Miles Industries 530XAN, 530XAP, 530XCN, 530XCP Owner's Manual

Model 530XAN/XAP

Model 530XCN/XCP

Direct Vent Gas Fireplace Heater

(With Logs or Coals)

Installation and Owner’s Manual

Please read this manual before installing and operating this heater

This manual should remain with the homeowner

- Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch: do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

- Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

This appliance may be installed in an

aftermarket permanently located,

manufactured (mobile) home, where not

prohibited by local codes.

WARNING: If the information in

these instructions is not followed

exactly, a fire or explosion may result

causing property damage, personal

injury or loss of life.

This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases, unless a certified kit is

used.

This appliance is a domestic room-heating

appliance. It must not be used for any

other purpose such as drying clothes etc.

B-Vent Installations

If this appliance is intended to be installed

with a B-Vent instead of direct vent, discard

this manual. Follow the installation and

operating procedure in the manual supplied

with the B-Vent adapter kit #552BVK.

This appliance is suitable for installation in a

bedroom or bed sitting room.

Massachusetts: the piping and the final

gas connection must be performed by a

licensed plumber or gas fitter in the State

of Massachusetts

Manufactured by

MILES INDUSTRIES LTD.

British Columbia, Canada

Vous pouvez vous procurer un exemplaire en langue Française de cette brochure chez votre marchand.

4000305/04

2 of 48

CONTENTS

1. SAFETY INFORMATION.....................................................................................................................................................................3

2. OPTIONS .................................................................................................................................................................................................. 4

2.1 Appliance styles................................................................................................................................................................................ 4

2.2 Additional optional features......................................................................................................................................................... 4

2.3 LP Gas................................................................................................................................................................................................ 4

2.4 Venting options................................................................................................................................................................................ 4

3. GENERAL.................................................................................................................................................................................................. 7

3.1 Approvals & codes ........................................................................................................................................................................... 7

3.2 Ratings................................................................................................................................................................................................ 7

3.3 Wall Thickness ................................................................................................................................................................................ 7

3.4 Supply Gas 7

3.5 Controls ............................................................................................................................................................................................. 7

3.6 Electrical............................................................................................................................................................................................ 7

4. LOCATION – PRESIDENT FS............................................................................................................................................................ 8

4.1 Wall & Floor Fixing ......................................................................................................................................................................... 8

4.2 Venting configurations...................................................................................................................................................................8

5. LOCATION – ZERO CLEARANCE ................................................................................................................................................ 15

5.1 Framing General............................................................................................................................................................................ 15

5.2 Finishing General............................................................................................................................................................................. 15

5.3 President 536/ Bolero 541 Fronts 15

5.4 Windsor Arch 539 Front 16

5.5 Z.C Venting Configurations ....................................................................................................................................................... 17

6. RECESSED INSERT APPLICATIONS........................................................................................................................................... 23

7.

DIRECT VENT TERMINAL LOCATION .......................................................................................................................................... 24

8. HEATER PACK CONTENTS 25

9. HEATER PREPARTION.....................................................................................................................................................................26

9.1 Detach the window ....................................................................................................................................................................... 26

9.2 Check ignition spark..................................................................................................................................................................... 26

9.3 Burner Module Removal ............................................................................................................................................................. 26

9.4 Conversion to Top Outlet........................................................................................................................................................... 27

9.5 Rear Outlet Preparation.............................................................................................................................................................. 28

9.6 DuraVent Co-Linear.....................................................................................................................................................................28

9.7 Valor 556 CLA Co-Linear Adapter............................................................................................................................................ 28

9.8 Air Restrictor.................................................................................................................................................................................. 29

10. INSTALLING HORIZONTAL TERMINATION. .......................................................................................................................30

11. INSTALLING ROOF TERMINATION..........................................................................................................................................32

12. REMOTE CONTROL INSTALLATION....................................................................................................................................... 33

13. GAS SUPPLY INSTALLATION....................................................................................................................................................... 34

14. AERATION SETTING CHECK ....................................................................................................................................................... 35

15. CERAMIC FUEL BED INSTALLATION....................................................................................................................................... 35

15.1 Ceramic Walls Installation.......................................................................................................................................................... 35

15.2 Ceramic Log Installation............................................................................................................................................................. 36

15.3 Ceramic Coals Installation..........................................................................................................................................................37

16. WINDOW REFITTING & CHECKING..........................................................................................................................................38

17. OPERATION CHECKS....................................................................................................................................................................... 38

18. INSTALLATION OF FRONTS AND COMPONENTS 39

18.1 President 531 Free Standing Front 39

18.2 President 536/Bolero 541 Z.C Fronts 40

18.3 Windsor Arch 539/549 Fronts..........................................................................................................................................................42

19. OWNERS INFORMATION................................................................................................................................................................ 44

19.1 Operating Your Fire

19.2 Operating remote control ........................................................................................................................................................... 44

19.3 Cleaning........................................................................................................................................................................................... 45

19.4 Checks.............................................................................................................................................................................................. 47

19.5 Servicing.......................................................................................................................................................................................... 47

19.6 General servicing

20. WARRANTY............................................................................................................................................................................................ 48

3 of 48

1.0 SAFETY INFORMATION

WARNING: Do not operate the appliance with the

glass front removed, cracked or broken.

Replacement of the glass should be done by a

licensed or qualified service person.

(The whole window unit may be temporarily

removed by the owner for cleaning the interior of

the firebox, etc.)

Only the authorized Valor replacement window

unit listed in the repair parts booklet must be

fitted - never use substitutes.

If the glass is damaged search inside and adjacent

to the appliance for any glass fragments.

Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

Children and adults should be alerted to the

hazards of high surface temperatures and should

stay away to avoid burns or clothing ignition.

Young children should be carefully supervised

when they are in the same room as the appliance.

Clothing or other flammable material should not

be placed on or near the appliance.

This appliance must be installed and repaired b y a

qualified service person. The appliance should be

inspected before use and at least annually by a

professional service person. More frequent

cleaning may be required due to excessive lint

from carpeting, bedding material, etc. It is

imperative that control compartments; burners

and circulating air passageways of the appliance

are kept clean.

Keep curtains, clothing, furniture and other

flammable materials a safe distance from all parts

of the appliance and its vent system.

Keep the appliance area well clear and free from

combustible materials, gasoline and other

flammable vapors and liquids.

Never attempt to burn paper or any other material

in the appliance.

The venting terminal must not be recessed into a

wall or siding.

The vent terminal on the outside wall must be

kept free from obstructions. No objects should be

placed within 2 feet (60cm) of the vent terminal.

The terminal is hot during operation and requires

a guard if it is accessible to any person. An

approved Valor guard is available from your

dealer.

During extreme weather conditions ensure that

the vent outlet is free from ice and snow before

attempting to light.

Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control,

which has been under water.

NOTE

When operating your new fireplace for the first time, some vapors may be released due to the burning of curing

compounds used in the manufacture of the appliance. They may cause a slight odor and could cause the flames to be the

full height of the firebox, or even slightly higher, for the first few hours of operation. It is also possible that these vapors

could set off any smoke detection alarms in the immediate vicinity. These vapors are quite normal on new appliances and

are totally harmless. After a few hours use the vapors will have disappeared and the flames will be at their normal height.

During the first hour of use the ceramic firebox walls may go a smoky color. This is not soot. It is a temporary effect

lasting only while the ceramic material becomes stabilized. The walls will revert to their initial color after your fire has

been used for one or two hours.

4 of 48

2.0 OPTIONS

Heater engine unit # 530 X is available in either natural

gas or LPG and comes equipped with either a simulated

log or coal fuel bed in either fuel. The 530X engine unit

is supplied standard with a rear vent D.V outlet and may

be converted to a top outlet D.V with no extra parts

required. The engine is not supplied suitable for zero

clearance, the parts required to make the engine zero

clearance are supplied with the various front trims

(except 549 front)

2.1 Appliance styles

President FS 531 Free standing cast iron stove.

(See figure 1).

President 536 For recessed application, either zero

clearance or insert . (See figure 2)

Windsor Arch 539/549 Arched Cast Iron Front for

recessed application, either zero

clearance(see fig 3) or insert (see fig

4). (549 version is insert only )

Bolero 541 Contemporary cast iron front for

recessed application, either zero

clearance or insert (see fig 5).

One of the above kits must be used with each installation.

2.2 Additional optional features

Circulating Fan Kit #555CFK Having variable speed

and temperature control, it is

designed to boost the natural

convection process through

the appliance. It may be fitted

before the fireplace is installed

or retrofitted at a later date.

Closure Plate #3336 CP 33” high x 36” wide black

closure plate with black aluminum extrusion edge. To

cover openings for insert applications.

2.3 LP Gas

LPG Conversion kit Burner & injector kit for

conversion from natural gas to

propane – Kit #554LPK.

2.4 Venting options

2.4.1 Direct vent installations (solid

piping)

One or more of the accessories listed below must be

used for each installation. See the “Location” section of

this manual.

Kit#

551DVK Valor Horizontal terminal kit with pipe

section. Maximum useable length 26”.

(66cm) (Maximum 14” thru combustible

wall section (36cm)

556 CLA Co-Linear appliance Adapter

558FLK Through the wall Dura-vent pipe

insulation kit

817VAK Adapter for Dura-vent pipes

984 Dura-vent DV GS horizontal square

terminal cap

942 Dura-vent DV GS wall thimble kit

945B 45° Dura-vent DV GS elbow

990B 90° Dura-vent DV GS elbow

908B 6” Dura-vent DV GS pipe length

907B 9” Dura-vent DV GS pipe length

906B 12” Dura-vent DV GS pipe length

904B 24” Dura-vent DV GS pipe length

903B 36” Dura-vent DV GS pipe length

902B 48” Dura-vent DV GS pipe length

911B Adjustable 11”-14

5

/8” Dura-vent DV GS

pipe length

981 Dura-vent DV GS snorkel termination

unit – 36” rise

982 Dura-vent DV GS snorkel termination

unit – 14” rise

980 Dura-vent DV GS Low Profile vertical

termination cap

991 Dura-vent DV GS high wind vertical

termination cap

940 Dura-vent DV GS round ceiling support

941 Dura-vent DV GS cathedral ceiling

support box

963 Dura-vent DV GS ceiling firestop

943 Dura-vent DV GS adjustable roof

flashing. Roof pitch 0/12 – 6/12

943S Dura-vent DV GS steep roof flashing.

Roof pitch 7/12 – 12/12

953 Dura-vent DV GS storm collar

988 Dura-vent DV GS wall strap

923GCL Dura-vent DV GS co-axial to co-linear

appliance connector

923GK Dura-vent DV GS co-linear termination

kit

984 Dura-vent DV GS square terminal cap

2280 Dura-vent DV GS co-linear flex

chimney liner 35ft. length.

835TG Terminal Guard

2.4.2 Direct Vent Co-Linear Installations –

for Free Standing or Recessed

Installations (flexible piping)

Converts the appliance outlet collars to accept

two 3” dia. Flex liners for installation into

existing solid fuel burning fireplaces and

chimneys. Requires 556 CLA adapter and 923

GK termination kit along with either a 980 or

991 termination cap.( 923GCL may be used in

lieu of 556 CLA adapter)

2.4.3 B-vent installations – For President

Free Standing only

Kit #552BVX converts this appliance from a

direct vent fireplace heater to a gravity vent

fireplace heater for use with a 4” “B” type vent.

A full installation and operating manual is

supplied with the kit.

5 of 48

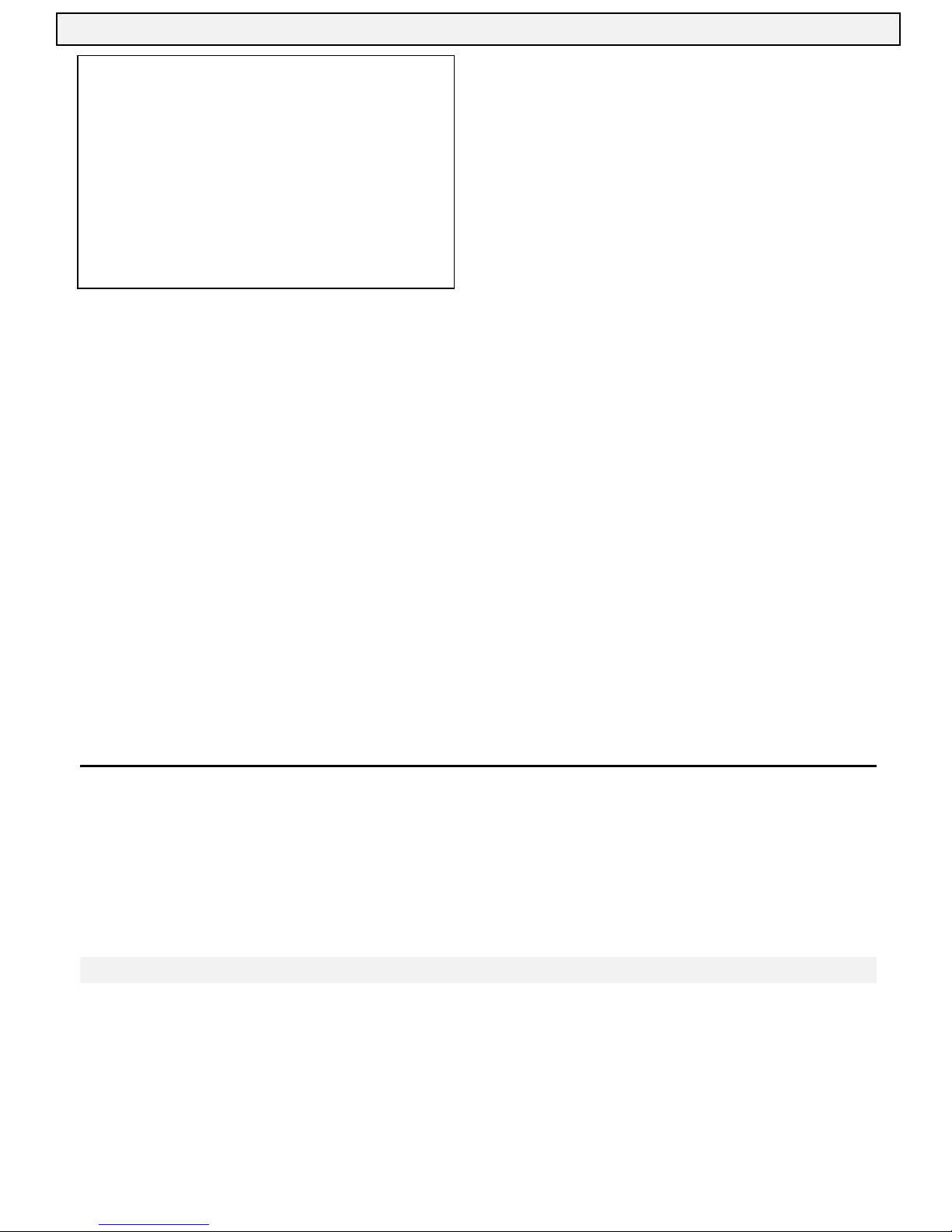

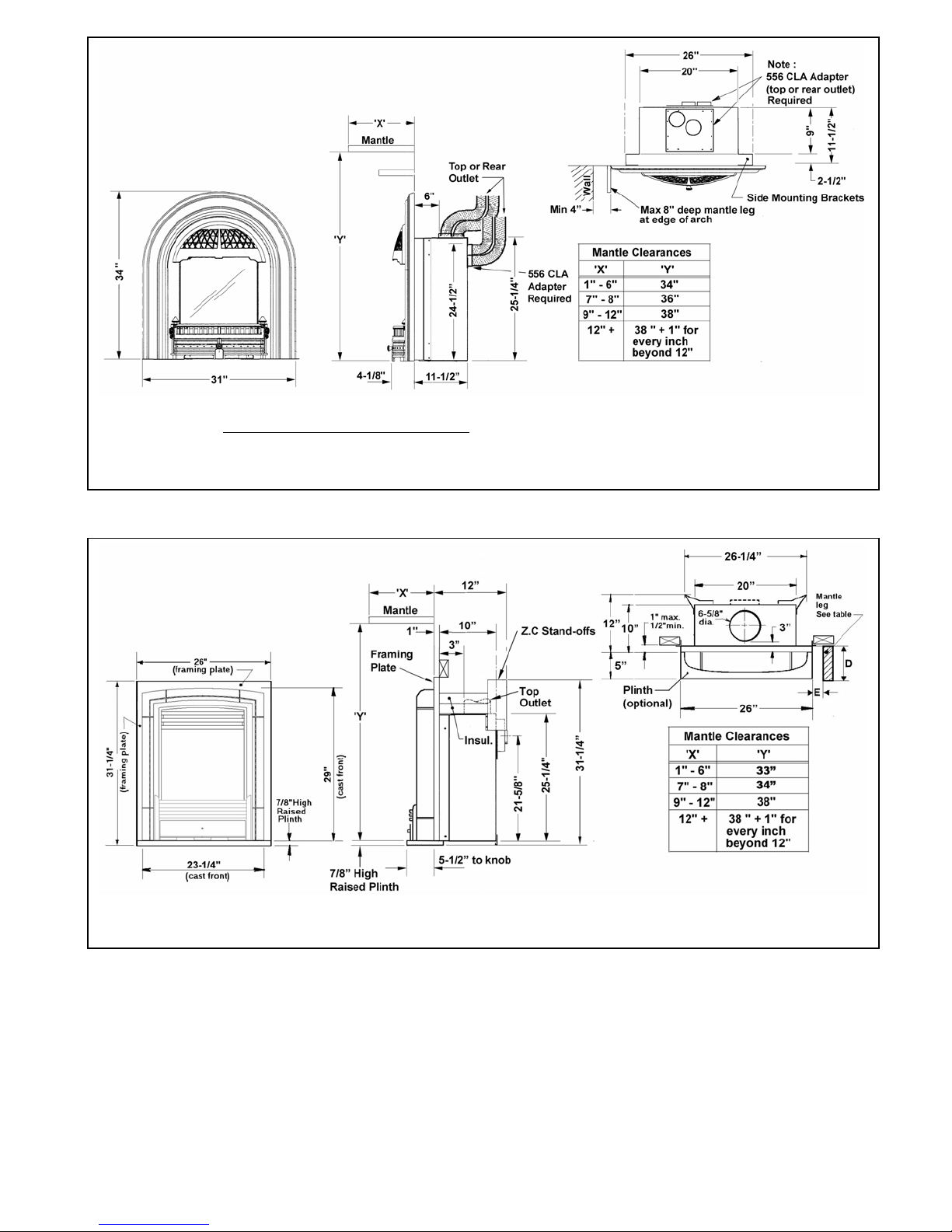

Figure 1. Model 531 President Free Standing – Dimensions

Figure 2. Model 536 Recessed President – Dimensions

Figure 3. Model 539 Windsor Arch. with Backplate - Dimensions

Mantle depth “A” Min. Clearance“B”

Up to 7” 4”

Above 7” up to 8” 5”

Above 8” up to 9” 7”

Above 9” up to10” 8”

Above 10” up to 12” 9”

More than 12” 9”+extra 1” for every

1” de

p

th above 12”

Mantle leg

projection “D”

Min clearance from

appliance side “E”

Up to 8” 0”

More than 8” 6”

Mantle depth “A” Min. Clearance“B”

Up to 12” 4”

Above 12” up to 18” 8”

More than 18” 8”+extra 1” for every

1” de

p

th above 18”

Mantle leg

projection “D”

Min clearance from

appliance side “E”

Up to 8” 1”

More than 8” 6”

6 of 48

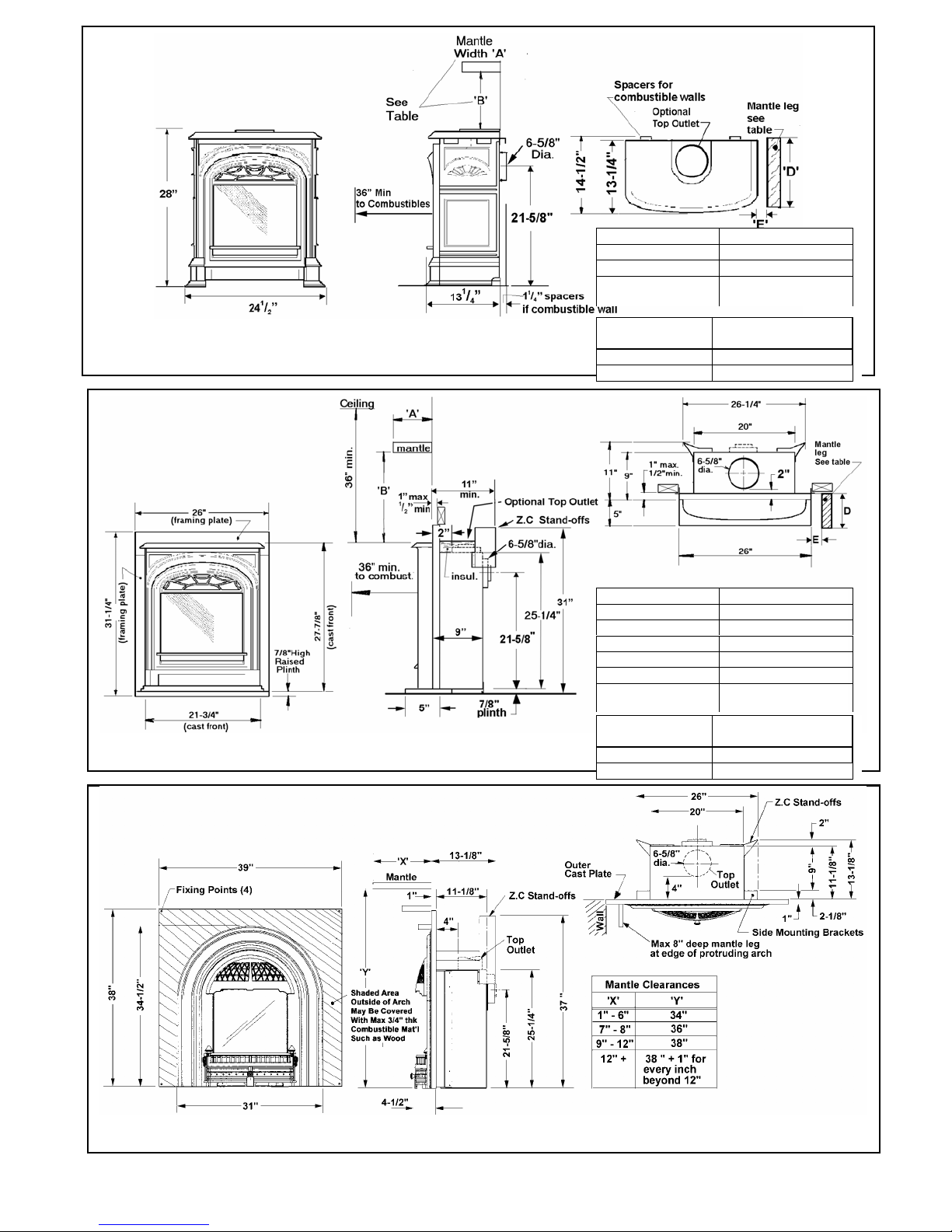

Fig 4. 549 Windsor Arch without backplate.

Note – this option

is intended for insert applications only and does not include the stand-offs and insulation pads

required for zero clearance applications. Most recessed 530 insert applications will also require a 556 CLA co-linear

adapter

Fig 5. - 541 Recessed Bolero Dimensions

7 of 48

3.0 GENERAL

3.1 Approvals & codes

This appliance is certified by International Approval Services for use in Canada and the USA.

The appliance complies with CGA P.4.1, Testing method for measuring annual fireplace efficiencies.

The installation must conform with local codes or, in the absence of local codes with the National Fuel Gas Code, ANSI

Z223.1or the Canadian installation code CAN/CGA-149. Only qualified licensed or trained personnel should install the

appliance.

The appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70 or the Canadian Electrical Code, CSA C22.1.

3.2 Ratings

Nat. Gas LPG

Altitude (Ft) 0-4500 *

Input Max. (Btu/h) 20,500 19,000

Input Min (Btu/h) 6,000 11,600

Manifold pressure (in.w.c.) 3.5 – 3.9 10.3 – 10.7

Min. Supply pressure (in. w.c.) 5.0 11.0

Max. Supply pressure (in. w.c.) 10.5 14.0

*Tested to CAN/CGA - 2.17 Gas fired appliances for use at high altitudes. In the USA installations may require deration over

2000ft - Check local codes.

3.3 Wall Thickness

The appliance vent is suitable for penetrating a combustible wall up to 14” (36cm) thick.

A non-combustible wall can be any thickness up to the maximum horizontal run of vent pipe allowed for the particular

installation – See sections 4 and 5.

3.4 Supply Gas

Heater engine 530XAN /XCN is used on Natural gas installations.

Heater engine 530XAP/XCP is used on Propane installations.

The supply pressure must be between the limits shown in section 3.2 above.

The supply connection is

3

/8’’NPT.

The opening for the gas supply line is at the rear left corner of the appliance.

3.5 Controls

The unit is supplied standard with a battery operated, hand held remote control and receiver which has the ability to adjust

the gas input of the unit between the pilot setting and the maximum input .The pilot light must be manually lit at the valve

and may be left on or turned off with each use. The remote control provides full thermostatic or manual operation with

the option of programming thermostat function between certain times of the day. Manual operation of the valve is also

possible should the batteries or remote control fail.

3.6 Electrical

The unit does not require an electrical power source unless fitted with an optional circulating fan.

8 of 48

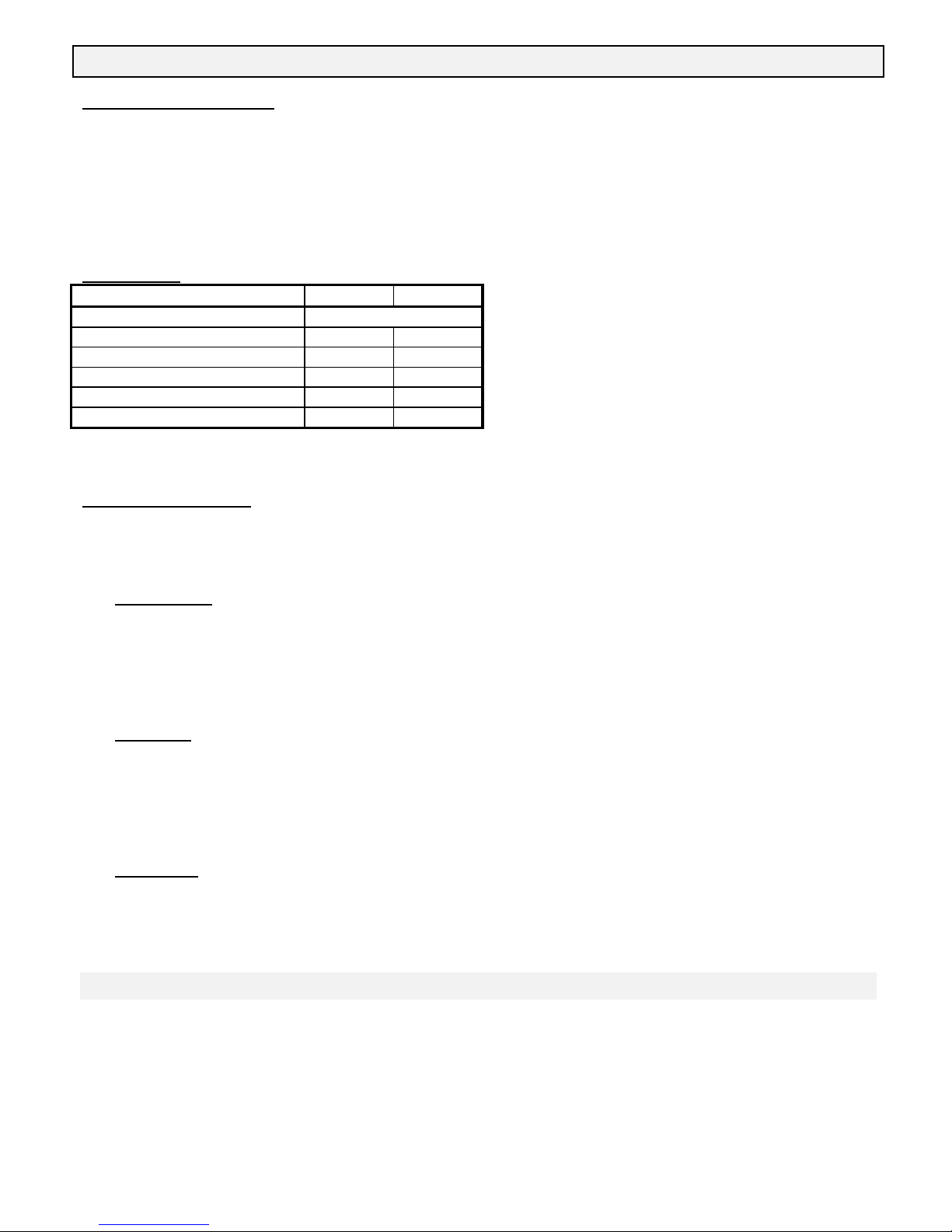

4.0 LOCATION – PRESIDENT FREE STANDING

4.1 Wall & Floor Fixing

Figure 6 President FS fixing holes

The President FS can be installed against a wall or in the

room away from walls. The appliance is designed to be fixed

to the floor. The appliance can additionally or alternatively

be fixed to a rear wall. The fixing positions are shown in

figure 6. The appliance is approved for installation directly

on wood flooring. If the appliance is installed directly on

carpeting, vinyl tile or other combustible material other than

wood flooring, it must be installed on a metal or wood panel

extending the full width and depth of the appliance.

4.2 Venting configurations

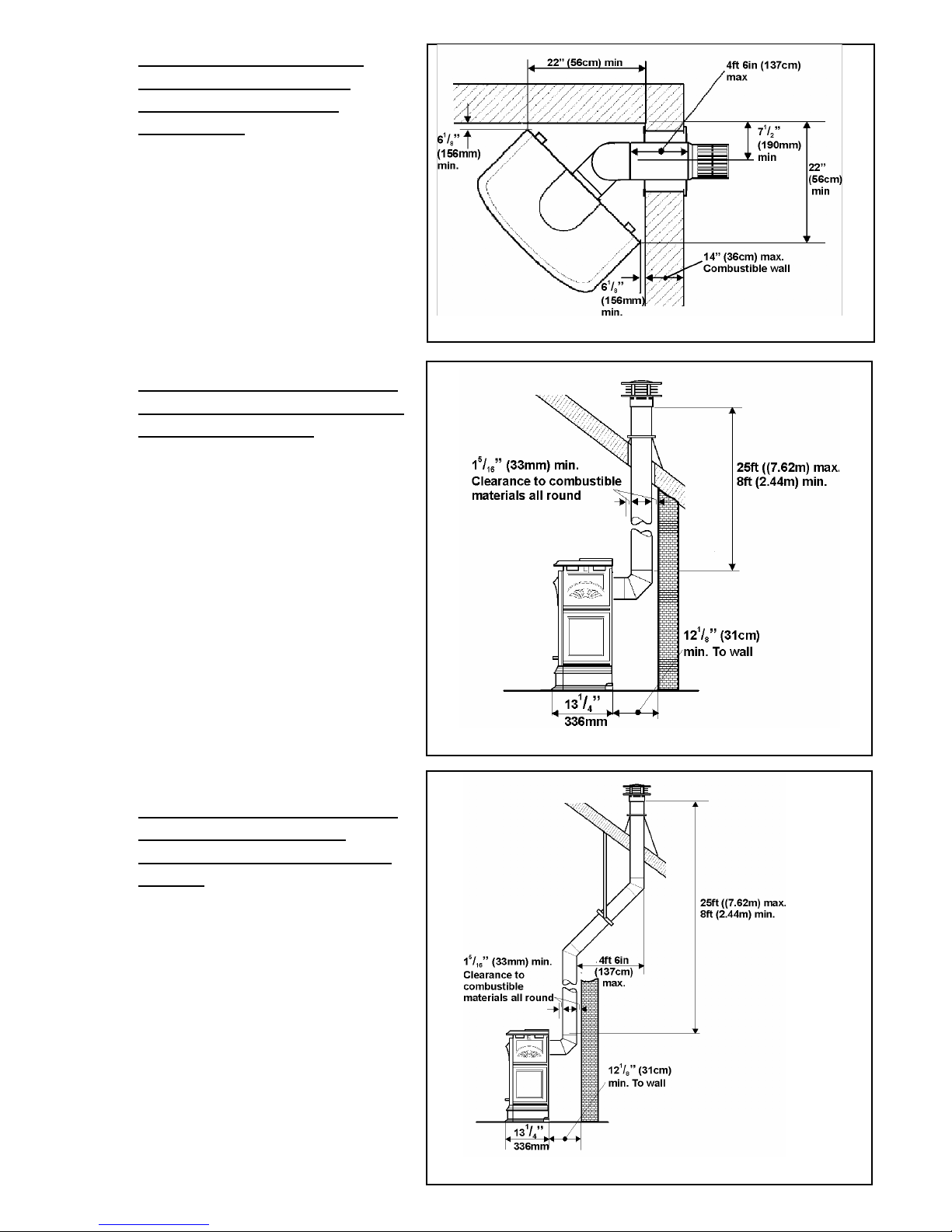

4.2.1 Flat on wall

Requires Valor vent kit #551DVK or Dura-vent pipe length

with adapter #817VAK and Dura-vent terminal cap.

The location requirements are shown in figure 7.

The horizontal vent run cannot be extended beyond the dimensions

shown in figure 5 by the use of any vent accessory pipes.

4.2.2 Flat on wall with snorkel termination

(Fig.8)

Figure 8

Figure 7

For use on horizontal vent installations where the outside

ground level is too close to the standard terminal. Adapter

#817VAK, a Dura-vent pipe length and snorkel termination

#981 or #982 will be required (See vent options section of

this manual).

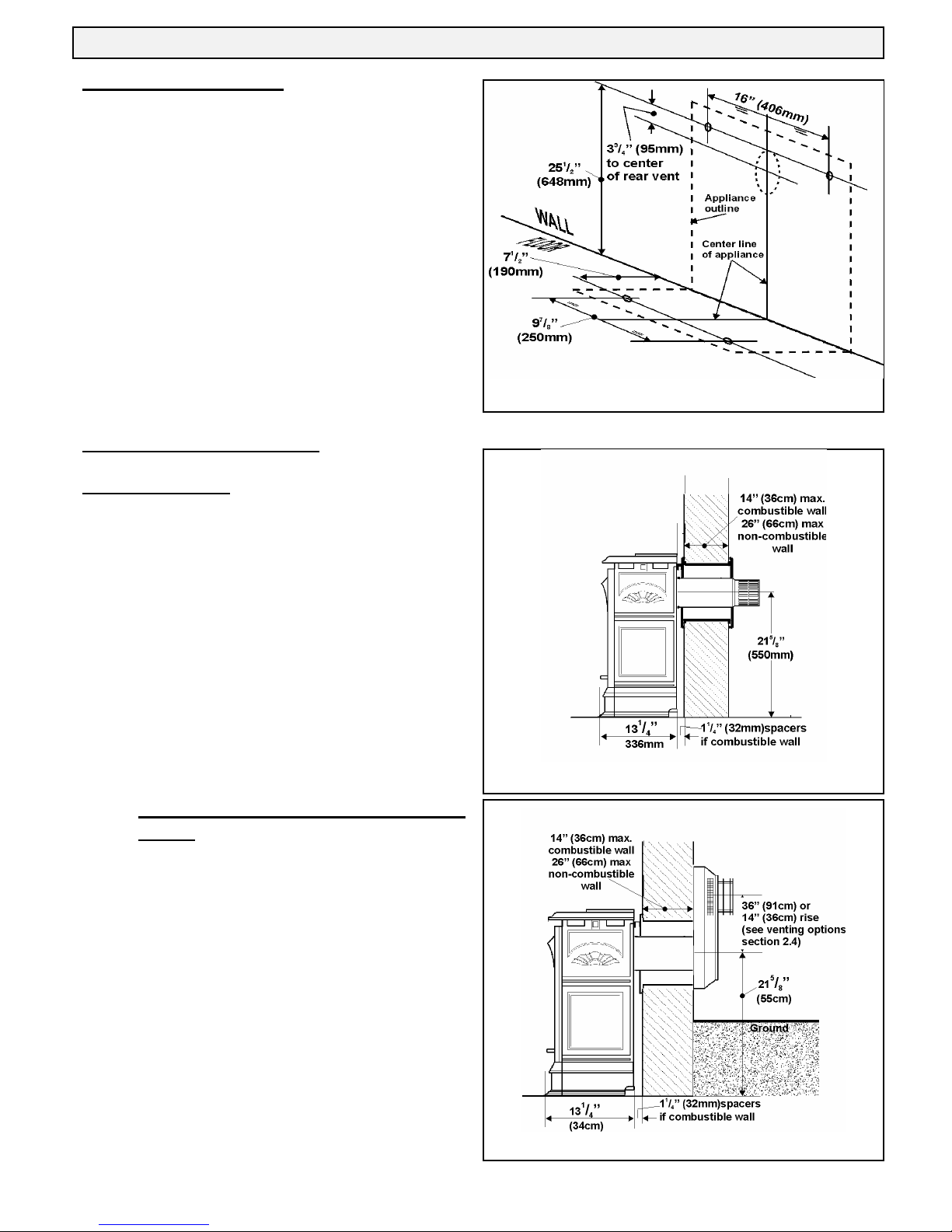

4.2.3

9 of 48

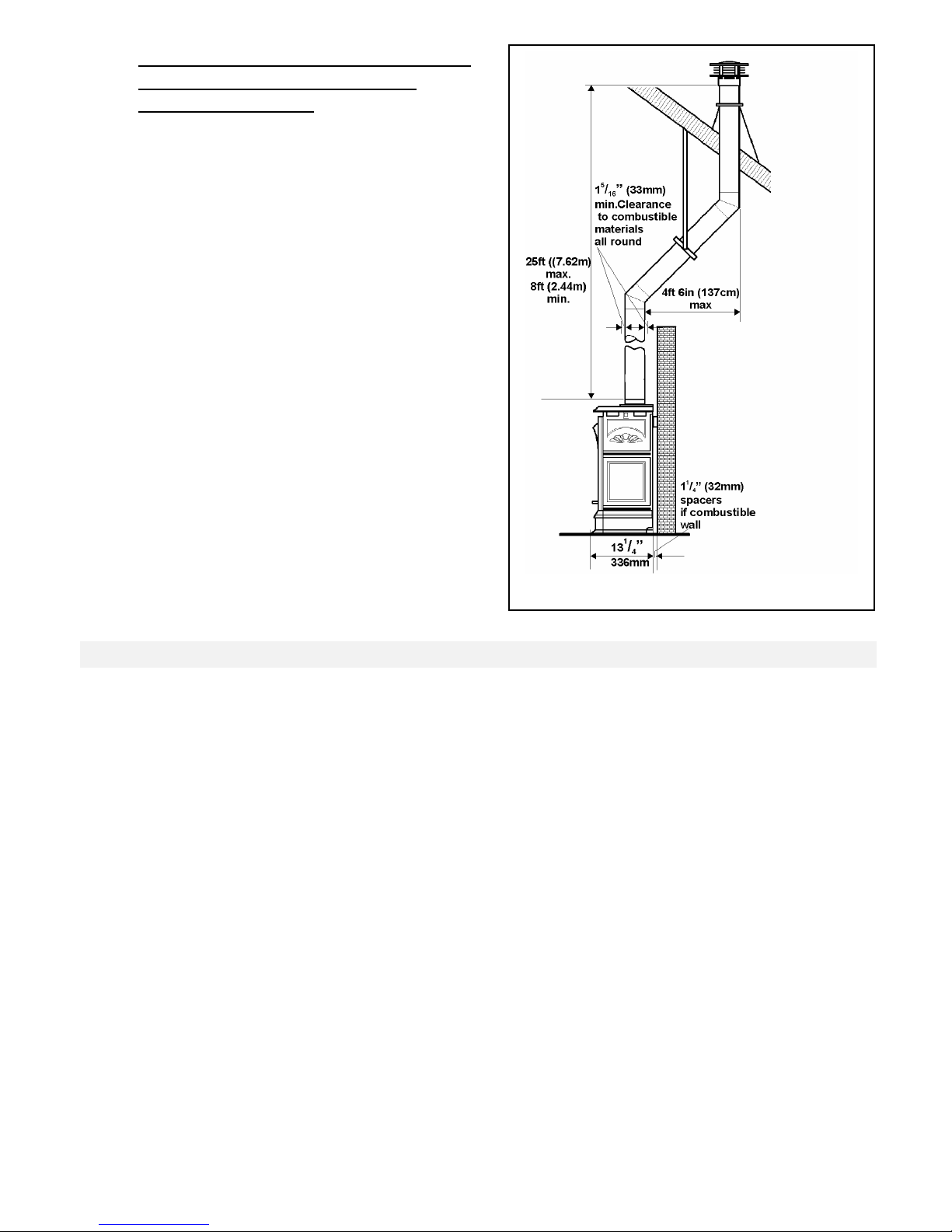

Rear vent connection, vertical vent rise

with horizontal termination (Fig. 9)

Can be used with either #551DVK standard vent kit or #984

Dura-vent terminal cap and accessories.

Adapter #817VAK, two 90° vent elbows #990B and Dura-vent

pipe lengths will be required.

(See venting options section of this manual).

No more than two 90°elbows must be used.

Minimum Maximum

A: From floor to top

of vent duct

3ft 7in

(109cm)

10ft 7in

(323cm)

B: Back of appliance

to outside wall

- 5ft 5in

(165cm)

C: Back of appliance

to inside wall

14

1

/8in

(36cm)

-

D: Vertical pipe run 12in (30cm) 8ft (244cm)

E: Horizontal pipe

run (Total before and

after elbows)

- 4ft 6in

(137cm)

F: Clearance to

combustible materials

above horizontal pipe

run

2

5

/8in

(6.7cm)

-

G: Clearance to

combustible materials

below horizontal pipe

run

1

5

/16in

(3.3cm)

-

H: Clearance to

combustible materials

all round vertical pipe

run and at sides of

horizontal pipe run

1

5

/16in

(3.3cm)

-

Figure 9

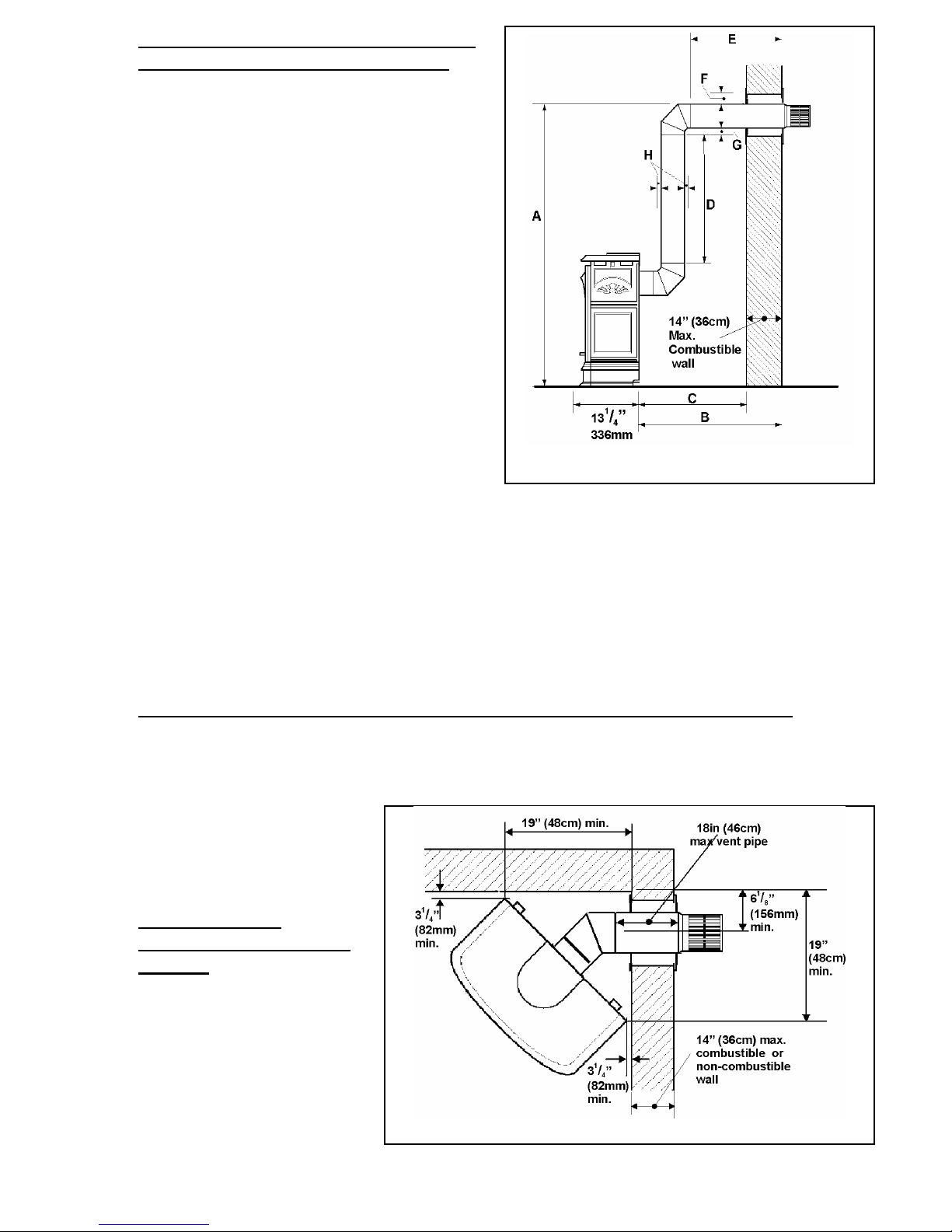

4.2.4 Rear vent connection, vertical vent rise with horizontal snorkel termination

For “semi-basement” situations where vertical vent rise does not raise horizontal termination sufficiently above ground

level.

The dimensional requirements in section 4.2.3 and figure 9 apply.

Adapter #817VAK, two 90° vent elbows #990B, Dura-vent pipe lengths and a Dura-vent snorkel termination will be

required.

Figure 10

#942 Dura-vent wall thimble kit may also be

necessary.

(See venting options section of this manual).

No more than two 90°elbows must be used.

4.2.5 Corner location,

horizontal vent run only

(Fig. 10)

Can be used with either #551DVK standard

vent kit or #984 Dura-vent terminal cap and

accessories.

Adapter #817VAK and 45° Dura-vent elbow

will be required.

(See venting options section of this manual).

Be aware of the limited maximum vent pipe

length and wall depth for this type of

installation – See figure 10.

Figure 11

4.2.6 Corner location, rear vent

connection, vertical rise,

horizontal termination

(Figs 9 & 11)

Can be used with either #551DVK standard vent

kit or #984 Dura-vent terminal cap and accessories.

Adapter #817VAK, two 90° vent elbows #990B and

Dura-vent pipe lengths will be required.

(See venting options section of this manual).

No more than two 90°elbows must be used.

All vertical dimensional limits are as section 4.2.3.

Figure 12

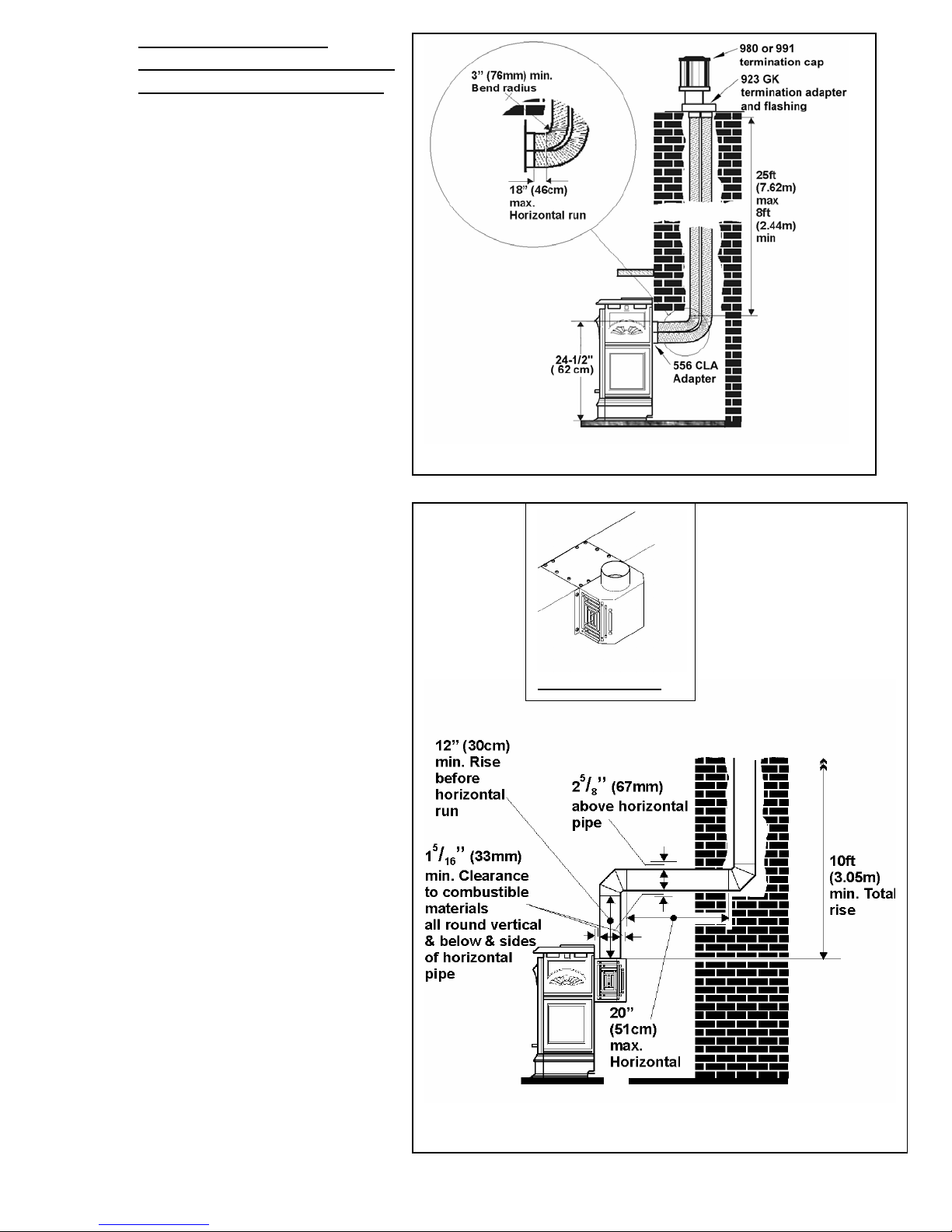

4.2.7 Rear vent connection, vertical

vent rise with through the roof

termination (Fig.12)

Adapter #817VAK, one 90° vent elbow #990B,

Dura-vent pipe lengths, a vertical vent terminal and

roof flashing will be required. Various other ceiling

or roof items may be necessary depending on the

particular installation (See venting options section

of this manual).

10 of 48

Figure 13

4.2.8 Rear vent connection, vertical

vent rise with offset and

through the roof termination

(Fig.13)

For situations where offset is necessary in

an attic to avoid obstructions or allow

useful space.

Adapter #817VAK, one 90° vent

elbow#990B, two 45° vent elbows #984,

wall straps, a vertical vent terminal, roof

flashing and Dura-vent pipe lengths will be

required. Various other ceiling or roof

items may be necessary depending on the

particular installation (See venting options

section of this manual).

4.2.9

Rear vent connection,

installed to fireplace chimney

with co-linear liners (Fig.14)

Only for use when retrofitting a noncombustible fireplace and chimney.

The appliance must not be connected to

a chimney flue serving a separate solidfuel burning appliance.

Requires 556 CLA Co-Axial to CoLinear appliance adapter, two lengths of

3” dia. Flexible Chimney liner , colinear termination kit and flashing

#923GK and either high wind vertical

vent terminal cap #991 or a 980 Low

Profile vertical termination cap .(See

vent options section of this manual).

Figure 14

Fig 15.

552 BVK Adapter

4.2.10 Rear Vent Conversion to B-

Vent using 552 BVK Adapter

Free Standing Only ( Fig 15)

Used to field convert heater from direct

vent to 4” dia. gravity vent on free standing

units only . A full installation and operating

manual is supplied with the kit.

4.2.11

11 of 48

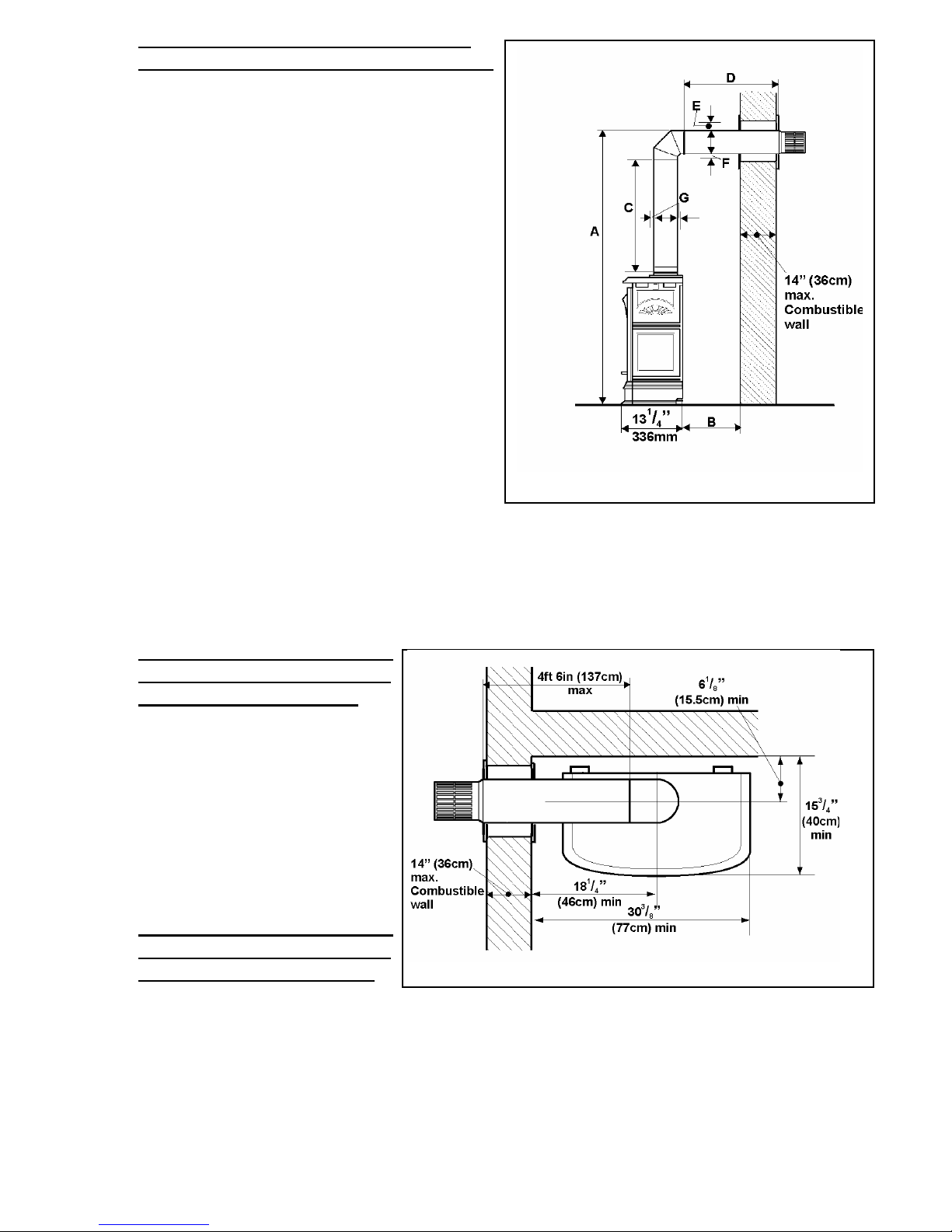

Top vent connection, vertical vent rise

with horizontal rear termination (Fig.16)

12 of 48

Can be used with either #551DVK standard vent kit or #984

Dura-vent terminal cap and accessories.

Adapter #817VAK, one 90° vent elbow #990B and Dura-vent

pipe lengths will be required.

(See venting options section of this manual).

No more than two 90°elbows must be used.

Minimum Maximum

A: From floor to top

of vent duct

4ft

(122cm)

11ft

(335cm)

B: Back of appliance

to inside wall

3

1

/4 in

(79mm)

-

C: Vertical pipe run 9in

(23cm)

8ft

(244cm)

D: Horizontal pipe

run

- 4ft 6in

(137cm)

E: Clearance to

combustible materials

above horizontal pipe

run

2

5

/8in

(6.7cm)

-

F: Clearance to

combustible materials

below horizontal pipe

run

15/16in

(3.3cm)

-

G: Clearance to

combustible materials

all round vertical pipe

run and at sides of

horizontal pipe run

1

5

/16in

(3.3cm)

-

Figure 16

4.2.12 Top vent connection, vertical

vent rise with horizontal side

termination (Figs.16 &17)

Figure 17

Can be used with either #551DVK standard

vent kit or #984 Dura-vent terminal cap and

accessories.

Adapter #817VAK, one 90° vent elbow #990B

and Dura-vent pipe lengths will be required.

(See venting options section of this manual).

No more than two 90°elbows must be used.

All vertical dimension, pipe run and clearance

limits are as section 4.2.11.

4.2.13 Top vent connection, vertical

vent rise with horizontal side

or rear snorkel termination

The dimensional requirements in sections

4.2.11 and 4.2.12 apply.

Adapter #817VAK, one 90° vent elbow #990B, Dura-vent pipe lengths and a Dura-vent snorkel termination will be

required.

#942 Dura-vent thimble kit may also be necessary.

(See venting section of this manual).

Figure 18

4.2.14 Top vent connection,

corner location, vertical

rise, horizontal

termination, 45° pipe

bend (Figs 16 & 18)

Can be used with either #551DVK

standard vent kit or #984 Dura-vent

terminal cap and accessories.

Adapter #817VAK, one 90° elbow #990B,

one 45° elbow #945B and Dura-vent pipe

lengths will be required. (See venting

section of this manual).

All vertical dimensions and clearance limits

are as section 4.2.11.

4.2.15 Top vent connection,

corner location, vertical

rise, straight horizontal

termination (Figs 16 &

19)

Figure 19

Can be used with either #551DVK

standard vent kit or #984 Dura-vent

terminal cap and accessories.

Adapter #817VAK, one 90° elbow #990B

and Dura-vent pipe lengths will be

required. (See venting section of this

manual).

All vertical dimensions and clearance limits

are as section 4.2.11.

.

Figure 20

4.2.16 Top vent connection, vertical vent rise,

through the roof termination (Fig. 20)

Adapter #817VAK, Dura-vent pipe lengths, a vertical vent

terminal and roof flashing will be required. Various other

ceiling or roof items may be necessary depending on the

particular installation (See venting options section of this

manual).

13 of 48

4.2.17 Top vent connection, vertical vent rise

with offset and through the roof

termination (Fig.21)

For situations where offset is necessary in an attic to avoid

obstructions or allow useful space.

Adapter #817VAK, two 45° vent elbows #984, wall straps, a

vertical vent terminal, roof flashing and Dura-vent pipe lengths

will be required. Various other ceiling or roof items may be

necessary depending on the particular installation (See venting

options section of this manual).

Figure 21

14 of 48

15 of 48

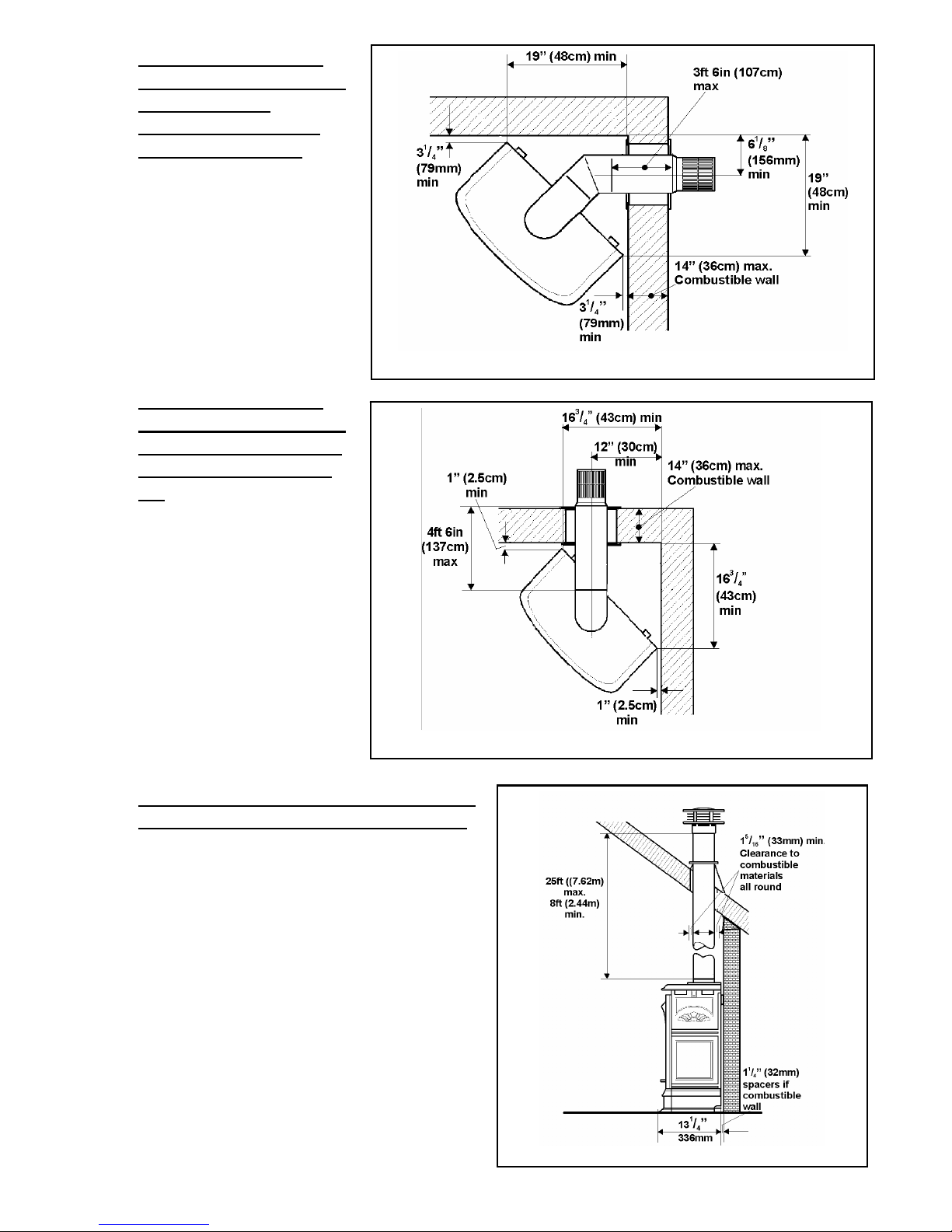

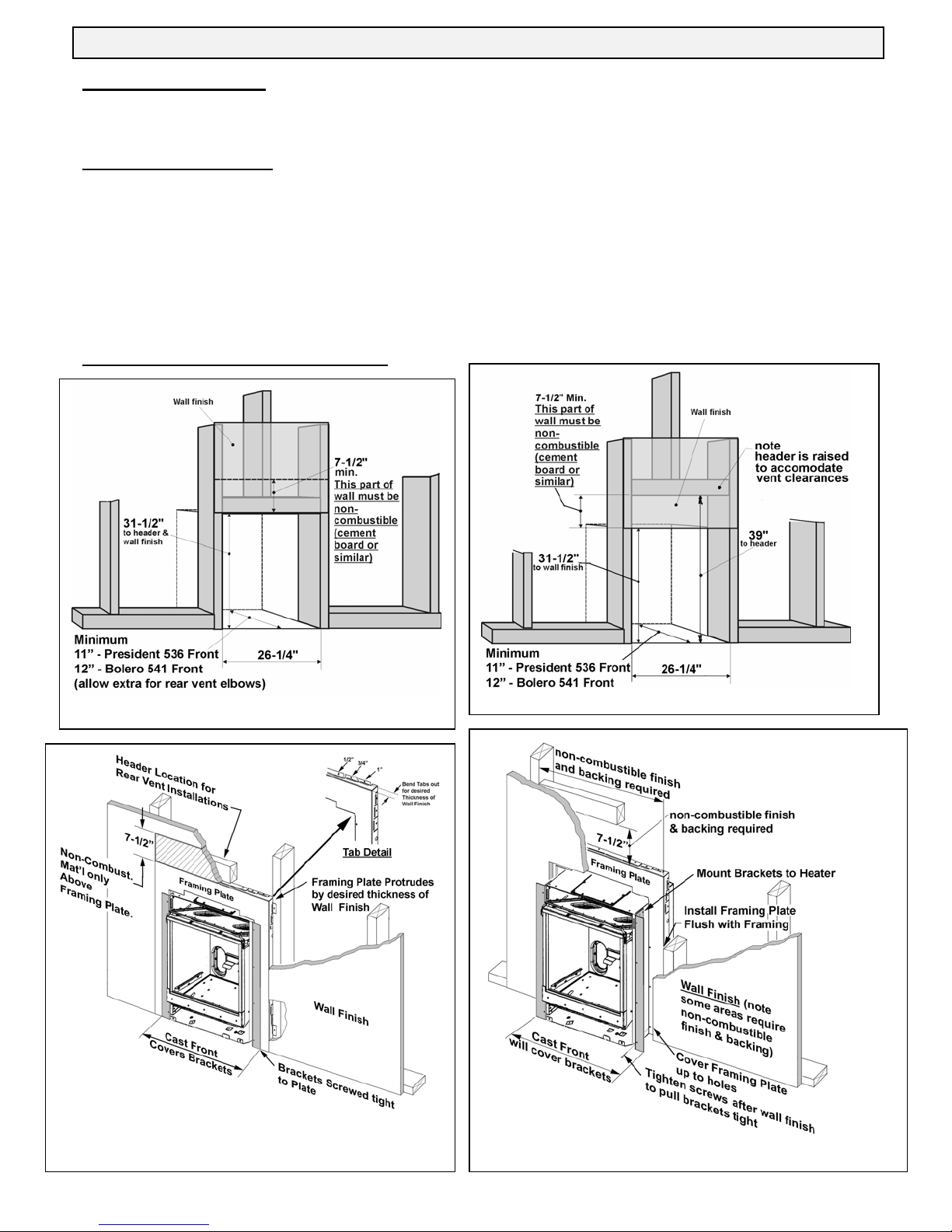

5.0 LOCATION –ZERO CLEARANCE

5.1 Framing -General

The framing dimensions vary with the different cast iron fronts and with different vent configurations, allowing for

elbows etc. Read framing drawings carefully.

5.2 Finishing- General

The President 536 and Bolero 541 Fronts come supplied with a Framing Plate for zero clearance applications. The

Framing Plate is painted black and may be left exposed beyond the perimeter of the of the cast iron front or may be

covered with non-combustible material if desirable ( see figs 24 &25 ). Windsor Arch 539 Front comes with an integral

back plate ( see fig 3)

• A non-combustible hearth is not necessary in front of this appliance.

• The appliance is approved to install directly on wood sub- flooring

• Any framing construction must be clear of standoffs (See figures 1-4 ).

• Be aware of the area 7

1/

2

” x 26¼” (19cm x 67cm) immediately above the Framing Plate used with the 536/541 Cast

Fronts must be constructed with non-combustible materials as shown in figures ( 22 &23 ).

5.3 President 536/ Bolero 541 Fronts

Fig 23 , Top Vent Framing, 536/541 Fronts.

Fig 22, Rear Vent Framing, 536/541 Fronts

Fig 25, Framing Plate covered, 536/541 Fronts

Fig 24, Framing Plate Exposed, 536/541 Fronts

Loading...

Loading...