TRS-PSK-003-01/MD-000074185A

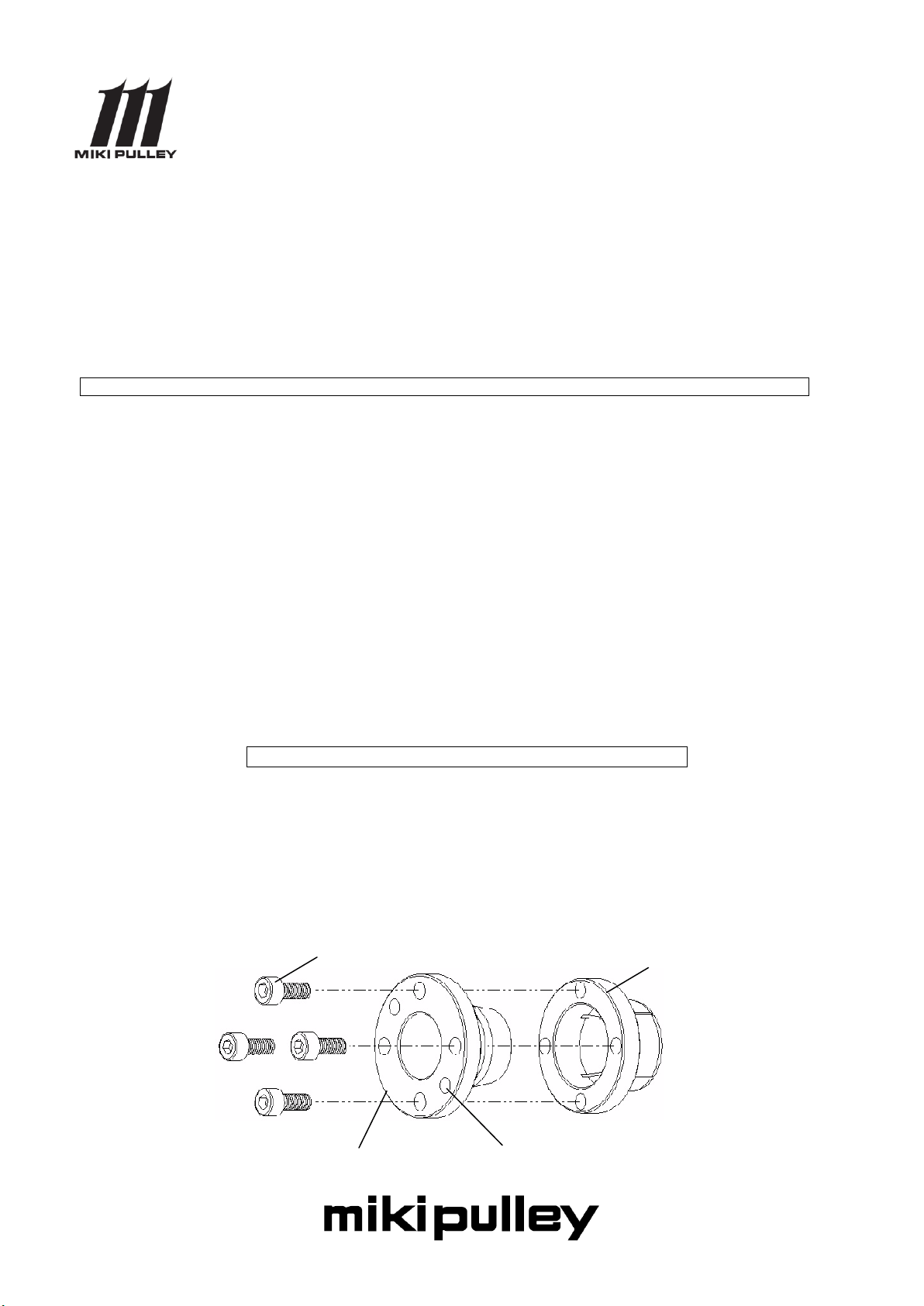

Inner sleeve

Detaching screw hole

Clamping bolt

Outer sleeve

POSI LOCK

PSL-K/PSL-K-B/PSL-K-C/PSL-K-F

Instruction Manual

This manual is common to standard, hexagon head bolt type, basic antirust type, and stainless

steel type.

Before use this product, read the instruction manual carefully and use the product safety and correctly.

1. Before using……………………………………………………………………P1

2. Safety Precaution…………………………………………………………..P2

3. Installation procedure …………………………………………………..P4

4. Removal …………………………………………………………………………P6

5. Other notes ……………………………………………………………………P6

1.Before using

1-1After opening the package

First, please check the following points.

1) Is the product what you ordered?

2) Is the product damaged during transportation?

If any problems are found, please contact your supplier.

1-2 Structure and parts

The main part consists of three parts. “Outer sleeve / Inner sleeve / Clamping bolt’’

-1-

1-3 Part quality of the material

DANGER

When death or serious injury may

result by mishandling

CAUTION

When disability or only physical

damage may result by mishandling

Structural precautions

Touching the product during operation could cause injury. Place a safety

cover to avoid any accident. Additionally, set up a safety mechanism for

quick stop of the product when opening the cover.

Do not use the product near flammable liquids or in the presence of gas

and other explosive air particles.

DANGER

PSL-K: Standard

Sleeve: equivalent of S45C thermal refining

Clamping bolt: SCM435, Black oxide finish

PSL-K-B: Hexagon bolt type

Sleeve: equivalent of S45C thermal refining

Clamping bolt: SCM435, Black oxide finish

PSL-K-C: Basic antirust type

Sleeve: equivalent of S45C thermal refining, Electro less nickel plating

Clamping bolt: SCM435, GEOMET treatment

PSL-K-F: Stainless Steel type

Sleeve: SUS 304

Clamping bolt: SUH660, Solid lubricant film treatment

2.Safety Precautions

Please read carefully through the instruction manual and the technical information for

proper use and safety. In this manual, safety precautions are classified by "DANGER" and

"CAUTION".

Equipment use (atomic energy, aerospace, medical treatment, transportation, or various

safety devices) that may result in serious bodily injury or loss of life directly by mechanical

failure or mishandling, careful examination is necessary. Contact us for further information.

The company has taken all possible measures to produce a quality product; however,

continuous rotational states when the clutch can not be disengaged or coasting of the

machine when the brakes went off is envisioned as emergency. Please pay attention to

safety measures in case anything goes wrong.

-2-

The driven and driving sides could be completely detached when the

product is damaged. Set up a safety mechanism such as a safety brake to

avoid any danger.

Mounting precautions

Depending on the tightening adjustment of bolt or screw, exceptionally

dangerous situations such as product damage or performance degradation

could occur. Always use a calibrated torque wrench and clamp at the

tightening torque specified by Miki Pulley.

It is very dangerous if the driving part starts by accident while

mounting the product. Be sure that the main power of the equipment is

turned off.

Cautions during operation

If the product is used in excess of more than its maximum rated

permissible speed, very dangerous product damage could occur by a large

vibration.

Due to the exposed rotor, touching the product during operation may

cause injury. Make sure not to touch the product during operation.

Using the product with more than the "maximum permissible

misalignment" could cause damage or adverse effect on the equipment.

Always operate the product within the specified "maximum permissible

misalignment."

Cautions for maintenance and inspection

It is extremely dangerous if the driving part starts operating by accident

while dismounting the product. Make sure that the main power of the

equipment is off.

Cautions for disposal

Do not leave the product around where young children may play.

Structural precautions

Do not use the product in an environment where chemicals may spill,

humidity is high, or in hot or cold temperature.

Mounting precautions

The installation of the product must be performed within the specified

maximum permissible error. Using the product with more than the

maximum permissible error could cause damage or adverse effect on the

equipment.

Using a bolt or screw that is not specified by our company could

damage the product. Do not use any bolt or screw unspecified.

To avoid any injury by stripping, spring pin or keyway, make sure to

wear protective equipment such as safety glasses or gloves.

Lifting of a heavy weight could cause back injury. Use a hoist when

carrying or mounting the product.

CAUTION

-3-

Cautions during operation

Using the product with more than the specified permissible torque could

cause damage or adverse effect on the equipment.

If abnormal noises or vibrations occur during operation, improper

mounting should be considered. Do not leave the situation as it is. It may

cause damage to the equipment itself. Also, for reasons other than above,

the belts and other screws may loosen or become defective even if the

product is mounted correctly.

Using the product when the locking part is in a slip condition could over

heat the product, which could cause damage to the equipment.

Cautions for maintenance and inspection

We will refuse to take responsibility as to the damaged product that is

dismantled, remodeled or repaired by a third party except our company

and the designated company. Therefore, for the product that the

assembly process or procedure of dismantlement is described in the

manual, we will not be responsible as well. Please use our service network

for repair and dismantlement.

Cautions for disposal

Call for a waste-control-collection company for disposal.

3. Installation procedure

3-1 Cleaning the shaft and hub

Wipe off any rust and dust adhering to the inner shaft and hub completely. And apply a thin

coating of oil or grease.

Notice

Do not use molybdenum containing oil. It will affect the coefficient of friction.

3-2 Cleaning the POSI LOCK

Wipe off any rust prevention oil or dust from the surface of the POSI LOCK (inner sleeve and

the outer sleeve). Do not disassemble and wipe off the other parts.

3-3 Mounting on the shaft and hub

Set the POSI LOCK to the shaft and hub. After fasten each clamping bolt lightly to contact,

position.

Notice

If the POSI LOCK is hard to be inserted, loose each clamping bolts slightly and then insert the

POSI LOCK.

Do not fasten the clamping bolt until the POSI LOCK is completely set to the shaft and hub.

3-4 Fastening the clamping bolts

Apply lock tight equally to each clamping bolt, and tighten each clamping bolt diagonally from

each other. Then, tighten all of the clamping bolts to the specified torque by using a torque

wrench. The material used for the clamping bolt of the PSL-K-F is stainless steel and easily

-4-

scratched. Careful handling is required especially when fastening the bolt.

PSL-K/-B/-C

Clamping bolt

size

Tightening torque

[Nm]

Detaching

screw hole

6-7

M4

2

M4

8-14

M4

4

M4

15-25

M5

8

M5

28-42

M6

14

M6

PSL-K-F

Clamping bolt size

Tightening torque

[Nm]

Detaching screw

hole

6-7

M4

2

M4

8-14

M4

3.5

M4

15-25

M5

7

M5

28-35

M6

12

M6

3-5 Installation precautions

If the hub is assembled as shown in the figure 1, the outer sleeve will slightly move in the axial

direction when tightening. If the hub is assembled as shown in the figure 2, the outer sleeve

doesn’t move in the axial direction, however, the torque, thrust power, and contact pressure will

drop to approximately 70% of the values indicated.

Figure.1 Figure.2

Clamping bolt tightening torque

PSL-K / PSL-K-B / PSL-K-C

Clamping bolt tightening torque

PSL-K-F

-5-

4. Removal

4-1 Safety inspection

Confirm that torque or thrust power is not applied to POSI LOCK. Also, make sure if there

is any danger of dropping due to the empty weight of the shaft and hub. And then start

mounting. POSI LOCK is no self- locking mechanism. By loosening clamping bolts, fastening

force is released instantaneously.

4-2 Removal

Since they lock automatically under certain conditions, they may not be able to be removed

by loosening the clamping bolts. In this case, do not forcibly remove them. It may cause

damage to the shaft, hub, and body.

First, loosen the clamping bolts to open a gap between the flange and the bearing surface of

the clamping bolt (2mm is sufficient). Then, screw the bolt into the detaching screw hole. By

this action, the fastening force is released. One detaching screw is sufficient. Otherwise, Use

two screws.

5. Other notes

5-1 Tightening tool

Use a torque wrench for tightening the clamping bolts.

Hand tightening is improper and can cause problems. Please do not hand tighten.

5-2 Clamping bolt

Do not use any other clamping bolt except what is attached to the product.

It is a special high intensity bolt and other bolts cannot be used.

If you need bolts for such as loss or exchange, please contact our company.

5-3 Case of re-use

Although POSI LOCK is reusable, please do not use if there is any abnormality.

5-4 Precision

Do not change tightening torque for adjust attachment accuracy. In order to demonstrate

sufficient performance, all the bolts need to be tightened equally.

Contact by email

Please contact us using the inquiry form and be aware that support for inquiries received on Saturdays,

Sundays, holidays, New Year's, and summer business holidays will be provided on the next business day.

Contact by phone

Japanese/English

Miki Pulley International Business Department

TEL +81-46-257-5109

-6-

Loading...

Loading...