Page 1

Go to Cloud

(G2C) click

U S E R M A N U A L

The WiFi IoT gateway Click board™ which

connects your IoT devices with the Click

Cloud service provided by MikroElektronika.

Simple and reliable.

Page 2

To our valued customers

I want to express my thanks to you for being interested in our products

and for having confidence in MikroElektronika.

The primary aim of our company is to design and produce high quality

electronic products and to constantly improve the performance thereof in

order to better suit your needs.

Nebojsa Matic

General Manager

Page 2

Page 3

Table of Contents

Introduction to Go to Cloud (G2C) click 4

mikroBUS™ pins 7

Onboard indicators and LED indicators 8

Pins description 8

UART interface – configuration 9

Boot-up sequence 10

Firmware update 12

Page 4

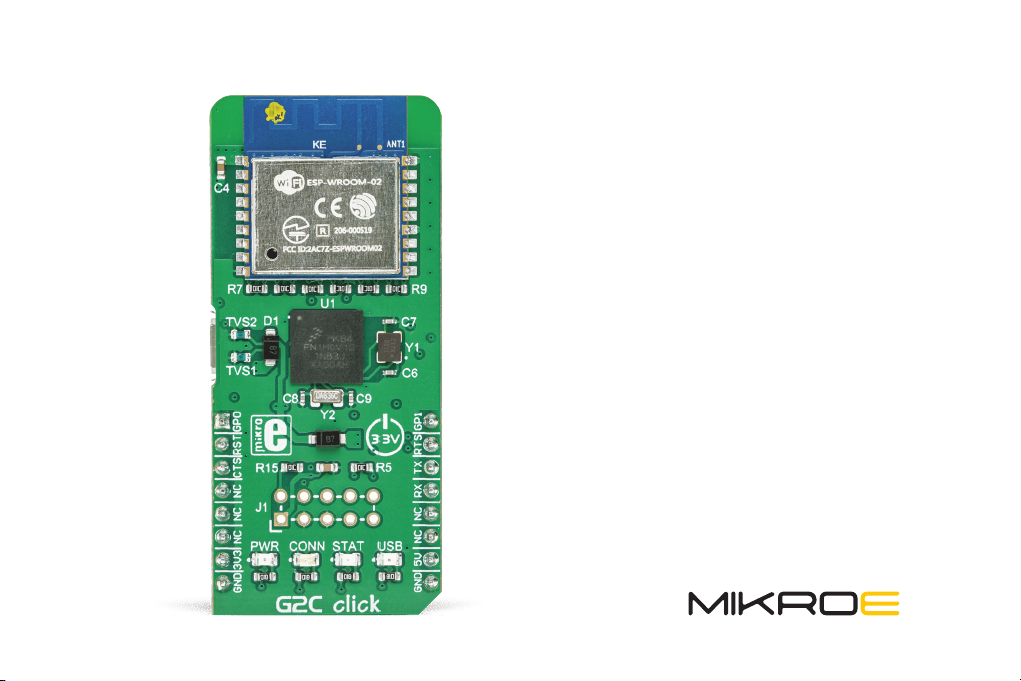

Introduction to Go to Cloud (G2C) click

Go to Cloud (G2C) click is composed of two main components:

∫ MK64FN1M0VDC12, a 32-bit ARM® Cortex® M4 microcontroller, from NXP

∫ ESP WROOM-02, a Wi-Fi connector module, from Espressif systems

The ESP-WROOM-02 is used as the connector module which can establish a link with the Click cloud service over the Internet.

It is an all-in-one solution, with the complete Wi-Fi stack on-board, which allows a very simple operation. This feature, along

with the proven reliability, small form-factor, and low count of components it requires, makes the ESP WROOM-02 module

an ideal solution for using it on the Go to Cloud (G2C) click.

The ESP-WROOM-02 module uses the UART communication interface, and it can be controlled by using simple AT

commands. However, the MK64FN1M0VDC12 MCU is added too, introducing an additional application layer, exposing

only a set of commands that allow connection with the Click Cloud, reducing the possibility of errors and failures due

to wrongly set connection parameters and simplifying HOST MCU application. The MCU is also used to drive status

LEDs, which are used to indicate a successful connection to the Internet, a successful connection with the Click Cloud

service, as well as some other types of indication.

Page 4

Page 5

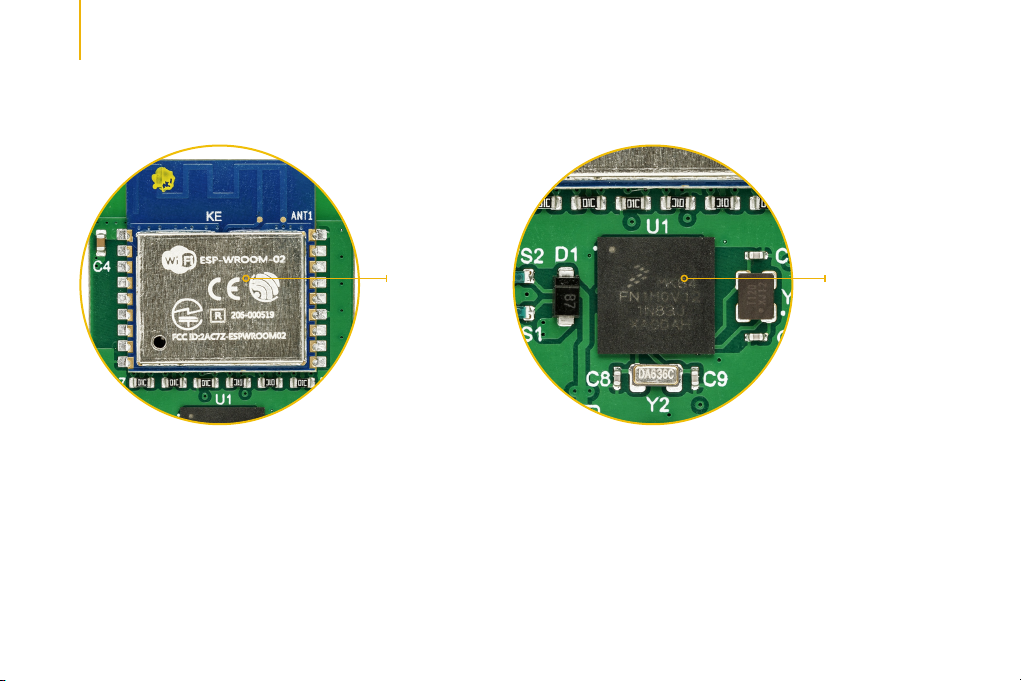

Figure 1:

ESP-WROOM-02

Finally, there is a micro USB connector, which is used to update the firmware of the Go to Cloud (G2C) click. The

firmware update is simple, error-proof, and straight-forward. More information about the update procedure can be

found in this manual.

Page 5

Figure 2:

MK64FN1

M0VDC12 MCU

Page 6

VOUT-3.3 VOUT-3.3

VCC-3.3

VCC-USB

R1

R2

1k

1k

LD1

LD2

PWR

USB

VCC-USB

CN1

1

VBUS

2

D-

3

D+

4

ID

5

GND

6

CONN_LED

STATUS_LE D

R3

1k

LD3

STAT

VCC-5V

D1

PMEG3010ER,115

R12 27

R11 27

R10

1M

TVS1 TVS2

VOUT-3.3

VCC-5V

R4

1k

LD4

CONN

VCC-5V

2.2µF

L7

C1

B11

C11

2.2µF

A11

K3

H4

E4

E3

E2

F4

E7

F7

H7

G4

F3

E6

G7

L6

F1

F2

G1

G2

H1

C5

H2

J1

J2

K1

K2

L1

L2

E1

U1

PTD15

RTC_WAKEUP_B

PTB12

PTB13

NC

NC

NC

PTE0

PTE1/LLWU_P0

PTE2/LLWU_P1

PTE3

VDD

VSS

PTE4/LLWU_P2

PTE5

PTE6

VDD

VSS

VSS

USB0_DP

USB0_DM

VOUT33

VREGIN

ADC0_DP1

ADC0_DM1

ADC1_DP1

ADC1_DM1

ADC0_DP0/ADC1_DP3

ADC0_DM0/ADC1_DM3

ADC1_DP0/ADC0_DP3

ADC1_DM0/ADC0_DM3

D2

D1

C1C2B1

PTD11

PTD13

PTD12

PTD10

PTD14

VREFH

VREFL

VSSA

VDDA

ADC1_SE16 / CMP2_IN2/A D C0_SE22

J3

F5

F6

G5

G6

32.768kHz

UART0_RTS

A10

A9

B2A2A3B3D3D4A4

B4C4A6A5B5

C3

A1

PTD1

PTD5

PTD3

PTD9

PTD8

PTD7

PTC18

PTC17

PTC19

LLWU_P13/P TD2

LLWU_P12/P TD0

LLWU_P14/P TD6

LLWU_P14/P TD4

MK64FN1M0VDC12

PTA0

PTA2

VREF_OUT/ CMP1_IN5 CMP0_IN 5/ADC1_SE1 8

ADC0_SE16/ CMP1_IN2/AD C0_SE21

L3

H3

C8

12pFC912pF

PTA1

VBAT

PTE25

DAC0_OUT/ CMP1_IN3/AD C0_SE23

DAC1_OUT/ CMP0_IN4 CMP2_IN 3/ADC1_SE2 3

XTAL32

PTE24

EXTAL32

PTE26

J5

J6

J7

L4

H5

K5

H8

K4L5K6

H6

Y2

JTAG_TDO

JTAG_TDI

JTAG_TCLK

D5B6C5

PTC15

PTC16

PTC14

PTA4/LLWU _P3

PTA5

PTA3

K7J8H9

JTAG_TMS

C6D6A7A8D7C7B7

MK64FN1M0VDC12

PTC9

PTC8

PTC7

PTC13

PTC12

PTC10

LLWU_P9/PT C5

LLWU_P10/P TC6

LLWU_P11/P TC11

LLWU_P8/PTC4

B8

LLWU_P7/PTC3

C8

PTC2

LLWU_P6/PTC1

PTC0

PTB23

PTB22

PTB21

PTB20

PTB19

PTB18

PTB17

PTB16

PTB11

PTB10

PTB9

PTB8

PTB7

PTB6

PTB3

PTB2

PTB1

LLWU_P5/PTB0

PTA29

RESET_b

PTA19

PTA18

VSS

VDD

PTA17

PTA13/LLWU _P4

PTA14

PTA16

PTA10

PTA15

PTA12

PTA11

VDD

VSS

J9

J4

E5

L8

L9

G3

K8

K9

J10

STATUS_LED

D8

ESP_RST

B9

E8

F8

F9

F10

C9

D9

E9

B10

C10

D10

VOUT-3.3

E10

D11

E11

F11

R5

G8

10k

G9

G10

ESP_EN

G11

CONN_LED

H11

J11

MCU_RST

K11

L11

K10

L10

H10

Y1

12MHz

C6

12pFC712pF

IO0

IO15

IO13

ESP_TXD

ESP_RXD

UART0_TX

UART0_RX

UART0_CTS

R15

10k

JTAG_TMS

JTAG_TCLK

JTAG_TDO

JTAG_TDI

MCU_RST

GP0 GP1

MCU_RST

UART0_CTS

GP1

GP0

IO0

12

34

56

78

C2

910

0.10µF

J1

VCC-3.3

AN

RST

CS

SCK

MISO

MOSI

+3.3V

GND

MIKROBUS DEVICE CONN

VOUT-3.3 VOUT-3.3 VOUT-3.3

VOUT-3.3

R6

10kR710kR810k

ESP_EN

IO14

IO12

IO13

IO15

R14

R13

10k

10k

VCC-3.3

IO2

PWM

INT

TX

RX

SCL

SDA

+5V

GND

C3 10µF

C4 0.10µF

1

3.3V

2

EN

3

IO14

4

IO12

5

IO13

6

IO15

7

IO2

8

IO0

GND

U2

VCC-5V

UART0_RTS

UART0_TX

UART0_RX

D2

PMEG3010ER,115

ESP-WROOM-02

R9

10k

18

18

GND

17

17

IO16

16

16

TOUT

15

ESP_RST

15

RST

14

14

IO5

13

13

GND

12

ESP_TXD

12

TXD

ESP_RXD

11

11

RXD

109

10

IO4

Figure 3: Main Schematic

Page 6

Page 7

An additional JTAG interface in the form of 2x5 pin header is used only during the production phase for the upload of

the initial firmware and it should not be used by the user, as it may lead to malfunction of the Go to Cloud (G2C) click

due to an internal firmware damage.

mikroBUS™ pins

Page 7

Page 8

Onboard indicators and LED indicators

NOTE:

The Go to Cloud (G2C) click requires both 3.3V and 5V for a proper operation.

Pins description:

∫ RST - Hardware reset - (INPUT) This pin is used to reset the MCU. This pin is internally pulled up to a HIGH logic level. Driving

this pin to a LOW logic level for 50 ms, a reset function will be performed. After each reset cycle, the complete boot sequence

of the Go to Cloud (G2C) click is repeated.

Page 8

Page 9

∫ CTS - Clear to send

is ready to receive data sent from Go to Cloud (G2C) click.

∫ RTS - Request to send

is ready to accept incoming data from the host MCU. There is also a secondary function of this pin: if set to a HIGH

logic level during the boot-up sequence, the five-second bootloader timeout will be completely skipped, allowing for

a faster start of the Go to Cloud (G2C) click. More information about the secondary function of this pin is provided in the

Boot-up section of this manual.

∫ GP0, GP1 - General purpose pins

is ready to receive data sent from Go to Cloud (G2C) click.

[1]

The current version of the firmware (ver.F091) does not have these options implemented yet, but they are

planned to be added in future updates.

[1]

- (INPUT) A LOW logic level on this pin means that HOST MCU

[1]

- (OUTPUT) A LOW logic level on this pin means that the Go to Cloud (G2C) click

[1]

- (INPUT) A LOW logic level on this pin means that HOST MCU

UART interface – configuration:

∫ Baud rate: 57600

∫ Data bits: 8

∫ Parity: NO

∫ Stop bit: 1

Page 9

Page 10

The complete control of the Go to Cloud (G2C) click is done over the UART interface, by using AT commands. The list

of the available AT commands, along with the explanation and example for each of them can be found in the

AT Command Manual.

The Go to Cloud (G2C) click firmware accepts AT commands, which can be sent over the UART interface pins of

the mikroBUS™, either from a terminal application on a personal computer (with the addition of the USB-to-UART

adapter) or from the host MCU. When transmitting the AT command string, a timing interval between consecutive

characters should not exceed 5 seconds. The timing interval greater than 5 seconds is considered as the EOL for any

AT command (end-of-line), and the received command will be parsed as such.

More information about all the available AT commands with the detailed explanation can be found in the AT Commands Manual.

UART interface – configuration:

After the power-on, the Go to Cloud (G2C) click will start in the bootloader mode, which will be terminated after 5

seconds. During these 5 seconds, the MK64F MCU onboard the Go to Cloud (G2C) click will be visible to the USB

HID Bootloader application, allowing its firmware to be updated. When the connection with the USB HID Bootloader

application is established, it will take over the control of the Go to Cloud (G2C) click and will keep it in the bootloader

Page 10

Page 11

mode. If there is no response from the USB HID Bootloader application while the Go to Cloud (G2C) click is in the

bootloader mode, the normal operation of the Go to Cloud (G2C) click will be resumed and the MK64F MCU will not be

visible for the USB HID Bootloader application anymore.

After a connection with the USB Bootloader application is established, the STAT LED will be turned on and it will stay

that way as long as the bootloader mode is active. Leaving the bootloader mode will be indicated by the CONN LED,

which will blink once, while the STAT LED will be turned off.

The bootloader mode will be automatically initiated after each power-on event, leading to a five-second startup

delay. To skip the bootloader mode completely and boot-up directly into the normal mode, the CTS pin can be set to

a HIGH logic level after the restart, for at least 100ms. This prevents the five-second delay during the power on if the

firmware update was not intended, shortening the boot-up time before the G2C click is ready to be used.

During the boot-up sequence, the default configuration values will be restored from the internal non-volatile memory.

More details about storing and restoring the default configuration parameters can be found in the AT Commands

Manual.

The end of the boot-up sequence will be indicated by a single blink of both the STAT and CONN LEDs, simultaneously.

NOTE:

After leaving the bootloader, a delay of at least 3 seconds has to be made, allowing the connector module to reboot properly.

Page 11

Page 12

Firmware update

The G2C click is shipped with the latest version of

firmware. However, the firmware will be continuously

improved in the future. Therefore, the Go to Cloud (G2C )

click has a firmware update option, in a form of a micro

USB connector (CN1) and an implementation of the HID

bootloader within the firmware itself.

To properly update the firmware, please use the provided

micro USB connector (CN1) with the HID bootloader

application and a proper firmware file. The JTAG 2x5-pin

header (J1) is not to be used for uploading the update

since it can destroy the base firmware and render the

G2C click inoperable. It is used only for the initial firmware

update during the production. The Go to Cloud (G2C )click

is shipped with this header unpopulated.

The firmware update can be done by using the USB HID

Bootloader application. After a USB cable is connected to

the micro USB connector on the Go to Cloud (G2C )click,

the application will detect the onboard MK64F MCU, as

displayed on the picture below:

Figure 4: USB HID Bootloader connected to the Go to

Cloudd (G2C) click

Page 12

Page 13

Note that there is a five seconds timeout interval during which the Go to Cloud (G2C )click operates in a firmware update

mode as explained in the Boot-up sequence section of this manual. After this, the Go to Cloud (G2C )click is restarted and

will continue running in a normal mode, completely skipping the bootloader, and will be undetectable for the HID bootloader

application. If this happens, it is necessary to disconnect the USB cable and connect it again, initiating another five seconds

interval.

After the MCU of the Go to Cloud (G2C )click is detected as on the picture above, an appropriate HEX file with a proper

firmware version should be selected by clicking on the Browse for HEX button. This will open a file selection window, where

you can browse for the updated firmware file with the .hex extension. Once selected, the programming process can be

started by clicking the Begin uploading button. The programming process should take up to 60 seconds. If it takes longer, or

the process is interrupted during the update, it should be repeated from the beginning.

Page 13

Page 14

DISCLAIMER

All the products owned by MikroElektronika are protected by copyright law and international copyright treaty. Therefore, this manual is to be treated as any other copyright material.

No part of this manual, including product and software described herein, may be reproduced, stored in a retrieval system, translated or transmitted in any form or by any means,

without the prior written permission of MikroElektronika. The manual PDF edition can be printed for private or local use, but not for distribution. Any modification of this manual is

prohibited. MikroElektronika provides this manual ‘as is’ without warranty of any kind, either expressed or implied, including, but not limited to, the implied warranties or conditions of

merchantability or fitness for a particular purpose. MikroElektronika shall assume no responsibility or liability for any errors, omissions and inaccuracies that may appear in this manual.

In no event shall MikroElektronika, its directors, officers, employees or distributors be liable for any indirect, specific, incidental or consequential damages (including damages for loss of

business profits and business information, business interruption or any other pecuniary loss) arising out of the use of this manual or product, even if MikroElektronika has been advised

of the possibility of such damages. MikroElektronika reserves the right to change information contained in this manual at any time without prior notice, if necessary.

HIGH RISK ACTIVITIES

The products of MikroElektronika are not fault – tolerant nor designed, manufactured or intended for use or resale as on – line control equipment in hazardous environments

requiring fail – safe performance, such as in the operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct life support machines

or weapons systems in which the failure of Software could lead directly to death, personal injury or severe physical or environmental damage (‘High Risk Activities’).

MikroElektronika and its suppliers specifically disclaim any expressed or implied warranty of fitness for High Risk Activities.

TRADEMARKS

The MikroElektronika name and logo, mikroC, mikroBasic, mikroPascal, Visual TFT, Visual GLCD, mikroProg, Ready, MINI, mikroBUS™, EasyPIC, EasyAVR, Easy8051, Click boards™ and

mikromedia are trademarks of MikroElektronika. All other trademarks mentioned herein are property of their respective companies.All other product and corporate names appearing in

this manual may or may not be registered trademarks or copyrights of their respective companies, and are only used for identification or explanation and to the owners’ benefit, with

no intent to infringe.

The FTDI Chip® and Windows® logos and product names are trademarks of FTDI Chip and Microsoft® in the U.S.A. and other countries.

Copyright © 2019 MikroElektronika. All Rights Reserved.

Page 14

Page 15

If you want to learn more about our products, please visit our

website at www.mikroe.com

If you are experiencing some problems with any of our

products or just need additional information, please place

your ticket at www.mikroe.com/support

If you have any questions, comments or business proposals,

do not hesitate to contact us at office@mikroe.com

Designed by

MikroElektroni

ka Ltd.

Loading...

Loading...