Page 1

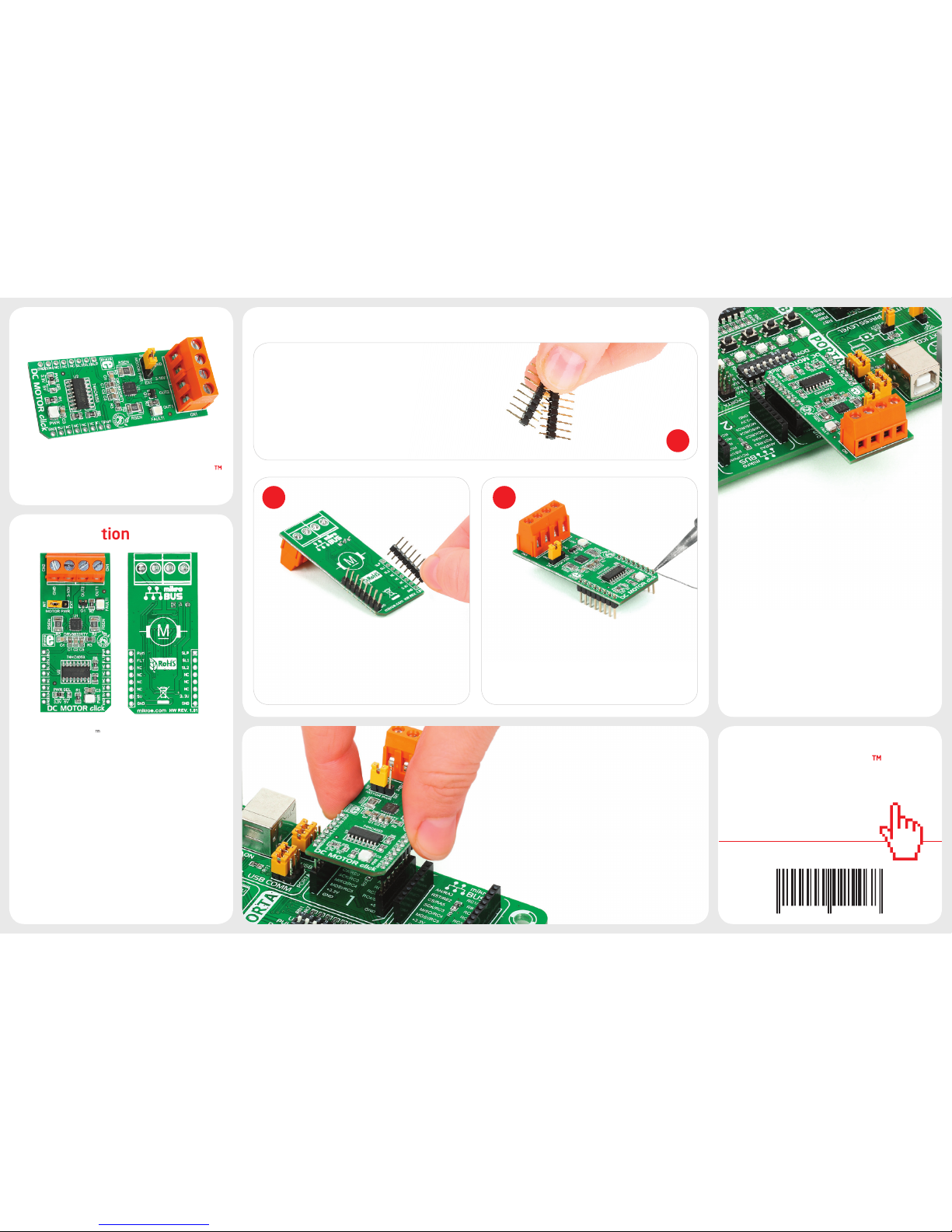

1. Introduction

Once you have soldered the headers your

board is ready to be placed into the desired

mikroBUS™ socket. Make sure to align the

cut in the lower-right part of the board

with the markings on the silkscreen at the

mikroBUS™ socket. If all the pins are aligned

correctly, push the board all the way

into the socket.

3. Plugging the board in

2 3

2. Soldering the headers

1

4. Essential features

Turn the board upward again. Make sure

to align the headers so that they are

perpendicular to the board, then solder the

pins carefully.

Turn the board upside down so that

the bottom side is facing you upwards.

Place shorter pins of the header into the

appropriate soldering pads.

Before using your click™ board, make sure

to solder 1x8 male headers to both left

and right side of the board. Two 1x8 male

headers are included with the board in

the package.

click

BOARD

www.mikroe.com

DC Motor click Manual

ver. 1.01

0 100000 025468

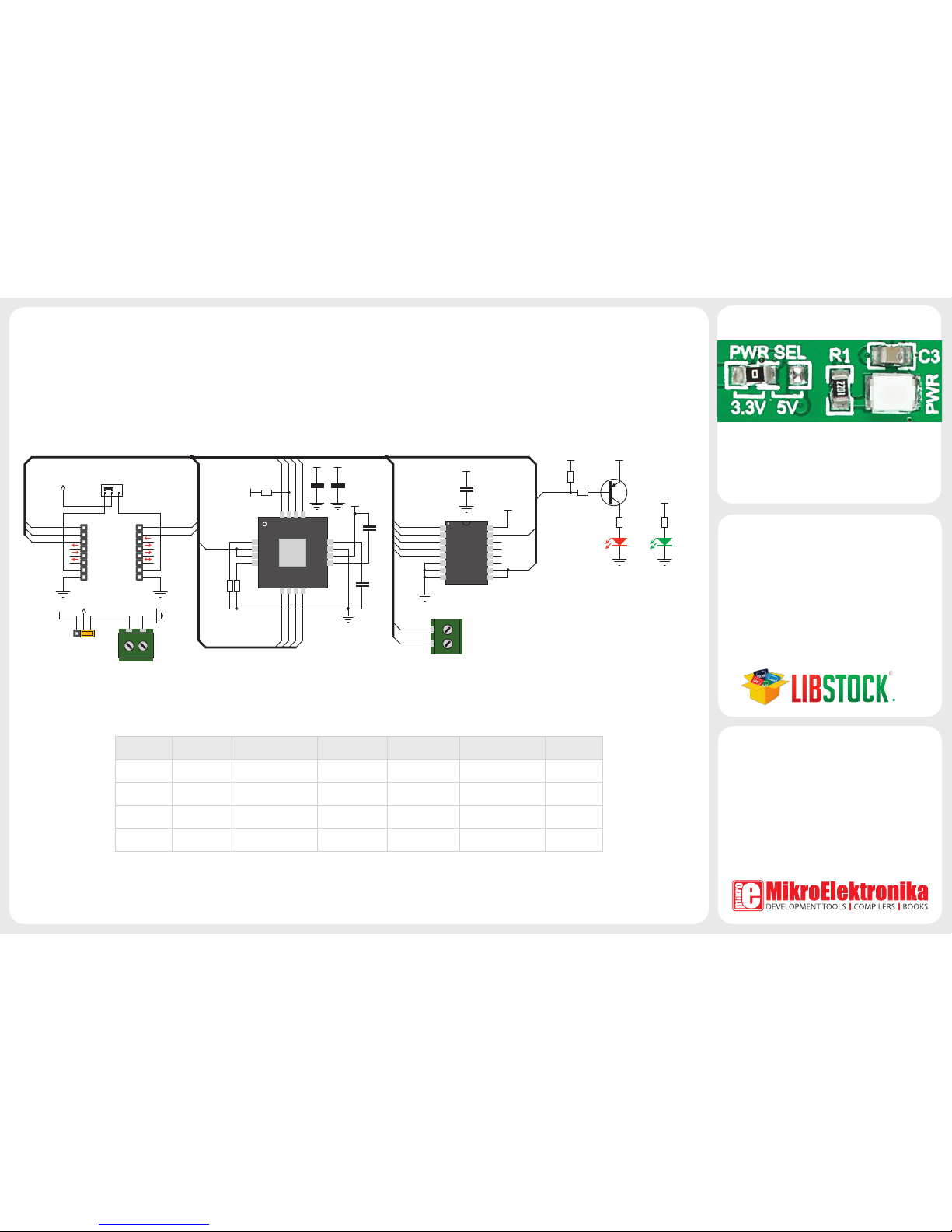

DC MOTOR click™ is a DC motor driver board

in mikroBUS™ form factor. It features the

DRV8833RTY H-Bridge motor driver,

74HC4053 multiplexer and two screw

terminals. DC MOTOR click™ communicates

with the target board via SELECT1,

SELECT2 and nSLEEP control lines, PWM

input line and nFAULT feedback line. The

board is designed to use 3.3V or 5V power

supplies. It has a GREEN power supply

indicator LED and a RED LED that indicates

active nFAULT line (in case of short-circuit).

DC MOTOR click™ with its DRV8833RTY

IC’s is limited to a 0.9A driving current

with 0.22Ω current sense resistor. The

74HC4053 IC is incorporated into the

design in order to run the motor with only

one PWM line available on the mikroBUS™

socket. Use jumper J2 to select whether you

want to power the board with the on-board

or external power supply connected to the

CN2 screw terminal. The motor should be

connected to the CN1 screw terminal.

DC MOTOR click

Page 2

8. Support

MikroElektronika oers Free Tech Support

(www.mikroe.com/support/) until the end

of the product’s lifetime, so if something

goes wrong, we’re ready and willing to help!

7. Code Examples

.com

Once you have done all the necessary

preparations, it’s time to get your click™ board

up and running. We have provided examples

for mikroC™, mikroBasic™ and mikroPascal™

compilers on our Libstock website. Just

download them and you are ready to start.

C1

10uF

AN

RST

CS

SCK

MOSI

MISO

+3.3V

GND

PWM

INT

RX

TX

SCL

SDA

+5V

GND

MIKROBUS DEVICE CONN.

R1

2K2

LD1

VCC

C4

10nF

J1A

PWM

SELECT2

C5

2.2uF

1

2

3

4

5

6

7

8

9

10

11

12

131415

16

nSLEEP

AOUT2

AISEN

AOUT1

BOUT2

BISEN

BOUT1

nFAULT

VCP

BIN2

AIN1

AIN2

VINT

GND

VM

BIN1

GND

U1

DRV8833RTY

nFAULT

R2

0.22

nSLEEP

nFAULT nSLEEP

OUT2

OUT1

VM

C2

100nF

R3

47K

VCC

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

2Y1

2Y0

3Y1

3Z

3Y0

E

VEE

GND

S1

S2

VDD

2Z

1Z

1Y1

1Y0

S3

74HC4053

U2

74HC4053

PWM

VCC

C3

100nF

VCC

PWM1

PWM0

SELECT1

GPIOA

GPIOB

SELECT2

PWM0

GPIOB

GPIOAPWM1

R5

0.22

OUT1

OUT1

OUT2

J2B

VM

VCC

VCC-EXT

VM VM

CN2

SCREW TERMINAL

SCREW TERMINAL

CN1

VCC

Q1

BC856

R4

2K2

R6

220

LD2

R7

10K

VCC VCC

FAULT POWER

nFAULT

SELECT1

MikroElektronika assumes no responsibility or liability for any errors or inaccuracies that may appear in the present document.

Specication and information contained in the present schematic are subject to change at any time without notice. Copyright © 2014 MikroElektronika. All rights reserved.

5. DC MOTOR click™ Board Schematic

6. SMD Jumpers

There is a single SMD jumper (zero-ohm

resistor) J1 which is used to select between

3.3V or 5V power supplies. By default, it’s

soldered in the 3.3V position.

0 0 0-100% Forward MIN-MAX @ 0% PWM Fast

0 1 0-100% Reverse MIN-MAX @ 0% PWM Fast

1 0 0-100% Reverse MAX-MIN @ 100% PWM Slow

1 1 0-100% Forward MAX-MIN @ 100% PWM Slow

SELECT1 SELECT2 PWM ROTATION SPEED BRAKE DECAY

With two control lines SELECT1, SELECT2 and PWM input you can choose from the following driving options described in the table:

Loading...

Loading...