Page 1

E &OE

Mikrofill Ethos

Condensing combination boiler

Installation & Maintenance Instructions

30/36

42/46

Page 2

E &OE

Contents

1 SAFETY PROVISIONS.........................1

2 TECHNICAL DATA ..............................2

2.1 Drawing of front view.........................................2

2.2 Technical data.....................................................3

3 INTRODUCTION..................................4

3.1 Function..............................................................4

3.2 Control................................................................4

3.3 Products of combustion.......................................5

3.4 Modulating fan....................................................5

3.5 Multi speed pump................................................5

3.6 Discription ofappliance..........................................5

3.7 Combination models..............................................5

4 INSTALLATION....................................5

4.1 Contents..............................................................5

4.2 Siting the boiler ..................................................6

4.3 Mounting the boiler................................................7

4.4 Air inlet-flue gas outlet connection......................7

4.5 Inlet and outlet air system....................................9

4.6 Influence of exhaust removal on load...................9

4.7 Flue material...........................................................9

4.8 Flue resistance table..........................................10

4.9 Removal of condensation ..................................11

4.10 CH and hot water circulation.............................11

4.10.1 General....................................................11

4.10.2 Connecting the expansion vessel ..............11

4.10.3 Domestic hot water circuit........................11

4.10.4 Multi speed pump.......................................12

4.11 Frost protection................................................. 12

4.12 Connecting the gas supply................................. 12

5 ELECTRICAL INSTALLATION

INSTRUCTIONS................................. 13

5.1 Terminal board ..................................................13

5.2 Wiring diagram................................................. 15

6 COMMISSIONING ............................. 16

6.1 Control panel ....................................................16

6.1.1 Display.........................................................16

6.1.2 Keypad Control............................................16

6.2 Sensors .............................................................17

6.3 Installer's programme...................................... 19

6.4 Filling and venting boiler and CH installation....25

6.5 Initial Operation................................................27

6.5.1 General ........................................................27

6.5.2 Starting up for the first time..........................27

6.6 Adjusting and setting load.................................27

6.6.1 Setting maximum load .............................27

6.6.2 Setting minimum load..............................27

6.7 Conversion to another type of gas...................... 28

6.8 Hot water temperature.......................................28

6.9 Closing down....................................................31

7 Faults ...................................................32

7.1 Cause of faults........................... 34

7.2 Table of solutions..................................36

8 MAINTENANCE............................. ...39

9 USERS' INSTRUCTIONS................ ...41

10 EXPLODED VIEW DRAWING.......42

11 SPARES LIST......................................45

12 GUARANTEE...........................................46

Tables

Table 1, Technical data ...........................3

Table 2, Mikrofill resistance table.........10

Table 3, Hot water ................................11

Table 4, Programme numbers................20

Table 5, CH Water Content...................20

Table 6, Hot water ...............................21

Table 7, Faults ......................................32

Table 8, Other faults .............................33

Table 9, Rotational speed......................28

Table 10, Gas settings...........................28

Table 11, Minimum setting ...................28

Table 12, Maximum setting...................30

Table 13, Possible faults .......................34

Table 14, Fault Finding.........................36

Page 3

Installation manual MIKROFILL ETHOS

Page 1

1 SAFETY PROVISIONS

Conditions:

MIKROFILL shall not be held responsible for damage arising from inadequate compliance

with the installation instructions.

For service purposes, only original MIKROFILL spare parts should be used

General conditions:

All Mikrofill boilers must be installed by a competent person with regard to the relevant

requirements of the Health and Safety regulations, The Building Regulations, IEE

Regulations, Water Supply (Water Fittings) Regulations, Water Byelaws (Scotland), The Gas

(Installation and Use) Regulations and any local planning requirements.

1. UK Building regulation Part L1 (Domestic) Part L2 (Commercial) in which reference is

made to the following norms:

Directives for existing gas installations compiled by British Gas

2. IM16 Guidance notes on the installation of gas pipework

3. BS6644 Installation of gas fired hot water boilers ratedeinputs above 60kW but not greater

that 2 mW

4. Britisg Standards Code of Practice – BS6880 – Code of practice for low temperature hot

water heating

5. CP342 – Code of Practice part 2 – Centralised hot water supply

The Mikrofill ETHOS range of boilers are built in total compliance with EN

Page 4

Installation manual MIKROFILL ETHOS

Page 2

2 TECHNICAL DATA

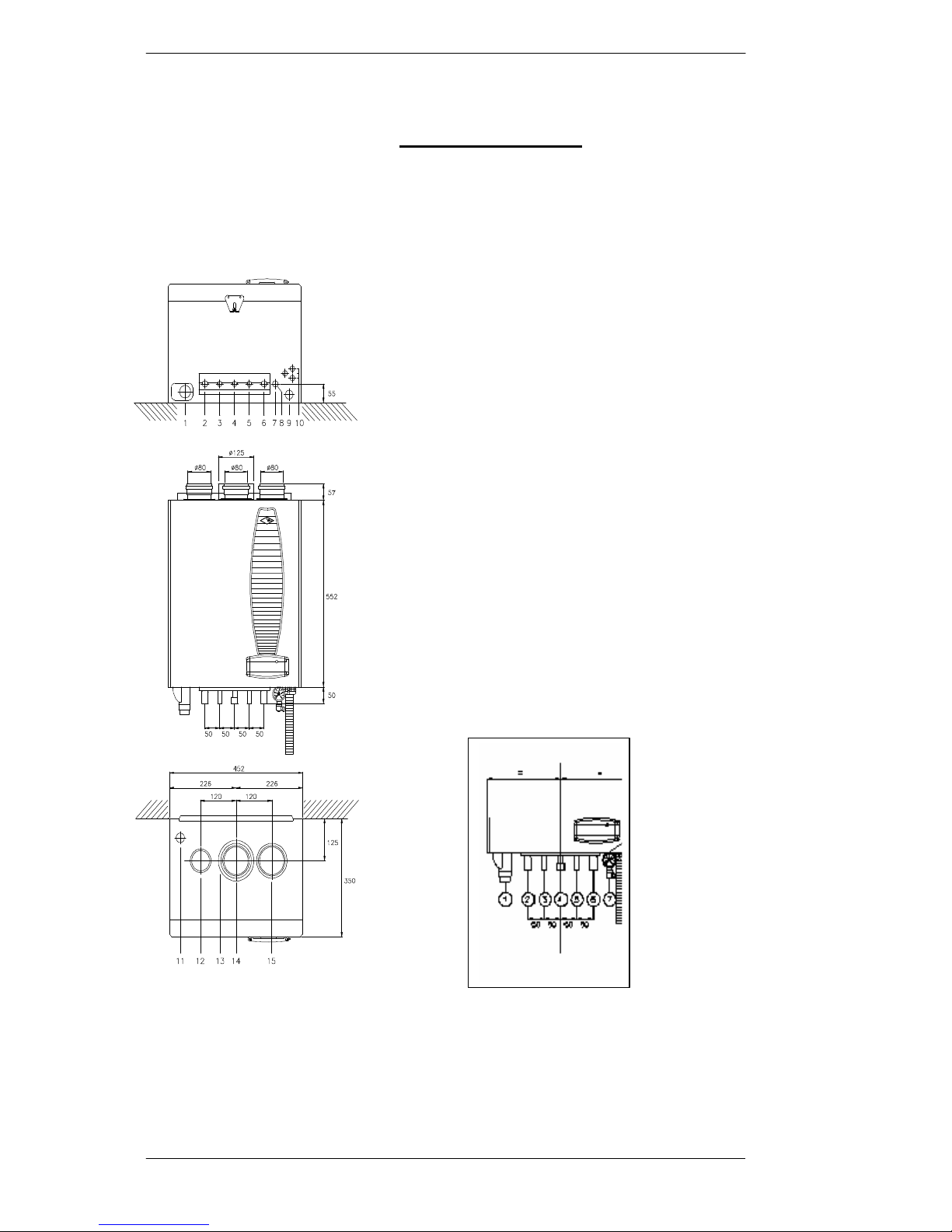

2.1 Drawing of front view

1 = Condense trap end cap

2 = CH flow (22mm)

3 = Domestic hot water (15mm)

4 = Gas

5 = Cold water inlet (15mm)

6 = CH return (22mm)

7 = Air Vent

8 = Manometer

9 = Condense drain outlet

10 = Cable entry

11 = Drain cock

12 = Air intake

13 = Air intake concentric

14 = Flue gas spigot

15 = Air inlet spigot

Page 5

Installation manual MIKROFILL ETHOS

Page 3

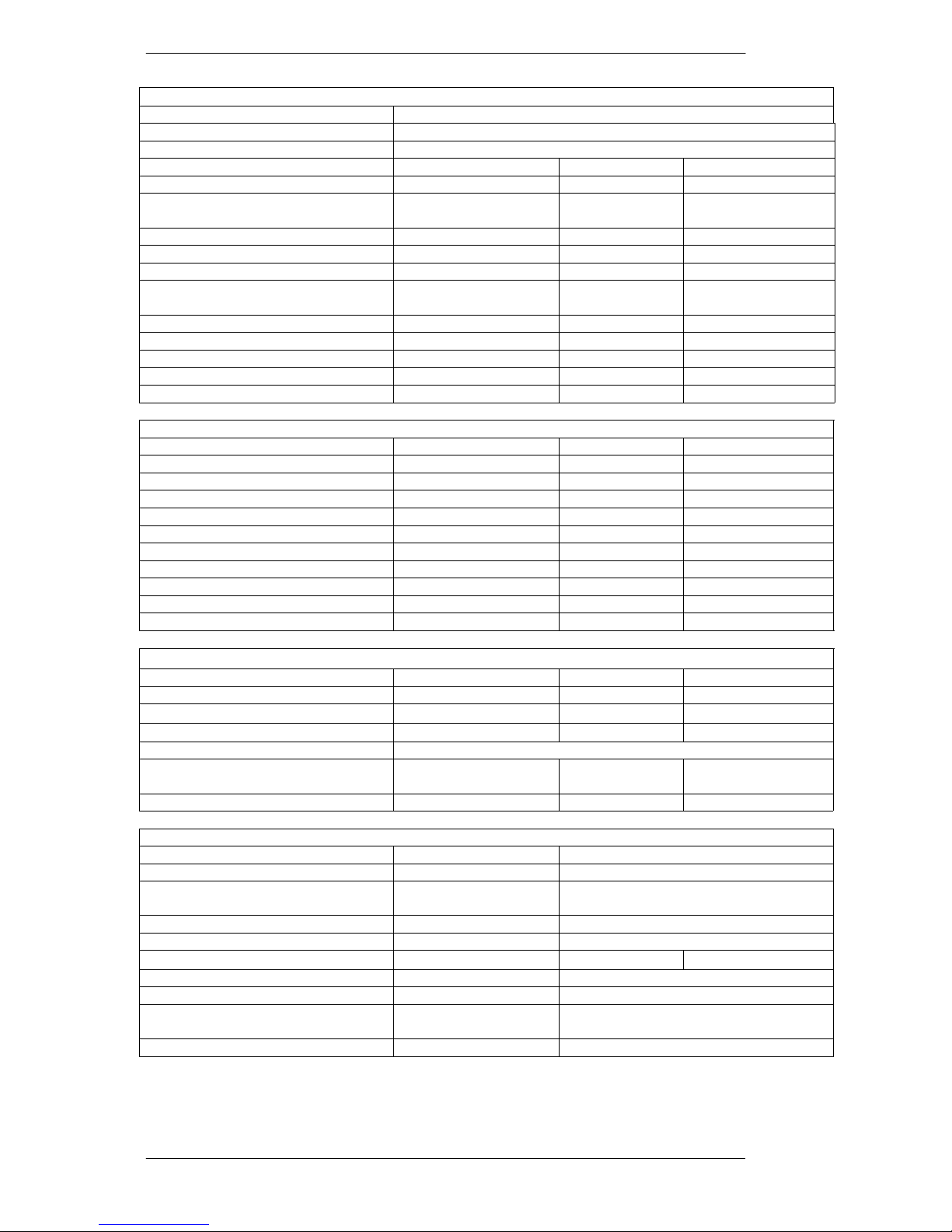

2.2 Technical data

Table 1, Technical data

General

CE Product ID number CE 0063 BL 3615- 2000

Dimensions (h x w x d) 550mm x 450mm x 350mm

Category II2L3P

Type of appliance Ethos

30/36 42/46

CH water content of appliance Litre 2,1 2,7

CH water content heat exchanger hot

water

Litre 1,5 1,5

Weight (empty) Kg 39 41

CH connections supply/return mm 22 22

Gas connection mm 15 15

Hot water, hot/cold mm 15

15

Flue gas connection mm 80 80

Air inlet mm 80 80

Concentric mm 80/125 80/125

Electrical power required kW 0.115 115

IP classification IP44 IP44

Capacity CH Operation

Nominal load (output) kW (min – max) 4.3 – 28.5 5.4 – 38.7

Nominal load (input) kW (min – max) 4.8 – 31.7 6.0 – 43

Max. gas use m³/hour 3.0 4.4

Efficiency at 50/30°C, full load % 106 106

Efficiency at 50/30°C, partial load % 109.5 109.5

Efficiency at 40/30°C, RAL 61 % 110 110

Nominal capacity at 80/60°C kW 4.1 – 27 5.3 – 38

Nominal capacity at 50/30°C kW 4.6 – 30 5.8 – 42

Gas approval HR Label 107 107

NOx emissions, RAL 61 mg/kWh <15 <15

CO emissions, RAL 61 mg/kWh <20 <20

Capacity Hot water

Nominal load (lower value) Kw 4.3 – 36 5.4 – 46

Nominal load (upper value) kW 4.8 – 40.0 6.0 – 51.0

Tap quantity at 60°C ( ?T=50K)

l/min 10 12.9

Tap quantity at 40°C ( ?T=30K)

l/min 17 21.4

WRAS Approval number 0204111

Annual use efficiency for EPC

calculation

% 83 82

Hot water (preset value) °C 60 60

Technical data

CO2 content flue gas % 9

Dew point of the flue gas °C 52

Temperature flue gas at 80/60 (with an

ambient temperature of 20 °C)

°C 75

Permitted resistance exhaust system* Pa Up to 100

PH value of the condensate 4 to 5.5

Available CH pump pressure kPa

15 at ?T20°C 28 at ?T25°C

Maximum supply temperature °C 90

Working pressure CH min/max. bar 1 / 3

Connection pressure sanitary water minmax

bar 0.2 - 10

NOx-class 6

Page 6

Installation manual MIKROFILL ETHOS

Page 4

3 INTRODUCTION

This manual is intended for the installer/user of the MIKROFILL range of

condensing boilers.This manual contains the necessary information relating to the

installation and settings of the Ethos 30/36 and 42/46.

You need to consult this manual before installation in order to ensure that you carry

out all the work correctly. In addition, it is advisable to keep this manual beside the

boiler, so it is immediately available if needed later.

3.1 Function of the appliance

High efficiency is achieved by means of a stainless steel heat exchanger, in which

the flue gases are cooled to below the condensation point, condense and release

further energy.

This is expressed in the efficiency exceeding 100%. The European method of

calculation assumes an efficiency of 100% for appliances in which provision is not

made for the condensation of flue gases and as a maximum efficiency of 110% in

condensing appliances.

In condensing boilers the flue gases are therefore at a low temperature (below

75°C), a stainless steel or thick-walled aluminium (1) HR [HE] approved flue

system or purpose designed plastic pipe needs to be used.

(1) When using an aluminium flue pipe, it is advisable to fit a condensation trap in

the flue system, to prevent pollution by aluminium corrosion.

The appliance is approved in accordance to all associated European norms (CE),

and the Netherlands requirements for Clean Air (SV), high efficiency (107% HR)

and the quality mark (Gas) as well as the quality mark for hot water (hot water class

CW) and as reheater for solar panels (NZ approval).

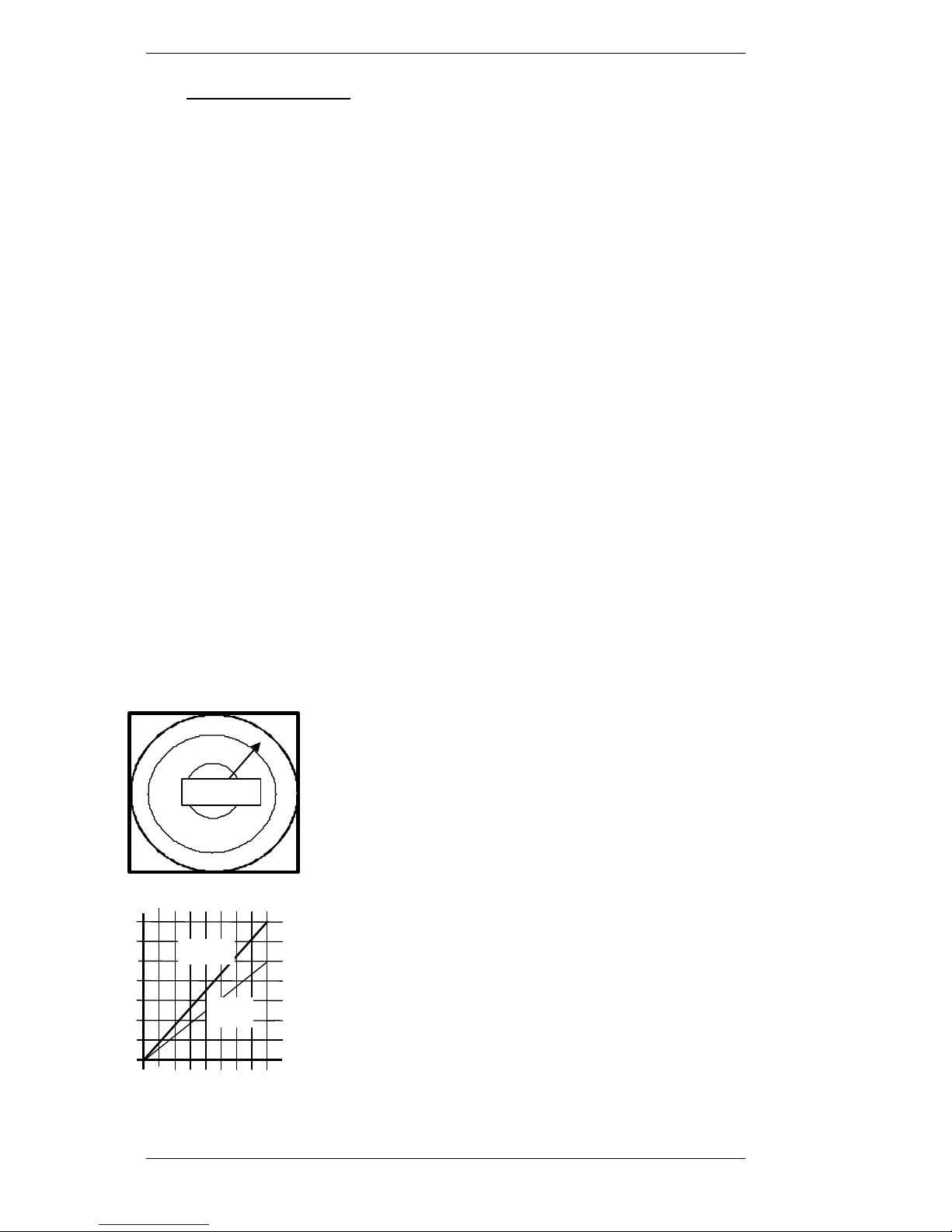

3.2 Control

The boiler can be controlled by way of a conventional

thermostat, or a modulating electronic room thermostat

(open therm), which can control the boiler output and

modulate between 12% and 100% of the total output of

the boiler.

The heat output is continuously adjustable ensuring that

the output of the boiler maintains a constant

temperature in the home irrespective of weather

conditions and provides hot water (combination boilers

only) at a constant temperature.

This variable heat output can also be achieved by

means of the built-in weather-compensation, by way

of an independent control or in conjunction with the

above thermostats. All forms of control can be used

with a conventional time clock.

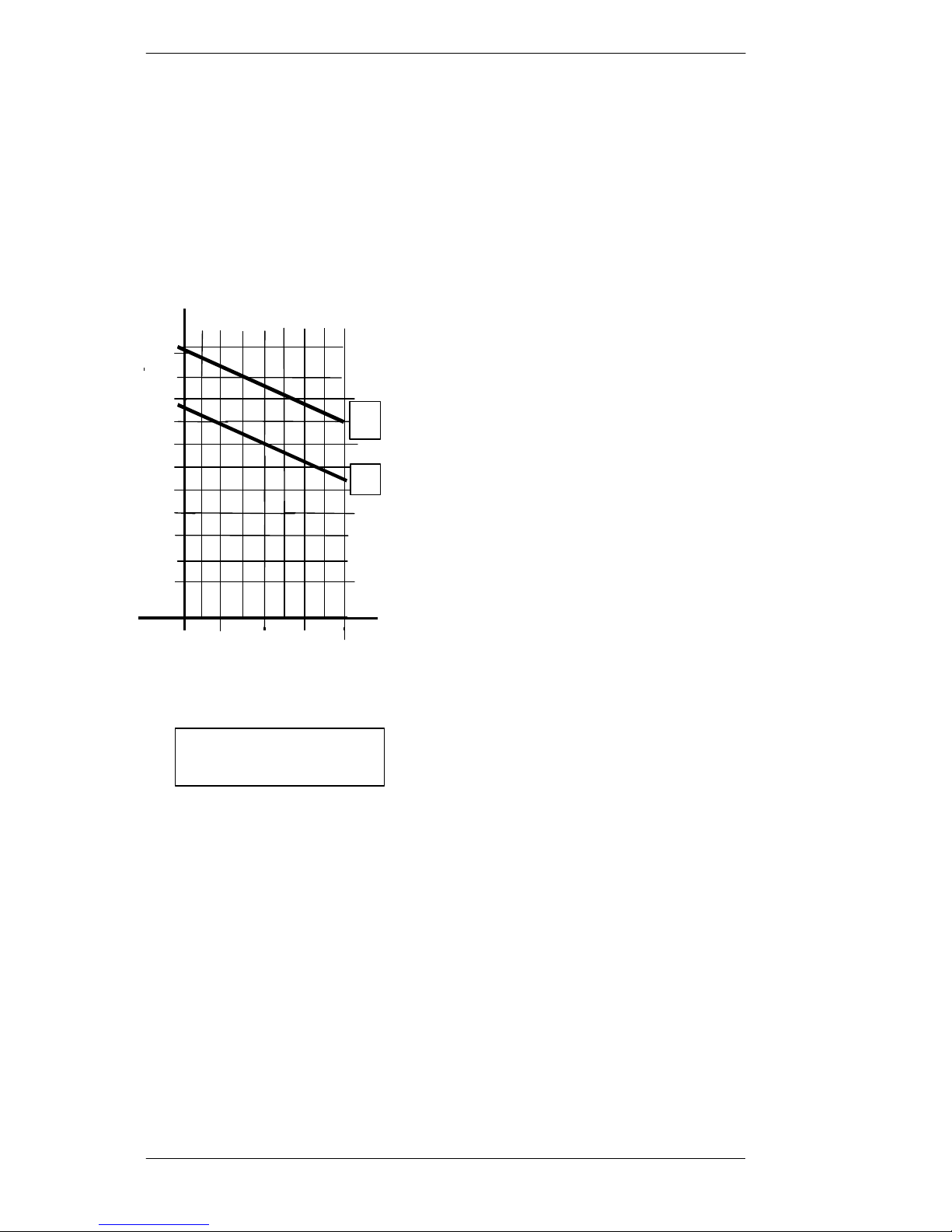

MTC

15

16 17 18 19 20 21 22 23

ETHOS

20

30 90 20 10 0

-10

-20

Ambient temperature

°C 40 50 60 70 80

CH water temperature

°C

supply

return

Page 7

Installation manual MIKROFILL ETHOS

Page 5

3.3 Products of combustion

As a result of the variable combustion and the burner used, the results achieved for

combustion comply with the strictest norms in Europe. Sedbuk A Rated, Ultra low Nox, Ultra

low CO.

3.4 Modulating fan

An energy saving 24 volt high efficiency fan is used with variable speed and current use.The

fan revolves more slowly when the heat requirement is less, thus saving electricity.

3.5 Multi-speed pump

The appliance is fitted with a Grundfos pump (type UBS 15 – 60 HP) provided with a 3

speed switch for regulating the speed to enable the correct flow rate to be selected.

3.6 Description of appliance

The appliance is suitable for supplying a central heating installation. It has a variable

capacity between 12 and 100%.

3.7 Combination Models

These boilers have a built-in heat exchanger with a limited provision for hot water supply. All

connections are internal, while a built-in flow restrictor provides a maximum quantity of hot

water maintaining a hot water temperature of approximately 60°C.

The hot water is set at 60°C to prevent contamination with “Legionella” bacteria.

4 INSTALLATION

4.1 Contents

Installation & Users’ Manual

Vent key

Mounting bracket

2 spare fuses

3 spare burner plate nuts for fixing the burner plate (fixed on the front of the gas valve)

Strainer syphon with tightening nut and packing

Check the contents immediately on receipt.

Any damage must be reported to the supplier immediately.

Mikrofill appliances are completely assembled

Page 8

Installation manual MIKROFILL ETHOS

Page 6

4.2 Siting the boiler

:

Mikrofill appliances are suitable for all gas

groups G20.

The flue, whether single or concentric, must be

installed in compliance with the current flue

recommendations BS5440

Combination boilers should be sited as close as

possible to the hot water draw off point to avoid

excessive water wastage.

The installer will need to select and install an

expansion vessel which will be sized according to

performance requirements, along with a pressure

relief valve.

Page 9

Installation manual MIKROFILL ETHOS

Page 7

For maintenance and service purposes the front

and underside of the appliance need to be

accessible; both sides need to be at least 20mm

from a wall or cupboard wall.

The following need to be available in the room

where the appliance is to be mounted

a. 240v 1ph Electric.

b. A suitable drain for condensation water.

c. The wall on which the appliance is going to be

mounted must be capable of bearing the weight of the

appliance.

d. ETHOS boilers incorporate a modulating fan.

Although noise levels are minimal care should be

taken in siting the boiler to reduce disturbance from

noise.

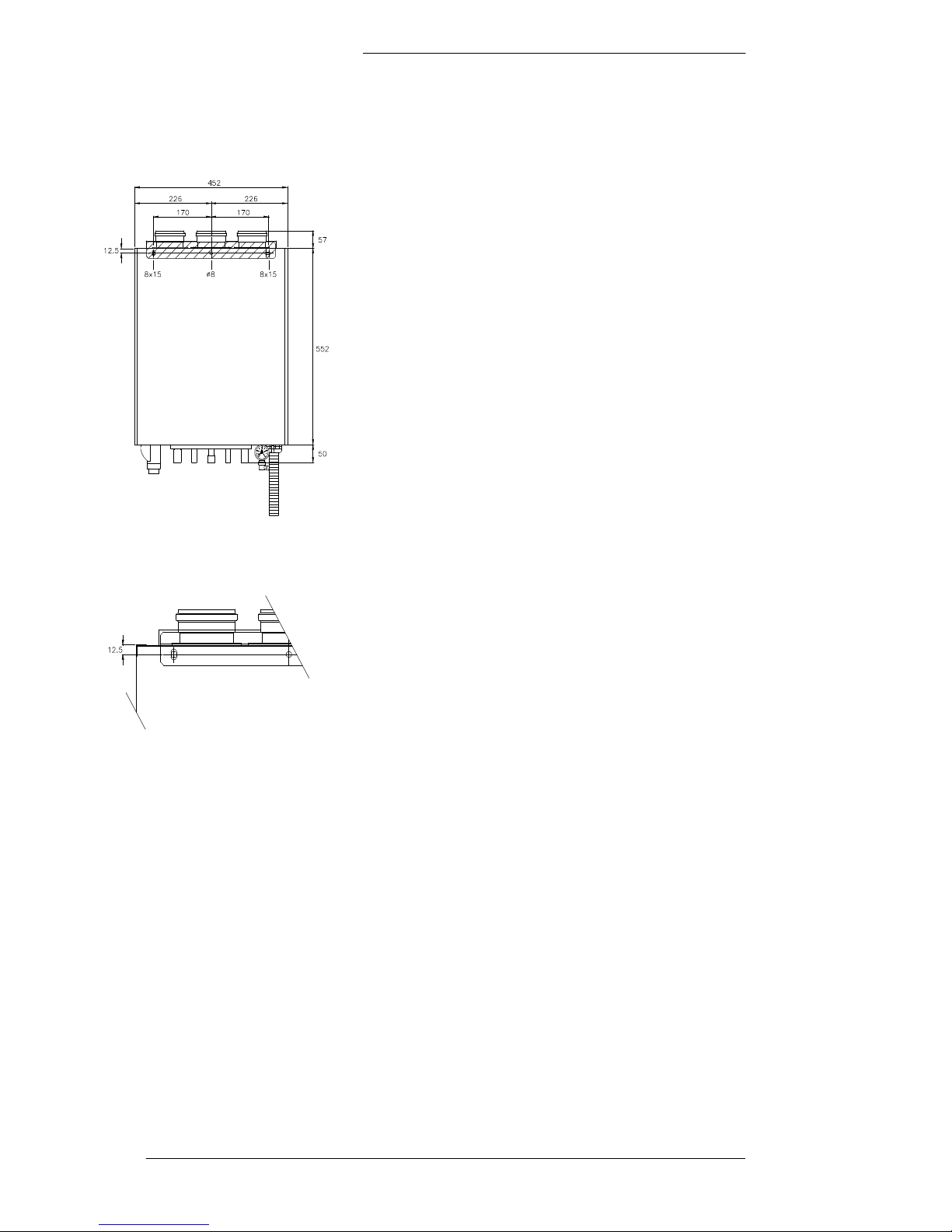

4.3 Mounting the boiler

a. Using the mounting bracket, mark the holes for the

mounting plate and determine the position for

connection of the inlet and outlet pipes..

Warning! 1.

Make sure when you mark the position of the bracket

that it is level.

Warning! 2

The head of the fixing bolt, must not be more than 6

mm.

b. Secure the mounting bracket to the wall using screws

and plugs.

c. Mount the boiler.

4.4 Air inlet-flue gas outlet connection

General

There are 2 options of flue connection:

A.: separate air inlet and flue outlet;

B.: concentric connection (pipe in pipe)

A. Separate air inlet and flue outlet.

The optimum connection for air inlet and flue gas removal is achieved by using a corrosionresistant inlet system.

The dimension of the flue gas outlet pipe is 80 mm; the air inlet is similarly 80 mm.

The air inlet can be placed on either the left or right hand side of the flue gas outlet pipe.

?

Page 10

Installation manual MIKROFILL ETHOS

Page 8

B. Concentric connection , a set is available for a concentric connection: air inlet 125 mm and

flue gas outlet 80 mm diameter.

Always place the plastic inlet connection on top of the mouth of the air inlet pipe. This plastic

connecting piece prevents damage to the appliance if there is moisture present in the inlet pipe

The air inlet with an 80 mm diameter, must be closed with the seal supplied with it.

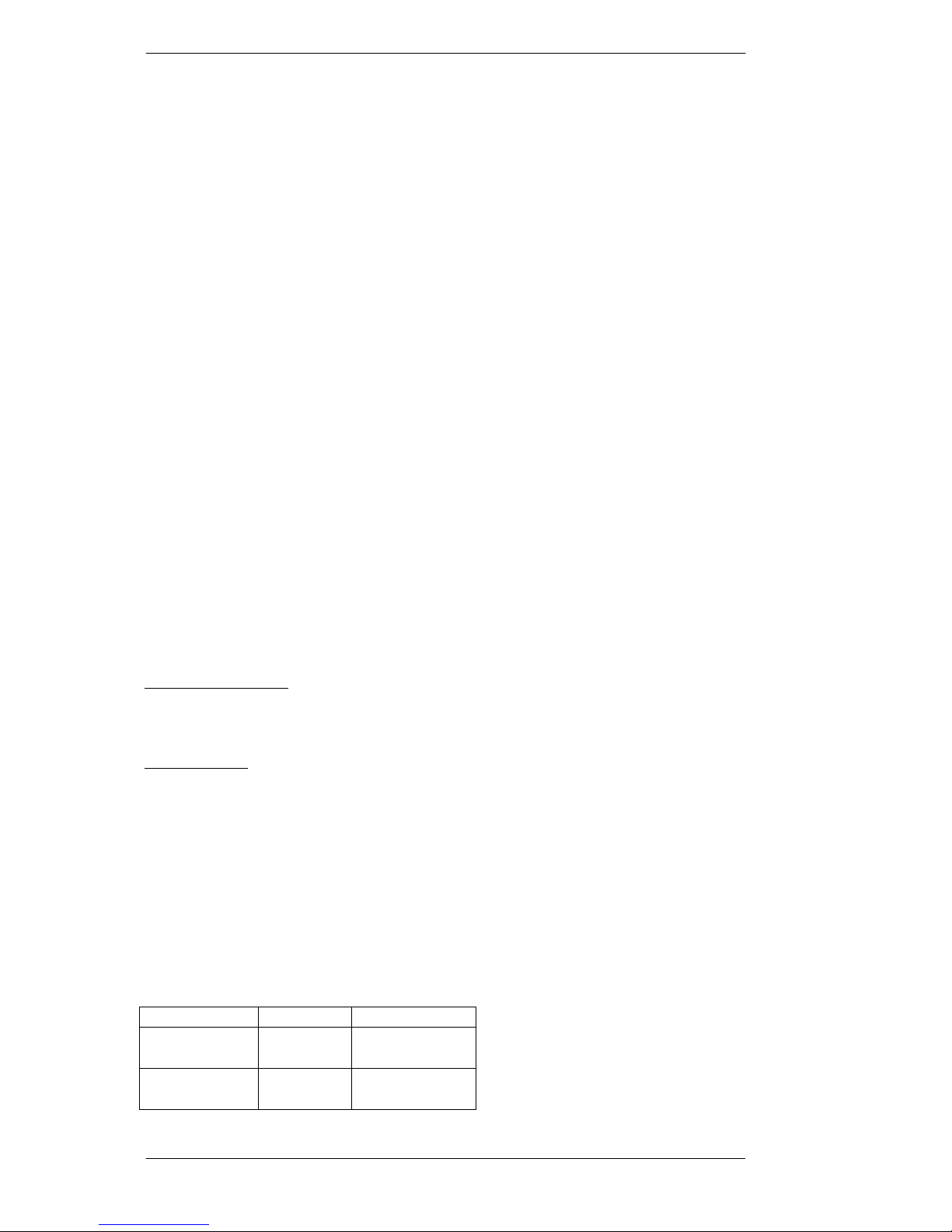

4.6(T)

1 = ETHOS 30/36

2 = ETHOS 42/46

kW

40 35 30 25 20 15 42

Load

100

200

300

400

500

( Pa )

Resistance

1

2

Page 11

Installation manual MIKROFILL ETHOS

Page 9

4.5 Air inlet and flue outlet system.

The MIKROFILL boiler is a room sealed appliance that does not use any oxygen from the

room in which it is installed; the casing is air tight, so that oxygen is provided only through

the air inlet pipe. The boiler must not be operated without the casing in place.

Note that horizontal parts need to have a gradient of 1% towards the boiler (1 cm per 1 m

length). If this is overlooked, condensation can collect in the flue gas outlet pipe which can

cause problems.

The resistance of the inlet and outlet system is 100 Pa in instances where the resistance is

greater than 100 Pa the maximum output of the boiler will be effected please refer to 4.6(T).

4.6 Influence of exhaust removal on load

The following table gives the ratio between the load and the resistance of the inlet and outlet

resistance of the system.

Up to a resistance of 100 Pa the load will remain near enough equal, with greater resistances

this changes with respect to the values on the type plate.

The resistance and change in the load influence only the maximum load and not the minimum

load.

Take account of possible load changes with hot water production and the transmission

calculation.

4.7 Flue material

The appliance must only be connected to systems manufactured from approved flue material

and must incorporate water tight seals to eliminate leakage of condensate.

To avoid exterior nuisance pluming (mist) we thoroughly recommend vertical flueing.

Page 12

Installation manual MIKROFILL ETHOS

Page 10

4.8 Flue resistance table

The load of the appliance is influenced by the resistance of the air inlet and outlet system

through the gas-air connection of the control of the appliance.

With a resistance up to 100 Pa., the load will be equivalent to what is shown on the type plate

of the appliance. The flue pipe induced draught is: 3 Pa/vertical metre.

Table 2, Flue resistance table

Example of calculation

Boiler type: 30/36 ETHOS

Air inlet pipe: diameter 80 mm; horizontal length: 5 m; vertical 25 m; 2 x 90° bend

Flue gas outlet pipe: diameter 80 mm; horizontal length 5 m; vertical 25 m; 2 x 90° bend

Concentric vertical flue terminal 80/125

Air inlet: Resistance

90° bend: 2 pieces 2 x 1.0 2.0 Pa

Straight pipe : 30 m. 30 x 0.8 24.0 Pa

Flue gas outlet

90° bend: 2 pieces 2 x 2.0 4.0 Pa

Straight pipe : 30 m. 30 x 2.0 60.0 Pa

Vertical terminal 4.5 Pa

94.5 Pa

Total resistance is now 94.5 Pa minus the vertical flue pipe induced draught of 3 Pa/vertical

metre therefore (25 x 3 Pa = 75) = 19.5 Pa (thus below 100 Pa); so that the capacity of the

boiler is not changed by the resistance.

Concentric Flue System (mm) Resistance inlet-outlet system

[Pa]

Part

ETHOS 30/36 ETHOS 42/46

Vertical Terminal 80/125 4.5 12.0

Horizontal Terminal 80/125 3.0 8.0

straight pipe/m 80/125 1.8 4.0

45° bend 80/125 0.9 2.0

90° bend 80/125 1.8 4.0

Two Pipe System (mm) Resistance inlet-outlet system

[Pa]

Air Inlet Part

ETHOS 30/36 ETHOS 42/46

straight pipe/m 80 0.8 2.2

45° bend 80 0.5 1.2

90° bend 80 1.0 2.0

Flue Gas Outlet

Vertical terminal 80 4.5 12.0

Horizontal terminal 80 3.0 8.0

straight pipe/m 80 2.0 4.0

45° bend 80 1.0 2.0

90° bend 80 2.0 4.0

Page 13

Installation manual MIKROFILL ETHOS

Page 11

4.9 Removal of condensation

The condensation outlet is on the underside of the appliance, on the right, and has a ¾”

diameter hose; place this flexible hose in the drain with an open connection .

Only use plastic parts for the condensation water outlet. Metal pipes are not permitted.

The appliance is provided with an in-built siphon, therefore the connection from the appliance

can be directly linked with the water supply in the house.

WARNING: blockage of this outlet can cause damage to the appliance. The guarantee for the

appliance does not cover any damage that arises in this way. In the correct situation the

condensation water flows away visibly, for example via a tundish.

The appliance is constructed in such a way that if the siphon becomes blocked the appliance

switches off before damage can occur to the burner.

4.10 Central heating and hot water circulation

4.10.1 General

If plastic pipes are used for supply and return, for radiators or under-floor heating, the pipes

should incorporate an oxygen diffusion barrier. In the absence of this barrier it is essential that

a Mikrofill air and dirt seperator or similar appliance is installed. This is good practice even

on steel/copper systems. This prevents contamination of the heat exchanger with system

debris and magnetite caused by oxidation of the pipework. The MIKROFILL guarantee may

be invalidated by failure to comply.

4.10.2 Connecting the expansion vessel.

Combination boilers

Combination boiler versions require an expansion vessel, safety relief valve and system

isolating valves. These can be supplied by Mikrofill.

System boilers

An expansion vessel needs to be fitted with a volume suited to the contents of the central

heating installation and static pressure; the expansion vessel is preferably fitted in the water

return pipework.

4.10.3 Domestic hot water circuit (Combination boilers only)

The boiler incorporates a domestic hot water flow control valve which must be adjusted

according to table 3 below.

Connect the cold water supply according to the current UK water regulations (April 2000); it

is advisable to fit a Mikrofill WRAS approved “quick fill loop” to enable recharging of the

boiler water system

Table 3, Hot water class

Appliance Setting HW class

ETHOS 30/36 10 l/min 5

ETHOS 42/46 12.9 l/min 6

Page 14

Installation manual MIKROFILL ETHOS

Page 12

To achieve a tap water temperature of 45°C or higher within 30 seconds, the hot water pipe

between the boiler and the outlet must be not more than approximately 20 metres long.

4.10.4 Multi speed pump

The pump has a multi speed regulator which is set at the highest level: in the models ETHOS

30/36, 42/46, setting II will usually be sufficient: Warning: Do not use level I, because the

flow rate will be insufficient.

The appliance has a built-in pump control with a delayed switch-off time of 3 minutes as

standard.

If more heat is demanded the pump will operate at maximum capacity; when the heat demand

ceases the pump will run for a further 3 minutes, and then stop.

Similarly the pump will run for 1 minute every 24 hours to reduce the possibility of the pump

seizing due to debris in the system.

This 24-hour period begins the moment that the electrical power to the appliance is switched

on.

4.11 Frost protection

The appliance has built-in frost protection, which activates the the central heating pump when

the water temperature in the boiler drops to 8°C.

At a boiler water temperature of 5°C, the burner ignites and burns until the feed temperature

reaches 10°C.

4.12 Connecting the gas supply

The gas supply must be suitable sized to ensure that there is no more than 1mbar of pressure

drop from the meter to the appliance, this is a mandatory requirement

Check the gas pipe for leaks. If an inert gas i.e. nirogen is to be used for the gas test,

precautions must be taken to ensure that the maximum pressure in the gas system is below

100mbar.

For the fitting of the gas pipe and valve only, to test for gas leaks, a pressure of 100 mbar is

briefly permitted.

Purge the gas pipe carefully, before the appliance is used for the first time.

Page 15

Installation manual MIKROFILL ETHOS

Page 13

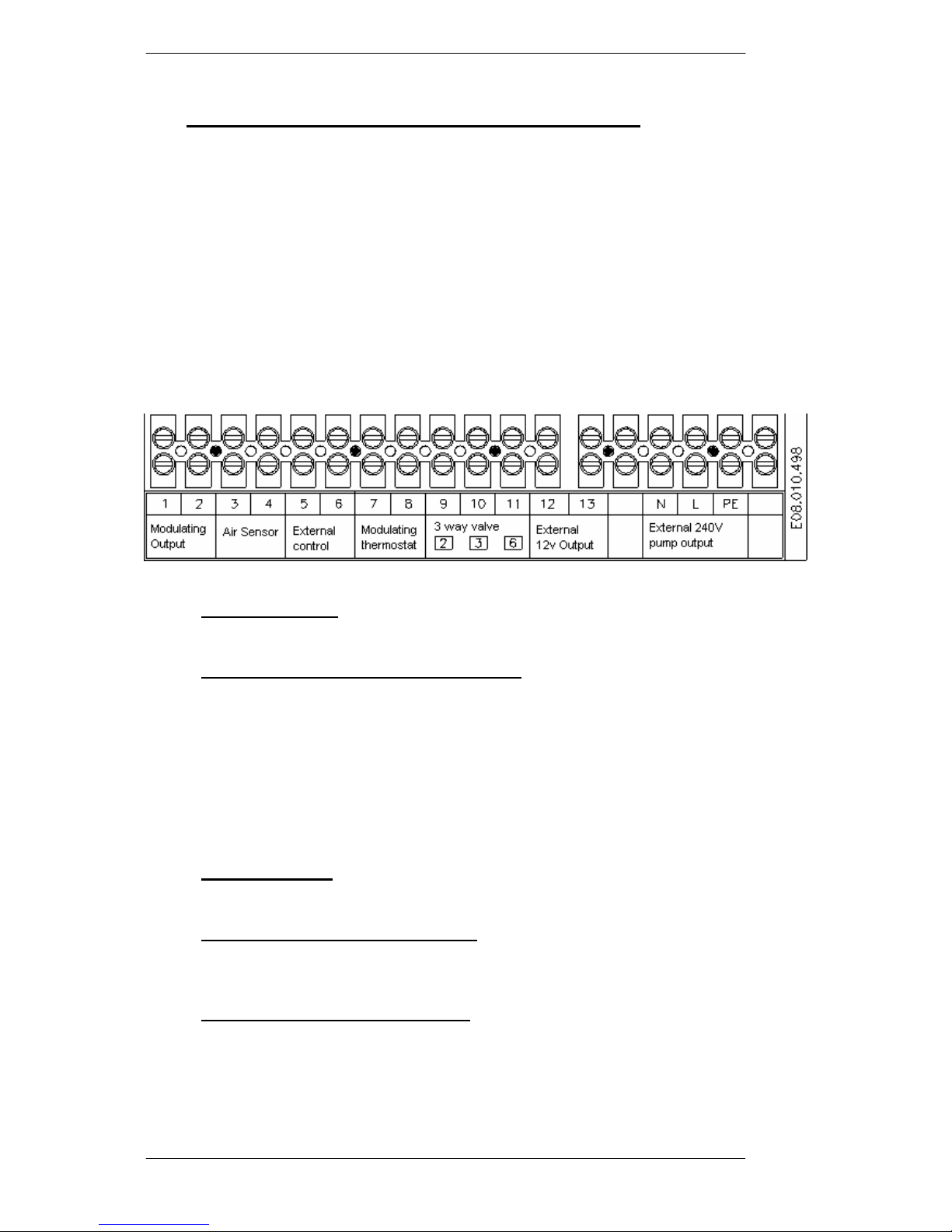

5 ELECTRICAL INSTALLATION INSTRUCTIONS

Connection to mains voltage.

The appliance has an earthed mains plug. The appliance needs to be connected to an earthed

240v single phase supply. Minimum cross-section is 3 x 0.75 mm²; the electrical installation

must of course conform to the current regulations (see page 1).

A terminal board is provided for the further connections..

Care must be taken to ensure that the isolator for this mains cable is accessible at all times, so

that, for servicing for example, the appliance can be disconnected from the power supply.

5.1 Terminal board

The following parts can be connected to the terminal connection board provided, see also the

diagram below:

1-2 PWM pump cable for the modulating signal for a modulating domestic or CH pump .

3-4. External sensor for weather compensation. If desired, the CH installation can be

regulated on the basis of the external temperature: if the external temperature drops,

the water temperature in the boiler is increased; the water temperature in the boiler is

therefore not subject to external influences such as the “sun” in the room, or an open

fire.

This regulation can be supplemented by a room thermostat.

If a room thermostat is not fitted, a wire loop needs to be fitted between terminals 5

and 6.

5-6. Room thermostat/ Time clock/BMS control can be connected here.

Maximum switch capacity is 2 VA.

7-8

Modulating thermostat (open therm)

Mikrofill has a series of modulating thermostats in its range, with which the boiler

modulation can be controlled.

9-10-11 External three-way valve - 24V only. If an external three-way valve is connected for

an indirect cylinder for instance, the three-way valve motor needs to be connected

here; in which case gate 9 is the neutral terminal, and terminals 10 and 11 are intended

for the 24 V AC Power open/Power closed.

These terminals can also be used for other 24V AC supply not exceeding 3VA

Page 16

Installation manual MIKROFILL ETHOS

Page 14

24 V AC For external regulation there is the option of having a 24 VAC power source;

terminals 10 and 11 can be used for this, with the limitation that:

a. remove the anticipation resistor (green) from the 4-gate terminal connection

board that is mounted on terminals 1 and 2.

b. maximum capacity must not exceed 3 VA.

12-13 If an external cylinder is connected, a sensor or a thermostat can be connected here.

If a sensor is connected, the boiler temperature can be read on the boiler display.

N-L-PE The 230VAC for an external pump is connected here; in combination with the PWM

signal this is connected to the terminals 1 and 2, or an internal modulating CH pump.

Temperature

Status

Service

Reset

--

+

Tap

Fault

Page 17

Installation manual MIKROFILL ETHOS

Page 15

5.2 Wiring Diagram

Page 18

Installation manual MIKROFILL ETHOS

Page 16

6. Commissioning

6.1Control panel

6.1.1. Display

Consists of two digits on the left hand side and one digit on the righthand side: left hand side

digits: feed water temperature of the boiler; right hand side digit: status of the boiler:

0 Stand by

1 Lock out fault/Control stop*

2 Flame proving/or ionisation fault

3 Fan pre-purge

4 Ignition

5 CH demand or timed overrun on CH pump

6 Domestic hot water demand

7 Circulating hot water heat exchanger or overrun on hot water pump

* With a longer period of “Control stop” may indicate shutdown on outside air

temperature. (Only if outside air control is fitted)

6.1.2. Keypad Control

The keypad provides access to various options for setting and controlling the appliance; this

always involves a combination of different buttons. The following combinations can be used:

1.Press “Service” and “Reset” simultaneously for 3 secs = Access to installation menu.

After these buttons have been pressed, the Status window will show “0”, while an “0”

will also appear in the temperature window. By means of the “+” and “-“ buttons in the

temperature display, the code with the value “8” needs to be set. After this press the

service button, to call up the various parameters.

If the appliance is functioning, a “-“ sign will be shown first, until combustion ceases,

after which the first parameter shows in the service window, and thereafter the various

parameters can be called up and adjusted.

Exit this installation menu by pressing the “Reset” button until the red LED above it goes

out, this stores the adjusted parameters automatically; if this is not required, the service

menu is exited automatically after a 1 minute delay, the amended data being stored.

1. Press “Service” and “+” simultaneously for 3 secs. = Gas valve set position, (an “h” is

shown in the display). By pressing the “+” or “-“ key, all the required number of

revolutions are set. The double display shows the number of revolutions in 100

revolutions (e.g. 35 means 3500 rpm).

Pressing “+” and “-“ keys simultaneously cancels setting the number of revolutions, and

the appliance functions automatically.

Page 19

Installation manual MIKROFILL ETHOS

Page 17

2. Press “Service” and ”-“ simultaneously for 3 secs. (=Faults). In this situation, an amended

software programme can be loaded or adjusted using a computer and the correct software

programme.

3. If the “TAP” button is pressed, the following data are displayed depending on the

situation:

-if water is not being drawn off: the heat maintaining temperature of the heating coil.

-when water is being drawn off: the hot water temperature.

6.2 Sensors

The following temperature sensors are fitted in the boiler:

S1 = flow sensor (vertical pipe on the front of the exchanger)

S2 = return sensor (on horizontal pipe between three-way valve and exchanger).

S3 = priority/heat maintenance sensor (sensor, on the right hand side of the heating coil).

S4= external temperature sensor (if fitted).

S5 = hot water (domestic) sensor (on 15 mm pipe, on the left hand side of the heating coil).

(Combination boilers only)

The sensors used are of the NTC (negative temperature control) type, and have the following

characteristics:

Sensor table

Temperature

[°C]

Resistance

Sensor 1, 2,

3, and 5

[Ohm]

Temperature

[°C]

Resistance

Sensor 4

[Ohm]

0 32550

-30 171800

5 25340

-25 129800

10 19870

-20 98930

15 15700

-15 76020

20 12490

-10 58880

25 10000

-5 45950

30 8059

0 36130

35 6535

5 28600

40 5330

10 22800

45 4372

15 18300

50 3605

20 14770

55 2989

25 12000

60 2490

30 9804

65 2084

35 8054

Page 20

Installation manual MIKROFILL ETHOS

Page 18

70 1753

40 6652

75 1481

45 5522

80 1256

85 1070

90 915

95 786

In addition the appliance has a high limit safety thermostat; this is mounted on the square

distribution pipe, on the right hand side of the stainless steel exchanger.

Page 21

Installation manual MIKROFILL ETHOS

Page 19

6.3. Installer’s programme

If the installer’s code is keyed in (after “Service” and “Reset” have been pressed for 3 secs.),

the following parameters can be set and adjusted (adjusted with the “+” and “-“ keys) , by

pressing the “service” button each time:

Programme

number

Name programme Adjustable between Factory setting

*0 Installer code 0 – 99 Installer code is 8

*1 Boiler type 0 = CH + coaxial coil

3 = CH + boiler with

own coil and external

three-way valve

0

*2 Pump action 0 = pump overrun

1 = pump continue

running

0

*3 Maximum CH capacity 19% and 99% 80%

*4 Maximum capacity during

drawing off

19% and 99% 99%

*5 Minimum supply temp. for

combustion line

10 … 25°C 20°C

*6 Minimum external temperature

for combustion line

-30°C…10°C -15°C

*7 Maximum external temperaure

for combustion line

15°C …30°C 20°C

*8 Pump overrun for CH function 1…15 min 3 min

*9 Pump overrun for HW function 0…90(0) sec. 6(0) sec = 1min.

*A OpenTherm Cascade 0 …99 kW 45 kW

*C Step modulation 0= step modulation ch is

not active

1= step modulation ch is

active; 5 minute steps

2= ditto, 10 min steps

3= ditto, 20 min steps

2

*d Regulating Central Heating 0 = room thermostat with

or without clock

1 = switch clock

0

*E Maximum supply temperature

CH function

18°C – 85°C 85°C

Exit this programme, after the parameters have been adjusted, by pressing the “Reset” key

until the Faults indicator light goes out.

Explanation of the set up options for the installer:

Programme number 1: Boiler type:

-For the normal combi boiler, key in the digit “0” here.

-if a boiler, with its own heating coil and an external three-way valve is used, programme in

“3”.

Page 22

Installation manual MIKROFILL ETHOS

Page 20

With respect to the three-way valve, a Honeywell three-way valve, type VC 80-10 needs to be

connected to the terminal strip, while the valve must be fitted in the circuit in such a way, that

the gate marked “B” is connected to the boiler circuit, gate “A” therefore on the CH circuit,

and on the “AB” gate on the CH boiler

Programme number 2: Pump action

Here it is possible to opt for the pump to over-run for the ch installation; this programming

has no influence on the over-run of the pump after drawing off: this over-run time is

established in parameter “9”.

For an over-run time for the CH installation, programme the digit “0”; the length of the overrun time is established under parameter “8”.

If continuous running is chosen (e.g. for underfloor heating), “1” needs to be programmed.

Programme number 3: Max. CH capacity (/revs of fan when CH functioning)

This allows the maximum CH capacity (40/30 °C) according to the type plate, to be reduced,

according to the accompanying table: CH functioning

Table 4, CH capacity

30/36

ETHOS

revs 42/46

ETHOS

revs

kW rpm kW rpm

100% 30.0 6250 42.0 6250

95% 26.6 5938 37.1 5938

90% 23.7 5625 32.8 5625

85%

21 5313 29.0 5313

80% 18.7 5000 25.6 5000

75% 16.6 4688 22.6 4688

70% 14.7 4375 20.0 4375

65% 13.1 4063 17.6 4063

60% 11.6 3750 15.6 3750

55% 10.3 3438 13.8 3438

50%

9.2 3125 12.2 3125

45%

8.1 2813 10.8 2813

40%

7.2 2500 9.5 2500

35%

6.4 2187 8.4 2187

30%

5.7 1875 7.4 1875

25%

5.1 1562 6.6 1562

19%

4.6 1188 5.8 1188

Page 23

Installation manual MIKROFILL ETHOS

Page 21

Combination boiler only

Programme number 4: Max. capacity during draw off ( revs of fan during HW function).

The revolutions of the fan during HW function are different from the revolutions during the

CH function, as the maximum load during draw off is higher.

The table for the load during draw off is shown below:

Table 5, Hot water capacity

36 ETHOS revs 46 ETHOS revs

kW rpm kW rpm

100%

36.0 7500 46.8 7500

95%

34.1 7110 45.4 7110

90%

32.3 6750 44.0 6750

85%

30.4 6350 42.2 6350

80%

26.6 6000 37.1 6000

75%

23.4 5550 32.4 5550

70%

20.4 5160 28.2 5160

65%

17.9 4800 24.5 4800

60%

14.7 4400 20.0 4400

55%

12.9 4000 17.3 4000

50%

11.2 3600 15.0 3600

45%

9.7 3200 12.9 3200

40%

8.1 2800 10.8 2800

35%

7.0 2400 9.2 2400

30%

6.0 2000 7.9 2000

25%

5.1 1675 6.6 1675

19%

4.6 1200 5.8 1200

Programme number E, 5, 6 and 7

Setting combustion line

A combustion line is drawn between two points

that are determined by a specific external

temperature and the associated required feed

temperature of the CH water.

Instructions for determining this combustion line

are given in the steps below.

1st combustion line point at lowest external

temperature.

STEP 1. First of all the maximum feed

temperature (design temperature transmission

calculation) in the winter must be determined and

set; with the help of Programme number “E”,

enter this temperature (temperature chosen can be

between 18°C and 85°C). Choose e.g. 75°C.and

fix it by pressing the “Service” key.

20

30 40 50 60 70 80 90 °C

Exter

temperature °C

20 10

0

-10

-20

-30

30 10

Feed temperature

Page 24

Installation manual MIKROFILL ETHOS

Page 22

STEP 2. Now the associated external

temperature, by which this max. supply

temperature is required, needs to be

programmed in.

Press the “Service” key until it shows

Programme number 6.

Enter the external temperature here (e.g –

15°C, this is the temperature that is taken for

the transmission calculation).

In this way the first point of the combustion

line is established.

2nd combustion line point with a higher

external temperature.

STEP 3. Then the external temperature at

which no further heating is required needs to

be set e.g.15 °C external temperature.

Programme number 7 needs to be

programmed with this value.

STEP 4. As the last step, the supply

temperature needs to be set with the chosen

external temperature: this feed temperature

then needs to be the same as the external

temperature otherwise the appliance will not

switch off.

For this Programme number 5 needs to be

programmed, e.g. 15°C.

For buildings that are very solidly built (e.g.

castle walls), it will be necessary to allow the

appliance to continue burning for longer; in

such cases 30°C can, for example, be chosen

as the external temperature

This last programming step determines the

second point of the combustion line, and a

line is drawn automatically between these two

points.

As the accompanying drawing shows, at point

“1”, the combustion line will set an

increasingly high feed temperature even at

lower external temperatures, but the setting in

Programme "E” prevents this: the temperature

set is not exceeded.

At point “2”, the CH boiler will no longer be

burning

1

20

30 40 50 60 70 80 90 °C

Exter temperature °C

20 10

0

-10

-20

-30

30 10

Feed temperature

1

20

30 40 50 60 70 80 90

Exter temperature °C

20 10

0

-10

-20

-30

30 10

Feed temperature

°C

2

20

30 40 50 60 70 80 90

Exter temperature °C

20 10

0

-10

-20

-30

30 10

Feed temperature

°C

2

Page 25

Installation manual MIKROFILL ETHOS

Page 23

Programme number 8: Pump over-run time for CH function

This sets the over-run time of the pump after the demand for central heating ceases.

3 minutes is programmed by default.

Programme number 9: Pump over-run time for HW function

This sets the over-run time for the HW pump after the heating of the built in hot water

provision.

The setting can be between 0 and 900 seconds (15 minutes); the default is 60 seconds (1

minute): in the display the time is shown by omitting one 0.

Programme A: Open Therm Cascade

If more than one boiler is used for the central heating, the cascade manager function of an

Open Therm Control can be used to regulate these boilers (see the data from the suppliers of

the Open Therm controls).

In this case the maximum central heating load of each appliance connected needs to be

programmed in.

Programme C: Step modulation

This parameter enables the supply temperature to be increased in steps early in the morning as

the house is being warmed up, so that during this heating the appliance continues to condense

and thus is highly efficient. There are 6 steps to this programme, with a programmable

duration:

C 0 = no steps, thus on/off on the basis of the room thermostat

C 1= 6 steps each lasting 5 minutes

C 2= 6 steps each lasting 10 minutes (factory setting)

C 3= 6 steps each lasting 20 minutes

At each step the capacity is increased by 20%, beginning with the minimum capacity.

The boiler therefore starts with the minimum capacity, and this capacity increases every “5,

10 or 20” minutes, by 20%, until the maximum capacity is reached, or this programme

finishes, because the house has come up to temperature.

a. With an on/off room thermostat:

When there is no demand for heating, this programme counts back with the same time

intervals until there is a new demand for heating: the appliance then starts up with the

capacity appropriate to the time.

The efficiency of the boiler during the warming up period will always be greater than

100% and during the day will always have optimum output and avoid undesirable

fluctuations in the temperature of the house.

b. With an “Open Therm” thermostat

When the room temperature reaches the set value, the step programme is abandoned, and

the “Open Therm “ thermostat takes over the regulation of the boiler, and the capacity of

the boiler is adapted to the need for heat: the boiler will modulate optimally and the room

temperature will be kept very constant.

Page 26

Installation manual MIKROFILL ETHOS

Page 24

Programme d: CH Regulation

The controller is extremely flexible and will accept many types of external control. Almost

all controls imaginable for the CH installation can be connected or activated and will be

automatically detected by the automatic burner, there is however a difference between control

on the basis of a simple time switch and a normal room thermostat: if a time switch is used it

needs to be programmed in, under this Programme d.

An overview of the options for connection and the operation of it for the central heating

installation follows.

1. Simple day/night time switch with a daily or a weekly programme, in association

with the built-in external temperature control and the external temperature sensor.

*No room thermostat is used with this.

*Fitting each radiator with a thermostatic control valve is recommended.

*Connect the time clock to terminals 5 and 6 of the terminal board in the boiler .

*Connect the external sensor to terminals 3 and 4 of the terminal board in the boiler .

*If the time clock contact is closed (thus heat demand), the boiler supply temperature is

going to assume a value according to the combustion line set (see page 21 for setting the

combustion line,).

* If the time clock contact is open (night reduction), an automatic night reduction of 2.5°C

in the room temperature is achieved through a value programmed into the automatic

burner; this can be adjusted only by means of a special programme (call Mikrofill

Infodesk).

*With the next heat demand (e.g. the early morning warming up) the combustion line will

be increased by approximately 5°C for one hour (booster function), to bring the house up

to temperature quickly; the step programme does not need to be activated.

*Setting parameters: (bold type: need to be adjusted, the others remain unchanged

(factory settings): 1-0; 2-0; 3-80; 4-99; 5,6,7 and E are the combustion line settings; 8-3;

9-0; A-45; C-0; d-1.

2. An on/off room thermostat (or clock thermostat), in conjunction with the built-in

external temperature control in the boiler and the external temperature sensor.

*Connect room thermostat to terminals 5 and 6 of the terminal board in the boiler .

*Connect the external sensor to terminals 3 and 4 of the boiler terminal connection board.

*With this type of control, the room thermostat acts as a “safety net”: if it becomes too

warm in the room in which the thermostat is situated, the thermostat opens and the boiler

is switched off.: the pomp will run for 3 minute every 13 minutes, until there is a further

heat demand from the room thermostat; if the room thermostat cuts in too often the

combustion line needs to be lowered.

*The supply temperature is determined by the combustion line set.

*the night time reduction can be set by means of the room thermostat, or via the clock of a

clock thermostat.

*With the next demand for heat (e.g. the early morning warming up) the combustion line

with be raised by approximately 5°C for one hour (Booster function), to bring the house

up to temperature quickly; the step programme does not need to be activated.

*Setting parameters: (bold type, need to be adjusted, the others can remain unchanged

(factory settings ): 1-0; 2-0; 3-80; 4-99; 5,6,7 and E are the combustion line settings; 8-3;

9-0; A-45; C-0; d-0.

Page 27

Installation manual MIKROFILL ETHOS

Page 25

*If a separate time clock combined with an on/off room thermostat and the external

temperature control is used instead of a clock thermostat, it needs to be programmed in

accordance with 1.

3. An Open Therm clock thermostat in conjunction with the built-in external

temperature control in the boiler and the external temperature sensor.

*Connect the Open Therm thermostat to terminals 7 and 8 of the terminal board in the

boiler .

*Connect the external sensor to terminals 3 and 4 of the terminal board in the boiler.

*Except where adjustment is possible, no parameters need to be adjusted for the factoryset pre-programmed combustion line.

*Setting parameters: (bold type, need to be adjusted, the others can remain unchanged

(factory settings ): 1-0; 2-0; 3-80; 4-99; 5,6,7 and E are the combustion line settings; 8-3;

9-0; A-45; C-2; d-0.

4. Connect a room or clock thermostat to the boiler

*Connect the room thermostat to terminals 5 and 6 of the terminal board in the boiler .

*Except for where adjustment is possible, no parameters need to be adjusted for the

factory-set pre-programmed values.

*Setting parameters: (bold type, need to be adjusted, the others can remain unchanged

(factory settings ): 1-0; 2-0; 3-80; 4-99; 8-3; 9-0; A-45; C-2;

d-0; E-85

5. Connect an Open Therm (clock)thermostat to the boiler

*Connect the Open Therm thermostat to terminals 7 and 8 of the terminal board in the

boiler .

*Except where adjustment is possible, no parameters need to be adjusted for the factoryset pre-programmed combustion line.

*Setting parameters: (bold type, need to be adjusted, the others can remain unchanged

(factory settings ): 1-0; 2-0; 3-80; 4-99; 8-3; 9-0; A-45; C-2;

d-0; E-85.

Programme E: Maximum supply temp. central heating istallation.

This sets the maximum central heating temperature of the boiler.

6.4 Filling and venting the boiler and installation

Use the fill and drain tap in the central heating installation to fill the boiler and the

installation.

Page 28

Installation manual MIKROFILL ETHOS

Page 26

The correct fill pressure is 1.5 bar.

To prevent corrosion of the central heating installation, pay attention to the following points:

a. The filling water: do not add anything to the CH water, while the pH value needs to

be above 5 (if this is not the case you need to contact the supplier).

b. Flush system thoroughly

c. If plastic pipes are used, they need to be proof against oxygen diffusion in

accordance with DIN 4726/4729; if this is not the case, a separation needs to be

introduced between the boiler circuit and the circuit with the plastic piping.

d. Check for leaks in the circuit

Before starting the appliance for the first time the heat exchanger needs to be vented, once the

installation and the boiler have been filled. Open the vent valve, found on the upper left hand

side, a whole turn. As soon as water comes out of the vent cock, close the vent valve with the

key.

The boiler is provided with an automatic air vent on the top of the CH pump, which needs to

be open when the appliance is running; check that the cap is open at least one turn.

Check the fill pressure shortly after the appliance starts up, and if necessary add more water to

maintain the required pressure. The electronic control of the wall-mounted boiler has a startup programme, specially for venting the appliance. This programme is activated when the

mains power is switched on for the first time and after the “Reset” button is pressed.

This start-up programme runs for 2 minutes: for the 1st minute display code “7” is shown for

the 1st minute and code “5” for the 2nd.

Hot water circuit

The connections for hot and cold water are on the underside of the appliance.

Connect the pipes in accordance with the current regulations; fit an “inlet combination” in the

cold water supply pipe; which can be combined with the overflow pipe, with the condensation

waste pipe from the boiler.

The built-in limit valve needs to be set, with the appliance working; measure the quantity of

water at the furthest removed drain point and set the limiter according toTable 3, page 11.

Closing down

1. Isolate and disconnent the electrical system and turn off the gas tap.

2. If the appliance is switched off when there is a risk of frost, the CH boiler and installation

need to be drained; to do this open the fill and drain taps of the CH installation and the boiler

drain tap on the right hand underside of the appliance.

6.5 Initial Operation

6.5.1 General

The pre-pressure in the gas pipe can be measured with the test nipple (3) on the gas regulator .

The minimum pre-pressure which will allow the appliance to function correctly with the

correct load is 10 mbar.

Page 29

Installation manual MIKROFILL ETHOS

Page 27

6.5.2. Starting up the first time

When you have tested the installation and everything is in order, you can connect the

electrical system.

When the appliance is connected to the mains supply, the double display will show the supply

temperature and the single display the status of the appliance.

An automatic venting programme for the boiler lasting approximately 2 minutes follows the

mains connection.

The ETHOS appliance has a built-in provision for hot water.

Set the room thermostat at a high value so that the burner needs to ignite.

In an appliance with provision for hot water, the hot water will be heated up first.

There is a four-fold electronic start, followed by a faults warning on the status display. Next

press the RESET button for a return to the attempts to start.

To set the gas pressure, use screw [3].

6.6 Adjusting and setting load

To check the gas regulator or when attaching a new one, there are three methods for setting

the correct load:

A. By measuring the percentage of CO2

B. Check the gas consumption via the gas meter method.

C. By flame colour

Both the minimum and the maximum load need to be set using one of the three methods: the

maximum load needs to be set first, followed by the minimum load.

6.6.1 Setting the maximum load

Approximately a minute after ignition, press the keys marked “Service” and “+”

simutaneously; the double display shows the revolutions in hundreds, while the single display

shows “h” (CH). The number of revolutions of the fan can be increased or reduced by

pressing the “+” key or the “-“ key.

To obtain the maximum load press the “+“ key until the maximum number of revolutions is

reached.

If the measurement lasts for more than 10 minutes the appliance will return to automatic

operation; press the “Service” and “+” again to continue the measurement.

To return to the normal menu without having to wait for 10 minutes, press the “-“ and “+”

keys simultaneously.

Page 30

Installation manual MIKROFILL ETHOS

Page 28

Table 6, Revolutions

Appliance ETHOS

36

ETHOS

46

Minimum revs.

(rpm)

CH or HW

1200 1200

Maximum revs

(rpm)

7500 7500

Turn the setting screw for the maximum load if necessary [2], for the following method of

setting:

A. By measuring the percentage of CO2; this needs to be in accordance with the table below.

B. Check via the gas meter method.

C. By flame colour: until a blue colour with red points is achieved on the burner surface.

Table 7, Gas settings

Type of gas

Nat. gas G 25

LPG

Injector: none none

Mod. (bw)(MJ/m3) 41.52 76.64

Cal.value ow (MJ/m3)

29.25 88.00

CO2 max.load (%) 8.8(+/-0.3)* 10.5(+/-0.3)*

CO2 min.load (%) 8.6(+/-0.3)* 10.0(+/-0.3)*

* measured without cover

B. Gas meter method

Measured with natural gas or propane according to the table below:

Table 8, Setting the minimum [maximum?]

Note: For adjustment, the methods under B and C approach the correct adjustment: measuring

CO2 % is the preferred method.

To measure emissions, the measuring point in the heat exchanger can be used by unscrewing

the plastic cap.

Page 31

Installation manual MIKROFILL ETHOS

Page 29

WARNING !! When measuring do not put the probe more

than 2 cm into the heat exchanger to avoid deviations in the

result.

6.6.2 Setting the minimum load

After setting the maximum load press the “-” key until the

minimum revolutions are reached (11 to 12 on the display).

To set or adjust this minimum load, turn screw [1] for the

minimum setting.

Appliance 30/36 42/46

Natural

gas

50 litres in 42

sec.

50 litres in 34

sec.

LPG 15 litres in 38

sec.

15 litres in 30

sec.

Appliance 30/36

ETHOS

42/46

ETHOS

Natural

gas

5 litres in

32 sec.

5 litres in

20 sec.

LPG 2 litres in

39 sec.

2 litres in

31 sec.

Page 32

Installation manual MIKROFILL ETHOS

Page 30

The CO2 % is reduced if the screw is turned anti-clockwise and increased when it is turned

clockwise.

A. Setting on the basis of the flame colour.

The flame colour needs to be red/orange.

B. Gas meter method.

Minimum load according to the table below:

Table 9, Setting the maximum [ minimum?]

values measured with a boiler water temperature of approximately 60°C.

Press the “-“ and “+” keys simultaneously, which returns the appliance to automatic function;

the set-up programme is interrupted in any case after 10 minutes and the appliance returns to

automatic function.

6.7 Conversion to another type of gas

If the appliance is set up for LPG the following steps need to be taken.

a. The white gas-air mixing chamber is situated on the side of the fan. This mixing chamber

has one or two air inlet ports, at the front and in the case of a second opening, also at the

back, depending on the type of boiler. These ports need to be closed for conversion to

butane/propane.

Mikrofill can supply the correct stoppers on request:

ETHOS 32/36 one stop 15 mm

ETHOS 42/46 one stop 15 mm

b. Turn the screw [2] 4 whole turns (clockwise).

Set the appliance running; if the burner has not ignited after 4 attempts, turn the screw [2] one

turn back (anti-clockwise).

c. If the burner has ignited: press the keys marked “Service” and “+” simultaneously for

approximately a minute after the ignition

d. Display shows the revolutions in hundreds, while the single display shows “h” (CH). By

then pressing the “+” key, or the “-“ key, the number of revolutions of the fan can be

increased or decreased.

e. For the maximum load press the “+“ key, until the maximum number of revolutions is

shown (75 in the display).

For setting the maximum and minimum burner load, follow the information under paragraphs

Error! Reference source not found. and Error! Reference source not found., with

associated tables.

6.8 Hot water temperature

This is set by the manufacturer at 60°C to avoid danger from “Legionella” bacteria at lower

temperatures.

Page 33

Installation manual MIKROFILL ETHOS

Page 31

This value cannot be adjusted.

6.9 Closing down

It is advisable to keep the appliance switched on winter and summer. This prevents the

appliance freezing and moving parts seizing up due to corrosion.

Switch off the appliance by reducing the setting of the room thermostat: this will ensure

minimum power consumption, as the CH pump and fan stop running after a short time.

If the appliance does need to be closed down, the following precautions need to be taken:

a. Close the gas valve

b. Disconnect mains electric

c. If there is a risk of frost drain the appliance and the installation.

To drain down the boiler, isolate the boiler from the heating system or drain the heating

system. Attach a suitably sized hose to the drain valve on the boiler and open drain valve.

For the domestic water supply part, the inlet combination stopcock needs to be closed and a hot

water tap opened.

Page 34

Installation manual MIKROFILL ETHOS

Page 32

7. Faults

In the unlikely event that the appliance develops a fault, it can be set to run again simply by

pressing the “Reset” button.

The following faults can occur, in which the digit below flashes in the single Status display

and a code appears in the two digit display.

You will find the solution to the faults in Table 12 on page 34 and Table 13 on page 36

Table 10, Faults

Flashing faults

text in the

single display

Two digit

display

code:

Description of the fault: Cause of the fault

(see page 34)

no indication none Fault with electrical supply 14;50

no indication none Fan runs continually 49

0 Maximum thermostat open 4;5;21;23;24;29;30,42,46

0 Glass fuse F5 defective 15

0 F1 Short circuit feed sensor (S1) 3;41;42;43

0 F2 Short circuit return sensor (S2) 3;41;42;43

0 F5 Short circuit HWsensor (S5) 3;41;42;43

0 1 Lack of feed sensor (S1) 41;42;43

0 2 Lack of return sensor (S2) 41;42;43

0 5 Lack of HW sensor (S5) 41;42;43

1 E1 Temp. feed sensor too high (S1) 4;5;23;29;46

1 E2 Temp. feed sensor too high (S2) 4;5;23;29;46

1 E3 Temp. priority sensor too high (S3) 24;45;46;51

1 E5 Temp. HW sensor too high (S5) 24;45;46;51

2 5 Feed and return sensor exchanged

2 21 Feed temp. lower than return temperature,

during running.

4;21;23;24;29;47

2 E Feed and return temp. unequal during stand

by

23;43

3 Supply temperature rises too quickly 4;5;21;24;28;29;46;51

4

No flame after 4 ignition attempts 10;11;16;18;22;25;35;48

5 Flame decreases while running 11;12;16;22;26;44

6 Flame signal during stand by 18;35;61

7 Appliance is programmed 62

8,9,A Fan revs incorrect 7;8;9;13;19;39;40;41

B One or more parameters are incorrect 63

C Gas valve or gas valve circuit is not correct 17;20;30;34;36;37

D Check on gas valve reg. shows fault 17;20;30;34;37

E Check on the mains voltage 64

F Software fault; EMC external radiation 34

H Reset button hanging or is defective; if the

“H” does not flash: memory defective.

65

Fuse F 1: for ignition 63 mA;

Fuse F 2: for regulation 630 mA;

Fuse F 3: 35 VAC 3.15 A; for fan

Fuse F4: 230 VAC 3.15 A; for mains voltage

Fuse F 5: 24 VAC 1 A, for three-way valve

All fuses are of type: Anti-surge

F4

F3

Trans

F1

Page 35

Installation manual MIKROFILL ETHOS

Page 33

In addition there are also a number of faults that cannot be shown on the display.

A number of these faults or symptoms are shown below:

Table 11, Other faults

Symptom

Cause of fault (see p34)

a House does not reach temperature, appliance firing 45;53;54

b Ignition is loud 35

c Boiler burns continuously but CH water does not warm

up

45

d Room thermostat demands heat, but boiler does not

ignite

1;42;52

e Boiler burning continuously, house too warm 2

f Boiler very noisy when CH working 29;46

g Radiators not hot enough at the top 55

h Water drawn off but water from the hot tap remains

cold

24;56

i Hot water much too hot 51;57

j Water is drawn off, but the water from the hot tap does

not reach 60°C

51;58

k Boiler very noisy during HW operation 23;59

l Fault after replacement of automatic burner 60

Page 36

Installation manual MIKROFILL ETHOS

Page 34

7.1 Causes of faults

The following causes can account for the faults on pages 32/33.

Table 12, Causes of faults

1. Room thermostat is incorrectly connected.

2. Room thermostat does not switch off, short circuit in the cable.

3. Sensor makes a short circuit in the cabl

e or internally.

4. Pump does not run; stuck

5. Water pressure in the CH installation is too low.

6. Water pressure in the CH installation is too high.

7. Fan is not connected (forgotten to connect plug).

8. Fan is dirty.

9. Fan is defective.

10. Valve

is not open.

11. Gas pressure is too low.

12. Incorrect pipe size

13. Fuse F3 defective

14. Fuse F4 defective.

15. Fuse F5 defective.

16. Gas valve setting at the lowest revs. is not correct.

17. Gas valve is not connected or incorr

ectly connected electronically.

18. Ignition cable not correctly connected.

19. Transformer defective.

20. Connection plug to gas valve incorrectly connected, or moisture in the surround

21. Pump plug incorrectly connected.

22. Siphon blocked.

23. Hand bleeder opens and closes after bleeding.

24. Three

-

way valve is dirty.

25. Too much resistance in the supply system or supply system dirty.

26. Exhaust system leaks to supply system; recirculation flue gas, only with

conc. connection.

27. Supply system lets in water.

28. Through flow setting tap is dirty.

29. Heat exchanger is blocked (insufficient circulation)

30. Maximum thermostat defective (insufficient circulation)

31. Maximum load too high.

34. Auto

matic burner defective.

35. Ignition electrode defective (porcelain cracked), gap to burner is incorrect

36. Moisture on the cables of the gas valve.

37. Moisture on printed circuit board of the automatic burner.

38. Moisture in the pump wiring.

39. Moisture on fan and/or connection.

40. Fan plug connected incorrectly.

41. Plug incorrectly connected.

42. Connection cable damaged.

43. Sensor defective.

44. Flue gas circulation behind from the heat exchanger.

45

Hot water drain tap leaking

Page 37

Installation manual MIKROFILL ETHOS

Page 35

46 Position of the revolution switch on the pump is set too low

47 Sensors interchanged (return sensor S2 and hot water sensor S5)

48 Fuse F1

49

Fuse F2

50

Mains voltage 230 VAC

51

Parameter(s) in the installers programme entered incorrectly

52

Open Therm room thermostat, or normal thermostat on an incorrect terminal board gate

53

Step programme in the installers menu not correctly programmed; or steps too long

54 Clock programme of the clock thermostat needs to start earlier in the morning

55 Supply and return pipe interchanged on the appliance

56

Cable or plug to three

-

way valve incorrectly connected

57

Preference sensor (S3) is incorrectly placed or is defective.

58

The through flow setting tap in the cold water pipe needs to be adjusted

. 59 Coil exchange for hot water needs to be descaled

60

Cable loom plugs on the printed circuit board incorrectly fitted

61

Gas regulator defective

62

After programming with a computer, confirmation of new settings

63 Incorrect parameters, or a value outside the scope of the programme, have been

programmed

64 The automatic burner carries out a frequent check on the supply voltage

65 Mechanical defect with the Reset button with a flashing “H”; with a steady H, there is a

defect in the automatic burner.

Page 38

Installation manual MIKROFILL ETHOS

Page 36

7.2 Table of solutions

Numbers correspond to Table 12

Table 13, Table of solutions

1. Check cable or replace cable, check if it is connected to the correct terminal board.

2. Replace room thermostat or replace cable: is the correct thermostat fitted.

3. Replace sensor or trace fault in cable.

4. Try to free the pump shaft or replace the the driving part of the pump.

5. Top up water and trace the leak, also check the expansion vessel for internal leaks.

6. Too much topped up or check pressure of expansion vessel or replace expansion vessel.

7. Insert plug: plug part with cables is on the side of the fan.

8. Clean the blades of the fan.

9. Replace the fan.

10. Open the gas tap.

11. Check the pipe and gas meter, possibly calculate resistance.

12. Replace gas pipe.

13. Replace fuses; F3 fan check: moisture, short circuit, plug, wiring

14. Replace fuses; F4 check all 230 V connections: pump, circuit board connection

15. Replace fuses; F5 check the connection, the plug and the motor for the three-way valve

16. See paragraph 6.4

17. Check the cabling using the wiring diagram, check the connection to the gas valve, check for

moisture.

18. Check cable for short circuit, overheating close by or pinched between steel plate; check the

spark plug cap for cracks, replace the cap.

19. Replace the automatic burner.

20. Moisture inclusion, check on the cable sockets which need to be plugged in correctly to the

electric plug, check the position of the cable sockets, possibly straighten, before the plug is

put in.

21. Check whether the plug(s) fit(s) correctly in each other, with the correct press-on force.

22. Open the flush pipe (left side of the appliance), by unscrewing the cap: hold a jar under it, to

catch the water that runs out. Poke out this pipe with a thin rod, to both upper left and upper

right. If necessary remove the burner unit from the appliance, and pour water into the heat

exchanger to rinse out the siphon.

23. Venting, not simply the boiler but the whole installation – with this complete venting, the

230 V plug of the appliance can be removed from the socket, as the CH does not need to

function during bleeding.

24. Inspect the shut-off valve of the three-way valve, by removing the pump motor by

unscrewing the four fixing screws; the valve can be inspected on the inside of the housing.

The drive motor can be removed, by removing the fixing screw on the front of the housing

(below right), and then pressing in the “snap” lip, situated on the side of the housing, just

above the motor, and at the same time pushing the motor downwards.

25. Check the feed-discharge pipe for blockages.

26. Check the feed-discharge system.

27. See 26.

28. Take off the cold water connection from the appliance and remove and clean the through

flow setting cock.

Page 39

Installation manual MIKROFILL ETHOS

Page 37

29. It is advisable to remove the automatic burner from the appliance first, to avoid water

damage to the printed circuit board.

After the appliance has been drained, the coupling of the T-piece in the supply pipe, and the

flat coupling of the return should be loosened near the pump.

Detach the earth and the spark plug cables, and the wires of the maximum thermostat (above

right).

After this detach the three tension bars, push the heat exchanger partially forward, and

detach the electrical plug on the fan; then remove the exchanger from the appliance.

30. Replace the maximum thermostat by unscrewing it from the brass nut: the system does not

need to be drained (do not remove the brass nut).

31. Follow the setting up procedure in paragraph 6.4.1.

34. Remove the automatic burner with housing from the appliance by:

a. Removing the lid

b. Remove the wiring on the printed circuit board –1 x 2 pin connector (back of printed

circuit, with green wires), 1 x 8 pin connector (front left), 2 x 16 pin connector, and the

230V plug (righthand side).

Remove two screws on the underside securing the housing, then the housing including the

automatic burner can be removed from the appliance.

Next remove the small display cable from the printed circuit board, push the automatic

burner out of the housing and replace it.

35. Replace or bend. warning: bend close to the burner plate, otherwise it could break.

36. Dry off, possibly blow dry with warm air (hairdryer) and check that it functions correctly,

Replace if necessary.

37. See 36.

38. See 36. Remove the connection and dry it; possibly by blowing or blow dry with a hairdryer.

39. See 36. Remove the connection and dry it; possibly by blowing or b low dry with a hairdryer.

40. Plug wire connection needs to point to the exterior of the fan and to drop with one side in the

slot of the printed circuit board.

41. Check the plugs and push them into each other correctly.

42. Check cables for possible damage or kinking and replace if necessary.

43. Check pipe connections, replace sensor.

44. Check the connection of the heat exchanger on the flue gas box, if necessary re-fit, fit new

lip ring.

45 Check all draw-off points, and possibly HW pipes for leaks.

46 Set the switch for the pump to position 3.

47 There is a sticker on the pipe indicating the colour of the sensor cabling.

48 Possibly replace the fuse (must be a reason for the defect); there is no spare fuse, see

diagram on p.22.[?]

49 Possibly replace the fuse (must be a reason for the defect); there is no spare fuse, see

diagram on p.22. [?]

50 Check the mains cable, the wall socket box for voltage; main fuse.

51 Check the programmed parameters on p.18

52 Check the type of room thermostat, and the sticker with the indication on the terminal

connection board on the appliance.

Page 40

Installation manual MIKROFILL ETHOS

Page 38

53 Adjust the step programme, see pp. 18 and 21.

54 Introduce an adjustment in the times for “rising”, in the clock thermostat.

55 Supply (water leaving) is on the left hand side of the appliance return on the right.

56 Push the 4-core cable with miniplug into the three-way valve motor; check the three cables

(2 x red and 1 x yellow) in the terminal connection board gate 9, on the cover, remove and

re-fit.

57 Check the correct fitting of this in-feed sensor in the immersion sleeve.

58 Set with an Allen key of the correct size (8 mm).

59 The appliance needs to be drained on both the CH side and the HW side.

The drain spiral can be taken out of the appliance if the two T pieces on each side of the

spiral are removed with the aid of the flat couplings.

Remove the fixing bracket on the underside of the spiral.

The space between the inner and outer tubes is rinsed with water from the domestic system

and may be furred up or dirty; this part needs to be washed through.

60 It is possible that one pin has been shifted too far in the 18-pin printed circuit board

connector so that the wiring does not connect with the correct pins: check both the left and

right hand sides of the printed circuit board to ascertain whether or not the connector(s) is/are

correctly fitted.

61 There are usually two reasons for a defective gas regulator: the electric coils are defective or

there is an internal fault in the gas valve; in either case it is advisable to replace the whole

gas tap.

62 If the boiler control can be adjusted using the“service software” and the adjusted parameters

are programmed, this is the confirmation that the boiler control has accepted the new

parameters.

63 The correct software (please check this) must be used for programming, at the same time the

threshold values must not be exceeded; try to programme again.

64 The supply voltage needs to be checked with a universal meter; if the supply voltage is

correct (it needs to be between 190 and 250 Volt) the automatic burner needs to be replaced.

65 In order to repair the Reset button, the display can be removed from the plastic spacers and

can once again be checked for correct functioning: if negative, the display needs to be

replaced; if the display functions outside the appliance, you need to check whether the button

has sufficient space under the the plastic cover (is it jammed?); loosen it.

If the “H” does not flash the automatic burner needs to be replaced.

Page 41

Installation manual MIKROFILL ETHOS

Page 39

8 MAINTENANCE

General maintenance / inspection needs at least every 12 months or sooner if the appliance is

not working correctly or the boiler control generates the same fault codes a number of times.

Inspection:

The following operations need to be carried out for inspection.

a. Ask the user about possible problems with the CH appliance and/or any other

problems.

b. Check the installation (water) pressure.

c. Remove the cover of the appliance and inspect all pipes and connections for traces of

water and/or water leaks.

d. Inspect the upper side of the cover and upper side of the appliance for signs of water

or leaks from the air inlet pipe or the venter.

e. Open the siphon, and remove any dirt.

f. If a laptop is available, connect it and check the service page about the reports of

faults, starts and failed/successful attempts at starting.

g. Set the appliance to maximum combustion and measure the load and CO2 % when

operating.

h. Set the appliance to minimum combustion and measure the load and CO2 % when

operating.

i. Note the noise of the CH pump and the fan.

j. For an ETHOS boiler, measure the quantity of hot water and the hot water temperature

with the hot water tap fully opened.

k. While the hot water is warming up, check that the supply to the CH installation does

not become warm.

l. Dismantle the burner unit by removing the 6 M6 nuts, disconnecting the ignition cable

and pulling the burner unit forward.

If the burner is pulled halfway along the furnace, the plug needs to be removed from

the fan cable.

Check the inside of the heat exchanger.

m. Dismantle the plastic air inlet box on the inlet side of the fan, inspect the fan blades.

n. Check the distance between the electrode and burner; this gap needs to be 4 to 5 mm.

4 to 5 mm

4 to 5 mm

Burner

Page 42

Installation manual MIKROFILL ETHOS

Page 40

Maintenance:

Depending on the result of the inspection, the maintenance should be preventative as far as

possible.

The reason for this is:

re a. The comments and remarks of the client need to be taken seriously and the causes need

to be found for any faults and problems.

re b. Pressure of the installation needs to be brought up to between 1 and 2 bar: any leaks in

the installation need to be traced; possibly rectified by installer or service department.

re c. Any leaks need to be rectified.

re d. If water is leaking from the air inlet pipe the cause must be traced; it may be in the roof