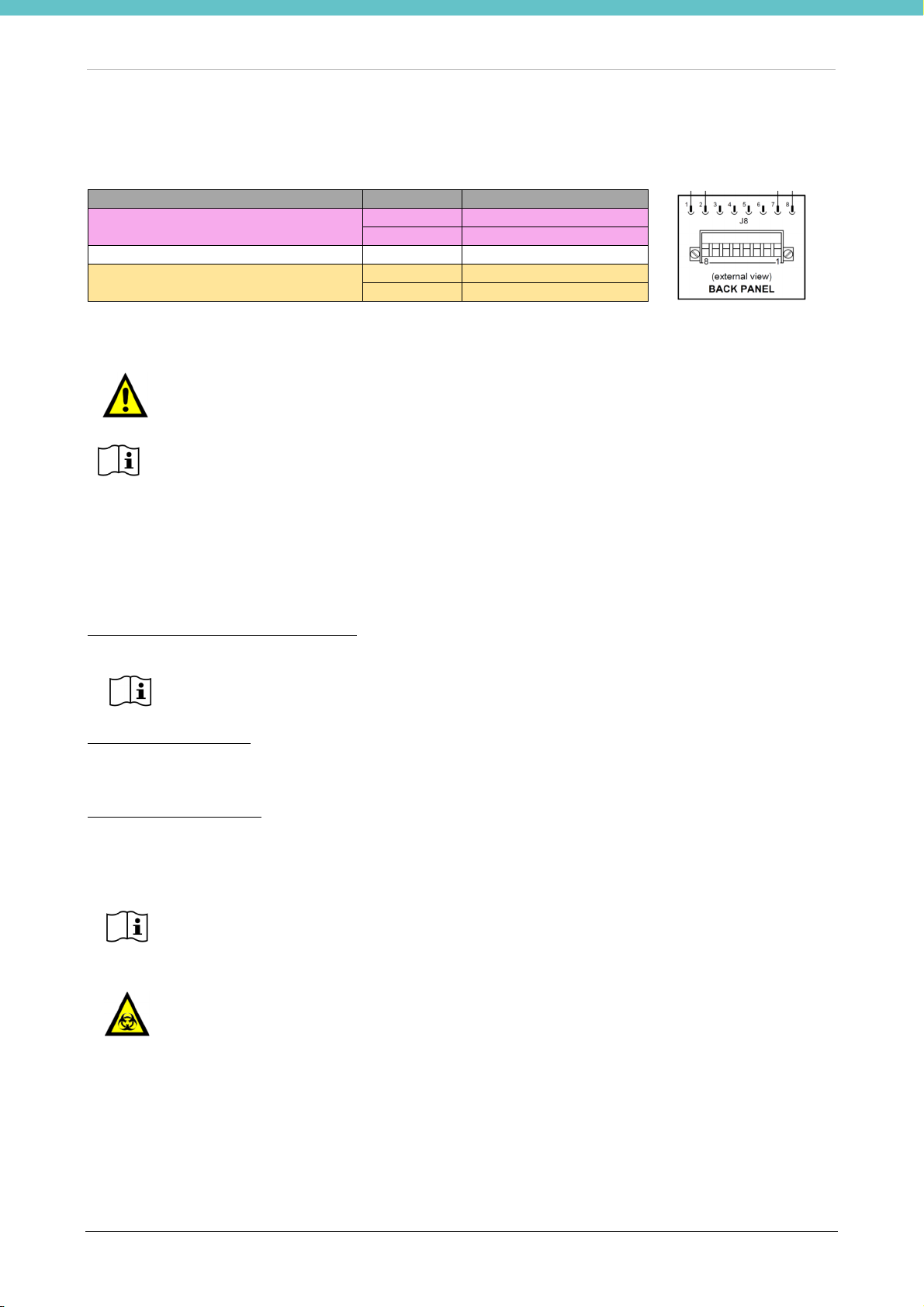

1

2

3

4

5

6

7

8

2.7.9. Rear panel

The following are found on the PRESTO PRO rear panel:

1. Connection to the fume extraction system

2. External alarms connector

3. Ethernet/LAN connection

4. General fuses

5. Spare fuses

6. Power plug

7. Label with serial number

8. Water inlet/outlet connections

27

Page 28

PRESTO PRO MM136-002 – Operator Manual

Reagent REQUIRED for operation: FineFIX Concentrate (5L tank: REF: 70148 or 10L

Please refer to manual MM029 for proper usage and dilution of FineFIX.

Handle reagents with care and store in a cold dry space using a tightly closed container.

2.8. Remote alarm connection

PRESTO PRO is also fitted with connection for external alarm devices.

Output Contact Status

1. Identifies the alarm status of the

PRESTO PRO

…

2. External pump command,

24Vdc 1A max output

Output 2, for the external pump, can be used only for demonstration purposes. It is strictly forbidden to use the

contact for auxiliary pumps during operation with histological samples.

For safety reasons and to prevent damages to the internal relays, the voltage of the

external devices that are connected to PRESTO PRO must be lower than 24 VDC - 1A.

See also the equipment's label which provides some important information.

Always provide the unit's serial number to Customer Support.

1 Normally OPEN

2 COMMON alarm

7 +0Vdc 1A max Pump

8 +24Vdc 1A max Pump

2.9. Reagents

Complete the set up with reagents, by providing at least:

FIXATION/PROCESSING REAGENTS:

• 200mL of diluted FineFIX

tank: REF: 70149) is not included in the unit, to be ordered apart.

STAINING REAGENTS:

• 200mL Hematoxylin

• 200mL Eosin

CLEANING REAGENTS:

• 200mL of Isopropanol

• 200mL 2% Acetic Acid in water

• 400mL 100% Ethanol (2 vessels).

The above reagents must be on site and available at the time of unit installation.

Vapours may build up in the vessels. Treat empty vessels as hazardous.

Waste reagents are to be disposed of in suitable incinerators, in compliance with all local,

regional and state laws.

For further information please refer to the SDS (Safety Data Sheet) provided by the

reagent’s supplier.

28

Page 29

PRESTO PRO MM136-002 – Operator Manual

2.10. Accessing and exiting the system

When the System is switched on, the LOG IN screen is displayed by default. Press the “Admin” button, enter

the password (published in the separate document inserted in the Operation Manual) and press “Enter”.

THE MAIN ADMINISTRATOR PAGE is displayed which shows the MAIN FUNCTIONS.

In any screen, press the HOME button to go back to the MAIN PAGE.

The MAIN PAGE may be customized in the USERS settings, choosing from FAVOURITE and MAIN

FUNCTIONS (see chapter 2.11).

Log-in as SERVICE is only available for authorized persons.

SERVICE has full access to all functions.

29

Page 30

PRESTO PRO MM136-002 – Operator Manual

2.11. Create a new user

Access the “Settings” screen by pressing the icon which is in the status bar on the left, then in the new

screen select “Users” to create a NEW USER.

The USERS setting screen is displayed, as shown below. Click on Add, a keyboard appears. Enter the NEW

USER name and press “Enter”.

Now select and configure the parameters of the NEW USER choosing the:

• CATEGORY.

• USER PASSWORD: click on the password box, a number pad appears as shown below, enter the

password (max 6 digits and minimum 1) and confirm.

• USER CONFIGURATION: select the control box “Set ‘Favourites’ as Home Page” in order to have the

FAVOURITE PROGRAMS set as the new user's main page.

30

Page 31

PRESTO PRO MM136-002 – Operator Manual

Ask p

assword for processing

Ask password for reagent replace

Now select the appropriate FUNCTIONS for the NEW USER:

WHEN MARKED the new USER can:

Create and edit programs

Replace waste reagents

Set reagent position, open the list of reagents and edit

reagents details

By pressing the arrow (see picture below) it is possible to choose the appropriate ACCESS LEVEL upon

program start “Ask for USER and PASSWORD” or “Automatically login as ADMINISTRATOR”.

The following screen is displayed:

Select:

procedure

procedure

The software recognizes who starts the program (through

password).

The software recognizes who is performing the reagent replace

procedure (through password).

31

Page 32

PRESTO PRO MM136-002 – Operator Manual

2.12. Changing the language

From the HOME PAGE, go to the “Settings” screen and select “Language” (see figure below).

Choose the required language from the drop down menu then press OK and Yes below the message displayed

and the system automatically reboots to enable the changes.

32

Page 33

PRESTO PRO MM136-002 – Operator Manual

2.13. Set Date and Time

Access the “Settings” screen from the MAIN PAGE by pressing the icon which is on the status bar on

the left, then in the new screen select “Date/Time”.

In the time setting window, it is possible to set the Time Zone, thus activating the automatic time update

throughout the year.

2.14. Fill the FineFIX reagent in the PRESTO PRO

2.14.1. Load the consumable changes

On each container of FineFIX there is a barcode to enable the use of PRESTO PRO and for counting the

reagent changes.

The barcode of a FineFIX 5L container (REF 70148) fills about 100 changes.

The barcode of a FineFIX 10L container (REF 70149) fills about 200 changes.

The amount of diluted FineFIX obtained with these containers is higher than required to perform the number

of changes loaded. The FineFIX that can be prepared in excess is intended for maintenance of wet slides, up

to loading in the PRESTO PRO, please refer to chapter 3.1.

33

Page 34

PRESTO PRO MM136-002 – Operator Manual

2.14.2. Sequence of software activation

Select the icon “FineFIX code”

Select “Recharge FineFIX loads”

These icons are on the FineFIX heater page.

Insert the FineFIX barcode with the reader or manually (in this case press ENTER)

The “FineFIX Heater” page indicates the available

number of loads.

It is now possible to load the code of another container

of FineFIX or fill in the vessel in position 1 of the

PRESTO PRO with the reagent, please refer to next

chapter.

The software accepts each code once.

There is a warning threshold in the “Owner settings” section (chapter 2.17), by default it is 10 loads.

When the available loads fall below this threshold, the reagents icon shows a yellow symbol, which indicates

that it will be shortly required to load another code.

34

Page 35

PRESTO PRO MM136-002 – Operator Manual

2.15. Load the reagents in the PRESTO PRO vessels

Follow the procedures below to load the PRESTO PRO with the staining reagents.

2.15.1. Labels

Each glass has two labels:

1. POSITION NUMBER

2. REAGENT NAME

Eight glasses already have the label with numbers up to 10, except for number 1 as this position is for the

aluminum container for the heated reagent, and number 3 as the container in this position is fixed and intended

for flushing water.

Place the label with the reagent name on the numbered glasses based on the configuration required for

staining, see section 2.7.7. The picture below shows an example of the rinsing ethanol in position 6.

Some white labels are available for customization of reagents (see chapter 2.2).

35

Page 36

PRESTO PRO MM136-002 – Operator Manual

2.15.2. Load fixation, staining and cleaning reagents in the PRESTO PRO

Select “Reagents” from the MAIN FUNCTIONS screen.

The slide rack support goes into position 5DOWN (see chapter 2.7.7), and the reagent in vessels management

screen is displayed (picture below right).

Reagents of the vessels loaded in the PRESTO PRO are divided into three categories, for diversified

management of reagents:

1. FIXATIVE

Milestone recommends the use of FineFIX as fixation reagent to achieve better quality results.

Thanks to its special composition, FineFIX fixates, dehydrates and clears the sample.

FineFIX is a concentrated reagent that is to be diluted in ethanol for use.

Please refer to manual MM029 for preparation of FineFIX to the work dilution and its usage.

To replace/load the fixation reagents select the Fixative section (blue circle in the picture below).

Tap the “Replace fixative reagents” box to open the reagent change page and update the date and clear the

number of cycles made by the fixative reagents.

Open the lid and remove the reagents cover disc, refer to chapter 2.7.1

Then remove the fixation reagents vessels. The software indicates the positions and short name of the glasses

containing the fixation reagents and shows a diagram of reagents configuration.

Glasses have labels with the position number and name of the reagent that help not to mix them up.

In the procedure to replace reagents, after emptying the glasses, it is advisable to clean them with paper in

order to remove any precipitate.

36

Page 37

PRESTO PRO MM136-002 – Operator Manual

T

he inside of the vessel has two etched lines, which indicate the MAX and MIN level (see

Add 160mL of reagent in the vessel and slowly and carefully place it back in the position indicated by the

software (position 1).

photo below). Keeping the reagents within the two levels assures proper staining of

specimens. Milestone recommends keeping the fixation and staining reagents level to the

minimum and the cleaning reagents to the maximum.

The vessel is to be placed inside the heating housing for the fixation reagent.

At the end of the procedure press the icon to go back to the reagent management page.

The fixation reagent is to be heated and brought to the operating temperature. If the heater is on, the following

message is displayed, asking to wait 5 minutes for the reagent to be ready before starting a process:

Press OK to complete the procedure.

At this point, the date and number of cycles performed by the fixation reagents are cleared.

It is possible to start a process before the heating time. Milestone recommends waiting for

the reagent to heat.

37

Page 38

PRESTO PRO MM136-002 – Operator Manual

The inside of the vessel has two etched lines, which indicate the MAX and MIN level (see

2. STAINING

To replace/load the staining reagents select the Staining section (blue circle in the picture below).

Tap the “Replace staining reagents” box to open the reagent change page and update the date and clear the

number of cycles made by the staining reagents.

Open the lid and remove the reagents cover disc, refer to chapter 2.7.1

Then remove the staining reagents vessels. The software indicates the position and short name of the glasses

containing the staining reagents and shows a diagram of reagents configuration.

Glasses have labels with the position number and name of the reagent that help not to mix them up.

In the procedure to replace reagents, after emptying the glasses, it is advisable to clean them with paper in

order to remove any precipitate.

Add 200mL of reagent in each vessel and slowly and carefully place it back in the position indicated by the

software.

photo below). Keeping the reagents within the two levels assures proper staining of

specimens. Milestone recommends keeping the staining reagents level to the minimum and

the cleaning reagents to the maximum.

38

Page 39

PRESTO PRO MM136-002 – Operator Manual

The vessel is to be placed inside the housing in the vessel tray. On this tray, positions are indicated by a central

label.

At the end of the procedure press the icon to go back to the reagent management page. At this point,

date and number of cycles performed by the staining reagents are cleared.

3. CLEANING

To replace/load the cleaning reagents select Cleaning reagents (blue circle in the picture below).

Tap the “Replace cleaning reagents” box to open the reagent change page and follow the instructions given

by the software as instructed above for the staining reagents.

At the end of the procedure press the icon to go back to the reagent management page. The date and

number of cycles made by the cleaning reagents will be reset to zero.

At the end of these operations, log out from the reagent change page by pressing the HOME icon.

39

Page 40

PRESTO PRO MM136-002 – Operator Manual

The right operating temperature of FineFIX is between 35 and 40°C

(95°F and 104°F)

. Within

Now the icon will no longer have the STOP red symbol.

2.15.3. FineFIX heating settings

FineFIX is the only reagent in PRESTO PRO that is used at a temperature other than room temperature.

Upon first switching on the unit FineFIX heating is not active and the relevant icon in the settings screen shows

a red symbol at bottom right (see picture below left).

For settings of the FineFIX reagent maintenance temperature, select “FineFIX heater” from the MAIN

FUNCTIONS screen. The “FineFIX heater” page shows that the heater is OFF.

Switch on FineFIX heating by clicking on the “ON” button in the center of the screen (picture at top right).

Heating enabled can only be set by ADMINISTRATOR and users authorized to modify the

reagents (Chapter 2.11).

this range, FineFIX is able to process and fixate tissue sections up to 6 µm thick in 15

seconds, with high quality results.

At this point, heating is enabled and brings the reagent to the set temperature. The time required to reach the

temperature varies from 10 to 20 minutes and depends on the laboratory and reagent temperature.

The icon shows an orange warning dot until the set temperature is reached. In this case, it is not advisable to

start a process but it is possible by replying YES to the following message displayed when the process is

started up:

40

Page 41

PRESTO PRO MM136-002 – Operator Manual

When the maintenance temperature is reached, heating status becomes “ready”, the icon no longer shows the

warning symbol and the process may be performed using the reagent at the optimal temperature.

41

Page 42

PRESTO PRO MM136-002 – Operator Manual

2.16. Most used programs

This function lets you insert FAVOURITE programs in the MAIN PAGE.

Access the “Settings” screen by pressing the icon which is on the status bar on the left and the

•

icon then select “Set favourites”. The “Choose the Favourite to set” page is displayed.

Press the “Not defined” icon.

•

Select the “Program” and Colour of the button.

•

The “Preview” is displayed at bottom left (see picture below).

Press “Save Favourite” to save changes.

•

The icon of the new program is now visible in the list of the "Choose the Favourite to Set" screen.

•

42

Page 43

PRESTO PRO MM136-002 – Operator Manual

If the user's main page is set as FAVOURITES (picture at bottom left), press to go back to the main

•

functions page.

If the main page is set as MAIN FUNCTIONS (picture at bottom right), press “Favourites” to open the screen

shown at bottom right.

43

Page 44

PRESTO PRO MM136-002 – Operator Manual

GENERAL

VENTILATION

2.17. Owner Settings

This function is available only for SERVICE and ADMINISTRATOR.

Access the “Settings” screen by pressing the icon which is on the status bar on the left, then select the

settings page by pressing the icon , then in the new screen select “Owner”.

The Owner's settings screen is displayed as shown in the pictures below.

Select “General” to modify:

Institute name where the unit is installed.

•

Department name where the unit is installed.

•

Consumable alert threshold of the number of

•

available loads below which the software alerts

to the need to load the FineFIX code (see

chapter 2.14.1).

By default, the threshold is set to 10 loads.

Select Ventilation to manage the work area's

extraction:

• Always ACTIVE: extraction is activated when

the machine is switched on.

• Always OFF: extraction is always off, even

during processing.

NOT RECOMMENDED.

Risk of fumes in the laboratory.

• Processing and cover opening: extraction is

only activated during the process and when the

cover is opened.

44

Page 45

PRESTO PRO MM136-002 – Operator Manual

ENABLES

INTERNET CONNECTION

Select “Enable” to choose whether to enable or not:

• Water during the entire run

• Sound 10 seconds before the end of the run

To connect PRESTO PRO to the internet.

MILEWATCH

Not available.

45

Page 46

PRESTO PRO MM136-002 – Operator Manual

3. USE PRESTO PRO

Milestone PRESTO PRO is controlled by a Touch Control Terminal, based on Windows CE 7.

Milestone PRESTO PRO has been specifically designed to fixate, process and stain slides for extemporaneous

diagnoses in a quick, reliable and standardized manner.

3.1. Loading slides in the rack

PRESTO PRO's rack can house up to 6 slides.

Insert the slides in the rack, gently, sliding them between the appropriate partitions.

To keep the slides wet, keep them immersed in FineFIX, using the reagent vessel with the specific label

“Cryostat FineFIX”.

While loading the slides in the rack, keep the rack immersed in FineFIX, to prevent the

specimens from drying.

It is important to ensure the “Cryostat FineFIX” is clean. Milestone recommends changing

it at least once a week.

3.2. Run a program

The default protocols on the PRESTO PRO are:

ULTRA QUALITY, which lasts 3 minutes and 52 seconds:

STEP. VESSEL REAGENT TIME

(sec)

1 1 FineFIX 60 35-40°C (95—104°F) YES NO

2 3 Water 10 Room YES NO

3 2 Haematoxylin 30 Room YES YES

4 3 Water 10 Room YES NO

5 4 Acetic ac. 4 Room YES NO

6 3 Water 4 Room YES NO

7 5 Eosin 14 Room YES YES

8 6 Ethanol 10 Room YES NO

9 8 Ethanol 10 Room YES NO

10 7 Isopropanol 10 Room YES NO

HIGH QUALITY, which lasts 2 minutes and 18 seconds

STEP. VESSEL REAGENT TIME

(sec)

1 1 FineFIX 15 35-40°C(95—104°F) YES NO

2 3 Water 5 Room YES NO

3 2 Haematoxylin 15 Room YES YES

4 3 Water 5 Room YES NO

5 4 Acetic ac. 1 Room YES NO

6 3 Water 3 Room YES NO

7 5 Eosin 5 Room YES YES

8 6 Ethanol 7 Room YES NO

TEMPERATURE IMMERSION DRIPPING

TEMPERATURE IMMERSION DRIPPING

46

Page 47

PRESTO PRO MM136-002 – Operator Manual

The first two steps of the program are fixed: it is not possible to change position and reagent

Water steps cannot last less than 3 seconds.

Milestone recommends using the following working solutions:

9 8 Ethanol 7 Room YES NO

10 7 Isopropanol 5 Room YES NO

CONTINUOUS, which lasts 2 minutes and 20 seconds

STEP. CONTAINER REAGENT TIME

(sec)

1 1 FineFIX 10 35-40°C (95—104°F) YES NO

2 3 Water 5 Room YES NO

3 2 Haematoxylin 15 Room YES YES

4 3 Water 5 Room YES NO

5 4 Acetic Acid 1 Room YES NO

6 3 Water 3 Room YES NO

7 5 Eosin 1 Room YES YES

8 6 Ethanol 10 Room YES NO

9 8 Ethanol 5 Room YES NO

10 7 Isopropanol 15 Room YES NO

TEMPERATURE IMMERSION DRIPPING

The Standard protocols (HIGH and ULTRA QUALITY) require the first cycle to end before the second one can

start.

The Continuous loading protocols allow another cycle to start even when the previous one is still in progress,

saving time as a result.

(FineFIX for step 1 and water for step 2).

When drawing up a new program, these stages cannot be deleted.

- Harris Haematoxylin

- 1% Alcohol eosin (with 0.1% Phloxine)

- 2% acetic acid in water

In the interest of safety, the operator must be present throughout the entire process.

47

Page 48

PRESTO PRO MM136-002 – Operator Manual

Before starting a process ensure the reagent vessels do not ha

ve the cap (see

chapter

3.2.1. Run a favourite standard protocol

For reasons of safety, if the cover of the work area is opened while the arm is moving, the

arm stops immediately.

2.7.5) and check proper reagent level, as they are subject to evaporation. The correct level

of reagents is between the two lines etched inside the vessel. Milestone recommends

keeping the staining reagents level to the minimum and the cleaning reagents to the

maximum.

Select a Favourite Standard Protocol (picture below) from the list of favourite protocols (see chapter 2.16).

The standard protocols do not have the word “CONTINUOUS” in the title.

The standard loading position (BLUE) of the slide rack goes in the loading position above the container in

position 1DOWN, ready to load the rack in the FineFIX container. Refer to chapter 2.7.7 for the positions in

the PRESTO PRO.

The support of the slide rack goes in the loading position above the vessel in position 1DOWN, ready to load

the rack in the FineFIX vessel. Refer to chapter 2.7.7 for the positions in the PRESTO PRO.

At the start of each process the software performs a water flow check which lasts few

seconds.

The screen to enter process data and to start it is displayed. Enter the number of slides in the rack, pressing

the number keys from 1 to 6, then enter “Case ID” and “Run ID” (process identification code) data. It is not

mandatory to enter any of this data.

The program is set already, based on the selected favourite, and cannot be changed.

48

Page 49

PRESTO PRO MM136-002 – Operator Manual

Open the PRESTO PRO cover and load the rack on the support, in position 1DOWN. Once closed, the START

button is displayed at bottom right: press this button to start a process.

The cycle starts only when the START button is pressed.

The processing screen is displayed, which shows process information.

On the left, the schematic depiction of the positions of PRESTO PRO's reagents, with the rack's position

highlighted in green and information concerning the stage in progress.

The following is displayed at top right: the selected protocol, the process identification code (if entered) and

the total process time. The remaining time before the end of the process is shown in the yellow box immediately

underneath.

Below are two examples of screens during processing: on the left during the FineFIX stage and on the right

while moving to the water cleaning stage after the haematoxylin phase:

Upon completing the process, the rack is kept immersed in the last reagent to prevent the specimens from

drying and a buzzer warns the user. Extract the rack.

The process ends when PRESTO PRO's cover is opened to remove the rack with the specimens.

49

Page 50

PRESTO PRO MM136-002 – Operator Manual

It is recommended

to close the reagent vessels with the relevant caps after using PRESTO

During a process, if required, press “A

bort” to stop the process and remove the rack with

Once the rack with slides is removed, the software goes back to the main screen.

PRO if it is not going to be used for a long time (more than 24 hours). Refer to chapter 2.7.5.

slides.

50

Page 51

PRESTO PRO MM136-002 – Operator Manual

Before starting a proce

ss ensure the reagent containers do not have the cap (see

chapter

3.2.2. Run a favourite “Continuous” protocol

For reasons of safety, if the cover of the work area is opened while the arm is moving, the

arm stops immediately.

2.7.5) and check proper reagent level, as they are subject to evaporation. The correct level

of reagents is between the two lines etched inside the container. Milestone recommends

keeping the staining reagents level to the minimum and the cleaning reagents to the

maximum.

With this type of protocol, a cycle can be started when the previous one is still in progress.

CYCLE 1 (Blue)

Select a Favourite Continuous Program (picture below) from the list of favourite protocols (see chapter 2.16).

The continuous loading programs have the word “CONTINUOUS” in the title.

The standard loading position of the slide rack goes in the loading position above the container in position

1DOWN, ready to load the rack in the FineFIX container. Refer to chapter 2.7.7 for the positions in the PRESTO

PRO.

At the start of each process the software performs a water flow check which lasts few

seconds.

A screen is displayed, in this case with blue background, for entering the data of the process and starting it.

Enter the number of slides in the rack, pressing the number keys from 1 to 6, then enter “Case ID” and “Run

ID” (process identification code) data. It is not mandatory to enter any of this data.

The protocol is set already, based on the selected favourite, and cannot be changed.

51

Page 52

PRESTO PRO MM136-002 – Operator Manual

Open the PRESTO PRO cover and load the rack on the support, in position 1DOWN. Once closed, the START

button is displayed at bottom right: press this button to start a process.

The cycle starts only when the START button is pressed.

The processing screen appears, which has two sections: the one on the left is for the process in the standard

position (BLUE) and the one on the right is for the process in the secondary position (YELLOW).

The following is shown in the left section when the first cycle starts: the selected protocol, the process

identification code (if entered) and the total process time. Immediately below are the timers counting down to

the end of the process and the end of the stage in progress. The yellow box provides information on the stage

in progress and the schematic depiction of the positions of PRESTO PRO's reagents, with the rack's position

highlighted in green and information concerning the stage in progress.

The section to the right shows the time remaining before the secondary position (YELLOW) can be used to

start a second cycle before the previous one has ended.

When the first cycle is in the Ethanol stage, the secondary position (YELLOW) of the arm is in the rack loading

position and a second cycle can therefore be started while the first is still in progress.

52

Page 53

PRESTO PRO MM136-002 – Operator Manual

The option of starting a second cycle is available while the ethanol stage of the first cycle is in progress (10

seconds). There is an audio alarm during this period of time and the time remaining to start the second cycle

and the button for starting it are shown in the right section of the page.

There are two courses of action:

A) If the second cycle does not need to be started, simply ignore the start button and the current cycle will

continue as normal.

In this case, the audio alarm can be silenced by pressing the relevant button in the bar on the right side

.

The following screen is displayed at the end of the first cycle and there is an audio alarm.

Remove the rack to end the cycle.

Once the rack with slides is removed and the cover of the work area is closed, the software goes back to the

main screen.

B) If other sections need to be processed/stained, press the start button to start the second cycle (yellow):

CYCLE 2 (Yellow)

A screen appears, in this case with yellow background, for entering the data of the process and starting it.

Enter the number of slides in the rack, pressing the number keys from 1 to 6, then enter “Case ID” and “Run

ID” (process identification code) data. It is not mandatory to enter any of this data.

The protocol is set already, based on the selected favourite. It is the same as that of CYCLE 1 and cannot be

changed.

53

Page 54

PRESTO PRO MM136-002 – Operator Manual

Open the PRESTO PRO cover and load the rack on the support, in position 1DOWN. Once closed, the START

button is displayed at bottom right: press this button to start the second cycle and continue the first.

The second cycle starts and the first continues only when the START button is pressed.

The processing screen appears. It has two sections: the one on the left is for the process in the standard

position (BLUE) and the one on the right is for the process in the secondary position (YELLOW).

When the second cycle starts, the two sections of the screen display the information of the relevant cycle: the

selected protocol, the process identification code (if entered) and the total time of the process, the time

remaining before the end of the process and before the end of the stage in progress, the information on the

stage in progress and the schematic depiction of the positions of PRESTO PRO’s reagents.

The following screen is shown at the end of the first cycle and there is an audio alarm.

Remove the rack to end cycle 1 and continue cycle 2.

54

Page 55

PRESTO PRO MM136-002 – Operator Manual

Once the rack is removed from the standard position (BLUE) and the cover of the PRESTO PRO is closed

again, stage 2 (yellow) continues and the time remaining to the option of starting the third cycle, using the

standard position again, is shown in the left section of the screen.

When the second cycle is in the Ethanol stage, the standard position (BLUE) of the arm is in the rack loading

position and a third cycle can thus be started while the second is still in progress.

The option of starting a third cycle is available when the ethanol stage of the second cycle is in progress (10

seconds). There is an audio alarm during this period of time and the time remaining to start the third cycle and

the button for starting it are shown in the left section of the page.

There are two courses of action:

A) If the third cycle does not need to be started, simply ignore the start button and the current cycle continues

as normal. In this case, the audio alarm can be silenced by pressing the relevant button in the bar on the right

side .

The following screen appears at the end of the second cycle and there is an audio alarm.

Remove the rack to end the cycle.

Once the rack with slides is removed, the software goes back to the main screen.

55

Page 56

PRESTO PRO MM136-002 – Operator Manual

Cycles can be run continuously one after the other until the reagents have expired.

It is recommended to close the reagent containers with the relevant caps after using

During a process, if required, press “Abort” to stop the process and remove the rack with

B) If other sections need to be processed/stained, press the start button to run the third cycle that uses the

standard position with blue reference colour.

Open the PRESTO PRO cover and load the rack on the support, in position 1DOWN. Once closed, the START

button is displayed at bottom right: press this button to start a process.

The third cycle starts and the second one continues only when the START button is pressed.

PRESTO PRO if it is not going to be used for a long time (more than 24 hours). Refer to

chapter 2.7.5

slides. If two cycles are in progress, both are stopped.

56

Page 57

PRESTO PRO MM136-002 – Operator Manual

Before starting a process ensure

the reagent vessels do not have the cap (see

chapter

3.2.3. Press the start button to run a standard protocol

For reasons of safety, if the cover of the work area is opened while the arm is moving, the

arm stops immediately.

2.7.5) and check proper reagent level, as they are subject to evaporation. The correct level

of reagents is between the two lines etched inside the vessel. Milestone recommends

keeping the staining reagents level to the minimum and the cleaning reagents to the

maximum.

Press “Start run” from the MAIN FUNCTIONS screen.

The standard loading position (BLUE) of the slide rack goes in the loading position above the container in

position 1DOWN, ready to load the rack in the FineFIX container. Refer to chapter 2.7.7 for the positions in

the PRESTO PRO.

At the start of each process the software performs a water flow check which lasts few

seconds.

The screen to enter process data and to start it is displayed. Enter the number of slides in the rack, pressing

the number keys from 1 to 6, then enter “Case ID” and “Run ID” (process identification code) data. It is not

mandatory to enter any of this data.

Press the arrow under the word “Protocol” to bring up the list of protocols in the software, if any have been

created (refer to chapter 3.3 Editing a program).

By pressing the start button, you can select the desired program from among the standard ones.

The software always suggests the last selected standard process.

Open the PRESTO PRO cover and load the rack on the support, in position 1DOWN. Once closed, the START

button is displayed at bottom right: press this button to start a process.

57

Page 58

PRESTO PRO MM136-002 – Operator Manual

During a process, if required, press “Abort” to stop the process and remove the rack with

The cycle starts only when the START button is pressed.

The processing screen is displayed, which shows process information.

On the left, the schematic depiction of the positions of PRESTO PRO's reagents, with the rack's position

highlighted in green and information concerning the stage in progress.

The following is displayed at top right: the selected protocol, the process identification code (if entered) and

the total process time. The remaining time before the end of the process is shown in the yellow box immediately

underneath.

Below are two examples of screens during processing: on the left during the FineFIX stage and on the right

while moving to the water cleaning stage after haematoxylin:

Upon completing the process, the rack is kept immersed in the last reagent to prevent the specimens from

drying and a buzzer warns the user. Extract the rack.

The process ends when PRESTO PRO's cover is opened to remove the rack with the specimens.

Once the rack with slides is removed, the software goes back to the main screen.

It is recommended to close the reagent vessels with the relevant caps after using PRESTO

PRO if it is not going to be used for a long time (more than 12 hours). Refer to chapter 2.7.5.

slides.

58

Page 59

PRESTO PRO MM136-002 – Operator Manual

Before starting a process ensure the reagent containers do not have the cap (see

chapter

3.2.4. Press the start button to run a “Continuous” protocol

For reasons of safety, if the cover of the work area is opened while the arm is moving, the

arm stops immediately.

2.7.5) and check proper reagent level, as they are subject to evaporation. The correct level

of reagents is between the two lines etched inside the container. Milestone recommends

keeping the staining reagents level to the minimum and the cleaning reagents to the

maximum.

Press “Start continuous” from the MAIN FUNCTIONS screen.

The standard loading position of the slide rack goes in the loading position above the container in position

1DOWN, ready to load the rack in the FineFIX container. Refer to chapter 2.7.7 for the positions in the PRESTO

PRO.