Page 1

ver. 1.07

INDU WRC-2010H Controller

User’s Manual

Sp. z o.o.

41-250 Czeladź, ul. Wojkowicka 21

Tel. 0 32 763–77–77

Fax: 0 32 763–75–94

www.mikster.pl e-mail: info@mikster.pl

v1.07 29.05.2008

Page 2

INDU WRC-2010H Controller – User’s Manual ver. 1.07

TABLE OF CONTENTS

page

1. STRUCTURE, APPLICATIONS, POTENTIAL.....................................................................................................4

2. “INDU WRC-2010H” - CONTROL PANEL............................................................................................................4

3. “INDU WRC-2010H” - START OF OPERATION..................................................................................................6

4. PROCESS PROGRAMS......................................................................................................................................6

4.1. Manufacturing process programming............................................................................................................6

4.2. Execution of program stored in memory .......................................................................................................8

4.3. Program execution interruption .....................................................................................................................9

4.4. Automatic process activation.........................................................................................................................9

4.5. Editing of parameters set during controller operation..................................................................................11

5. CONTROLLER CONFIGURATION....................................................................................................................12

5.1. User’s functions...........................................................................................................................................13

5.1.1. Time and date setting ...........................................................................................................................13

5.1.2. Setting menu language.........................................................................................................................13

5.2. Service functions 1......................................................................................................................................15

5.2.1. Controller parameter setting .................................................................................................................15

5.2.2. Setting of step parameters....................................................................................................................20

5.2.3. Alarm setting.........................................................................................................................................22

5.2.4. Parameter setting for pause mode, stop mode and key functions F1..F4............................................26

5.2.5. I/O output parameter setting.................................................................................................................27

5.2.6. Washing parameter setting...................................................................................................................31

5.3. Service functions 2......................................................................................................................................31

5.3.1. Test for digital outputs...........................................................................................................................31

5.3.2. Key test.................................................................................................................................................32

5.3.3. Diode test..............................................................................................................................................32

5.4. Washing ......................................................................................................................................................33

5.4.1. Washing programming .........................................................................................................................33

5.4.2. Washing activation................................................................................................................................33

6. ADDITIONAL INFORMATION............................................................................................................................34

6.1. Display of additional measurements............................................................................................................34

7. HOW TO CONNECT THE CONTROLLER TO PC COMPUTER.......................................................................34

8. TECHNICAL DATA.............................................................................................................................................35

II INDU WRC CPU-01 MODULE............................................................................................................................36

1. MODULE ASSEMBLING....................................................................................................................................36

2. MODULE FUNCTION.........................................................................................................................................36

3. FIGURE..............................................................................................................................................................36

4. TECHNICAL DATA.............................................................................................................................................37

III. INDU WRC AI-01/6 MODULE ...........................................................................................................................38

1. MODULE ASSEMBLING....................................................................................................................................38

2. MODULE FUNCTION.........................................................................................................................................38

3. FIGURE..............................................................................................................................................................38

4. TECHNICAL DATA.............................................................................................................................................39

IV. INDU WRC DI-01MODULE..............................................................................................................................40

1. MODULE ASSEMBLING....................................................................................................................................40

2. MODULE FUNCTIONS......................................................................................................................................40

3. FIGURE..............................................................................................................................................................40

4. TECHNICAL DATA.............................................................................................................................................41

- 2-

29.05.2008

Page 3

INDU WRC-2010H Controller – User’s Manual ver. 1.07

V. INDU WRC RO-01 MODULE............................................................................................................................42

1. MODULE ASSEMBLING....................................................................................................................................42

2. MODULE FUNCTIONS......................................................................................................................................42

3.FIGURE...............................................................................................................................................................42

4. TECHNICAL DATA.............................................................................................................................................43

5. C

ARDS ADDRESSING IN THE SYSTEM

:.....................................................................................................................43

VI. INDU WRC TO-01 MODULE............................................................................................................................44

1. MODULE ASSEMBLING....................................................................................................................................44

2. MODULE FUNCTION.........................................................................................................................................44

3. FIGURE..............................................................................................................................................................44

4. TECHNICAL DATA.............................................................................................................................................45

5. C

ARDS ADDRESSING IN THE SYSTEM

:.....................................................................................................................45

VII. INDU WRC COM-01 MODULE........................................................................................................................46

1. MODULE ASSEMBLING....................................................................................................................................46

2. MODULE FUNCTION.........................................................................................................................................46

3. FIGURE..............................................................................................................................................................46

4. TECHNICAL DATA.............................................................................................................................................47

VIII. INDU WRC PS-01 MODULE...........................................................................................................................48

1. MODULE ASSEMBLING....................................................................................................................................48

2. MODULE FUNCTION.........................................................................................................................................48

3.FIGURE...............................................................................................................................................................48

4. TECHNICAL DATA.............................................................................................................................................49

- 3-

29.05.2008

Page 4

INDU WRC-2010H Controller – User’s Manual ver. 1.07

1. STRUCTURE, APPLICATIONS, POTENTIAL

The INDU WRC-2010H Controller is a unit designed to control those industrial processes, in which temperature is

the most important element, such as: smoke-chambers, brewing boilers, defrosting chambers, etc. Smokechamber control is the main purpose, for which this controller has been built, and this is reflected in the type of data

being shown, controller operation procedure, etc. The controller consists of modules - users may fit their number

and type to their own needs. The main module is the “Control Panel”, indispensable in any controller, which allows

to:

- configure the whole controller

- set parameters controlling the process

- observe current measurements

Other modules, which may be added to the controller (in brackets: maximum number of modules of a given type):

- analog input module (2 modules – 12 input lines) – temperature measurements using the PT100

- digital input module (1 module – 11 input lines) – inputs signaling alarm, or additional external control signals

- relay output modules (6 modules – 32 output lines [1 module has 6 lines]) - relays to control executive

equipment

- communication module (1 module) – allows to communicate with the PC computer, and stores recordings of

process course parameters

- power supply module (1 module) – the controller power supply – indispensable

Modules may be put together in any configuration.

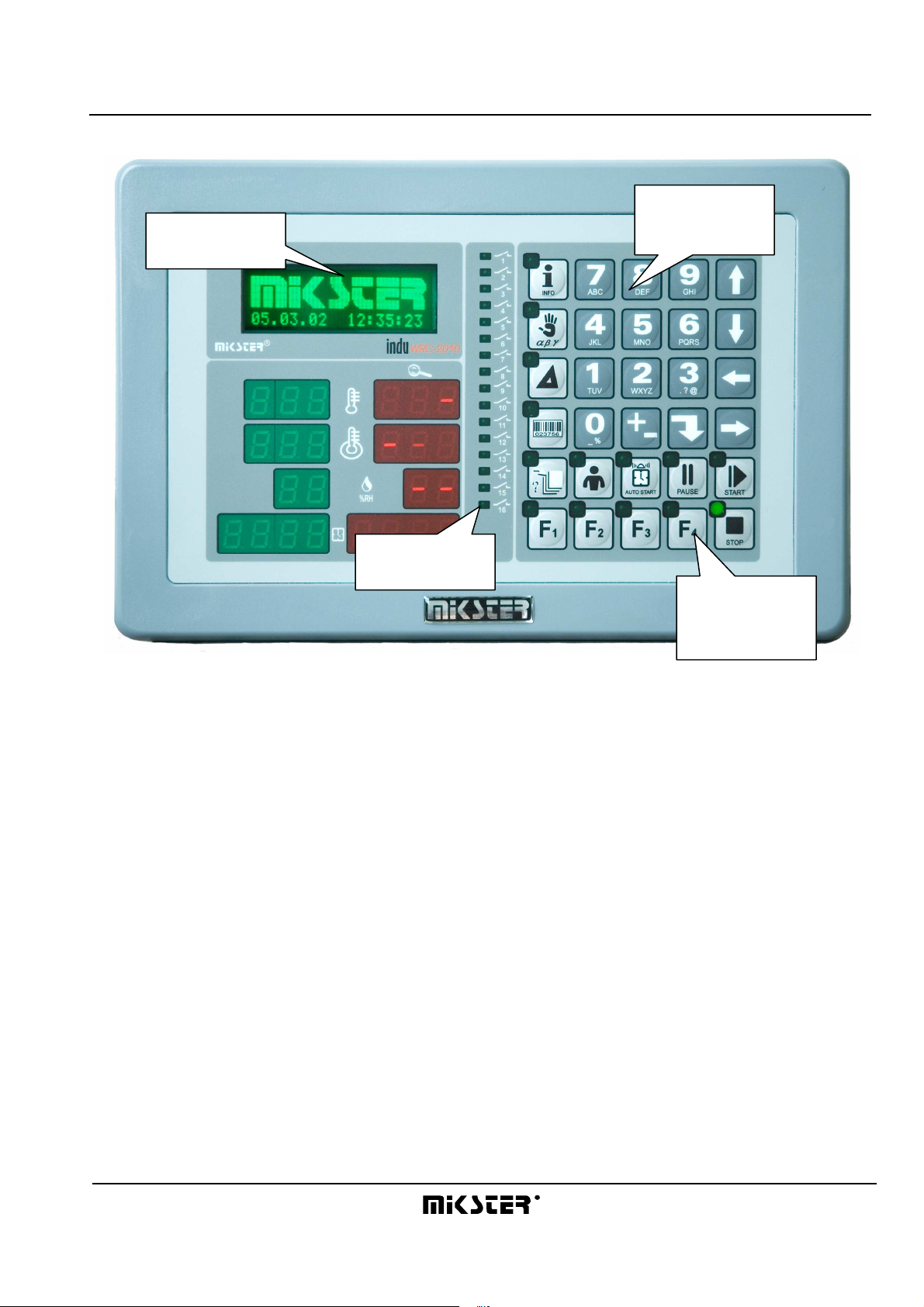

2. “INDU WRC-2010H” - CONTROL PANEL

All operations related to the controller activation, programming, etc., are executed through the control panel.

Keys on the control panel are arranged in the following keypads:

- numeric display keypad (1) – displays process preset parameters [green], and current measurements [red]

- graphic display (2) - displays all information related to the panel configuration and operation

- NUMERIC keys with FUNCTION keys (3) – allow to operate the controller

- diodes signaling OUTPUT EQUIPMENT STATUS (4) – show status of output relays

Process control is divided into stages referred to as process cycles, each process may consist of 30 cycles, and

each cycle is characterized by:

- currently executed process step

- preset chamber temperature

- preset bar temperature

- preset humidity

- preset cycle duration time

Process step is the information stored in the controller stating which outputs are to be active, and what is the

condition for particular cycle termination. 16 process steps may be stored in the INDU WRC-2010H memory.

Information regarding status of working controller, as process number and name, or process step number and

name, is shown on graphic display.

- 4-

29.05.2008

Page 5

INDU WRC-2010H Controller – User’s Manual ver. 1.07

1. Numeric

2. Graphic

display keypad

display

4. Signaling

diodes

3. Numeric keys

with function

keys

Fig. 1

The INDU WRC-2010H Controller “control panel”

- 5-

29.05.2008

Page 6

INDU WRC-2010H Controller – User’s Manual ver. 1.07

3. “INDU WRC-2010H” - START OF OPERATION

As soon as power is turned on, all numeric displays and diodes will light, and graphic display will show “WRC 2000

Init”. After some time displays and diodes will be switched off, which proves correct work of the system. The

controller will switch to stand-by mode. Graphic display will show request to enter operator’s number, and then

password. Before operators are entered, it is enough to press “Enter” key twice.

4. PROCESS PROGRAMS

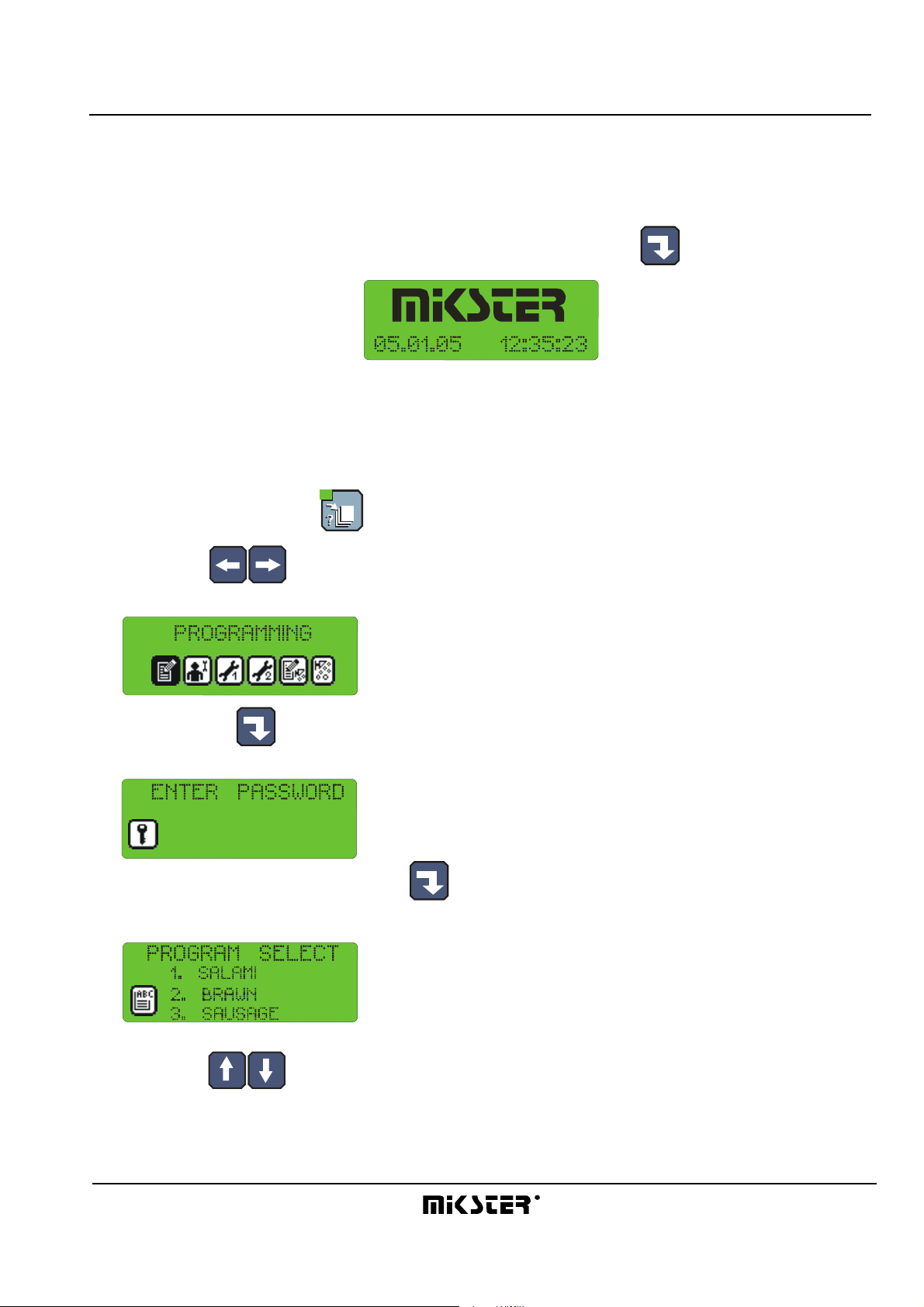

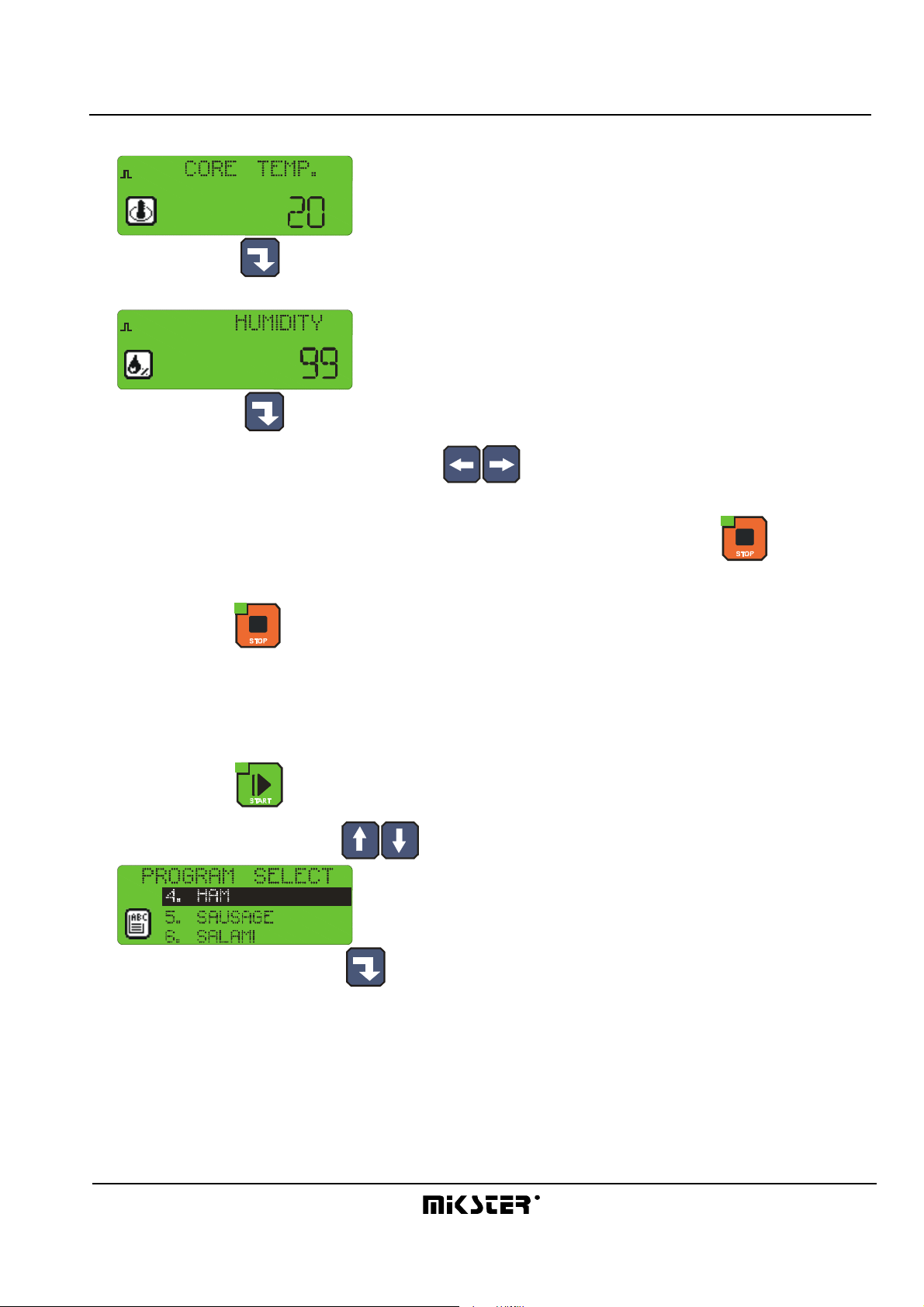

4.1. Manufacturing process programming

Do the following in order to create a new program or edit an already existing one:

- press the “Configuration” key

- using arrows “left” - “right”, position the cursor so as to make the figure blink and to have the word

“Programowanie” [“Programming”] displayed

press the “Enter” key

- password will be requested

******

enter the code “003011” and press “Enter”

- program selection list will be displayed

- using arrows “up” - “down”, select the program you wish to enter or modify

- 6-

29.05.2008

Page 7

INDU WRC-2010H Controller – User’s Manual ver. 1.07

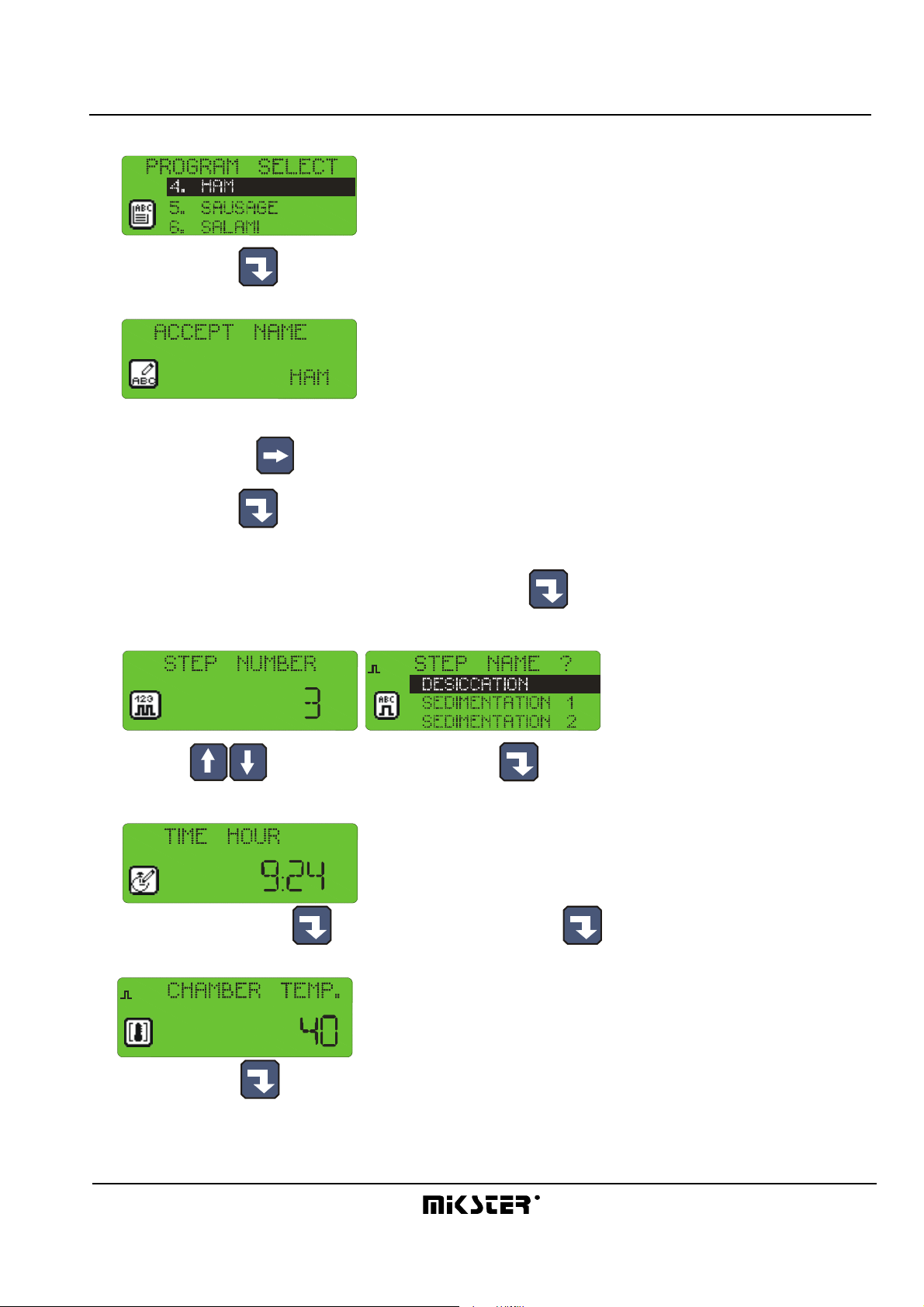

- selected program blinks

- press “Enter” key to edit the program

- first enter program name

(enter letter in position by pressing key with selected letter as many times as required, move to next position by

pressing right arrow )

- press “Enter” key

- start process cycle editing

- enter the number of cycle you wish to edit and press “Enter”

- select step number to be executed during the cycle

1

(using arrows “up” - “down”), and press “Enter”

- enter the cycle duration,

first hours, press “Enter” , then minutes, and press “Enter” again

- enter preset chamber temperature

1

and press “Enter”

- 7-

29.05.2008

Page 8

INDU WRC-2010H Controller – User’s Manual ver. 1.07

- enter preset bar temperature

1

and press “Enter”

- enter preset humidity

1

and press “Enter”

- shift between data you are entering with arrows

- this ends editing of a single process; if you wish to edit another cycle, enter its number and then proceed as

before, whereas if all cycles in a given program have been edited, then press “Stop” key

- thus you have completed program editing, now you can select another program for editing, or:

- press “Stop” key and thus end manufacturing process programming

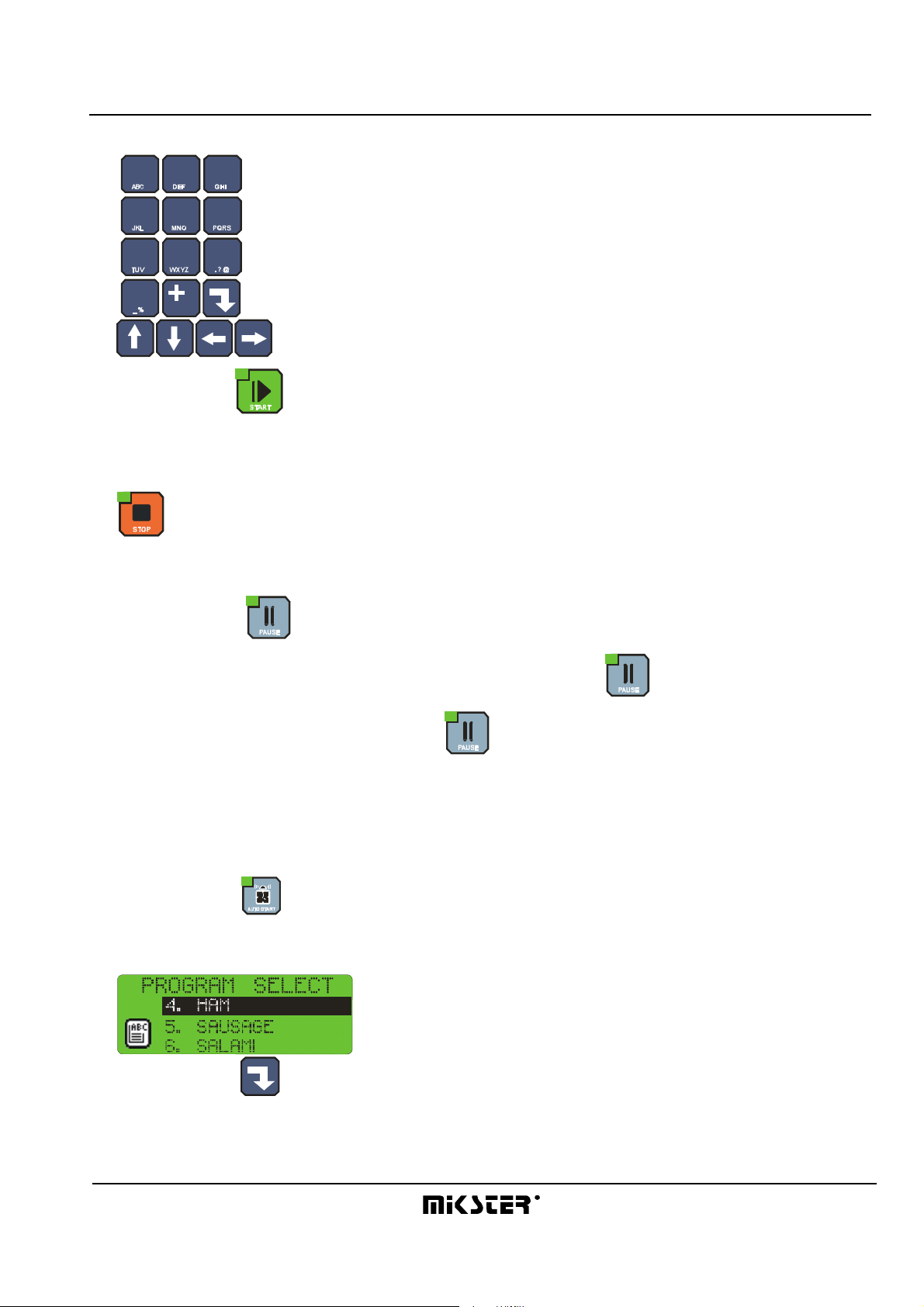

4.2. Execution of program stored in memory

Do the following in order to execute any program previously saved in the controller memory:

- press “Start” key

- select the process using arrows “up” - “down”

to be executed and press “Enter”

- 8-

29.05.2008

Page 9

INDU WRC-2010H Controller – User’s Manual ver. 1.07

-

- enter product identification data by using numeric keys and arrows

7

8

9

4

5

6

1

2

3

0

- press “Start” key again

4.3. Program execution interruption

We are able to interrupt program execution any time without possibility to resume it; in order to do that press “Stop”

key .

It is also possible to interrupt currently executed program, and then return to its execution; follow the procedure

below to do that:

- press ”Pause” key

- the controller will interrupt program execution and diode at ”Pause” key will go on

- the program will be resumed when ”Pause” key is pressed again, or when pause time passes (value set

during controller configuration, which is described later in this Manual).

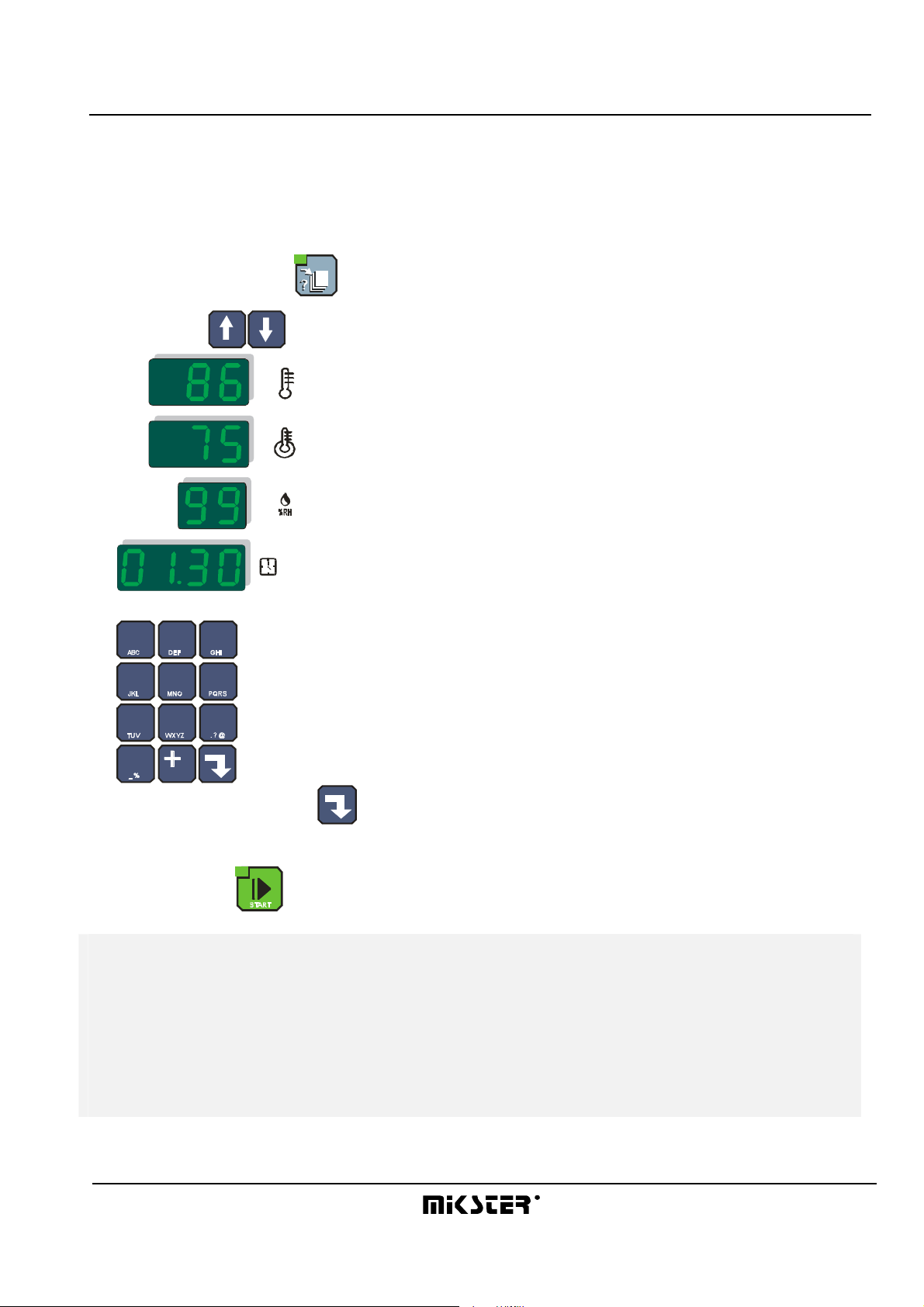

4.4. Automatic process activation

The INDU WRC-2010H Controller allows to activate a program at any previously set hour. Follow the procedure

below to allow for automatic activation of the controller:

- press “Clock” key

- select program, which is to be activated

and press “Enter”

- enter process start hour

- 9-

29.05.2008

Page 10

INDU WRC-2010H Controller – User’s Manual ver. 1.07

- enter process start date (current date is prompted by default)

- press “Start”

- graphic display will show program name, date and program activation time, as well as current date and time,

the lamp at “Clock” key will go on

At specified hour the controller will automatically start execution of appropriate program from the first step. While

the controller waits for process start, it is impossible to introduce any modification of settings.

You may cancel automatic process start by pressing “Stop” key .

- 10-

29.05.2008

Page 11

INDU WRC-2010H Controller – User’s Manual ver. 1.07

-

4.5. Editing of parameters set during controller operation

It is possible to correct previously set parameters while the controller executes a program. Follow the procedure

below (during program execution) to do that:

- press “Configuration” key

- using arrows “up” - “down”, select parameter that you wish to change (selected parameter blinks)

- enter the new value using numeric keys

7

8

9

4

5

6

1

2

3

0

and confirm with “Enter” key

- if it is necessary, modify next parameters

- press “Start” key after having introduced all changes

ATTENTION !!!

Alterations introduced during controller operation are valid only until the end of manufacturing

process. After closing the program, the controller “remembers” program with data set during the

programming process. During the program data edition the time count as well as the control of

condition of the cycle end – are stopped. The controller automatically returns to the normal mode of

operation if no key was pressed for one minute.

- 11-

29.05.2008

Page 12

INDU WRC-2010H Controller – User’s Manual ver. 1.07

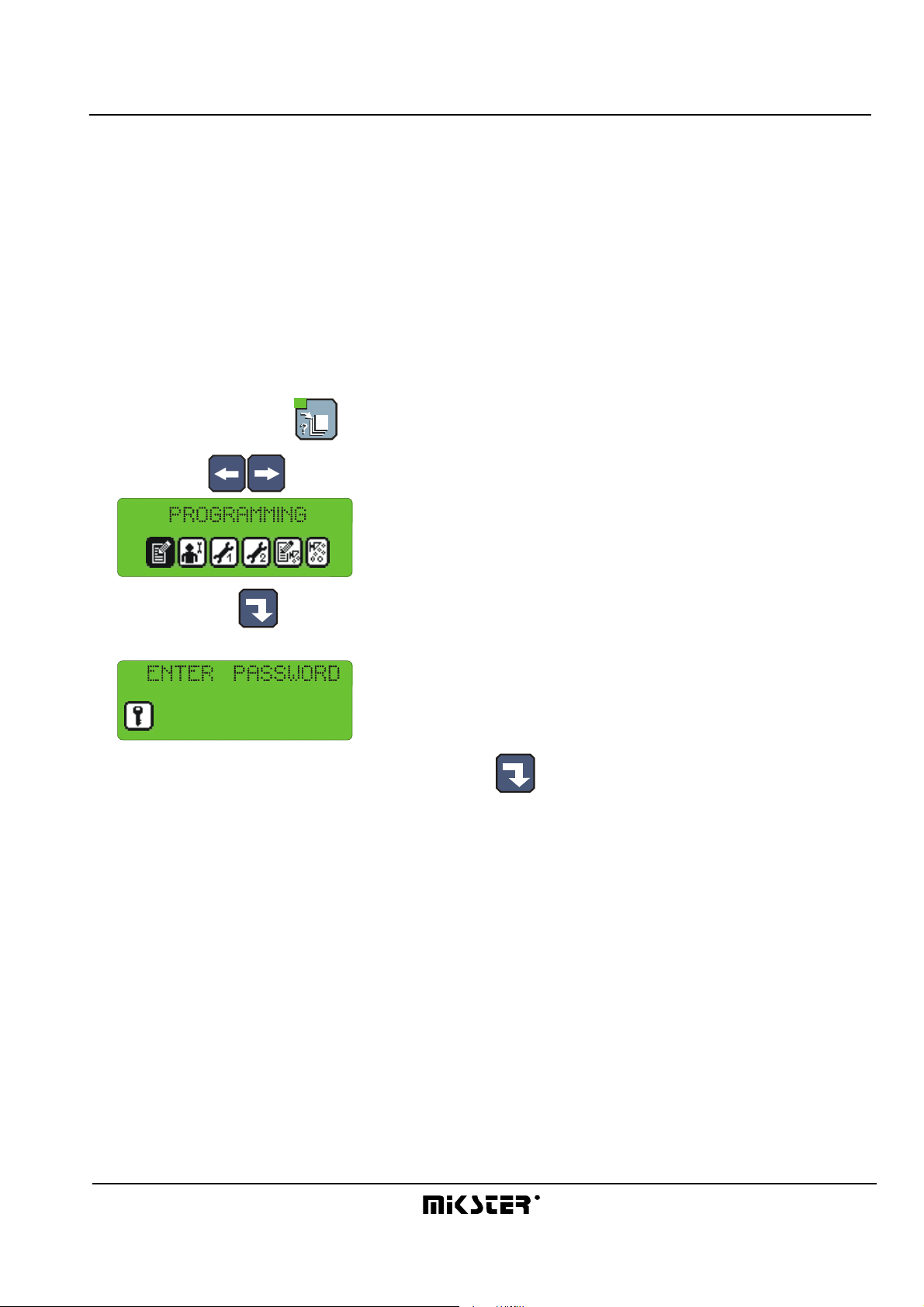

5. CONTROLLER CONFIGURATION

The controller possesses very highly developed configuration functions, which allow to adjust its parameters and

way of working to user’s individual needs. Suitable settings entered through the configuration menu are stored in

the controller memory and used during its work.

Controller configuration has been divided into the following functions:

- user’s functions

- service functions 1

- service functions 2

- access control

Follow the procedure below to start editing selected functions:

- press “Configuration” key

- using arrows “left” - “right”, select functions you wish to edit

- press “Enter” key

- you will see on screen request to enter password for access to selected functions

******

- enter right code and press “Enter”

- 12-

29.05.2008

Page 13

INDU WRC-2010H Controller – User’s Manual ver. 1.07

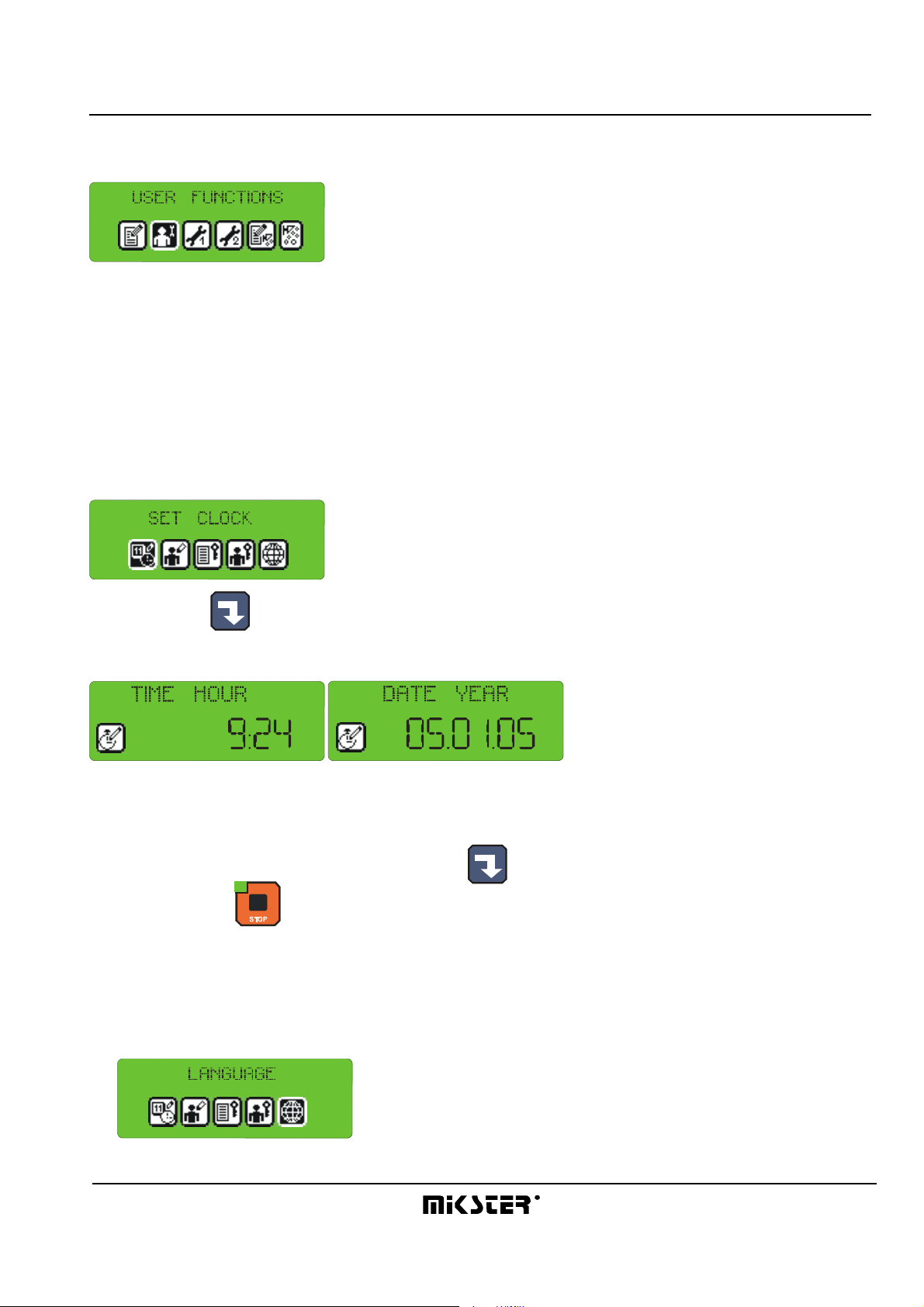

5.1. User’s functions

These functions allow to set the following:

- time and date

- menu language

- so far other functions are inactive

5.1.1. Time and date setting

Follow the procedure below to set time and date:

- select function “Set clock”

- press “Enter”

enter time and then date using numeric keys

- as soon as you enter each item, press “Enter”

- press “Stop” key after entering all items

5.1.2. Setting menu language

Follow the procedure below to set language:

- select function “Language”

- 13-

29.05.2008

Page 14

INDU WRC-2010H Controller – User’s Manual ver. 1.07

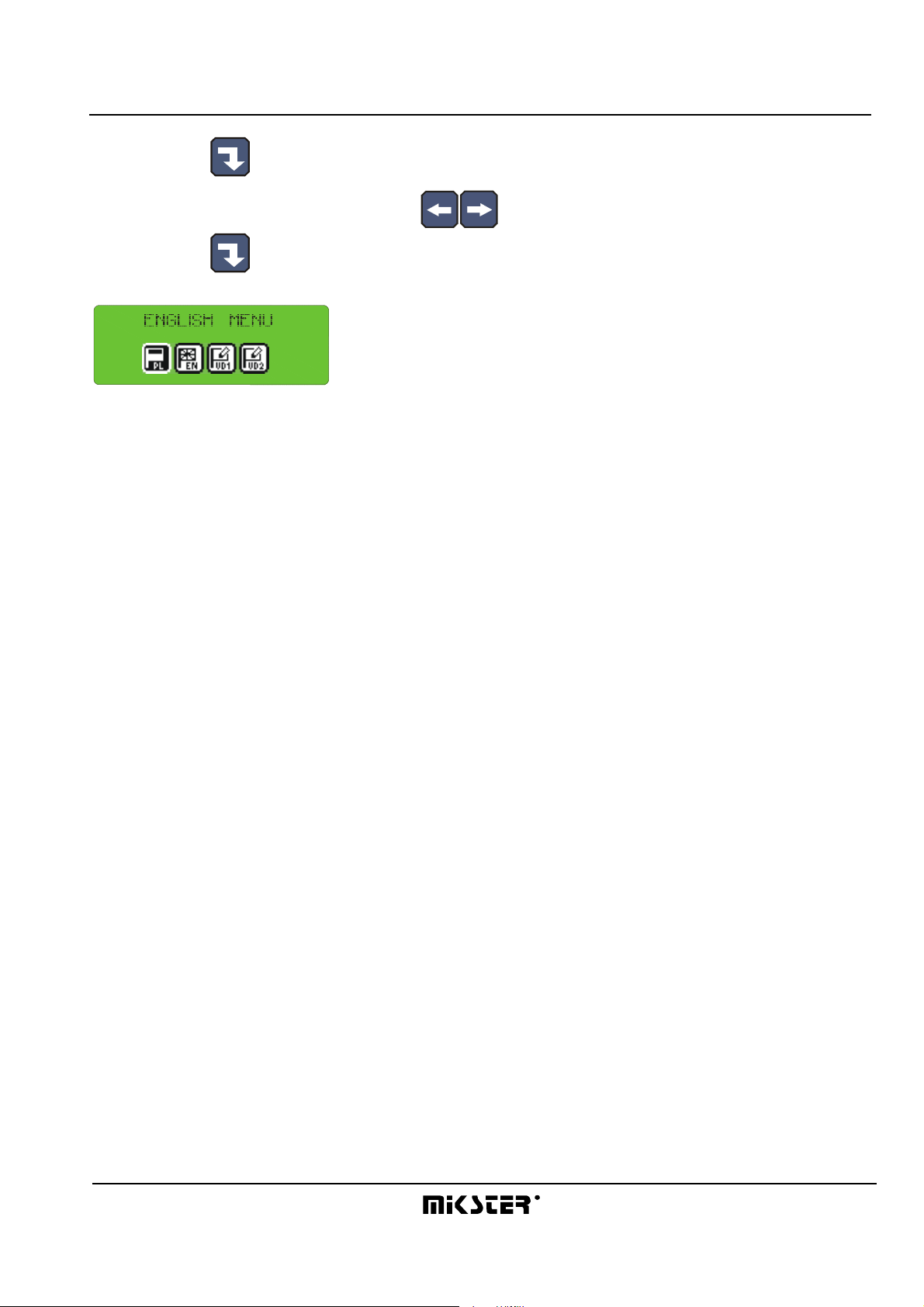

- press “Enter”

- select one of 4 languages using arrow keys “left” - “right”

press “Enter”

4 languages are available:

- Polish

- English

- two languages defined by user and transferred to the controller via PC computer – instruction how to do this is

enclosed to the program for PC.

- 14-

29.05.2008

Page 15

INDU WRC-2010H Controller – User’s Manual ver. 1.07

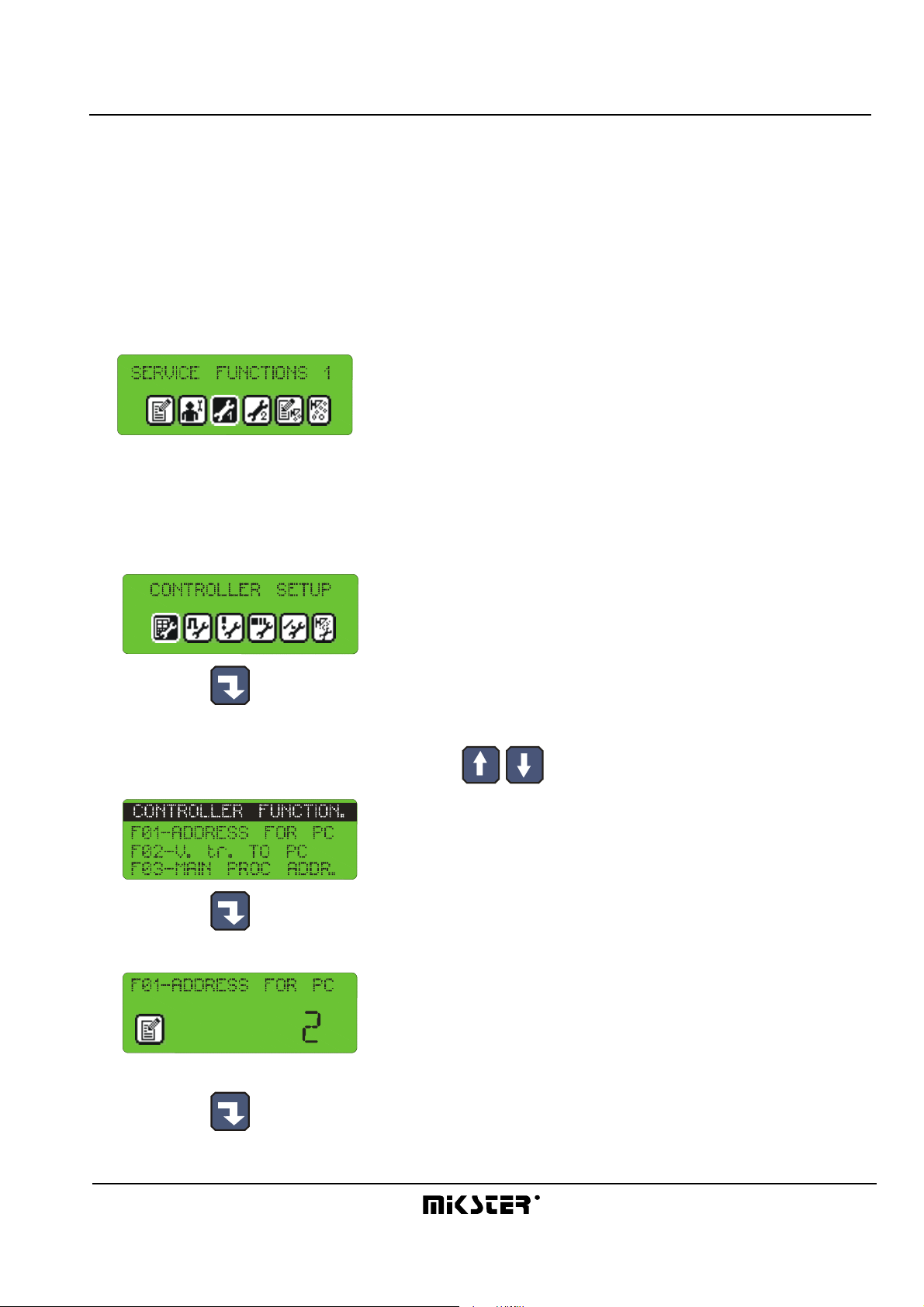

5.2. Service functions 1

In these functions it is possible to set the following:

- controller parameters

- step parameters

- alarms

- STOP and PAUSE mode parameters, and parameters of key functions F1..F4

- I/O output parameters

- washing parameters

5.2.1. Controller parameter setting

Follow the procedure below to set controller parameters:

- select function “Controller parameters”

- press “Enter”

Now begin editing controller parameters (parameters are stored in cells numbered from F01):

- select cell, which you wish to set using arrow keys “up” - “down”

- press “Enter”

- enter proper value for a given cell

- press “Enter”

- 15-

29.05.2008

Page 16

INDU WRC-2010H Controller – User’s Manual ver. 1.07

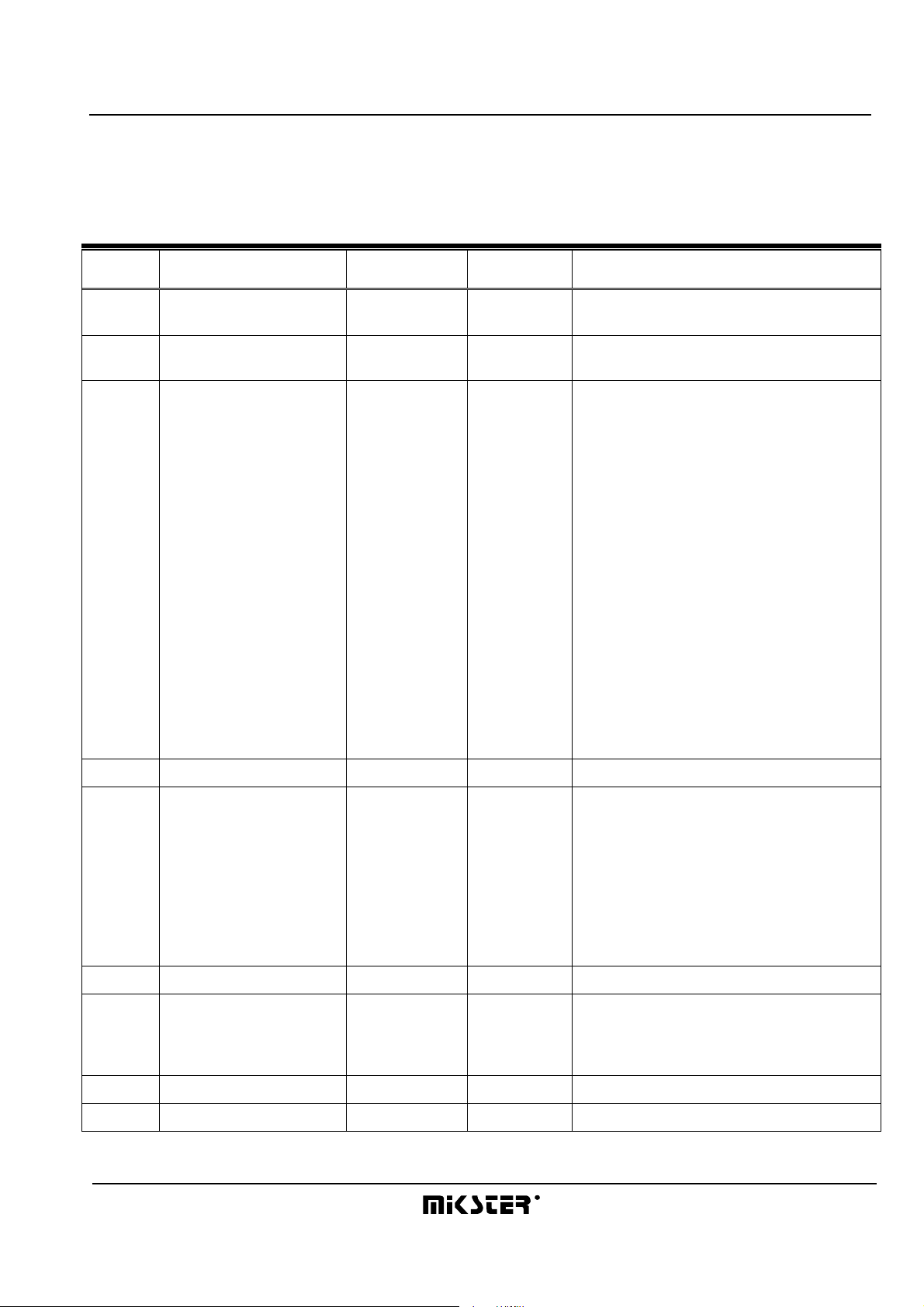

Repeat the procedure shown before until required values are set in each cell. The table below shows the meaning

of individual cells:

CELL

NO.

F 01

CELL NAME FACTORY-SET

RANGE DESCRIPTION

VALUE

ADDRESS FOR PC 1 1..32 Number in the RS - 485 network, by which

the PC computer recognizes the controller

F 02

F 03

F 04

V.tr. TO PC 0 0..1 Baud rate RS - 485 – connection with PC: 0

- 9600, 1 – 19200

MENU INFO 0 0..11 Menu INFO configuration

Display after button INFO press:

0 – 3 temperatures,

1 – channel 3,

2 – channelł 4,

3 – channel 5,

4 – channel 6,

5 – channel 7,

6 – channel 8,

7 – channel 9,

8 – channel 10,

9 – channel 11,

10 – channel 12,

11 – counter

END COND.TIME 1 0..99 Additional time to process end

F 05

F 06

F 07

F 08

F 09

NOT USED 0 0..2 0 - pause from button

1 - pause from program settings (work time

pause time). Cycle time stopped during

pause

2 - pause from program settings (work time

pause time). Cycle time running during

pause

NOT USED

TEMP. UNIT 0 0..1 Temperature measurement unit

0 – 0C

1 – 0F

‘PLATE’ TEMP. 380 -99..999 Smoke temperature

‘SMOKE’ TEMP. 250 -99..999 Smoke-generator plate temperature

- 16-

29.05.2008

Page 17

INDU WRC-2010H Controller – User’s Manual ver. 1.07

F 10

DELTA STATUS 0 0..2 0 - "delta" OFF, 1 - delta bar-chamber,

2 - "delta" temperature rise in time

F 11

F 12

F 13

F 14

F 15

F 16

F 17

F 18

F 19

REC. FREQ. 1 0..99 Recording frequency

TIME FOR RESTART 40 0..200

MAX. SET CHAMBER

200 -99..999 Maximum preset chamber temperature

TEMP.

MAX. SET BAR TEMP. 200 -99..999 Maximum preset bar temperature

HUMIDITY

MEASUREMENT TYPE

0 0..1 Moisture measurement type:

0 – psychrometric method

1 – with current detector 4...20 mA

TIME TO WASHING 40 0..999 Allowable number of hours between

washing processes

START FROM PC 0 0..1 Process activation from computer

0 – off

1 – on

ID ON/OFF 0 0..1 Process ID

0 – off

1 – on

OPERATOR ON/OFF 0 0..1 Operator logging in

0 – off

F 20

F 21

F 22

F 23

F 24

F 25

F 26

F 27

F 28

F 29

F 30

F 31

1 – on

KEY ”CLICK” 2 0..20 Sound level after pressing the 0 key - audio

signaling off

MAX.CHAMBER TEMP. 100 -99..999 Maximum allowable chamber temperature

MAX.BAR TEMP. 90 -99..999 Maximum allowable bar temperature

MAX.PLATE TEMP. 800 -99..999 Maximum allowable smoke temperature

MAX.SMOKE TEMP. 800 -99..999 Maximum allowable smoke-generator plate

temperature

MAX. HUMIDITY1 99 0..99 Maximum allowable moisture

TCH-OFFSET (D) 0 -200..200 Chamber temperature correction value –

dry sensor

TCH-OFFSET (W) 0 -200..200 Chamber temperature correction value –

wet sensor

TCO- OFFSET 0 -200..200 Bar temperature correction value

TPL- OFFSET 0 -200..200 Smoke temperature correction value

TSM- OFFSET 0 -200..200 Smoke-generator plate temperature

correction value

HUMIDITY OFFSET 0 0..99 Humidity correction value

- 17-

29.05.2008

Page 18

INDU WRC-2010H Controller – User’s Manual ver. 1.07

F 32

TYPE OF DIGIT.INPUT 0 0..1 Type of voltage delivered to control inputs:

0 – constant voltage

1 – variable voltage

F 33

F 34

F 35

F 36

F 37

F 38

F 39

F 40

F 41

F 42

F43

F44

STAT. REL.FOR END 0 0..1 Type of input signal for cycle termination

condition:

0 – input signal from control input

1 - input signal from relay output

REL. NO. FOR END 1 1..32 Number of control input or relay for cycle

termination condition

MIN. CHAMB. SET T

MIN CORE SET T

MIN HUMIDITY SET

MAX HUMIDITY SET

MIN ADDITION1 SET

MAX ADDITION1 SET

MIN ADDITION2 SET

MAX ADDITION2 SET

0 -99..999 Minimum temperature set for chamber

0 -99..999 Minimum core set

0 -99..999 Minimum humidity set

0 -99..999 Maximum humidity set

0

0

0

0

-199..999

-199..999

-199..999

-199..999

Minimum addition set 1

Maximum addition set 1

Minimum addition set 2

Maximum addition set 2

RELAY S.G. ON 0 1..32 Number of smoking relay – the relay for

time count in between consecutive

washings of the chamber

CH6 REG. SET. 0 -99..99 Set value for channel 6

F45

F46

F47

F48

F49

F50

F51

F52

F53

F54

F55

F56

F57

F58

F59

CH7 REG. SET. 0 -200..200 Set value for channel 7

CH8 REG. SET. 0 -200..200 Set value for channel 8

CH9 REG. SET. 0 -200..200 Set value for channel 9

CH10 REG. SET. 0 -200..200 Set value for channel 10

CH11 REG. SET. 0 -200..200 Set value for channel 11

CH12 REG. SET.

CH6 OFFSET

CH7 OFFSET

CH8 OFFSET

CH9 OFFSET

CH10 OFFSET

CH11 OFFSET

CH12 OFFSET

DISPLAY TIME TYPE

MAN. MODE

0 -200..400 CH12 REG SET

0 -200..200 Set value for channel 6

0 -200..200 Set value for channel 7

0 -200..200 Set value for channel 8

0 -200..200 Set value for channel 9

0 -200..200 Set value for channel 10

0 -200..200 Set value for channel 11

0 -200..200 Set value for channel 12

0 0..1 Display time type

0 0..1 Manual work

- 18-

29.05.2008

Page 19

INDU WRC-2010H Controller – User’s Manual ver. 1.07

F60

ADDITIONAL SET 0 0..1 Additional set1 and additional set2 during

program editing

F61

F62

F63

F64

F65

F66

F67

F68

F69

NOT USED

NOT USED

NOT USED

MAX CARD ERROR 1 0..9 Maximum card error

WEITHT TAR. 0 0..3

0-tare off

1-tare on F4 pressed

2-automatic tare on start every step

3- automatic tare on start every step or F4

pressed

COUNTER TAR. 0 0..5

0- tare off

1- tare on F4 pressed

2- automatic tare on start every step

3- automatic tare on start every step or F4

pressed

4- tare on F3 pressed

5- automatic tare on start every step or F3

pressed

VACUM IMPULSE TIME

0 Value set for INDU WRC 200

(s)

VACUM IMPULSE

0 Value set for INDU WRC 200

DELAY

COUNTER CONST. 0 0…9999 Counter constans

- regulator devider for impulses counter

F70

LOOP PROG STEPS. 0 -1..200 -1 program loop

0 i 1-program executing once

2 do 200 – program loop set

- 19-

29.05.2008

Page 20

INDU WRC-2010H Controller – User’s Manual ver. 1.07

5.2.2. Setting of step parameters

Each process controlled by INDU WRC-2010H consists of steps executed in a sequence. The controller may store

settings for 16 steps. Define the following elements for each step:

- name

- relay status

- step termination condition

Follow the procedure below in order to set these parameters:

- select function “Step parameters”

- press “Enter”

- the list of all steps will be displayed,

2

select step that you wish to edit and press “Enter”

- enter name – same as at programming, and press “Enter”

- select function “Relay status”

and press “Enter”

- symbols indicating individual relays are displayed

(the symbol informs that in a given step the relay will be on, whereas the symbol informs that the relay will

be off), do the following in order to alter relay status:

- move the arrows “left” - “right” so as to have digit indicating selected relay blink

- 20-

29.05.2008

Page 21

INDU WRC-2010H Controller – User’s Manual ver. 1.07

- then, using arrow “up” , switch on relay , or, using arrow “down” , switch off relay

- after having set statuses of all relays press “Stop” key

- select function “Step end”

and press “Enter”

- using arrows “up” - “down” select appropriate step termination condition; all available step

termination conditions are shown in the table below:

Symbol Step termination condition

TIR>TIS cycle end after reaching preset time value

TCHR>TCHS

TCR>TCS

cycle end after exceeding preset value of temperature

inside chamber

cycle end after exceeding preset value of bar

temperature

HUR>HUS cycle end after exceeding preset humidity value

TIR>TIS OR

TCHR>TCHS

cycle end after reaching preset time value, or after

exceeding preset value of temperature inside chamber

TIR>TIS OR TCR>TCS cycle end after reaching preset time value, or after

exceeding preset value of bar temperature

TIR>TIS OR HUR>HUS cycle end after reaching preset time value, or after

exceeding preset moisture value

TIR>TIS AND

TCHR>TCH

TIR>TIS AND

TCR>TCS

TIR>TIS AND

HUR>HUS

cycle end after reaching preset time value and after

exceeding preset value of temperature inside chamber

cycle end after reaching preset time value and after

exceeding preset value of bar temperature

cycle end after reaching preset time value and after

exceeding preset humidity value

TCHR<TCHS cycle end after drop of temperature inside chamber

below preset value

TCR<TCS cycle end after drop of temperature in bar below preset

value

HUR<HUS cycle end after drop of humidity below preset value

TIR>TIS OR

TCHR<TCHS

cycle end after reaching preset time value, or after drop

of temperature inside chamber below preset value

- 21-

29.05.2008

Page 22

INDU WRC-2010H Controller – User’s Manual ver. 1.07

TIR>TIS OR TCR<TCS cycle end after reaching preset time value, or after drop

of temperature in bar below preset value

TIR>TIS OR HUR<HUS cycle end after reaching preset time value, or after drop

of humidity below preset value

TIR>TIS AND

TCHR<TCH

TIR>TIS AND

TCR<TCS

TIR>TIS AND

HUR<HUS

cycle end after reaching preset time value and after drop

of temperature inside chamber below preset value

cycle end after reaching preset time value and after drop

of temperature in bar below preset value

cycle end after reaching preset time value and after drop

of humidity below preset value

INn=1 cycle end when “end release” is on

TIR>TIS AND INN=1 cycle end after reaching preset time value, and “end

release” must be on

TIR>TIS OR INN=1 cycle end after reaching preset time value, or after

switching on “end release”

INn=0

cycle end when “end release” is off

TIR>TIS AND INN=0 cycle end after reaching preset time value, and “end

release” must be off

TIR>TIS OR INN=0

cycle end after reaching preset time value, or after

switching off “end release”

- press “Enter”

- complete setting of parameters for one step by pressing “Stop” key

- select next step to edit, or press “Stop” and finish editing step parameters

5.2.3. Alarm setting

21 alarms my be activated in the controller:

- 11 from control inputs

- 5 from sensors

- 5 when measurements exceed allowable values

The following items may be defined for each alarm:

- name

- relay status

- alarm delay time – time from alarm detection to its activation

- 22-

29.05.2008

Page 23

INDU WRC-2010H Controller – User’s Manual ver. 1.07

- logics of outputs

- alarm status

Follow the procedure below to set alarm parameters:

- select function “Alarm settings”

- press “Enter”

- the list of all alarms will be displayed

select an alarm to set its parameters and press “Enter”

- enter name

analogically as when programming, and press “Enter”

- one by one, select functions:

- “Outputs when alarm”

and press “Enter”

- set relay statuses analogically as when setting parameters for steps – additionally properly set the

function “Alarm output logics”

- press “Stop”

- “Alarm delay”

- 23-

29.05.2008

Page 24

INDU WRC-2010H Controller – User’s Manual ver. 1.07

and press “Enter”

- enter time, after which the controller should react to alarm occurrence

- time is given in seconds

- press “Enter”

- “Alarm output logics”

and press “Enter” - this function specifies how to link status preset in function “Outputs when alarm” with

relays; the following options are possible:

- “Status setting” – symbol - exactly those relays will be switched on, which have been set in

function “Outputs when alarm”

- “Status adding” – symbol - those relays will be switched on, which result from regular controller

operation, and additionally relays set in function “Outputs when alarm”

- “Status removal” – symbol - those relays will be removed from working relays, which (regular

controller operation) are set in function “Outputs when alarm”

- set right symbol using arrows “left” - “right”

- press “Enter”

- “Alarm status”

and press “Enter” – this function specifies, how the controller should react if a given alarm occurs; the

following options are possible:

- 24-

29.05.2008

Page 25

INDU WRC-2010H Controller – User’s Manual ver. 1.07

- “Alarm off” – symbol - the controller will ignore particular alarm

- “Process interruption” – symbol - if the controller is in process execution phase and an alarm will

occur, the process will be interrupted

- “Process continuation” – symbol - if the controller is in process execution phase and an alarm will

occur, the controller will adequately set relays, and the process will be continued

- set right symbol using arrows “left” - “right”

- press “Enter”

- as soon as you set all functions for a given alarm, press “Stop”

- if you wish, select another alarm to set its parameters, and repeat the procedure specified before, otherwise

press “Stop”

- 25-

29.05.2008

Page 26

INDU WRC-2010H Controller – User’s Manual ver. 1.07

5.2.4. Parameter setting for pause mode, stop mode and key functions F1..F4

The controller has two special modes: stop and pause; you may set the following for each of them:

- which outputs are to be active

- how long should particular mode last

- logics of output setting in relation to relays being set by any process in progress

Moreover, the controller has 4 key functions F1..F4. These functions are activated

by pressing keys F1..F4. Should these functions be activated, they allow for additional relay control during process

execution. These functions are described by the same parameters as stop and pause modes, thus setting

procedure for these parameters is exactly the same, and so it will be described together.

Follow the procedure below to set these parameters:

- select function “Stop/Pause Setting” from menu SERVICE FUNCTIONS 1

- press “Enter”

- select function or mode, for which parameters

are to be set (arrows “left” - “right”) and press “Enter”

- one by one, select functions:

- “Outputs when ...”

and press “Enter”

- set, which relays are selected for particular function

- 26-

29.05.2008

Page 27

INDU WRC-2010H Controller – User’s Manual ver. 1.07

- press “Stop”

- “End time ...”

and press “Enter”

- enter time, after which function or mode operation will be terminated – in seconds

- press “Enter”

- “Output logics ...”

and press “Enter”

- select logics for mode – analogically as described for alarms

- press “Enter”

- press “Stop”

- if you wish to set parameters for another function, select it and repeat the procedure specified before, and if

parameters for all functions are set, press “Stop” .

5.2.5. I/O output parameter setting

Each of the 32 relays possesses individually set working parameters. Operation of each relay is described by the

following:

- name

- time type, and time values Ta, Tb

- regulator type and regulator measurement channel

- regulator set value shift in relation to the value set in program

- shift of operation level for algorithm with dynamic set value

- “lower” hysteresis

- “upper” hysteresis

- 27-

29.05.2008

Page 28

INDU WRC-2010H Controller – User’s Manual ver. 1.07

Follow the procedure below to set these parameters:

- select function “Parameters of outputs 0/1”

- press “Enter”

- the list of all relays will be displayed

select the relay to se tits parameters, and press “Enter”

- enter name

1

analogically as for programming, and press “Enter”

- the controller will go to next settings after pressing “Enter”

- set time mode first; available modes:

- always off

1

– the relay unconditionally off

- always on

1

– the relay activated according to definition for currently executed step; if during particular step the relay is on,

then it is on throughout that step

- delayed activation

- 28-

29.05.2008

Page 29

INDU WRC-2010H Controller – User’s Manual ver. 1.07

1

OFF ON

Time Ta

- delayed deactivation

nd

e

Cycle

nd

OFFON

e e

Cycl

Time Ta

- pulse generator

ON ON ONOFFOFF

Time Ta

Time Tb Time Ta Time Tb

Wyłączony

- then set times Ta and Tb – time value is given in seconds

- select regulator controlling particular relay, available regulator options:

- regulator off

- heating progress

nd

e

cle

Cy

- 29-

29.05.2008

Page 30

INDU WRC-2010H Controller – User’s Manual ver. 1.07

Window

Window

SET

ON

OFF

SET

SET

Window

H g

H d

O ffset

¼ O kno

ZA D

O kno

ZA Ł

W Y Ł

- cooling progress

- heating hysteresis

H g

H d

O ffset

ZA D

ZA Ł W Y Ł

ON

- cooling hysteresis

H g

H d

O ffset

OFF

½ O kno

ZA Ł

ON

ZA D

OFF

ZA ŁW Y Ł

ON

OFF

ZA ŁW Y Ł W Y Ł

ON

OFF

- select channel, upon which the regulator will act

- enter offset

- enter “window”

- enter lower hysteresis

- enter upper hysteresis

- select next relay for parameter setting and repeat operations listed before,

or press “Stop” if all are set.

- 30-

29.05.2008

Page 31

INDU WRC-2010H Controller – User’s Manual ver. 1.07

5.2.6. Washing parameter setting

The “Washing” program (described later in this manual) is executed on the basis of special process steps, for

which parameters are set independently of process steps used in regular programs.

Follow the procedure below in order to set parameters for individual steps used in the “Washing” program:

- select function “Washing parameters”

- press “Enter”

- proceed analogically as when programming regular process steps (described in section 5.2.2.)

5.3. Service functions 2

These functions allow to test the controller.

5.3.1. Test for digital outputs

Follow the procedure below to test digital outputs (relay outputs):

- select function “Digital output test”

- press “Enter”

The screen will display output statuses numbered from 1 to 32

– the symbol „ ” indicates output on, and symbol „ ” indicates output

off. Do the following operations to alter status of any output:

- using arrows “left” - “right”, position cursor on the number of output, which status you wish to

change

- switch on relay with arrow “up”, and switch it off with arrow “down”

As soon as testing is complete, press the “Stop” key .

- 31-

29.05.2008

Page 32

INDU WRC-2010H Controller – User’s Manual ver. 1.07

5.3.2. Key test

Follow the procedure below to test correct operation of keys:

- select function “T2”

- press “Enter”

The display of “chamber temperature set value” shows the number attributed to the key pressed last; if any other

key is pressed, displayed number will be changed.

Exit the test mode by pressing and holding down any key.

5.3.3. Diode test

Follow the procedure below to check whether all control panel diodes and displays operate correctly:

- select function “T3.”

- press “Enter”

First pressing down of any key switches on all diodes and all segments of each display. Next pressing of any key

switches off all diodes.

Exit the test mode by pressing and holding down any key.

- 32-

29.05.2008

Page 33

INDU WRC-2010H Controller – User’s Manual ver. 1.07

5.4. Washing

“Washing” is a special program hidden in the controller memory, independent of any other programs, and based on

dedicated process steps, which is activated in a special way. According to its name, it is designed for automatic

washing of units controlled by INDU WRC-2010H.

5.4.1. Washing programming

Follow the procedure below to set the “Washing” program configuration:

- select function “Wash programming”

- press “Enter”

- proceed in the same way as when programming regular process steps (described in section 4.1.); the only

difference is a possibility to select from among process steps designed specially for the “Washing” program,

and described before.

1

5.4.2. Washing activation

Follow the procedure below in order to activate the “Washing” program:

- select function “Washing start”

- press “Enter”

- enter access code and confirm with “Enter”

- press “Start” key

- 33-

29.05.2008

Page 34

INDU WRC-2010H Controller – User’s Manual ver. 1.07

6. ADDITIONAL INFORMATION

6.1. Display of additional measurements

The LED displays the temperatures of the chamber and the meat-bar as well as moisture. To see the

temperature values of: smoke, plate and the chamber moisture sensor the „Info” key should be pressed. The

graphic display will show the current readings from those sensors. The values can be checked at „Stop” as well as

during the program operation.

7. HOW TO CONNECT THE CONTROLLER TO PC COMPUTER

KRAKOWSKA

SUSZENIE

1 2

7

8

1

3

2/3

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

2

1/3

9

4

5

6

1

2

3

0

023756

-

Fig. No. 2

INDU WRC-2010H Controller connection to PC computer

- 34-

29.05.2008

Page 35

INDU WRC-2010H Controller – User’s Manual ver. 1.07

8. TECHNICAL DATA

OVERALL DIMENSIONS:

Width 182 mm

Height 324 mm

POWER SUPPLY:

12-24 V DC

CASING:

Single-element, “FRONT PANEL”-type

PROTECTION DEGREE:

from front IP 65

HUMIDITY:

0..75 % (relative humidity)

TEMPERATURE:

Ambient -20..+70 °C

Working 0..+60 °C

DISPLAY:

Seven-segment LED displays,

graphic display

KEYBOARD:

Foil-type, 42 keys

STATUS SIGNALLING:

26 LED diodes

- 35-

29.05.2008

Page 36

INDU WRC-2010H Controller – User’s Manual ver. 1.07

II INDU WRC CPU-01 MODULE

1. MODULE ASSEMBLING

Module should be assembled on a rail and then connected with other modules by a belt (module of the

power supply PS01 is necessary for the module operation).Description of outputs for RS485 is on the casing. The

upper connection RS A B is connected to the converter in the Rennon Slicer panel.Communication with the

processor is done with the rate of 19200 bits/sec, while communicatin with the cards with the rate of 9600

bits/sec.When the panel and belt (eventually a computer) are connected the device is ready for operation.

2. MODULE FUNCTION

The module is used for controlling the operation of all modules and for the communication with the panel.

Only one CPU-01 module can be connected to the system.

3. FIGURE

- 36-

29.05.2008

Page 37

INDU WRC-2010H Controller – User’s Manual ver. 1.07

4. TECHNICAL DATA

POWER SUPPLY:

CASING:

PROTECTION DEGREE:

TEMPERATURE:

DISPLAY:

KEYBOARD:

STATE SIGNALLISATION:

BISTABLE OUTPUTS:

ANALOG OUTPUTS:

ANALOG INPUTS:

DIGITAL INPUTS:

COMMUNICATION:

5 V DC, 12 V DC

Dimensions: 45x75x105 mm

for assembling on a rail TS 35

EG45 from the Phoenix Contact

Company

IP 30

Storage: -40..+80 °C

Operation: -20..+65 °C

7 segments

none

LED 7-segment display

none

none

none

none

• 1 x RS-485 optoinsulated

• 1 x RS-485

• Communication bus with other

modules

- 37-

29.05.2008

Page 38

INDU WRC-2010H Controller – User’s Manual ver. 1.07

AI-0 1/6

“PŁYTY”

III. INDU WRC AI-01/6 MODULE

1. MODULE ASSEMBLING

Module should be assembled on a rail and then connected with other modules by a belt.

PT 100

TEMP.

“SUCHY”

PT 100

TEMP.

“MOKRY”

PT 100

TEMP.

“BATON”

PT 100

TEMP.

PT 100

TEMP.

“DYM”

2. MODULE FUNCTION

Module serves for controlling by means of analogue outputs. Maximum output current ±5mA

The module is used for the temperature measurement by means of the resistance platinum sensors Pt100. Only

one AI-01/6 module can be connected to the system.

3. FIGURE

- 38-

29.05.2008

Page 39

INDU WRC-2010H Controller – User’s Manual ver. 1.07

4. TECHNICAL DATA

POWER SUPPLY:

CASING:

PROTECTION DEGREE:

TEMPERATURE:

DISPLAY:

KEYBOARD:

STATE SIGNALLISATION:

BISTABLE OUTPUTS:

ANALOG OUTPUTS:

ANALOG INPUTS:

DIGITAL INPUTS:

COMMUNICATION:

5 V DC, 12 V DC

Dimensions: 45x75x105 mm

for assembling on a rail TS 35

EG45 from the Phoenix Contact

Company

IP 30

Storage: -40..+80 °C

Operation: -20..+65 °C

none

none

LED diode - status, LED diode ± 15V

none

4 outputs ±10V, fun-out ±5mA

none

none

Communication bus to other modules

- 39-

29.05.2008

Page 40

INDU WRC-2010H Controller – User’s Manual ver. 1.07

IV. INDU WRC DI-01MODULE

1. MODULE ASSEMBLING

Module should be assembled on a rail and then connected with other modules by a belt.

2. MODULE FUNCTIONS

DI-01 module is a bistable input module, which serves for controlling input signals (e.g. failure control).

3. FIGURE

- 40-

29.05.2008

Page 41

INDU WRC-2010H Controller – User’s Manual ver. 1.07

4. TECHNICAL DATA

POWER SUPPLY:

CASING:

PROTECTION DEGREE:

TEMPERATURE:

DISPLAY:

KEYBOARD:

STATE SIGNALLISATION:

BISTABLE OUTPUTS:

ANALOG OUTPUTS:

ANALOG INPUTS:

DIGITAL INPUTS:

COMMUNICATION:

5 V DC, 12 V DC

Dimensions: 45x75x105 mm

for assembling on a rail TS 35

EG45 from the Phoenix Contact

Company

IP 30

Storage: -40..+80 °C

Operation: -20..+65 °C

none

none

LED diode for each input, LED diode -

status

none

4 outputs ±10V, fun-out ±5mA

none

11 inputs 24V (direct or alternating)

logic levels:

- 0-3 V law

- 10-24 high

Communication bus to other modules

- 41-

29.05.2008

Page 42

INDU WRC-2010H Controller – User’s Manual ver. 1.07

V. INDU WRC RO-01 MODULE

1. MODULE ASSEMBLING

Module should be assembled on a rail and then connected with other modules by a belt.

2. MODULE FUNCTIONS

Module serves for controlling by means of relay outputs. fan-out of a single output: 4A.

Maximum 6 RO-01 modules can be connected to the system.

Note: cards of the same type must have different addresses!

(Altogether 32 outputs can be connected to the system – RO-01 and TO-01 can be connected)

RO-01 = 6 outputs

TO-01 = 8 outputs

3.FIGURE

- 42-

29.05.2008

Page 43

INDU WRC-2010H Controller – User’s Manual ver. 1.07

012

3

4

4. TECHNICAL DATA

POWER SUPPLY:

CASING:

PROTECTION DEGREE:

TEMPERATURE:

DISPLAY:

KEYBOARD:

STATE SIGNALLISATION:

BISTABLE OUTPUTS:

ANALOG OUTPUTS:

ANALOG INPUTS:

DIGITAL INPUTS:

COMMUNICATION:

5 V DC, 12 V DC

Dimensions: 45x75x105 mm

for assembling on a rail TS 35

EG45 from the Phoenix Contact

Company

IP 30

Storage: -40..+80 °C

Operation: -20..+65 °C

none

none

LED diode for each output, LED diode

status

6 relay outputs

fan-out:

- 4A 230 V AC

- 4A 24 V DC

none

none

none

Communication bus to other modules

5. Cards addressing in the system:

Output no 1 for the panel is the first output of the card with the lowest address.

Note: cards of the same type must have different addresses!

Address:

5

6

7

.

8

- 43-

29.05.2008

Page 44

INDU WRC-2010H Controller – User’s Manual ver. 1.07

VI. INDU WRC TO-01 MODULE

1. MODULE ASSEMBLING

Module should be assembled on a rail and then connected with other modules by a belt.

2. MODULE FUNCTION

of all outputs < 6.3A.

Maximum 4 TO-01 modules can be connected to the system.

Note: cards of the same type must have different addresses!

(Altogether 32 outputs can be connected to the system – RO-01 and TO-01 can be connected)

Module serves for controlling by means of transistor outputs. Fun-out of a single output 0.8A, total current

RO-01 = 6 outputs

TO-01 = 8 outputs

3. FIGURE

- 44-

29.05.2008

Page 45

INDU WRC-2010H Controller – User’s Manual ver. 1.07

012

3

4

4. TECHNICAL DATA

POWER SUPPLY:

CASING:

PROTECTION DEGREE:

TEMPERATURE:

DISPLAY:

KEYBOARD:

STATE SIGNALLISATION:

BISTABLE OUTPUTS:

ANALOG OUTPUTS:

ANALOG INPUTS:

DIGITAL INPUTS:

COMMUNICATION:

5 V DC, 12 V DC

Dimensions: 45x75x105 mm

for assembling on a rail TS 35

EG45 from the Phoenix Contact

Company

IP 30

Storage: -40..+80 °C

Operation: -20..+65 °C

none

none

LED diode for each output, LED diode

status

8 transistor outputs

fun-out:

- 0.8A

total current for all outputs < 6.3A

none

none

none

Communication bus to other modules

5. Cards addressing in the system:

Output no 1 for the panel is the first output of the card with the lowest address.

Note: cards of the same type must have different addresses!

Address:

5

6

7

.

8

- 45-

29.05.2008

Page 46

INDU WRC-2010H Controller – User’s Manual ver. 1.07

VII. INDU WRC COM-01 MODULE

1. MODULE ASSEMBLING

Module should be assembled on a rail and then connected with other modules by a belt.

2. MODULE FUNCTION

The module is used for communication between the INDU WRC set and the PC. Apart from storing the recordings

the module enables readout of the set technological process parameters and values measured by controller’s

modules.

Only one COM-01 module can be connected to the system.

3. FIGURE

- 46-

29.05.2008

Page 47

INDU WRC-2010H Controller – User’s Manual ver. 1.07

4. TECHNICAL DATA

POWER SUPPLY:

CASING:

PROTECTION DEGREE:

TEMPERATURE:

DISPLAY:

KEYBOARD:

STATE SIGNALLISATION:

BISTABLE OUTPUTS:

ANALOG OUTPUTS:

ANALOG INPUTS:

DIGITAL INPUTS:

COMMUNICATION:

5 V DC, 12 V DC

Dimensions: 45x75x105 mm

for assembling on a rail TS 35

EG45 from the Phoenix Contact

Company

IP 30

Storage: -40..+80 °C

Operation: -20..+65 °C

7 segments

none

7 segments LED diode

none

none

none

RS-485

Communication bus to other modules

- 47-

29.05.2008

Page 48

INDU WRC-2010H Controller – User’s Manual ver. 1.07

VIII. INDU WRC PS-01 MODULE

1. MODULE ASSEMBLING

Module should be assembled on a rail and then connected with other modules by a belt.

2. MODULE FUNCTION

The module is used for supplying the INDU WRC controller. It is supplied by 24V AC.

Only one PS-01 module can be connected to the system.

3.FIGURE

- 48-

29.05.2008

Page 49

INDU WRC-2010H Controller – User’s Manual ver. 1.07

4. TECHNICAL DATA

POWER SUPPLY:

CASING:

PROTECTION DEGREE:

TEMPERATURE:

DISPLAY:

KEYBOARD:

STATE SIGNALLISATION:

BISTABLE OUTPUTS:

ANALOG OUTPUTS:

ANALOG INPUTS:

DIGITAL INPUTS:

COMMUNICATION:

24V AC

Dimensions: 45x75x105 mm

for assembling on a rail TS 35

EG45 from the Phoenix Contact

Company

IP 30

Storage: -40..+80 °C

Operation: -20..+65 °C

none

none

LED Diode for 5V

LED Diode for 12V

none

none

none

none

Communication bus to other modules

.

- 49-

29.05.2008

Page 50

INDU WRC-2010H Controller – User’s Manual ver. 1.07

Fig. Modules connection

- 50-

29.05.2008

Page 51

INDU WRC-2010H Controller – User’s Manual ver. 1.07

- 51-

29.05.2008

Loading...

Loading...