Page 1

1

NRG 150

User’s operating manual

Made in Bulgaria

Page 2

2

In order to use the device for a maximum long time and without problems, as well as to

be able to use all of its options, please read carefully the whole instruction manual and

observe the directions in it.

Your NRG 150 is shipped with these parts:

- Upper Pole Assembly – fully assembled, including upper pole stem with

handle grip

- Middle pole assembl y with pole lock

- lower pole - made of plastic in order to not disturb the work of the coil.

- 27 cm DD search coil

- electrical set box – made of extremely strong plastic, including 8 AA alkaline

batteries or 10 rechargeable accumulators NiMH 1,2V/2800mAh.

- 220V automatic charger

- Operation user’s manual

Warranty card

If any of these items are missing, immediately inform us or our authorized

dealer where you purchased your detector.

Assembling the NRG150 is simpl e and you don’t need any special tool s .

Just mount the search coil on the lower pole assembly, connect the pole

assemblies together, adjust the pole length, wrap the excess cable around the

pole and plug the cable into the control unit. Finally adjust search coil angle to

your preference and you are ready.

NOTE: Do not allow the cable to flop loosely over the search coil. Since the

detector is sensitive enough to „see“ the tiny wires in the cable, a floppy cable

can cause false signals as the search coil senses the moving wires.

Page 3

3

CONTROLS:

NRG 150

control panel:

- “ GROUND BALANCE” – eliminates the signals of the ground mineralization.

- “ DISC” – regulates degree of elimination of iron and unwanted objects.

- “ THRESHOLD” – used for adjusting sound level and regulates depth of.

- “ ON / VOLUME” – switches on the detector and adjust sound level

- “ SAT SPEED” - (Self Adjustment Threshold) SAT Speed – adjustable rate

beep on detection of metal objects.

- Button “ Auto GEB” – turns on and off automatic ground balance.

- Button “ LIGHT” – switch on and switch off LCD backlit.

- J ack “Phones” – used for head phones (one 3,5mm on the front panel, and one

6,3mm. on the bottom side of the box)

1. Assembling of the device:

The bearing rod is assembled by inserting of the lower part into the upper

one. Choose the desired length of the whole construction and the fixing clamp

is tightened between both parts of the bearing rod. The lower part of the

bearing rod is put with the opening between the ears of the coil an d the plastic

bolt is tightened by choosing the position of the coil to be parallel to the

ground surface. The coil cable must be wind up tightly around the bearing rod

and is switched to the socket of the box with electronic. Upon switching of the

Page 4

4

cable of the coil to the socket on the box, tighten the well the metal nut of the

coupling to the terminal of the box. Upon switching off, unscrew the nut

completely and pull out the coupling without pulling or twisting the cable of

the coil. This way, you will prevent the cable and the conductors in it from

breakdown or short circuit.

The searching coil is approached to the surface of earth by paying attention to

avoid presence of metals within its range.

NOTE: Detector may not work as expected indoors due to the high degree of

metals used in modern construction. It is best to tune and practice outdoors to

ensure stable, predictable results.

2. Switch on and work with NRG 150.

1. Tur n the “ON / VOLUME” knob to “ ON” an d adju s t pref e ren c e volume of

sound. The display will momentarily show an opening screen which lists the

software version.

2. Setting t he “THRESHOLD” - While holding the detector a few feet above

ground and away from any metal object, slowly turn the “THRESHOLD” knob

until you hear a very slight audio tone through the speaker or headphones. This

is the optimum set-point for the “THRESHOLD” . If the search coil is not in

motion and not close to metal, the detector should be silent. A light “ buzz ”

adjustment is recommended to insure optimum depth and maximum

performance.

As “ THRESHOLD” i s in l ow p o si t ion, a s l o w is sens i t ivit y. Too low of a

threshold setting ma y cause ver y weak signals to not be heard. Too high of a

threshold setting may cause operating instabilit y.

3. You can work in manual or in automatic “GROUND BALANCE” modes:

- In manual ground balance mode:

Search for and select a clear piece of ground or sand that does not contain any

metallic targets. With the coil elevated at least waist high and away from any

metallic target, slowly adjust the THRESHOLD control until a very faint audio

threshold signal is heard.

Page 5

5

2 - 20cm.

Lower the search coil to within one-inch of the ground surface while listening

to the threshold audio signal. If the threshold signal is high tone, the

“GROUND BALANCE” control needs to be decreased (rotate counter

clockwise). If the threshold signal is low tone, the “ GROUND BALANCE”

control needs to be increased (rotate clockwise). Keep repeating this step until

threshold si gnal is the same within one -inch of the ground as it is in the air.

Once this is accomplished, the detector is properly ground balanced .

When the ground mineralization is rejected, the detector can see deeper targets,

and is less susceptible to ground interference.

While balancing the detector, you have to be sure there are no metal objects

around the search coil. If it seems difficult or impossible to get little change in

the steady threshold as the coil is lowered, you may be attempting to tone on

top of a peace of metal. Move to a different spot on the ground and repeat

balancing. Once the initial ground balance is completed, the detector is ready to

be used.

Fig. 1

A prope r a d j ust m e nt of th e man u al gro u n d balan c e will en a b le a l ittl e m o re

dep t h over automatic ground balance. Howe v e r, an i mp r o per adjus t ment of the

manu a l g r o un d ba l a nce cou l d an d in all p rob a b ili t y de c rea s e th e d e p th

per f orman ce o f t h e me t a l d e t ect o r gr e atl y .

- In automatic ground balance mode: push the button “Auto GEB” and

you will hear a beep.

The ,,GROUND BALANCE” kn o b d o n o t have t o b e t u rne d o n a t t hat ti m e!! If

you sweep the search coil over non-ferrous metals (gold, silver, copper, bronze)

a high-toned sound can be heard; and if you sweep over ferrous metals a low

sound is heard. Without the ability to cancel ground mineralization, a metal

detector could respond to mineralization as if it where a good target.

Page 6

6

Always try to manual balance to the ground surface, and if it seem difficult or

impossible to get little change in a steady thr eshold as coil is lowered, we

rec o mmend use “ Auto GEB” r e gi m e . Use “Auto GEB” when you find yourself

in a situation that does not allow manual ,,GROUND BALANCE” to be

adjusted correctly.

The ground conditions are really bad with mineralized ground, hot rocks and

iron trash, so your sweep speed must be reduced for best results.

“Auto GEB” is recommended when searching in wet salt sand too.

NOTE: Under some severe mineral conditions ground balancing may not be

possible. The best result you will get if searching when the soil is dry.

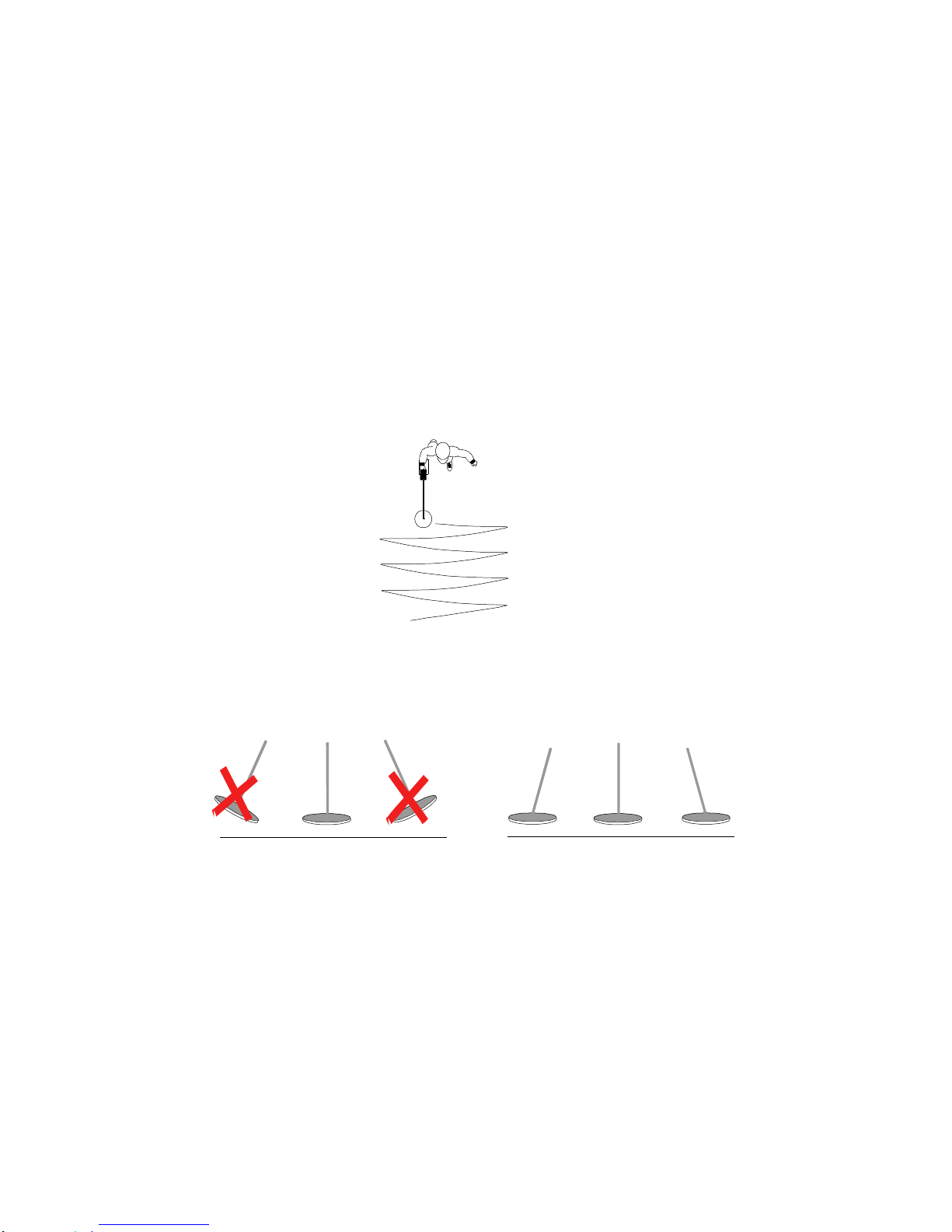

Fig.2

NRG 150 working in dynamic regime - searching metal objects is made by

moving search coil toward ground surface – fig.2 , fig.3

Wrong Correct

Fig.3

Start swinging the search coil in wide sweeps that overlap each other, as near to

the ground surface as possible-Fig.2 The search coil should not touch the

ground during your sweep. The pole length should be adjusted to allow this

without having to lift the detector wit h your elbow or shoulder. The search coil

should rest about one inch above the ground while you are standing erect. The

angle of the search coil should allow the bottom to be parallel to the ground.

Page 7

7

If you experience false signals or constant beeping or popping and you are not

near common sources of electrical interference, push " Auto GEB" to switch on

automatic balancing and/or reduce Threshold (counterclockwise) slightly and

try again.

As a search coil is swept over the ground, ignore the display and concentrate on

the sound the detector makes. As a search coil is passed over a metal that is

likely iron trash, the sound will be low tone (245Hz). Once familiar with the

sound typical iron produce, an operator may pass over such targets without

consulting the display indication, and continue searching, saving more time.

As a search coil is passed over a metal that is likely good, high tone sound will

be heard (700Hz). A good target typically produce a longer, more solid sound,

no partial signals and mixed signals: high-low tone. Once a smooth solid signal

is heard, sweep the search coil over the target several times and look at the

display indication.

When a metal target is detected, probable target type will be indicated at

the top of the LCD screen. The Upper Scale, where the VDI cursor is

illuminated when hunting, consists of eight (8) graphical segments for more

precise Target ID and discrimination.

- First segment indicates the metal is likely iron or steel, such a nails, steel

bottle cap, or iron relic. At the same time, the sound is low tone (if not switch

on IRON MASK mode). Dig if onl y iron/steel is of interest.

- Second segment indicates of small foils. However, some very small gold

jewelry can also be indicated by this segment. You may want to dig this target

in areas where small gold jewelries are suspected.

- Third segment indicates small gold coins, rings, medium jewelry, and

small ancient coins. The most desired metal - gold, usually displayed in this

segment. However, large and solid foils can be indicated by this segment too.

- Fourth segment indicates most likely old bronze coins, medium to larger

gold jewelry or gold coins. However, aluminum pull tab can also be indicated

by this segment.

Page 8

8

- Fifth segment indicates medium copper or zinc coin, or large aluminum

screw caps. Sometimes, a large gold rings or coins can be indicated by this

segment.

- Sixth and seventh segment most often indicates small silver coins, also

big bronze or copper coins.

- Eight segment almost always indicates high purity silver, big silver coins,

but sometimes, old big bronze coins and other items of bronze without impurity.

Each of the 8 segments operates independently. It can't be displayed

simultaneously two or more segments.

Often when detecting very old rusty iron objects and some iron with

impurities of nonferrous metal such as galvanized steel, or iron bottle caps,

indication on the 1-st row jumps from the first to the last segment, and vice

versa. This is always a signal that is detected magnetic object. Such items of

dubious and mixed signals more accuratel y identified as iron, if you detect with

the edge of a search coil than if you are just belo w the center of the coil.

Highly mineralized soils have a greater impact on the detector and thus the

accuracy of VDI. In high mineralization detected signals can be changed with

graphical and digi tal indication, than when tested in air or in low mineralized

or sandy soil. Usually such places VDI is shifted to the left. For example, if one

normal metal object is detected with the "sign" of the fourth or fifth segment, if

buried in such mineralized ground, indication may be the second or third

segment. So whenever in doubt of the display, check the detected object, and so

over time you will learn to some extent to recognize what has detected metal

detector!

When a metal target is detected, аlong with the VDI cursor of the first row,

you can see their common VDI numbers (0-99), on the bottom row on the

screen. “ VDI = “ .

VDI (Visual Discrimination Indication) is a digital indication which

depends on the metal targets exact alloy, size, and shape. The reference label

below the display provides a comparison of known targets and their common

VDI numbers. Different metal targets may share the same VDI numbers based

Page 9

9

on their electrical characteristics. VDI numbers from 0 to 99 are available and

cover the entire range of alloys and sizes.

Whenever detection of metal objects, initially concentrate on the sound

signal, so you can better determine the exact location of the object.

3. “DIS C ” knob is used to eliminate any target that you do not want the

detector to audibly respond to.

If you need to eliminate more ferrous metals over the ground, the “ DISC”

control mu s t be set in a pos i tion ov e r “ Rings” or “Coins” . I f you come up o n

non-ferrous metals /gold, silver, copper, bronze/ a high sound can be heard; and

if you come upon ferrous metal a low sound is heard. If the “DISC” control is

in low position - “ Iron”, every ferrous object will be signalized with high tone

(like non – ferrous). I f t h e s o i l i s t o o m i ner a l ize d we re co m mend the “ Foil” or

“Iron” position.

Some trash metals such as pieces of lead, tin, cannikin or pot metal will

produce a good sound regardless of the DISC position.

4. IRON MASK modе.

With the trigger on the hand grip in the forward position, you can switch on

IRON MASK mode. Indication that you will see the di splay - the first segment

will be blacked out with the symbol IRON MASK.

When you switch on this mode, will be disabled low tone on detection of a

magnetic metal. This mode is preferable when working in areas heavily

contaminated with iron trash.

IRON MASK symbol VDI cursor

Page 10

10

Note: If the potentiometer "DISC" is reduced to a minimum, the detector will

detect ferrous (magnetic) objects with high tones, but will not display an

indication of the type of metal, as it would be the f irst segment, and in this

mode it is indicated by a symbol for IRON MASK. Therefore it is preferable

when use mode IRON MASK, potentiometer "DISC" to be increased to at least

position FOIL or more.

When switch off mode IRON MASK, i.e. return the trigger in the middle

position, the detector will work again in t he Two Tone mode - high tone for

non-ferrous metals and low tone for ferrous metals. At the same time, will

disappear and the symbol for IRON MASK on the first line of the display.

5. Searching:

NRG-150 can work with 2 search coils - 27 cm. and 36 cm. Large 36cm. search

coils are used to detect large and bulky metal objects deeply buried to about 1.2

to 1.5 m maximum, and a small probe is used to detect and precisely locate

single coin depth of about 30-40cm. or a large metal objects at depths up to 1 to

1.20 m (depending on size). Also, smaller coils can be used in bushes, bumpy

and uncomfortable search location where it is impossible to use large coils.

The greater the size of the search coil, the greater will be the depth of

detection, but with the increase of the coil size, will be hard to detect very

small metal objects. The difference in depth of detection using large coils is

appreciable for large metal objects s uch as a large metal object is, the greater

the difference in depth of detection between large and small search coils! I.e. if

the difference in depth of detection of large and small coils for medium coin is

3-4cm., the difference in depth of detection as metal cup or pot of coins is

about 15 cm. Therefore, the use of large coils makes sense if you look bulky

items and it is important to find the best possible depth. Disadvantage of larger

sensors is their size, require a flat and clean places to look. In contaminated

areas with lots of scrap metal is advisable to use smaller probes.

To test for studying the characteristics of the device, you can make polygon

where buried various metal objects at different depths. Also you can put to the

Page 11

11

ground sizes metal objects. Move the search coil at different heights above

them and you will learn to evaluate the size and depth of the metal object

depending on th e intensit y and d uration of the sound. Af ter a while you will

learn to recognize objects that lie just below the surface or at depth. For

example, the signal from a small object located near the surface of the earth

will disappear or decrease significantly if you raise the coil, while if the object

is large, even the deep signal it will hardly change if you raise the coil. Also,

note the duration and frequency of the sound mode when plugged PinPoint

(VCO).

6. Pinpointing a Target

A good method for pinpointing is "X-ing" the target with the search coil.

Remember that the target's response sound is always greatest when the target is

directly under the center of the search coil.

To "X" a target, squeeze and hold the trigger

located on the handle and sweep the search coil over the target from side to side

and then from front to back until you can identify the center of the X — the spot

on the ground where the target response sound is the greatest. Use loudest tone,

display level indication – bars on the 1st row, to indicate targets exact center.

Pinpointing a target is proba bly best done by " X-ing" as well. Remember that

the detector will beep just as the target passes under the center of the search

coil. Slowing the sweep speed down will help you pick out the center of the X,

but remember that the search coil must always be moving slightly for target

detection.

Page 12

12

Another easy meth od is to sweep the coil from side to side across the target in

very short sweeps as you slowly move forward and backward acros s the target.

Slow down the sweep rate and shorten the sweeps until you just barely get a

response at o ne spot. The target will be directly below the coil center at this

response time – fig.4 Then turn 90 degrees and sweep the coil side to side

noting the center from this new direction. "X" marks the spot that you need to

dig. Where the two loudest beep intersect, is t he center of the target. Release

the toggle switch to the center position bef ore continue to search

You can practice with a coin on top of the ground to become acquainted

with this technique.

fig.4

7. The detection depth depends on the following:

-size, shape and location of the object in the soil. The bigger the reflecting

surface of the object the deeper it is to be found;

-soil composition and mineralization level – the drier and more homogeneous

the soil the easier it will be to adapt the device and for the device to detect

deeper. Under stones, dry sand or in clay ute nsil, metals are easier to be found

than in freshly dug out or damp soil.

-the longer the object has been in the soil the easier it will be to be found as a

result of the good contact with the soil.

-type of detecting coil. The bigger the diameter of the coil the deeper it will be

able to detect metals.

-operator's experience and skills.

Page 13

13

You can do field tests by yourself using the device if you bury different metal

objects in different depth but you should leave th em in the ground for at least

3 months. Thus the test results will be more reliable. You should mind the soil

type and the moisture composition in it. Best results are received when the soil

is dry.

Freshly-buried targets will not produce the normal depth and discrimination

results of targets that have been naturally lost and settled in the ground. It may

take a number of years for freshly-buried targets to respond at true depths and

discriminate accurately.

The best way to determine true detection depth is to use real search co nditions.

To reduce false signals when searching in a very trashy ground, scan only a

small area at a time using slow, short overlapp ing sweeps.

Keep the search coil moving at a comfortable rate. If you walk too fast, you

can ’ t ov e rlap you r s s w eeps and you will mis s a l ot o f g r o und . Al s o if you swe e p

too fast, you will lose sensitivity and miss the deep targets

8. Using a headphone

You should always use a headphone whenever you search with your metal

detector. Head phone is especially useful in nois y are a, such us the beach and

rear city area. It enhances audio perception by bringing the sound directly to

your to your e ars whi l e m aski n g “ ou t s ide” no i s e inte r f er e n ces . You sh e ll b e

amazed at how much better you can hear the detector signals with the

headphone than you can with the speaker alone. Using head phones also save

battery power.

To connect a headphone to the detector, insert the 3,5mm. headphone jack

into t h e “ Phones” on th e f ron t p ane l , or 6,3mm. headphone jack into the socket

on the bottom of the box.

NOTE: The detector internal speaker will be disconnected when you

connect a headphone.

9. Charging storage batteries and indications for their status.

Page 14

14

If a l i g ht “ Low battery” a ppe a r s w h ile usin g th e d e tec t or t hat means yo u

have to stop using it and recharge the batteries as follows: put the jack of the

charge device into “ CHARGE” n e st a n d place the device into electric net of

220V.

The charging is automatic and begins when the device is SWITCHED

OFF and you plug the charger into the charging jack of the back panel of the

device. The jack cage is “-” an d the midd l e te r min a l is “ +”.

Charg ing dep e ndin g o n th e lev e l o f d i s cha r g e o f t h e b a t ter i e s. I t’s n ot n ece s sar y

to keep eyes on charge device, because it is supplied with automatic turn off

and bat t e rie s co u ldn ’ t b e damag e d no matte r ho w l o ng the y w ill sta y i n the

charge device. The charging continues till the moment when the batteries reach

their maximum capacity When reaching their full capacity the red light on the

charger will not light any more.

When they are ready pull the device out of the electric net and unplug the jack

out of the “ CHARGE”

NOT E : D o n ’t u np l u g th e ch a r ger if c har g e pr o c ess i s n ot finished.

Always charge device's storage batteries ONLY with the paired chargers to

it. Thus yo u w i l l p r e ven t da m a ges or conf u s io n be t w een “+ ” and “ -” b e c aus e

the use of other chargers or adaptors may lead to irretrievable damages in

the batteries!

10. Possible problems during exploitation of NRG 150:

1.When switching it on you can not hear a sound, no any indication on the

LCD that the device is switched on. It might indicate for:

-storage batteries are dead (usually after a long period of time). Charge the

batteries with the charger. If the problem is not solved contact the service station (office) of the company manufacturer or the loca l distributor.

-the accumulator block consists of 10 elements 1,2V / 2800mAh connected in

series. If just one of them is damaged the connection between them will be

destroyed and practically the device will be left without power supply.

Page 15

15

2. The working depth is significantly shallower than the normal. It mi ght

indicate for:

-storage batteries could be dead – charge the batteries with the automatic

charger. If you can not solve the problem contact the service-station (office) of

the company manufacturer or the local distributor.

3. During detection the device does not work stable, makes strange sounds

which are not due to a metal detection. It might indicate for:

- irregular electromagnetic ex ternal interruptions.

- problems with the aerial cable – disconnected conductor, a shot circuit or bad

connection in the coupling.

It is possible after continuance work and many times of switching on and

off the cable's coupling to the jack box the contact between them to be

destroyed. There are 2 terminals with sight holes in the jack of the back panel

of the device. Put something sharp like a knife or a screwdriver in the sight

holes and make them wider. Thus the coupling will fit better into th e jack which

will improve the contact between them. It is possible in the presence of some

kind of dirty like dust or moisture to clean the terminals with cotton-wool and

alcohol. If you can not solve the problem contact the service-station (of fice) of

the company manufacturer or the local distributor.

4. The device works only with headset and when working with amplifier

you can not hear a sound. Usually that happens when the headset jack is

damaged. In that case contact the service-station (office) of the company

manufacturer or the local distributor to change the jack.

5. Batteries charge quickly and after that during the work ing process they

go dead quickly. Usually that happens when the batteries are really old and

need replacement. Contact the service-station (office) of the company

manufacturer or the local distributor for change of the storage batteries.

11. GUARANTEE

Page 16

16

The detector NRG 150 is offered with 36months of guarantee of electronics,

labor and materials used, for harms which are not caused on purpose or

irresponsibly.

The warranty does not cover rechargeable batteries!

We can upkeep your device after period of guarantee if it is necessary.

12. Protecting your invest ment

Often detectorists are disappointed when their new detector slowly becomes

less and less responsive and seems to have lost some of its original peak

performance. You can help avoid this from happening to your detector by

following these basic care and protection guidelines:

Operate your detector exactly as recommended in this Operator Instruction

Manual.

The search coil cable is hard-wired to the search coil and protected by a

strain relief. It is very important that the strain relief remains inta ct and should

never be adjusted or tampered with.

Keep cables properly wound around the pole stems and protect them during

use. Floppy, pinched, or cables that become snagged during use may short,

causing erratic noises or unnecessary replacement of the search coil.

Sweep the search coil carefully, especially when using around rocks and

building f oundations. Avoid hitting the search coil against hard, solid ob jects

and surfaces.

Keep your search coil slightly off of the ground during the sweep, especi ally

when using in gravel or hard, rocky dirt.

Remove and clean out scuff covers periodically to avoid buildup of

mineralized dirt particles which will affect performance.

The search coil is waterproof and can be submerged in either fresh or salt

water. After the search coil is used in salt water, rinse it and the lower stem

assembly well with fresh water to prevent corrosion of the metal parts.

Page 17

17

The search coil is waterproof but the electronics are not, so always prevent

any moisture or water from entering the control housing and never allow the

cable connector to become submerged in water.

If working in or near water, or if there is a possibility of rain, use a

protective weather resistant pouch or plastic bag to cov er the control housing.

Make sure it can "breathe" in order to ensure

against condensation buildup inside.

After each use, clean the detector with a soft cloth to remove dust, moisture,

or other contaminants.

When transporting the detector in a car during hot weather, store it on the

floor of the passenger compartment if possible. Using a carry bag gives

additional prot ection. In any case, never allow the detector to roll around

unprotected in the trunk or back of a pickup truck.

Protect your detector from dust, moisture, and extreme temperatures during

storage.

Treat your detector as you would any sensitive electronic instrument. Though

ruggedly constructed and designed to withstand the demands of normal treasure

hunting, proper care is essential.

The Manufacturer (trader) does not bear any responsibility if you use the device in violation of

the law, on archeological or forbidden for search places as well as on private property without

the knowledge or the permission of the owner.

Protect the environment and always fill back in the holes you have dugged out!

www.mikronbg.com

Loading...

Loading...