Page 1

mikromedia

for STM32

Compact multimedia development system rich with on-board peripherals for

all-round development on STM32F207VGT6 and STM32F407VGT6 devices

™

®

Page 2

Page 3

TO OUR VALUED CUSTOMERS

I want to express my thanks to you for being interested in our products and for having

condence in MikroElektronika.

The primary aim of our company is to design and produce high quality electronic products

and to constantly improve the performance thereof in order to better suit your needs.

Nebojsa Matic

General Manager

The STM32®, ARM® and Windows® logos and product names are trademarks of STMicroelectronics®, ARM® Holdings and Microsoft® in the U.S.A. and other countries.

Page 3

Table of Contents

Introduction to mikromedia for STM32® 4

Package Contains 5

Key Features 6

System Specication 7

1. Power supply 8

USB power supply 8

Battery power supply 8

2. Key microcontrollers features 10

STM32F207VGT6 10

STM32F407VGT6 11

3. Programming the microcontroller 12

Pro gramming with mikroBootloader 14

step 1 – Connecting mikromedia 14

step 2 – Browsing for .hex le 15

step 3 – Selecting .hex le 15

step 4 – Uploading .hex le 16

step 5 – Finish upload 17

Programming with mikroProg™ programmer 18

mikroProg Suite™ for ARM® Software 19

Programming with ST-LINK V2 programmer 20

4. Reset buttons 22

5. Oscillators 24

6. MicroSD Card Slot 25

7. Touch Screen 26

8. Audio Module 28

9. USB connection 30

10. Accelerometer 32

11. Flash Memory 33

12. Pads 34

13. Pinout 35

14. Dimensions 36

15. Mikromedia Accessories 37

16. What’s Next 38

Page 3

Page 4

Page 5

Introduction to mikromedia for STM32®

The mikromedia for STM32® is a compact

development system with lots of on-board

peripherals which allow development of devices

with multimedia contents. The central part

of the system is a 32-bit STM32F207VGT6

or STM32F407VGT6 microcontroller. The

mikromedia for STM32® features integrated

modules such as stereo MP3 codec, TFT

320x240 touch screen display, accelerometer,

USB connector, MMC/SD card slot, 8 Mbit ash

memory, 2x26 connection pads and other. It

comes pre-programmed with USB bootloader,

but can also be programmed with external

programmers, such as mikroProg™ for STM32®

or ST-LINK. Mikromedia is compact and slim,

and perfectly ts in the palm of the hand, which

makes it convenient platform for mobile devices.

Page 4

Page 5

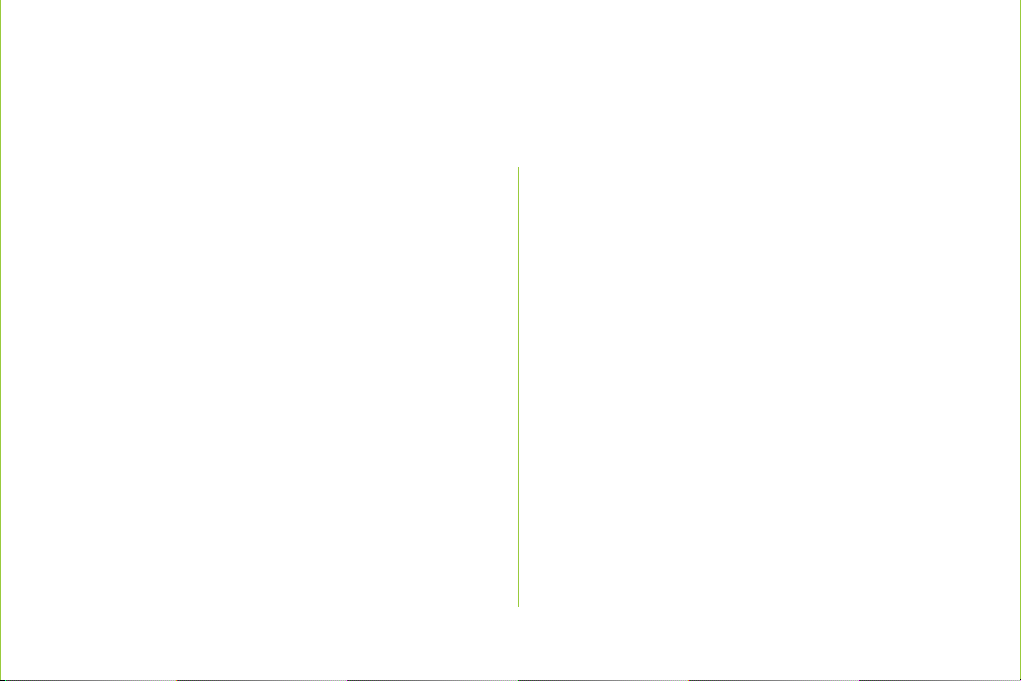

Package Contains

Copyright ©2011 Mikroelektronika.

All rights reserved. Mikroelektronika, Mikroelektronika logo and other

Mikroelektronika trademarks are the property of Mikroelektronika.

All other tradmarks are the property of their respective owners.

Unauthorised copying, hiring, renting, public performance and

broadcasting of this DVD prohibited.

20122011

www.mikroe.com

Damage resistant

01

protective box

mikromedia for STM32®

04 05

user’s guide

mikromedia for STM32®

02

development system

mikromedia for STM32®

schematics

Page 5

DVD with documentation

03

and examples

USB cable and ST-LINK V2

06

to mikroProg™ adapter

Page 6

Page 7

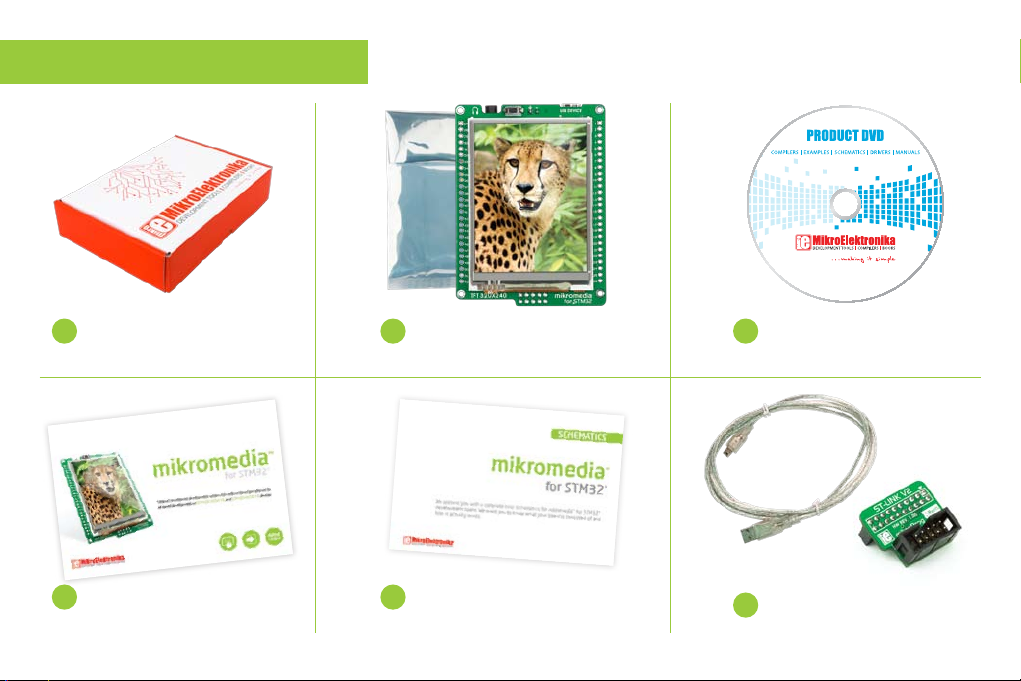

Key Features

01

Connection Pads

02

TFT 320x240 display

03

USB MINI-B connector

Charge indication LED

04

LI-Polymer battery connector

05

3.5mm headphone connector

06

Power supply regulator

07

Crystal oscillator

08

VS1053 Stereo mp3 coder/decoder

09

RESET button

10

STM32F207VGT6 or STM32F407VGT6

11

microcontroller

Accelerometer

12

Serial Flash memory

13

microSD Card Slot

14

Power indication LED

15

JTAG/SWD programmer connector

16

01

02

Page 6

Page 7

03

04

05

15

11

07

13

08

16

10

12

14

09

06

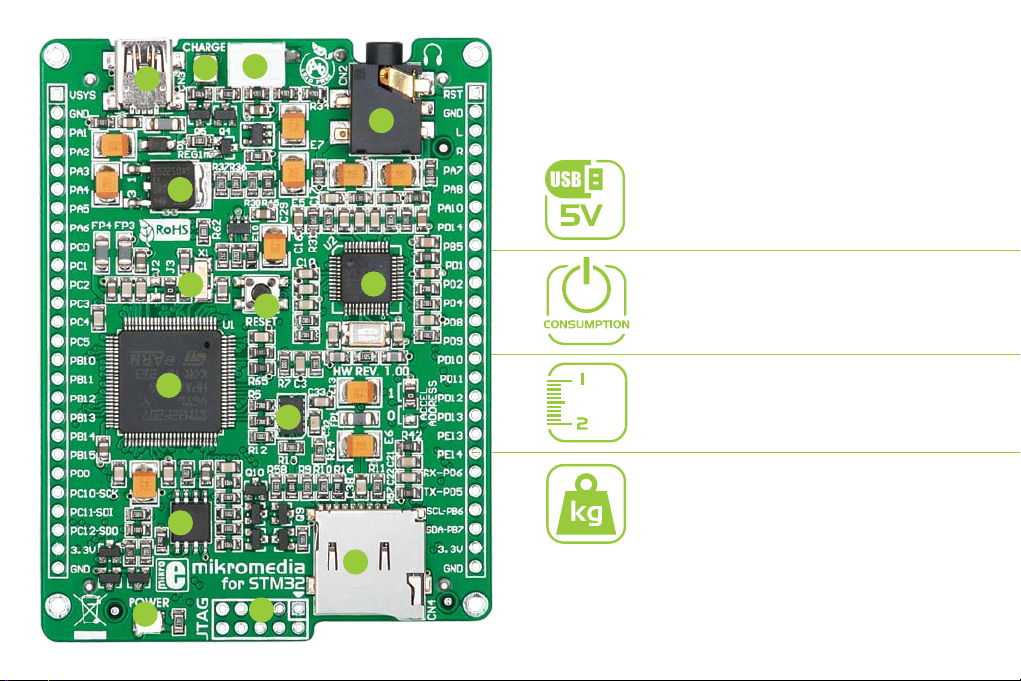

System Specication

power supply

Via USB cable (5V DC)

power consumption

46.5 mA with erased MCU

(when on-board modules are inactive)

board dimensions

81.2 x 60.5 mm (3.19 x 2.38 inch)

weight

~45 g (0.10 lbs)

Page 7

Page 8

Page 9

1. Power supply

Battery power supply

You can also power the board using Li-Polymer battery,

via on-board battery connector. On-board circuit

MCP73832 enables you to charge the battery over

USB connection. LED diode (RED) will indicate battery

charging. Led is o when battery is full. Charging current

is ~250mA and charging voltage is 4.2V DC.

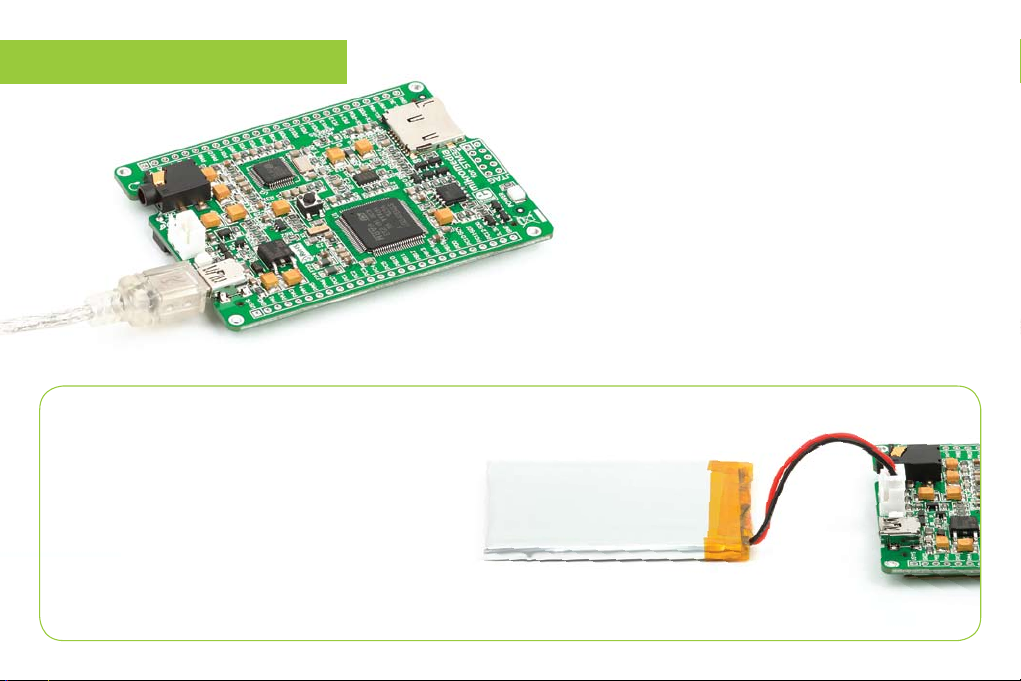

USB power supply

You can apply power supply to the board

using MINI-B USB cable provided with

the board. On-board voltage regulators

provide the appropriate voltage levels

to each component on the board. Power

LED (GREEN) will indicate the presence of

power supply.

Figure 1-1: Connecting

USB power supply

Figure 1-2: Connecting Li-Polymer battery

Page 8

Page 9

2

3

5

4

1

VCC-SYS VCC-3.3

E3

10uF

E4

10uF

R26

2K2

3

1

2

GND

Vin

Vout

REG1

LD29080DT33

VCC-BAT

D1

PMEG3010ER

R44

3K9

Charging Current approx. 250mA

R39

4K7

VCC-3.3

E7

10uF

C40

2.2uF

R34

4K7

R6

4K7

VCC-BAT

VSENSE

VCC-SYS

VCC-SYS

R43

10K

R37

10K

R36

10K

VCC-3.3

STAT

R38

10K

R45

1K

VCC-3.3

E5

10uF

R35

10K

VCC-3.3

R49

4K7

+

-

CN1

BATT CONN

M1

DMP2160UW

STAT

VSS

VBAT VDD

PROG

U5

MCP73832

Q4

BC846

Q5

BC846

C28

10nF

FP2

FERRITE

1

2

3

4

5

GND

ID

D+

D-

VBUS

CN3

USB MINIB

VCC-USB

C29

2.2uF

VCC-3.3

R46

22K

E10

10uF

R47

120K

VCC-1.8

VCC-1.8

R50

12K1

1

2

3

5

4

Vin

GND

EN ADJ

Vout

U3

AP7331-ADJ

DATA BUS

LD2

CHARGE

LD1

POWER

VCC-BAT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

HDR1

M1X26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

HDR2

M1X26

VCC-3.3 VCC-3.3

VCC-SYS

VCC-1.8VREF-1.8

FP3

VCC-3.3AVCC

FP4

C25

100nF

C30

2.2uF

C34

100nF

C36

2.2uF

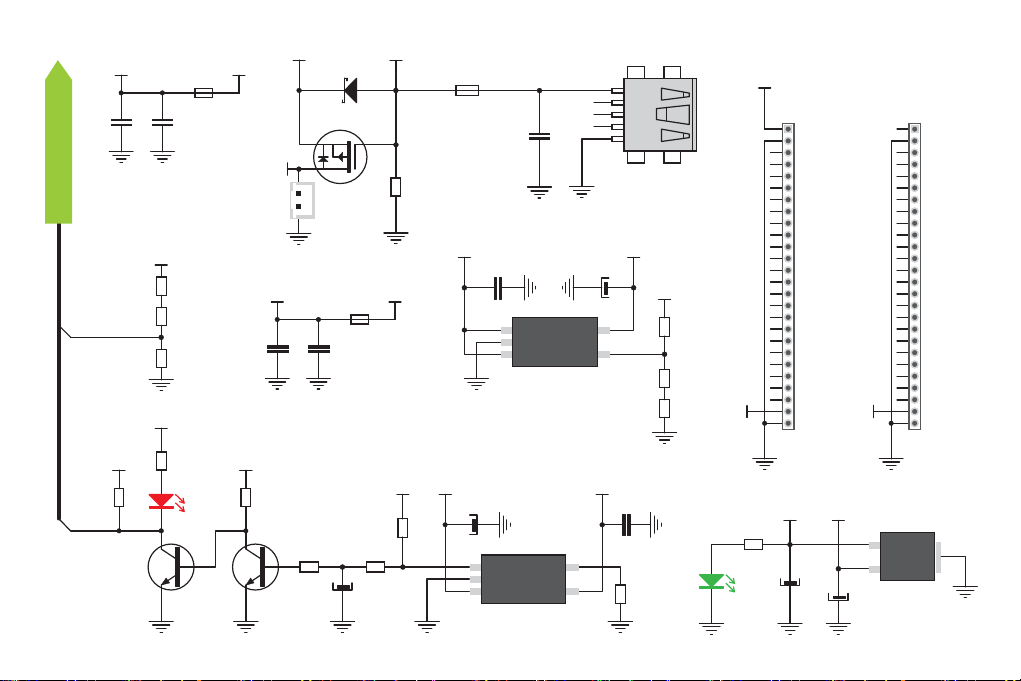

Figure 1-3: Power supply schematics

Page 9

Page 10

Page 11

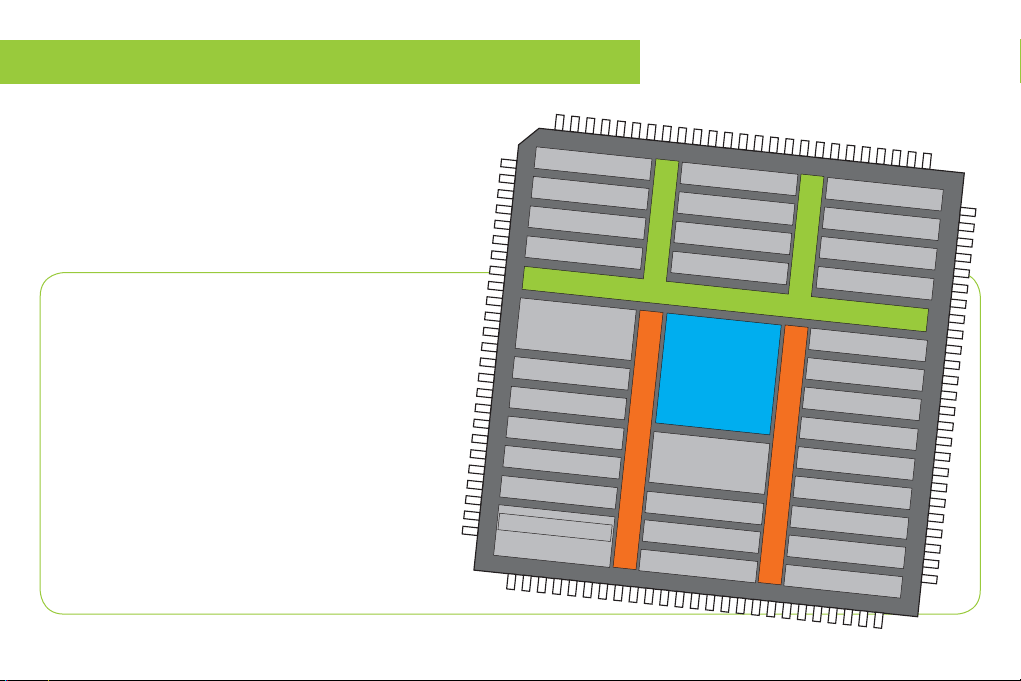

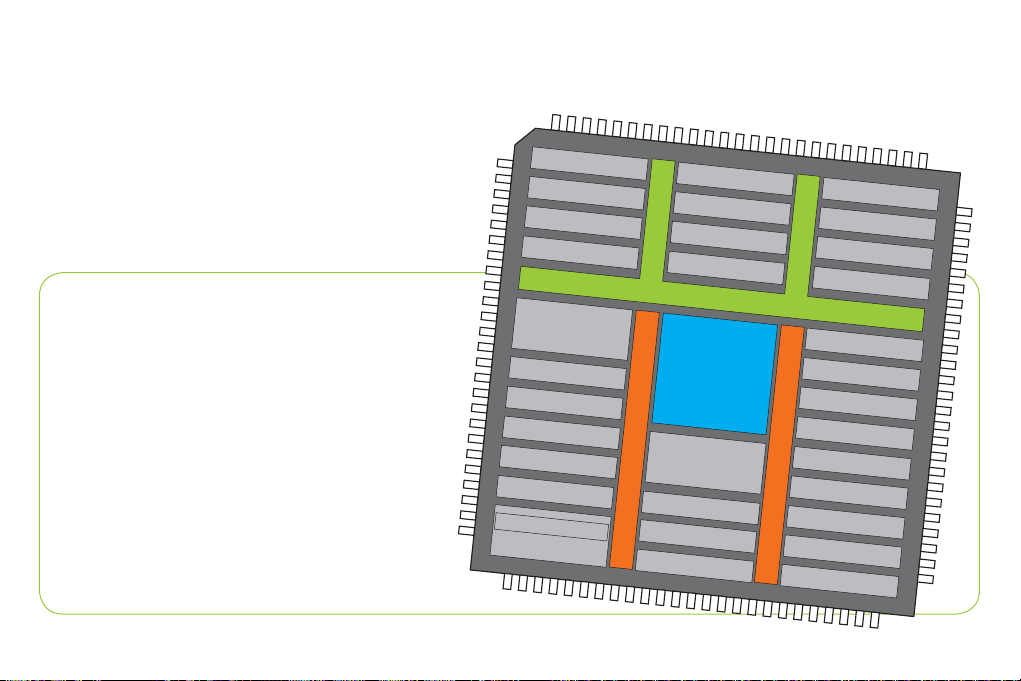

2. Key microcontrollers features

APB2 60MHz

3 x ADC

temperature sensor

1 x SPI

1 x USART

3 x TIMER 16-bit

3 x TIM/PWM 16-bit

SDIO/MMC

2 x CAN

3 x I2C

2 x SPI

2 x UART

2 x USART

5 x TIMER 16-bit

2 x TIMER 32-bit

APB1 30MHz

2 x DAC

3 x TIMER 16-bit

WWDG

RTC

IWDG

SRAM 112KB

FLASH 1MB

EXT. MEM. CONTR

DMA 2

ETH. MAC 10/100

JTAG & SW

USB OTG FS

CAM. INTERFACE

RNG

DMA 1

SRAM 16KB

USB OTG HS

AHB BUS - MATRIX

POWER / RESET

GPIO PORT

(A,B,C,D,E,F,G,H,I)

ARM

Cortex™-M3

STM32F207VGT6

The mikromedia for STM32® M3 development system comes

with the STM32F207VGT6 microcontroller. This highperformance 32-bit microcontroller with its integrated

modules and in combination with other on-board modules is

ideal for multimedia applications.

STM32F207VGT6

- 1.25 DMIPS/MHz, 32-bit Cortex™-M3 Core;

- 1 Mbyte Flash memory;

- 128 + 4 Kbytes of SRAM;

- 83 I/O pins;

- SPI, I2C, CAN, USB, Ethernet;

- USART, UART

- 16-bit and 32-bit Timers, up to 120Mhz;

- Internal Oscillator 16MHz, 32kHz, PLL;

- ADC, DAC, etc.

Page 10

Page 11

APB2 84MHz

3 x ADC

temperature sensor

1 x SPI

1 x USART

3 x TIMER 16-bit

3 x TIM/PWM 16-bit

SDIO/MMC

2 x CAN

3 x I2C

2 x SPI

2 x UART

2 x USART

5 x TIMER 16-bit

2 x TIMER 32-bit

APB1 42MHz

2 x DAC

3 x TIMER 16-bit

WWDG

RTC

IWDG

SRAM 176 KB

FLASH 1MB

EXT. MEM. CONTR

DMA 2

ETH. MAC 10/100

JTAG & SW

USB OTG FS

CAM. INTERFACE

RNG

DMA 1

SRAM 16KB

USB OTG HS

AHB BUS - MATRIX

POWER / RESET

GPIO PORT

(A,B,C,D,E,F,G,H,I)

ARM

Cortex™-M4

STM32F407VGT6

The mikromedia for STM32® M4 development system comes

with the STM32F407VGT6 microcontroller, which can deliver

even more processing power. With up to 168MHz operation,

this 32-bit microcontroller with other on-board modules is a

perfect choice for performance-demanding applications.

STM32F407VGT6

- 1.25 DMIPS/MHz, 32-bit Cortex™-M4 Core;

- 1 Mbyte Flash memory;

- 192 + 4 Kbytes of SRAM;

- 83 I/O pins;

- SPI, I2C, CAN, USB, Ethernet;

- USART, UART

- 16-bit and 32-bit Timers, up to 168Mhz;

- Internal Oscillator 16MHz, 32kHz, PLL;

- ADC, DAC, etc.

Page 11

Page 12

Page 13

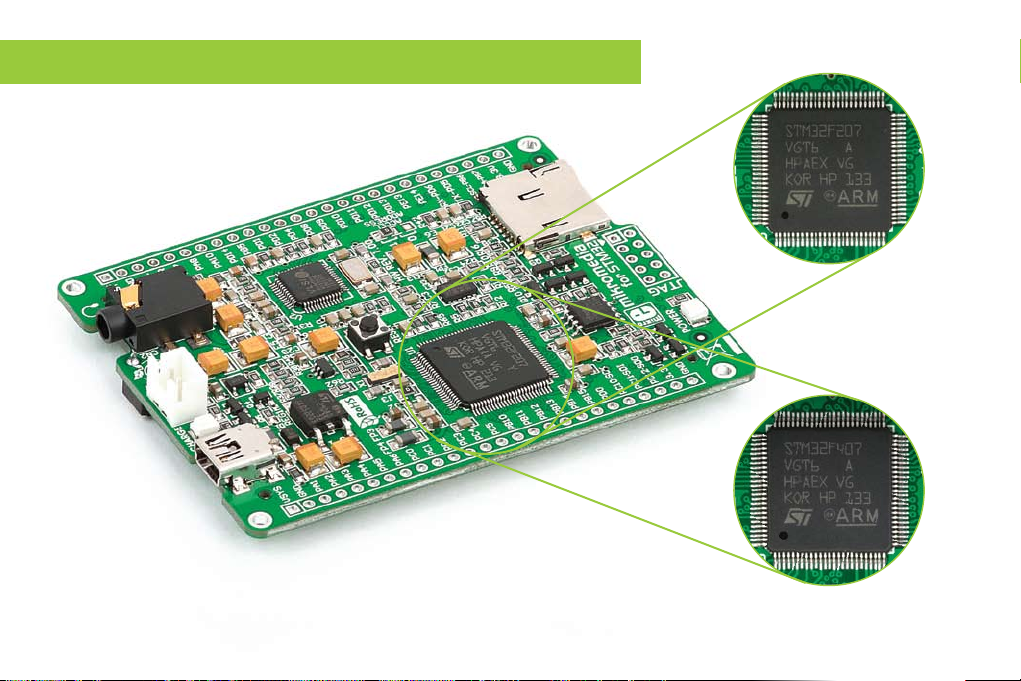

3. Programming the microcontroller

STM32F407VGT6

Microcontroller

Figure 3-1:

STM32F207VGT6

Microcontroller

Figure 3-2:

Page 12

Page 13

The microcontroller can be programmed in three ways:

Via USB mikroBootloader Using external mikroProg™

01 02

010101010101010101010101010101

programmer

Using external ST-LINK V2™

03

programmer

The mikromedia for STM32® development system can be programmed in three dierent ways.

pre-programmed into device by default or via external programmers (02 mikroProg™ or 03 ST-LINK V2™) .

Page 13

01

Using bootloader which is

Page 14

Page 15

Programming with mikroBootloader

You can program the microcontroller with bootloader which

is pre-programmed into the device by default. To transfer

.HEX le from a PC to MCU you need bootloader software

(mikroBootloader USB HID) which can be downloaded from:

http://www.mikroe.com/eng/products/view/853/

mikromedia-for-stm32/

After software is downloaded unzip it to desired location and

start mikroBootloader USB HID software.

step 1 – Connecting mikromedia

01

02

Figure 3-3: USB HID mikroBootloader window

To start, connect the USB cable, or if already connected

01

press the Reset button on your mikromedia board. Click the

”Connect” button within 5s to enter the bootloader mode,

otherwise existing microcontroller program will execute.

Page 14

Page 15

step 3 – Selecting .HEX le step 2 – Browsing for .HEX le

01

01

Figure 3-4: Browse for HEX Figure 3-5: Selecting HEX

01

Click the ”Browse for HEX” button and from a

01

pop-up window (Figure 3.5) choose the .HEX le

which will be uploaded to MCU memory.

Page 15

Select .HEX le using open dialog window.

01

02

Click the ”Open” button.

Page 16

Page 17

step 4 – Uploading .HEX le

01

Figure 3-6: Begin uploading Figure 3-7: Progress bar

01

To start .HEX le bootloading click the

01 01

”Begin uploading” button.

Page 16

You can monitor .HEX le uploading via progress bar

Page 17

step 5 – Finish upload

01

Figure 3-8: Restarting MCU

Click the ”OK” button after uploading is nished

01

and wait for 5 seconds. Board will automatically

reset and your new program will execute.

Figure 3-9: mikroBootloader ready for next job

Page 17

Page 18

Page 19

Programming with mikroProg™ programmer

The microcontroller can be programmed with external mikroProg™ for STM32® programmer and mikroProg Suite™ for ARM® software.

The mikroProg™ programmer is connected to the development system via the CN5 (JTAG) connector. You can choose between two ways to

program microcontrollers , Figure 3-14:

Via J TAG interface

01

Via Serial wire debug (SWD) interface

02

STM32® family. Outstanding performance, easy

operation and elegant design are it’s key features.

Before attaching the programming connector, you have to solder the provided 2x5 male header to the JTAG pads (CN5)

NOTE:

Page 18

programmer with mikroICD™

hardware In-Circuit Debugger.

It supports over 180 ARM® Cortex™

M3 and Cortex™ M4 microcontrollers from

Figure 3-10:

Connecting

mikroProg™ to

mikromedia™

mikroProg™

is a fast USB 2.0

Page 19

mikroProg Suite™ for ARM® Software

Copyright ©2011 Mikroelektronika.

All rights reserved. Mikroelektronika, Mikroelektronika logo and other

Mikroelektronika trademarks are the property of Mikroelektronika.

All other tradmarks are the property of their respective owners.

Unauthorised copying, hiring, renting, public performance and

broadcasting of this DVD prohibited.

20122011

www.mikroe.com

On-board mikroProg™ programmer requires special programming software called mikroProg

Suite™ for ARM®. This software is used for programming of all supported microcontroller

families with ARM® Cortex™-M3 and Cortex™-M4 cores. Software has intuitive

interface and SingleClick™ programming technology. To begin, rst locate the

installation archive on the Product DVD:

DVD://download/eng/software/development-tools/arm/mikroprog/

mikroprog_suite_for_arm_v110.zip

A

v

a

i

l

a

b

l

e

o

n

P

!

D

After downloading, extract the package and double click the executable

V

D

t

c

u

d

o

r

setup le, to start installation.

Figure 3-11:

Quick Guide

Click the Detect MCU button in order to recognize the device ID.

01

02

Click the Read button to read the entire microcontroller memory. You can click the Save

mikroProg Suite™ for ARM®

button to save it to target HEX le.

03

If you want to write the HEX le to the microcontroller, rst make sure to load the target

HEX le. You can drag-n-drop the le onto the software window, or use the Load button to

open Browse dialog and point to the HEX le location. Then click the Write button to begin

programming.

Page 19

window

Page 20

Page 21

Programming with ST-LINK V2 programmer

The microcontroller can be also programmed with ST-LINK V2 programmer and

mikroProg Suite™ for ARM® software, Figure 3-11 . This programmer connects

with mikromedia board via mikroProg to ST-LINK V2 adapter.

In order to adjust the ST-LINK™ V2 programmer

to be connected to the development system, it

is necessary to provide the appropriate adapter

such as the mikroProg to ST-LINK V2 adapter.

2x5 male headers should be rst soldered on the

CN5 connector pads. Then you should plug adapter into

the ST-LINK V2 programmer (2x10 male header), and plug

IDC10 at cable in male headers, Figure 3-13

Page 20

Figure 3-12:

mikroProg™ to

ST-LINK™ V2 adaper

Figure 3-13:

Connecting ST-LINK™ V2

programmer

Page 21

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

VCC-3.3

C5

100nFC6100nF

C7

100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3

VCC-3.3 VCC-3.3

VCC-3.3

C31

100nF

VCC-3.3

C2

22pF

C1

22pF

X1

32.768KHz

AVCC

TCK/

TMS/

TDI

TDO

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON (RFU)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

STM32F207VGT6

U1

OSC32_IN

OSC32_OUT

VREF-1.8

C41 2.2uF

C42

2.2uF

R66 100K

RESET#

VCC-3.3

TDO

SWCLK

SWCLK

SWDIO

TDI

RESET#

6

8

109

7

5

1 2

3 4

CN5

TRST

JTAG

decoupling

capacitors

R65

100K

VCC-3.3

J3

J2

TRST

TMS/

TCK/

(SWD)

STM32F407VGT6

SWDIO

Figure 3-14: mikroProg™

or JTAG programmer

connection schematics

Page 21

NOTE:

Jumper J3 is soldered by default

Page 22

Page 23

4. Reset Buttons

Board is equipped with two reset buttons. First is located at the back side of the

board (Figure 4-1), and second one is at the top of the front side (Figure 4-2) .

If you want to reset the circuit, press either of two buttons. It will generate low

voltage level on microcontroller reset pin (input). In addition,

a reset can be externally provided through pin 27 on

side headers (Figure 4-3).

NOTE:

Do not press the reset buttons

during programming

Figure 4-1: Reset button located at the backside of the board

Page 22

Figure 4-2: Frontal reset button

Page 23

decoupling

capacitors

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

R8

10K

VCC-3.3

C3

100nF

T1

R7 100

T2

VCC-3.3

C5

100nFC6100nFC7100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3 VCC-3.3 VCC-3.3VCC-3.3

C31

100nF

VCC-3.3

C2 22pF

C1 22pF

X1 32.768KHz

AVCC

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_O N(RFU)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

OSC32_IN

OSC32_OUT

VREF-1.8

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

RST

VCC-3.3

J3

J2

RX

TX

SDA

SCL

PWM

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

HDR2

M1X26

VCC-3.3

STM32F207VGT6

STM32F407VGT6

Figure 4-3: Reset circuit schematics

Page 23

Page 24

Page 25

5. Oscillators

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

VCC-3.3

C2

22pF

C1

22pF

X1

32.768KHz

AVCC

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON(RF U)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

OSC32_IN

OSC32_OUT

VREF-1.8

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

decoupling

capacitors

C5

100nFC6100nFC7100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3 VCC-3.3 VCC-3.3VCC-3.3

C31

100nF

VCC-3.3

VCC-3.3

J3

J2

STM32F207VGT6

STM32F407VGT6

STM32F207VGT6 and STM32F407VGT6

microcontrollers are equipped with internal

16MHz RC oscillator that provides stable clock

signal. Since the chips have an integrated PLL, this

base frequency is suitable for further clock multiplication.

Board also contains 32.768kHz Crystal oscillator (X1)

which provides external clock for internal RTCC module.

Figure 5-2:

Crystal oscillator

schematics

Crystal oscillator module (X1)

The use of crystal in all other schematics is implied even if it is

NOTE:

purposely left out, because of the schematics clarity.

Page 24

Figure 5-1:

Page 25

6. MicroSD Card Slot

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

SD-CS#

R11

10K

R10

10K

VCC-MMC

R9

10K

SD-CD#

VCC-MMC

R16

27

VCC-3.3

E6

10uF

C38

100nF

FP1

FERRITE

VCC-3.3

1

2

4

5

6

7

CS

Din

+3.3V

SCK

GND

Dout

CD

GND

CN4

MMC CARD MICRO

AVCC

SD-CD#

SD-CS#

SCK3-PC10

MOSI3-PC12

MISO3-PC11

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON(RF U)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

MISO3-PC1 1

R427R5

27

SCK3-PC10

MOSI3-PC1 2

VREF-1.8

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

decoupling

capacitors

C5

100nFC6100nFC7100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3 VCC-3.3 VCC-3.3VCC-3.3

C31

100nF

VCC-3.3

VCC-3.3

J3

J2

STM32F207VGT6

STM32F407VGT6

Board contains microSD card slot for using microSD cards in your

projects. It enables you to store large amounts of data externally,

thus saving microcontroller memory. MicroSD cards use Serial Peripheral

Interface (SPI) for communication with the microcontroller.

Page 25

Figure 6-2:

microSD Card Slot module connection schematics

Figure 6-1:

microSD card slot

Figure 6-3:

Inserting microSD card

Page 26

Page 27

7. Touch Screen

The development system features a TFT 320x240 display covered with a resistive

touch panel. Together they form a functional unit called a touch screen. It enables

data to be entered and displayed at the same time. The TFT display is capable of

showing data in 262.144 die rent colors.

Figure 7-1:

Touch Screen

Page 26

Page 27

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

R23

10K

VCC-SYS

LCD-RST

LCD-RS

LCD-CS#

LCD-YU

LCD-XL

LCD-YD

LCD-XR

VCC-3.3

E13

10uF

R25

10K

VCC-3.3

R24

10K

LCD-RST

LCD-CS#

VCC-3.3

LCD-BLED

R40

12

VCC-3.3

PMRD

PMWR

2

15

12

35

11

36

3

4

5

6

14

7

8

9

13

43

33

10

37

38

39

40

44

45

46

34

1

47

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

41

42

LED-K

LED-A1

LED-A2

LED-A3

LED-A4

IM0

IM1

IM2

IM3

RESET

VSYNC

HSYNC

DOTCLK

ENABLE

DB17

DB16

DB15

DB14

DB13

DB12

DB11

DB10

DB9

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

SDO

SDI

RD

WR/SCL

RS

CS

FMARK

VCC-IO

VCC

VCC-I

GND

XR

YD

XL

YU

TFT1

MI0283QT2

VCC-3.3

VCC-3.3

AVCC

Q9

BC856

Q10

BC846

R58

10K

R41

1K

VCC-1.8

R15

10K

R3

4K7

VCC-3.3

Q8

BC856

VCC-1.8

R55

10K

Q6

BC846

R14

10K

C21

100nF

R42

100K

Q7

BC846

R56

10K

C22

100nF

R57

100K

R54

4K7

VCC-3.3

LCD-XR

LCD-YU

LCD-XL

LCD-YD

DRIVEA

DRIVEB

Q3

BC846

Q2

BC846

Q1

BC846

T-D0

LCD-BLED

PMWR

P

MRD

LCD-RS

T-D2

T-D3

T-D6

DRIVEA

DRIVEB

-CS#

LCD-RST

T-D4

T-D7

T-D5

LCD-XL

LCD-YD

T-D1

T-D5

T-D7

T-D4

T-D3

T-D2

T-D1

T-D0

T-D6

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON(R FU)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

VREF-1.8

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

R51

1K

LCD

decoupling

capacitors

C5

100nFC6100nFC7100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3 VCC-3.3 VCC-3.3VCC-3.3

C31

100nF

VCC-3.3

VCC-3.3

J3

J2

STM32F207VGT6

STM32F407VGT6

Figure 7-2: Touch Screen

connection schematics

Page 27

Page 28

Page 29

8. Audio Module

Figure 8-2:

Inserting 3.5mm

headphones jack

Figure 8-1:

On-board VS1053

MP3 codec

The mikromedia for STM32® features stereo audio codec VS1053. This module

enables audio reproduction by using stereo headphones connected to the

system via a 3.5mm connector CN2. All functions of this module are controlled

by the microcontroller over Serial Peripheral Interface (SPI).

Page 28

Page 29

23456

7

11

12

13

14

5

24

23

22

21

18

17

16

15

8

1

19

9

107

6

20

890123456

37

38

39

40

41

42

43

44

45

46

47

48

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

MP3-CS#

C20

22pF

C19

22pF

C11

100nF

R1 1M

R20

10K

R21 10K

MP3-DR

EQ

MP3-RST#

C10

100nF

C4

100nF

C12

100nF

C9

100nF

R2

10K

R19

10K

C23

100nF

VCC-3.3

C24

100nF

VCC-3.3

C26

100nF

VCC-3.3 VCC-3.3

C27

100nF

X2

12.288MHz

C13

1uF

VCC-3.3

GPIO

VCC-3.3

LEFT

RIGHT

GBUF

VCC-1.8 VCC-1.8 VCC-1.8 VCC-1.8

VCC-3.3

E1 10uF

E2 10uF

CN2

PHONEJACK

LEFT

RIGHT

C16

10nF

C14

47nF

C15

10nF

R27

10

R3020R31

20

R28 10

R29 10

R32

470

C17

3.3nF

R17

100K

R33

470

C18

3.3nF

R18

100K

L

R

R22

27

22222333333

3

MCP/LN1

MICN

XRESET

DGND0

CVDD0

IOVDD0

CVDD1

DREQ

GPIO2

GPIO3

GPIO6

GPIO7

XDCS/BSYNC

IOVDD1

VC0

DGND1

XTAL0

XTAL1

IOVDD2

DGND2

DGND3

DGND4

XCS

CVDD2

GPIO5RXTX

SCLKSISO

CVDD3

XTEST

GPIO0

GPIO1

GND

GPIO4

AGND0

AVDD0

AVDD2

AGND1

AGND2

AGND3

LN2

LEFT

RCAP

AVDD1

GBUF

RIGHT

VS1053

U2

VCC-1.8 VCC-3.3

MP3-CS#

MP3-RST#

VCC-3.3

AVCC

MP3-DCS

MP3-DCS

MP3-RST#

MP3-DREQ

MP3-CS#

MISO3-PC 11

SCK3-PC10

MOSI3-PC 12

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON(R F U)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

MISO3-PC 11

R427R5

27

SCK3-PC10

MOSI3-PC 12

VREF-1.8

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

decoupling

capacitors

C5

100nFC6100nFC7100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3 VCC-3.3 VCC-3.3VCC-3.3

C31

100nF

VCC-3.3

decoupling

capacitors

VCC-3.3

J3

J2

STM32F207VGT6

STM32F407VGT6

Figure 8-3: Audio module connection schematics

Page 29

Page 30

Page 31

9. USB connection

STM32F207VGT6 and STM32F407VGT6

microcontrollers have integrated USB

module, which enables you to implement

USB communication functionality to your

mikromedia board. Connection with target USB

host is done over MINI-B USB connector which

is positioned next to the battery connector.

Figure 9-1:

Connecting USB

cable to programming

connector

Page 30

Page 31

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

VCC-USB

C28

10nF

FP2

FERRITE

VCC-3.3

R62 100

1

2

3

4

5

GND

ID

D+

D-

VBUS

CN3

USB MINIB

AVCC

USB-DET

USB-DET

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON (RFU)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

R64

100K

VREF-1.8

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

USB-D_N

USB-D_P

USB-D_N

USB-D_P

C5

100nFC6100nF

C7

100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3

VCC-3.3 VCC-3.3

VCC-3.3

C31

100nF

VCC-3.3

decoupling

capacitors

VCC-3.3

J3

J2

STM32F207VGT6

STM32F407VGT6

Figure 9-2: USB module connection schematics

Page 31

Page 32

Page 33

1

2

3

4

5

6 8

9

10

11

12

13

14

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

C32

100nF

C33

100nF

VCC-3.3

R12

10K

R13

10K

VCC-3.3

ACC ADDRESS

VCC

GND

Res

GND

GND

VCC

7

CS

INT1

INT2

NC

Res

ADD

SDA

SCL

U9

ADXL345

VCC-3.3

VCC-3.3

VCC-3.3

VCC-3.3

AVCC

SDA1-PB7

SCL1-PB6

SDA1-PB7

SCL1-PB6

1

2

3

J1

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON(RFU )

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

VREF-1.8

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

decoupling

capacitors

C5

100nFC6100nFC7100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3 VCC-3.3 VCC-3.3VCC-3.3

C31

100nF

VCC-3.3

VCC-3.3

J3

J2

STM32F207VGT6

STM32F407VGT6

10. Accelerometer

On board ADXL345 accelerometer is used to

measure acceleration in three axis: x, y and z. The

acceleromer’s function is dened by the user in the

program loaded into the microcontroller. Communication

between the accelerometer and the microcontroller is

performed via the I2C interface.

Figure 10-2: Accelerometer

connection schematics

Page 32

Figure 10-1:

Accelerometer

module

You can set the accelerometer

address to 0 or 1 by re-soldering the

SMD jumper (zero-ohm resistor) to the

appropriate position. Jumper is placed

in address 1 position by default.

Page 33

11. Flash Memory

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

C37

100nF

R48

10K

VCC-3.3

VCC-3.3

VCC-3.3

VCC-3.3

1

2

3

54

6

7

8

CS

SDO

WP

GND SDI

SCK

HOLD

VCC

U10

M25P80

AVCC

R59 27

FLASH-CS#

FLASH-CS#

MISO3-PC11

SCK3-PC10

MOSI3-PC12

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON(RF U)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

MISO3-PC1 1

R427R5

27

SCK3-PC10

MOSI3-PC1 2

VREF-1.8

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

decoupling

capacitors

C5

100nFC6100nFC7100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3 VCC-3.3 VCC-3.3VCC-3.3

C31

100nF

VCC-3.3

VCC-3.3

J3

J2

STM32F207VGT6

STM32F407VGT6

Figure 11-2:

Flash memory module connection schematics

Figure 11-1:

Flash memory module

Page 33

Since multimedia applications are

getting increasingly demanding, it is

necessary to provide additional memory

space to be used for storing more data.

The ash memory module enables the

microcontroller to use additional 8Mbit

ash memory. It is connected to the

microcontroller via the Serial Peripheral

Interface (SPI).

Page 34

Page 35

58

57

56

55

54

53

52

72

69

68

67

66

65

64

63

8

7

9

0

62

61

60

59

71

51

70

6

75

74

73

123456789

0

1

234

5

6

7

8

9

0

R7 100

VCC-3.3

AVCC

PA1

PA2

PC0

PA3

U2Rx-PD6

U2Tx-PD5

SDA1-PB7

SCL1-PB6

PA5

PA6

PA4

302928

27

34

33

46

36

35

42

43

44

45

37

50

9

48

49

11

12

3

2

4

3

7

7

24

23

18

17

16

15

14

13

5

6

7

8

10

7

8

1

2

22

21

20

19

38

39404

1

47

31

26

25

7

8888888889999999999

10

PE11

PE10

PE6

VBAT

PC13/TAMPER_RTC

PC14/OSC32_IN

PA10

PA9

PA8

PD9

PE13

PE12

PB13

PB14

PB15

PD8

PE14

PE15

PB5

PB4

PB3

PB7

PD7

PD6

PE5

PE4

PE1

PE0

PB9

PB8

BOOT0

PB6

OSC_IN

PA0-WKUP

VDDA

VREF+

GNDA

VDD

PC3

PA12

PA11

PB12

PC8

NRST

VDD

GND

PE7

PDR_ON(RF U)

VDD

PE2

PE3

PA2

PA1

VCAP

VDD

PC9

PD13

PB10

PB11

PD10

PE8

PB2

PD11

PD14

PD5

PC2

PC1

PC0

PB1

PE9

PD12

PC7

OSC_OUT

PC15/OSC32_OUT

PD15

PC6

PA13

PC10

PA14

VCAP

GND

VDD

PA15

PC11

PC12

PD0

PA6

PA5

PC4

PA7

PC5

PB0

GND

VDD

PA3

PA4

PD1

PD2

PD3

PD4

U1

MISO3-PC1 1

R427R5

27

SCK3-PC10

MOSI3-PC1 2

VREF-1.8

PD0

P

A7

PA8

PA10

PD14

PC1

PC2

PC3

PC4

P

C5

SCL2-PB10

SDA2-PB11

PB12

SCK2-PB13

MISO2-PB14

MOSI2-PB15

PB5

PD1

PD2

PD4

PD8

PD9

PD10

PD11

PD12

PD13

R65

100K

C41 2.2uF

C42

2.2uF

R66 100K

RST

RX

TX

SCK

SDI

SDO

SDA

SCL

AN

INT

PWM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

HDR1

M1X26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

HDR2

M1X26

VCC-3.3

VCC-3.3

VCC-SYS

RST

L

R

PC4

U2Rx-PD6

U2Tx-PD5

MISO3-PC11

SCK3-PC10

MOSI3-PC12

SDA1-PB7

SCL1-PB6

PA1

PA2

PC0

PA3

PA4

PA6

PA5

PD2

PC2

PC3

PC5

PD0

PA7

PA8

PA10

PD14

PC1

SCL2-PB10

SDA2-PB11

SCK2-PB13

PB12

MISO2-PB14

MOSI2-PB15

PB5

PD1

PD4

PD8

PD9

PD10

PD11

PD12

PD13

PE13

PE14

PE13

PE14

decoupling

capacitors

C5

100nFC6100nFC7100nFC8100nF

E8

10uF

VCC-3.3 VCC-3.3 VCC-3.3 VCC-3.3VCC-3.3

C31

100nF

VCC-3.3

VCC-3.3

J3

J2

STM32F207VGT6

STM32F407VGT6

12. Pads

Pads HDR2 Pads HDR1

Most microcontroller pins are available for further connectivity via two 1x26 rows of connection

pads on both sides of the mikromedia board. They are designed to match additional shields,

such as Battery Boost shield, Gaming, PROTO shield and others.

Figure 12-1: Pads connecting schematics

Page 34

Page 35

13. Pinout

VSYS RST Reset pinSystem power supply

GND GND Reference GroundReference Ground

PA1 L

PA2 R

Analog Lines

Interrupt Lines

Digital I/O lines

SCK

SPI Lines

3.3V power supply

Reference Ground

Pin functions Pin functions

SDI

SDO

PA3 PA7

PA4 PA8

PA5 PA10

PA6 PD14

PC0 PB5

PC1 PD1

PC2 PD2

PC3 PD4

PC4 PD8

PC5 PD9

PB10 PD10

PB11 PD11

PB12 PD12

PB13 PD13

PB14 PE13

PB15 PE14

PD0 PD6

PC10 PD5

PC11 PB6

PC12 PB7

3.3V 3.3V 3.3V power supply

GND GND Reference Ground

left ch.

right ch.

PWM lines

Digital I/O lines

RX

TX

SCL

SDA

audio out

UART Lines

2

I

C Lines

Digital lines

Page 35

SPI LinesInterrupt LinesAnalog Lines

I2C Lines

UART lines

PWM lines

Page 36

Page 37

73.66 mm

81.15 mm

63.5 mm

2.67 mm2.54 mm

36.58 mm

55.88 mm

60.45 mm

2.03 mm

(3195 mils)

(2900 mils)

(2380 mils)

(2200 mils)

(2500 mils)

(1440 mils)

(105 mils)(100 mils)

(80 mils)

8.89 mm

(350 mils)

7.62 mm

(300 mils)

14. Dimensions

Page 36

Page 37

15. Mikromedia accessories

We have prepared a set of

extension boards pin-compatible

with your mikromedia, which

enable you to easily expand

your board basic functionality.

We call them mikromedia

shields. But we also oer other

accessories, such as Li-polymer

battery, stacking headers, wire

01

jumpers and more.

Connect shield

02

BatteryBoost shield PROTO shield

03

04

Gaming shield

05 06 07

Li-Polimer battery Wire Jumpers Stacking headers

Page 37

Page 38

Page 39

What’s next?

You have now completed the journey through each and every feature of mikromedia for STM32® board. You got to know it’s modules and

organization. Now you are ready to start using your new board. We are suggesting several steps which are probably the best way to begin. We

invite you to join the users of mikromedia™ brand. You will nd very useful projects and tutorials and can get help from a large ecosystem of

users. Welcome!

Compiler

You still don’t have an appropriate compiler? Locate ARM® compiler that suits you best on

the Product DVD provided with the package:

DVD://download/eng/software/compilers/

Choose between mikroC™, mikroBasic™ and mikroPascal™ and download fully functional

demo version, so you can begin building your rst applications.

Projects

Once you have chosen your compiler, and since you already got the board, you are ready to start writing your rst

projects. Visual TFT software for rapid development of graphical user interfaces enables you to quickly create your

GUI. It will automatically create necessary code which is compatible with mikroElektronika compilers. Visual TFT is

rich with examples, which are an excellent starting point for your future projects. Just load the example, read well

commented code, and see how it works on hardware. Visual TFT is also available on the Product DVD.

Page 38

Page 39

DISCLAIMER

All the products owned by MikroElektronika are protected by copyright law and international copyright treaty. Therefore, this manual is to be treated as any

other copyright material. No part of this manual, including product and software described herein, may be reproduced, stored in a retrieval system, translated or

transmitted in any form or by any means, without the prior written permission of MikroElektronika. The manual PDF edition can be printed for private or local use,

but not for distribution. Any modication of this manual is prohibited.

MikroElektronika provides this manual ‘as is’ without warranty of any kind, either expressed or implied, including, but not limited to, the implied warranties or

conditions of merchantability or tness for a particular purpose.

MikroElektronika shall assume no responsibility or liability for any errors, omissions and inaccuracies that may appear in this manual. In no event shall MikroElektronika,

its directors, ocers, employees or distributors be liable for any indirect, specic, incidental or consequential damages (including damages for loss of business

prots and business information, business interruption or any other pecuniary loss) arising out of the use of this manual or product, even if MikroElektronika has

been advised of the possibility of such damages. MikroElektronika reserves the right to change information contained in this manual at any time without prior

notice, if necessary.

HIGH RISK ACTIVITIES

The products of MikroElektronika are not fault – tolerant nor designed, manufactured or intended for use or resale as on – line control equipment in hazard-

ous environments requiring fail – safe performance, such as in the operation of nuclear facilities, aircraft navigation or communication systems, air trac

control, direct life support machines or weapons systems in which the failure of Software could lead directly to death, personal injury or severe physical or

environmental damage (‘High Risk Activities’). MikroElektronika and its suppliers specically disclaim any expressed or implied warranty of tness for High

Risk Activities.

TRADEMARKS

The MikroElektronika name and logo, the MikroElektronika logo, mikroC™, mikroBasic™, mikroPascal™, mikroProg™, mikroBUS™, Click Boards™, EasyMx PRO™ and

mikromedia™ are trademarks of MikroElektronika. All other trademarks mentioned herein are property of their respective companies.

All other product and corporate names appearing in this manual may or may not be registered trademarks or copyrights of their respective companies, and are only

used for identication or explanation and to the owners’ benet, with no intent to infringe.

Copyright © MikroElektronika, 2012, All Rights Reserved.

Page 39

Page 40

mikromedia for STM32® M3/M4

Manual ver. 1.00

0 100000 019511

If you want to learn more about our products, please visit our website at www.mikroe.com

If you are experiencing some problems with any of our products or just need additional

information, please place your ticket at www.mikroe.com/esupport

If you have any questions, comments or business proposals,

do not hesitate to contact us at oce@mikroe.com

Loading...

Loading...