Miles Industries DV ZC 1100IN, DV ZC 1100IP, DV ZC 1150ILN, DV ZC 1150ILP, H5 1100IN Owner's Manual

...

H5 SERIES

DV ZC Gas Fireplace

1100IN (NG) & 1100IP (LPG)

1150ILN (NG) & 1150ILP (LPG)

Installation & Owner’s Manual

!

A barrier designed to reduce the risk of burns from the hot

viewing glass is provided with this appliance and shall be

installed for the protection of children and other at-risk

individuals.

! WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

— Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

▪ Do not try to light any appliance.

▪ Do not touch any electrical switch; do

not use any phone in your building.

▪ Leave the building immediately.

▪ Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

▪ If you cannot reach your gas supplier,

call the fi re department.

— Installation and service must be

performed by a qualifi ed installer, service

agency or the gas supplier.

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

This manual contains instructions to install the

ENGINE ONLY. A trim kit is REQUIRED to

complete the installation. A barrier screen is

provided with the trim kit. Refer to the manual

supplied with the trim for installation.

This appliance may be installed in an

after-market permanently located,

manufactured (mobile) home where not

prohibited by local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certifi ed kit is used.

This appliance is a domestic room-heating

appliance. It must not be used for any other

purposes such as drying clothes, etc.

This appliance is suitable for installation in a

bedroom or bed sitting room.

Ce guide est disponible en français sur demande.

INSTALLER

Leave this manual

with the appliance.

CONSUMER

Retain this manual

for future reference.

Please read this manual

BEFORE installing and

operating this appliance.

4003682-04

©2015, Miles Industries Ltd.

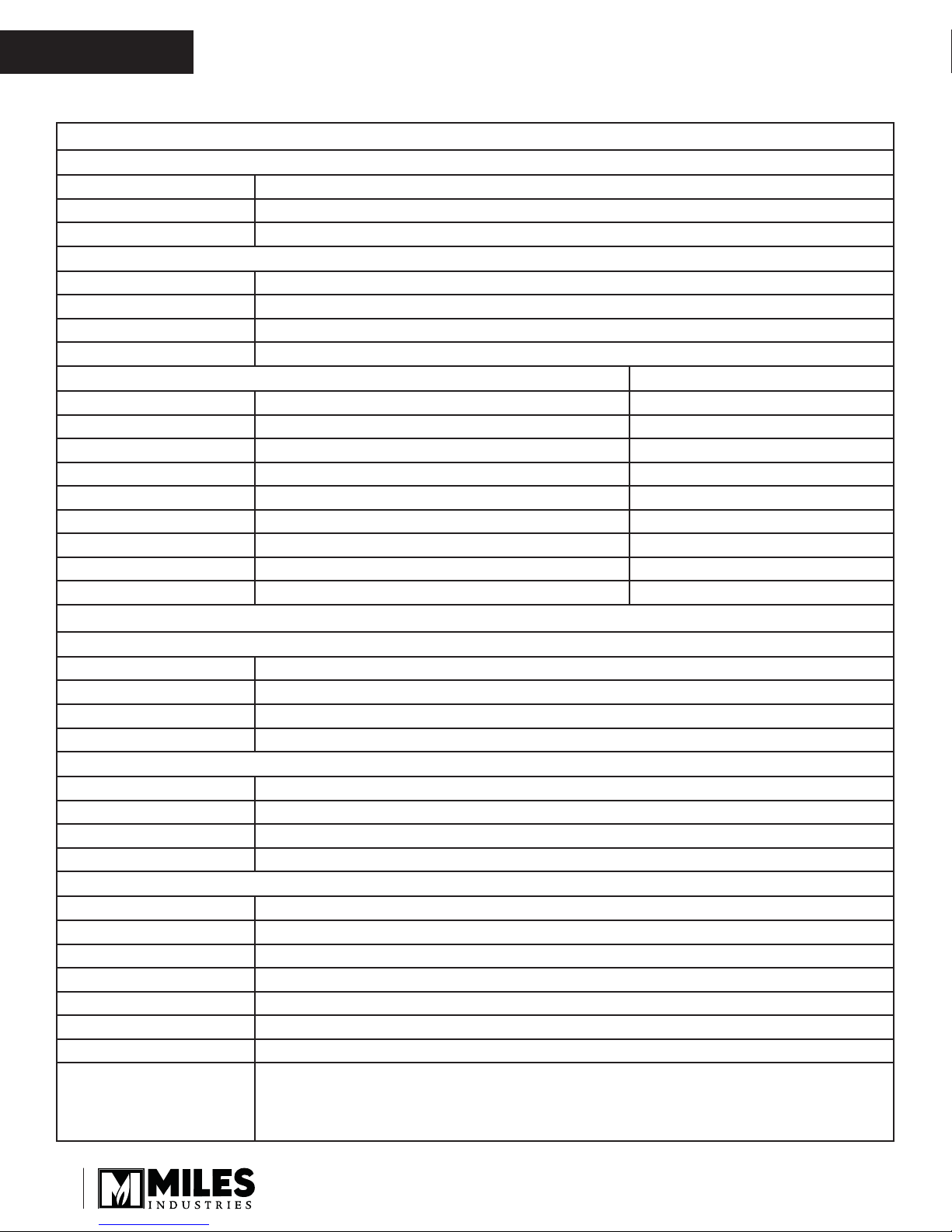

Table of Contents

W

A

R

R

A

N

T

Y

P

R

O

G

R

A

M

V

A

L

O

R

C

O

M

F

O

R

T

V

A

L

O

R

C

O

M

F

O

R

T

FOR THE OWNER FOR THE QUALIFIED INSTALLER

Safety Precautions ................................................. 3

Safety and Your Fireplace ...................................... 4

Owner’s Information ............................................... 5

Operating Your Fireplace for the First Time ...............5

Cleaning Your Fireplace ............................................6

Checking Pilot and Burner Flames ............................8

Replacing Batteries ...................................................8

Using Handset Wall Holder ........................................9

Locating Lighting, Operation and Rating

Information Card .....................................................9

Servicing Your Fireplace ............................................9

Operating Your Fireplace ...........................................9

How to Turn Your Fireplace OFF

(including pilot) .....................................................10

How to Ensure Your Fireplace Cannot

Be Turned ON Inadvertently .................................10

Remote Control Operation ................................... 11

Options .................................................................. 16

Lighting Instructions ............................................ 17

Warranty ................................................................67

R

O

M

L

A

R

A

G

Warranty Card at the

back of this manual.

W

O

V

R

P

Y

T

T

N

A

R

R

R

A

O

C

F

O

M

Massachusetts: The piping and fi nal gas connection

must be performed by a licensed plumber or gas fi t-

ter in the State of Massachusetts. Also, see Carbon

Monoxide Detector requirements on page 18.

The information contained in this installation manual is

believed to be correct at the time of printing. Miles Industries Ltd. reserves the right to change or modify any

information or specifi cations without notice. Miles Indus-

tries Ltd. grants no warranty, implied or stated, for the

installation or maintenance of your heater, and assumes

no responsibility for any consequential damage(s).

Commonwealth of Massachusetts......................18

Specifi cations ....................................................... 20

Overview................................................................21

Dimensions & Location ........................................ 22

Mantel & Hearth Clearances ................................23

Hearth Requirements ........................................... 25

Framing Requirements ........................................28

Venting ...................................................................32

Co-axial Venting....................................................33

Co-linear Venting .................................................. 37

Installation Planning ............................................39

Appliance Height in Framing ...................................39

Appliance Depth in Framing ....................................39

Plan Wall Finish .......................................................40

Installation ............................................................. 42

Unpack Appliance ....................................................42

Convert from Top to Rear Outlet

(if required) ...........................................................42

Remove Window .....................................................43

Install Appliance for 1130 Fixed Framing Kit ...........44

Install Appliance for 3 and 4-Sided Trim, Doors

or Cast Mantel ......................................................47

Install Electrical Wiring (if necessary) .....................50

Connect Gas Supply ................................................51

Install Liners ............................................................52

Install Driftwood Kit 1101DWK (1100 models) .........53

Install Decorative Glass Murano 1103DGM

(1100 models) .......................................................55

Install Decorative Glass Set 1104DGS

(1100 models) .......................................................56

Install Traditional Logs (1150 models) .....................57

Refi t and Check Window .........................................60

Remote Control Initial Pairing ..................................61

Check Operation ......................................................62

Adjust Aeration if needed .........................................62

Install Trim and Barrier Screen ................................62

Install Remote Control Handset Wall Holder ...........63

Wiring Diagram .....................................................64

Approved Venting Components .......................... 65

Warranty ................................................................67

Spare Parts............................................................68

190–2255 Dollarton Highway, North Vancouver, BC, CANADA V7H 3B1

2

Designed and Manufactured by / for

Miles Industries Ltd.

Tel. 604-984-3496 Fax 604-984-0246

www.valorfi replaces.com

© Copyright Miles Industries Ltd., 2015. All rights reserved.

Safety Precautions

!

READ and UNDERSTAND all instructions carefully

before starting the installation. FAILURE TO FOLLOW

these installation instructions may result in possible fi re

hazard and will void the warranty.

Prior to the fi rst fi ring of the fi replace, READ the

Owner’s Information section of this manual.

DO NOT USE this appliance if any part has been under

water. Immediately, CALL a qualifi ed service technician

to inspect the unit and to replace any part of the control

system and any gas control that has been under water.

THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

Installation and repair should be PERFORMED by a

qualifi ed service person. The appliance and venting

system should be INSPECTED before initial use and at

least annually by a professional service person. More

frequent cleaning may be required due to excessive

lint from carpeting, bedding, etc. It is IMPERATIVE that

the unit’s control compartment, burner, and circulating

air passageways BE KEPT CLEAN to provide for

adequate combustion and ventilation air.

Always KEEP the appliance clear and free from

combustible materials, gasoline, and other fl ammable

vapors and liquids.

NEVER OBSTRUCT the fl ow of combustion and

ventilation air. Keep the front of the appliance CLEAR

of all obstacles and materials for servicing and proper

operation.

This unit MUST be used with a vent system as

described in this installation manual. NO OTHER vent

system or components MAY BE USED.

This gas fi replace and vent assembly MUST be vented

directly to the outside and MUST NEVER be attached

to a chimney serving a separate solid fuel burning

appliance. Each gas appliance MUST USE a separate

vent system. Common vent systems are PROHIBITED.

INSPECT the external vent cap on a regular basis to

make sure that no debris, plants, trees, shrubs are

interfering with the air fl ow.

TURN OFF the gas before servicing this appliance.

It is recommended that a qualifi ed service technician

perform an appliance check-up at the beginning of each

heating season.

DO NOT use this heater as a temporary source of heat

during construction.

State of California. Proposition 65 Warning. Fuels

used in gas, wood-burning or oil fi red appliances,

and the products of combustion of such fuels, contain

chemicals known to the State of California to cause

cancer, birth defects and other reproductive harm.

California Health & Safety Code Sec. 25249.6.

Due to the high temperature, the appliance should be

LOCATED out of traffi c areas and away from furniture

and draperies.

Clothing or fl ammable material SHOULD NOT BE

PLACED on or near the appliance.

This appliance is a DOMESTIC ROOM-HEATING AP-

PLIANCE. It must not be used for any other purposes

such as drying clothes, etc.

DO NOT place furniture or any other combustible

household objects within 36” of the fi replace front.

BE CAREFUL not to put any decorating objects

sensitive to heat to close above or around the fi replace

as it gets very hot when operating.

The glass door assembly MUST be in place and sealed

before the unit can be placed into safe operation.

DO NOT OPERATE this appliance with the glass door

removed, cracked, or broken. Replacement of the glass

door should be performed by a licensed or qualifi ed

service person. DO NOT strike or slam the glass door.

The glass door assembly SHALL ONLY be replaced

as a complete unit, as supplied by the fi replace

manufacturer. NO SUBSTITUTE material may be used.

DO NOT USE abrasive cleaners on the glass door

assembly. DO NOT ATTEMPT to clean the glass door

when it is hot.

A BARRIER DESIGNED TO REDUCE THE RISK OF

BURNS from the hot viewing glass is provided with

this appliance and SHALL BE INSTALLED for the

PROTECTION OF CHILDREN and other AT-RISK

INDIVIDUALS.

If the barrier becomes damaged, the barrier SHALL BE

REPLACED with the MANUFACTURER’S BARRIER

for this appliance.

Any safety screen, guard or barrier removed for ser-

vicing the appliance, MUST BE REPLACED prior to

operating the appliance.

Children and adults should be ALERTED to the hazards

of high surface temperature and should STAY AWAY to

avoid burns or clothing ignition.

YOUNG CHILDREN should be CAREFULLY

SUPERVISED when they are in the same room as the

appliance. Toddlers, young children and others may

be susceptible to ACCIDENTAL CONTACT BURNS.

A physical barrier is recommended if there are at-risk

individuals in the house. To restrict access to a fi replace

or stove, INSTALL AN ADJUSTABLE SAFETY GATE

to keep toddlers, young children and other at-risk

individuals out of the room and away from hot surfaces.

3

Safety and Your Fireplace

!

Safety and Your Fireplace

Please Read and Carefully Follow all Safety Warnings and

Operating Instructions Contained in Your Owner’s Manual

(Replacement Manuals are available by contacting our service department at

1-800-468-2567 or visit www.valorfi replaces.com).

Please Follow These Important

Child Safety Precautions and

Recommendations,

• Parts of your Valor Fireplace become

extremely hot while in operation.

• The glass viewing window

temperature can

exceed 500 F

at full capacity.

Momentary contact

with a hot glass

surface can cause

a severe burn, even if the fi replace

is operating at reduced heating

capacity.

withdraw in the event of accidental

contact with a hot surface.

• A physical barrier is strongly

recommended if there are young

children, or at-risk individuals in the

house. Install an approved aftermarket safety gate to keep toddlers,

young children and other at-risk

individuals a safe distance from the

fi replace.

• Keep the remote control handset

out of reach of children at all

times. A wall mount storage holster

is provided with your remote control

handset.

• The glass window will remain hot

for an extended period of time after

the fi replace has been turned off.

Ensure that children are prevented

from touching the fi replace during the

cool down period.

• Toddlers and Young Children

must be closely supervised at all

times when they are in the same

room as the operating fi replace. They

lack full awareness of danger and

rely on your protection. Toddlers,

in particular , do not have the motor

skills and response refl exes to

4

• Ensure that the fi replace, including

the pilot light, is completely turned

off when children are present and

close supervision and safety barriers

are not available—see pages 9–10 of

Owner’s Information section.

• If the fi replace is not going to be used

for the summer or any extended

period of time, remove the batteries

from the remote control handset

and receiver. It is recommended that

batteries are replaced annually in any

event—see page 8.

Owner’s Information

• • Some materials or items, although safe, may

discolor, shrink, warp, crack, peel, and so on

because of the heat produced by the fi replace.

AVOID PLACING

candles, paintings, photos,

and other items

SENSITIVE TO HEAT

• • Solid wood fl ooring in front of the fi replace (if

allowed) may shrink during the heating season

due to heat.

OWNER’S

INFORMATION

WARNING

!

EXTREMELY HOT!!!

• READ the SAFETY information on pages

3 and 4 of this manual BEFORE operating

your gas heater.

• Some parts of your fi replace are EXTREMELY

HOT, particularly the GLASS window.

• DO NOT LET CHILDREN touch the glass or

any parts of your fi replace even after it is

turned off as it is still hot.

• USE THE BARRIER SCREEN provided with

the trim or a GATE to reduce the risk of severe

burns.

• Keep the remote control handset OUT OF

REACH of children.

• HOT WALL SURFACES! The wall directly above

the fi replace is VERY HOT when the fi replace

heats. It is constructed of non-combustible

materials and although safe, it may reach

temperatures in excess of 200º F depending

on choice of trims. DO NOT TOUCH IT!

• HOT HEARTH/FLOOR SURFACE! The

hearth or fl oor directly in front of the fi replace

is VERY HOT when the fi replace heats. Even

if constructed of non-combustible materials,

and although safe, it may reach temperatures

in excess of 200º F depending on choice of

materials. DO NOT STEP ON IT!

Some materials or items, although safe, may

discolor, shrink, warp, crack, peel, and so on

because of the heat produced by the fi replace.

AVOID PLACING

and other items

36 inches (0.9 m) around the fi replace.

Solid wood fl ooring in front of the fi replace (if

allowed) may shrink during the heating season

due to heat.

Performance of LPG appliances may be affected by

the quality of commercial gas supplied in your area.

candles, paintings, photos,

SENSITIVE TO HEAT

within

Thank You ...

For purchasing a Valor by Miles Industries. Your new

radiant gas heater is a technical appliance that must

be installed by a qualifi ed dealer. Each Valor fi replace

is fully tested during the production process for your

safety and comfort.

Your unit has been professionally installed by:

Dealer Name: ________________________________

Phone Number :_______________________________

Should you encounter an operational problem, call

your dealer immediately.

Do not try to repair the unit as you may cause an

injury or damage the fi replace.

This manual and particularly the preceeding

and following pages contain very important

information regarding the safe operation of your

fi replace as well as maintenance instructions.

Read carefully BEFORE operating your fi replace

and pay special attention to the SAFETY

WARNINGS.

A heating gas appliance does require safe handling

and for this reason, we very strongly recommend that

no children be allowed to touch the fi replace and its

controls at all times. Do install a screen or barrier

in front of the fi replace to protect your children

against severe burns.

Operating Your Fireplace for the First Time

When operating your new fi replace for the fi rst time,

some vapors may be released due to the burning of

curing compounds used in the manufacture of the

appliance. They may cause a slight odor and could

cause the fl ames to be the full height of the fi rebox, or

even slightly higher, for the fi rst few hours of operation.

It is also possible that these vapors could set off any

smoke detection alarms in the immediate vicinity.

These vapors are quite normal on new appliances. We

recommend opening a window to vent the room. After

a few hours use, the vapors will have disappeared and

the fl ames will be at their normal height.

Fireplace

Hearth

Do not put

furniture or other objects

in this space in front of

the replace:

36” (0.9 m)

Flame Supervision Device

For your safety, this appliance is fi tted with a fl ame

supervision device which will shut-off the gas supply

if, for any reason, the pilot fl ame goes out. This device

incorporates a fi xed probe, which senses the heat

from the pilot fl ame. If the probe is cool, the device will

prevent any gas fl ow unless manually lighting the pilot.

See full lighting instructions on page 17 of this manual.

5

OWNER’S

INFORMATION

Owner’s Information

Cleaning Your Fireplace

WARNING

!

DO NOT TOUCH THE GLASS WHILE IT IS HOT!

Let the fi replace cool fi rst before cleaning it.

Important - Glass cleaning - Mineral deposits

One of the by-products of the combustion process in

a gas appliance is a mineral which can show up as a

white fi lm on the ceramic glass of the viewing door.

The composition of the deposit varies with location and

time. It is believed to be associated with the varying

sulfur content of the gas. You may have the problem

intermittently.

We have consulted with ceramic glass manufacturers

and they cannot offer a defi nitive solution to this prob-

lem. Dealers have tried various cleaning products with

varying results. The following are recommendations

only and are not meant to guarantee results.

NOTE: This is a problem beyond Miles Industries’

control and is not covered under warranty.

• Clean the glass regularly as soon as you notice

the buildup (white fi lm). If the fi lm is left for a longer

period of time, it will etch into the glass. It is then

much harder, if not impossible, to remove.

• NEVER use an abrasive cleaner on the

ceramic glass. Any abrasion of the surface

has the immediate effect of compromising the

strength of the glass. An emulsion type cleaner is

recommended.

• Use a soft damp cloth to apply the cleaner. Dry the

glass with a soft, dry, preferably cotton cloth. Most

paper towels and synthetic materials are abrasive to

ceramic glass and should be avoided.

• Our dealers have had good results from the

products listed below. We cannot, however,

guarantee the results of these products.

• Brasso, Polish Plus by Kelkem, Cook Top Clean

Creme by Elco, White Off by Rutland, Turtle Wax

Do not clean the glass while it is hot!

Always securely replace the window and the barrier

screen before lighting.

If broken, the glass pane may only be replaced

as a complete window unit as supplied by the

manufacturer.

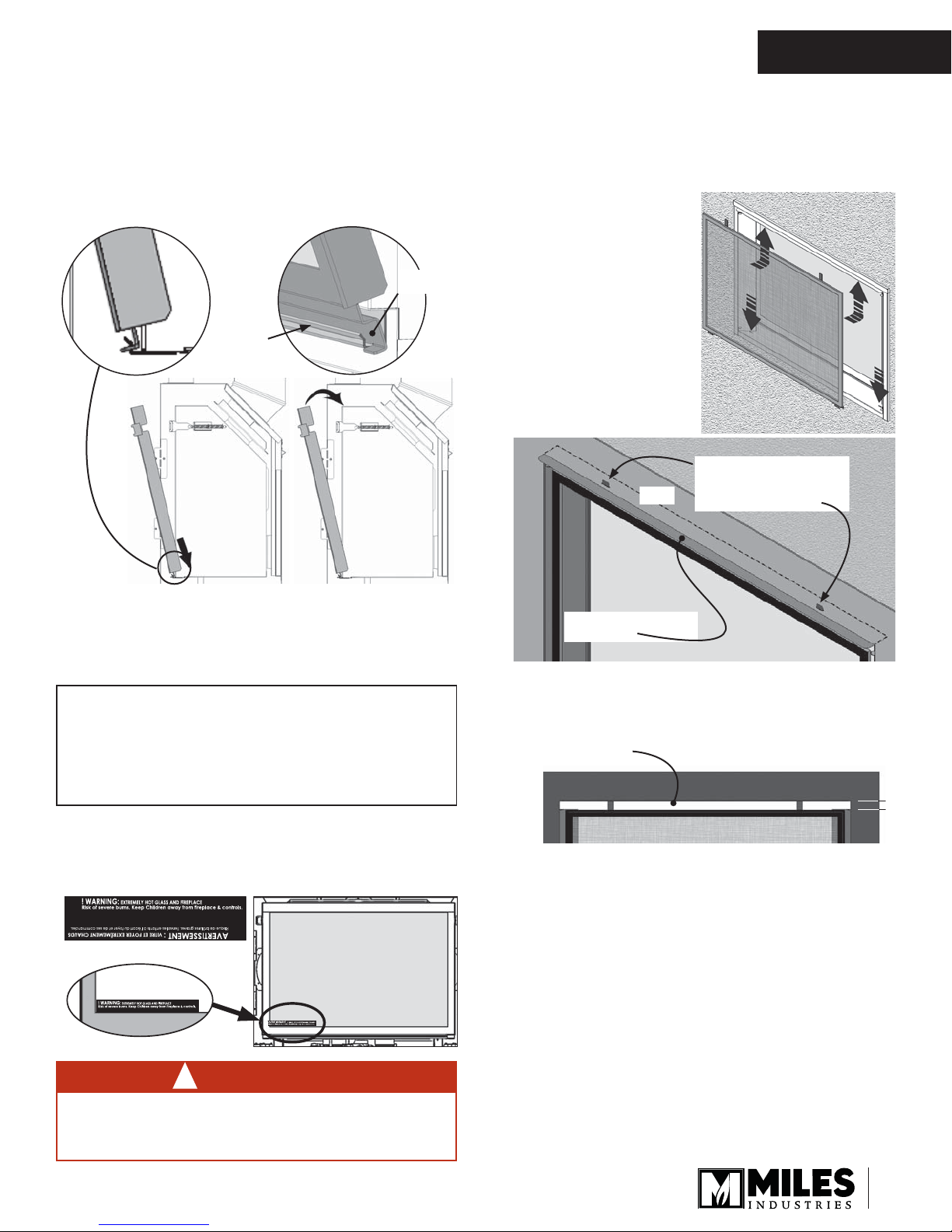

To remove the window for cleaning:

1. Remove the barrier

screen. Slide the screen

up to disengage the

bottom tabs then unhook

the top tabs.

2. Remove the side panels

by pulling them sideways

towards the center,

sliding them out of their

slots behind the trim

face.

3. Find the levers on each

side of the window

towards the top. Using

your fi nger, pull the

levers towards you and

unhook them from the

window frame brackets.

4. Gently pull the top of the

window outward.

5. Lift the window out of its

bottom railing and set it aside in a safe place to

avoid damage.

Clean the window following the guidelines in this section.

Clean the steel trims with mild soap and warm water.

Any alcohol/solvent base cleaner will weaken the coating and damage it.

Clean the cast iron trims dusting with a soft brush.

Clean the barrier screens dusting with a soft brush.

Clean the fi rebox ceramic logs/rocks and walls dust-

ing them with a soft brush. Dust can also be removed

from the burner using a soft brush after removing the

ceramic logs. When cleaning, make sure that no par-

ticles are brushed into the slots of the burner.

WARNING

!

b

a

Spring Loaded

Window Levers

CHOKING HAZARD! Ensure that the fi replace

area is clear of fi reglass or shale particles as

these could be ingested by small children. Vacuum

thoroughly around the fi replace area after cleaning.

If the barrier becomes damaged, the barrier shall

be replaced with the manufacturer’s barrier for this

appliance.

6

Owner’s Information

OWNER’S

INFORMATION

To refi t the window:

1. Place it in its bottom railing and push its top against

the fi rebox.

Note: Ensure to remove any shale or glass particles

in the railing before installing the window.

Window

frame

Bottom

railing

5. Reinstall the side doors sliding them sideways to

insert their tabs behind the front face of the trim.

6. Reinstall the barrier screen on the trim.

a) 1130, 1135, 1140,

1145 trims: Insert

the screen’s top

tabs in the slots on

the underside of the

convectio n baffl e or

heatshield, then insert

the screen’s bo ttom

tabs in the slots of the

removable panel at

the bottom to lock it in

position.

Barrier screen’s top tabs

coming through slots in

Trim

baffl e/heatshield (behind

the face of the trim)

2. While you hold it, pull the side levers back into the

window brackets on each side.

3. Apply light hand pressure against the window frame

sides to bed-in the window seal.

IMPORTANT: To ensure a safe operation, verify that

the levers are hooked properly to the window tabs;

then, pull out the top of the window and release it to

insure the springs return it.

Also, double-check that the bottom of the window

frame is correctly installed in its the bottom railing.

4. If the Hot Glass Warning plate has been removed

from the front lower corner of the window,

reinstall it by sliding it between the glass and

the frame as indicated.

Hot Glass Warning Plate

Convection baffl e or

heatshield

Ensure the screen is secure and seated all the

way down into the bottom slots. There should be

a 1” gap between the top of the barrier screen

and the trim.

b) 1135 Edgemont trims: Hook the top of the

screen to the top of the trim. While hooking the

top hooks, direct the bottom tabs into the slots

of the removable panel at the bottom to lock it in

position. Ensure the screen is secure and seated

all the way down into the bottom slots.

7. Verify that the screen is properly hooked and

secure.

WARNING

!

FOR SAFETY PURPOSE, ensure the barrier

screen is re-installed on the fi replace front after

maintenance.

7

OWNER’S

INFORMATION

Owner’s Information

Checking Pilot and Burner Flames

A periodic check of the pilot and burner fl ames should

be made. Check after the fi re has been on for at least

30 minutes. The pilot fl ame must cover the tip of the

thermocouple probe. The main burner fl ame pattern will

vary from appliance to appliance depending on the type

of installation and climatic conditions.

Pilot Flame can be seen

under the right rear logs

1100 Driftwood Kit—Correct Flame Picture

Pilot Flame can be seen at

the back of the fi re bed

1100 Decorative Glass Murano—Correct Flame Picture

1100 Decorative Glass Set—Correct Flame Picture

Pilot Flame can be seen

behind the rear log

The appliance area must always be kept clear and

free from combustible materials, gasoline and other

fl ammable vapors and liquids.

Inspect the vent terminal outdoors regularly to make

sure that snow, trees, bushes, leaves, or other objects

do not obstruct it.

Examine the vent system and terminal regularly. We

recommend annually.

Replacing Batteries

WARNING

!

DO NOT ATTEMPT TO CHANGE THE BATTER-

IES WHILE THE FIREPLACE IS STILL HOT! Let

the fi replace cool fi rst before touching it.

CAUTION

DO NOT USE a screwdriver or other metallic

object to remove the batteries from the receiver or

the handset! This could cause a short circuit.

Low batteries signal: see page 15.

The appliance uses four 1.5 V AA alkaline batteries

for its receiver and two AAA alkaline battery for its

handset. Batteries should last one to two seasons,

depending on usage. Removing the batteries in the offseason will extend the battery life.

To replace the batteries in the receiver:

The receiver is located to the left side of the gas valve

under the removable panel in front of the appliance.

1. Remove the barrier screen and the removable

panel. It is not necessary to remove the side doors.

Note: If it is diffi cult to pull out the panel from its

front edge, use your fi nger and pull from the notches

in the panel at the bottom of the window.

1150 Log Set—Correct Flame Picture

Thermocouple

Probe must be in

Flame

8

Pilot Flame

Removable

panel

2. Pull the receiver out.

Receiver

Gas valve

Owner’s Information

OWNER’S

INFORMATION

3. Slide the receiver battery compartment’s cover off.

4. Replace the batteries with 4 AA alkaline batteries

orienting them as indicated inside the compartment.

5. Replace the cover.

6. Put the receiver back in its location at the left of the

gas valve.

7. Reinstall the removable panel sliding it back under

the side doors until it is fl ush with the sides of the

trim.

8. Reinstall the barrier screen.

Using Handset Wall Holder

Your fi replace equipment includes

a wall holder to store the handset.

If it hasn’t be installed, refer to the

instructions further on in this manual

for the installation.

Locating Lighting, Operation and Rating

Information Card

WARNING

!

DO NOT ATTEMPT TO TOUCH THE INFORMATION CARD WHILE THE FIREPLACE IS STILL

HOT! Let the fi replace cool fi rst before touching it.

The Lighting, Operation and Rating Information card is

rolled up and clipped located at the right-hand side of

the fi rebox.

Servicing Your Fireplace

If any attention is required for your appliance, contact

your supplier quoting the model number. It will be

helpful if the appliance’s serial number can also

be quoted. This number is on the rating plate. The

replacement parts are shown at the end of this manual.

Please always quote the part number and description

when requesting spare parts.

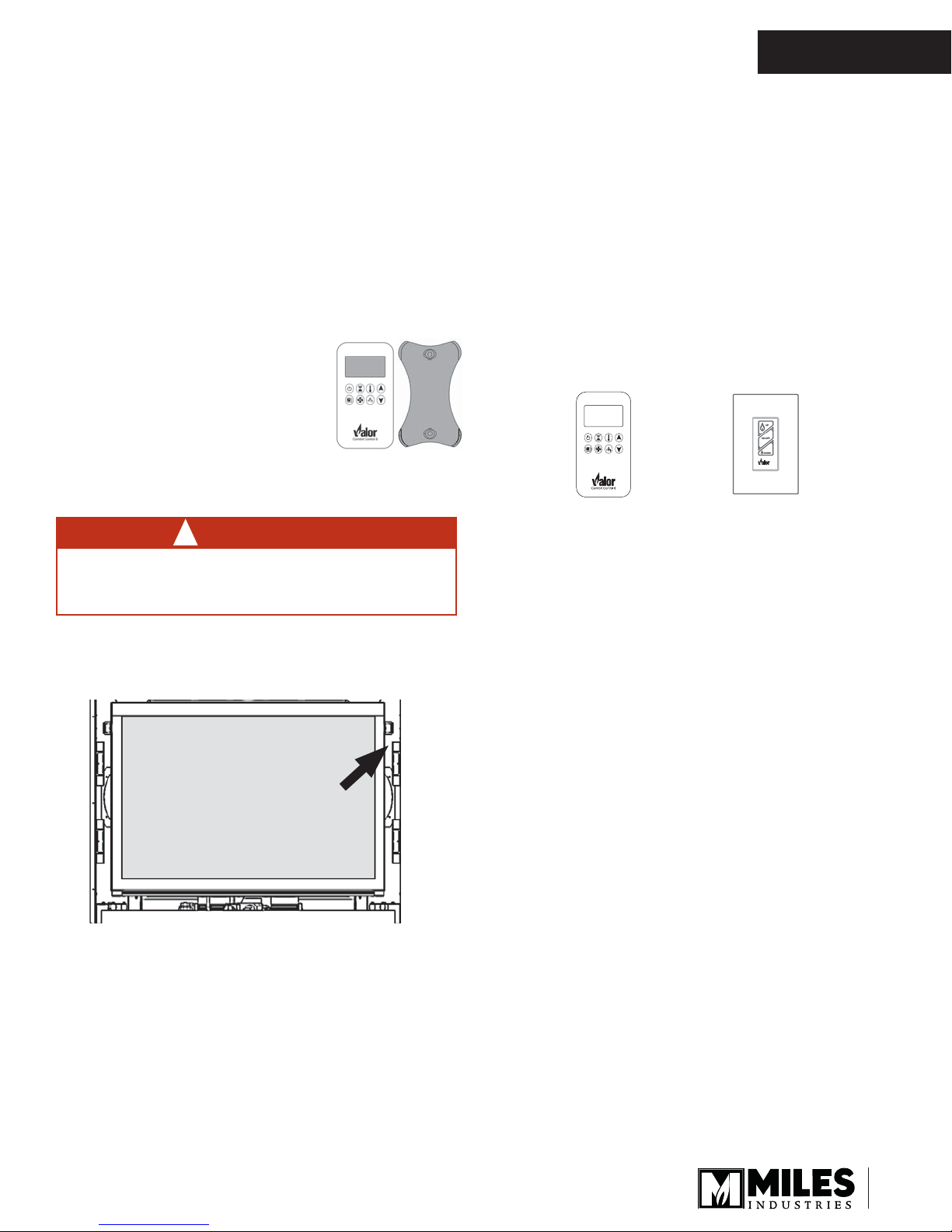

Operating Your Fireplace

There are two ways to control your fi replace.

1. Thermostatic Remote Control;

2. Wall Switch (optional).

Thermostatic

Remote Control

The Thermostatic Remote Control can be programmed

to function automatically—see pages 11–15.

The Wall Switch can be used to turn on, off and to

increase or decrease the fl ame height—see the

1265WSK—Wall Switch Kit.

Wall Switch

(optional)

To access the information card, remove the barrier

screen and the right-hand side door. Pull it out and

read the important information on both sides.

9

OWNER’S

INFORMATION

Owner’s Information

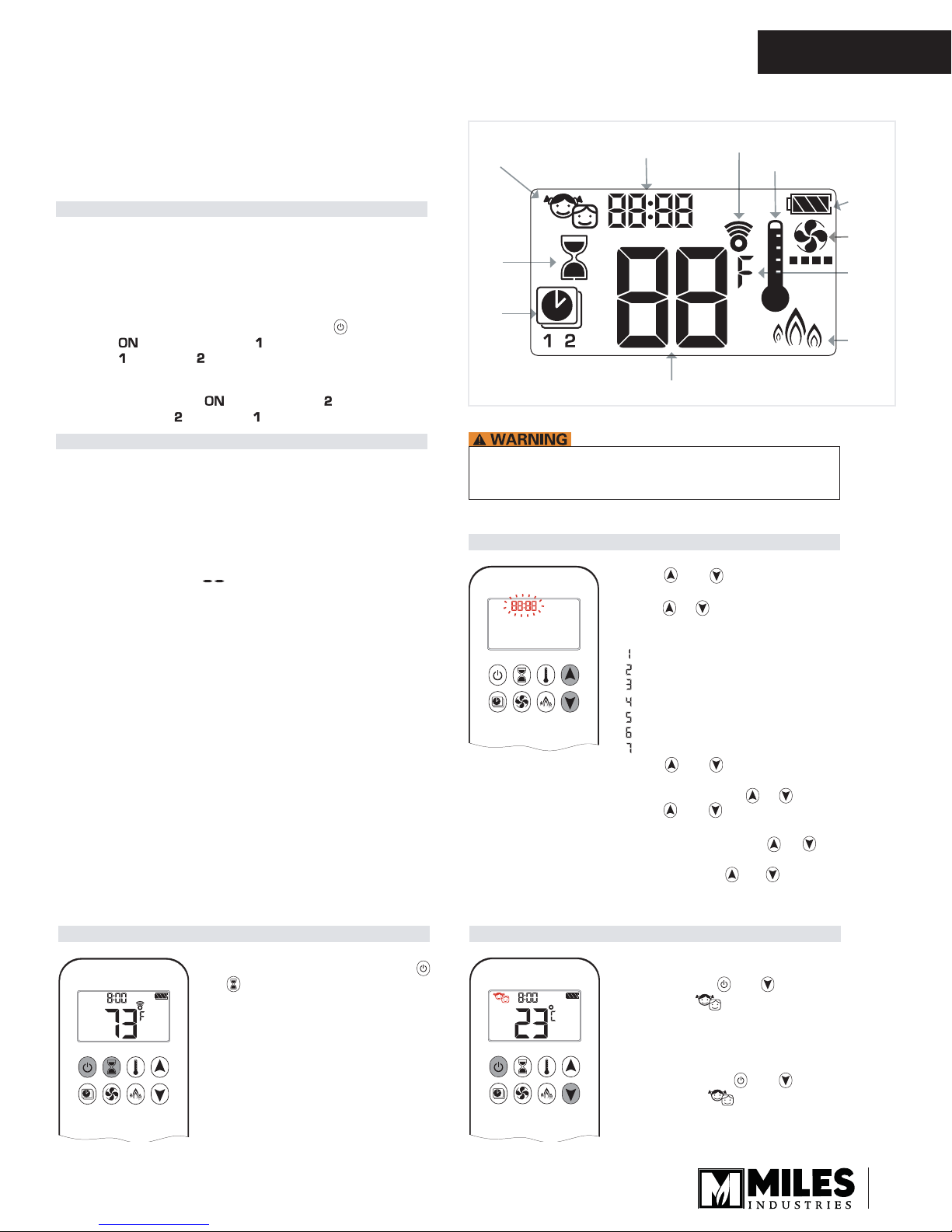

How to Turn Your Fireplace OFF

(including pilot)

Familiarize yourself with each of the following methods

before operating your fi replace.

Press and hold for 4 seconds the button on the

handset or OFF button on the optional wall switch.

NOTE: The fi rst tap on the button “wakes up” the

handset. Tap again to use the function.

AM

Remote control handset

If the fl ames are on, they go down and you hear the

valve motor wind down. You hear a clunk and a beep

indicating that the valve has received the signal from

the remote control.

As well, familiarize yourself with the gas shut-off valve

location in your house. As indicated below, the gas is

running when the handle is parallel with the pipe. The

gas is off when the handle is perpendicular with the

pipe.

Wall Switch

(optional)

How to Ensure Your Fireplace Cannot

Be Turned ON Inadvertently

You can use one of the two following methods to

ensure that your fi replace will not turn on when you

don’t want it on.

First, ensure your fi replace is turned off—including

the pilot—and cold BEFORE going ahead.

Receiver Gas valve

• Turn the dial on the gas valve from the ON position

to the MAN position as shown. Turning the dial to

MAN (arrow up) will ensure that the main burner

can not come on. The pilot will remain on if it is lit.

ON

ON: parallel to pipe

OFF:

perpendicular

to pipe

10

Gas valve

• Alternately, remove all batteries from the receiver

as well as the battery from the handset.

Automatic Shut-Off (in certain conditions)

Your fi replace’s remote control is equipped with an

automatic shut-off mechanism which is activated in

certain conditions. See page 15 in the Remote Control

Operation section for a description of this feature.

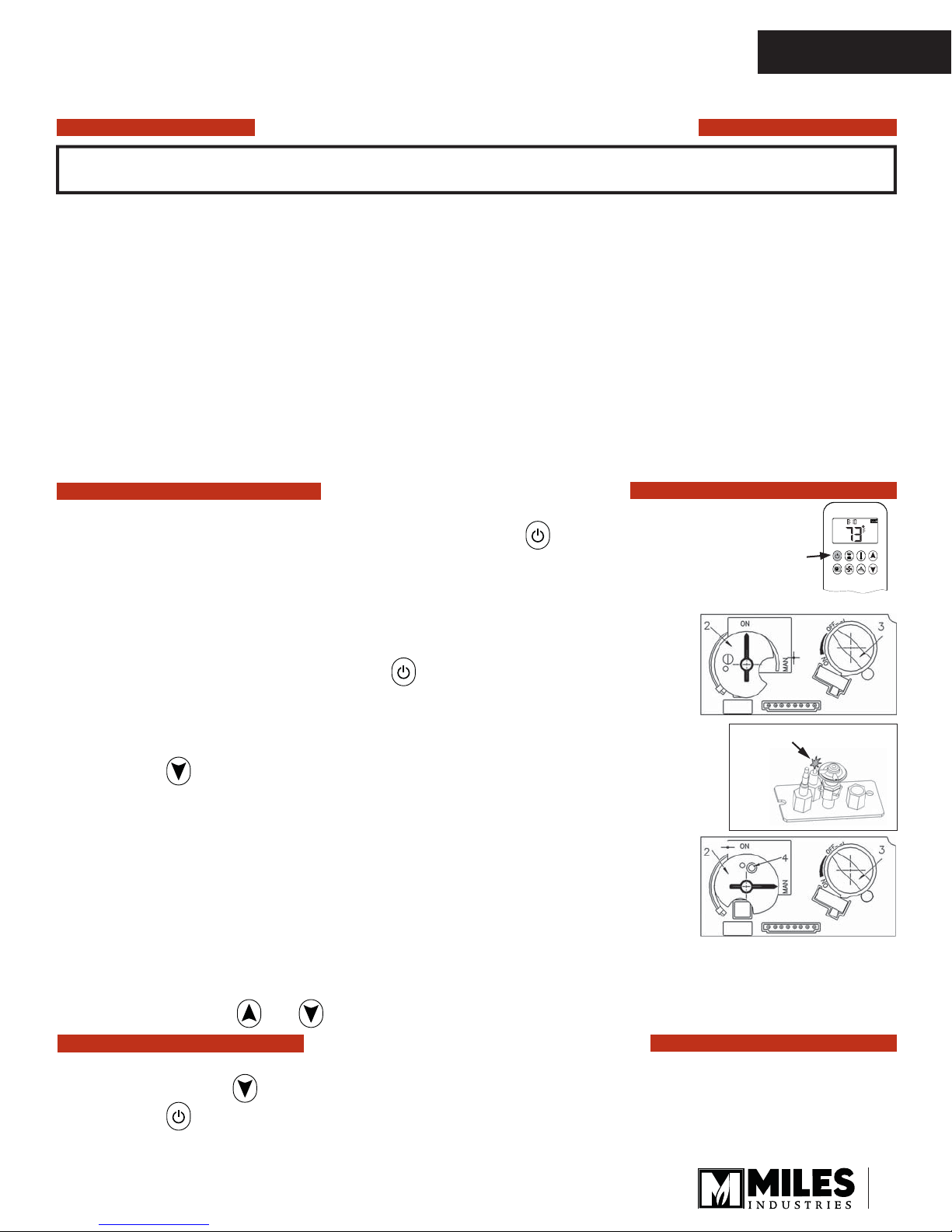

Remote Control Operation

OWNER’S

INFORMATION

NOTE: Before using the remote control system for

the fi rst time, the receiver and the handset must be

paired. See the section Remote Control Initial Pairing

on page 61 of this manual.

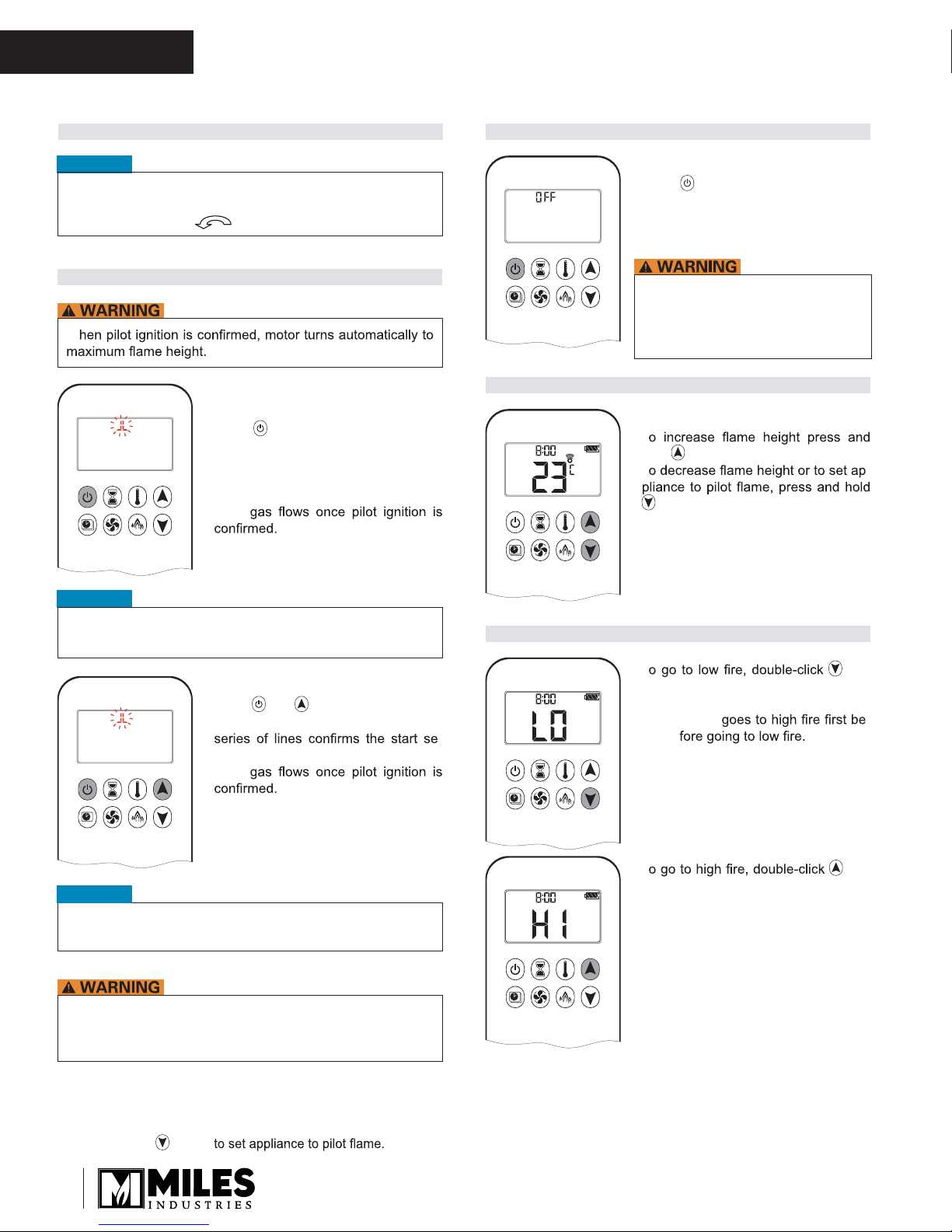

CHOOSING ONE-BUTTON OR TWO-BUTTON IGNITION

On this remote control handset, you can choose a one-button or

two-button ignition. Y ou can also choose to activate or disactivate

some of the functions. By default, the handset is set to a one-button ignition.

To change from 1-button ignition to 2-button ignition, remove

the batteries, wait 10 seconds, reinsert them and immediately

when the display flashes, press and hold the button for 10

seconds. is displayed and is flashing. When change is

complete changes to .

To change from two-button ignition to one-button ignition, proceed

the same way as above. is displayed and is flashing. When

change is complete changes to .

DEACTIVATING OR ACTIVATING FUNCTIONS

Some functions can be deactivated or activated.

Deactivate Functions

.gnihsa À dna deyalpsid era snoci llA .seirettab llatsnI .1

hsa À era snoci eht elihW .2

and hold for 10 sec.

activation is complete when the function icon and two horizon-

tal bars are displayed.

NOTE: ,

and two horizontal bars are displayed.

NOTE: .seirettab fo egnahc retfa tceffe ni sniam

er noitavitcaeD

Activate Functions

A .seirettab llatsnI .1

veler eht sserp ,noitcnuf a etavitca oT .2

10 sec.

nuf ehT .3

plete. Activation is complete when the function icon is displayed.

The following Functions can be Deactivated/Activated

ƒ

CHILD PROOF

ƒ

PROGRAM MODE

ƒ

THERMOSTATIC MODE (also deactivates Program Mode)

ƒ

ECO MODE

ƒ

CIRCULATING FAN OPERATION

ƒ

COUNTDOWN TIMER

noitcnuf on si ereht ,desserp si nottub detavitcaed a fI

.gnihsa À dna deyalpsid era snoci ll

Child

Time

Signal Indicator

Proof

AM

PM

Countdown

Timer

Program

Mode

Handset Display

IMPORTANT: If the display on the handset indicates OFF,

it may not mean that the fire is off. Always check the fire

and pilot visually to ensure they are off.

nottub noitcnuf tnaveler eht sserp ,gni

-eD .etelpmoc si noitavitcaed litnu hsa À lliw noci noitcnuf ehT .3

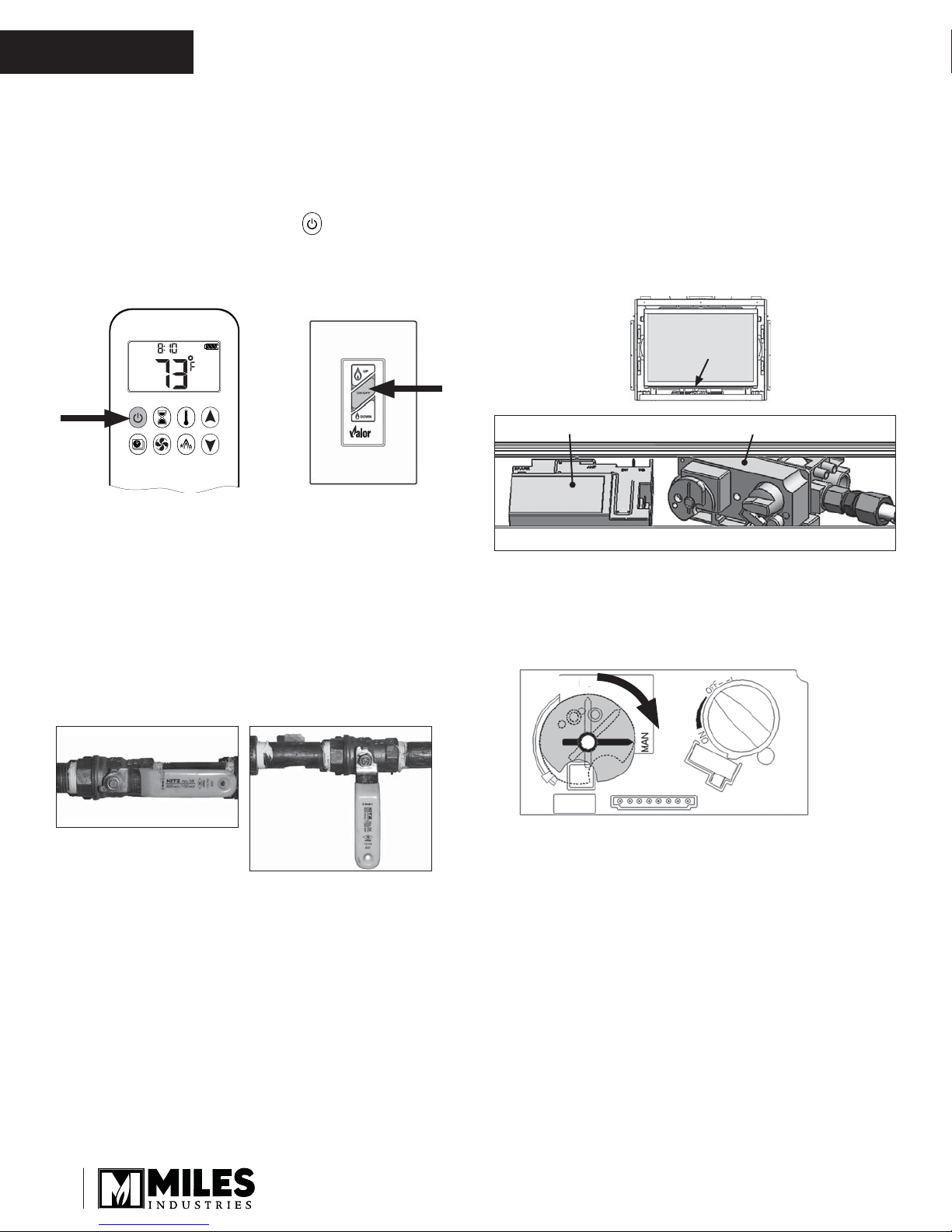

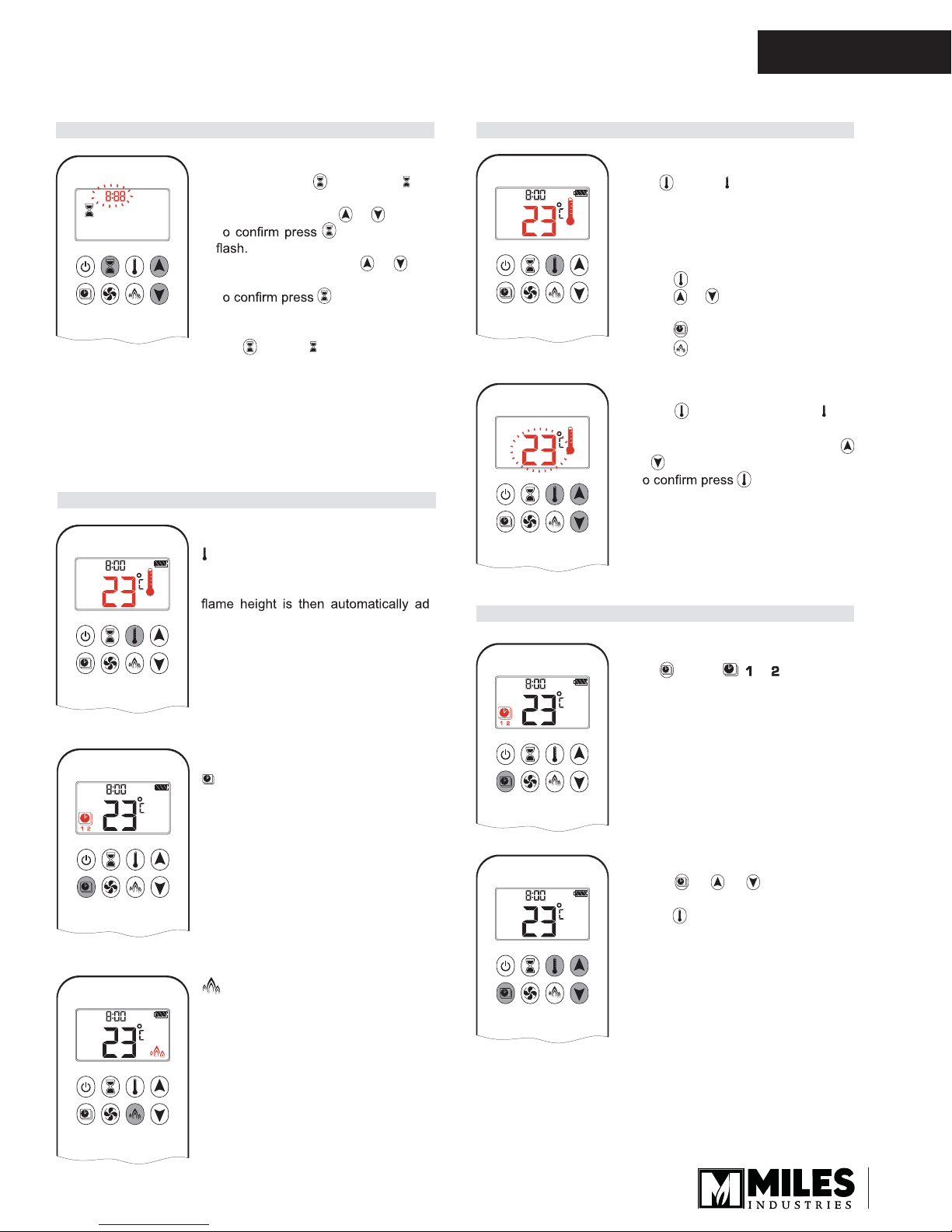

SETTING THE TIME

ON

OFF

rof dloh dna nottub tna

-moc si noitavitca litnu hsa À ot eunitnoc lliw noci noitc

ON

OFF

Temperature

1. Press and buttons simultane-

AM

PM

ously. Day flashes.

2. Press or button to select a

number to correspond with the day

of the week.

= Monday

= Tuesday

= Wednesday

= Thursday

= Friday

= Saturday

= Sunday

3. Press and buttons simultaneously. Hour flashes.

4. To select hour press or button.

5. Press and buttons simultaneously. Minutes flash.

6. To select minutes press or

button.

7. To confirm press and buttons

simultaneously or wait.

Thermostatic Mode

Battery

Status

Fan

°F or °C

Eco

Mode

SETTI

NG CELSIUS OR FAHRENHEIT

To change between °C and °F, press

and

AM

PM

ON

OFF

buttons simultaneously.

NOTE: Choosing °F results in a 12 hour

clock. Choosing °C results in a

24 hour clock.

CHILD PROOF

AM

PM

ON

OFF

ON:

To activ ate press

and button s simultaneously. displayed and the

handset is rendered inoperable,

except for the OFF function.

OFF:

To d e a c ti v a te p re s s

and buttons

simultaneously. disappears.

11

OWNER’S

INFORMATION

Remote Control Operation

MANUAL MODE (HANDSET))

NOTICE

BEFORE OPERATING

Make sure MANUAL knob on the GV60 Valve is in the ON,

full counterclockwise

position.

TO TURN ON FIRE

W

Handset One-Button Operation

AM

PM

ON

OFF

(Default Setting)

Press button and hold for four

ƒ

seconds until two short beeps and

a blinking series of lines confirms

the start sequence has begun;

release button.

ƒ Main

ƒ Handset automatically goes into man-

ual mode after main burner ignition.

TO TURN OFF FIRE

Handset

ƒ

AM

PM

ON

OFF

FLAME HEIGHT ADJUSTMENT

AM

PM

ON

OFF

Press button and hold for four

seconds to turn OFF.

NOTE: There is a 5 sec delay before

IMPORTANT: If the display on the

handset indicates OFF, it may not

mean that the fire is off. Always

check the fire and pilot visually

to ensure they are off.

Handset

ƒ

T

hold

ƒ T -

button.

the next ignition is possible.

button.

NOTICE

To change from one-button to two-button ignition operation,

go to page 1 for instructions.

Handset Two-Button Operation

ƒ Press

AM

PM

ON

OFF

until two short beeps and a blinking

quence has begun; release buttons.

and button simultaneously

ƒ Main

ƒ Handset automatically goes into man-

ual mode after main burner ignition.

NOTICE

To change from two-button to one-button ignition operation,

go to page 1 for instructions.

If the pilot does not stay lit after several tries, turn the gas control

knob to OFF (3) and call your local service technician or gas

OFF

supplier. See page 17 for more information.

DESIGNATED LOW FIRE AND HIGH FIRE

ƒ T but-

AM

ton. “LO” is displayed.

NOTE: Flame

-

-

ƒ T but-

AM

ton. “HI” is displayed.

STANDBY MODE (PILOT FLAME)

Handset

ƒ

Press and hold

button

12

Remote Control Operation

OWNER’S

INFORMATION

COUNTDOWN TIMER

ON/SETTING:

Press and hold button until

AM

PM

ON

OFF

1.

displayed, and hour flashes.

2. To select hour press

3. T

button. Minutes

4. To select minutes press

ton.

5. T

button or wait.

OFF:

Press button, and countdown

time disapear.

NOTE:

At end of countdown time period, the fire turns off. The

CountdownTimer only works in Manual, Thermostatic, and

Eco Modes. Maximum countdown time is 9 hours and 50

minutes.

MODES OF OPERATION

AM

PM

ON

OFF

Thermostatic Mode

The room temperature is measured and

compared to the set temperature. The

justed to achieve the set temperature.

or button.

or but-

THERMOSTATIC MODE

ON:

AM

PM

ON

OFF

Press button. displayed, preset

temperature displayed briefly, and then

room temperature displayed.

played.

OFF:

1. Press

2. Press

button.

or button to enter Manual

Mode.

3. Press button to enter Program Mode.

4. Press

button to enter Eco mode.

SETTING:

Press button and hold until dis-

AM

PM

ON

OFF

-

PROGRAM MODE

1.

played, temperature flashes.

2. To adjust SET temperature press

or

button.

3. T

button or wait.

ON:

AM

PM

ON

OFF

AM

PM

ON

OFF

Program Mode

Programs 1 and 2, each can be

programmed to go on and off at specific

times at a set temperature.

Press

displayed.

button. , or , ON or OFF

OFF:

AM

PM

ON

OFF

1. Press

Manual Mode.

2. Press

Mode.

or or button to enter

button to enter Thermostatic

Eco Mode

AM

Flame height modulates between high

and low. If the room temperature is

lower than the set temperature, the

flame height stays on high for a longer

period of time. If the room temperature

is higher than the set temperature, the

flame height stays on low for a longer

period of time. One cycle lasts approximately 20 minutes.

NOTE: The set temperature for Ther mostat ic Mode is th e tem -

perature for the ON time in Program Mode. Changing

the Thermostatic Mode set temperature also changes

the ON time temperature in Program Mode.

13

OWNER’S

INFORMATION

Remote Control Operation

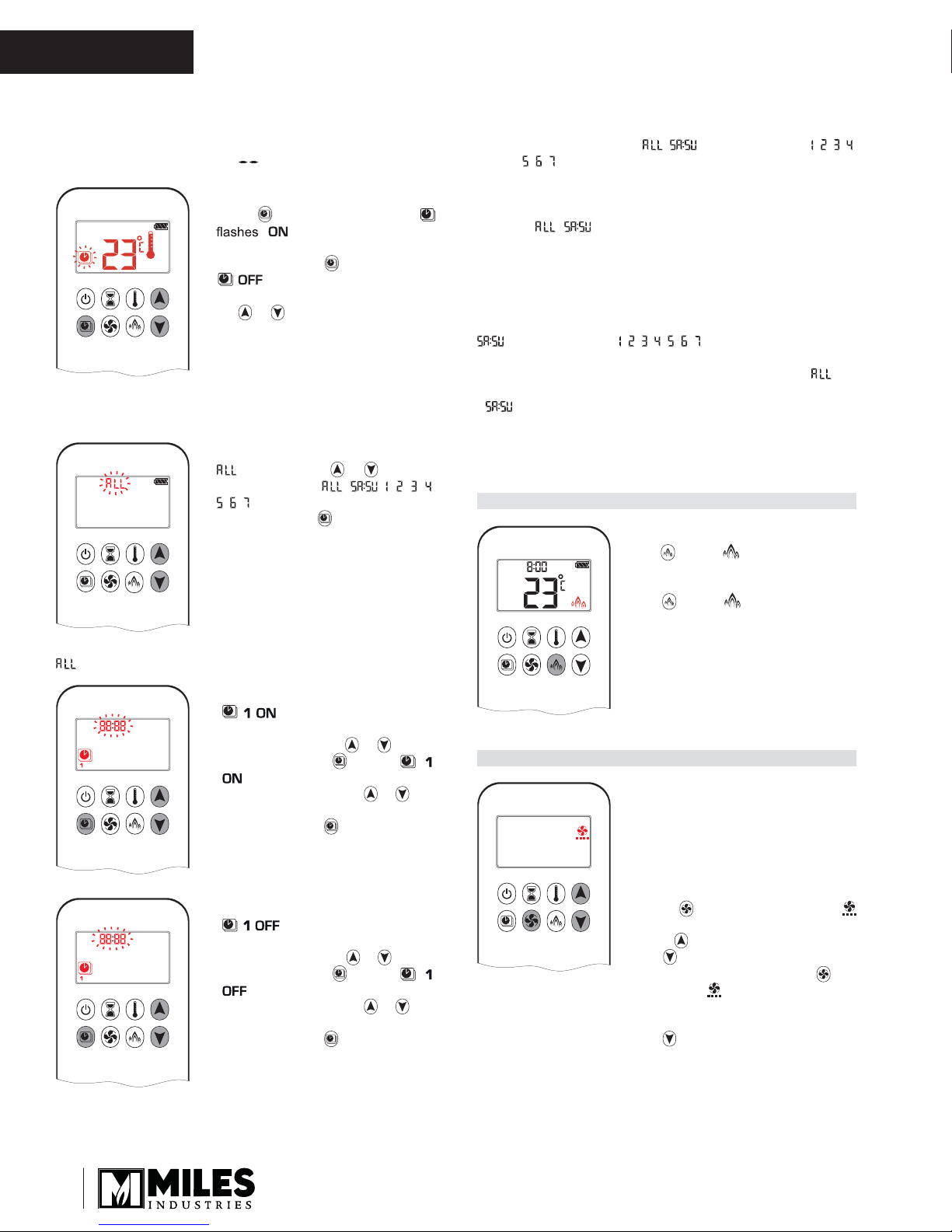

Default settings:

ON TIME (Thermostatic) TEMPERATURE: 21°C (70°F)

OFF TIME TEMPERATURE: “ ” (pilot flame only)

TEMPERATURE SETTING:

AM

PM

ON

OFF

1. Press

ting in Thermostatic Mode) displayed.

2. To continue press button or wait.

button and hold until

.

and set temperature (set-

, displayed, temperature flashes.

3. Select off temperature by pressing

the

or button.

NOTE: The ON (Thermostatic) and OFF set temperatures are the

same for each day.

DAY SETTING:

4.

AM

PM

ON

OFF

À ashes. Press or button to

choose between

, , , , , ,

, , .

sserp mr ¿noc oT .5

button.

NOTE: PROGRAM 1 and 2 use the same on (Thermostatic) and

off temperatures for

, and “Daily Timer” ( , , , ,

, , ). Once a new on (Thermostatic) and/or off temper-

ature has been set, that temperature becomes the new

default setting.

NOTE: fI

, or “Daily Timer” are programmed for PROGRAM 1 and PROGRAM 2 on and off times, these become the new default times. The batteries must be removed to clear the PROGRAM 1 and PROGRAM 2 on

and off times and temperatures.

or “Daily Timer” ( , , , , , , ) selected

teS ƒ on time and off time using same procedure as “

se-

lected” (above).

ƒ

:

Set on time and off time for both Saturday and Sunday.

ƒUnique on and off times may be set for a single day of the week,

for multiple days of the week, or for every day of the week.

.gnittes hsin ¿ ot tiaW ƒ

ECO MODE

ON:

AM

Press

button. displayed.

OFF:

Press

button. disappears.

selected

ON TIME SETTING (PROGRAM 1):

6.

AM

PM

ON

OFF

, , displayed, day is displayed

shortly, and hour À ashes.

sserp ruoh tceles oT .7

or button.

sserp mr ¿noc oT .8

button. , ,

displayed, minutes À ash.

sserp setunim tceles oT .9

or but-

ton.

10. To con¿ rm press

OFF TIME SETTING

AM

PM

ON

OFF

11. , , displayed, day is displayed

shortly, and hour À ashes.

button.

(PROGRAM 1):

sserp ,ruoh tceles oT .21

or button.

sserp mr ¿noc oT .31

button. , ,

displayed, minutes À ash.

sserp setunim tceles oT .41

or but-

ton.

15. T o con¿ rm press

button.

CIRCULATING FAN OPERATION

NOTE: SETTING only. Fan is switched

AM

on automatically when gas

opens. Circulating fan has 4

speed levels from low (1 bar) to

high (4 bars).

SETTING:

sserP .1

À ashes.

sserP .2

and

ton or wait (

:FFO

sserP

bars disappear.

button and hold until

button to increase fan speed

button to decrease fan speed.

sserp rehtie gnittes mr ¿noc oT .3

but-

displayed).

button until all 4 speed level

NOTE: Either continue to PROGRAM 2 and set on and off times

or

stop programming at this point, and PROGRAM 2 re-

mains deactivated.

14

Remote Control Operation

LOW BATTERY INDICATION

'RQRWXVHDVFUHZGULYHURURWKHUPHWDOOLFREMHFWWRUHPRYH

WKHEDWWHULHVIURPWKHUHFHLYHURUWKHKDQGVHW7KLVFRXOG

FDXVHDVKRUWFLUFXLWRIWKHUHPRWHFRQWUROV\VWHP

Handset

ƒ

7KHEDWWHU\LFRQZLOOVKRZZKHQWKHEDWWHU\QHHGVWREH

UHSODFHG5HPSODFHZLWKWZR9$$$alkaline EDWWHULHV

Receiver

ƒ

7KUHHVKRUWEHHSVZLOOVRXQGZKHQWKHPRWRUWXUQVZKHQWKH

EDWWHULHVQHHGWREHUHSODFHG5HSODFHZLWKIRXU9alkaline

EDWWHULHV

AUTOMATIC TURN DOWN

3 Hour No Communication Function

ƒ

7KHYDOYHZLOOWXUQWRSLORWIODPHLIWKHUHLVQRFRPPXQLFDWLRQ

EHWZHHQKDQGVHWDQGUHFHLYHUIRUDKRXUSHULRG7KHILUHZLOO

FRQWLQXHWRIXQFWLRQQRUPDOO\ZKHQFRPPXQLFDWLRQLVUHVWRUHG

OWNER’S

INFORMATION

Receiver Overheating

RQO\LIRSWLRQDOFLUFXODWLQJIDQFRQWUROPRGXOHLVFRQQHFWHG

ƒ

9DOYHWXUQVWRSLORWIODPHLIWKHWHPSHUDWXUHLQWKHUHFHLYHULV

KLJKHUWKDQ°)°&7KHPDLQEXUQHUWXUQVEDFNRQ

PDQXDOO\RULQ7KHUPRVWDWLF0RGHRQO\ZKHQWKHWHPSHUDWXUH

LVEHORZ°)°&

AUTOMATIC SHUT OFF

Countdown Timer

ƒ

$WHQGRIFRXQWGRZQWLPHSHULRGWKHILUHWXUQVRII7KH

&RXQWGRZQ7LPHURQO\ZRUNVLQ0DQXDO7KHUPRVWDWLFDQG(FR

0RGHV0D[LPXPFRXQWGRZQWLPHLVKRXUVDQGPLQXWHV

Low Battery Receiver

:LWKORZEDWWHU\SRZHULQWKHUHFHLYHUWKHV\VWHPVKXWVRIIWKH

ƒ

ILUHFRPSOHWHO\7KLVZLOOQRWKDSSHQLIWKHSRZHUVXSSO\LV

LQWHUUXSWHG

Five Day Shut Off

7KHV\VWHPVKXWVRIIWKHILUHFRPSOHWHO\LIWKHUHLVQRFKDQJH

ƒ

LQIODPHKHLJKWIRUGD\V

15

OWNER’S

INFORMATION

Options

Required Kits

Fuel Beds (choose one)—1100 units only

1101DWK Driftwood Kit

1103DGM Murano Glass Kit

1104DGS Decorative Glass Set

Ceramic Liners (choose one)—1100 and 1150 units

1110VRL Valor Red Liners

1115LSL Ledgestone Liners

1125FBL Fluted Black Liners

1160BLS Black Liners

Trims (choose one)—1100 and 1150 units Barrier Screen Number

1130FFK Fixed Framing Kit 4003810

1 135TSB Three-Sided Trim Black 4003810

1135TSBEN Three-Sided Trim Edgemont Nickel 4004423

1135TSBEZ Three-Sided Trim Edgemont Bronze 4004423

1 140FSB Four-Sided Trim Black 4003810

1 140FSN Four-Sided Trim Nickel 4003810

1 140FSZ Four-Sided Trim Bronze 4003810

1145CBP+1145BDK Cast Backing Plate w Barrier and Door Kit 4003810

1149EDV Edgemont Double Doors

Optional Accessories

Trim Optional Accessories—1100 and 1150 units

1147CMS Cast Mantel Surround

1148CIR Cast Inlay Reeds

1148CIS Cast Inlay Sheffi eld

1148CIT Cast Inlay Tatch

Conversion Kits—1100 and 1150 units

1100PGK From NG to LPG—1100 units only

1100NGK From LPG to NG—1100 units only

1150PGK From NG to LPG—1150 units only

1150NGK From LPG to NG—1150 units only

Other Accessories—1100 and 1150 units

1105RGL Refl ective Liner for 1125FBL or 1160BLS

1 156CLA Co-Linear Adapter

1195CFK Circulating Fan Kit

1265WSK Wall Switch Kit

1270RBK Remote Blower Kit

1506DRK Decorative Rock Kit—1100 units only

GV60PAK Power Kit

Hearth Gate

Hearth gates such as Cardinal’s VersaGates are available at retail stores carrying safety

products for children.

*Information accurate at the time of printing and subject to change without notice.

16

OWNER’S

Lighting Instructions

INFORMATION

FOR YOUR SAFETY, READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fi re or explosion may result

causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand, remote control, or wall switch. Follow these instructions

exactly. To save gas, turn the pilot off when not using the appliance for a prolonged period of time.

B. BEFORE LIGHTING, smell all around the appliance area for gas. Be sure to smell next to the fl oor because

some gases are heavier than air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fi re department.

C. Use only your hand to push in or turn the control knobs. Never use tools. If the knobs will not push in or turn by

hand, don’t try to repair them; call a qualifi ed service technician. Force or attempted repair may result in a fi re or

explosion.

D. Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician to

inspect the appliance and to replace any part of the control system and any gas control, which has been under water.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. TO CLEAR ANY GAS, turn main valve off by pressing the button on remote handset (1).

• Wait fi ve (5) minutes to clear out any gas, then smell for gas, including near the fl oor. If you

smell gas, STOP! Follow “B” in the safety information above on this label. If you don’t smell

gas, go to the next step.

3. AUTOMATIC IGNITION: MAN-knob (2) in ON position. Ensure Flame Adjustment

knob (3) is set to lowest setting () (Fig. 1). Locate the pilot (Fig. 3.) inside the

fi rebox.

• On the remote control handset, press the button; a short acoustic signal

confi rms the start has begun.

• Further short acoustic signals indicate the ignition process is in progress.

• When the pilot is lit, the Flame Adjustment knob (3) will automatically rotate to

the highest setting.

• Press the button on the remote control handset to reduce the fl ame height.

Fig 3

4. MANUAL IGNITION: MAN-knob (2) in MAN position (Fig. 2). With the window

off, locate the pilot (Fig. 3) inside the fi rebox.

• Set Flame Adjustment knob (3) to the lowest setting ().

Pilot

• Push down the metallic core (4) with a pen or similar instrument; this will establish

the pilot gas fl ow.

• Light gas at the pilot (5) with a match.

• Continue holding down metal core (4) for about 10 seconds; after release, pilot

should remain lit.

• If the pilot will not stay lit after several tries, turn the gas control knob (3) to OFF () and call your local

service technician or gas supplier.

• Reinstall the window and set the MAN-knob (2) to ON; turn Flame Adjustment knob (3) up () or down ()

manually or use the and buttons on the remote control handset to adjust the fl ame height.

1

OFF

Spark

AM

Fig 1

5

Fig 2

AUTOMATIC SHUT-OFF (using the remote control handset):

• Press and hold the button on the remote control handset to shut-off the main burner gas fl ow.

• Press the button on remote handset to shut-off the appliance, including pilot fl ame.

TO TURN OFF GAS TO APPLIANCE

17

QUALIFIED

INSTALLER

Commonwealth of Massachusetts

State of Massachusetts Carbon Monoxide

Detector/Vent Terminal Signage

Requirements

For all side wall horizontally vented gas fueled

equipment installed in every dwelling, building or

structure used in whole or in part for residential

purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust

vent termination is less than seven (7) feet above

fi nished grade in the area of the venting, including

but not limited to decks and porches, the following

requirements shall be satisfi ed:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing

plumber or gas fi tter shall observe that a hard wired

carbon monoxide detector with an alarm and battery

back-up is installed on the fl oor level where the gas

equipment is to be installed. In addition, the installing

plumber or gas fi tter shall observe that a battery

operated or hard wired carbon monoxide detector

with an alarm is installed on each additional level of

the dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment. It shall

be the responsibility of the property owner to secure

the services of qualifi ed licensed professionals for the

installation of hard wired carbon monoxide detectors.

3. SIGNAGE. A metal or plastic identifi cation plate

shall be permanently mounted to the exterior of the

building at a minimum height of eight (8) feet above

grade directly in line with the exhaust vent terminal for

the horizontally vented gas fueled heating appliance

or equipment. The sign shall read, in print size no less

than one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of

the side wall horizontally vented gas fueled equipment

shall not approve the installation unless, upon

inspection, the inspector observes carbon monoxide

detectors and signage installed in accordance with the

provisions of 248 CMR 5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt

from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the most

current edition of NFPA 54 as adopted by the Board;

and

2. Product Approved side wall horizontally vented

gas fueled equipment installed in a room or structure

separate from the dwelling, building or structure used in

whole or in part for residential purposes.

a. In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space or

an attic, the hard wired carbon monoxide detector with

alarm and battery back-up may be installed on the next

adjacent fl oor level.

b. In the event that the requirements of this subdivision

can not be met at the time of completion of installation,

the owner shall have a period of thirty (30) days

to comply with the above requirements; provided,

however, that during said thirty (30) day period, a

battery operated carbon monoxide detector with an

alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in

accordance with the above provisions shall comply

with NFPA 720 and be ANSI/UL 2034 listed and IAS

certifi ed.

(c) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM PROVIDED.

When the manufacturer of Product Approved side

wall horizontally vented gas equipment provides a

venting system design or venting system components

with the equipment, the instructions provided by the

manufacturer for installation of the equipment and the

venting system shall include:

1. Detailed instructions for the installation of the venting

system design or the venting system components; and

2. A complete parts list for the venting system design or

venting system.

18

Commonwealth of Massachusetts

(d) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a Product Approved side

wall horizontally vented gas fueled equipment does

not provide the parts for venting the fl ue gases, but

identifi es “special venting systems”, the following

requirements shall be satisfi ed by the manufacturer:

1. The referenced “special venting system” instructions

shall be included with the appliance or equipment

installation instructions; and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for that

system shall include a parts list and detailed installation

instructions.

(e) A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists

for venting instructions, and/or all venting design

instructions shall remain with the appliance or

equipment at the completion of the installation.

QUALIFIED

INSTALLER

19

QUALIFIED

INSTALLER

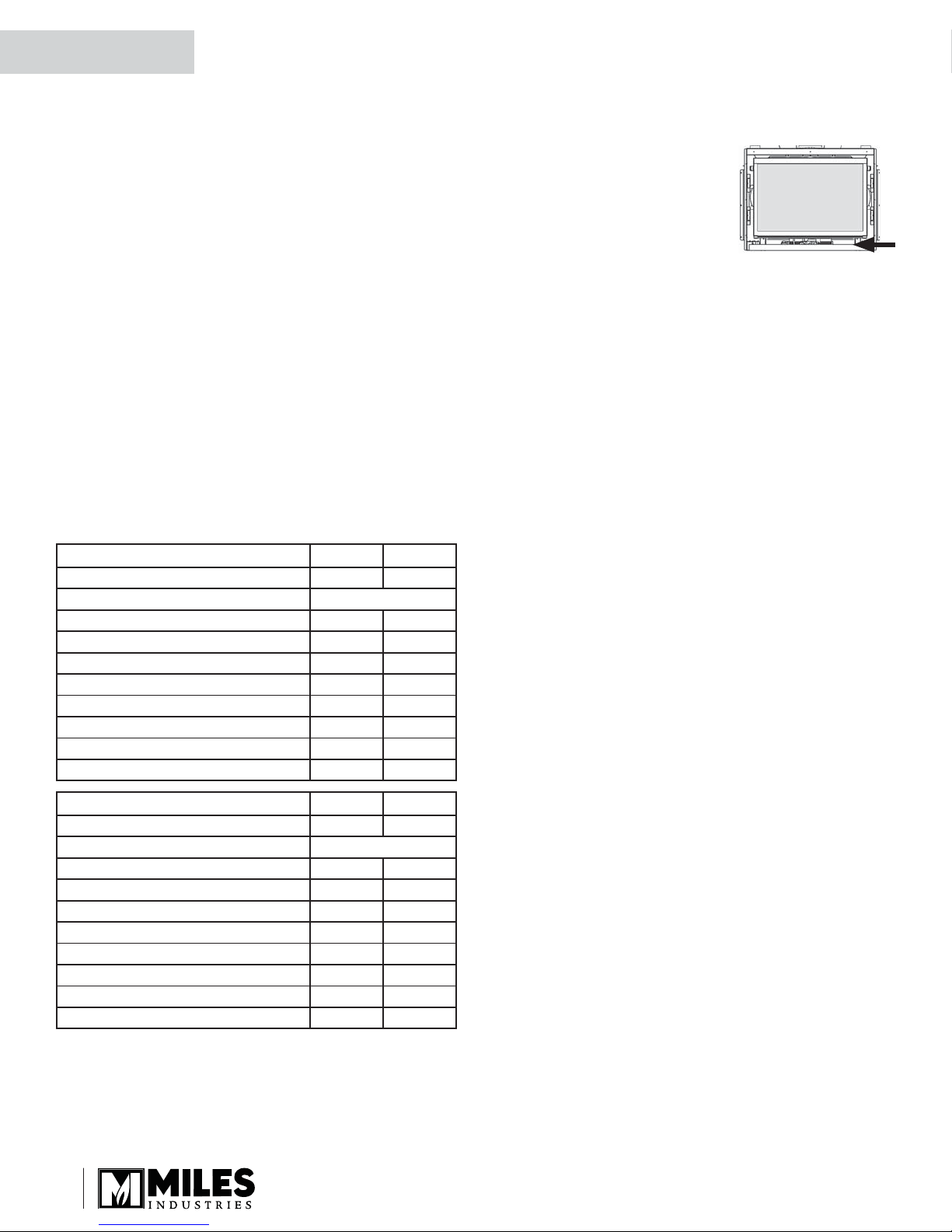

Specifi cations

Approval & Codes

This appliance is certifi ed to ANSI Z21.88-2014/

CSA 2.33-2014 American National Standard / CSA

Standard for Vented Gas Fireplace Heaters for use in

Canada and USA, and to CGA 2.17-91 High Altitude

Standard in Canada. This appliance is for direct vent

installations.

This appliance complies with CSA P4.1-09 Testing

method for measuring annual fi replace effi ciencies.

The installation must conform to local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 or the Natural Gas and Propane

Installation Code CAN/CGA-B149. Only qualifi ed

licensed or trained personnel should install this

appliance.

This appliance must be electrically grounded in

accordance with local codes, or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA

70 or the Canadian Electrical Code, CSA C22.1.

Ratings

Model 1100IN 1100IP

Gas Natural Propane

Altitude (Ft.)* 0-4,500 feet*

Input Maximum (Btu/h) 28,000 28,000

Input Minimum (Btu/h) 13,000 13,000

Manifold Pressure (in w.c.) 3.5” 9”

Minimum Supply Pressure (in w.c.) 5” 11”

Maximum Supply Pressure (in w.c.) 10” 14”

Main Burner Injector Marking 850 300

Pilot Injector Marking 51 30

Min. Rate By-Pass Screw 185 125

Model 1150ILN 1150ILP

Gas Natural Propane

Altitude (Ft.)* 0-4,500 feet*

Input Maximum (Btu/h) 30,000 30,000

Input Minimum (Btu/h) 16,000 16,000

Manifold Pressure (in w.c.) 4” 9”

Minimum Supply Pressure (in w.c.) 5” 11”

Maximum Supply Pressure (in w.c.) 10” 14”

Main Burner Injector Marking 850 360

Pilot Injector Marking 51 30

Min. Rate By-Pass Screw 195 135

*High Altitude Installations

Input ratings are shown in BTU

per hour and are certifi ed without

deration for elevations up to

4,500 feet (1,370 m) above sea

level.

X

For elevations above 4,500 feet

(1,370 m) in USA, installations

must be in accordance with the current ANSI Z223.1

and/or local codes having jurisdiction. Heating value

of gas in some areas is reduced to compensate for

elevation—consult your local gas utility to confi rm.

For installations at elevations above 4,500 feet

(1,370 m) in Canada, please consult provincial and/or

local authorities having jurisdiction.

Supply Gas

Heater engines 1100IN and 1150ILN are used with

natural gas.

Heater engines 1100IP and 1150ILP are used with

propane gas.

The supply pressure must be between the limits shown

in the Ratings section.

The supply connection is 3/8” NPT male and located on

the right hand side of the fi rebox. A shut-off valve (not

supplied) is required on the supply line to isolate the

unit during service. See Supply Gas Installation section

for details.

Conversion Kits

The 1100 and 1150 are supplied as natural gas or

propane gas and are fi eld convertible between fuels.

See instructions packaged with the conversion kits for

further information.

Electrical

The 1100 and 1150 are designed to run on battery

power and do not require an electrical power source to

operate as a heater. However, they require electrical

power to operate optional 1195CFK Circulating Fan

Kit, 1270RBK Remote Blower Kit or GV60PAK Power

Adapter.

20

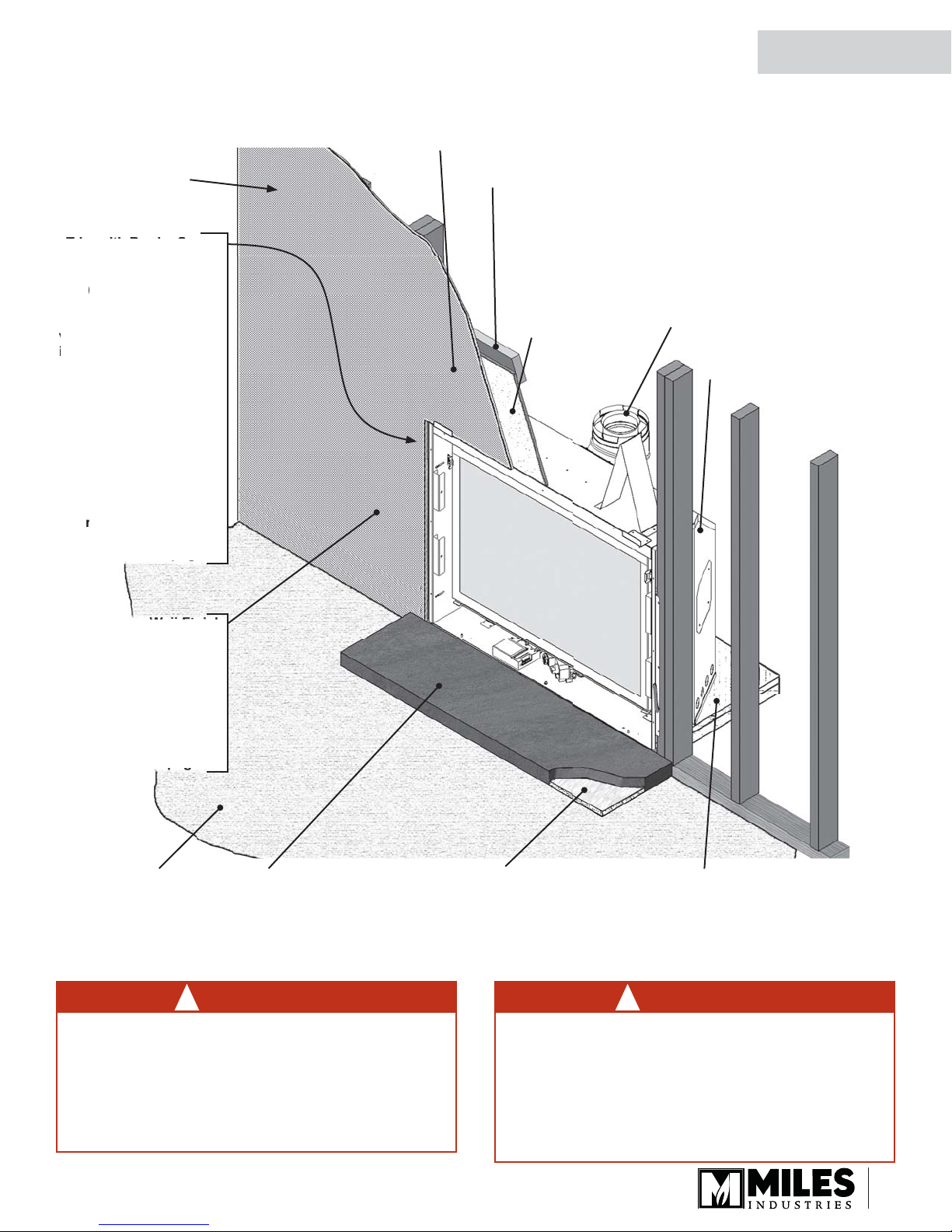

Tr

im with Barrier Sc

(

)

(

f

w

bustib

le

w

w

p

th

mtie wallfin

h

2”nonombustible

f

tyyy

ppag

g

g

Remote Handset

WaFh

ag

g

g

g

g

g

g

g

g

g

.

Wall Holder

Overview

Mantel—See Mantel & Hearth Clearances

Framing—See Framing Requirements

QUALIFIED

INSTALLER

reen

required

Fixed Framingkit

1130FFK) installs at

raming stage and

s non-com

ll fi nish to fi nish up to

. All other trims overla

e surrounding non-

nd are adjustable to

ccomodate material

to 3/4” thickness

overtop of the base

oard. For material

thickness greater than

4”, the heater requires

epositioning further

orward in the framing

avi

—see

Any wall fi nishes

lied over non-

ombustible board

non-combustible.

ombustible mantels

re ok provided they

onform to chart

on

e 47

ust be also

e 23

1/2 inch thick noncombustible board

or equivalent –

NOT supplied—see

page 29 for board

specifi cations

Supplied as

vertical outlet, fi eld

convertible to

horizontal outlet.

1100 or 1150 heater

Combustible

Floor

Non-combustible Hearth—

See Hearth Requirements

WARNING

!

Some materials or items, although safe,

may discolor, shrink, warp, crack, peel, and

so on because of the heat produced by the

fi replace. Avoid placing candles, paintings,

photos, and other items sensitive to heat

around the fi replace.

1/2” Micore supplied

with unit. Use as a

thermal break between

non-combustible hearth

material and combustible

material underneath.

HOT WALL SURFACES! The wall directly

above the fi replace is constructed of non-

combustible materials and, although safe, it

may reach temperatures in excess of 200° F

depending on choice of trims. Do not touch.

Finish the wall using materials suitable for

these temperatures.

Combustible Framing Allowed Beneath Fireplace.

When the appliance is installed directly on

carpeting, tile or other combustible material other

than wood fl ooring, the appliance shall be installed

on a metal or wood panel extending the full width

and recessed depth of the appliance.

WARNING

!

21

f

d

cal

t

uct

p

)

uct

t

)

e

Access Point

ce

s

ing

f

e

o

t

t

d

r

t

t

e

ll

f

f

bustib

board.

)

4”

/

”

f

f

d

/

”

(

)

o

a

o

b

ble

d

”

/

”

/

”

”

”

”

Zero Clearance to Stand-offs

59” (1499 mm)

”

QUALIFIED

INSTALLER

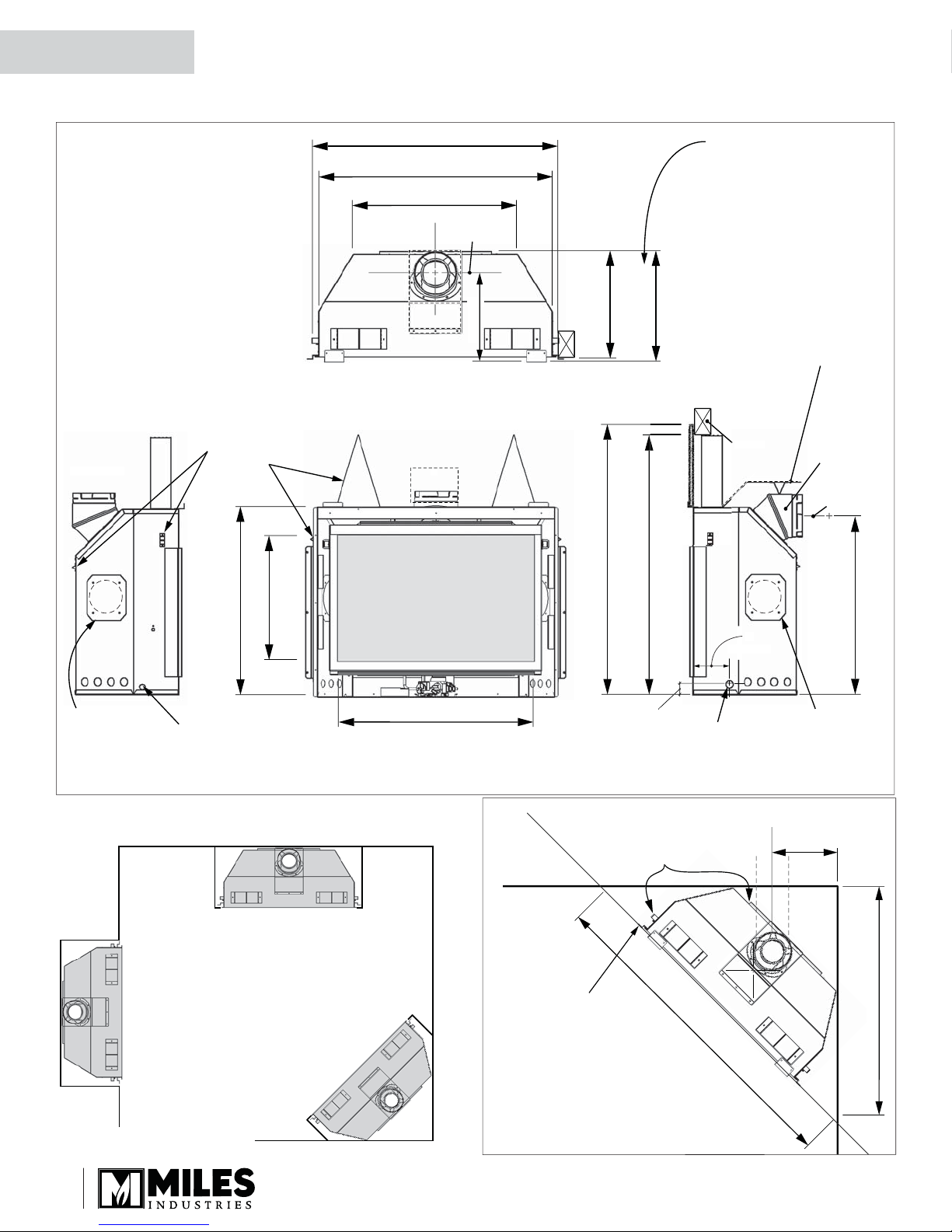

Dimensions & Location

Dimensions

Zero Clearan

nd-Off

9

4

9-1

8”

6-1/8

25-1/4

Top View

Center

ne

4

13-3

stu

2

6-1

ront o

to

cement boar

f

ce

nt f

432 mm

fr

7”

40”

e: This dimension is for th

130FFK Fixed Framing Kit. For a

other trims this is the maximum

equired and may be reduced

if positioning the unit forward

the framing to accomodate

o

thickness o

aterial over top of

n-com

usti

oar

on-com

non-combustible

le

eader

Heat shiel

required fo

rear ven

outle

applications

6-5/8” dia.

Vent

ield-

nvertibl

from top t

rear outle

Center of ven

2

7-1

1270RBK D

Kit Inle

(remove plate

Location

lectri

nlet Poin

in. 41-1/2” to top o

30

38 mm

Gas Lin

Front ViewLeft Side View Right Side View

270RBK D

it Inlet

(remove

late

22

Corner Dimensions

Loading...

Loading...