Mikrofill Maxi Single, Maxi Single (HP), Maxi Plus, Maxi Plus (HP) Technical Documentation Manual

Page 1

I N S P I R E D E F F I C I E N C Y

MAXI & MAXI PLUS

Floor mounted

Pressure manager

TECHNICAL

DOCUMENTATION

Issue 06/14

Page 2

stnetnoC stnetnoC

3Technical Data

1

1.1

1.2

1.3

1.4

2 Electrical connections 7

2.1 Electrical diagram 7

3 Keypad Function 8

4 Status Display

4.1 Pressure correct 8

4.2 Filling stopped due to low mains water pressure 8

4.3 Hours run facility 8

4.4 Hours run reset 8

5 Alarm conditions 9

5.1 Low Water Level Alarm 9

5.2 Optional System Failure/leak alert 9

5.3 High or low pressure alarms 9

5.4 Pump Failure 9

5.5 Frequent use alarm 10

5.6 Frequent use reset 10

Installation

Mains/boosted cold water supply

Connection to the system

Overflow Connection

Dimensions

4

4

5

5

6

8

6 Fault diagnosis 11

7 Manual override 12

8 Audible alarm override 12

9 Service Mode ( adjusting settings ) 12

10 Menu functions 13

11 Maintenance 13

12 Pump Curve and Data 14

2

Page 3

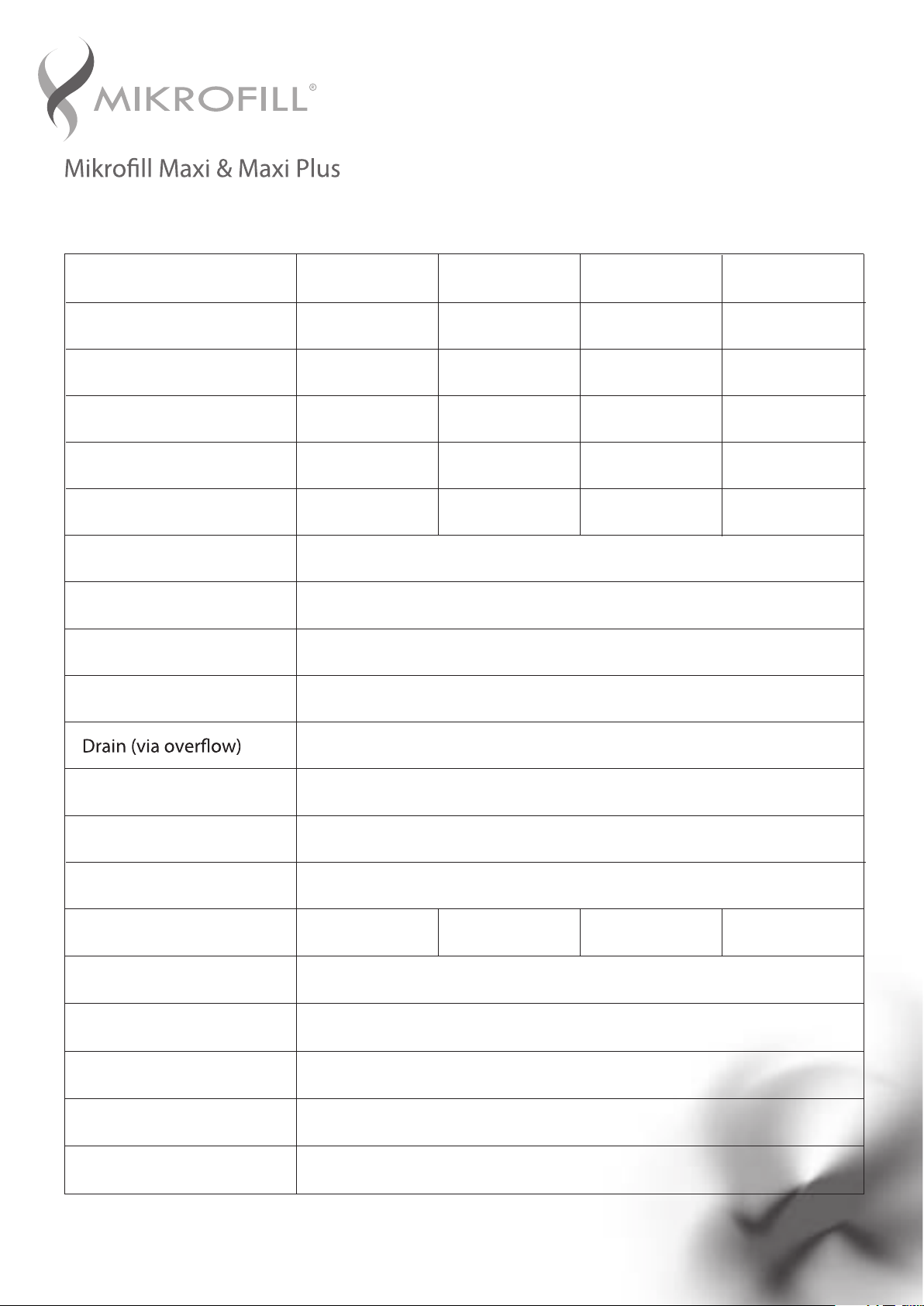

Technical Data

Electrical Details

Supply Voltage

Full Load Current

Start Current

Fuse Rating

Max Load BMS Relays

Connection Details

W ater Inlet

Water Outlet

Maxi Single Maxi Plus

230 Volt

2.5 Amp

2.5 Amp

5 Amp

5 Amp

Maxi Single (HP) Maxi Plus (HP)

230 Volt

4.5 Amp

4.5 Amp

8 Amp

5 Amp

15mm Compression

15mm Compression

230 Volt

2.5 Amp

2.5 Amp

5 Amp

5 Amp

230 Volt

4.5 Amp

4.5 Amp

8 Amp

5 Amp

3/4” BSP

Max Coldfill Pressure Maxi 3.0 Bar / Maxi HP 6.0 Bar

Dimensions

Unit Weight

Height

Width

Depth

27 Kg

35 Kg 29 Kg 38 Kg

600mm

465mm

390mm

3

Page 4

Maxi & Maxi Plus pressurisation units

The Maxi range is a fully automatic heating / chiller system pressurisation device, and is suitable for the water

management in all domestic and commercialheating and cooling systems. It is supplied as a fully commissioned unit and

should require no "on site" commissioning.

1 Installation

All productsshould be installed by a competent person with regard to the relevant requirements of the Health and

Safety Regulations, Building Regulations, IEE Regulations, Water Supply (water

(Scotland) and any other local bye-laws or planning requirements.

Regulations, Water Bye-laws

The

crystal display to be easily read.

Maxi is intended for mounting: the unit should be situated in such a position as to enable the liquid

1.1 Mains/boosted cold water supply

The Maxi is designedto be connected directly to the mains cold water supply, or a boosted cold water supply, the

unit is supplied complete with all necessary isolating valves, but an inlet water isolating valve is recommended. The water

inlet is 15mm compression and should be connected to the mains cold water supply by 15mm copper tube or equivalent

approved plastic pipework. If the

to install a single check valve adjacent to the mains cold water supply.

To reduce the pressure drop on very long supply routes then 22mm supply pipework is recommended.

Maxi is sited some distancefrom the mains cold water supply it may be advisable

4

Page 5

1.2 Connection to the system

The Mikrofill Maxi is connected to the heating/chiller system by way of the 15mm outlet valve, the pipework from the unit

should be made in 15mm copper or similarly approved plastic pipework. A suitably sized expansion vessel should be

incorporated into the system at this point. Please refer to typical installation diagram on page 3. If you require any

assistance regarding vessel sizing please contact our technical sales department. The final connection into the

heating/chiller systemshould be sized accordingly, recommendations are shown below:

Vessel sizeupto100L 1/2" (15mm) expansion pipework.

Vessel sizeupto300L 3/4" (22mm) expansion pipework

Vessel sizeupto1000L 1" (28mm) expansion pipework.

For vessel sizes in excess of 1000L capacityplease contact our technical sales department.

IMPORTANT NOTE

The expansion vessel nitrogen/air charge must be set at the same pressure as the cold fill pressure of the system.* All

Mikrofill expansion vessels are factory commissioned to the correct pressure.

* When the installed height of the expansion vessel is different to that of the MAXI then please contact our service

department who will advise on the nitrogen/air charge.

1.3 Overflow connection

The Maxi is supplied with a 3/4" bsp plastic overflow (warning pipe) connection which should be led to a drain and be

visible at point of discharge, MIKROFILL SYSTEMS LTD cannot accept any responsibility for flood damage caused by failure

toconnect the overflow.

5

Page 6

DimensionsDimensions

600

540

480

320

390 465

View on arrow 'A' Front view

Typical installation diagramTypical installation diagram

Safetyvalve

Pump

Flow Return

The expansion vessel is usually

connected on the inlet side of the

pump on the system return. For

systems exceeding 90oC contact

our technical department for

advice.

See notes on pipework sizing on

page 5.

Mains

cold

water

Overflow

Alternative

pump position

6

Page 7

2 Electrical connections

The Mikroll Maxi requires a permanent 230V 50Hz 1 phase supply rated at 6 amp. The unit is internally fused at 5 amp

(seeelectrical installation diagram).

The Maxi also incorporates two BMS relays oering volt free contacts for the remote indication of high or low pressure

conditions within the heating/chiller system. These relays are also independently fused at 5 amp to protect the Mikroll

Maxi from external electrical faults. A further volt free rel

control circuits. Should either of the alarmrelays operate then the relay will shut down the boiler or chiller, indication of

any alarm situation will be indicated onthe display. The relays aresuitable for use oncontrol voltages up to 250V.

Once the Mikroll Maxi has been correctly connected the unit is ready for use. Ensure that the unit has anadequate water

supply and the servicevalves are open. Check for wat

to vent the pump(s) before operation. This is achieved by slackening the brass plug (14mm A/F).situated on the pump

ho

using, until all air is eliminated. Switch on electrical supply to the unit and the on/o switch to the lower right hand

side of the unit and the unit will start to pressurise the system. When the system has achievedthe set pressure, the unit

will stop lling, and go tostandby.

Important note, " pump type" pressurisation units are not designed to ll systems fromempty, they are only capable of " top

up" and pressurisation. The systemshould be lled by other means in compliance with the water regulations. The Mikroll

Maxi is capable and approved to ll heating/chiller systems.

ay is included in the unit, this is to interlock the boiler or chiller

er leaks. Although every Maxi unit is factory tested it is still advisable

2.1 Electrical diagram

Electrical data

Supply: 230V 1ph 6 amp

Full loadcurrent: 2.5 amp

Start current: 4.5 amp

Fuserating: 5 am p / 8 amp

BMS relays and boiler/chiller

relays: volt free contacts rated

at 250VAC at 5 amp

All relays are independently

fused at 5 amp

Low pressurealarm High pressurealarm Boiler/chiller

common alarm

230 VAC 50Hz

7

Page 8

3 Keypad function

System Data Button

This button operates a scroll function normally for information only. When in the service mode, it allows selection

of particular setting parameters.

Button - used when in service mode to increase parameter values

Button - used when in service mode to decrease parameter values

Service Mode

A multi-function button that, when in operational mode, is used to mute alarm conditions. In normal mode the

keypad buttons are for information only and do not affect any of the parameters preset in the service mode.

( For information on service mode see section 8,page12 )

4 Status Display

4.1 Pressure Correct

The Maxi continuously monitors the system pressure, when the system pressure is within the set parameters the unit

will show Pressure Correct on the LCD display

4.2 Hours run /water usage

This is accessed by scrolling the system data button.

4.3 Hours run / water usage reset

This is achieved by depressing the buttons simultaneously.

8

Page 9

5 Alarmconditions

Please note the Maxi is a factory pre-commissioned product, should you require to change any of the preset parameters pleasesee "Settings" .

5.1 Low water level alarm

The Maxi continuously monitors the water level in the feed tank. If this falls to below an acceptable level then the unit will

operate a safety shut down. When water level is reinstated the unit will automatically reset.

Optional system failure/leak alert

5.2

The Maxi can differentiate between normal system fill rates and excessive water demand usually due to a severe

system leakage. If this situation occurs the Maxi will shut down, and issue a leak alert warning showing ‘System

Failure’ on the LCD. This alert must be reset manually, by switching off the Maxi and switching back on. If the

leak has been rectified the unit will operate as normal.

In some cases it may be required to disable or enable the leak alert facility.

To disable/enable the leak alert press and hold the service button until the display shows ‘ Service mode’

on the LCD display. Use the system data button to scroll through the settings to leak alert and enable /

disable using the or buttons

5.3 High or low pressure alarms

If, for any reason the system water pressure reaches a high or low condition, as determined by the preset parameters the

LCDwill show the alarmmessage, the relevant BMS relay will operate and the Boiler/chiller control relay will shut down the

boiler or chiller. When normal operating pressure is resumed the unit will automatically reset,

5.4 Pump failure

The Maxi can alsodetermine whether a pumphas developeda fault. This is achieved bymonitoring the system pressure and

if an increase in pressure is not sensed in a set period of time it will stop operation of that pump and the " pump failure"

message will appear on the LCD. If the Maxi Plus is used, it will automatically change to the remaining pump, and a pump

failure message will be displayed.

9

Page 10

5.5 Frequent use alarm

This alarmis to assist in diagnosing any leaks that may be present inthe heating (or cooling system). If in any 24 hr period

the Maxi operates more than a preset limit i.e. 5, then a frequent use alarmwill show, (the operation of the system will not

be affected, this function is for information only).

5.6 Frequent use reset

This is achievedby switchingthe power supply to the unit off and on again.

10

Page 11

6 Fault diagnosis

System faults will be apparent from the alarm message displayed. The Maxi itself has a full self-diagnostic

microprocessor unit which continually self-checks the operation. If an internal fault is diagnosed then the fault will

be displayed on the screen, e.g. sensor failure.

Fault conditions

Fault indications

Low water level

Sensor failure

Low pressure alarm

High pressure alarm

Cause

No water in tank

Possible sensor fault

Incoming voltage instability

Systempressure low

Systempressure high

Remedies

Reinstate water supply to tank

1. Switch unit off and back on, if sensor failure does not

reappear on the display see note 2. If sensor failure does

reappear check sensors are connected to the printed

circuit board correctly. If the problem persists ring our

service department.

2. If this occurs switch the unit off and back on, the unit

should then operate as normal. If this fault appears on

a regular basis then a mains electrical filter (anti surge

device) is required. Ring our service department for

advice.

Check system for leaks. Switch unit off and back on to

reinstate. Check Low Alarmsetting.

Reduce pressure in system and check expansion vessel

air charge/size. Check High Alarmsetting.

Systemfailure

Pump failure

Frequent use alarm

The Mikrofill Maxi and Maxi Plus have been designed such that most apparent 'faults' can be

remediedon site, if in doubt ring our service department on08452 606020

Possible excess water leak

on the system

Possible pumpfault

Possible persistent leak on

system

Check system for leaks, then switch unit off and back on

toreinstate.

Switch unit off and back on to reinstate, if pump does

not operate when required replace pump. If pump

operates, dry run setting may need to be increased.

If the unit operates more than the set value in a 24hr

period the unit will bring up the frequent use alarm, this

will not stop the unit from operating but indicates that

there may be a small leak on the system. Switch the unit

off and back on to reinstate. Investigate possible leak.

11

Page 12

7 Manual override

In the unlikely event of a sensor failure the unit may give incorrect readings and could cause alarm conditions. If this

occurs, a manual override can be employed by depressing the and the service mode buttons simultaneously

for 3 seconds; thus reinstating the BMS relays in the unit. Before operating the manual override you must ensure there

is sufficient pressure in the system. The manual override must not be employed if the unit has shown a flood

alarm condition or, if there is insufficient pressure in the system.

8 Audible alarm mute

If the Mikrofill Maxi does indicate a fault, an audible alarm will sound. This can be muted by depressing the

service mode button.

9 Service Mode ( adjusting settings )

The settings can be adjusted on site as follows:

9.1 Press and hold the service mode button for approx 8 seconds

9.2 The display will indicate that you are now in the service mode

9.3 Use the system data button to scroll through the settings, each setting can be adjusted by use of the

buttons.

9.4 After adjusting the settings, the unit will return to its normal operating mode approximately 30 seconds after

release of the buttons.

12

Page 13

10 Menu Functions

Cold fill pressure - this is the required pressure of the system when the system is cold

Alarm low - the pressure at which the low pressure alarm relay will operate. Usually set 0.6 - 0.7 bar below

the cold fill pressure.

Alarm high - the pressure at which the high pressure alarm relay will operate. Usually set 0.2 bar below the

system safety valve setting.

Usage - for information on water used in the system, no setting required - please note, to zero the usage, the

buttons need to be pressed simultaneously for 3 seconds.

minutes ) the less responsive the flood protection, set at 0.00 to disable pump failure.

O&M Maxi 1109

prevents under shoot, decreasing time prevents over shoot.

Frequent use - this setting warns of frequent use which would indicate a system leak and will show a

warning message if in any 24hr period the unit operates in excess of the frequent use setting.

caused when pumps start.

Contrast adjust - alters the contrast of the LCD display.

Fault log - Logs the last five faults

MP - Low mains water pressure

LP - Low system pressure alarm

HP - High system pressure alarm

SF - Sensor failure

DR - Leak alert due to no increase in pressure while filling

FS - Leak alert due to drop in pressure while filling

11 Maintenance

Maxi - The filter which is housed in the inlet ball valve to the pump should be checked and cleaned annually.

EXPANSION VESSELS - Charge pressure should be checked annually, when the system is cold the air charge must be

equal to the cold fill pressure of the Maxi.

13

Page 14

12 Pump Curve and Data

7

6

5

4

3

Head (bar)

2

1

0

0 5 10 15 20 25 30 35

PRODUCT DATA

Mikrofill Pump Range Performance

Maxi Pump

Maxi HP Pump

Flow (l/min)

Pump

Max

Pressure

(bar)

Max

Flow

(l/min)

Input

Power

(W)

Current

(A)

Supply

Voltage

Frequency

Size (mm)

L x W x H

Weight

(kg)

Maxi Pump 3.65 29 510 2.53 230V ± 10% 50 Hz 210 x 145 x 185 8.3

Maxi HP 6.2 31 960 4.3 230V ± 10% 50 Hz 220 x 145 x 185 9.5

14

Page 15

Page 16

Mikrofill Systems Ltd

West Court

Merse Road

Redditch

B98 9HL

T

+44 (0) 8452 606020

F

+44 (0) 8452 606021

W

mikrofill.com

E

info@mikrofill.com

Loading...

Loading...