Page 1

Installation and Operating manual

Ethos 28cc

Ultra High Efficiency Gas Fired

Condensing Combination Boiler

Page 2

Contents

1. Why choose Mikrofill?................................ 6

2. Safety Considerations................................ 7

3. Symbols .................................................... 7

3.1 Gas Safety................................................... 7

4. Electrical Supply........................................7

5. Terms of Warranty..................................... 8

6. Commissioning Certificate ......................... 8

6.1 Requirements for the system quality............. 8

7. Existing Installations .................................. 8

7.1 Considerations prior to Connection............... 8

7.2 Expansion Vessels9

8. Introduction................................................ 9

8.1 Variable Controlled Output. .......................... 9

8.2 Emissions.................................................... 9

8.3 PPS Plastic Flue System.............................. 9

8.4 Approvals .................................................... 9

8.5 Additional Features...................................... 9

9. Description of Appliances......................... 10

9.1 EC 16, 23, 31 and 38 H.............................. 10

9.2 EC 16, 23, 31 and 38 HS............................ 10

9.3 EC 16, 23, 31 and 38 S.............................. 10

10. Technical Information............................. 11

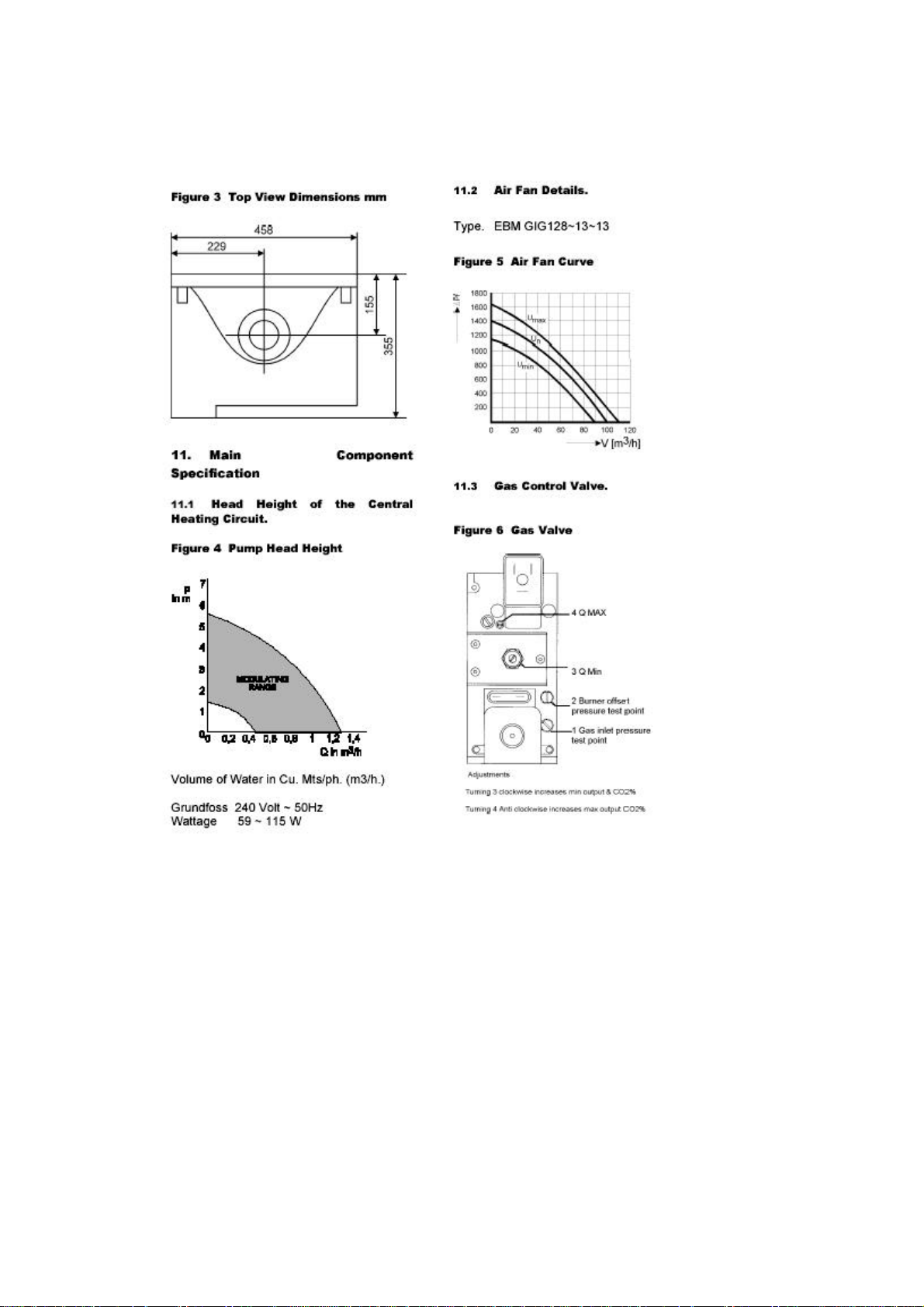

11. Main Component Specification............... 13

11.1 Head Height of the Central Heating Circuit.13

11.2 Air Fan Details......................................... 13

11.3 Gas Control Valve.................................... 13

12. Unpacking & Items Supplied .................. 14

13. Accessories........................................... 14

14. Operation............................................... 15

14.1 Variable Controlled Output ....................... 15

14.2 Variable pump.......................................... 15

14.3 Frost Protection........................................ 15

14.4 Year Long Protection................................ 15

15. Siting the Appliance............................... 15

15.1 Timber Framed Dwellings......................... 16

16. Hydraulic Connections........................... 16

16.1 First Fixing Pipe-work............................... 16

16.2 Type ‘H’ Connections ............................... 16

16.3 Type ’HS’ Connections............................. 16

16.4 ‘S’ Connections........................................ 17

16.5 Clearances .............................................. 17

16.6 Checks before Siting................................ 17

16.7 Fixing the boiler........................................ 17

16.8 Removing the Casing............................... 17

Page 3

17. Flues and Ventilation............................. 18

17.1 Maximum Flue Lengths............................ 18

17.2 Available Flue Components ...................... 20

17.3 Pluming................................................... 21

17.4 Condensate in the Flue. ........................... 21

17.5 Flue Options. ........................................... 21

17.6 Installing a Concentric Flue ...................... 21

17.7 Vertical flue Installations........................... 23

17.8 Modular Installations................................ 23

17.9 Fan Flued Terminal Positions................... 26

18. Gas Supply............................................ 26

18.1 Gas Supply.............................................. 26

18.2 LPG Gas Supply...................................... 27

18.3 Setting The Gas Type .............................. 27

18.4 Conversion to LPG................................... 27

19. Air Supply.................................................28

19.1 Concentric Flue........................................ 28

19.2 Conventionally Flue.................................. 28

19.3 Compartment Ventilation.......................... 28

20. Hydraulic Requirements...........................29

20.1 Expansion Vessel..................................... 29

20.2 Hydraulic Resistance................................ 30

20.3 Condensate Drain.................................... 30

20.4 System By-Pass....................................... 30

21. Electrical Connections..............................33

22. Heating Control Options...........................33

22.1 240 Volt Connections. .............................. 33

22.2 Low Voltage Connections......................... 34

22.3 Built-in clock............................................. 34

23. Boiler Control panel..................................34

24. Boiler Control Panel.................................35

24.1 System water pressure gauge.................. 35

24.2 On / off switch.......................................... 35

24.3 Lcd control display ................................... 35

24.4 Menu - reset button.................................. 35

24.5 Summer winter button.............................. 35

24.6 Engineers button...................................... 35

24.7 Test button............................................... 36

24.8 General.................................................... 36

25. Menu options............................................36

25.1 Party........................................................ 36

26. User programming................................... 36

26.1 Hot Water Temperature............................ 36

26.2 Day temperature function........................... 36

26.3 Time/day function....................................... 36

26.4 Setting the ch timer.................................... 36

26.5 Setting the HW timer.................................. 38

26.6 Setting MR03 times.................................... 38

26.7 Night-time lower 0oc................................... 38

26.8 Holiday function...................................... ... 38

26.9 Installer................................................... ... 38

Page 4

27. Installer Programming..............................39

28. Outside Temperature Control...................40

28.1 Flow Temperature at + 20°C...................... 40

28.2 Outside Temp. Control at - 1°C.................. 41

28.3 Minimum pump speed............................... .41

28.4 Maximum pump speed............................... 41

28.5 Flow temperature secondary circuit........... 41

28.6 Service counter.......................................... 41

28.7 Pump continuous....................................... 41

28.8 Eco/eco+................................................ .... 41

28.9 Post running of pump after HW.................. 41

28.10 Post running of pump after CH............... . 41

28.11 Minimum DHW Capacity.......................... 42

28.12 Maximum DHW Capacity......................... 42

28.13 Maximum CH capacity............................. 42

28.14 Function Setting....................................... 43

29. Commissioning...........................47

29.1 Electrical Checks.................................... ... 47

29.2 Gas Supply............................................. ... 47

29.3 Connection to Pipe-work............................ 47

29.4 Water Treatment........................................ 47

29.5 Flushing System Pipe-work.................... ... 47

29.6 Filling and Venting the System............... ... 47

30. Combustion Ratio.......................48

30.1 Commissioning NG and LPG..................... 48

31. Setting the Maximum CO2 Value.48

31.1 Flue System Check.................................... 49

31.2 STB Test Button (Green)........................... 49

32. Diagnostics.................................49

32.1 Control panel.................................. ...........49

33. Fault Finding...............................50

34. Handing the boiler over..............54

34.1 Customer Familiarisation................. ... .......54

35. Annual Servicing... ...... ...............54

35.1 Service Inspection..................... ................54

35.2 Pre-preventative Maintenance..... .. ...........55

35.3 Service records..................................... .....55

36. Decommissioning the boiler........55

37. User Instructions.........................56

37.1 Annual Servicing...................... .................56

37.2 Decommissioning the boiler.......... ............56

37.3 Built-in clock.................................... ... .......56

37.4 Boiler Control Panel.................................. .57

37.5 System water pressure........................... ... 57

37.6 On / off switch............................................ 57

37.7 Lcd control display..................................... 57

37.8 Menu - reset button.................................... 57

37.9 Summer winter button................................ 57

Page 5

37.10 Engineers button...................................... 57

37.11 Test button............................................... 57

37.12 General.................................................... 57

38. Programming Menu options.......58

38.1 Party........................................................... 58

38.2 Hot Water Temperature.......................... ... 58

38.3 Day temperature function........................... 58

38.4 Time/day function....................................... 58

38.5 Setting the ch timer.................................... 58

38.6 Setting the hw timer................................ ... 59

38.7 Setting MR03 times.................................... 60

38.8 Night-time lower 0oc................................... 60

38.9 Holiday function...................................... ... 60

38.10 Installer................................................... . 60

Figure 1 Overall Dimensions mm........................... 12

Figure 2 Bottom View Dimensions mm.................. 12

Figure 3 Top View Dimensions mm....................... 13

Figure 4 Pump Head Height.................................. .13

Figure 5 Air Fan Curve........................................... 13

Figure 6 Gas Valve.......................................... ...... 13

Figure 7 Pipe-work Layouts............................ ....... 16

Figure 8 Minimum Clearances.............................. .17

Figure 9 Removing the Casing............................... 17

Figure 10 Fixing Dimensions.................................. 18

Figure 11 Flue Design............................................ 19

Figure 12 Thermal Lift........................................ .... 20

Figure 13 Flue Preparation..................................... 21

Figure 14 Dimensions for cutting flue hole............. 22

Figure 15 Wall Terminal......................................... 22

Figure 16 Vertical Wall Terminal............................ 23

Figure 17 Vertical Flue Application......................... 23

Figure 18 Modular Installation................................ 23

Figure 19 Vertical Roof Terminals.......................... 24

Figure 20 Concentric flue fittings............................ 25

Figure 21 Concentric 80mm adaptor...................... 25

Figure 22 80mm Flue Tubes.................................. 25

Figure 23 Fan Flued Terminal Positions............ .... 26

Figure 24 H Type Hydraulic system design............ 31

Figure 25 HS Type Hydraulic system design......... 31

Figure 26 S Type Combi Hydraulic system design 32

Figure 27 Electrical Connections............................ 32

Figure 28 Connecting to the Mains.................... .... 33

Figure 29 Boiler Control panel................................ 34

Figure 30 Weather Compensation..................... .... 40

Figure 31 O/T Ctrl Flow temp 85

Figure 32 O/T Ctrl Flow temp 70oC....................... .40

Figure 33 O/T Ctrl Flow temp 50oC........................ 40

Figure 34 Internal Wiring........................................ 46

Figure 35 Gas valve adjustments........................... 49

Figure 36 Boiler Control panel................................ 56

o

C........................ 40

Table 1 Dimensions & Connections....................... 11

Table 2 Heating Specifications.............................. .11

Table 3 Capacities & Weights............................... .11

Table 4 Hot Water Specifications.......................... .12

Table 5 Connection Values.................................... 12

Table 6 Minimum Clearances................................. 17

Table 7 Flue Resistance......................................... 19

Table 8 Flue Terminal Positions............................. 26

Page 6

Table 9 Ventilation.................................................. 28

Table 10 Expansion Vessel Req............................ 29

Table 11 System Contents..................................... 30

Table 12 Programming Functions.......................... 39

Table 13 Installer Functions................................... 39

Table 14 Minimum & Maximum fan speeds........... 48

Table 15 CO2 Outputs............................................ 49

Table 16 LCD Display

Table 17 LCD

Table 18 Fault Display

Table 19 Non Display Faults and Errors................ 51

Table 20 Reasons For Error Display...................... 52

‘NON FLASHING’

‘NON FLASHING’

FLASHING

burner off..... ..... 50

........................ 51

.............. 50

Page 7

HEALTH & SAFETY INFORMATION FOR THE

INSTALLER AND SERVICE ENGINEER

Under the current issue of the Consumer Protection Act and the Health and Safety at

Work Act it is a requirement to provide information on substances hazardous to health

(COSSH Regulations).

Mikrofill takes every reasonable care to ensure that these products are designed and

constructed to meet these general safety requirements, when properly used and

installed. To fulfil this requirement each boiler is comprehensively tested before

despatch.

When working on the appliance it is the Users/Installers responsibility to ensure that any

necessary personal protective clothing or equipment is worn appropriate to parts that

could be considered as being hazardous to health and Safety.

This appliance may contain some of the items below.

INSULATION AND SEALS

Glass Rope, Mineral Wool, Insulation Pads, Ceramic Fibre, Glass Insulation. Which

may be harmful if inhaled and may be irritating to the skin, eyes, nose or throat? When

handling avoid inhalation and contact with eyes.

Use (disposable) gloves, face masks and eye protection where necessary.

After handling, wash hands and other exposed parts.

When disposing, reduce dust with water spray, ensure parts are securely wrapped.

GLUES, SEALANTS & PAINT

Glues, Sealant and Paints used in the product present no known hazards when used in

the manner for which they are intended.

Page 8

2. Safety Considerations

The installation of this appliance must be carried out by a competent person in

accordance with the relevant Gas Safety Regulations (as amended), Building

Regulations, Model Water Bylaws and the Building Standards (Scotland) Regulations.

Mikrofill shall not be responsible for any damage or loss resulting from failure to carefully

observe the instructions given.

The boiler, except for commissioning purposes, should not be left operating

without the casing being attached and firmly secured

3. Gas Safety

All gas appliances must, by law, be installed by competent persons, e.g. members of

CORGI, in accordance with the Gas Safety Regulations. Failure to install appliances

correctly could lead to prosecution

It is in your own interest and that of safety to ensure that the law is complied with.

Installer training courses are available for CORGI registered installers. Please contact

Mikrofill for more information.

This installation manual contains all the necessary information required to install and

commission the Ethos 28 range of boilers.

Please read this manual thoroughly before commencing installation. The installation

must be carried out in accordance with the manual otherwise the warranty will be void.

Use only original parts for service and maintenance.

After installation ensure the manual is kept close to the boiler and available for reference

purposes.

The installation should also be in accordance with current editions and comply with the

recommendations of the following British Standard Codes of Practice.

CP.331.3 Low pressure installation pipes.

BS.6798 Boilers of rated output not exceeding 60kW.

BS.5546 Installation of gas hot water supplies for domestic purposes.

BS. 5449.1 Forced circulation hot water systems.

BS.5440.1 Flues (for gas appliances of rated input not exceeding 60kW).

BS.5440.2 Air supply (for gas appliances of rated input not exceeding

60kW).

Page 9

4. Electrical Supply

The wiring must comply with the current I.E.E. Wiring Regulations.

The Health and Safety Document No. 635 and the Electricity at Work Regulations 1989

must be followed where applicable.

The boilers are supplied for 230V +10/-15% 50Hz operation. The method of connection

to the mains electrical supply MUST facilitate complete electrical isolation of the boiler.

This may be achieved using a readily accessible 3 amp fused double pole switch clearly

labeled.

THESE APPLIANCES MUST BE EARTHED.

IMPORTANT This boiler is an EC Certified Appliance and must not be modified or

installed in any way contrary to these ‘Installation and Servicing Instructions’.

The manufacturers instructions must NOT be taken in any way as over-riding statutory

obligations.

5 Requirements for the system quality

Before commissioning the appliance it is essential to clean the installation in accordance

with BS 7593: 1992. Installation of in-line strainers is obligatory. As a protection from

corrosion and impurities the water additive Fernox MB1 has to be used and maintained

(4%).

6. Existing Installations

6.1 Considerations prior to Connection

.

IMPORTANT

All Ethos boilers are low water content units. In order to protect and prolong the

working life of the appliance, it is important the general condition of older systems

is carefully considered.

When connecting to an existing installation it is important that system deposits

are removed and are not allowed to contaminate boiler.

This involves the application of a cleanser and allowing it to circulate around the whole

system for a specified time, then flushing to drain. It is important to select the cleanser

appropriate to the installation i.e. for a new installation, or for an existing installation.

It is good practice to clean the system prior to the installation of the new boiler.

The removal of debris, flux residue, grease, metal swarf etc. from new systems and any

black magnetic iron oxide sludge and lime scale from old systems is essential.

In-line strainers must be fitted to the return water connections for full protection. All

installations must be treated with Fernox MB1 at a concentration of 4%.

If plastic pipes are used to connect the boiler to radiators or under floor heating, it

is essential that only those types of plastic pipe that incorporate an oxygen

diffusion barrier be used. If such pipes are not used, the Mikrofill guarantee will

become null and void.

Page 10

6.2 Expansion Vessels

The Ethos 28 models are designed for connection to a fully pumped sealed heating

system only. The appliance is fitted with a 10 litre expansion vessel.

An additional suitable sized expansion vessel may be required to accommodate water

volume change on larger capacity systems.

Select an expansion vessel that matches the volume of the CH system and the static

pressure.

Please contact Mikrofill Technical Department for assistance is required.

Installation should comply with BS7074 part 1 and BS5449.

Page 11

7. Introduction

The boiler features the very latest in technology. Developed around an innovative back

panel the boiler uses laser welded waterways to interconnect the boilers main

components.

To facilitate ease of servicing stainless steel coiled heat exchanger and other major

components are simply plugged into the panel.

The boilers incorporate a premixing, fully modulating, radiant gas burner, 3 bar pressure

relief valve, manometer and circulating pump.

7.1 Variable Controlled Output

The Ethos 28 cc incorporates a fully modulating output to ensure that the burner

output is matched to the system requirements at all times.

7.2 Emissions

.

The premium burner has excellent combustion efficiencies and ultra low

emissions levels, in excess of Zedbuk A classification.

7.3 Approvals

The unit has been approved according to the European standards (CE) and the

requirements for cleaner combustion (RAL UZ61)

7.4 Additional Features

Corrosion resistant stainless steel heat exchanger. Integral sensors (PTC) for monitoring

flow and return water temperatures. 3 way valve and facilities for connection to DHW

storage. Computer controlled combustion analysis with built in fault diagnosis facility.

8. Description of Appliances

8.1 Ethos 28cc

This model is suitable for a central heating system with hot water output controlled using

a 3 way diverter valve (spring return to heating). The appliance produces a low

temperature output for under-floor heating or a fixed/variable temperature output for

connection to radiators. Flow temperature to hot water cylinder can be set as required

(max. 85OC)

Hot water cylinders must be indirect and to aid efficiency and fast recovery times (all

appliances are hot water priority) should be of the high recovery type. Recommended

minimum primary heat requirement - 25kW.

The unit has a variable capacity of 20 to 100%, while the maximum capacity can be set

and adapted to the capacity of the CH system.

Page 12

8.2 Ethos 28cc

This unit has a built-in heat secondary heat exchanger and Hot water production is

continuous. The unit has a variable capacity of 20 to 100%, while the maximum capacity

can be set and adapted to the capacity of the CH system.

10. Technical Information

Table 1 Dimensions and Connections

Product Identification Number CE ~ 0085AR0057

Appliance Category 2ELL3B/P

Dimensions (H x W x D) 950mm x 458mm x 355mm

Heating Circuit Connections 22mm

Gas Connection 15mm

Condense Drain Connection ¾ BSP

Air Supply/Flue Connections

Table 2 Heating Specifications

Model – Ethos 28cc

Maximum Rated Input kW 22

Nominal Output To Heating 80/600C

Minimum Output To Heating 80/600C

Nominal Output To Heating 50/300C kW 23.1

Minimum Output To Heating 50/300C kW 3.6

CO2 % content at max/min load CO2 % 9 9

Dew Point of Flue Gases 00C 52

Flue Gas Temp @ 80/600C (Amb 200C) 00C 75

* Maximum Flue Resistance Pa 100

pH value of condensate water PH 4-5.5

Pump Pressure @ 30kW and 20K Bar

Maximum Flow Temperature 00C 85

Min/Max filling pressure

**Efficiency @ 75/600C

**Efficiency @ 40/300C % 108.5

125/80mm

kW

kW

bar

%

E28

21.4

3.1

0.15

0.5 - 3.0

104

* At this resistance, the load will remain within the limits indicated on the data plate.

** European calculation methods are based on efficiency of 100% in units that do not

condense the flue gases, and of 110% in condensing units.

Page 13

Table 3 Capacities and Weights

Model

Heating Water Capacity litres 1.8

Heating Water Coil Capacity (S models) Litres 1.3

Weight (empty) Kg 37

Table 4 Hot Water Specifications

Model

Maximum Rated Input kW 28.0

Modulating Output kW 3.4-28

Hot Water Flow rates at .ô 30K (S type) L/min 13.4

Maximum Tap Water Pressure bar 10

Table 5 Power Details

Min/Max Gas Pressure mbar 15/50

Minimum Input Rate Natural Gas m/h3 0.36

Maximum Input Rate Natural Gas m/h3 2.67

Electrical Supply VAC 230

Power Consumption Average

W

EC23

EC23

60

Page 14

12. Unpacking & Items Supplied

The following items are supplied with the Boiler.

Installation manual (to be left with the boiler). Replacement fuses (located top left of

control panel). Vent key. Mounting bracket. Outside air temperature sensor

13. Accessories

The following items are also available from Mikrofill at extra cost.

Colour coded 1/4 Turn Isolating Valves.

Stainless Steel Flexible Pipe Connections.

In line Filter/Strainers.

Page 15

Condensate sump pump for below ground installations. N.B. LPG installations must not

be installed below ground level.

Mikrofill servicing software and RS 2323 interface cable for connection to a PC.

Mikrofill modulating room sensor.

Mikrofill Cable for connecting three way diverter valve (external to boiler).

Mikrofill cascade manager for controlling multiple boiler installations supplying heat to

the same system. A maximum of five boilers can be connected.

Mikrofill mixing valve control unit

For more details please contact the

Mikrofill technical department.

Mikrofill comprehensive range of flue kits, fittings and accessories.

80/125 Concentric 500 mm Fanned Flue Kit

80/125 1000mm length Galvanised Concentric Flue

80/125 500mm length Galvanised Concentric Flue

80/125 Galvanised 90 degree elbow

80/125 Galvanised 45 degree elbow

80mm 1000mm flue pipe

80mm 45 degree Elbow

80mm 45 degree connector

80/125 Roof Terminal

Pitched roof tile flashing

Aluminium flat roof terminal/chimney top flashing

80mm Wall Fixing Clamp

125mm Wall Fixing Clamp

80mm flexible flue liner (per metre)

80mm flexible flue liner 360 degree spacers

80mm flexible flue liner chimney terminal

80mm flexible flue liner chimney terminal clamp

80mm flexible flue liner boiler flue connector

14. Operation

A key component of the boiler is the fully modulating premix, radiant, gas burner, which

is capable of producing a Variable Output (20% to 100% ratio).

As a result of the extremely low combustion temperatures produced during combustion,

emissions of harmful atmospheric pollutants are dramatically reduced, (NOx 20mg\kWh

CO 14mg\kWh).

Page 16

14.1 Variable Controlled Output

The microprocessor controlled modulation system with integral fault diagnostic facility,

ensures that optimum efficiency is maintained when operating in both heating and DHW

modes.

The premixing radiant burner modulates according to the required heat output.

A 24-Volt, high efficiency fan is used with a variable speed and power capacity; if the

heat demand decreases, the fan will turn at a lower speed, which results in a lower

power consumption.

The fan is programmed to supply given amounts of air for specific burner outputs.

The air pressure generated by the fan then controls the gas valve which in turn, matches

the gas pressure to the required gas to air ratio.

The combustion gases then pass through the stainless steel heat exchanger to

atmosphere.

14.2 Variable pump

A variable speed integral circulating pump is supplied, which operates at different

speeds and results in a lower power consumption (between 30 and 119 Watts). This

feature is to help maintain a temperature difference of 20OC between the flow and return

temperatures on systems using radiators.

14.3 Frost Protection

If the flow temperature falls below 80C, in order to provide frost protection, the pump will

run even though there may be no demand for heat. If the temperature continues to fall,

at 50C, the burner will also ignite. At 100C the appliance will return to standby mode.

Remember when handing over the appliance to advise the end user on the precautions

necessary to prevent frost damage to the system during frosty conditions. Stress the

importance of leaving the system turned on e.g. continuous low temperature setting in

extremely cold weather.

14.4 Year Long Protection

During summer months, the pump and mixer valve (if fitted) are exercised daily. This

prevents seizure of internal components thus reducing maintenance costs.

15. Siting the Appliance

In siting the boiler, the following limitations MUST be observed

The boiler is not suitable for external use.

The installation MUST allow space for servicing to the front and below the boiler and for

the circulation of ventilation air around the boiler. Figure 8 shows the minimum

clearances required for safety and subsequent service. Due regard must be given to the

flue discharge position to minimize possible pluming.

Page 17

The room must be dry and protected from frost.

With condensing boilers pluming at the flue is a normal occurrence.

Any combustible material near to the boiler or its flue system and water pipe-work must

be protected to ensure it does not exceed 650C.

In certain locations the flue outlet may be susceptible to high winds or air turbulence

which may create a negative flue pressure. Flue terminal outlets in such exposed

conditions should be avoided. When operating at low fan speeds flame lift may occur.

This can be overcome by raising the minimum fan speed.

The Ethos 28cc may be installed on the inner face of an external wall and some internal

walls providing they are flat, vertical, of a non-combustible material and are capable of

supporting the weight of the boiler and any other ancillary equipment.

Where installation will be in an unusual location, special procedures may be necessary.

Detailed guidance on this subject can be found in BS. 6798.

15.1 Timber Framed Dwellings

When installing the boiler into a timber framed dwelling, it must be fitted in accordance

with the British Gas publication ‘Guide for Gas Installations in Timber Framed Housing’

ref. DM2.

For further advice contact the Mikrofill Technical Helpline.

16. Hydraulic Connections

16.1 First Fixing Pipe-work

All the pipe-work and wiring connections enter at the bottom of the unit. To ensure a tidy

installation it is important to consider at the first fixing stage the order you arrange the

pipe-work and if applicable any electrical trunking. Figure 7 shows the order in which to

fix the pipe-work.

16.2 Type ‘H’ Connections

Page 18

1) Cable Gland

2) Syphon Flush (No permanent connection required)

3) Heating Flow ~ 22mm

4) Additional Cable Entry Point

5) Gas Inlet ~ 15mm.

6) Heating Return ~ 22mm.

7) Condensate Discharge ~ ¾ M.I.

16.3 Type ’HS’ Connections.

1) Cable Gland

2) Syphon Flush (No permanent connection required)

3) Heating Flow ~ 22mm

4) Additional Cable Entry Point

5) Flow Domestic Hot Water 22mm

6) Gas Inlet ~ 15mm

7) Return Domestic Hot Water 22mm

8) Heating Return ~ 22mm

9) Condensate Discharge ~ ¾ M.I.

16.4 ‘S’ Connections

.

16.5 Clearances

1) Cable Gland

2) Syphon Flush (No permanent connection required)

3) Heating Flow ~ 22mm.

4) Additional Cable Entry Point

5) Flow Domestic Hot Water 22mm

6) Gas Inlet ~ 15mm

7) Cold Mains Water ~ 22mm

8) Heating Return ~ 22mm

9) Condensate Discharge ~ ¾ M.I.

For ease of installation, necessary inspection and commissioning, the following

clearances are recommended.

Table 6 Minimum Clearances

Sides 50mm

Above 250mm

Below 150mm

Front 455mm

Page 19

16.6 Checks Before Siting

Before commencing to install this appliance ensure the design specification complies

with all of the requirements contained in these installation and servicing instructions and

any statutory documents which may apply.

16.7 Fixing the boiler.

When unpacking the unit for the first time, take adequate precautions to protect the

surrounding floor coverings. The boilers are factory tested and contain residues of water

that could cause dampness and possible staining if contact with carpets and floor

coverings is not prevented. Unpack the appliance and ensure that the items listed on

have been supplied.

16.8 Removing the Casing

To remove the casing lay the unit down on the floor with the casing facing upper most.

Loosen the centre screw and undo the two toggle casing clips located on the bottom of

the unit. Pull the casing upwards, lifting up and off the internal locating lugs. Place the

casing to one side taking care not to scratch the casing or control panel cover. (see

figure 9.)

Take any necessary precautions to protect the surrounding working area and

decorations from dust and damage. Make one final check on the location pay particular

attention to the flue outlet (consider pluming) and the condensate discharge pipe route.

Page 20

Install the Ethos 29cc as close as possible to the hot water taps to avoid the hot water

pipes from becoming too long. This prevents unnecessary waste of water.

When you are satisfied the location meets all the required criteria mark out the wall for

required fixing points. Use the fixing bracket as a template.

Check for horizontal and vertical alignment and drill 4 holes as marked using a No.14

masonry drill. Clear the surrounding area of any dust and debris and secure the

mounting frame to the wall using suitable screws and plugs. Locate the boiler on the

mounting frame.

NB The appliance should be 10mm off the wall measured at the base of the panel.

Failure to observe this will result in condensate becoming trapped inside the heat

exchanger. Component failures as a result of incorrect installation will not be covered by

the boilers normal warranty.

Please remember when using power tools to take all necessary safety precautions and

always wear safety goggles.

17. Flues and Ventilation

The internal boiler flue system is manufactured in P.P.S plastic and the flue outlet may

be connected to an external P.P.S plastic or stainless steel flue system.

17.1 Maximum Flue Lengths

The flue materials, flue insulation, the amount of vertical and horizontal pipe and the

amount of bends incorporated determine the maximum permissible flue length. The

excess fan pressure available for overcoming the frictional resistance of the flue system

is 100 p.a.

Page 21

Thermal lift is generated naturally in the vertical part of a flue system, reducing the

overall resistance of the system.

The available lift may be calculated from the Thermal lift graph and deducted from the

total calculated flue resistance.

For installations requiring greater flue lengths - please contact the Mikrofill technical

department for advice.

The flue should terminate with a suitable terminal.

17.3 Pluming

The siting of the terminal is not critical with regard to the performance of the appliance.

However In certain locations the flue outlet may be susceptible to high winds or air

turbulence. Sudden gusts may create a negative flue pressure. Flue terminal outlets in

Page 22

such exposed conditions should be avoided. When operating at low fan speeds flame lift

may occur. This can be overcome by raising the minimum fan speed.

In certain conditions pluming from the flue, although harmless, may cause a nuisance.

Please site the flue outlet to minimise any inconvenience the discharge of combustion

products or possible pluming may cause. Where a terminal is so sited to be less than

2m above the level of any ground, balcony, flat roof, or place to which people have

access, or there is a likelihood of accidental contact by persons or damage to the

terminal, a suitable guard MUST be fitted. Terminal guards are available from Mikrofill.

17.4 Condensate in the Flue

Condensate formed must be cleared from the flue system and adequate care is required

to ensure all flue pipes are self draining. All internal and external potential collecting

points must be drained. In addition to avoid freezing external flue ductwork must be

insulated.

To ensure the safe and satisfactory operation of the boiler the chimney system must be

capable of the complete evacuation of combustion products at all times.

17.5 Flue Options

The boiler may be installed either as a room sealed, fanned flued appliance using the

Mikrofill P.P.S plastic 125mm/80mm concentric flue system or alternatively,

conventionally flued, using a single skin 80mm P.P.S. plastic pipe.

17.6 Installing a Concentric Flue

Connect the concentric elbow into the flue/vent connection. Mark the wall around the

flue, remove the concentric elbow cover the appliance and cut or drill a 130mm diameter

hole through the wall. Measure and cut the concentric flue pipe to pass through the

previously made hole and into the concentric 90o bend. Figure 13 Flue Preparation

Apply a chamfered edge to the cut ends, apply silicone lubricant and insert through the

wall and into the flue/air socket. The overall projection of the finished pipe should leave

the air holes 20mm clear of the surrounding wall as per figure 15.

NOTE: When fitted, it is important to position the flue outlet with a slight fall so that the

80mm flue pipe is sloped back towards the boiler.

Page 23

Failure to observe this requirement will result in condensate running out of the flue pipe

and over the external brickwork causing possible staining and or freezing. Installed

correctly the flue pipe will self drain back through the boilers internal condensate route.

Make good to internal and external walls and fix an external stainless steel terminal

guard if required.

The final location of the Flue Outlet terminal should comply with figure 23 and table 8.

In certain circumstances the location of the boiler may leave the flue outlet in a position

that does not comply with figure 23, or where pluming is a nuisance.

The Mikrofill flue system has been designed to overcome this and the 80mm P.P.S. flue

pipe may be simply re-routed to terminate in a more suitable location. To do this simply

remove the 80mm stainless steel flue grill and insert either a 900 or 450 bend

Note: two 450 may be used to form a swan neck returning the flue pipe back to the wall

for clipping.

Route the pipe to the desired location and terminate with a suitable bend to direct the

flue gases away from the wall or any obstruction. When you are satisfied that the

location complies with the requirements of figure 23 replace the stainless steel 80mm

flue grill..

Alternatively a 900 terminal fitting may be purchased from Mikrofill and the flue routed

vertically.

Page 24

17.7 Vertical flue Installations

For vertical flue applications a range of fittings for both pitched and flat roofs are

available. Please contact Mikrofill for further advice.

17.8 Modular Installations

For multiple boiler (modular) installations Mikrofill supply a range of larger diameter flues.

Sizes are available in 150mm, 200mm and 250mm. For assistance in flue design and

specification please call the Mikrofill technical department.

Concentric vertical flue fittings are available from Mikrofill.

Concentric flue components have push together spigot and socket joints. The inner flue

gas tube has silicone seal rings located in the socket component. The outer air tube has

Page 25

EPDM rubber seal rings located in the socket component. To aid assembly and

assurance that the joints have been fully pushed home, the seal rings and make ends of

tubes and fittings should be lightly lubricated with silicone grease.

Additional 80/125mm concentric flues tubes and fittings are available

17.9 Fan Flued Terminal Positions

Page 26

Terminal Positions Min distance

A: Directly below an opening window or other

opening, e.g. air brick

Directly above an opening window or other opening,

e.g. air brick

B: Below gutters, soil pipes or drain pipes. 75mm

C: Below eaves 200mm

D: Below balconies or car port roof 200mm

E: From vertical drain pipes and soil pipes 150mm

F: From internal and external corners 300mm

G: Above ground roof or balcony 300mm

H: From a surface facing a terminal 600mm

J: From an opening in a car port (e.g. door, window)

into a dwelling

K: Vertically from a terminal on the same wall 1500mm

L: Horizontally from a terminal on the same wall 300mm

300mm

300mm

1200mm

18. Gas Supply

The boiler is set for use with natural gas.

18.1 Gas Supply

Pipe-work from the meter to the boiler MUST be of an adequate size.

DO NOT use pipes of smaller size than the boiler inlet gas connection.

The gas supply to the boiler must be capable of maintaining a minimum pressure

of 20 mbar measured at the inlet to the boiler, with all other gas appliances working.

The installer should install a pressure test point adjacent to the gas inlet connection.

18.2 LPG Gas Supply

For LPG the gas supply to the boiler must be capable of maintaining a minimum

pressure of 37 mbar measured at the inlet to the boiler, with all other gas appliances

working. The complete installation MUST be tested for soundness and purged in

accordance with C.P. 331.3. The gas valve fitted to the boiler is not designed to

withstand pressures in excess of 60 mbar.

When carrying out the pressure test on the service pipe-work it is essential that the gas

cock fitted to the boiler is in the closed position, failure to do so will result in serious

damage to the boiler.

18.3 Setting the Gas Type

When the Ethos 28cc leaves the factory it set up for use with Natural Gas. It can

however be easily adjusted for use with LPG

Page 27

18.4 Conversion to LPG

If the appliance is being used with LPG then a conversion kit is available from Mikrofill.

The contents of the LPG conversion kit include the following items:

1 x Propane injector 5.7mm

1 x Injector 3.5mm

1 x 10mm plastic air box plug

(for EC 16 & 23)

1 x 15mm plastic air box plug

1 x 13mm plastic air box plug

To convert the appliance to LPG complete the following procedure.

Isolate the boiler from the gas and electricity supplies.

Disconnect the unions either side of the gas valve.

Screw the 3.5 injector into the gas inlet side of the valve and the 5.7mm injector into the

gas outlet side of the valve.

Close the hole in the front of the air box (attached to the air fan assembly) using a plastic

plug included in the conversion kit.

Re-connect the gas valve making sure the sealing washers are located properly.

Turn on gas supply and check for gas soundness.

Write on the identification plate that the appliance has been converted for LPG.

All gas service pipe-work from the meter to the boiler should be either mild steel pipe or

copper.

Page 28

19. Air Supply

19.1 Concentric Flue

If installed with a concentric flue and as a room sealed appliance the boiler does not

require that room or internal space to have a permanent air supply.

19.2 Conventionally Flue

Safe, efficient and trouble-free operation of conventionally flued gas boilers is dependant

on the provision of an adequate supply of fresh air to the room in which the appliance is

installed. Ventilation by grilles communicating directly with the outside air or a ventilated

adjacent room is required. Where the combustion air is being taken from an adjoining

room the room itself must be ventilated to satisfy the combustion air requirement of the

appliance. Where the appliance is to be installed as a conventionally flued appliance

sufficient combustion air should also be allowed. To calculate the amount of free

combustion air required for the appliance table 9 should be used. Permanent openings

are based on the total maximum rated input.

Position ventilation grilles to avoid the risk of accidental obstruction by blocking or

flooding. BS 5540.2

Table 9 Ventilation

Vent Position Into room or internal

space

High level 9 cm2 per kW of input 4.5 cm2 per kW of input

Low level 9 cm2 per kW of input 4.5 cm2 per kW of input

In a room or internal space None required None required

Conventionally flued appliance

Direct to outside air

Vent Position Into room or internal

space

High level 9 cm2 per kW of input 4.5 cm2 per kW of input

Low level 18 cm2 per kW of input 9.0 cm2 per kW of input

Direct to outside air

Any air vent, which is to supply air to an open flued appliance, must not communicate

with any room/space containing a bath or shower or private garage.

If further guidance on ventilation is required then consult BS. 5440.2.

Detailed recommendations for air supply requirements are given in BS.5440.2. and can

also be found in the CORGI Gas

Installer Manual. The following notes are intended for general guidance only. Where

open flued appliances total input ratings exceed 7 kW the room or internal space

containing them must have an air vent of minimum effective area 4.5 cm2 for every 1 kW

in excess of 7 kW.

19.3 Compartment Ventilation

Due to the low standing losses compartment ventilation is not required.

20. Hydraulic Requirements

Page 29

The boilers are intended to be used in conjunction with FULLY PUMPED, SEALED

systems subject to the requirements below. They are NOT SUITABLE for use on gravity

circulation systems. The boiler must not be used for direct hot water supply.

Under floor heating:

Despite the low boiler flow temperatures feature, in the event of control and/or

mechanical failure or incorrect adjustment, to prevent damage to the installation or

associated pipe work all low temperature under floor installations require an obligatory

mixing valve installing as part of the system controls or a high limit thermostat set at

60oC.

In hard water areas suitable protection should be provided to prevent the build up of

deposits in the primary hot water heat exchanger. The appliance guarantee does not

extend to failure because of lime scale or other contamination.

Recommended minimum coil capacity 25kW.

The boiler must be capable of being adequately vented of air. Drain taps MUST be

located in accessible positions, which permit the draining of the whole system - including

the boiler. Drain taps should be at least 1/2 inch BSP nominal size and be in accordance

with BS. 2879.

In order to facilitate servicing of the unit, full flow isolating valves must be fitted to all

water and gas connections.

20.1 Expansion Vessel

For systems having a larger water capacity, multiply the total water content (boiler and

system) by the factor to obtain vessel size in litres.

EXAMPLE 1.

Central heating system filled to 1 bar. Total system water content 60 litres Multiply 60

(water content litres) x 0.11 (factor from chart) = 6.6 litres. Vessel required 6.6 litres.

Vessel supplied 10 litres. Vessel adequate.

EXAMPLE 2.

Central heating system filled to 1 bar. Total system water content 150 litres

Multiply 150 (water content litres) x 0.11 (factor from chart) = 16.5 litres.

Vessel required 16.5 litres. Vessel supplied 10 litres. Vessel inadequate.

Additional vessel 6.5 litres required.

When system content unknown or difficult to determine the following table can assist

with calculating water content.

Table 11 System Contents

New Radiators

Old Radiators 12

U/Floor Heating 22

Approx. Litres per

kW

9

Page 30

Expansion vessels should be connected to the system at a point close to the pump inlet

in order to maintain positive pressure throughout the system.

The central heating system should be in accordance with the recommendations given in

BS. 6798 and BS. 5449.

20.2 Hydraulic Resistance

The integral boiler pump is designed to provide an adequate flow rate through the boiler

at all times. Therefore, if an additional duty pump is to be fitted to the system, the boiler

resistance can be ignored.

20.3 Condensate Drain

The condense discharge pipe should be continued in ¾ inch plastic waste pipe into the

household drainage system or out through the wall to an existing gully or soak away. To

minimise the risk of freezing all condensate waste pipe-work fitted externally should be

32mm. (The existing drainage system should be corrosion resistant).

In order to avoid damage to the boiler caused by a blocked drainage system, the

condense disposal pipe should include a tundish. In these cases the pipe-work

connected to the internal household drainage system should be fitted with a deep seal

running trap.

Horizontal runs of condense discharge pipe must fall at a rate of 40mm per metre and

any external sections of pipe must be protected against the risk of freezing. Due care

should be taken when installing the condensate disposal system to minimise the risk of

blockage, as this would cause the condensate to back up inside the boiler.

Mikrofill will not accept any liability for damage caused to the boiler should this situation

occur. If the connection to an existing drain is not possible, the condensate may be

discharged in to a purpose-built soak away.

When the boiler is installed below ground level, i.e. a basement or cellar, (NB the

appliance must not be installed below ground when using LPG) provision should be

made for the disposal of the condensate via a sump pump arrangement.

20.4 System By-Pass

The boiler incorporates a bypass making it unnecessary to fit a system bypass.

Page 31

Typical installation serving domestic hot water and heating using integral expansion

vessel and modulating circulating pump. Hot water production has priority controlled by

spring return to heating diverter valve wired to boiler. Flow temperature to hot water is

constant temperature to heating may be fixed or variable (weather compensated).

Page 32

21. Electrical Connections

The boiler has a “Wieland” plug connector for connection to the mains as part of the

wiring cen tre located at the bottom left hand side of the boiler.

Any external wiring to the boiler must be carried out in accordance with the IEE Wiring

Regulations and any local regulations.

Page 33

The Ethos 29cc is designed for 230 ~ 240v 50Hz single phase operation. The method of

connection to the mains supply should allow for complete electrical isolation of the boiler,

preferably by labelled double pole switched spur. The boiler must be protected by a 3

amp fuse. The point of connection to the mains should be readily accessible and

adjacent to the boiler. If the boiler is to be sited in a bathroom the connection should be

outside the room.

It is essential that the electrical supply in the property should be properly earthed in

accordance with current IEE Wiring Regulations.

Using 3 core 1.5mm2 cable connect the boiler to the mains electrical supply by passing

the cable through the cable duct and connecting to the Wieland connector as shown in

figure 28.

22. Heating Control Options

There are various methods of controlling the heating system from the boiler.

Using a regular room thermostat.

If a room thermostat is installed there must not be any thermostatic radiator valves on

the radiator in that room.

Using a modulating room stat

With this special type of room thermostat, the boiler can be regulated in a modulating

fashion. Please contact the Mikrofill technical department for more information.

If a room unit is installed there must not be any thermostatic radiator valves on the

radiator in that room.

Using the built-in weather compensating control

This only requires an outside temperature sensor. (Mounted on North facing wall)

The integral boiler weather compensating controller is adjusted so the relationship

between the outside temperature and the boilers flow temperature is sufficient to

maintain the building temperature.

Page 34

As the outside air temperature rises and falls a modulating control is achieved. Set up

this way the temperature for the house is not controlled from one room, but on the basis

of the outside temperature.

Using a regular room thermostat, it is also possible to change the relationship between

the outside temperature and the supply temperature. Outside temperature is the

preferred control if control from one room is not required or not possible. If outside

temperature control is used, the radiators must be fitted with thermostatic valves.

22.1 240 Volt Connections

The 240 volt terminal strip can be used to connect the following.

External pump(s) with a maximum of 500 Watt. This connection will supply external

pump(s) when the boilers integral pump is running.

A 240 Volt room thermostat.

Switch over three way valve (spring return type) or loading pump for the hot water

cylinder.

Three way modulating mixing valve for a secondary circuit. The mixing valve and pump

for this circuit has to be wired back to the control unit MR03 (available form Mikrofill) an

additional pump greater than 500watts may also be connected.

22.2 Low Voltage Connections

The low voltage terminal strip can be used to connect the following.

Hot water cylinder sensor.

External temperature sensor.

RE2132 Modulating room sensor.

All of the above are available from Mikrofill

NB

Do not connect 240 volts to the low voltage terminal strip.

22.3 Built-in clock

The appliance has a unique built-in 3 channel programmable time clock. This enables

not only the setting of the heating times for various temperatures, but also the heating

times for hot water. During programmed off periods Combi models will maintain a

minimum storage temperature of 40oC. For H and HS type appliances connected to hot

water cylinder for this function to operate temperature control has to be provided with a

sensor (available from Mikrofill). When hot water temperature control is provided by a

cylinder thermostat this function is not recognised.

Page 35

23. Boiler Control panel

24. Boiler Control Panel

The boiler control panel incorporates the following features.

24.1 System water pressure gauge

Informs user of current system water pressure.

24.2 On / off switch Boiler isolating switch

24.3 Lcd control display

The display has two lines: the upper line indicates the current operating status e.g HW

DEMAND and either “S” (summer) or “W” (winter / “D” (day) or “n” (night).

b. the lower line indicates on the left-hand side the current boiler water temperature, and

on the right-hand side the time.

If the button is pressed briefly, the following data may be viewed in the following order:

Press 1 T1 supply temperature in the system

Press 2 T3 tap water temperature

Press 3 T4 return temperature in the system

Press 4 T5 water, if connected, or the maintained temperature of the built-in tap water

exchanger of the boiler

Press 5 T6 outside temperature

.

Page 36

Press 6 Room 1 - heat demand value of connected room unit

Press 7 Speed 1 - fan speed

Press 8 Pump - % pump speed in relation to maximum

NB Only the values of connected components are shown.

24.4 Menu - reset button

This button when pressed allows: Access to 3 layer menu programming options. Access

to current boiler status displays. Confirms an entry when programming control. Reset the

boiler after lockout. For meaning of lockout “FLASHING” display please refer to installer

manual.

24.5 Summer winter button

The "-" button is used in combination with the menu button for programming purposes.

The "chimney sweep" symbol (meant for the fitter).

Press once: The unit will operate continuously at 50%; sensors or room units will not

switch it off, on ly the maximum control thermostat.

This mode is meant for measuring emissions (CO, CO, NOx).

Press twice: The unit can now operate at all loads, by pressing the "+" and "-" buttons if

the menu button is also pressed seven times, the display will show the speed. This

mode is used to set the gas valve, both at minimum and at maximum load.

24.7 Test button

Checks overheat safety feature. When the burner is on and the button depressed, the

burner will shut down when button released, the unit will start up again. . If the unit does

not switch off, the wiring harness must be checked for short circuits, or the maximum

thermostat must be replaced.

Checks pump function. When the burner is off and the button depressed, the pump will

run at 100% speed for approx 2 seconds.

Page 37

24.8 General

To access the programming mode for times, temperatures, etc., the "Menu" button must

be depressed for 3 seconds the screen will briefly display “-MENU-“ and display a menu

option. Use the "+" and "-" buttons to scroll through the various options and the "MENU"

button to select and confirm changes.

25. Menu options

25.1 Party/Extension Time

This function allows you to extend the current heating period. To access the party option

press the “-MENU-“ button once and “____hours” will flash on the screen, press “+” or “-“

to enter a value then press “-MENU-“ button once to confirm entry. After expiry of the

extension time set, the night-time temperature will start; if the lower night temperature

had already started at the time of setting the party time, the daytime temperature will be

obtained for the duration of the time set, after which the night-time temperature will be

resumed.

Range 0 – 24 hours. Default 0 hours.

26. User programming

26.1 Hot Water Temperature

This function allows you to select the maximum hot water temperature. For appliances

connected to hot water cylinders where temperature control is provided with a sensor

(available form Mikrofill) this function allows you to select the maximum temperature for

the water in the cylinder. To access the “TEMP DHW” option press the "MENU" button

until “_____” oC flashes on the screen. press “+” or “-“ to enter a value then press “MENU-“ button once to confirm entry. Temperature range 40 - 60oC. Default 60oC.

26.2 Day temperature function

When the boiler is set up for outside temperature control (with or without a room

thermostat or room unit) adjusting this setting raises or lowers the heating curve. This

has the effect of increasing or lowering the boiler water temperature and ultimately

increasing or lowering the room temperatures as the cooler or warmer water circulates

through the heat emitters. Raising or lowering the building ambient temperature is

possible without adjusting the setting of the room thermostat or room unit. If the boiler is

set up to work without outside temperature reference then the feature has no function.

To access press "MENU" button as before then press “+” or “-“ to enter a value then

press “-MENU-“ button once to confirm entry. The default value for this setting is 20oC

26.3 Time/day function

Having selected this function, there is a subprogram with two options:

the correct time, in minutes

To change the time press “-MENU-“ button once and the use the press “+” or “-“ to

change the time then press “-MENU-“ button once to confirm entry.

the day

Page 38

To change the day press “-MENU-“ button once and the use the press “+” or “-“ to set

the day then press “-MENU-“ button once to confirm entry.

26.4 Setting the ch timer

When a RE2132 room unit is fitted the built in timer function takes priority over the

boilers timer control. In this case the boiler timer should be set to 00.00 hours.

This programme enables the setting of 3 time blocks (3 start and 3 end times) per day

(24 hours) for higher and lower room temperatures. This menu has two submenus:

a. the days of the week

b. the start and end times of each block

To access this function from the main menu display press “MENU” button for three

seconds.

You will arrive at “PARTY O HOURS” in the display.

Press the “+” button three times to arrive at SET CH TIMER

Press the "MENU" button once and the first display will be "Monday" use the "+" and "-"

buttons to scroll through this submenu to reach the day you want to change.

Having found the correct day, press the "MENU" button once to arrive at “CopySU>MO”

ignore this and press the "+” button once to arrive at “SWITCH ON 1”

“MO 00:00”

Press the "MENU" button once and the hours “00” part of the display will start flashing.

This sets the hour the heating will start for the first of three possible on times per day

Adjust the hour by pressing the "+" and "-" buttons. When the correct time is displayed

confirm by pressing "MENU" button once and the minutes part of the display “00” will

start flashing.

Adjust the minutes by pressing the "+" and "-" buttons. When the correct time is

displayed confirm by pressing "MENU" button once. Press the "+” button once to arrive

at “SWITCH OFF 1” “MO 00:00”

This sets the hour the heating will switch off for the first of three possible off times per

day.

Adjust the hour by pressing the "+" and "-" buttons. When the correct time is displayed

confirm by pressing "MENU" button once and the minutes part of the display “00” will

start flashing. Adjust the minutes by pressing the "+" and "-" buttons. When the correct

time is displayed confirm by pressing "MENU" button once. Press the "+” button once to

arrive at “SWITCH ON 2” “MO 00:00”

Repeat as above to programme all 3 start and 3 end times

Page 39

If you wish to ignore any periods then simply enter "0.00".

Please note due to the nature of the pre-programmed boiler software there may be a

half-hour delay in the CH system start and off times.

This period can be offset by adjusting the on and off times.

e.g. if you leave the house at 10:00 then enter 9:30 and if you are returning at 12:.30

enter 12.00.

Always confirm the times with the "MENU" button.

Programming all periods - note: you may ignore any blocks by entering 00:00 with the

exception of “SWITCH ON 1” and “SWITCH OFF 1” for which you must enter a real time.

After you have programmed all three on and off period’s press the "+" button to arrive at

“<-BACK” Press the MENU button and you will arrive at TUESDAY.

Press the MENU button again and you will arrive at COPY “MO -> TU”

You can now copy the previous days program onto the next day e.g. Mondays times to

Tuesday by pressing MENU or alternatively program in new times by pressing “+” button

and repeating the process described in the previous section.

To copy the previous days program Press the "MENU" button, you arrive at:

“MON -> TUESDAY”

Press the "MENU" button once to copy and the display will change to “WEDNESDAY”.

Press the "MENU" button, you arrive at:

“TU -> WEDNESDAY”

Press the "MENU" button once to copy and the display will change to “THURSDAY”

Repeat the process until all day have been copied or changed as required and you

arrive at <- BACK.

To exit this second submenu, from <-BACK press "MENU" button once and you will

arrive at SET HW TIMER

From here you can either continue to programme the unit or return to the operating

display menu by pressing “+” repeatedly until you arrive at <-BACK then exit by pressing

menu.

26.5 Setting the HW timer

This programme enables the setting of 3 time blocks (3 start and 3 end times) per day

(24 hours) for higher and lower temperatures of the supply of tap water.

This menu has two submenus:

a. the days of the week

Page 40

b. the start and end times of each block

For programming, repeat as for section CH timer. During programmed off periods

Combi models will maintain a minimum storage temperature of 40oC.

For appliances connected to hot water cylinder for this function to operate temperature

control has to be provided with a sensor (available from Mikrofill). When hot water

temperature control is provided by a cylinder thermostat this function is not recognised.

26.6 Setting MR03 times

When a MR 03 secondary circuit control unit has been fitted then this programme

enables the setting of 3 time blocks (3 start and 3 end times) per day (24 hours) for

higher and lower temperatures for a second central heating circuit. Note unless a MR 03

is connected this function will not be seen.

26.7 Night-time lower 0oc.

This is used t o programme the value for the night time set back temperature in relation to

the room temperature during the day.

NOTE ! If the difference between the daytime temperature and night time setback

temperature is considerable, the start time of the central heating unit must be set earlier

than required to compensate.

Statistically, it has been proven that a night time decrease of 5°C is best; if a lower nighttime temperature is set, heating in the morning requires too much energy.

With “SETBACK” displayed on the screen press "MENU" button until “_____” oC flashes

on the screen. press “+” or “-“ to enter a value then press “-MENU-“ button once to

confirm entry.

26.8 Holiday function

Use the "+" and "-" buttons to set the number of days of the holiday period.

During this period, the night time temperature will be maintained, while the tap water

temperature will be set at a minimum of 20°C.

If you are away for an extended period then to save energy adjust the night time

temperature to 10°C.

After the number of days has expired, the unit will start operating according to the clock

programme set.

Remember when you return to re-adjust the night time temperature to it’s original setting.

Having completed the setting, press the "MENU" button to confirm the new value.

Page 41

26.9 Installer

This function is for the service engineer only and is code protected.

The Main Menu contains the following sections:

Table 12 Programming Options

Programme Number Programme Name

1 Party 0-24 hours

2 Hot Water Temperature 40 - 60°C

3

4 Time / Day Mon-Sun 0.00 – 24.00

5 Set Central Heating Timer 3 x time blocks

6 Set Hot Water Timer 3 x time blocks

7 Set Mixing Valve Timer 3 x time blocks

8 Night Setback Temperature 0 - 10°C

9 Service In 365 Days

10 Holidays 0 – 99 days

11 Installer access code 21

12

- MENU -

Day Temperature 10 – 30°C

less than daytime

Back

Setting Range

27. Installer Programming

A number of programming options are provided for the installer. These can only be

accessed and programmed by means of a code. If this code is entered (21) the following

parameters can be changed:

Table 13 Installer Functions

Programme No. Programme name Setting range

1

2 Heating plan at -15°C outside temperature 10 - 85°C

3 * Minimum pump speed 20 - 50%

4 * Maximum pump speed 50 - 100%

5

6 Service counter 0 - 1500 days

7 Pump continuous 0 or 1

8 ECO/ECO

9

10 Post running of pump after central heating demand 0 – 5 minutes

11 Minimum output Hot Water supply 20 – 50%

12 Maximum output Hot Water supply 20 – 100%

14 Maximum output Central Heating 20 – 83%

Heating plan at +20° C outside temperature

Flow Temp at +20°C outside for secondary circuit

Post running of pump after hot water demand

0 - 40°C

0 - 40°C

0 – 5 minutes

Page 42

15 Function

16 Back

* can only be set if an outside temperature sensor has been installed.

* can only be set if a modulating pump has been installed.

28. Outside Temperature Control

The weather compensating factory settings are as figure 30 below.

Page 43

Page 44

28.2 Outside Temp. Control at - 1°C

Setting the flow temperature when outside air temperature is -1°C

Enter here the flow temperature at -1°C outside temperature. The flow temperature is

normally dependent on the size of the radiators and the calculated mean water

temperature (generally 80°C). The limiting factor will be the function number setting.

Confirm by pressing the "MENU" button.

The supply temperature will automatically adapt to any changes in the outside

temperature in relation to this outside temperature.

28.3 Minimum pump speed

If a modulating pump has been installed in the boiler, this function can be used to set the

minimum pump speed. Normally, this value is 38%, but if the system resistance is high

the minimum value must be set higher.

Use the "+" and "-" buttons to change the minimum percentage.

Confirm by pressing the "MENU" button.

28.4 Maximum pump speed

Normally the pump speed is 100%; if the water velocity or the noise from the radiators is

too high, it is recommended to decrease the speed, taking into account the radiators that

are furthest from the boiler must still maintain a sufficient flow.

28.5 Flow temperature secondary circuit

When a secondary circuit control has been connected (MR 03 available from Mikrofill) to

the boiler, the heating curve between the flow temperature of this circuit has to be set.

Enter the required flow temperature when outside air temperature is + 20°C, normally no

heating would be necessary and the setting should be 20°C adjust if necessary.

The flow temperature -1°C is set at the MR 03 control unit.

28.6 Service counter

The boiler programme has a service counter, which is programmed at 365 days; after

this period the message: "INSPECTION" appears. No other displays are shown until the

fitter has reset the value of 365 days, or a different number of days, by pressing the "+"

button. If necessary, this message can be removed from the system.

28.7 Pump continuous

Pressing the "+" button will cause the pump to operate continuously, except if the

Summertime Mode is selected. Pressing "-" indicates that a pump switch is present.

28.8 Eco/eco+

If a modulating pump has been installed, the pump will modulate automatically in order

to maintain the 20°C difference between the supply and return water temperatures.

After heating in the morning, this modulation will only start after the desired supply

temperature has been reached.

Page 45

If the resistance in the system is high, it is often desirable to obtain a higher pump

pressure: if "ECO" is selected, the pump will start modulating when a return temperature

of 50°C or higher has been reached.

In the "ECO+" mode, the pump will modulate at any water temperature, with the

exception of the heating cycle in the morning.

28.9 Post running of pump after HW

This function is used to set the post running time for the pump after the boiler has

reached the required temperature. The default is 2 minutes, unless there is a demand

from the CH system.

28.10 Post running of pump after CH

This function is used to set the post running time for the pump after the boiler has been

switched off. The default is 1 minute.

28.11 Minimum DHW Capacity

Using this function the default setting can be changed. In certain locations at low fan

speeds the influence of the wind across the flue terminal outlet can lead to flame lift.

The minimum fan speed should be increased until burner pressure is equalised. This

minimum is also the minimum output for central heating.

28.12 Maximum DHW Capacity

If the boiler starts to cycle during how water production then a lower value could be set.

However due to the boilers modulating control this is rarely necessary.

28.13 Maximum CH capacity

If the boiler starts to cycle when in heating mode then a lower value could be set.

However due to the boilers modulating control this is rarely necessary.

28.14 Function Setting

This “FUNCTION” number has to be set ALWAYS

Outside temperature controlled without mixing circuit

Function No. Room Temp

Control

1

2 RE 2132 70°C

3 RE 2132 85°C

4 240v Room Stat 55°C

5 240v Room Stat 70°C

6

7 TRV’s 55°C

8 TRV’s 70°C

9 TRV’s 85°C

RE 2132

240v Room Stat

Max Flow

Temperature

55°C

85°C

Outside temperature controlled with mixing circuit

Function No. Room Temp

Control

Max Flow

Temperature

Page 46

10 With two RE 2132 70°C primary

11 With two RE 2132 85°C primary

12 With one RE 2132 70°C primary

13 With one RE 2132 85°C primary

14 240v Room Stat 70°C primary

15 240v Room Stat 85°C primary

16 TRV’s 70°C primary

17 TRV’s 85°C primary

Room temperature controlled without mixing valve

Function No.

18 RE 2132 55°C

19 RE 2132 70°C

20 RE 2132 85°C

21 240v Room Stat 55°C

22 240v Room Stat 70°C

23

Room Temp

Control

240v Room Stat

Max Flow

Temperature

85°C

Room temperature controlled with mixing valve

Function No. Room Temp

Control

24 With two RE 2132 70°C primary

25 With two RE 2132 85°C primary

26 With one RE 2132 70°C primary

27 With one RE 2132 85°C primary

28 240v Room Stat 70°C primary

29 240v Room Stat 85°C primary

Max Flow

Temperature

Without room unit, thermostat or outside temperature control, constant flow temperatures

without a mixing or secondary circuit.

Function No.

30 None 55°C

31 None 70°C

32 None 85°C

Room Temp

Control

Max Flow

Temperature

Without room unit, thermostat or outside temperature control, constant flow temperatures

with a mixing or secondary circuit.

Function No. Room Temp

Control

33 None 70°C primary

34 None 85°C primary

Max Flow

Temperature

Page 47

Mikrofill cascade manager KKM2 Settings (for controlling up to nine boilers)

Function No. Cascade manager Max Flow

Temperature

35 KKM2 CH temp on KKM2

Analogue cascade manager with signal 0…3 Volts.

Function No.

36 Analogue 0…3

Cascade manager Max Flow

Temperature

CH temp on

Volts

manager

The following function numbers are valid when a pump is used to load the hot water

cylinder

Outside temperature controlled without mixing circuit

Function No. Room Temp

Control

37 RE 2132 55°C

38 RE 2132 70°C

39

40 240v Room Stat

41 240v Room Stat

42 240v Room Stat

TRV’s 55°C

44 TRV’s 70°C

45 TRV’s 85°C 43

RE 2132

55°C

70°C

85°C

Max Flow

Temperature

85°C

Outside temperature controlled with mixing circuit

Function

No.

46 With two RE 2132 70°C primary

47 With two RE 2132 85°C primary

48 With one RE 2132 70°C primary

49 With one RE 2132 85°C primary

50 240v Room Stat