Patents Pending

Model RF24DN/DP

Direct Vent Fireplace Insert

Installation and Owner’s Manual

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Please read this manual BEFORE installing and operating this appliance.

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury or loss of life.

Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light the appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fi re department.

Installation and service must be performed

by a qualifi ed installer, service agency or

the gas supplier.

This appliance may be installed in

an after-market permanently located,

manufactured (mobile) home where not

prohibited by local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certifi ed kit is used.

This appliance is a domestic room-heating

appliance. It must not be used for any

other purposes such as drying clothes,

etc.

This appliance is suitable for installation in

a bedroom or bed sitting room.

Massachusetts: The piping and fi nal

gas connection must be performed by a

licensed plumber or gas fi tter in the State

of Massachusetts.

4000607-11

© 2007 Miles Industries Ltd. All rights reserved.

Manufactured by

MILES INDUSTRIES LTD.

British Columbia, Canada

www.milesfi replaces.com

Thank You ...

For purchasing a Retrofi re by Miles Industries. Your new radiant gas heater is a

technical appliance that must be installed by a qualifi ed dealer. Each Retrofi re is fully

tested during the production process for your safety and comfort.

Your unit has been professionally installed by:

Dealer Name _______________________________________

Phone Number ______________________________________

Should you encounter an operational problem, call your dealer immediately.

Do not try to repair the unit as you may cause an injury or damage the

fi replace.

The information contained in this installation manual is believed to be correct at the time of printing.

Miles Industries Ltd. reserves the right to change or modify any information or specifi cations without

notice. Miles Industries Ltd. grants no warranty, implied or stated, for the installation or maintenance

of your heater, and assumes no responsibility for any consequential damage(s).

We recommend that our gas

hearth products be installed

and serviced by professionals

who are certifi ed in the

United States by NFI (National

Fireplace Institute®).

2

Contents

Safety and Warning Information...................................................................4

Options ...........................................................................................................5

Specifi cations ................................................................................................5

Dimensions ....................................................................................................6

Vent Confi gurations .......................................................................................7

Vent Termination ............................................................................................8

Pack Contents ................................................................................................9

Existing Fireplace Preparation ...................................................................10

Supply Gas ................................................................................................... 11

Vent Liner Rough-In .....................................................................................12

Appliance Preparation .................................................................................12

Firebox Installation ......................................................................................13

Ceramic Fuel Bed Installation ....................................................................15

Window Refi tting and Checking .................................................................17

Remote Control Installation ........................................................................17

Operation Check and Aeration Adjustment ..............................................18

Cast Iron Fret Installation ...........................................................................18

Owner’s Information ....................................................................................19

Lighting Instructions ...................................................................................22

Warranty .......................................................................................................23

Parts ..............................................................................................................24

3

Safety and Warning Information

READ and UNDERSTAND all instructions carefully

before starting the installation. FAILURE TO FOLLOW

these installation instructions may result in possible fi re

hazard and will void the warranty.

Prior to the fi rst fi ring of the fi replace, READ the Owner’s

Information section of this manual.

DO NOT USE this appliance if any part has been

under water. Immediately, CALL a qualifi ed service

technician to inspect the unit and to replace any part of

the control system and any gas control that has been

under water.

THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

Installation and repair should be PERFORMED by a

qualifi ed service person. The appliance and venting

system should be INSPECTED before initial use and at

least annually by a professional service person. More

frequent cleaning may be required due to excessive

lint from carpeting, bedding, etc. It is IMPERATIVE that

the unit’s control compartment, burner, and circulating

air passageways BE KEPT CLEAN to provide for

adequate combustion and ventilation air.

Always KEEP the appliance clear and free from

combustible materials, gasoline, and other fl ammable

vapors and liquids.

NEVER OBSTRUCT the fl ow of combustion and

ventilation air. Keep the front of the appliance CLEAR

of all obstacles and materials for servicing and proper

operation.

Due to the high temperature, the appliance should be

LOCATED out of traffi c areas and away from furniture

and draperies. Clothing or fl ammable material SHOULD

NOT BE PLACED on or near the appliance.

Children and adults should be ALERTED to the hazards

of high surface temperature and should STAY AWAY to

avoid burns or clothing ignition. Young children should

be CAREFULLY SUPERVISED when they are in the

same room as the appliance.

This gas fi replace and vent assembly MUST be

vented directly to the outside and MUST NEVER be

attached to a chimney serving a separate solid fuel

burning appliance. Each gas appliance MUST USE

a separate vent system. Common vent systems are

PROHIBITED.

INSPECT the external vent cap on a regular basis to

make sure that no debris, plants, trees, shrubs are

interfering with the air fl ow.

The glass door assembly MUST be in place and sealed

before the unit can be placed into safe operation.

DO NOT OPERATE this appliance with the glass door

removed, cracked, or broken. Replacement of the glass

door should be performed by a licensed or qualifi ed

service person. DO NOT strike or slam the glass door.

The glass door assembly SHALL ONLY be replaced

as a complete unit, as supplied by the fi replace

manufacturer. NO SUBSTITUTE material may be

used.

DO NOT USE abrasive cleaners on the glass door

assembly. DO NOT ATTEMPT to clean the glass door

when it is hot.

TURN OFF the gas before servicing this appliance.

It is recommended that a qualifi ed service technician

perform an appliance check-up at the beginning of

each heating season.

Any safety screen or guard removed for servicing MUST

BE REPLACED before operating this appliance.

DO NOT place furniture or any other combustible

household objects within 36” of the fi replace front.

BE CAREFUL not to put any decorating objects

sensitive to heat too close to the fi replace as it gets

very hot when operating.

DO NOT use this heater as a temporary source of heat

during construction.

This unit MUST be used with a vent system as described

in this installation manual. NO OTHER vent system or

components MAY BE USED.

NOTE: When operating your new fi replace for the fi rst time, some vapors may be released due to the burning

of curing compounds used in the manufacture of the appliance. They may cause a slight odor and could cause

the fl ames to be the full height of the fi rebox, or even slightly higher, for the fi rst few hours of operation. It is also

possible that these vapors could set off any smoke detection alarms in the immediate vicinity. These vapors are

quite normal on new appliances. We recommend opening a window to vent the room. After a few hours use, the

vapors will have disappeared and the fl ames will be at their normal height.

4

Options

Fuel

RF24DVN—Natural Gas Installations

RF24DVP—Propane Gas Installations

Decorative Cast Iron Frets

RA24CV—Contemporary, Vintage Iron Finish

RA24AV—Avant-Garde. Vintage Iron Finish

RA24TB—Traditional, Black Finish

Venting

Pipe—generic 3” diameter fl exible aluminum liner

Termination—Miles Industries’ 559CLT Co-Linear

Termination. 559SFK Square Flashing Kit required for

terminating existing masonry chimney applications.

Circulating Fan

555CFK—Circulating Fan Kit with 6’–0” c/w grounded

cord set.

Conversion Kits

RA24NK—to convert from LPG to Natural Gas

RA24PK—to convert from Natural Gas to LPG

approved for gas venting.

Specifi cations

This appliance is intended for installation into existing masonry or factory-built, solid-fuel burning fi replaces

only.

Approvals and Codes

This appliance is certifi ed to ANSI Z21.88-2007/CSA

2.33-2007 Vented Gas Fireplace Heater standard for

use in Canada and the USA and to CGA 2.17-N91 High

Altitude Standard in Canada. This appliance is for direct

vent installation terminating at the roof only.

Model RF24DVN is for use with Natural Gas only.

Model RF24DVP is for use with LPG only.

Conversion between fuels may only be done using the

approved conversion kits listed above.

This appliance complies with CGA P.4.1, Testing

method for measuring annual fi replace effi ciencies.

The installation must conform to local codes or, in the

absence of local codes with the National Fuel Gas Code,

ANSI Z223.1 or the Canadian Installation Code CAN/

CGA-B149. Only qualifi ed licensed or trained personnel

should install this appliance.

This appliance, when installed , must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFP A 70 or the Canadian Electrical Code,

CSA C22.1

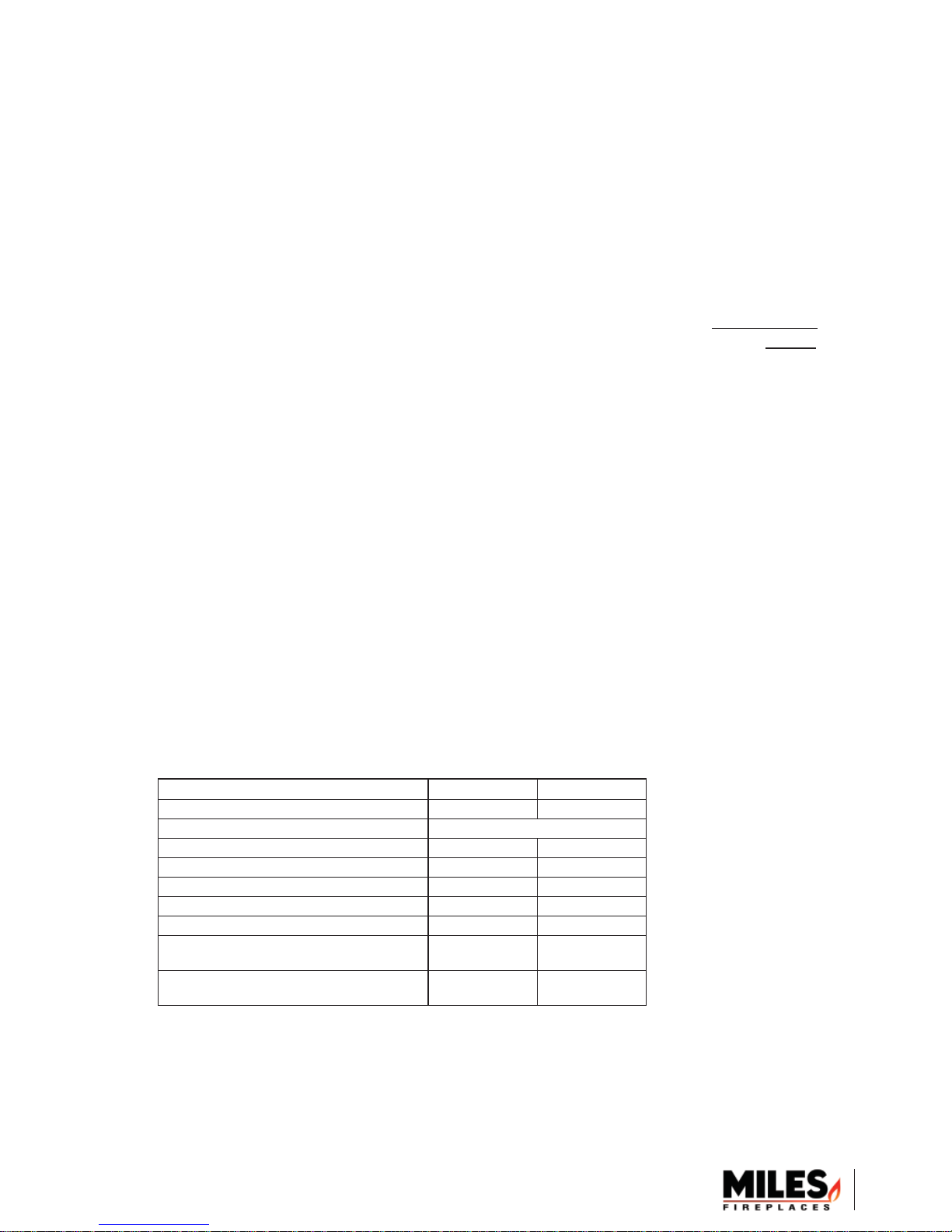

Ratings

Model RF24DVN RF24DVP

Gas Natural Propane

Altitude (Ft.) 0-4,500 Feet*

Input Max. (Btu/h) 24,000 24,000

Input Min. (Btu/h) 10,500 10,500

Manifold pressure (in w.c.) 3.95 9.5

Min. Supply pressure (in w.c.) 5.0 11.0

Max. Supply pressure (in w.c.) 10.5 14.0

Main Burner Injector

Catalogue Number (this is not a drill size)

Pilot Injector

Catalogue Number (this is not a drill size)

*High Altitude Installations

Input ratings are shown in BTU per hour and are

certifi ed without deration for elevations up to 4,500 feet

(1,370 m) above sea level.

For elevations above 4,500 feet (1,370 m) in USA,

installations must be in accordance with the current

Bray Cat.

#82-580

S.I.T.

#62

Bray Cat.

#92-260

S.I.T.

#30

ANSI Z223.1 and/or local codes having jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370 m).

5

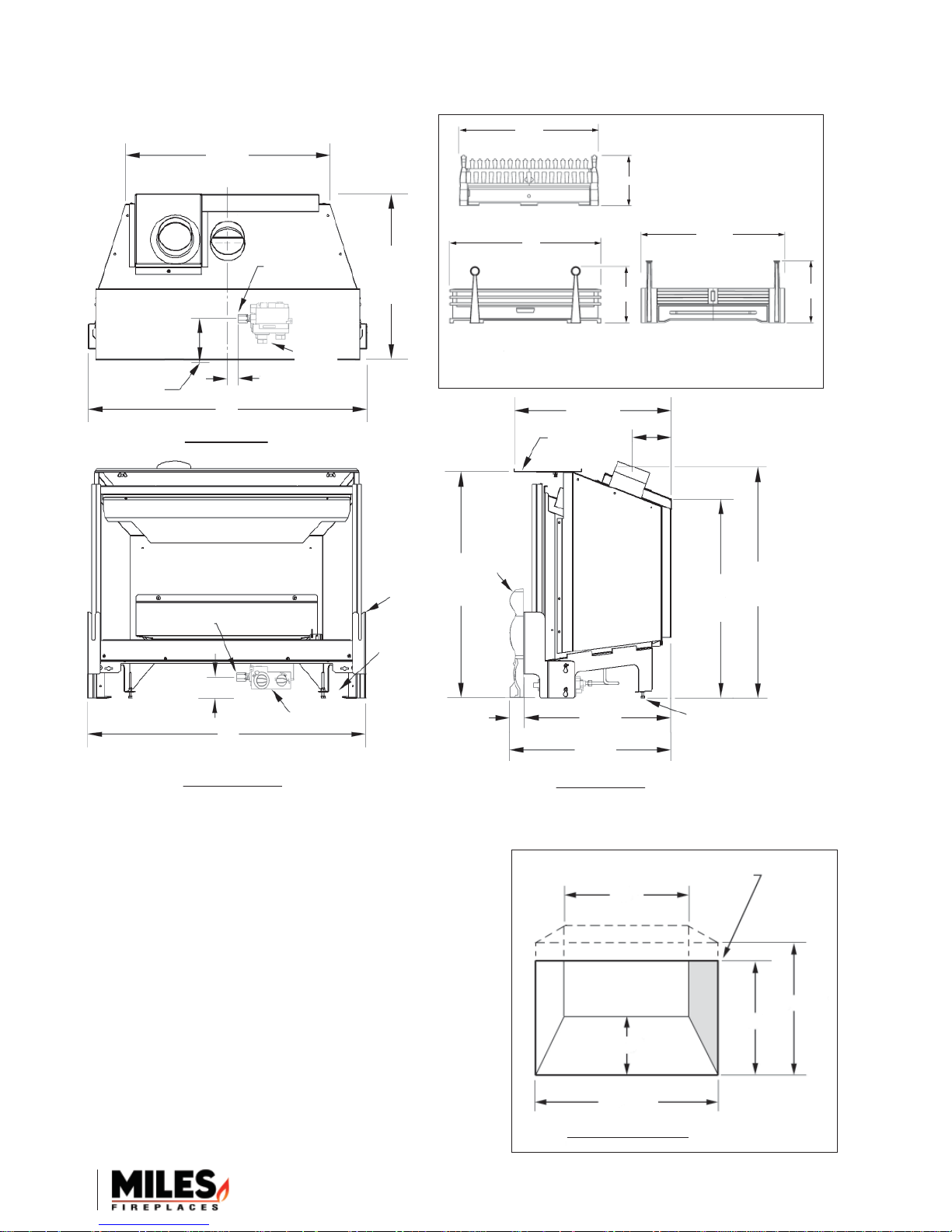

Dimensions

Dimensions

3” dia.

Inlet

Front Face of

Cast Fret

17-1/4”

3” dia.

Exh

4-1/2”

24”

Top View

Gas Inlet

3/8” NPT Female

Control Valve

Location

1”

Min. 12”

Max 14”

24-1/2”

8”

RA24TB Fret (Black)

27”

10”

RA24CV Fret (Vintage Iron) RA24AV Fret ( Vintage Iron)

25-1/2”

Optional Frets

Min. 12”

Optional

Cast

Fret

Max 14”

Adjustable

Convection

Baffle

3-1/4”

11”

Gas Inlet

3/8” NPT Female

1-3/4”

Control Valve

Fret

Mounting

Brackets

(removeable)

Optional Fan

Speed Control

Location

(this side at front)

18-3/4”

1-1/4”

24”

Front View

Minimum Cavity Dimensions

The diagram shows minimum dimensions required to

install the RF24. Cavities having a combination of all the

minimum dimensions shown, although possible, may

prove to be diffi cult installations.

12-1/2”

13-3/4”

Side View

Height to Smoke Curtain

18”

14”

Levelling

Feet

19-1/4”

16-1/2”

19-1/2”

17”

6

25-1/2”

Minimum Cavity

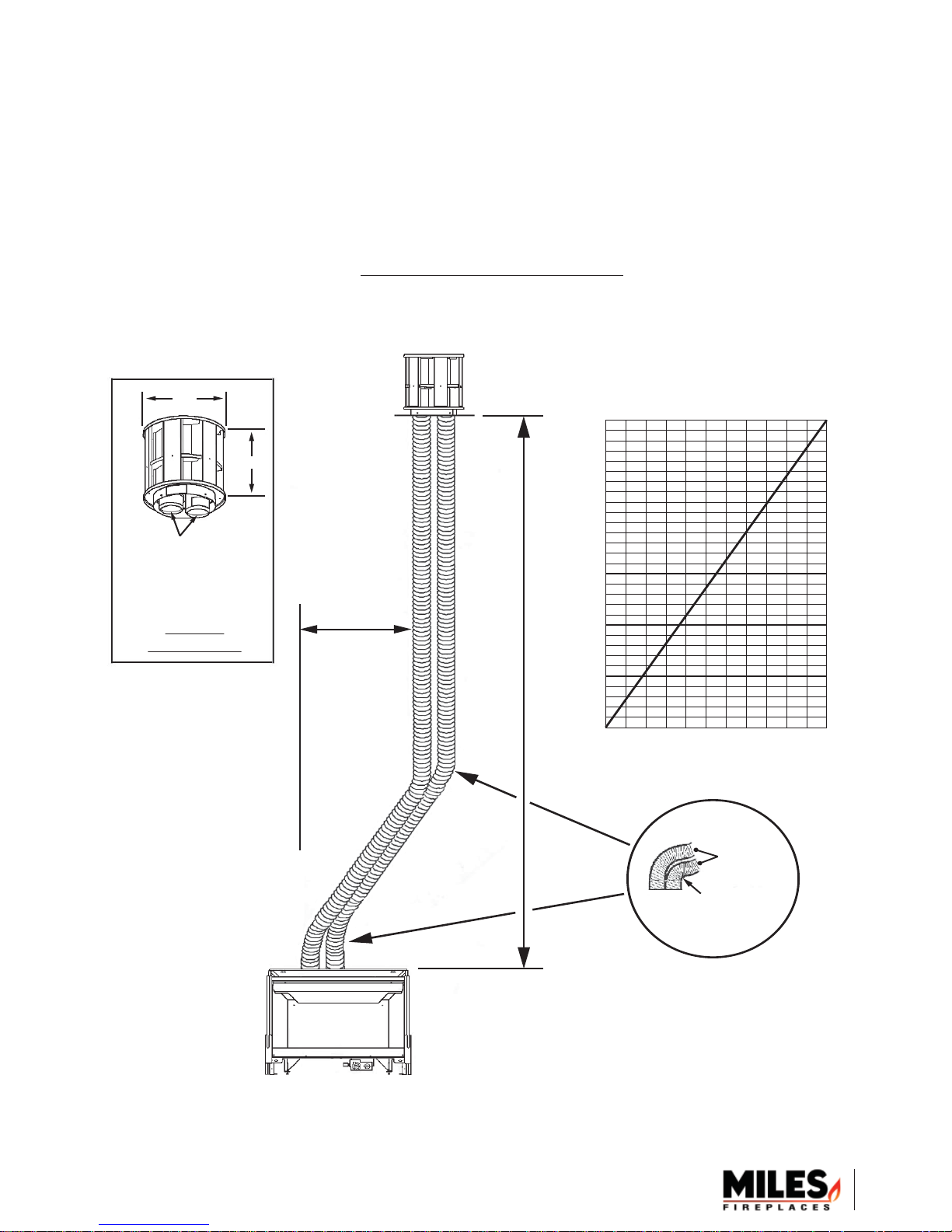

Vent Confi gurations

Allowable Vent Confi gurations

The RF24 is certifi ed for use with approved 3” diameter fl exible venting installed into an approved existing solid

fuel burning masonry or factory built chimney system. The venting system must terminate vertically at the roof

using an approved termination cap. Both inlet and exhaust liners must be run continuously from appliance to roof

termination. Where possible, avoid joints in fl ex pipe. If joints are required, use only connectors approved by the

manufacturer of the fl ex pipe. Field fabricated joints are not allowed.

Any generic 3” diameter fl exible venting approved for venting gas appliances is acceptable.

559CLT

Co-Linear Terminal

10”

40’

3” Inlet & Exhaust

Collars (exhaust collar

is slighthly longer)

559CLT

Termination

10”

See

Chart

Vertical Vent Height

10’ min. - 40‘ max.

35’

30’

25’

20’

15’

10’

5’0”

4’6”

5’6”

6’0”

6’6”

7’0”

7’6”

8’0”

Allowable Horizontal Offset

3” Liners

3” min. Bend

Radius

8’6”

9’0”

9’6”

10’0”

7

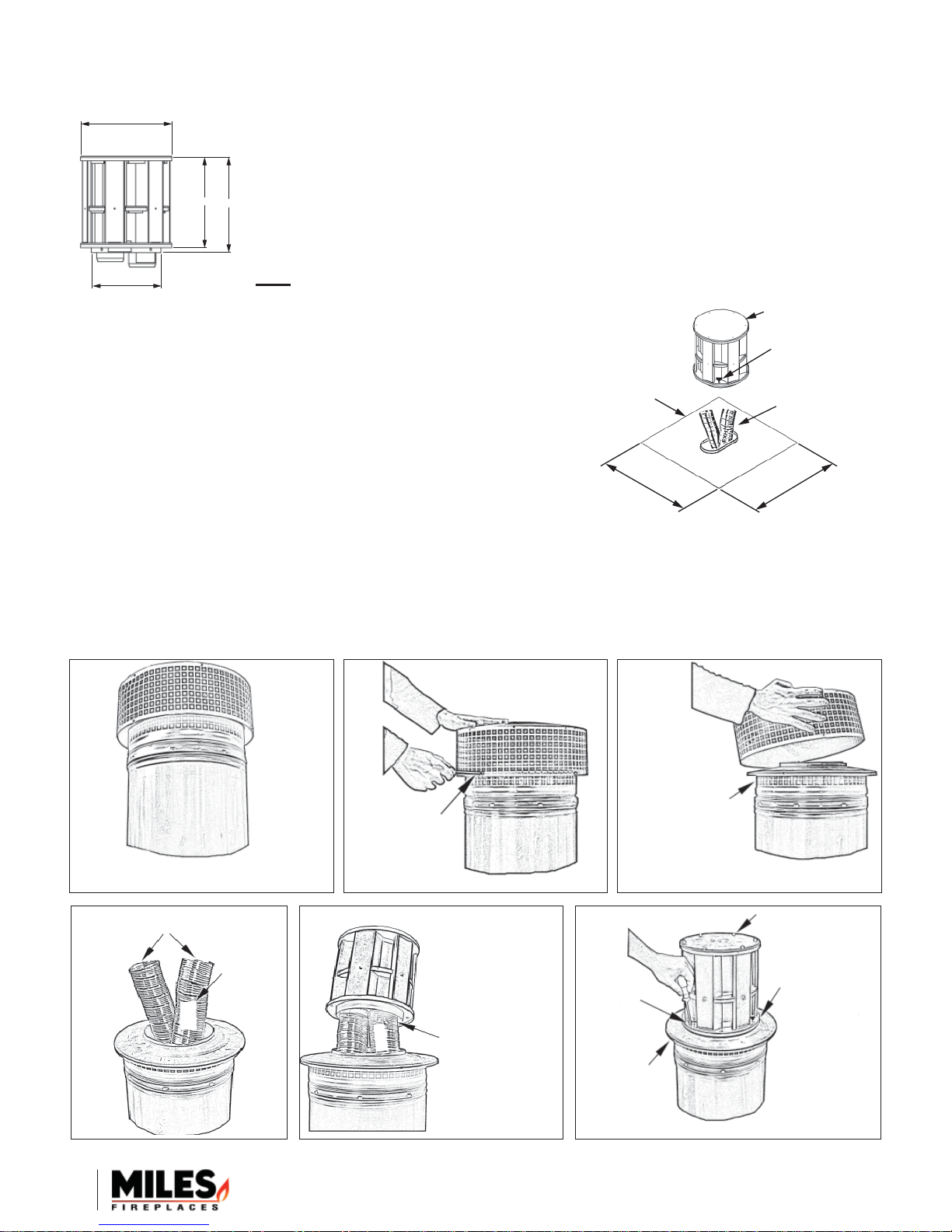

Vent Termination

”

10” dia.

The RF24 is approved for Vertical Co-Linear Termination Only. Two 3” diameter

liners are required from top to bottom. The vent liners must be connected to the proper

collars (intake and exhaust) or the unit will not operate properly. The method of fl ashing

will depend on whether the liners are installed into a rectangular masonry or round

10”

factory-built solid-fuel burning chimney. It is important to seal the gap at the top

11

of the chimney in either case to avoid convective air loss up the chimney. The

integrity of the air-cooled function of factory-built chimney systems must be maintained

when installing terminations. Termination of the chimney may need to be completed

7-5/8” dia.

559CLT

after the RF24 fi rebox is installed and the slack vent liner pulled up—see Section

Installing Firebox.

Existing Square Chimneys

559CLT Co-Linear Terminal and 559SFK Square Flashing Kit are

required. Cut fl ashing kit to size. Allow extra around perimeter for drip

edge to be formed on site. Seal fl ashing to top of chimney using sealant

(not supplied). Fasten terminal to fl ashing using sheet metal screws as

shown.

Existing Round Factory-Built Chimneys

559SFK Flashing

(cut to required

size and form

drip edge on site)

18”

559CLT Terminal

Fasten to Flashing

with Sheet Metal

Screws (3 locations)

2 - 3” Flex Liners

18”

The 559CLT terminal is designed to fi t existing 7” or 8” diameter factory-built round chimneys without requiring

additional fl ashing. Ensure the installation of the terminal seals off the top of the chimney space to avoid convective

air loss. The diagrams below show a typical terminal installation for an 8” diameter air-cooled chimney system.

Maintain Air-Cooled

Function of Existing

Chimney System

Fasten Terminal

to Flashing

(3 locations)

Ensure Flashing

Remains over

Air-Cooled

Openings

559CLT Termination

Ensure Exhaust

Portion of Chimney

is Sealed at Top

Existing Air-Cooled Chimney

(Factory-Built Fireplaces)

Install 2 - 3” dia.

Flex Liners

Identify

which

Liner is

Exhaust

EXH.

Remove Top

Portion of

Terminal

EXH

Connect Liners to

Corresponding

Collar on Terminal

using Sheet Metal

Screws (longer

collar is exhaust

collar)

8

Pack Contents

RF24 Engine Pack

Content as shown

•

3” dia Stainless Gear Clamps (2)

•

Fret Retainer Thumbscrews (4)

•

Convection Baffl e Wing nuts (2)

•

Batteries—4 AA, 1 9V

•

Rear Brick

Brick Set

Adjustable

Convection Baffle

(packed loose)

Rear Log

L/H Cross

Log

Right BrickLeft Brick

Middle

Cross Log

Front Log

R/H Cross

Log

Log Set

Firebox Unit

Top Baffle

Wingnuts (2)

Window Unit

Burner Module

Handset

Handset

Wall

Holder

Receiver

Wiring

Harness

Rear Log Support

Support Legs

Thumb Screws

Fret Retainer

Brackets

Warning : Failure to position

the parts in accordance with the

diagrams in this manual, or failure

to use only parts specifi cally

approved with this appliance

may result in property damage or

personal injury

Remote Control

9

Pack Contents

Optional Frets (sold separately)

Choice of cast iron frets available separately. Simply slide into place on fret retainers supplied with engine.

24-1/2”

27”

25-1/2”

11”

RA24TB Fret (Black)

8”

RA24CV Fret (Vintage Iron)

10”

RA24AV Fret (Vintage Iron)

555CFK Circulating Fan Kit (sold separately)

Thermally actuated fan (blower), mounting plate, and variable speed control complete with 6’–0” grounded cord

set. Complete instructions packaged with kit.

Conversion Kits (sold separately)

RA24NK to convert from LPG to Natural Gas.

RA24PK to convert from Natural Gas to LPG.

Kits include main burner orifi ce, pilot burner orifi ce, instructions, special screwdriver to access regulator.

Note: A manometer is required to reset pressure regulator on valve.

Existing Fireplace Preparation

A few points must be considered before inserting the RF24 into an existing fi replace cavity. Generally, no

modifi cations are allowed to the existing fi replace that will compromise the integrity of the existing fi replace.

Components that are bolted or screwed on such as dampers or baffl es may be removed to accommodate the

installation of the RF24 engine. Cutting away any sheet metal parts of the existing fi replace to accommodate

the installation of the RF24 is prohibited. Check with local authorities if in doubt.

Clean Fireplace and Chimney

Have the chimney swept and the fi replace cavity cleaned before installing the RF24 heater and vent liners. Any

creosote or soot residue remaining in the fi replace cavity or chimney may cause odors once the RF24 insert is

installed. Consult with chimney sweep for information on how best to clean.

Existing Dampers

Factory-built, zero-clearance fi replaces will require the damper to be removed in order to install the vent liners.

These dampers are usually bolted into place. Dampers in masonry fi replaces must be fi xed open and may remain

in place.

Ash Retaining Curbs

Some fi replaces (particularly factory-built) have a raised curb at the front edge to retain ashes. Check the dimensions

carefully to ensure the RF24 engine will fi t behind any raised curb (some curbs may be removed separately from

the refractory base). The fret retainers allow for some vertical adjustment of the cast iron fret should the fret need

to sit on top of the curb, otherwise the fret will need to be eliminated or adequate room provided behind the curb.

Gas Line Routing

Plan the routing of the gas line before proceeding. Utilize the existing hole for the gas line. If the factory-built

fi replace has no access hole, carefully drill an access hole of 1.5 inch (38 mm) or less through the lower sides or

bottom of the fi rebox. The access hole must be plugged with non-combustible insulation after the gas supply line

has been installed. See General Dimension drawing for detailed location of gas inlet. Also, take into consideration

whether or not a fan or shut-off valve will interfere when planning routing of the gas line.

10

Existing Fireplace Preparation

Existing Glass Doors and Wire Screens

Existing glass doors must be permanently removed prior to installing the RF24 insert. Existing wire fi re screens

may remain in place or new ones may be added. The RF24 has been tested and approved to operate with wire

fi re screens in the closed or open positions.

Combustible Mantels

Combustible mantel clearances must conform to those required for the original solid-fuel fi replace into which the

RF24 is being installed.

Paint Existing Refractory Liners

It may be desirable, for visual reasons, to paint the existing refractory liners in black to blend in with the RF24

insert once installed.

Attach Warning Label to Existing Fireplace (label supplied loose with RF24 heater)

Attach the “This fi replace has been converted...” label to the existing fi replace using screws or other mechanical

means and store any removed parts in back of the existing fi replace for future use.

Supply Gas

It’s preferable to rough-in the gas line at this point before proceeding with the fi rebox installation.

•

The gas supply inlet connection is a 3/8” NPT female connector. For detailed location of this connector, see drawing

•

in section Dimensions. If a circulating fan or isolating valve is to be installed, adjust the routing of the gas line to

suit.

Use only new black iron or steel pipes or copper tubing if acceptable—check local codes. Note that in USA, copper

•

tubing must be internally tinned for protection against sulfur compounds.

Unions in gas lines should be of ground joint type.

•

The gas supply line must be sized and installed to provide a supply of gas suffi cient to meet the maximum demand

•

of the appliance without undue loss of pressure.

Sealant used must be resistant to the action of all gas constituents including LP gas. Sealant should be applied

•

lightly to male threads to ensure excess sealant does not enter gas lines.

The supply line should include a manual shut-off valve and union to allow the appliance to be disconnected for

•

servicing.

Pressure test the supply line for leaks.

•

The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during any

•

pressure testing of that system at test pressures in excess of ½ psig (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve during

•

any pressure testing of the gas supply piping system at test pressures equal to or less than ½ psig (3.5 kPa).

Failure to either disconnect or isolate the appliance during pressure testing may result in regulator or valve damage.

•

Consult your dealer in this case.

The minimum supply pressure is given in the section Specifi cations of

•

this manual.

All piping and connections must be tested for leaks after installation or

•

servicing. All leaks must be corrected immediately.

When testing for leaks:

•

•

Make sure that the appliance is turned off.

Open the manual shut-off valve.

•

Test for leaks by applying a liquid detergent or soap solution to all

•

joints. Bubbles forming indicate a gas leak. Never use an open

fl ame to check for leaks.

Correct any leak detected immediately.

•

The pressure test tapping locations are shown in fi gure above. A built-

•

in non-adjustable regulator controls the burner manifold pressure. The

correct pressure range is shown in the table in section Specifi cations of

this manual. The pressure check should be made with the burner alight

and at its highest setting. See lighting instruction section for full operating details.

Inlet Pipe

Manifold Pressure

Tes t Ta p

Loosen screw to check

(tighten afterwards)

Supply Pressure

Tes t Ta p

Pressure Test Tappings

11

Vent Liner Rough-in

Rough-in the two 3” diameter vent liners into existing chimney system being careful not to tear or damage the

liners in the process. It may be easier to install both liners at the same time rather than one at a time. Leave plenty

of liner at the bottom end if the Heater will be connected while on the hearth (see diagram). When connecting the

liner in this manner it is best to leave the top termination until later so the slack liner can be lifted after the

insert is in place (see separate section for top termination). Designate and mark the top and bottom of one

liner as “EXHAUST” to avoid confusion later.

EXH.

Two 3” dia.

Aluminum Liners

Existing Fireplace Rough-In Liners

Appliance Preparation

The size of the existing fi replace cavity will affect the method of installation. Smaller fi replaces, particularly factory-

built zero-clearance fi replaces will require the RF24 fi rebox to be disassembled then reassembled inside the

fi replace. Plan your particular installation accordingly.

Unpack appliance.

•

Remove window.

•

Remove log pack from fi rebox.

•

Strip fi rebox down by removing:

•

Burner Module (10 screws),

•

Support Legs (2 screws per leg)

•

(required when inserting into

small fi replaces only)

Remove

Burner

Module

(10 screws)

Remove

Support Legs

(2 screws/leg)

Spring-loaded

Fastening Studs (2)

1/4 Turn

Remove Window

12

Firebox Installation

Connection of liners to fi rebox

Trim liners if necessary and connect to the fi rebox either while the fi rebox is on the hearth or with the fi rebox in the

cavity. Use gear clamps provided to connect the liners to the fi rebox. If the liners are connected with the fi rebox on

the hearth, it will be necessary to pull the slack liner up from the top of the chimney after the fi rebox is installed.

Gear Clamps

Option 1 - Connect liners with

Firebox on Hearth

Reach Through Front

to Connect Liners

Reach Through

Top or Sides

to Connect Liners

Option 2 - Connect Liners

in Fireplace

Support Legs Reinstallation (if removed)

With the fi rebox recessed behind the smoke curtain of the existing fi replace, raise the fi rebox and place the

individual support legs under the fi rebox. Placing a temporary shim under the fi rebox, such as a 2” x 4”, may help

while positioning the support legs. Tabs are provided on the support legs to help position them. Fasten the support

legs at the points indicated by the arrows using the bolts provided (2 per side).

Thread thumbscrews

into Support Leg.

Raise right side of firebox

and slip RH Support Leg

Under. Fasten with 2 bolts

as indicated.

Thread thumbscrews

into Support Leg.

Raise left hand side of firebox

and slip LH Support Leg

Under. Fasten with 2 bolts

as indicated.

13

Firebox Installation

Leveling the fi rebox in the hearth

The backside of each support leg has a leveling bolt. If necessary, adjust the level of the fi rebox in the hearth.

Fret bracket

Leveling

bolt

Leveling

bolt

Front View

Leveling bolt

Side View

Leg

BackFront

Burner Module Reinstallation

Note: If the circulating fan is to be installed it should be done at this point before installing the burner

module. See instructions packaged with the fan for details of the fan installation.

Reinstall the burner module using the 10 screws removed previously. Note: The upper baffl e may be removed to

gain more room for the screwdriver to install the rear screws.

Edge Fits Into

Cleat at Back

Reinstall Burner

Module

(10 screws)

Remove Top Baffle

(2 screws)

Remove Top Baffle (optional)

(to provide space for a screwdriver)

Gas Line Connection and Fire Unit Testing

Connect the gas line to the burner module. Check for leaks, purge the line, and test-fi re the unit before installing

the window or proceeding with the remainder of the install—see section Lighting Instructions.

Top Baffl e Reinstallation (if removed)

Edge Fits Into

Cleat at Back

Reinstall Top Baffle

(2 screws)

14

Firebox Installation

Top Convection Baffl e Installation

Position the fi rebox as far back as possible within the existing fi replace to allow ample space at front for the fret

and to allow convection air to fl ow under the smoke curtain of the existing fi replace. Position the top convection

baffl e with the threaded studs pointing downwards into the slots at the top of the fi rebox. Slide the convection

baffl e as far forward as possible, angled down if possible, to force the air under the smoke curtain, and tighten

the wing nuts.

Convection Baffle

Start wingnuts on studs. Slide

Convection Baffle into slots.

Wingnuts (2)

Adjust Baffle Forward to Touch

Back of Smoke Curtain of

Existing Fireplace. Tighten

Wingnuts.

Ceramic Fuel Bed Installation

Ceramic Brick Liner Installation

Install the ceramic brick liner taking care not to damage them as the material is fragile. The top rounded edges of

the side panels should face inwards and the front edge bevelled. Place the side brick panels fl at against the side

of the fi rebox up high and slide downward into place behind the front return edge on the fi rebox.

Rear Brick

Rest Brick on

Rear Log Support

Side Brick in front of Rear Brick

Rear Brick

Left

Brick

Side Brick Behind

Firebox Return

Left

Brick

Rear Brick

Right

Brick

15

Ceramic Fuel Bed Installation

Ceramic Log Set Installation

Carefully remove the ceramic logs from the packaging taking care not to damage them. Install the logs as described

below. Please note that the Rear Log will have a different position depending of the gas type. The position

of the logs is critical to insure the good performance of the appliance.

NG ONLY: Drop Rear Log into place

behind front log retainers.

LPG ONLY:

Drop Rear Log into

place centered sideto-side against back

support so the log

sits more vertical.

Rear Log Touches

Front Log Here

Right Log

Locating Pins

Front Log locating pins

1 2

Place R/H Cross Log

Onto Locating Pins

43

Place L/H Cross Log

Onto Locating Pins

Place Font Log onto locating

Pins at Each End

L/H Log Locating Pins

Place Middle Cross Log

Across Gap in Front Log

5

16

Window Refi tting and Checking

Hook the window over the top edge of the fi rebox,

and fasten the bottom two spring loaded bolts by

pushing in and turning 90 degrees. Check that the

window moves freely against the spring by pulling

out at the bottom. If broken, the window may only

be replaced as a complete unit as supplied by the

manufacturer.

Note: To remove the window, the cast iron

fret and fret retainers will need to be removed

fi rst—see section Cast Iron Fret Installation.

Check that Window

Moves Freely After

Reinstallation

Spring Loaded

Fastening Studs (2)

1/4 Turn

Remote Control Installation

Caution! Don’t connect the batteries to the remote control receiver until the

wires are connected to the burner control unit, as short-circuit could result in

destruction of the electrical components.

1.

Connect the wiring harness to the receiver box, by pushing the wire connector

on to the receiver circuit board. The plug will only go on one way so please

ensure that the wires are pointing up and slot in the board is in line with the

tab on the wiring harness plug.

2.

Connect wires as shown. Please note that the “L” connectors are different

sizes, the smaller one fi ts to the lower connection and the larger one the

top connection on the top left hand side of the valve. The other two wire

connectors can be fi tted to either terminal located to the left of the fl ame

control button.

3.

Remove the remote control receiver lid.

4.

Fit four AA 1.5 V batteries.

5.

Place the remote control receiver on the base of the fi replace beside the

valve.

6.

Fit the 9 V battery to the handset transmitter.

Remote Receiver

Remote control operating instructions are on pages 19–20 of this manual and are supplied with the remote

control kit.

Receiver Valve

Push-on

Connector

17

Operation Check and Aeration Adjustment

Turn the fi replace up and down using the remote control to confi rm that

the full range of inputs is achieved.

Light the fi re and allow to warm up for 10–15 minutes to evaluate the

fl ame picture.

control primary aeration. See fi gures below. The shutter is factory-set

at an aeration gap, which will give optimum performance for the vast

majority of installations. In a few unusual installations, fl ame picture may

be improved by adjusting the aeration. The need for adjustment should be

determined only by operating the appliance with the ceramic fuel effects

and window installed.

Increasing aeration will cause the fl ame to appear more transparent and

blue making the ceramic fuel effects glow more.

Decreasing aeration will

cause the fl ames to appear

more yellow or orange

making the fuel effects glow

less.

Too little aeration may

result in black carbon

forming and dropping

into the fi rebox.

The burner is equipped with an adjustable air shutter to

Air Shutter in

Open Position

Air Shutter

Air Shutter Retainer

Air Shutter Components

Air Shutter in

Closed Position

Cast Iron Fret Installation

Note: The fret retainer brackets are designed to maintain

the required space in front of the window to allow the

window to move and relieve during a hard start. It is very

important to ensure this area in front of the window

is kept clear at all times.

Fret Retainer Brackets Installation

Screw 2 thumbscrews into sides of each support leg if not

done previously when support legs were installed. Fit the

slotted holes in the fret retainers over the thumbscrews,

push fret retainers downwards and tighten screws.

Drop Fret with Bolt

into Slotted Retainer

(fret adjusts up or down

to suit)

Slip Fret Retainer

over thumbscrews

and tighten screws

Cast Iron Fret Installation

Adjust screw heads on back of fret to the thickness of

the retainer bracket and drop the fret into place while

guiding the screw heads into the slots in the bracket.

Clip the ash pan cover onto the fret.

18

Owner’s Information

Please read the Safety and Warning Information section at the beginning of this manual.

Operating Your Fire

For your safety, this appliance is fi tted with a fl ame supervision device which will shut-off the gas supply if, for

any reason, the pilot fl ame goes out. This device incorporates a fi xed probe, which senses the heat from the pilot

fl ame. If the probe is cool, the device will prevent any gas fl ow unless the burner control knob is kept pushed in at

the PILOT position. See full lighting instructions on page 22 of this manual.

Programmable Remote Control

Your fi replace remote control helps you get the comfort, convenience and

aesthetics you want from your gas fi replace. The remote controls your fi replace

in different ways.

IMPORTANT: BEFORE YOU BEGIN, please note that on this system,

the settings of time, temperature and automatic ON/OFF can only be

programmed when the function display is fl ashing. Be patient when

programming as it can take a few seconds to set.

Setting the Time

The fi rst thing to do is to set the time.

1.

With your thumb, hold down both the AUTO and TIMER buttons until F fl ashes.

Let go.

2.

Note the digital clock on the bottom right hand corner. The ▲

button sets the hour; the ▼ button sets the minutes. Set the time.

Note: You must start setting the time while the F is fl ashing. If it stops fl ashing,

go back to 1.

3.

The display shows °C/24-hour or °F/12-hour. To change the temperature/hour

display, press on the AUTO button while the display fl ashes.

4.

Let go and wait until the fl ashing stops. The remote shows the time you set. It

also shows the current temperature.

Setting the Temperature

Use this setting when you come in and want to enjoy a specifi c temperature.

1.

Push the AUTO button until a number and F fl ash. Let go.

2.

While it is still fl ashing, push the ▲ and ▼ buttons to the temperature you

want. Let go.

Your fi replace will reach that temperature and the remote will check the temperature

every fi ve minutes, adjusting the amount of fuel needed to give you a steady, even

heat.

Setting the Flame

Use this setting when you want a particular fl ame level. For instance, you want to

watch fl ames burn at their highest level and you don’t mind if the room is too hot.

1.

To raise the fl ame, press and hold the ▲ button until the flame gets to the

desired level. Let go.

2.

To lower the fl ame, press and hold the ▼ button until the fl ame gets to the

desired level. Let go.

The fl ame level will remain just as you set it.

19

Owner’s Information

Automatic ON/OFF

You can set your fi replace to come on before you wake up and turn off after you

leave and then, turn on again just before you come home and turn off after going

to bed.

You can leave it like this for the heating season.

Decide what temperature you want your fi replace to be at. Also, decide what

1.

time you want your fi replace to turn on and off. Finally, decide what time you

want it to come back on and off in the afternoon or evening. For the fi rst few

times you set the timer, it’s handy to write these times down.

Set the temperature (just as you did in the section Setting the Temperature.)

2.

Press the TIMER button and hold it until P1

3.

While fl ashing, push the buttons▲ (hour) and ▼ (minutes) to set the time at

which you want your fi replace to turn on in the morning.

4.

Press the TIMER button and hold it until P1 ☽ appears and fl ashes. Let go.

While fl ashing, push the buttons ▲ (hour) and ▼ (minutes) to set the time at

which you want your fi replace to turn off when you leave.

5.

Press the

While fl ashing, push the buttons ▲ (hour) and ▼ (minutes) to set the time at

which you want your fi replace will turn back on in the afternoon.

6.

Press the TIMER button and hold it until P2 ☽ appears and fl ashes. Let go.

While fl ashing, push the buttons ▲ (hour) and ▼ (minutes) to set the time at

which you want your fi replace to turn off in the evening.

Note: If you want to set your fi replace for only one time on and off, set P2

P2 ☽ for the same times as P1 ☽. The remote will record the P1 ☽ off time for

both P2 times.

To temporarily override the timer setting, just press AUTO or ▲ and ▼ to go back

to manual settings. Press TIMER to go back to your settings.

TIMER button and hold it until P2 ☼ appears and fl ashes. Let go.

☼ appears and flashes. Let go.

☼ and

When your remote control displays BATT, you need to replace the battery with a

new 9 volt alkaline battery—6LR61/MN1604.

20

Owner’s Information

Cleaning

It will be necessary to clean the glass periodically. During startup,

condensation, which is normal, forms on the inside of the glass and causes

dust, lint etc. to cling to the glass surface. Initially paint, while curing, may

deposit a slight fi lm on the glass. We therefore recommend that, during

the fi rst few weeks of use, the glass be cleaned two or three times with

non-abrasive common household cleaners and warm water. Ammonia

based cleaners should not be used. Subsequently, the glass should be

cleaned two or three times a season depending on the circumstances.

Do not clean the glass while it is hot. Always securely replace the window

before lighting. If broken, the glass pane may only be replaced as a

complete window unit as supplied by the manufacturer.

It is necessary to remove the cast iron fret and brackets before

removing the window—see section Cast Iron Fret Installation).

The window can be removed for cleaning by rotating the two fastening studs at the bottom corners

90 degrees to release, and swinging the bottom of the window unit outwards to unhook the top edge.

After refi tting the window, apply light hand pressure against the window frame sides to bed-in the window seal.

Dust, etc. can be brushed from the ceramic fuel effects and fi rebox walls after removing the front unit and opening

the window. Dust etc. can also be removed from the burner using a soft brush after removing the ceramic fuel

effects. When cleaning, make sure that no particles are brushed into the slots in the burner.

Check that Window

Moves Freely After

Reinstallation

Spring Loaded

Fastening Studs (2)

1/4 Turn

Checks

Performance of LPG appliances may be affected by the quality

of commercial gas supplied in your area.

A periodic check of the pilot and burner fl ames should be made. Check after the

fi re has been on for at least 30 minutes. The pilot fl ame must cover the tip of

the thermocouple probe. The main burner fl ame pattern will vary from appliance

to appliance depending on the type of installation and climatic conditions—see

fi gures at right.

The appliance area must always be kept clear and free from combustible

materials, gasoline and other fl ammable vapors and liquids.

Inspect the vent terminal outdoors regularly to make sure that, snow,

leaves, bushes, trees, etc, do not obstruct it.

Examine the vent system and terminal regularly. We recommend

annually.

Thermocouple

Probe must be

in Flame

Pilot Flame

Batteries Replacement

All appliances use four 1.5 V AA batteries for remote control receivers

and the handset uses a 9 V battery.

Batteries are accessible by removing the lid of the remote control

receiver. Batteries should last one to two seasons, depending on

usage. Removing batteries in the off season will extend battery life. Should the batteries loose power, the control

may be operated by manually turning the control knob at the valve.

Correct Flame Picture

General Servicing

If your appliance needs to be serviced, contact your supplier quoting the model number. It will be helpful if the

appliance serial number can also be quoted. This is on the rating plate, which is attached to the unit.

The repair parts are shown in the repair parts list. Please always quote the part number and description when

requesting spare parts.

21

Lighting Instructions

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING:

property damage, personal injury or loss of life.

A. This appliance has a pilot, which must be lighted by hand. When lighting the pilot, follow these

instructions exactly. To save energy, turn the pilot off when not using the appliance.

B. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the control knobs. Never use tools. If the controls will not

push in or turn by hand, don’t try to repair them, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the appliance and to replace any part of the control system and any gas

control, which has been under water.

If you do not follow these instructions exactly, a fire or explosion may result causing

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the flame adjustment knob as far

clockwise

3. Turn the gas control knob clockwise

NOTE: The knob cannot be turned from PILOT to

OFF unless it is pushed in partially. Do not force.

4. Wait five (5) minutes to clear out any gas, then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety

information above. If you don’t smell gas, go to

the next step.

5. Find the pilot. It is at the left side of the firebox

viewed through slotted hole in front log.

6. Push in and turn the gas control knob counterclockwise until resistance is felt just before the

“IGN” position.

7. Keep pushed in for a few seconds to allow gas to flow then, keeping knob depressed, turn to

“PILOT” to light pilot. Hold knob in for a further 5 seconds then release. The knob should pop

back out. Pilot should remain lit. If pilot goes out repeat steps 3 through 7.

· If knob does not pop out when released, stop and immediately call your service technician or

gas supplier.

· If pilot lights but will not stay lit after several tries, turn the gas control knob to “OFF” and call

your service technician or gas supplier.

8. When pilot is lit, partially depress the knob and turn to “ON” position (Burner alight).

· Do not leave knob set between “PILOT” and “ON”.

9. Set the flame height to desired setting

as possible*.

to OFF.

*

.

TO TURN OFF GAS TO APPLIANCE

1. Set the flame adjustment knob as far clockwise as possible*

2. Push in gas control knob slightly and turn clockwise to “OFF”. Do not force.

*

The flame height can be increased or decreased by depressing the remote control hand set

button.

22

Warranty

If you have a problem with this unit, please contact your dealer or supplier immediately. Under no

circumstances should you attempt to service the unit in any way by yourself. The warranties in paragraphs

1 and 2 are provided only to the fi rst purchaser/user of this unit, are not transferable and are subject to the

conditions and limitations in paragraphs 3, 4 and 5. Please review the conditions and limitations carefully

and strictly follow their requirements.

1. Extended Warranty Coverage

For a period of up to ten (10) years, Miles Industries Ltd., (the “Company”) or its appointed distributor will at its option pay the

initial purchaser for the repair of, or will exchange the following parts or components which are found to be defective in material or

workmanship under normal conditions of use and service:

Part or Component Defect Covered Maximum Warranty Period

Exterior steel casing Corrosion 10 years

Glass Loss of structural integrity 10 years

Cast iron parts Corrosion 10 years

Firebox and heat exchanger

2. Two-Year Parts Warranty

In addition, for two (2) years from the date of purchase, the Company, at its option, can repair or exchange all parts and

components not listed above but that are found to have a bona fi de defect in material or workmanship under normal conditions of

use.

Corrosion (but not discoloration) causing

loss of structural integrity

10 years

3. Conditions and Limitations

The warranty registration card must be completed by the initial owner and returned to the Company within 90 days of purchase.

a)

Installation and maintenance must be performed by an authorized and trained dealer in accordance with the Company’s

b)

installation instructions.

This warranty is void where installation of the unit does not conform to all applicable codes including national and local gas

c)

appliance installation codes and building and fi re codes.

The owner must comply with all operating instructions.

d)

The Company is not responsible for the labor costs to remove defective parts or re-install repaired or replacement parts.

e)

The fi rst purchaser or user of the unit will be responsible for any shipping charges for replacement parts as well as travel time

f)

incurred by the dealer to perform the warranty work.

This warranty applies to non-commercial use and service and is void if it is apparent that there is abuse, misuse, alteration,

g)

improper installation, accident or lack of maintenance to the unit.

This warranty does not cover damage to the unit through:

h)

i) Improper installation, operational or environmental conditions.

ii) Inadequate ventilation in the area or competition for air from other household equipment or appliances.

iii) Damage due to chemicals, dampness, condensation, or sulphur in the fuel supply lines which exceeds industry

standards.

This warranty does not cover glass, log breakage or damage to the unit while in transit.

i)

The Company does not allow anyone to extend, alter or modify this warranty and assumes no responsibility for direct, indirect

j)

or consequential damages caused by the unit. State or provincial laws where the fi rst purchaser or user resides may provide

specifi c rights to extend this warranty and, if so, the Company’s sole obligation under this warranty is to provide labor and/or

materials in accordance with those laws.

4. Discharge of Liability

After two (2) years from the date of purchase, the Company may, at its option, fully discharge all obligations under this warranty by

paying to the fi rst purchaser/user the wholesale price of any defective parts.

5. No Other Warranty

All obligations to repair this unit are defi ned in this warranty. Some states or provinces may specifi cally mandate additional

warranties on the part of manufacturers, but in the absence of such specifi c legislation, there is no other warranty or obligation

expressed or implied.

23

Parts

KEY DESCRIPTION

1 Firebox Assembly 400634AH

2 Restrictor (2) 400767

3 Convection Baffl e 4000744

4 Fret Support LH 4000693

5 Wing Nut (2) 4000741

6 Leg LH 4000662

7 Leveling Bolt (2) 4000242

8a Log Support NG 4000621

8b Log Support LPG 4001456

9 Leg RH 4000663

10 Fret Support RH 4000694

11 Thumbscrew # 10-32x1/2” (4) 4000753

12a Burner Tray Assy DV, NG 4000635

12b Burner Tray Assy DV, LPG 4000653

13 Airshutter 4000657

14a Injector Elbow NG 82-580 720A580

14b Injector Elbow LP 92-260 9730007

15 Valve Tray, DV 4000714

16 Gasket Rear 4000642

17 Gasket LH Side 4000643

18 Gasket Front 4000641

19 Gasket RH Side 4000644

20 Burner Support 4000579

21 Burner 4000599

22 Shutter Slider 4000759

23 Front Log Bracket 4000739

24 Olive 8mm 519779

25 Olive Nut 523389

26 Pipe Valve to main Burner 4000600

27 Tube Nut 523389

28 Valve Mount 4000141

29a 190 Series Pilot Assy NG 4000727

29b 190 Series Pilot Assy LPG 4000728

30 Electrode Nut 720A200

31 Pilot Gasket 4000715

32 Pilot Bracket 190 Series 4000729

Threaded Plug Pilot Bracket 4000726

33 Thermocouple 4000061

34a NG Pilot Injector #62 4001352

34b LPG Pilot Injector #30 4000736

PART

NUMBER

KEY DESCRIPTION

35 2-Flame Pilot Hood 4000730

36 Electrode 720A543

37 Pilot Tube 4000732

38 Straight Connector 544079

39 Maxitrol Valve GV34 4000056

Valve Cover 4000801

Servo Motor 4000802

Minimum Rate Screw #160,

40a

NG

Minimum Rate Screw # 105,

40b

LPG

41 Inlet Connector 4000746

42 Ignition Wire N/A

43 Remote Control Kit 4000754

44 Transmitter N/A

45 Receiver N/A

46 Wall Bracket N/A

47 Wiring Harness N/A

48 Window Assy 4000604

49 Brick Set, Retrofi re 4000648

50 Brick Panel, Rear 4000666

51 Brick Panel, LH 4000668

52 Brick Panel, RH 4000667

53a Log Set, Retrofi re NG 4000603

53b Log Set Retrofi re LPG 4000603P

54a Rear Log NG 4000688

54b Rear Log LPG 4000688P

55 RH Log 4000691

56 Centre Log 4000689

57 Front Log 4000692

58 LH Log 4000690

PART

NUMBER

4000810

4000824

24

Parts

3

19

4

21

20

5

7

6

8a, 8b

23

22

13

14a,

14b

12a, 12b

15

16

2

1

48

9

10

11

49

50

35

34a,

34b

32

31

33

42

41

40a, 40b

36

30

37

18

28

27

38

39

24

25

26

29a, 29b

17

45

46

44

53a, 53b

43

47

51 52

54a, 54b

58

55

56

57

25

Loading...

Loading...