Miles Industries H5, 1100LPG, 1100NG, 1150NG, 1150LPG Installation Instructions Manual

H5

Gas Conversion Kit

1100NGK / PGK & 1150NGK / PGK

Use with with Valor Models 1100/1150 Heaters ONLY

Installation Instructions

This appliance is certifi ed for use from 0–4500 feet. For

altitudes above 4500 feet, see local codes.

Kit Contents

1 Pilot injector

1 Main burner elbow injector

1 Set of conversion labels

1 Minimum rate by-pass screw

Tools Required

• Wrenches, to disconnect gas line

• Phillips (+) screwdriver, to remove burner module

• Small (jewelers size) fl at blade screwdriver, to set

pressure

• Small fl at blade screwdriver, to release pressure tap

on valve

• Needle nose pliers, to remove by-pass screw

• Hex (Allen) wrench, 4 mm or 5/32”, to remove pilot

injector

• Manometer, to set pressure when regulator is integral

with valve

WARNING

This conversion kit shall be installed by

a qualifi ed service agency in accordance

with the manufacturer’s instructions and

all applicable codes and requirements of

the authority having jurisdiction. If the

information in these instructions is not

followed exactly, a fi re, explosion or pro-

duction of carbon monoxide may result

causing property damage, personal injury

or loss of life. The qualifi ed service agency

is responsible for the proper installation of

this kit. The installation is not proper and

complete until the operation of the converted appliance is checked as specifi ed in

the manufacturer’s instructions supplied

with the kit.

Use this manual in conjunction with the

installation manual supplied with the

appliance.

Specifi cations

Model

Gas Natural Propane Natural Propane

Altitude (Ft.)* 0-4,500 feet* 0-4,500 feet*

Input Maximum (Btu/h) 28,000 28,000 30,000 30,000

Input Minimum (Btu/h) 13,000 13,000 16,000 16,000

Manifold Pressure (in w.c.) 3.5” 9.0” 4.0” 9.0”

Minimum Supply Pressure (in w.c.) 5.0 11.0 5.0 11.0

Maximum Supply Pressure (in w.c.) 10.0 14.0 10.0 14.0

Main Burner Injector Marking 850 300 850 360

Pilot Injector Marking 51 30 51 30

Min. Rate By-Pass Screw 185 125 195 135

4004585-03

©2014, Miles Industries Ltd.

1100NG 1100LPG 1150NG 1150LPG

General Notes Regarding Conversion

The conversion may be done before or after the

appliance is installed into the cavity. However, the gas

must be connected to set the manifold pressure.

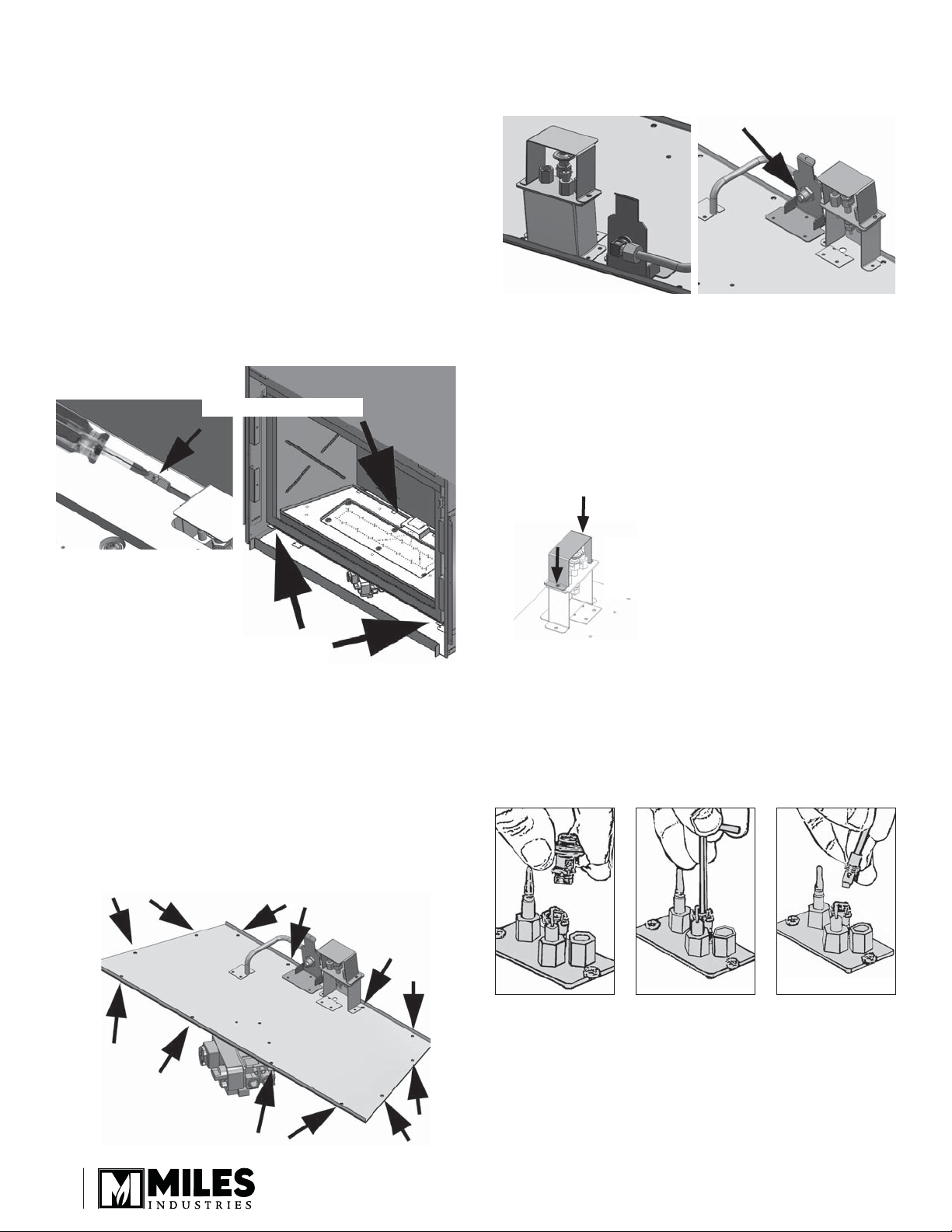

Prepare the appliance

1. If the fi replace is already installed, remove the

access side doors, the front trim, the window, and

fuel bed. Be careful with fuel bed as components

are fragile.

2. Locate shut off valve and isolate.

3. Remove the ceramic liner panels

4. Remove the burner platform, unscrew the 2

thumbscrews fi xing the front of the burner to the

fi rebox as indicated, also 1 screw at rear of burner.

Rear fi xing screw

4. Supporting injector elbow, unlock and remove

pipe assembly, remove injector locknut from inside

manifold housing.

Injector elbow pipe

connection

5. Exchange injector elbow from kit, verify the new

injector before you install—see Specifi cations table

on page 1. Reverse the assembly.

6. Reconnect injector elbow to the pipe. tightening pipe

connection.

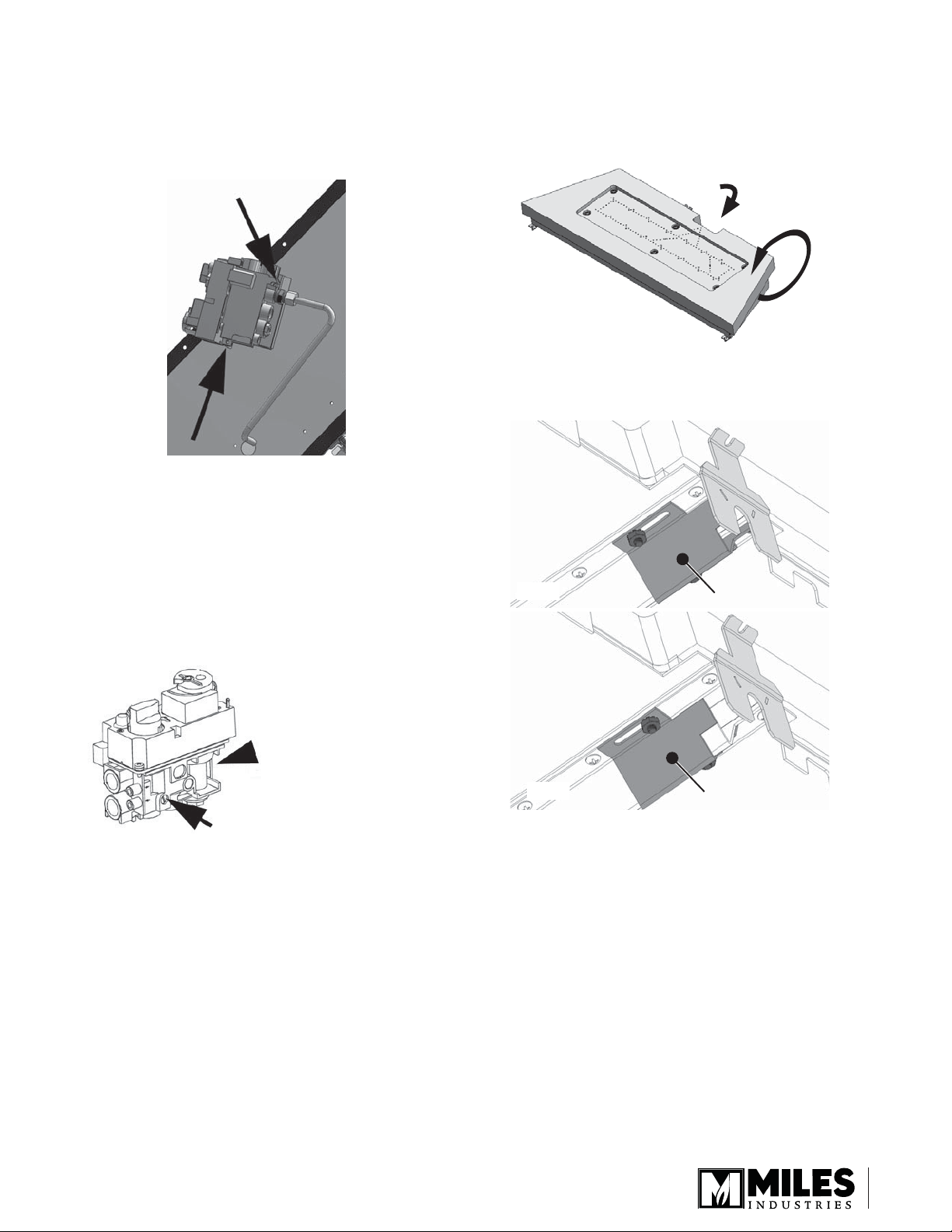

Convert the pilot injector

1. Remove the pilot hood by pulling on it.

Fixing points underside

of fi rebox

5. Gently pull up the burner rear fi rst and then the

front. Be careful not to hook the pilot hood as

you pull the burner up.

Replace the burner injector

1. Using two wrenches disconnect inlet to valve

control.

2. Remove 12 screws holding module plate to fi rebox

base.

3. Withdraw module from fi rebox.

Remove

pilot cover

(2 screws)

2. Unscrew the pilot injector using an Allen key.

Discard the pilot injector.

3. Replace with the appropriate pilot injector—see

Specifi cations table on page 1. Screw in the new

injector.

4. Refi t the pilot head by pushing down on it. Ensure

that it snaps into position.

2

Replace the minimum rate by-pass screw

1. Turn module assembly upside down, unlock and

remove pipe assembly.

2. Remove two screws retaining the valve to

mounting bracket, being careful not to disturb other

connections.

3. Locate and remove the by-pass screw from the

valve and discard. The by-pass screw has a rubber

O-ring and may need to be pulled out using pliers

after unscrewing.

4. Insert the replacement minimum rate by-pass

screw and hand tighten using a screwdriver. Refer

to the Specifi cations table on page 1 for proper

by-pass screw. Note that the number is stamped on

the barrel of the screw.

Adjust the air shutter

The air shutter is located under the ceramic fuel bed at

the back.

1. Carefully turn the fuel bed upside down and locate

the air shutter.

Air shutter

2. Loosen the screws on each side of the shutter and

slide the shutter as indicated below according to the

type of gas used.

NG

Air shutter

Top side of

control valve

Minimum rate

By-pass screw

location

Re-assemble module

1. To reinstall, is a reversal of the procedure.

2. Position and locate module in the fi rebox inserting

the valve fi rst. be careful not to trap cables

between fi rebox fl oor and module

3. Secure module to fi rebox with previously used

screws.

4. Reconnect gas inlet to valve tightening pipe

connection. Open shut off valve and inspect

5. Test for leaks by applying a liquid detergent or soap

solution to inlet connection joint. Bubbles forming

indicate a gas leak.

Never use an open fl ame to check for leaks.

Correct any leak detected immediately.

LPG

3. Re-tighten the screws.

Air shutter

3

Loading...

Loading...