Page 1

PRESSURISA TIO N U NIT

MIKROFILL 3 PRESSURISATION UNIT

TECHNICAL DOCUMENTATION

ISSUE 12/15 Rev. 01

INSP I R E D E FFI C IENC Y

Page 2

Page 3

TABLE OF CONTENTS

TECHNICAL DOCUMENTATION 03

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Technical Data

Electrical Details

Connection Details

Installation

Mains / Boosted Cold Water Supply

Fill Pressure

Connection to the System

Drain

Dimensions

Diagram of a Typical Installation

Wall Mounting Plate Dimensions for Fixing

Electrical Connections

Electrical Diagram

Electrical Data

Keypad Functions

System Data

Up

Power

Down

Service Mode

Status Display

Pressure Correct

System Filling

Filling Stopped due to Low Mains Water Pressure

Frequent Use

Service Mode

Adjusting Settings

Parameter Functions

Fault Diagnosis

Status / Fault Conditions

Status / Fault Conditions continued.

Manual Override

Component List

Maintenance

Removing the Controls Assembly

Cleaning the Solenoid Valves

Cleaning the Inlet Ballofix Valve

Declaration of Conformity

04

05

06

07

08

09

10

10

11

12

13

14

14

15

16

17

18

Page 4

TECHNICAL DATA

04 TECHNICAL DOCUMENTATION

WRAS Approval Number:

ELECTRICAL DETAILS

• Supply Voltage:

• Full Load Current:

• Start Current:

• Fuse Rating:

• Maximum Load BMS Relays:

CONNECTION DETAILS

• Cold Water Inlet:

• System Outlet:

• Drain (via Tundish):

• Maximum Inlet Pressure:

• Maximum Cold Fill Pressure:

•Nominal Flow Rate:

•Dry Weight:

1806078

230 Volt

1 Amp

1 Amp

3 Amp

5 Amp

15mm Compression

15mm Compression

¾” BSP

5 Bar

4.7 Bar

14 l/min at 2 Bar

5 kg

Page 5

TECHNICAL DATA

TECHNICAL DOCUMENTATION 05

The Mikrofill 3 is a fully automatic sealed system filling device and is suitable for the water management in

domestic and commercial heating and cooling systems. It is designed for use in a normal environment. It is not

suitable for installation outside, or in environments where there are excessively cold temperatures.

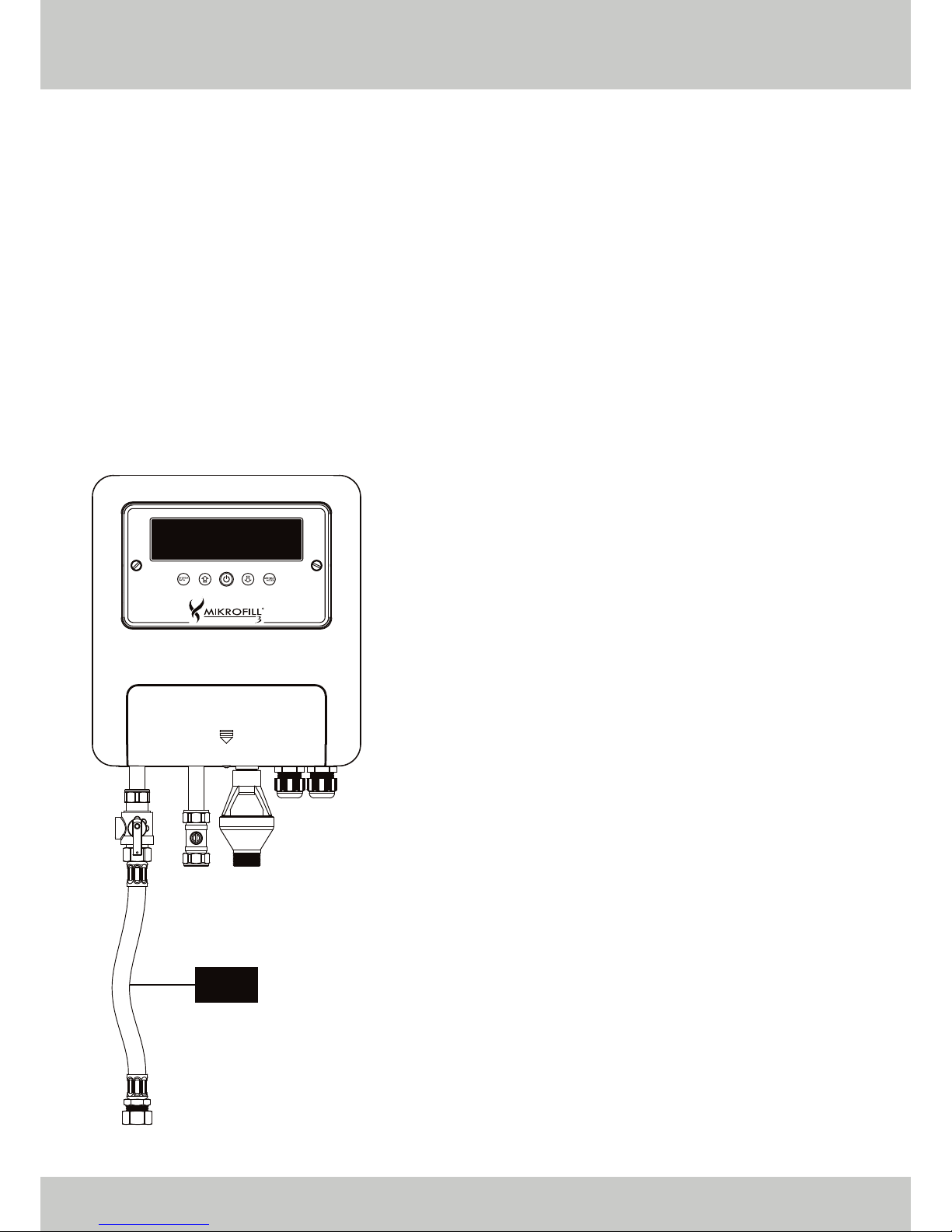

INSTALLATION

All Mikrofill products should be installed by a competent person with regard to the relevant requirements of

the Health and Safety Regulations, Building Regulations, IEE Regulations, Water Supply (Water Fittings)

Regulations, Water By-laws (Scotland) and any other by-laws or planning requirements.

The Mikrofill 3 is WRAS approved with certificate number 1806078.

It is intended for wall mounting (see page 08) and should be mounted at such a height as to enable the

display to be easily read.

MAINS / BOOSTED COLD WATER SUPPLY

The Mikrofill 3 is designed to be connected directly to the mains cold water supply, or a boosted cold water

supply. The unit is supplied complete with all necessary isolating valves and incorporates a basket filter in the

inlet ballofix valve.

A flexible hose is supplied with the unit which MUST be connected to

the inlet ballofix valve, as shown in the diagram to the left. Failure to

do so may result in damage to the inlet pressure sensor due to water

hammer, resulting in a SENSOR FAILURE. Under such circumstances,

this would not be considered a warranty fault.

The water inlet connection is 15mm compression and should be

connected to the mains cold water supply by 15mm copper pipe or

equivalent approved plastic pipework.

If the Mikrofill 3 is sited some distance from the mains cold water

supply it may be advisable to install a single check valve adjacent to

the mains cold water supply.

To reduce the pressure drop on very long supply routes 22mm supply

pipework is recommended.

FILL PRESSURE

The Mikrofill 3 is capable of filling a system to within 0.3 bar of its

current inlet water pressure.

Where the incoming water pressure exceeds 5 bar please contact

our technical department on 03452 60 60 20 for further installation

information.

FLEXIBLE

HOSE

Page 6

TECHNICAL DATA

06 TECHNICAL DOCUMENTATION

CONNECTION TO THE SYSTEM

The Mikrofill 3 is connected to the system by way of the 15mm outlet isolation valve. The pipework from the unit

should be made in 15mm copper or similarly approved plastic pipework. A suitable sized expansion vessel

should be incorporated into the system at this point (please refer to the typical installation diagram on page

07 for more information).

Please contact our technical department on 03452 60 60 20 if you require any assistance regarding vessel

sizing.

The final connection into the system should be sized accordingly, recommendations are shown below:

• Vessel size up to ½”

• Vessel size up to ¾”

• Vessel size up to 1”

For vessel sizes in excess of 1000L capacity please contact our technical department.

IMPORTANT NOTE:

DRAIN

Following every fill procedure the unit will discharge a small amount of water, establishing an air break. For this,

the unit is supplied fitted with a ¾” BSP tundish, which must be connected to a suitable drain.

Mikrofill Systems Ltd. cannot accept responsibility for any consequential damage caused by failure to

connect the tundish to a suitable drain.

100L:

300L:

1000L:

(15mm) expansion pipework

(22mm) expansion pipework

(28mm) expansion pipework

The expansion vessel air / nitrogen charge must be set to the same pressure as the cold fill

pressure of the system.

If the installed height of the expansion vessel is different to that of the unit then please

contact our technical department who will advise on the air / nitrogen charge required.

A suitably sized pressure relief / safety valve MUST be fitted on all sealed systems.

Page 7

TECHNICAL DATA

TECHNICAL DOCUMENTATION 07

DIMENSIONS (IN MILLIMETRES)

DIAGRAM OF A TYPICAL INSTALLATION

Please note that for the purpose of clarity, system valves are not shown. For systems exceeding 90°C contact

our technical department on 03452 60 60 20 for advice.

Further installation guidelines can be found on page 05 of this technical documentation.

Page 8

TECHNICAL DATA

08 TECHNICAL DOCUMENTATION

WALL MOUNTING PLATE DIMENSIONS FOR FIXING (IN MILLIMETRES)

• A maximum size of No. 8 screws or M4 bolts are to be used.

• A minimum of 25mm clearance either side of the unit is required.

• A minimum of 250mm clearance above the unit is required.

• The unit must be fitted on a sound, solid surface.

262

205

170

177

Page 9

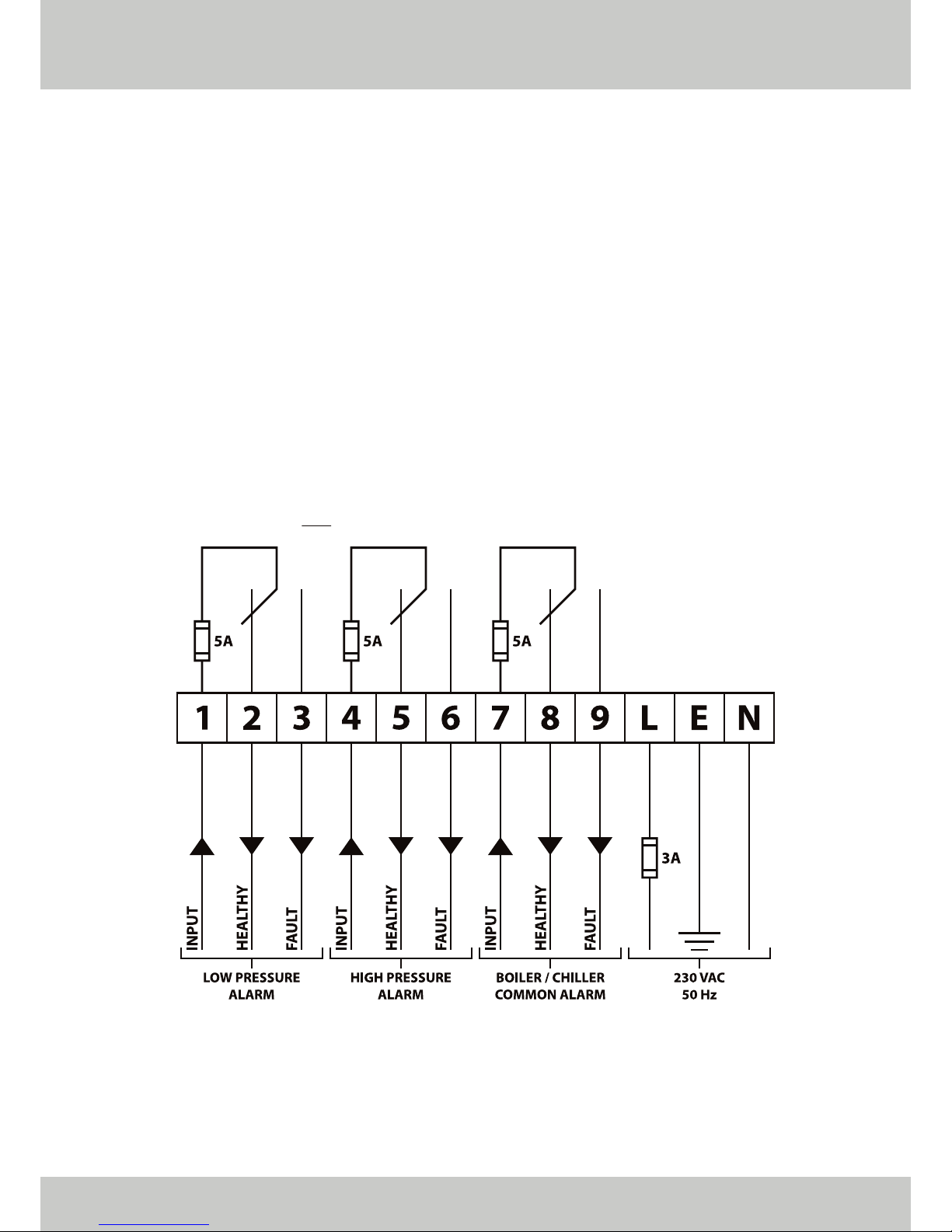

ELECTRICAL CONNECTIONS

TECHNICAL DOCUMENTATION 09

The Mikrofill 3 requires a permanent 230 V 50 Hz 1 phase fused supply rated at 3 Amp. The unit is internally fused

at 3 Amp (see electrical installation diagram below).

The unit also incorporates two BMS relays offering volt free contacts for the remote indication of low or high

pressure conditions within the system. These relays are also independently fused at 5 Amp to protect the

Mikrofill 3 from external electrical faults. Alternatively, if only a common fault signal is required by the BMS as

opposed to individual low and high alarms, a further volt free relay is included in the unit which can be used

to interlock the boiler or chiller control circuits. Should either the low or high alarm relay operate, then this third

relay will shut down the boiler or chiller and indication of any alarm situation will be shown on the display. The

relays are suitable for use on control voltages up to 250 V.

To access the wiring connections on the Mikrofill 3, the cover on the lower front of the unit will first need to be

removed by unscrewing the PZ2 screw located on the underside. Removing this cover will reveal a 12 way

terminal block, with each connection labelled 1 - 9 for the volt free relays (see electrical installation diagram

below), Live, Earth and Neutral. The wiring can be passed through the cable glands on the underside of the

unit, through an opening in the front casing, then connected as required into the terminal block.

Once the Mikrofill 3 has been correctly connected, the unit is ready for use. Ensure that the unit has a water

supply and that the service valves are open. Check for water leaks, switch on the electrical supply to the unit

and press the central power button on the front of the unit until the display illuminates. After a brief period, the

unit will start to fill the system. Once the system has achieved its set cold fill pressure, the unit will stop filling,

discharge a small amount of water to drain and then go to PRESSURE CORRECT.

ELECTRICAL DIAGRAM (WHEN NOT AT FAULT)

ELECTRICAL DATA

• Supply: 230 V 1 ph 3 Amp.

• Full Load Current: 1 Amp.

• Start Current: 1 Amp.

• Fuse Rating: 3 Amp.

• BMS Relays and Boiler / Chiller Relays: Volt Free Contacts rated at 250 VAC at 5 Amp.

• All relays are independently fused at 5 Amp.

Page 10

KEYPAD FUNCTIONS

STATUS DISPLAY

10 TECHNICAL DOCUMENTATION

The top line of the display on the Mikrofill 3 will provide information on the current status of the unit as well as

the system that it is managing, providing information on any potential issues and / or faults as and when they

occur.

The following status messages will be displayed on the unit based on current conditions:

If the unit displays any messages other than those detailed above, then there is likely a fault either with the unit

or the system. For a list of possible fault displays, along with causes and remedies, please refer to pages 13 and

14 of this technical documentation.

-

-

-

-

-

-

-

-

-

SYSTEM DATA

This button is used primarily to scroll through the various settings of the unit. Repeatedly pressing this

button will cycle through each setting (see page 12 for information on each of these settings).

Pressing this button whilst the unit is in SERVICE MODE will again cycle through each setting, but in

this mode the settings can now be adjusted (described in further detail on page 11).

UP

When the unit is in SERVICE MODE this button is used to increase parameter values.

POWER

Pressing and holding this button for approximately 2 seconds will turn the unit on or off. When the

unit is powered on, the display should always be illuminated.

NOTE: This button will turn the unit off, but it does not isolate power to the unit.

DOWN

When the unit is in SERVICE MODE this button is used to decrease parameter values. This button can

also be used to view the calibration code for the unit’s pressure sensors by pressing and holding it

down for 2 seconds. The top line of numbers displayed will relate to the calibration of the unit.

SERVICE MODE

This is a multi-function button that, when the unit is in operational mode, is used to mute the audible

alarm conditions. Pressing and holding this button for approximately 8 seconds will put the unit into

SERVICE MODE where various parameters can then be adjusted (described in further detail on

page 11).

PRESSURE CORRECT

The Mikrofill 3 continuously monitors the system pressure. When the system pressure is within set

parameters, the unit will show this message on the display.

SYSTEM FILLING

This message indicates that the unit is currently filling the system to its target fill pressure.

FILLING STOPPED DUE TO LOW MAINS WATER PRESSURE

The Mikrofill 3 continuously monitors the inlet pressure. If this inlet pressure falls below an acceptable

level (within 0.3 bar of the current system pressure) whilst the unit is attempting to fill the system then

the unit will operate a safety shut-down, displaying this message. Once the incoming pressure is

reinstated, the unit will return to operating as normal.

FREQUENT USE

There is a FREQUENT USE setting on the Mikrofill 3 which can be adjusted by accessing the SERVICE

MODE (described in further detail on page 11). If the unit cuts in to top up the system more than the

number of times this setting is set to within a 24-hour period then the unit will alarm and display this

message. This alert is for informational purposes as it informs that the unit is having to top up the

system unusually often, suggesting there may potentially be a leak somewhere on the system.

Page 11

SERVICE MODE

TECHNICAL DOCUMENTATION 11

ADJUSTING SETTINGS

The settings on the Mikrofill 3 can be adjusted on site by following the below steps:

STEP 01:

STEP 02:

STEP 03:

STEP 04:

STEP 05:

Press and hold the button for approximately 8 seconds.

The display will indicate that you are now in SERVICE MODE. You can then release the button.

The button can now be used to scroll through the various settings.

To increase or decrease the value of a setting use the or buttons respectively.

After adjusting the settings, the unit will save any changes made and return to its normal

operating mode when no button is pressed for approximately 30 seconds.

Page 12

PARAMETER FUNCTIONS

12 TECHNICAL DOCUMENTATION

The following lists each parameter of the Mikrofill 3 which can be adjusted through the SERVICE MODE, along

with an explanation of their functions:

• Cold Fill Pressure

• Alarm Low Pressure

• Alarm High Pressure

• Usage

• Lvl 1 Leak Alert Time

• Delay Off

• Frequent Use Alarm

• Delay On

• Time & Date

• Audible Alarm

• Fault Log

• Leak Alert

-

-

-

-

-

-

-

-

-

-

-

-

-

-

the required pressure of the system when cold.

the system pressure at which the low pressure alarm relay will operate,

typically set 0.6 - 0.7 bar below the cold fill pressure.

the system pressure at which the high pressure alarm relay will operate,

typically set 0.2 - 0.3 bar below the system safety valve setting.

provides information on water usage in the system based on the amount of

water the unit has put into the system and how long it has been operating (this

is for information only and thus no setting is required).

to reset the usage, both the and buttons can be held together

for 3 seconds.

affects the flood protection facilities of the unit, if the Mikrofill 3 does not

register a pressure increase in the system whilst filling for the period set here

then it will assume that there must be a leak in the system and alarm, the

longer the Lvl 1 Leak Alert setting (which is calculated in minutes) the less

responsive the flood protection.

set at 0.00 to disable Lvl 1 Leak Alert protection.

refers to the amount of time in seconds that the unit will continue to fill the

system once the cold fill pressure has been reached, to prevent overshoot or

undershoot of the fill pressure - increasing the time prevents undershoot and

decreasing it prevents overshoot.

warns of frequent filling, which would indicate a system leak, by showing a

warning message if in any 24-hour period the unit operates in excess of this

value.

refers to the amount of time in seconds that the unit will wait before it begins

operation once the system pressure has dropped to its cut in point, increasing

the setting will reduce the units sensitivity to temporary drops in system

pressure.

alters the time and date displayed on the unit.

enables or disables the audible alarm when the unit goes to fault.

provides information of the last five registered faults (described in further detail

on pages 13 and 14), displayed as two letter codes which refer to the

following:

• MP - Low Mains Water Pressure when filling.

• FS - Low System Water Pressure (if Leak Alert is enabled).

• LP - Low System Water Pressure (if Leak Alert is disabled).

• HP - High System Water Pressure.

• DR - Leak Alert due to no increase in pressure whilst filling.

• FR - Frequent Run / Use.

enables or disables flood protection for the unit, it is highly recommended that

this setting is enabled.

Page 13

FAULT DIAGNOSIS

TECHNICAL DOCUMENTATION 13

The Mikrofill 3 has a full self-diagnostic microprocessor unit which continually self-checks its operation. If an

internal fault is diagnosed then this will be displayed on the screen in place of the usual status display

(described on page 10). The message displayed will directly relate to the issue that the unit has registered and

will aid in resolving the fault.

If you continue to experience a fault, or are having difficulty in diagnosing the specific cause, then please

contact our technical department on 03452 60 60 20 for further assistance.

STATUS / FAULT CONDITIONS

continued on page 14...

CAUSE

The system pressure is not

rising due to a leak.

The unit is going to fault

when trying to fill due to low

incoming water pressure.

Low system pressure.

Low incoming water

pressure.

Blocked inlet ballofix valve

filter.

Possible persistent leak on

the system.

High system pressure.

Possible damaged sensor.

RESOLUTION

The unit has been filling the system for longer than the Level

1 Leak Alert Time set in SERVICE MODE. The system should be

checked for leaks. To reinstate the unit, power it off and

back on again.

The unit has been trying to fill the system but has been

unable to due to a lack of mains water pressure, causing

the unit to go to fault for the duration of the Level 1 Leak

Alert Time. Check the incoming mains pressure when the

unit is filling (see also “FILLING STOPPED DUE TO LOW MAINS

WATER PRESSURE”).

The system pressure has dropped below the Alarm Low

setting. Check for leaks and that the Alarm Low has not

been set incorrectly (refer to page 12). To reinstate the unit,

power it off and back on again.

The unit requires a dynamic mains pressure of 0.3 bar or

more above its cold fill setting. If the mains pressure usually

satisfies this requirement, then the cause of the mains

pressure drop should be investigated.

The filter in the included mains inlet ballofix valve should be

removed and cleaned to ensure flow into the unit is not

being restricted (see page 17 for details).

If the unit operates more than the Frequent Use set point

during a 24-hour period this message will be displayed. This

will not stop the unit from operating or trigger the BMS fault

relays but it does indicate that there may be a small leak on

the system which should be investigated. To reinstate the

unit, power it off and back on again.

The system pressure has exceeded the Alarm High setting.

Drain down and check the air charge of any expansion

vessels on the system. Confirm the diaphragm is still intact

and check that the vessel is adequately sized. Also check

the Alarm High has not been set incorrectly (refer to page

12). This fault will automatically reset when the pressure

drops back down below the Alarm High setpoint.

Power the unit off and back on, and the unit will return to

normal operation. If the unit displays a ‘#’ in the corner of

the display then this indicates that there is still a possible

fault. After 10 minutes the unit will recheck the sensors and

return to displaying “SENSOR FAILURE” if the issue still

remains.

Obtain the calibration code for the sensors (as outlined on

page 10) and then contact our technical department on

03452 60 60 20 and we will be able to confirm if this is a

genuine sensor fault.

FAULT INDICATION

“FILLING STOPPED DUE TO

LEVEL 1 LEAK ALERT - CHECK

SYSTEM FOR LEAKS!”

“FILLING STOPPED DUE TO

LEVEL 2 LEAK ALERT - CHECK

SYSTEM FOR LEAKS!”

“FILLING STOPPED DUE TO

LOW MAINS WATER

PRESSURE”

“FREQUENT USE!”

“HIGH PRESSURE FAULT -

CHECK EXPANSION VESSEL!”

“SENSOR FAILURE”

Page 14

FAULT DIAGNOSIS

MANUAL OVERRIDE

14 TECHNICAL DOCUMENTATION

STATUS / FAULT CONDITIONS continued.

In the unlikely event of “SENSOR FAILURE”, the Mikrofill 3 may begin to give incorrect readings and could cause

alarm conditions. If this occurs, a MANUAL OVERRIDE can be employed which will reinstate the BMS relays in

the unit, forcing them into a healthy position and preventing the unit from locking out any equipment that the

unit has been linked to.

To put the unit into MANUAL OVERRIDE, press and hold both the and buttons simultaneously for

approximately 2 seconds.

Before operating this feature, it must be ensured that there is sufficient pressure in the system. MANUAL

OVERRIDE must not be employed if the unit has shown a potential leak condition or if there is insufficient

pressure in the system.

FAULT INDICATION

“SENSOR FAILURE” cont.

Water continuously passing

through the tundish to drain.

CAUSE

Incoming voltage instability.

Solenoid valve blocked.

Solenoid valve or double

non-return valve has failed.

RESOLUTION

The sensors use the voltage as a baseline to measure

pressure. If the incoming voltage supply to the unit is

fluctuating then this can cause the unit to go to “SENSOR

FAILURE”. If the pressure readings on the display are

fluctuating, or the voltage is unstable when measured with

a multimeter then there is likely an issue with the supply.

The unit can be powered from an alternative source or a

power suppressor can be fitted to try and stabilise the

incoming voltage to the unit.

In either case of “SENSOR FAILURE”, the Mikrofill 3 can be put

into MANUAL OVERRIDE to stop it from locking out any

equipment on-site (described in further detail below).

Over time either or both solenoid valves inside the unit can

become blocked up with limescale or debris and this can

affect their operation. The valves can be taken apart and

cleaned, which will most likely resolve the issue.

To diagnose which of the two valves is blocked, when the

unit is still passing to drain it should be powered off. If the unit

continues to pass then the normally closed solenoid valve in

the top left of the unit will require cleaning. If the unit stops

passing when powered off then the normally open solenoid

valve directly above the tundish will require cleaning.

For detailed instructions of how to access and successfully

clean either valve, please refer to pages 16 and 17 of this

technical documentation.

If cleaning the solenoid valves does not resolve the issue,

then this will mean that either the solenoid valve or double

non-return valve has failed and will require replacing.

For more information please contact the technical

department on 03452 60 60 20.

Page 15

COMPONENT LIST

TECHNICAL DOCUMENTATION 15

Any components within the Mikrofill 3 that may require replacing have been listed in this section, along with

their respective part codes. If any part needs replacing which is not listed here, please contact our technical

department on 03452 60 60 20 for assistance.

“(PART CODE) PART NAME”:

01

02

03

04

05

06

07

08

09

10

(EFD000005)

(EFD000006)

(EFD000007)

(MK3000009)

(MK3000010)

(MK3000053)

(EFD000012)

(MK3000014)

(MK3000015)

(MK3000033)

¾” TUNDISH (½” FEMALE x ¾” MALE)

AIR VENT VALVE (⅜” MALE)

BALLOFIX VALVE - INLET (15mm COMPRESSION)

CHECK VALVE (

Ø 15mm

)

CHECK VALVE WITH FLOW REGULATOR (

Ø 15mm

)

CONTROLS ASSEMBLY WITH SENSORS

ISOLATION VALVE - OUTLET (15mm COMPRESSION)

NORMALLY CLOSED SOLENOID VALVE

NORMALLY OPEN SOLENOID VALVE

O-RING (NITRILE) (3mm I.D. x 3mm C.S.)

11

12

13

14

15

16

17

18

19

(MK3000034)

(MK3000017)

(MK3000028)

(MK3000029)

(MK3000019)

(MK3000020)

(MK3000021)

(MK3000024)

(MK3000025)

O-RING (NITRILE) (14.5mm I.D. x 3mm C.S.)

PCB (POWER)

PIPE - CAPILLARY - INLET (COPPER) (

Ø 4mm)

PIPE - CAPILLARY - OUTLET (COPPER) (

Ø 4mm)

PUSH FIT - ELBOW (

Ø 4mm FEMALE x ⅛” FEMALE

)

PUSH FIT - REDUCER (

Ø 6mm MALE x Ø 4mm FEMALE

)

PUSH FIT - REDUCER (

Ø 8mm MALE x Ø 4mm FEMALE

)

STOP END (BRASS) (10mm COMPRESSION)

STOP END (BRASS) (15mm COMPRESSION)

16

13

10

15

17

18

14

10

15

18

08

02

19

19

09

04

04

05

04

11

11

03

07

01

06

12

Page 16

MAINTENANCE

16 TECHNICAL DOCUMENTATION

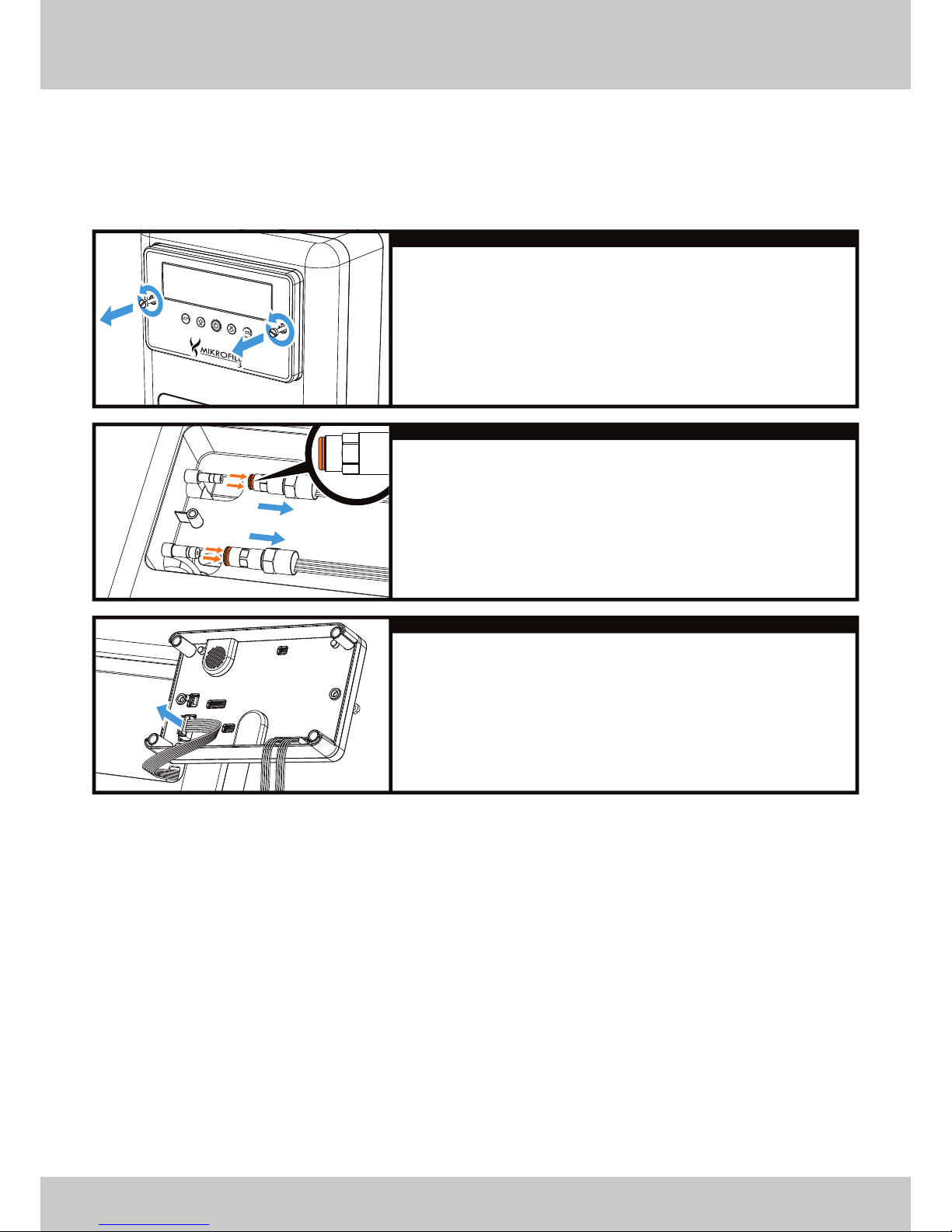

REMOVING THE CONTROLS ASSEMBLY

In the unlikely event of either a sensor or PCB failure, it may be necessary to replace the controls assembly. If

this is the case then the unit must first be isolated mechanically and electrically, and then drained down by

slackening the top inlet and system valve nuts, allowing any water in the internal pipework of the unit to drain

out. Once this is done, the controls assembly may be removed by following the steps listed below.

CLEANING THE SOLENOID VALVES

Over time either or both solenoid valves inside the unit can become blocked up with limescale or debris and

this can affect their operation. The most common indication that a solenoid valve is blocked is a steady flow

of water constantly passing through the unit and out to drain.

To diagnose which of the two solenoid valves is blocked, when the unit is still passing to drain it should be

powered off completely. If the unit continues to pass then the normally closed solenoid valve in the top left of

the unit will require cleaning. If the unit stops passing when powered off then the normally open solenoid valve

directly above the tundish will require cleaning.

To clean the solenoid valve(s) and stop them passing, the unit must first be isolated and disconnected both

mechanically and electrically. The wiring cover at the bottom of the unit is held in position by a single screw

which can be removed with a PZ2 screwdriver to give access to the terminal block where the unit can then

be disconnected electrically. Once fully isolated and disconnected both mechanically and electrically, the

unit can be removed from the wall by unscrewing the slot-head bolt on the topside of the unit and lifting then

pulling the unit from its backplate.

With the unit removed from the wall, the steps detailed on the following page will explain how to access and

clean out both solenoid valves.

Unscrew the two retaining screws on either side of the front of the

controls housing until they are extended enough to be able to grip and

pull the control assembly forward and clear of the unit, ensuring not to

pull it too far as to damage the wiring still connecting the controls

assembly to the main unit.

Unclip the two push-fit connectors holding the sensors to the pipework

fittings.

This is done by depressing the orange retaining clip on the push-fit

connector inwards and then pulling the connector and sensor away

from the pipework fitting, which should be clipped into a slot in the front

casing to hold it in place.

With both sensors disconnected from the pipe fittings, the ribbon cable

should then be removed from the back of the controls assembly. Once

this is done, the controls assembly will be completely detached from the

main unit and the above steps should be reversed in order to refit or

replace the controls assembly back into the Mikrofill 3.

Care should be taken when fixing a controls assembly into the main unit

to ensure that the two retaining screws are not over-tightened as this can

damage the PCB and / or plastic casings.

STEP 01:

STEP 02:

STEP 03:

Page 17

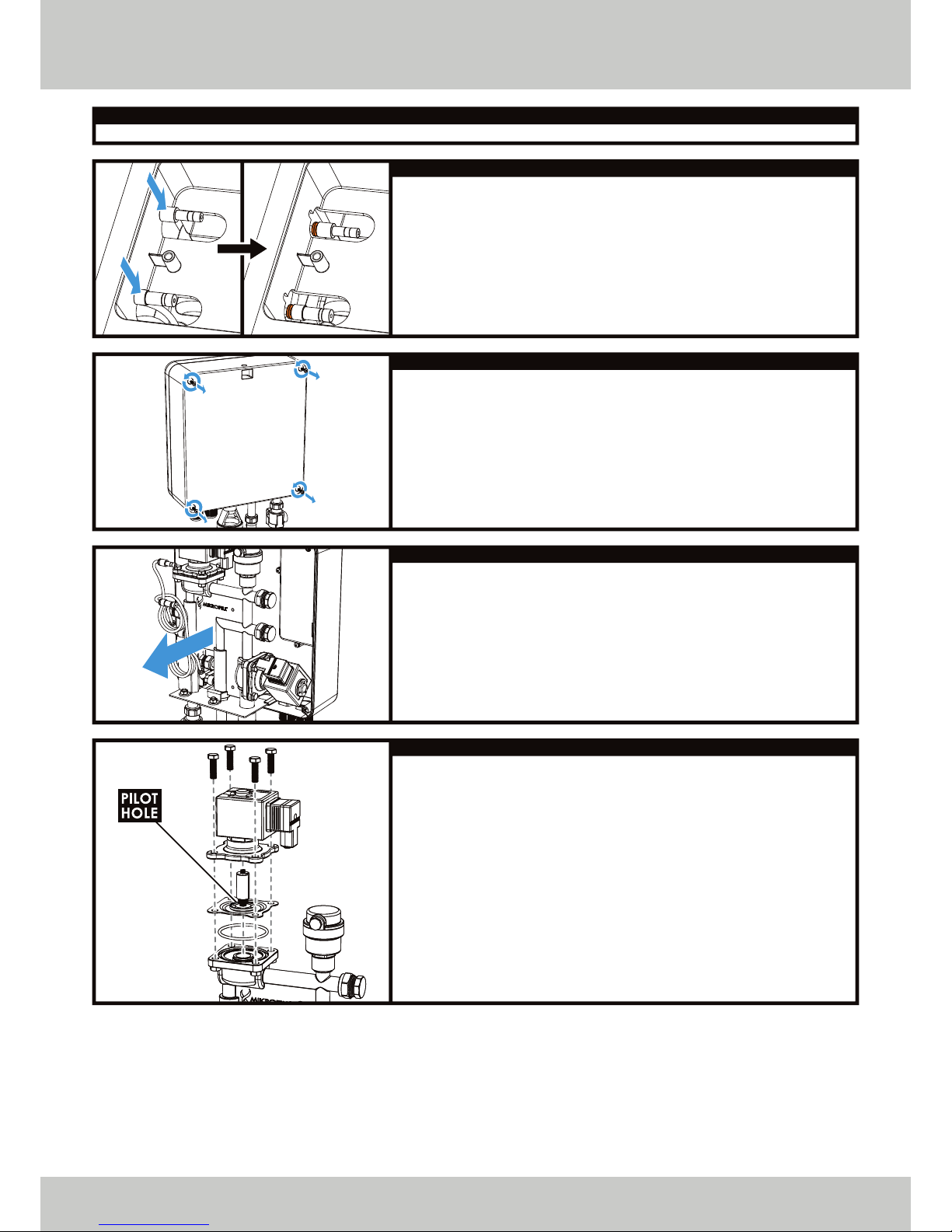

MAINTENANCE

TECHNICAL DOCUMENTATION 17

CLEANING THE INLET BALLOFIX VALVE

As part of the annual maintenance for the unit we recommend cleaning the integral basket filter in the

incoming ballofix valve to ensure it does not become blocked over time with dirt or debris from the incoming

water supply. To do this, the valve must be isolated and the cap on the left hand side of the valve should be

removed utilising a flat-head screwdriver. This will provide access to the filter which can be removed using a

pair of long nose pliers or similar tool. Once the filter is clean, the cap and filter must both be refitted and the

valve reopened.

STEPS 01 - 03

STEP 04:

STEP 05:

STEP 06:

STEP 07:

First follow STEPS 01 - 03 for REMOVING THE CONTROLS ASSEMBLY detailed on page 16.

Once the controls assembly has been removed from the unit, the

pipework fittings can be gently pushed down to unclip them from their

slot in the front casing.

Turn the unit around and there will be four recessed retaining screws, one

in each corner, which can now be unscrewed using a PZ2 screwdriver.

This will allow the casing to be opened, though care should be taken as

the front and back casing will still be connected together with wiring.

If required, the wiring can be separated using the plug and socket

connectors so that the front casing can be fully detached.

Three PZ2 screws will be holding the manifold assembly in place inside

the casing. Unscrewing these will allow the entire assembly to be slid

forward out of the casing, granting easy access to the solenoid valves.

Plug and socket connectors will allow the solenoid valves wiring to be

separated, detaching the valves and the manifold assembly from the

main unit.

Once the valve to be cleaned has been identified (see page 14 or 16 for

details) the valve head should be removed from the manifold by

unscrewing the four bolts using an 11mm spanner or socket. The valve

should then be lifted from the manifold body, ensuring the internals are

not disturbed in the process.

There is a small pilot hole in the diaphragm which aids in equalising the

pressure when the valve opens or closes. This must be cleared of any

obstruction. Depending on the valve, there may also be a small brass pin

and ferrule in the pilot hole which can safely be removed, ensuring that

the diaphragm is not damaged in doing so. The valve and manifold

base should then be given a general clean.

To reassemble the unit, STEPS 01 - 07 should be reversed.

Page 18

Mikrofill Systems Ltd.

11 Merse Road

North Moons Moat

Redditch

B98 9HL

T +44 (0) 3452 60 60 20

F +44 (0) 3452 60 60 21

DECLARATION OF CONFORMITY

We Mikrofill Systems Ltd. 11 Merse Road, North Moons Moat, Redditch, B98 9HL declare that the Mikrofill 3

pressurisation unit satisfies the essential requirements of the Electromagnetic Compatibility (EMC) Directive

2004/108/EC and the Low Voltage Directive (LVD) 2006/95/EC and is manufactured in accordance with the

harmonised European standard:

BS EN 60730-1:2011

Signed by:

Steven Cherrington

Technical Director

United Kingdom, 28th August 2015

Page 19

ISO 9001

Registered

Quality

Management

015

Page 20

North Moons Moat, Redditch, Worcestershire B98 9HL , UK

T +44 (0)3452 60 60 20 F +44 (0)3452 60 60 21

E info@mikrofill.com www.mikrofill.com

Mikrofill Systems Ltd. 11 Merse Road,

Loading...

Loading...