Mile HaoXianG Model Technology DLE-20, DLE-55 User Manual

Engine Start

1. Close the choke and turn on the ignition, Advance the throttle to the full position.

2. Flip the prop until the engine fires and dies. It may take a few more flips if it is the

initial engine start.

3. Open the choke, advance the throttle to just above idle, flip the prop until it starts.

Maintenance

1. Use standard or premium unleaded.

2. Break in engine for 2 hours at half throttle.

3. Check fuel system for air leaks when running.

4. Keep the engines exterior clean and inspected regularly.

5. Keep fuel filter clean.

6. Remove and inspect reed valve every 6 months.

DLE Engines are made by Mile HaoXianG Model Technology Co. Ltd

DLE

Engine

User Manual

DLE – 20

Caution – Read Manual carefully before operation. Serious injury may result from improper

use.

USER Manual

DLE series engines are a professionally designed engine for model aircraft. With its

high power output and light weight its ideal for your model aircraft. Read and

follow all of the instructions before you use your engine.

Safety Instructions

1. Engines are not a toy. Serious injuries may result from improper use. We are

not responsible for any injury, damage or other loss resulting from its use.

2. Before every use check the engine assembly, propeller and airframe carefully

for loose screws and nuts. Loctite is strongly recommended on all screws.

3. During the break-in process the engine must be mounted on a shock

absorbing mount or in a model aircraft.

4. Always stand clear of and behind of the propeller, never allow anyone

including yourself to be in front of or to the sides of the propeller when

starting or running the engine. Anyone near the engine should wear

protective eye ware. Do not wear loose clothing near the engine or propeller.

Specifications

1. Performance

2.5HP at 9000 RPM

Idle speed – 1700

Static thrust at 100m altitude – 6.3 Kg

Static thrust at 1800m altitude – 5.6 Kg

Recommended Props: 14x10; 15x8; 16x6; 16x8; 17x6

Spark Plug - CM6 or equivalent

2. Parameters

Exhaust Amount – 20cm

3

Piston Diameter x Stroke; 32mm x 25mm

Compression ratio – 10.5:1

Ratio of lubricating oil: Mineral based oil – 32-1

Synthetic Oil – between 32-1 and 50-1

Weight: Engine – 650g

Exhaust – 50g

Ignition – 120g

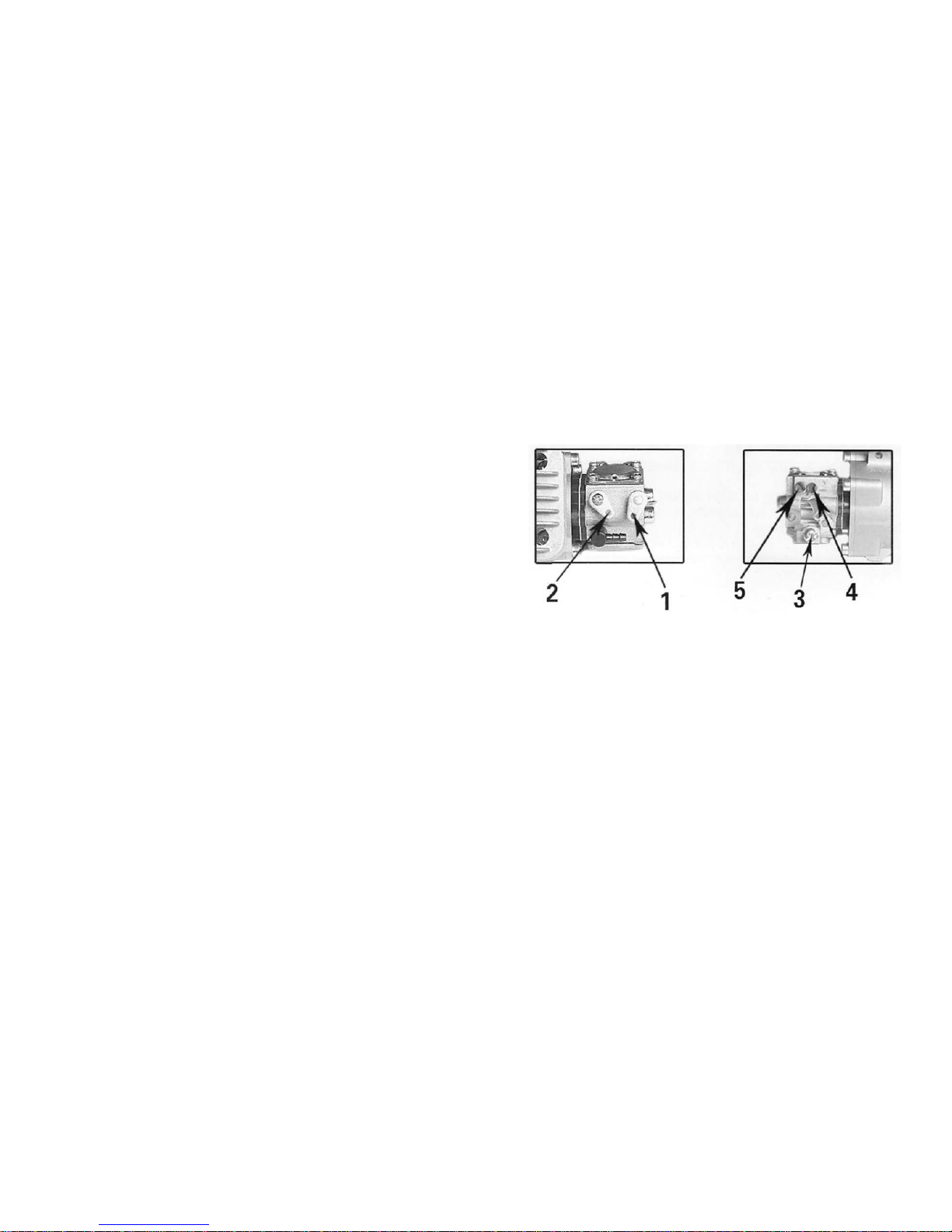

Carburetor Adjustment

Every engine has been adjusted to average mixture settings which will most likely

allow the engine to start and run in most locations. However as altitudes and

barometric pressures vary by location, it is very likely that the carburetor mixture

settings will need to be adjusted to obtain optimum performance.

1. Choke lever

2. Throttle lever

3. Idle speed adjustment screw

4. Low speed adjustment screw

5. High speed adjustment screw

Carburetor Adjustment

A general starting point is 1.1 turns out for the low speed needle and 1.5 turns out for the

high speed needle. Adjust the high speed needle for peak RPM. If the engine slows or dies

while at full throttle the high speed mixture is likely too lean. Adjust the low needle until

you achieve a smooth idle and a reliable transition to high speed. If the engine dies when the

throttle is advanced the mixture is likely to lean. If the engine stumbles when the throttle is

advanced the mixture is likely to rich.

Caution: Do not be tempted to run an overly rich mixture. A rich mixture will only

result in poor engine performance, Premature carbon build up, a fouled plug and excessive

exhaust residue. However a lean mixture will also damage the cylinder and piston.

Loading...

Loading...