Page 1

E a s y P I C v 8

D E V E L O P M E N T B O A R D

U S E R M A N U A L

P A G E 1

E a s y P I C v 8 M a n u a l

Page 2

P A G E 2

It’s time to rethink the way you approach rapid prototyping

Let us introduce you to the latest generation of Mikroe development boards – E a s y P I C v 8

Time saving embedded tools

E a s y P I C v 8 M a n u a l

Page 3

Table of contents

Introduction 5

Development board overview 6

Power supply unit 8

Detailed description 8

Voltage reference 9

Programming voltage 9

PSU connectors 10

Power/debug, USB-C connector 10

Power 12VDC, external power supply 10

Battery power supply 11

Power redundancy and uninterrupted power supply (UPS) 12

Powering up the development board 12

Dual power supply 12

CODEGRIP – programmer/debugger module 14

Device setup 15

PGC/PGD switches 15

DBG selection 15

Connectivity 16

MCU sockets 18

How to properly install the MCU into the DIP socket? 18

VCAP and VCC 19

Crystal oscillator 19

INPUT/OUTPUT section 20

PORT buttons 20

BUTTONS PRESS LEVEL switch 20

UP-PULL-DOWN switch 20

PORT LEDs 20

2x5 pin headers 21

1x20 GLCD graphical display connector 22

1x16 LCD character display connector 25

mikroBUS

Click boards

Communication 28

USB-UART 28

CAN 28

USB ON DEVICE 30

Additional GNDs 31

What’s Next? 34

™

sockets 26

™

27

All images shown in the manual are for illustration purpose only.

Page 4

P A G E 4

E a s y P I C v 8 M a n u a l

Page 5

The EasyPIC v8 is a development board designed for the rapid

EasyPIC v8 off ers two display options, allowing even the basic 8-bit PIC

development of embedded applications, based on 8-bit PIC

microcontrollers (MCUs). Redesigned from the ground up, EasyPIC v8

off ers a familiar set of standard features, as well as some new and

unique features, common for the 8th generation of development

boards: programming and debugging over the WiFi network,

connectivity provided by USB-C connectors, support for a wide range

of diff erent MCUs, and more.

The development board is designed so that the developer has everything

that might be needed for the application development, following the

Swiss Army knife concept: a highly advanced programmer/debugger

module, a reliable power supply module, a huge set of connectivity

options including USB (DEVICE), USB to UART, CAN, etc.

EasyPIC v8 board off ers a number of diff erent DIP sockets, covering a

wide range of 8-bit PIC MCUs, from the smallest PIC MCU devices with

only 8 pins, all the way up to 40-pin "giants".

The development board supports the well-established mikroBUS

™

MCU devices to utilize them and display graphical or textual content.

One of them is the 1x20 graphical display connector, compatible with

the familiar Graphical Liquid Crystal Display (GLCD) based on the

KS108 (or compatible) display driver, and EasyTFT board that contains

TFT Color Display MI0283QT-9A, which is driven by ILI9341 display

controller, capable of showing advanced graphical content. The other

option is the 2x16 character LCD module, a four-bit display module

with the embedded character-based display controller, which requires

minimal processing power from the host MCU for its operation.

There is a wide range of useful interactive options at the disposal:

high-quality buttons with selectable press levels, LEDs, pull-up/pull-

down DIP switches, and more. All these features are packed on a

single development board, which itself uses innovative manufacturing

technologies, delivering fl uid and immersive working experience. The

EasyPIC v8 development board is also an integral part of the Mikroe

rapid development ecosystem. Natively supported by the Mikroe

Software toolchain, backed up by hundreds of diff erent Click board

™

designs with their number growing on a daily basis, it covers many

P A G E 5

connectivity standard, off ering fi ve mikroBUS™ sockets, allowing

access to a huge base of Click boards

E a s y P I C v 8 M a n u a l

™

.

diff erent prototyping and development aspects, thus saving precious

development time.

Page 6

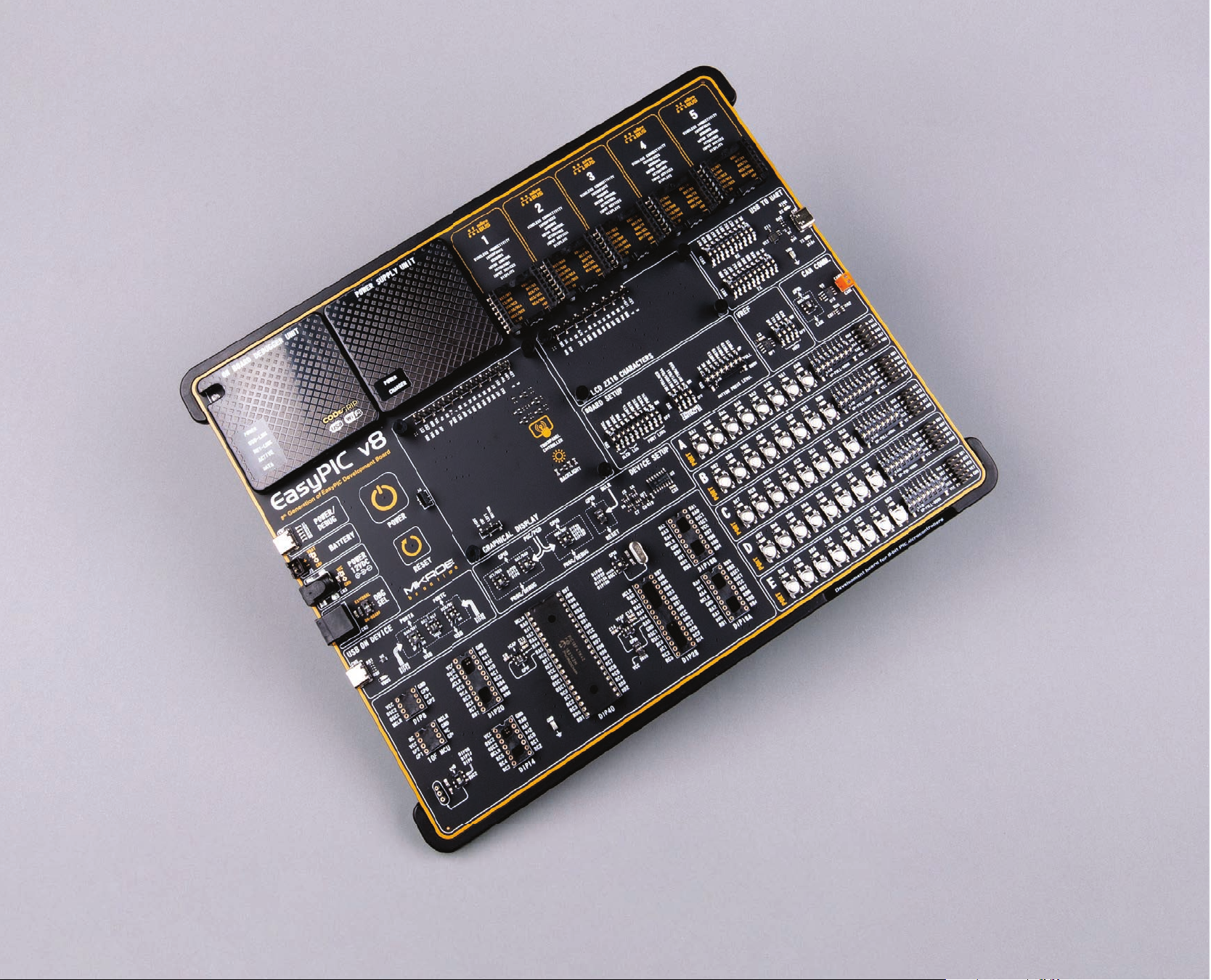

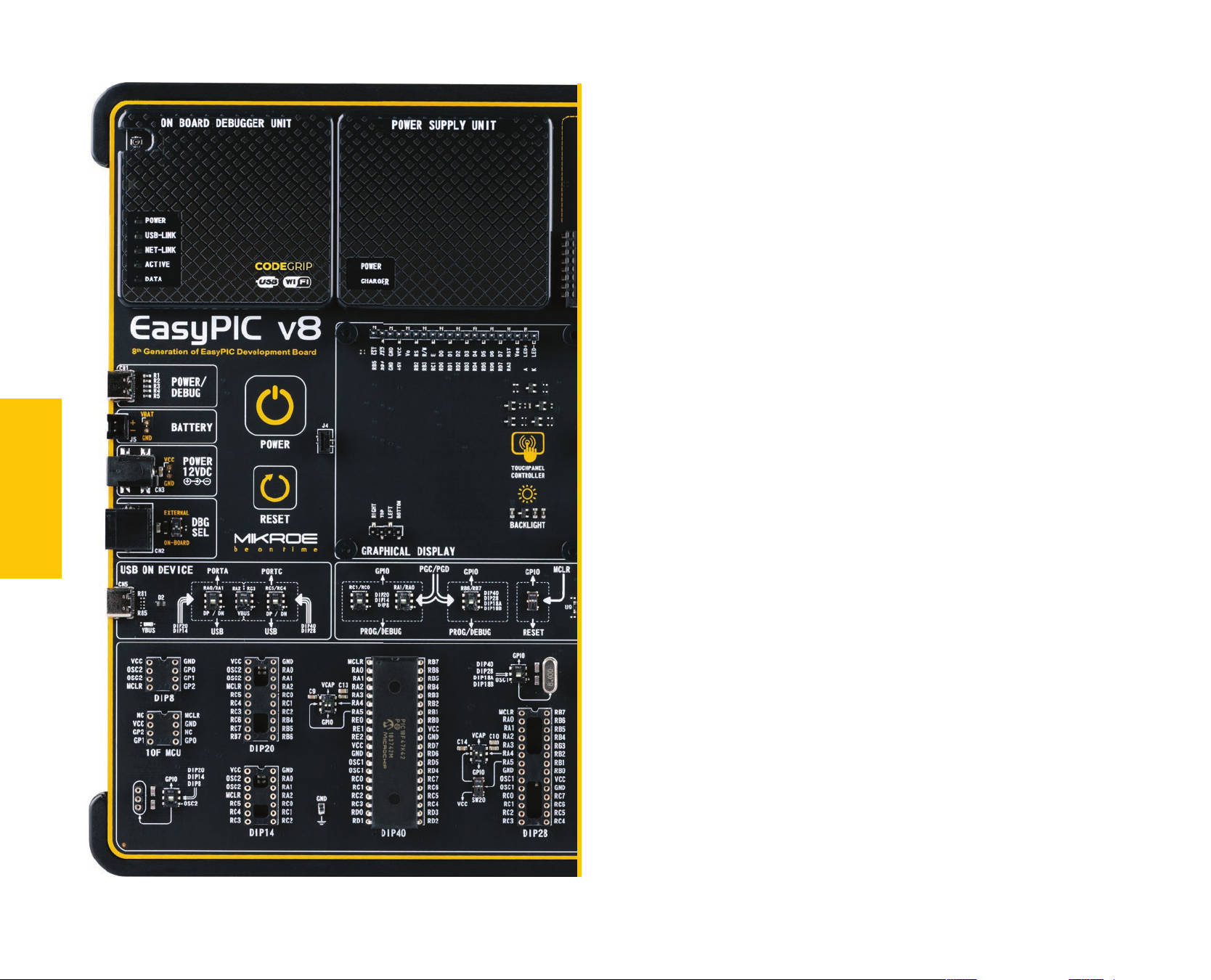

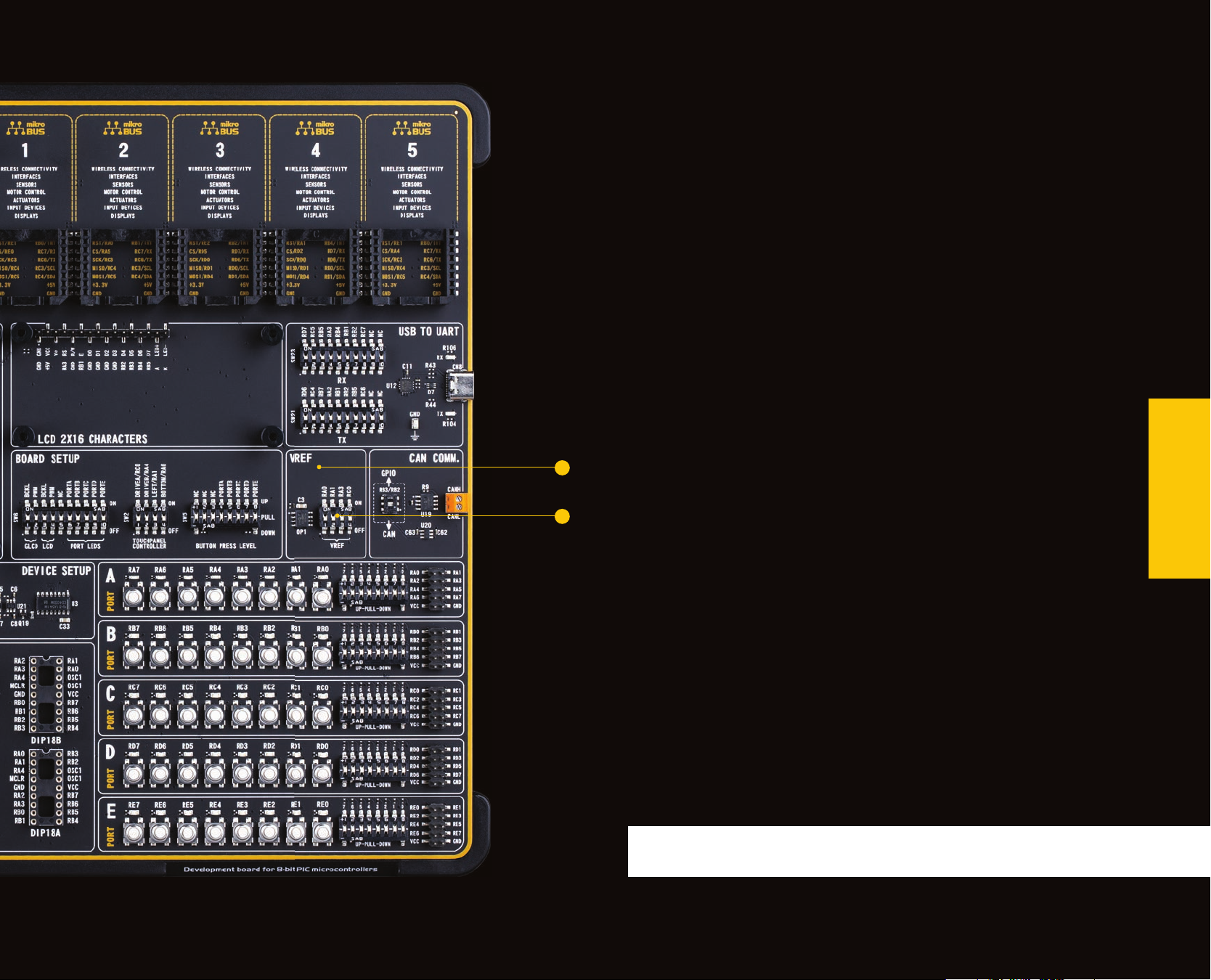

O V E R V I E W

P A G E 6

Development

board overview

The EasyPIC v8 development board features a clean and intuitive layout, allowing the

user to instantly understand how to set it up and how to easily tune it according to

needs. The development board is divided into several sections, arranged so that all the

related interactive components such as switches, buttons, indicators, and connectors,

are logically positioned and grouped together.

Each section of the development board contains components important for reliable

operation of the board itself. The Power Supply Unit (PSU), the CODEGRIP programmer/

debugger module, and fi ve mikroBUS™ sockets are located at the upper section of

the development board. This is where the MCU is powered from, programmed, and

interfaced with various Click boards

The PSU module provides a clean and well-regulated voltage for the development

board. It can use a wide range of external power sources, including a battery, an

external 12V power supply, and a power source over the USB-C connector. It supports

the power supply redundancy function (power ORing) for uninterrupted operation.

The onboard PSU module regulates, fi lters, and distributes the power across all the

connected peripherals. The development board is equipped with two touch-sensitive

buttons labeled as POWER and RESET. These buttons are used to power up the board

and reset the MCU. Their sleek design and fl awless responsiveness add up to the whole

experience. These touch-sensitive buttons are resistant to wear over time and do not

exhibit any bouncing eff ect, unlike mechanical switches.

™

.

The powerful CODEGRIP module, an integrated programmer/debugger module

supports a wide range of diff erent 8-bit PIC MCUs, produced by Microchip. It allows

in-place programming and debugging of all the supported MCUs, off ering many

useful programming/debugging options and seamless integration with the Mikroe

software environment. It also off ers some powerful and unique features such as the

programming/debugging over WiFi; a feature that will revolutionize the way that the

embedded applications are developed.

The CODEGRIP module uses the USB-C connector for a reliable and secure connection

with the personal computer (host PC). It does not require any additional drivers

because it utilizes a HID driver model, natively supported by the computer's operating

E a s y P I C v 8 M a n u a l

Page 7

system (OS). The USB-C connector is also used to power the development board,

simplifying the cable management.

The EasyPIC v8 development board off ers fi ve improved mikroBUS

™

sockets,

allowing interfacing with a vast amount of electronic circuits and reference designs,

standardized under the Click board trademark. Click boards

™

are simple to use, require

no additional hardware confi guration and can be easily connected to the development

board by inserting them into any of the available mikroBUS

of the mikroBUS

™

socket allows even easier interfacing with the Click board™ line

of products: it has a sturdier design which helps to align the Click board

™

sockets. A new design

™

correctly.

To read more about development improvements and huge benefi ts off ered by the

mikroBUS

™

and Click board™ line of products, visit the offi cial Mikroe web page at

www.mikroe.com

The EasyPIC v8 development board is equipped with two display connectors, located

in the middle section of the board. One connector is a 1x16 pin header used for

connecting a character-based LCD in 4-bit mode. The second display connector is a

single row 20 pin header, which supports monochromatic GLCD and EasyTFT board.

The 1x20 pin graphical display connector is accompanied by two 4-pin connectors

(4-pin FFC connector and 1x4 pin header), which are used for the touch panel

connection. The development board also provides the required circuitry, allowing the

resistive touch panel to be interfaced with the installed MCU. Both the LCD and GLCD

display connectors support a PWM-driven (dimmable) or fi xed backlight functionality.

The I/O section occupies the lower part of the development board and contains

available MCU pins routed to 2x5 pin headers for easy access. There are confi gurable

pull-up or pull-down resistors and buttons for applying logic states to MCU pins.

LED indicators provide visual feedback of logic states for each pin. The MCU pins are

divided into groups, following the grouping concept used on the MCU itself (PORTA,

PORTB, PORTC, PORD and PORTE). The I/O section is where the most interaction with

the MCU takes place.

O V E R V I E W

P A G E 7

Communication options such as USB-UART, USB (DEVICE) and CAN are also included.

All the connectors are positioned at the edges of the development board, so they can

be easily accessed. This is also true for the power connectors, as well as for an external

RJ12 ICD connector. This allows clean and clutter-free cable management.

The EasyPIC v8 development board is equipped with the onboard CODEGRIP module

and supported by a powerful CODEGRIP Suite, enabling complete control over the

programming and debugging tasks. It is also used to confi gure various other options

and settings, providing visual feedback through its clean and comprehensive Graphical

User Interface (GUI). Detailed explanation on how to confi gure and use the CODEGRIP

module fi nd at the following link: www.mikroe.com/debuggers/codegrip

E a s y P I C v 8 M a n u a l

Page 8

Power supply unit

The power supply unit (PSU) (1) provides clean and regulated power, necessary for

proper operation of the development board. The host MCU, along with the rest of the

peripherals, demands regulated and noise-free power supply. Therefore, the PSU

is carefully designed to regulate, fi lter, and distribute the power to all parts of the

development board. It is equipped with three diff erent power supply inputs, off ering

all the fl exibility that EasyPIC v8 needs, especially when used on the fi eld. In the case

when multiple power sources are used, an automatic power switching circuit with

predefi ned priorities ensures that the most appropriate will be used.

The PSU also contains a reliable and safe battery charging circuit, which allows a

single-cell Li-Po/Li-Ion battery to be charged. Power OR-ing option is also supported,

providing uninterrupted power supply (UPS) functionality when an external or USB

power source is used in combination with the battery.

1

3

4

Detailed description

The PSU has a very demanding task of providing power for the host MCU and all the

peripherals onboard, as well as for the externally connected peripherals. One of the key

P O W E R S U P P L Y

P A G E 8

P A G E 8

requirements is to provide enough current, avoiding the voltage drop at the output.

Also, the PSU must be able to support multiple power sources with diff erent nominal

voltages, allowing switching between them by priority. The PSU design, based on a

set of high-performance integrated devices produced by Microchip, ensures a very

good quality of the output voltage, high current rating, and reduced electromagnetic

radiation.

At the input stage of the PSU, the MIC2253, a high-effi ciency boost regulator IC

with overvoltage protection ensures that the voltage input at the next stage is wellregulated and stable. It is used to boost the voltage of low-voltage power sources

(a Li-Po/Li-Ion battery and USB), allowing the next stage to deliver well-regulated

3.3V and 5V to the development board. A set of discrete components are used to

determine if the input power source requires a voltage boost. When multiple power

sources are connected at once, this circuitry is also used to determine the input

priority level: externally connected 12V PSU (2), power over USB (3), and the Li-Po/LiIon battery (4). The transition between available power sources is seamless, providing

uninterrupted operation of the development board.

2

(1) This image is only for demonstration purpose, please do not

remove the PSU plastic cover nor touch any of the components

below. The development board can be permanently damaged.

E a s y P I C v 8 M a n u a l

E a s y P I C v 8 M a n u a l

Page 9

Figure 1: Power supply unit view

The next PSU stage uses two MIC28511, synchronous step-down (buck) regulators,

capable of providing up to 3A at their output. The MIC28511 IC utilizes the HyperSpeed

Control® and HyperLight Load® architectures, providing an ultra-fast transient

response and high effi ciency for light loads. Each of the two buck regulators is used

to supply power to the corresponding power supply rail (3.3V and 5V), throughout the

entire development board and connected peripherals.

Voltage reference

The PSU is able to provide a very accurate, programmable voltage reference (VREF) (5)

in the range from 0V to 4.096V. VREF is very useful for many diff erent applications

including A/D and D/A converters, comparators, etc.

The programmable VREF design is based on several diff erent ICs produced by

Microchip: the MCP1501, a high-precision buff ered voltage reference IC is used to

provide a very precise VREF of 4.096V for the MCP4726, a 12-bit D/A converter (DAC)

with integrated EEPROM. The MCP4726 DAC is controlled and programmed by the

CODEGRIP module, over the I2C interface. Finally, the MCP606, a single rail-to-rail

operational amplifi er is used to provide an additional buff ering at the output. By using

5

a 4-pole DIP switch (6) located in the VREF section of the development board, it is

possible to route VREF to four diff erent MCU pins:

6

ON (up): connects VREF to the MCU pins (RA0, RA1, RA3, and RC0)

OFF (down): disconnects VREF from the MCU pins (RA0, RA1, RA3, and RC0)

P O W E R S U P P L Y

Programming voltage

P A G E 9

P A G E 9

Not all PIC MCU devices support low voltage programming. Therefore, the PSU module

has to provide the required high voltage (VPP) for the programming of such devices.

The VPP is controlled by the CODEGRIP module automatically, it depends on the

programmed MCU and can’t be modifi ed by the user. To provide a suffi cient voltage

level, the MIC2250, a high-effi ciency, low EMI boost regulator is used. It is used to

provide 14V for the operational amplifi er circuit composed of a dual operational

amplifi er, labeled as MCP6H02T, and produced by Microchip. This circuit has a fi xed

gain, allowing the CODEGRIP programmer/debugger module to reach up to 14V for

the high-voltage programming of various PIC MCU devices.

N O T EIn order to protect host MCU and development board, VREF values higher then

3.3V can only be set if the board voltage is previously set to 5V.

E a s y P I C v 8 M a n u a l

E a s y P I C v 8 M a n u a l

Page 10

PSU connectors

As explained, the advanced design of the PSU allows several types of power sources to

be used, offering unprecedented flexibility: when powered by a Li-Po/Li-ION battery,

it offers an ultimate degree of autonomy. For situations where the power is an issue,

it can be powered by an external 12VDC power supply, connected over the 5.5mm

barrel connector. Power is not an issue even if it is powered over the USB cable. It can

be powered over the USB-C connector, using power supply delivered by the USB HOST

(e.g. personal computer), USB wall adapter, or a battery power bank.

There are three power connectors available, each with its unique purpose:

POWER/DEBUG, USB-C connector

BATTERY, standard 2.5mm pitch XH battery connector

POWER 12VDC, barrel type male 2mm x 6.5mm power connector

Power/debug, USB-C connector

The development board can be powered over the USB-C connector, labeled as POWER/

P O W E R S U P P L Y

DEBUG. This connector provides power from the USB host, USB power bank, or USB

wall adapter. When powered over the USB connector, the available power will depend

on the USB power source capabilities.

When using a PC as a power source, the maximum power can be obtained if the host

PC supports the USB 3.2 interface and is equipped with USB-C connectors. If the host

PC has a USB 2.0 interface, it will be able to provide the least power, since only up to

500 mA (2.5W at 5V) is available from the host in that case. Note that when using

long USB cables or USB cables of low quality, the voltage may drop outside the rated

operating voltage range, causing unpredictable behavior of the development board.

N O T EIf the host PC is not equipped with the USB-C connector, a Type A to Type C USB

adapter may be used (included in the package).

Power 12VDC, external power supply

An external 12V power supply can be connected over the 12VDC barrel connector.

When using an external power supply, it is possible to obtain an optimal amount of

power, since one external power supply unit can be easily exchanged with another,

while its power and operating characteristics can be decided per application. The

development board allows a maximum current of 2.8A per power rail (3.3V and 5V)

when using an external 12V power supply. The barrel-type connector is useful for

connecting wall-adapters.

P A G E 10

Maximum power ratings, along with the allowed input voltage range in the case when

the USB power supply is used, are given in the table below:

USB Power Supply

Input Voltage [V] Output Voltage [V]

MIN

4.4 5.5

Figure 2: USB power supply table

MAX

3.3

3.3 & 5

5

Max Current [A] Max Power [W]

1.8

1.4

0.8 & 0.8

6

7

6.64

Maximum power ratings, along with the allowed input voltage range in the case when

the external power supply is used, are given in the table below:

External Power Supply

Input Voltage [V] Output Voltage [V]

MIN

10.6 14

Figure 3: External Power supply table

MAX

3.3

3.3 & 5

5

Max Current [A] Max Power [W]

2.8

2.8

2.8 & 2.8

E a s y P I C v 8 M a n u a l

9.24

14

23.24

Page 11

N O T E When connecting an external power supply over a barrel connector, make sure

that the polarity of the barrel connector is matched with its counterpart on

the development board, according to the image printed next to the male DC

connector.

Battery Power Supply

Input Voltage [V] Output Voltage [V]

MIN

MAX

3.3

Max Current [A] Max Power [W]

1.6

5.28

Battery power supply

When powered by a single-cell Li-Po/Li-Ion battery, the development board offers an

option to be operated remotely. Combined with the fact that the board can be remotely

programmed and debugged over the WiFi network, the EasyPIC v8 development board

allows complete autonomy, allowing it to be used in some very specific situations:

hazardous environments, agricultural applications, etc.

N O T E It is advised to disable the battery charging circuitry if there is no battery

connected to the EasyPIC v8 development board. This can be done using

CODEGRIP Suite.

The development board uses a 2.5mm pitch XH battery connector. It allows a range

of Li-Po and Li-Ion batteries to be connected. The development board offers battery

charging functionality from both the USB connector and the external power supply.

The battery charging circuitry of the PSU module manages the battery charging

process, ensuring optimal charging conditions and longer battery life. The charging

process is indicated by a CHARGER LED indicator.

5

3.5 4.2

3.3 & 5

Figure 4: Battery Power Supply table

Using USB hubs, long USB cables, and low-quality USB cables, may cause a

significant USB voltage drop, which can obstruct the battery charging process.

1.2

0.7 & 0.7

5.81

6

P O W E R S U P P L Y

The battery charging current can be configured by using the CODEGRIP Suite, which

offers a choice between 100mA and 500mA when the USB power supply is used,

or between 100mA and 200mA when the external 12V power supply is used. In the

case when the development board is powered OFF, the charging current will be set to

500mA by default (200mA with the external power supply).

If both the external 12V power supply and the USB cable are connected to the

development board, the battery will be charged from the external 12V power supply,

thus minimizing the USB power consumption.

Maximum power ratings at a fully charged battery, along with the allowed input

voltage range when the battery power supply is used, are given in the following table:

E a s y P I C v 8 M a n u a l

P A G E 11

Page 12

Power redundancy and uninterrupted

power supply (UPS)

The PSU module supports power supply redundancy: it will automatically switch to

the most appropriate power source if one of the connected power sources fails or

becomes disconnected. The power supply redundancy also allows for an uninterrupted

operation (e.g. UPS functionality, the battery will still provide power if the USB cable is

removed, without resetting the MCU during the transition period).

Powering up the development board

Two touch-sensitive buttons are used to power up and reset the EasyPIC v8

development board. These capacitive buttons are processed by two AT42QT1011,

digital burst mode charge-transfer sensors, specifi cally designed for human-machine

interfaces (HMI), from Microchip. The AT42QT1011 allows very responsive and reliable

touch detection for the connected button pad.

As soon as a valid power source is connected, the development board will enter the

Stand-By mode. When the capacitive POWER button is pressed, the PSU module will

P O W E R S U P P L Y

start distributing the power to the rest of the development board. This is indicated by

the POWER LED indicator, located on the PSU module itself.

GPIO (up): if the MCU uses the MCLR/GPIO pin as the GPIO

RESET (down): if the MCU uses the MCLR/GPIO pin as the MCLR (RESET)

N O T EThe MCLR/GPIO pin should be set via the CONFIG bits as MCLR, and the MCLR switch

should be in the RESET (down) position, in order for the RESET button to work.

Dual power supply

EasyPIC v8 development board supports both 3.3V and 5V power supply on a single

board. Advanced PSU module provides the possibility to chose power supply for board

and host MCU, between 3.3V (default) and 5V. This setting can be easily confi gured

from CODEGRIP Suite, and this feature greatly increases the number of supported

MCUs.

P A G E 12

P A G E 12

Right under the POWER LED, there is a CHARGE LED, indicating the charging status of

the Li-Po/Li-Ion single cell battery, if connected. The complete battery power supply

section, including the battery charger circuit, is explained in the respective chapter

of this manual.

Below the POWER capacitive button (1), there is a RESET capacitive button (2) which

is not entirely power-related, but it has a similar function: it is routed to the MCLR

pin of the MCU, allowing the RESET function to be performed. However, since low pin-

count MCUs often use multiple functions on the same pin, the development board

off ers a choice in the form of a DIP switch (3) labeled as MCLR, which allows to specify

whether the MCLR/GPIO pin should be used as GPIO or it should be connected to the

RESET circuit of the development board:

E a s y P I C v 8 M a n u a l

E a s y P I C v 8 M a n u a l

Page 13

Figure 4: Battery power supply connection

1 2 3

Page 14

1

CODEGRIP

C O D E G R I P

programmer /

debugger module

P A G E 14

P A G E 14

Envisioned as the unifi ed development platform for all the 8-bit PIC MCUs in DIP

package, the EasyPIC v8 development board is equipped with the onboard CODEGRIP

programming/debugging module, to support programming/debugging feature.

The CODEGRIP module can be interfaced with the host computer over the USB-C

connector.

Besides the USB cable, the CODEGRIP module (1) can be accessed over the WiFi

network. This is a revolutionary new feature, which allows some unique usage

scenarios, currently not available on any other programming/debugging solution in

the world. The WiFi connectivity option of the CODEGRIP module off ers a complete

autonomy of the development board. Running in the hazardous environment while

2 34

debugging the software in real time, programming the MCU with a new software

during exposure, having the sensor responses collected and logged remotely from

several diff erent base points, debugging a drone fi rmware while it is in mid-air... These

are just simple examples of what EasyPIC v8 development board can off er.

CODEGRIP module is equipped with LED indicators that provide visual feedback about

its status:

POWER (GREEN) Indicates that the development board is powered on

USB-LINK (YELLOW) After the host OS completes the USB enumeration of the

CODEGRIP module, this LED will indicate that the connection has been established

Figure 5: Programmer/debugger view

E a s y P I C v 8 M a n u a l

Page 15

NET-LINK (AMBER) When the CODEGRIP module is connected to the WiFi network,

this LED will indicate that the connection has been established

If using DIP40, DIP28, DIP18A, or DIP18B MCU sockets, a DIP switch with the RB6/

RB7 label printed above it should be used to confi gure the programming lines:

ACTIVE (RED) Indicates the operational state of the CODEGRIP module: when

CODEGRIP module is in the bootloader mode, this indicator will blink. Normal operation

of the CODEGRIP module is indicated by the ACTIVE LED being constantly turned ON

DATA (BLUE) Indicates that there is a data transfer ongoing between the MCU and the

CODEGRIP module

The onboard CODEGRIP module requires no additional drivers, as it utilizes a HID driver

model, which is natively supported by the computer OS. This makes its installation

very easy and straightforward in the case when the USB cable is used. As soon as the

USB cable is connected to the host PC, the CODEGRIP module is enumerated and the

development board is ready to be used.

CODEGRIP programmer/debugger module is supported by CODEGRIP Suite. Detailed

explanation on how to confi gure and use the CODEGRIP module on the EasyPIC v8

development board fi nd at the following link: www.mikroe.com/debuggers/codegrip

CODEGRIP device setup

Since the development board supports many diff erent MCUs with a diff erent number

of pins and functionalities, it is necessary to connect the CODEGRIP programmer/

debugger to the correct programming lines (PGC, PGD) of the particular MCU. The

development board allows easy selection of the programming lines by off ering a set of

high-quality DIP switches (2), which ensure reliable operation. For more information

about MCU DIP sockets and how to use them, please refer to the MCU sockets chapter.

All DIP switches required to set up the programming and reset lines for each DIP

socket, are grouped under the DEVICE SETUP (3) label, in a section located in the

middle of the EasyPIC v8 development board.

RB6/RB7 (DIP40, DIP28, DIP18A, DIP18B)

GPIO (up): allows the RB6 and RB7 pins to be used as GPIO lines

PROG/DEBUG (down): connects the RB6 and RB7 pins to the CODEGRIP

programmer/debugger module

If using DIP20, DIP14, DIP8 or 10F MCU sockets, two DIP switches are available for

confi guration of the programming lines, depending on a particular MCU that is used:

RA1/RA0 (DIP20, DIP14, DIP8,10F MCU)

GPIO (up): allows the RA1 and RA0 pins to be used as GPIO lines

PROG/DEBUG (down): connects the RA1 and RA0 pins to the CODEGRIP

programmer/debugger module

RC1/RC0 (DIP20, DIP14, DIP8,10F MCU)

GPIO (up): allows the RC1 and RC0 pins to be used as GPIO lines

PROG/DEBUG (down): connects the RC1 and RC0 pins to the CODEGRIP

programmer/debugger module

DBG selection

The EasyPIC v8 development board is equipped with the RJ-12 connector (4),

compatible with Microchip® ICD external programmers/debuggers. If an external

programmer/debugger is connected, the onboard CODEGRIP module should be

disabled to avoid data corruption. A DIP switch located next to RJ-12 ICD connector

allows selection of a programmer/debugger that will be used:

EXTERNAL (up): an external programmer/debugger is connected, the onboard

CODEGRIP module is disabled

ONBOARD (down): an external programmer is not connected, the

onboard CODEGRIP module is enabled

C O D E G R I P

P A G E 15

P A G E 15

PGC/PGD switches

There are three switches located in the DEVICE SETUP section, labeled as PGC/PGD. These

switches allow to redirect the programming lines of the CODEGRIP onboard module to the

corresponding programming pins of the MCU. These switches have an MCU DIP socket name

printed next to it, so it is very easy to know which one should be used for which socket.

E a s y P I C v 8 M a n u a l

Page 16

Connectivity

One of the key features of the EasyPIC v8 development board is its connectivity.

It features a diversity of connecting options making the board very versatile, adaptable to any situation, and very easy

to work with.

The EasyPIC v8 development board supports all 8-bit PIC MCUs in DIP package type. To allow this, the development

board off ers a total of eight DIP socket sizes: DIP8, DIP14, DIP18 (A, B), DIP20, DIP28, DIP40 and an additional DIP8

socket for 10F MCU families.

The development board also features two display connectors (1x16 character display connector and 1x20 graphical

display connector), USB-UART, an external ICD compatible programmer/debugger connector and more. The PORT I/O

section is the most distinctive connectivity option. It allows direct interfacing with the MCU pins. This section also

contains LEDs for visual indication of pin states, BUTTONs for applying the desired logic states to the pins, and DIP

switches for confi guring pull-up or pull-down resistors.

C O N N E C T I V I T Y

CONNECTIVITY

P A G E 16

All LEDs, buttons, and headers are logically organized and grouped as PORTs, following the pin organization topology

of the MCU itself.

Availability of fi ve standardized mikroBUS

special: the world of Click boards

virtually an unlimited number of combinations is possible, considering the fact that the Click board

already has several hundreds of various Click boards

EasyPIC v8 development board with the whole Mikroe ecosystem, allows seamless and eff ortless prototyping, and

truly rapid embedded application development. For more info about the mikroBUS

of products, please visit the offi cial Mikroe web page at: www.mikroe.com

™

sockets is something that makes the EasyPIC v8 development board very

™

is now just under your fi ngertips. By combining up to 5 diff erent Click boards™,

™

repository

™

, with more added on a daily basis. Tight integration of the

™

standard and the Click board™ line

E a s y P I C v 8 M a n u a l

Page 17

Easily create an IoT Weather Station with the EasyPIC v8 development board.

Use the following tools:

EasyPIC v8 development board

EasyTFT board

G2C click

OLED C click

Temp-Log 2 click

Thunder click

LPS22HB click

E a s y P I C v 8 M a n u a l

C O N E C T I V I T Y

P A G E 17

Page 18

Figure 6: Main board with MCU socket section view

MCU sockets

As previously mentioned, the EasyPIC v8 development board supports all 8-bit PIC

MCUs in DIP package type. There are eight diff erent sockets, ranging from DIP8 (8-pin

DIP socket), up to DIP40 (40-pin DIP socket). All DIP sockets are grouped in the lower

left area of the board (1).

Only a single DIP socket should be populated at a time since their lines are shared.

Each DIP socket allows an MCU with the specifi c pin-count to be used. For example, if

using a 40-pin MCU, it should be placed into the DIP40 socket, exclusively (i.e. placing

an 8-pin MCU into the DIP14 socket will cause pin misalignment and other problems).

However, there are exceptions to this rule: if using an MCU in DIP18 package type,

there are two options available, depending on its pinout: DIP18A and DIP18B. To

determine the correct socket that should be used in this case, the pinout of the MCU

should be compared with the pinout which is printed next to these sockets.

P A G E 18

A similar exception applies to the DIP8 socket: if using an 8-pin MCU from PIC10F

MCU families, it should be installed in the 10F MCU socket instead of the DIP8 socket.

How to install the MCU into the DIP socket?

First make sure that a half circular cut in the microcontroller DIP packaging matches

the cut in the DIP socket (2). Align both ends of the microcontroller with the socket.

Then put the microcontroller slowly down until all the pins match the socket. Check

again if everything is placed correctly and gently press the microcontroller until it is

completely plugged into the socket.

Only a single MCU must be installed into the development board at a time.

29 64108

51 3 7

E a s y P I C v 8 M a n u a l

Page 19

Crystal oscillator

VCAP and VCC

Most of PIC MCU devices can use an external quartz-crystal oscillator. There are two

sockets for installing the crystal oscillator, depending on which MCU socket will be

used:

Crystal oscillator socket OSC1 is routed to DIP40, DIP28, DIP18A, and DIP18B MCU sockets (7)

Crystal oscillator socket OSC2 is routed to DIP20, DIP14, and DIP8 MCU sockets (8)

10F MCUs do not use external oscillators. Consequently, none of the crystal oscillator

socket pins are routed to the 10F MCU DIP socket.

Above the DIP28 MCU socket, there is a DIP switch (9) used to specify whether the

OSC1/RA6 and OSC1/RA7 pins will be used as GPIOs on the corresponding MCU

sockets, or connected to the OSC1 crystal oscillator socket:

RA6, RA7 (OSC1)

UP position: allows the RA6 and RA7 pins to be used as GPIO lines

DOWN position: connects the RA6 and RA7 pins to the crystal oscillator socket OSC1

Below the two DIP8 MCU sockets, there is a DIP switch (10) used to specify whether

the OSC2/RA4 and OSC2/RA5 pins will be used as GPIOs on the corresponding MCU

sockets, or connected to the OSC2 crystal oscillator socket:

RA4, RA5 (OSC2)

UP position: allows the RA4 and RA5 pins to be used as GPIO lines

DOWN position: connects the RA4 and RA5 pins to the crystal oscillator socket OSC2

For some of the PIC MCU devices, the manufacturer (Microchip) suggests using

additional bypass capacitors for improved stability. These MCUs use internal

voltage regulators since their cores operate at diff erent (lower) voltages than their

peripherals. For some applications, it may be necessary to use bypass capacitors,

in order to ensure better noise immunity. This applies to DIP40 (2) and DIP28 (3)

sockets. However, the EasyPIC v8 development board off ers a choice, since each pin

on these low pin-count MCUs can be very valuable.

Next to the DIP40 MCU socket, there is a two-pole DIP switch (4) used to specify

whether the VCAP/RA4 and VCAP/RA5 pins will be used as GPIOs on this MCU socket,

or connected to the onboard bypass capacitors:

RA4/RA5 (DIP40)

VCAP (up): connects the RA4 and RA5 pins to the onboard capacitors

GPIO (down): allows the RA4 and RA5 pins to be used as GPIO lines

Next to the DIP28 MCU socket, there is another two-pole DIP switch (5) used to

specify whether the VCAP/RA4 and VCAP/RA5 pins will be used as GPIOs on this MCU

socket, or connected to the onboard bypass capacitors:

RA4/RA5 (DIP28)

VCAP (up): connects the RA4 and RA5 pins to the onboard capacitors

GPIO (down): allows the RA4 and RA5 pins to be used as GPIO lines

Next to the DIP28 MCU socket, there is an additional DIP switch labeled as SW20 (6).

This switch is used if the MCU installed in the DIP28 socket requires an analog voltage

supply (VCC) to be connected:

C O N N E C T I V I T Y

P A G E 19

N O T E 10F MCU families do not use an external crystal oscillator. Consequently, none

of the crystal oscillator socket pins are routed to the 10F MCU DIP socket.

E a s y P I C v 8 M a n u a l

SW20:

UP position: redirects the RA5 pin to be used either as the VCAP or as the GPIO

(depending on the RA4/RA5 DIP switch settings)

DOWN position: Connects the RA5 pin to the power supply rail (for MCUs that

require VCC on this pin)

When using MCU devices that require the analog voltage supply pin to be

connected to the power source (such as PIC18F2331 or PIC18F2431), the

SW20 switch must be in the DOWN position.

Page 20

INPUT/OUTPUT section

I/O pins of any MCU are internally grouped as PORTs. The same grouping concept is

kept throughout the development board as well, off ering a clean and organized user

interface.

There are fi ve PORTs (1) on the EasyPIC v8 development board, labeled from PORTA to

PORTE. Depending on the pin-count of the MCU, not all PORTs will be used. However,

the development board supports the highest pin-count MCUs in DIP package type (40

pins). The PORTs are located at the lower right side of the board, each containing a

set of eight buttons, eight LEDs, an eight-pole DIP switch, and a single 2x5 pin header

with the standard 2.54mm pitch. The PORTs are labeled according to the MCU PORT

they are routed to.

PORT buttons

PORT buttons (2) can be used to apply an arbitrary logic state to the pins of the MCU.

These buttons are small tactile SPST buttons that work in combination with a DIP

switch (SW5), labeled as BUTTONs PRESS LEVEL. This DIP switch is located in the

BOARD SETUP section.

C O N N E C T I V I T Y

P A G E 20

BUTTONs PRESS LEVEL switch

This eight-pole, tri-state DIP switch allows the button to apply a LOW logic level to an

MCU pin when pressed (connecting it to the GND), or to apply a HIGH logic level when

pressed (connecting it to the power rail). It can also be used to completely disconnect

the button, preventing accidental button presses. To limit the pin current and prevent

the excessive inrush of currents when a button is pressed, a protective 220Ω resistor is

used, connected in series with the switch. Each position of the BUTTONs PRESS LEVEL

switch (3) is used to determine the applied logic level of a button press for the entire

PORT. As a result, only fi ve poles of this DIP switch are used, allowing control of all

fi ve groups of buttons (unused poles are marked with the NC label - Not Connected).

BUTTONs PRESS LEVEL:

UP position: a button press applies HIGH logic level to the corresponding PORT pins

MID position: a button is completely disconnected

DOWN position: a button applies LOW logic level to the corresponding PORT pins

UP-PULL-DOWN switch

Besides buttons, each of the fi ve PORTs has an eight-pole DIP switch associated with

it. It is labeled as UP-PULL-DOWN (4) and it is used to enable a pull-up or pull-down

resistor for the specifi c pin or to leave the pin in a fl oating state:

UP-PULL-DOWN:

UP position: connects a 4.7kΩ resistor between the MCU power rail and the pin (the

pin is pulled up)

MID position: Disables both pull-up and pull-down resistor connections from the

pin (the pin is in the fl oating state)

DOWN position: Connects the 4.7kΩ resistor between the GND and pin associated with

the DIP switch position (the pin is pulled down)

PORT LEDs

Each PORT contains a group of eight LEDs (5) used to provide a visual indication

of the logic state of the specifi c pin. The maximum current through a single LED is

limited with the 4.7kΩ resistor. Each LED is connected to a PORT pin and it is labeled

according to the name of the connected pin (RA0 to RE7). LEDs on each PORT should

be disconnected when not used. Having a LED on a communication line or an A/D

converter input might alter expected results since LED represents an additional

electrical load. There is a ten-pole DIP switch (SW6) (6) located in the BOARD SETUP

section. Five poles of this DIP switch, labeled as PORT LEDs are used to enable or

disable LEDs on each PORT:

E a s y P I C v 8 M a n u a l

Page 21

Figure 8: I/O PORTs view

SW6.6 - SW6.10 (PORT LEDS):

UP position: Enables LEDs for a specifi c PORT, associated with the particular DIP

switch position

DOWN position: Disables LEDs for a specifi c PORT, associated with the particular DIP

switch position

C O N N E C T I V I T Y

1 2 65 3 4 7

E a s y P I C v 8 M a n u a l

2x5 pin headers

Besides LEDs, there are also 2x5 pin headers (7) in the PORT sections. All the pins

which belong to a specifi c PORT are routed to the 2x5 pin header located in that PORT

section, along with the GND and the power rails. The pins on these headers are labeled

according to the names of the MCU pins to which they are routed (from RA0-RA7 to

RE0-RE7).

These 2x5 pin headers can be used to expand the connectivity of the EasyPIC v8

development board, allowing interfacing with other devices, peripherals, and

measurement equipment, either by using IDC10 extension cables, IDC10 female

sockets, or simply by using jumper wires. Enhanced connectivity is one of the key

features of the EasyPIC v8 development board, therefore, there are many connectivity

options provided. However, 2x5 pin headers off er the most extensive connectivity

option as they expose all the available MCU pins to the outside world.

P A G E 21

Page 22

1x20 graphical display connector

The EasyPIC v8 development board is equipped with the 1x20 graphical display

connector [1], off ering support for GLCDs with the resolution of 128x64 pixels, driven

by the KS108 or compatible display controller.

Graphical Liquid Crystal Displays (GLCDs) [2] can be used to display monochromatic

graphical content such as text, images, etc. Besides data lines, 1x20 GLCD connector

also contains command lines, necessary power supply rails (GND, +5V for the backlight

and for the display module), backlight PWM control, and contrast control voltage.

GLCDs usually come with a touch-sensitive panel, which allows them to be used as

input devices. The EasyPIC v8 development board provides support for the resistive

touch panel over two separate connectors: one 1x4-pin header and one 4-pin fl at-

cable connector (FFC) labeled as J4 [3], typically used for GLCDs. This connector is

perfectly aligned with the GLCD modules which are available for purchase from the

offi cial Mikroe store. For more information about the GLCD displays, please visit our

web page: www.mikroe.com

Two DIP switches (SW6 and SW2) located in the BOARD SETUP section of the

development board are used to set up the confi gurable options for both the GLCD

backlight and touch panel control. Two poles of the SW6 DIP switch (4), grouped

under the GLCD label, are used to control the backlight options of the GLCD:

C O N N E C T I V I T Y

SW6.1:

ON (up): GLCD backlight is ON

OFF (down): GLCD backlight is OFF

P A G E 22

SW6.2:

ON (up): PWM signal at the RC2 pin controls the GLCD backlight brightness

OFF (down): Backlight brightness amount is fi xed and can't be controlled by the MCU

If you want to upgrade your GLCD application with TFT display, EasyTFT board (5)

is a perfect choice. It features connector compatible with 1x20 graphical display

connector (1) on EasyPIC v8 development board, and a touch panel connector.

The EasyTFT board contains 2.83" TFT color display MI0283QT-9A with 320x240 pixel

resolution, which is driven by ILI9341 display controller, capable of showing advanced

graphical content. Each pixel can display 262K diff erent colors. TFT display is covered

with a resistive touch panel which can be used as input device, supported with 1x4 pin

header [6] on EasyPIC v8 development board.

The board is primarily designed to be used as a display board on Mikroe Easy

development boards. After testing and building the fi nal program, this board can also

be used in your fi nal device. The board also contains mounting holes (7) for easier

integration into your designs.

A four-pole DIP switch (8) labeled as SW2 located in the BOARD SETUP section of the

development board is used to set up the confi gurable options for touch panel control.

It allows to connect the pins RA0, RA1, RA4, and RC0 to the touch panel control circuit:

SW2:

ON (up): A specifi c touch panel control is connected to the respective MCU pin

OFF (down): A specifi c touch panel control is disconnected from the respective MCU pin

The EasyTFT board and LCD use the same pins, thus are unable to operate if

simultaneously plugged in.

N O T E

A four-pole DIP switch (8) labeled as SW2 allows to connect the pins RA0, RA1, RA4,

and RC0 to the touch panel control circuit:

SW2:

ON (up): A specifi c touch panel control is connected to the respective MCU pin

OFF (down): A specifi c touch panel control is disconnected from the respective MCU pin

In order to use backlight PWM dimming, both SW6.1 and SW6.2 switches must

be enabled at the same time.

E a s y P I C v 8 M a n u a l

Page 23

Figure 9: 1x20 pin board connector view

23 4 85 761

E a s y P I C v 8 M a n u a l

E a s y P I C v 8 M a n u a l

C O N N E C T I V I T Y

P A G E 23

Page 24

14 3

2

Figure 10: 1x16 display header view

Page 25

1x16 character display connector

Character-based Liquid Crystal Display (LCD) (1) is a cheap and popular way of

representing application results, short messages, or some other type of information

to users. The EasyPIC v8 development board natively supports 2x16 character LCD

module, connected in 4-bit mode. It off ers a dedicated 1x16 pin header (2) that

can host a compatible LCD module. Each pin of the connector is labeled on the

development board and should be connected to the respective pin of the LCD module.

There are four plastic spacers (3) used to provide physical support for both types of

connected displays (LCD and GLCD), ensuring a reliable connection and preventing

bending of their pins.

The LCD and GLCD use the same pins, thus are unable to operate if simultaneously

plugged in.

Two poles of the SW6 DIP switch (4), grouped under the LCD label, are used to control

the backlight options of the LCD:

SW6.3:

ON (up): LCD backlight is ON

OFF (down): LCD backlight is OFF

N O T E

SW6.4:

ON (up): PWM signal at the RC2 pin controls the LCD backlight brightness

OFF (down): Backlight brightness amount is fi xed and can't be controlled by the MCU

In order to use backlight PWM dimming, both SW6.3 and SW6.4 switches must

be enabled at the same time.

Make sure to turn off the power supply before placing either of the display

modules on the board. Otherwise, the display module or the development board

can be permanently damaged.

C O N N E C T I V I T Y

P A G E 25

Figure 11: EasyTFT board, 1x16 LCD and

Graphic LCD 128x64 with TouchPanel

Page 26

1

™

mikroBUS

sockets

The superior connectivity features of the EasyPIC v8 development board are rounded

up with fi ve standardized mikroBUS

for the board, as it allows interfacing with the vast amount of Click boards

™

mikroBUS

smallest number of pins. More information at www.mikroe.com/mikrobus

is the add-on board standard that off ers maximum expandability with the

™

host connectors (1). It is a considerable upgrade

™

.

P A G E 26

All the mikroBUS

sturdier, allowing a better grip of the Click board

supports between two 8-pin connectors, the right lower edge is chamfered at the

angle of 45°, the same as the Click board

socket. The new mikroBUS™ socket is now a fully-fl edged, standardized monolithic

component with all its pins clearly labeled, off ering very good grip for the Click board

preventing it to fl ip over or to be placed incorrectly.

The mikroBUS

and I2C. There are also single pins reserved for PWM, Interrupt, Analog input, Reset,

and SPI Chip Select. The mikroBUS

(3.3V and 5V), along with the GND pins.

Each MCU socket has the appropriate pins routed to the mikroBUS

Therefore, each mikroBUS

This helps users to identify to which MCU pin its routed to. Also, each mikroBUS

socket is labeled on the development board with its ordinal number, by which the

connector is referenced to in the Mikroe development environment, software

Figure 12: Main board with mikroBUS™ socket close up view

applications, tutorials, etc.

™

sockets are now redesigned and improved. They became much

™

. In addition to added horizontal

™

, making it seamlessly fi t into the mikroBUS

™

socket supports the following communication interfaces: SPI, UART,

™

socket also contains pins with the two power rails

™

sockets.

™

socket pin is clearly labeled on the development board.

E a s y P I C v 8 M a n u a l

™

™

,

™

Page 27

Figure 13: Click boards

™

™

Click boards

THE LARGEST AND FASTEST-GROWING

BASE OF ADD-ON BOARDS IN THE WORLD!

Click boards™ are standardized add-on boards that carry a variety of diff erent electronic

devices. They are designed to perfectly fi t the mikroBUS

the best performances for the used components, they save developers of testing and

troubleshooting often associated with the prototyping phase. They enhance rapid

development and accelerate time to market. These ready-to-use boards require no

additional hardware confi guration. More information at www.mikroe.com/click

™

socket. Engineered to deliver

C O N N E C T I V I T Y

P A G E 27

P A G E 27

E a s y P I C v 8 M a n u a l

Page 28

Communication

COMMUNICATION

P A G E 28

Communication connectors allow the development board to be connected with many

diff erent devices that use high-layer communication protocols such as USB, CAN, etc.

Also, there is a USB-UART converter, which enables simplifi ed communication with the

personal computer over the emulated serial interface. Each of these connectors will be

described in more detail, in the following sections of the manual.

USB-UART

UART (Universal Asynchronous Receiver/Transmitter) interface (1) is one of the most

common interfaces for data exchange between the MCU and other external devices.

The EasyPIC v8 development board off ers the UART connectivity over the USB-C

connector (2) by utilizing the FT230XQ (3), a popular USB-UART signal conversion

IC, produced by FTDI Chip. This IC contains the complete USB stack necessary for the

interface bridging between the UART peripheral of the MCU and the USB interface of

the PC. FT230XQ drivers are available for download from the offi cial FTDI drivers web

page www.ftdichip.com/Drivers/VCP.htm

To enable UART data exchange via the USB-C connector, RX and TX lines of the MCU

UART peripheral must be connected to the corresponding pins of the FT230XQ IC. Two

ten-pole DIP switches located in the USB TO UART section of the board, labeled as TX

(SW21) (4) and RX (SW23) (5), allow fully independent control of the UART RX and TX

lines, off ering complete freedom of pin selection. The TX DIP switch (SW21) connects

the specifi c MCU pin (labeled next to the related switch) as the UART transmission

line, while the RX DIP switch (SW23) connects the specifi c MCU pin (labeled next to

the related switch) as the UART receiving line. This allows custom UART TX/RX pair

confi guration, allowing the development board to adapt to many diff erent UART pin

confi gurations, found on various PIC MCU devices:

SW21 (TX)

ON (up): connects the respective UART TX pin to the USB-UART conversion circuit

OFF (down): disconnects the respective UART TX pin from the USB-UART conversion circuit

SW23 (RX)

ON (up): connects the respective UART RX pin to the USB-UART conversion circuit

OFF (down): disconnects the respective UART RX pin from the USB-UART conversion circuit

UART traffi c is indicated by two LED indicators, located in the USB TO UART section of

the board, near the USB-C connector:

Yellow LED (TX) (6) indicates outgoing data transfer

Red LED (RX) (7) indicates incoming data transfer

CAN

Controller Area Network (CAN or CAN Bus) (8) is a serial network technology, originally

designed for the automotive industry, but due to its robustness and noise immunity,

it has become popular in many other applications. The CAN Bus is primarily used in

embedded systems, allowing to establish fast communication between MCUs or other

peripherals, eliminating the need for expensive and complex technology. The CAN

Bus consists of only two wires, allowing both high data rates and message collision

prevention.

The EasyPIC v8 utilizes the MCP2561FD (9), a high-speed CAN fl exible data rate

transceiver from Microchip, off ering support for both CAN and CAN FD (CAN

Flexible Data Rate) for MCUs equipped with the CAN peripheral. The MCP2561FD

transceiver meets all the automotive requirements for CAN FD, exceeding 2Mbps

data rate, featuring low quiescent current, electromagnetic compatibility (EMC), and

electrostatic discharge (ESD) immunity. Some features provided by the MCP2561FD

include:

∫ Optimized for CAN FD at 2Mbps, 5Mbps, and 8 Mbps operation

∫ CAN Bus Pins are disconnected when the CAN transceiver is unpowered

∫ Detection of ground fault

∫ Protection against damage due to short-circuit conditions

∫ Protection against high-voltage transients in automotive environments

∫ Automatic thermal shutdown

E a s y P I C v 8 M a n u a l

Page 29

11

10

The development board off ers a single DIP switch located in the CAN COMM. section,

which is used to specify whether the RB2 and RB3 pins should be used as GPIOs or

they should be connected to the CAN transceiver circuit as CAN TX and CAN RX lines.

CAN connectivity is provided only for MCUs installed in DIP28 and DIP40 MCU sockets:

RB3/RB2 (DIP28, DIP40) (10)

1

GPIO (up): Allows the RB2 and RB3 pins to be used as GPIOs

CAN (down): Connects the RB2 and RB3 pins to the CAN transceiver circuit

5

7

2

6

3

The development board can be connected to the CAN Bus by using the 2-pole screw

terminal (11), located in the CAN COMM section. Please note that the CAN H and

CAN L diff erential signals need to be properly connected to the CAN Bus, else no CAN

communication will be possible.

4

8

9

COMMUNICATION

Figure 14: Main board partial right side view

E a s y P I C v 8 M a n u a l

P A G E 29

P A G E 29

Page 30

COMMUNICATION

P A G E 30

P A G E 30

USB ON DEVICE

USB (Universal Serial Bus) (1) is a very popular industry standard that defi nes cables,

connectors, and protocols used for communication and power supply between

devices. USB-C connector (2) is the latest version of the USB connector, developed

by the USB Implementation Forum (USB-IF). Due to its many advantages including

symmetrical pinout, higher current capacity, and support for faster data rates, it

off ers a signifi cant improvement over the previous versions. This allows MCU devices

equipped with the USB peripheral to connect to an external USB HOST (such as a PC,

Laptop, etc.), allowing the development of USB-based applications. The connection to

the USB HOST is indicated by a yellow LED labeled as VBUS (3), located in the USB ON

DEVICE section, near the USB-C connector.

When a PIC MCU does not support USB interface or USB connection is not required by

application itself, the USB pins should be disconnected from the USB-C connector and

accompanying circuitry. Therefore, the development board off ers two DIP switches

located in the USB ON DEVICE section (one per group of MCU sockets), allowing to

specify whether these pins should be used for other purposes (i.e. as GPIO lines) or

they should be used as USB data lines:

RA0/RA1 (DIP14, DIP20) (4)

PORTA (up): allows the RA0 and RA1 pins to be used for other purposes

USB (down): connects the RA0 and RA1 pins to the USB-C conn. and accompanying circuitry

RC5/RC4 (DIP28, DIP40) (5)

PORTC (up): allows the RC5 and RC4 pins to be used for other purposes

USB (down): connects the RC5 and RC4 pins to the USB-C conn. and accompanying circuitry

An additional two-pole DIP switch is used to provide an external power source for the

internal USB transceiver of the MCU. When the internal MCU regulator is disabled via

the CONFIG bits, an external power supply must be provided through the VBUS pin

for the internal USB transceiver. Depending on the MCU installed in the specifi c MCU

socket, either RA2 or RC3 pin is used as the VBUS. The development board off ers yet

another two-pole DIP switch to specify whether these two pins should be used for

other purposes (i.e. as GPIO lines) or they should be connected to an external power

supply for the internal USB transceiver:

1

4

2

3

6

7

5

8

Figure 15: Main board partial left side view

E a s y P I C v 8 M a n u a l

Page 31

RA2 (DIP14, DIP20) (6)

RA2 (up): allows the RA2 pin to be used for other purposes

VBUS (down): connects the RA2 pin to the 3.3V power rail

RC3 (DIP28, DIP40) (7)

RC3 (up): allows the RC3 pin to be used for other purposes

VBUS (down): connects the RC3 pin to the 3.3V power rail

When using an external power supply for the internal USB transceiver of the

MCU, the internal MCU regulator must be disabled via CONFIG bits.

Additional GNDs

The EasyPIC v8 development board contains exposed GND (8) pins which can be

used to connect measurement or testing equipment. These additional GND pins

allow secure connection with the instrumentation probes, avoiding loose cables or

unreliable contacts that might compromise the accuracy of the readings.

E a s y P I C v 8 M a n u a l

COMMUNICATION

P A G E 31

Page 32

What makes you want to be an embedded developer? Is it the recognition of your skills,

invention, or the development process? Whatever the reason is, we want to let you know

that we are here for you every step of the way.

You can enjoy the process focused, yet relaxed – everything else is taken care of.

Enjoy premium.

Page 33

Page 34

What’s Next?

You have now completed the journey through each and every feature of the EasyPIC v8 development board. You have become familiar with its modules, organization, and the programmer/

debugger. Now you are ready to start using your new board. We suggest following steps which are highly recommended to begin with.

1 COMPILERS

Easy programming, clean interface, powerful debugging, great support - our compilers

come in three different flavors: mikroC PRO for PIC, mikroBASIC PRO for PIC and

mikroPASCAL PRO for PIC, offering a complete rapid embedded development solution for

these 3 major programming languages. www.mikroe.com/compilers/compilers-pic

3 COMMUNITY

We invite you to join thousands of users of Mikroe development tools. You will find useful

projects and tutorials and get help from a large user community. If you want to download

free projects and libraries, or share your own code, please visit the Libstock website.

With user profiles, you can get to know other programmers, and subscribe to receive

notifications on their code. www.libstock.mikroe.com

2 PROJECTS

Once you have chosen your compiler, and since you already got the board, you are ready to

start writing your first projects. We have equipped our compilers with dozens of examples

that demonstrate the use of each and every feature of the EasyPIC v8 development board.

This makes an excellent starting point for future custom projects. Just load the example,

read well commented code, and see how it works on hardware.

4 SUPPORT

Mikroe offers free Tech Support to the end of its life span, so if anything goes wrong, we are

ready and willing to help. We know how important it is to be able to rely on someone in the

moments when we are stuck with our projects for any reason, or facing a deadline. This is

why our Support Department, as one of the pillars upon which our company is based, now

also offers the Premium Technical Support to business users, ensuring even shorter time-

frame for solutions. The WiFi debugger feature offers additional level of technical support,

allowing our team to provide help by directly connecting to the end users hardware.

www.helpdesk.mikroe.com

Page 35

D I S C L A I M E R

All the products owned by MikroElektronika are protected by copyright law and international copyright treaty. Therefore, this manual is to be treated as any other copyright material. No

part of this manual, including product and software described herein, must be reproduced, stored in a retrieval board, translated or transmitted in any form or by any means, without

the prior written permission of MikroElektronika. The manual PDF edition can be printed for private or local use, but not for distribution. Any modification of this manual is prohibited.

MikroElektronika provides this manual ‘as is’ without warranty of any kind, either expressed or implied, including, but not limited to, the implied warranties or conditions of

merchantability or fitness for a particular purpose.

MikroElektronika shall assume no responsibility or liability for any errors, omissions and inaccuracies that may appear in this manual. In no event shall MikroElektronika, its directors,

officers, employees or distributors be liable for any indirect, specific, incidental or consequential damages (including damages for loss of business profits and business information,

business interruption or any other pecuniary loss) arising out of the use of this manual or product, even if MikroElektronika has been advised of the possibility of such damages.

MikroElektronika reserves the right to change information contained in this manual at any time without prior notice, if necessary.

HIGH RISK ACTIVITIES

The products of MikroElektronika are not fault – tolerant nor designed, manufactured or intended for use or resale as on – line control equipment in hazardous

environments requiring fail – safe performance, such as in the operation of nuclear facilities, aircraft navigation or communication boards, air traffic control, direct life

support machines or weapons systems in which the failure of Software could lead directly to death, personal injury or severe physical or environmental damage (‘High Risk

Activities’). MikroElektronika and its suppliers specifically disclaim any expressed or implied warranty of fitness for High Risk Activities.

TRADEMARKS

The MikroElektronika name and logo, the MikroElektronika logo, mikroC, mikroBasic, mikroPascal, mikroProg, mikromedia, Fusion, Click boards™ and mikroBUS™ are trademarks of

MikroElektronika. All other trademarks mentioned herein are property of their respective companies.

All other product and corporate names appearing in this manual may or may not be registered trademarks or copyrights of their respective companies, and are only used for

identification or explanation and to the owners’ benefit, with no intent to infringe.

Copyright © MikroElektronika, 2019. All Rights Reserved.

Page 36

If you want to learn more about our products, please visit our website at www.mikroe.com

3500000229731

If you are experiencing some problems with any of our products or just need additional

information, please place your ticket at www.mikroe.com/support

If you have any questions, comments or business proposals,

do not hesitate to contact us at office@mikroe.com

Loading...

Loading...