Page 1

Manual

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

LOGO 600 SX

www.mikado-heli.de

Mikado Model Helicopters GmbH • Friedrich-Klausing-Straße 2 • 14469 Potsdam • Germany

phone +49 (0)331 23749-0 • fax +49 (0)331 23749-11 • www.mikado-heli.de

© Mikado Model Helicopters GmbH 2015, V1.0029

Page 2

Index

5

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

Tools for Assembly & R/C Equipment

Manual Mikado LOGO 600 SX

Safety Instructions . . . . . . . . . . . . . . . . . 2

Tools for Assembly & R/C Equipment . . . . . . . 2

1 Mainframe . . . . . . . . . . . . . . . . . . . . . 3

2 Tail Rotor . . . . . . . . . . . . . . . . . . . . . 4

3 Tail Boom . . . . . . . . . . . . . . . . . . . . . 5

4 Main Gear & Tail Boom Assembly . . . . . . . . 6

5 V-Bar Rotor Head . . . . . . . . . . . . . . . . . 7

6 Servo Installation . . . . . . . . . . . . . . . . . 8

7 Mounting the Motor . . . . . . . . . . . . . . . . 9

8 Canopy Mounting . . . . . . . . . . . . . . . . . 9

9 Radio and Battery . . . . . . . . . . . . . . . 10

10 Overview Chassis . . . . . . . . . . . . . . . 11

11 Overview Tail Rotor . . . . . . . . . . . . . . 12

12 Overview V-Bar Head . . . . . . . . . . . . . 13

Note: There is no bag 4 and 10. The bags are numbered 1 to 12, with the exception of 4 and 10.

Max. rotorhead rpm LOGO SX 600: 2100

Max. collective range: +/- 12°

Max. Rotor blade size: 600 mm - 620 mm

Max. LiPo Akku size: 10S 5000 mAh

Max. LiPo Akku size: 12S 3300 mAh

LOGO 600 SX is not recommended for novices. This helicopter is a complex system. Basic knowledge of the function of a model helicopter is required to build and operate

the LOGO 600 SX.

Rubber Hammer

Screwdrivers

(plus and minus)

(.055/.079/.098/.118 in)

Ball

link

pliers

Hex Wrenches

1.5/2.0/2.5/3.0 mm

circlips

pliers

Threadlock

Grease

Scissors

Pitch Gauge

OPERATING YOUR MODEL SAFELY

Operate the helicopter in spacious areas with no

people nearby.

!Warning: Do NOT operate the helicopter in the following places and situations (or else you risk severe

accidents):

• in places where children gather or people pass

through

• in residential areas and parks

• indoors and in limited space

• in windy weather or when there is any rain, snow,

fog or other precipitation

If you do not observe these instructions you may be

held reliable for personal injury or property damage!

Always check the R/C system prior to operating your

helicopter. When the R/C system batteries get weaker,

the operational range of the R/C system decreases.

Note that you may lose control of your model when

operating it under such conditions.

Keep in mind that other people around you might also

be operating a R/C model.

Never use a frequency which someone else is using

at the same time. Radio signals will be mixed and you

will lose control of your model.

If the model shows irregular behavior, bring the model

to a halt immediately. Turn off all power switches and

disconnect the batteries. Investigate the reason and

Safety Instructions

fi x the problem. Do not operate the model again as

long as the problem is not solved, as this may lead to

further trouble and unforeseen accidents.

! Warning: In order to prevent accidents and personal

injury, be sure to observe the following:

Before fl ying the helicopter, ensure that all screws are

tightened. A single loose screw may cause a major

accident.

Replace all broken or defective parts with new ones,

as damaged parts lead to crashes.

Never approach a spinning rotor. Keep at least 10 meters/yards away from a spinning rotor blades.

Do not touch the motor immediately after use. It may

be hot enough to cause burns.

Perform all necessary maintenance.

PRIOR TO ADJUSTING AND OPERATING YOUR MODEL, OBSERVE THE FOLLOWING

!Warning: Operate the helicopter only outdoors and

out of people’s reach as the main rotor operates at

high rpm!

! Warning: While adjusting, stand at least 10 meters/

yards away from the helicopter!

Novice R/C helicopter pilots should always seek advice

from experienced pilots to obtain hints with assem-

bly and for pre-fl ight adjustments. Note that a badly

assembled or insuffi ciently adjusted helicopter is a

safety hazard!

In the beginning, novice R/C helicopter pilots should

always be assisted by an experienced pilot and never

fl y alone!

Alle shown products are examples. You may use different brands.

Motor + Speed Controller (check the Mika-

do webpages for recommended motors)

V-Bar

Radio with Heli-Software

Battery

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 2

Page 3

1 Mainframe

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

Bag 1

3x17

3x7x3

Before you combine the two sides of the main

frame, attach the two belt tensioners (#4089,

bag 6).

Using the rod M2.5x60 from bag 7, position all

14 nylon nuts in the right side frame.

10x19x5

321

17x M2,5

1x SW5x59

After assembling the chassis. please move the

battery plate in to the frame.

M2,5x12

3 x

2x 3x17

4x

4x M3x20

2x M3x16

2x 2,2x6

4x M2,5x8

9 x M2,5x10

4x M2,5x16

4x M2,5x12

2x M3x20

2x M3

5x49

3x5x2,5

Bag 1

tapping screw

2,2x6

M3x16

M3x20

M3 Stop

M3x20

SW Ø5x59

M2,5 Stop

M2,5x12

M2,5x10

M2,5x16 (4x)

M2,5x8

Ø5x49

All parts shown in the boxes are displayed in real size.

M3 Stop

M3x20

You should position the motor pinion

on the motor shaft, before you mount

M3x16

raised head

the motor plate. You may also mount

the motor pinion at a later stage, but

the process will be more cumbersome. For reading on how to mount

M3x20

raised head

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 3

the motor pinion, please fl ip to page 9.

Page 4

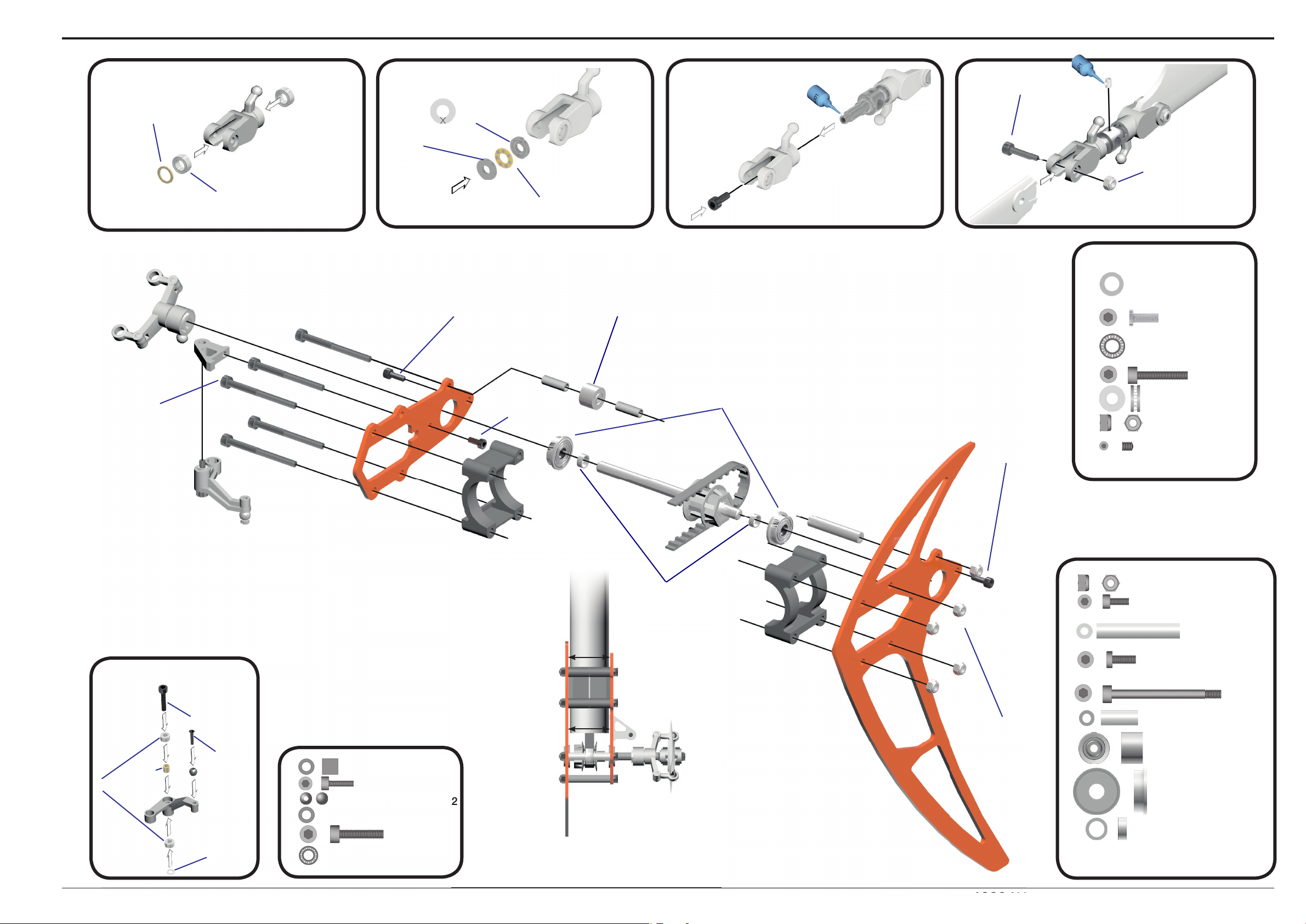

2 Tail Rotor

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

1

Beutel 5

6x8x0,5

M3x35 (5x)

5x8x3

a

smaller

inner Ø

larger

inner Ø

M3x8

M2,5x6

Apply grease

on bearing

3x10x7

b

Glue ball bearings

using 5min. Epoxy

5x13x4

Apply Loctite only in the

threaded section inside the

tail rotor hub!

c

M3x16

M3 Stopp

Bag 5

2x 6x8x0,5

2x M3x8

4x 5x8x3

2x

2x 4x8x3,5

d

M3x16

1

1

3x6x2,5

3x5x5

2

Bag 5

M3x14

3x5x0,5

2

M2x8

1x

1x M2x8

1x

1x 3x5x0,5

1x M3x14

2x 3x6x2,5

3x5x5

Kugel/ball/Rotule Ø4,8x2

2

5x7x2,3

3

3x8

M3 Stopp

M3 Stop

(5x)

(5x)

2x M3

1x M3x3

Bag 5

5x M3

1x M2,5x6

1x 5x27

2x

5x

2x 3x5x10

1x

2x 5x13x4

2x 5x7x2,3

M3x8

3x10x7

3

M3x35

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 4

Page 5

3 Tail Boom

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

Bag 6 • Bag 11

Bag 6

2x M3

1x M2x6

1x M2 Stop

2x M3x16

4x Kugel/ball/Rotule Ø6x3

5 Min. Epoxy

Bag 6 + 11

M3x16 (2x)

Ø4x680 mm

M2x6

M2

M3x40

Ball Ø6 mm

2x

2x 3mm

2x

M3x40

Bag 6 + 11

5 Min. Epoxy

Ball Ø6 mm

M3 Stop

Bag 5

M3x3

Ø5x520 mm

Attach the ball links so that the engraved

number is on the outer surface pointing

towards you.

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 5

Page 6

4 Main Gear & Tail Boom Assembly

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

Bag 2 • Bag 3 • Bag 8

1

3

2

4

Tighten tooth belt:

Pull tail rotor backwards and tighten screws

Carefully push in ... Do not damage the tail

boom holders.

For wider batteries,

you may enlarge this

cut-out.

Bag 2

2x

1x

1x

4x M3

4x M3x10

4x M3x3

10x16x0,5

3x16

M2,5x8

Bag 8

5

1x 2,2x6

Attach the tail boom with a

screw 2.2x6

M3x10

M3x10

10x16x0,5

M3x20

M3x8

M3 Stopp (4)

•To remove the battery, rotate locking mechanism until it

locks.

•After inserting a battery, rotate back to secure the battery

plate in place.

Swashplate bag 3

Tighten the pivot bolts

very carefully. Do not

overtighten them, as

they will break off.

(7x)

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 6

Page 7

5 Servo Installation

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

Bag 1 • Bag 9

LOGO Rotor Head (V-Stabi, ybarless head)

16 mm 16 mm 16 mm

14-16mm

1

2

4

2,2x13 (4x)

If you are installing Futaba servos, add the

distance plate for the two aileron servos.

5

M2,5x10 (4x)

Bag 1

1x M3x47

2x

3x5x1,2

Bag 9

4x

12x 2,2x13

2x M2x10

1x M2x12

4x

9x M2

3x M2,5x35

M2,5x10

Bag 9

(4x)

Aileron left Aileron right

Attach the ball links so that the engraved number is on the outer surface

pointing towards you.

Elevator

Rudder

3

2,2x13

(4x)

6

7

Bag 1

Apply a small amount

of oil to the rotor shaft.

9

23 mm

8

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 7

Page 8

6 V-Bar Rotor Head LOGO 600SX

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

Bag 7

M3x6

Please supply silicon oil or grease

on o-rings and spindle shaft!

7x5

3

8x15x2,6

1 2

4

M5x12

Small inner

diameter

Large inner

diameter

11,5x15,8x0,3

5x15x1

M5x12

5

Apply grease to bearing. Mounting

direction is not critical.

11,5x15,8x0,3

Center the spindle

shaft exactly!

After mounting, the blade holders

will move a little bit tightly at fi rst.

3x12

8x16x5

3x7x3

6

Bag 7

1x M3x6

4x

6x 7x5 O-Ring

2x

4x

2x

8x15x2,6

8x16x5

8x16x5

M3x20

3x5x0,5

M3x20

7

28 mm

8

M3x35

M3 Stopp

2x

3x6x2,5

3x5x2

4x 11,5x15,8x0,3

M3x20

2x M3x35

2x M5x12

2x M4x35

2x

2x M3 Stop

2x M4 Stop

2x Ø4,8x3

2x 3x12

4x 3x7x3

4x 3x6x2,5

2x 3x5x2

2x M3x20

5x15x1

2x

4x

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 8

M2,5x40

Page 9

7 Mounting the Motor 8 Mounting the Canopy

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

Bag 1,2Bag 1

6x9x0,2

1

For mounting the new motor counterbearing with rotorshaft suport, please follow these steps: First, mount the

main gear, the rotor shaft assembly and all shims. Secure

assembly with the 10 mm c-clip (Picture 2). The main gear

will have 0.5 mm axial play. This is normal and will facilitate the mounting and positioning of the pinion later on.

Now mount the motor and the counterbearing. Once the

motor position is set (please ensure correct gear backlash!), please screw the rotorshaft support onto the counterbearing, using the three M3x6 screws.

4x

1x

2x

3x M3x6

4x 10x16x0,5

M3x8

6x9x0,3

Bag 2

M4x32

Bag 1

2

M4x32

Please mount the motor, motor plate, pinion

and counterbearing as illustrated in the above

picture. When positioning the pinion, please

ensure that it sits exactly on the ball bearing of

the counterbearing with only one shim (6.9x0.2)

inbetween. Also make sure that the M4 set screw

sits on the flattened area of the motor shaft.

5x10x1

10x16x0,5

10x16x0,5

10x16x0,5

Bag 9

2x M3x20

2x

2x

Installation of the Motor Pinion

Screw the motor pinion onto the motor shaft, making sure that it

can still be moved. Now mount the motor on the motor plate and

move the pinion so it is aligned well with the main gear. As visual

help for aligning the pinion you may use the small ridge which

separates the two parts of the pinion. When the pinion is aligned

correctly it will easily engage with the main gear. If the pinion does

not engage with the main gear, it is not correctly aligned. After the

pinion is correctly aligned, take the motor out of the mainframe

and tighten the set screw.

Gear Backlash

Move the motor with the pinion until it is limited by the gear. Tighten

one of the M4x32 screws slightly. You must still be able to swivel

the motor around its own axis. In this way you can easily determine the correct distance between the main gear and the pinion.

There should be no (!) gear backlash. At the same time, the motor

should not (!) exert any pressure onto the running surface of the

main gear. After you have determined the correct distance, tighten

the second M4x32 screw.

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 9

Page 10

9 Radio and Battery

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

To adjust, leave the heli unpowered. The exact center position of the

servo arm will be determined in the trim fl ight.

2

1

Position for V-Bar gyro

4

Position for Mini V-Bar

speed

controller

3

5

Position of servo arms for the aileron servos

when sticks are centered (0 deg. Pitch)

Battery:

Attach the battery with the 3 velcro

straps. Mount the battery in a position

where the center of gravity is met with

the battery holder installed.

Velcro Strap

Velcro (adhesive)

6

7

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 10

Page 11

2383

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

10 Overview Chassis

4915

1938

2071 (14x)

4102

1329

1329

930

4236

4091

4072 (20mm)

4713 (22mm)

4089

2385

4192

4064

4103

2364 (550)

4191

4868 (600/690)

2010 (10x16x0,5)

2009 (10x16x0,2)

4919

1953

4912

4914

4917

4099

4913

1954

1941

4651

2074

1958

4059

1974

2010

1915

4094 M07-153

4183 M1-106, 11mm

4621 M1-106, 13mm

4067

1344

4622 (6mm Motorshaft)

4714 (5mm Motorshaft)

4311 white

2775 black

4930

1920

4290 black LOGO 500/600/690

4288 white LOGO 500/600/690

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 11

Page 12

11 Overview Tail Rotor

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

4344 EDGE 95

4345 EDGE 105

4615

4630

727

1956

2462

4145

2074

4630

4235

4137

3077

2447

4625

1961

4627

4634

4273

4096

04074

3069

2466

4107

2074

4634

4626

4073 LOGO 600

4355 LOGO 600 SE

4081 (730XL LOGO 600)

4325 (770XL LOGO 600 SE)

4098 LOGO 600

4354 LOGO 600 SE

4097 (SET) LOGO 600

4354 (SET) LOGO 600 SE

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 12

Page 13

1974

Modellbau Lindinger GmbH e-Mail: office@lindinger.at www.lindinger.at

12 Overview V-Bar Head

1980

840

4708

954

2076

915

2074

04050

1574

4049

4619 (for mainshaft #4620)

4631 (for main shaft #4075)

845

2330

930

4617

4618

4133

1961

1586 (60mm)

1579 (65mm)

1588 (40mm)

1565

www.mikado-heli.de

Construction & Rendering: Mehran Mahinpour Tirooni, André Doil • Layout & Realisation: CDT, André Doil

Manual LOGO 600SX - ©Mikado Model Helicopters GmbH - Page 13

Loading...

Loading...