Page 1

www.mikado-heli.de

LOGO 400 SE

©Mikado Model Helicopters GmbH, V2.0

Manual

Mikado Model Helicopters GmbH • Friedrich-Klausing-Straße 2 • 14469 Potsdam • Germany

Phone +49 (0)331 23749-0 • Fax +49 (0)331 23749-11 • www.mikado-heli.de

Page 2

Manual LOGO 400 SE Page 2 ©Mikado Modellhubschrauber

Details

Page 3

Manual LOGO 400 SE Page 3 ©Mikado Modellhubschrauber

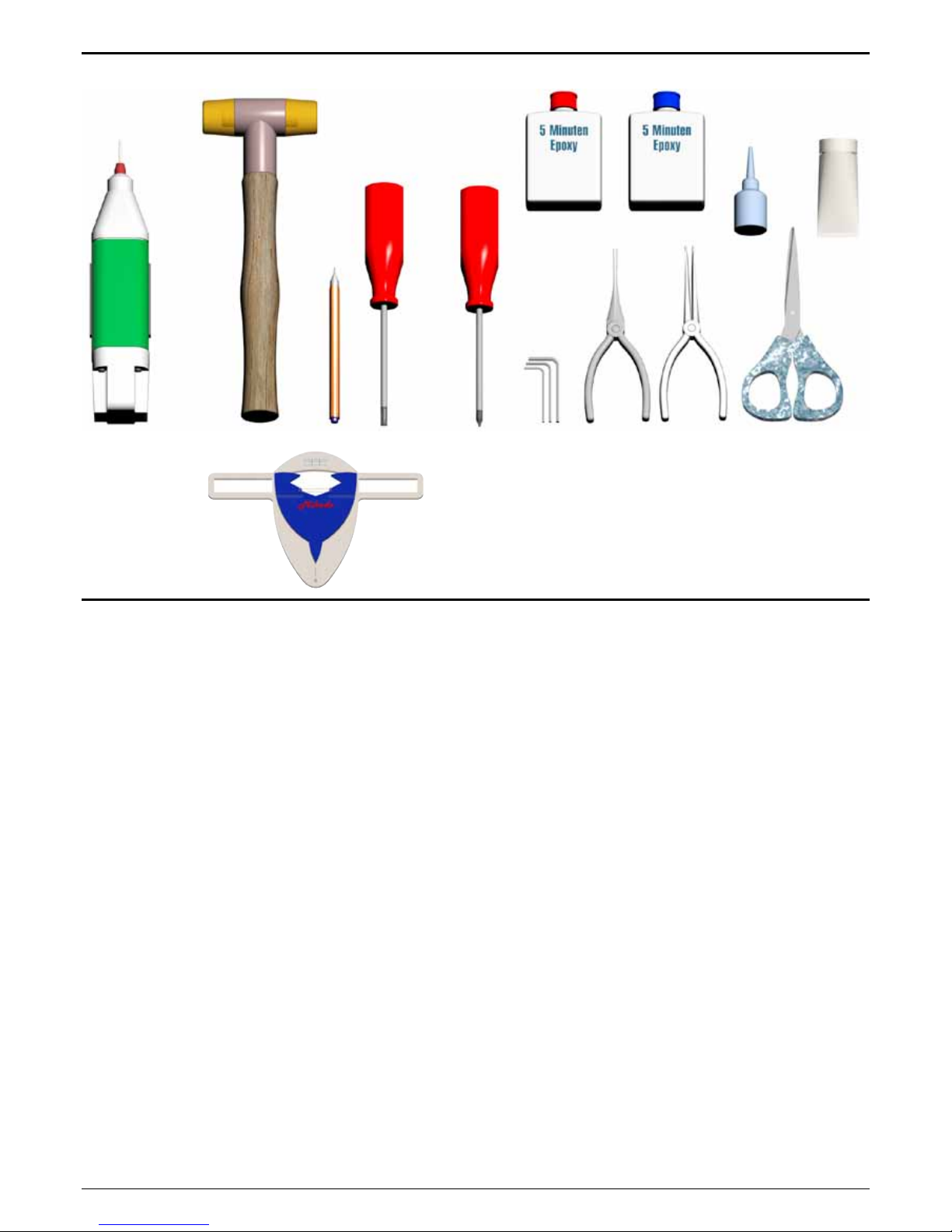

Tools for Assembly & R/C Equipment

Scissors

Rubber Hammer

Drill with

1.5mm bit

(.059 in)

Marker

Screwdrivers

(plus and minus)

Hex Wrenches

1.5/2.0/2.5/3.0 mm

(.055/.079/.098/.118 in)

Ball

link

pliers

Threadlock

Ball

link

pliers

Grease

Pitch Gauge

Safety Instructions

OPERATING YOUR MODEL SAFELY

Operate the helicopter in spacious areas with no people nearby. !Warning: Do NOT operate the helicopter in the following

places and situations (or else you risk severe accidents):

• in places where children gather or people pass through

• in residential areas and parks indoors and in limited space

• in windy weather or when there is any rain, snow, fog or other

precipitation

If you do not observe these instructions you may be held reliable

for personal injury or property damage!

Always check the R/C system prior to operating your helicopter.

When the R/C system batteries get weaker, the operational range

of the R/C system decreases. Note that you may lose control of

your model when operating it under such conditions.

Keep in mind that other people around you might also be operating

a R/C model. Never use a frequency which someone else is using

at the same time. Radio signals will be mixed and you will lose

control of your model.

If the model shows irregular behavior, bring the model to a halt

immediately. Turn off all power switches and disconnect the batteries. Investigate the reason and x the problem. Do not operate

the model again as long as the problem is not solved, as this may

lead to further trouble and unforeseen accidents.

! Warning: In order to prevent accidents and personal injury, be

sure to observe the following:

Before ying the helicopter, ensure that all screws are tightened.

A single loose screw may cause a major accident.

Replace all broken or defective parts with new ones, as damaged

parts lead to crashes. Never approach a spinning rotor. Keep at

least 10 meters/yards away from a spinning rotor blades. Do not

touch the motor immediately after use. It may be hot enough to

cause burns. Perform all necessary maintenance.

PRIOR TO ADJUSTING AND OPERATING YOUR MODEL,

OBSERVE THE FOLLOWING

! Warning: Operate the helicopter only outdoors and out of

people’s reach as the main rotor operates at high rpm!

! Warning: While adjusting, stand at least 10 meters/yards away

from the helicopter!

Novice R/C helicopter pilots should always seek advice from

experienced pilots to obtain hints with assembly and for pre-ight

adjustments. Note that a badly assembled or insufciently adjusted helicopter is a safety hazard! In the beginning, novice R/C

helicopter pilots should always be assisted by an experienced

pilot and never y alone! Throttle channel should be in motor OFF

position while powering up. When switching the R/C system ON

or OFF, always proceed in the following order:

When switching ON:

Position the throttle control stick (on transmitter) to a position

where the LOGO 10 motor does not operate.

• Turn on the transmitter.

• Turn on the receiver.

• Connect the motor battery.

• Operate your model.

When switching OFF:

• Turn off the motor (move throttle control to a position where

motor does not operate).

• Wait until the rotor head has stopped spinning.

• Disconnect the motor battery.

• Turn off receiver.

• Turn off transmitter.

Page 4

Manual LOGO 400 SE Page 4 ©Mikado Modellhubschrauber

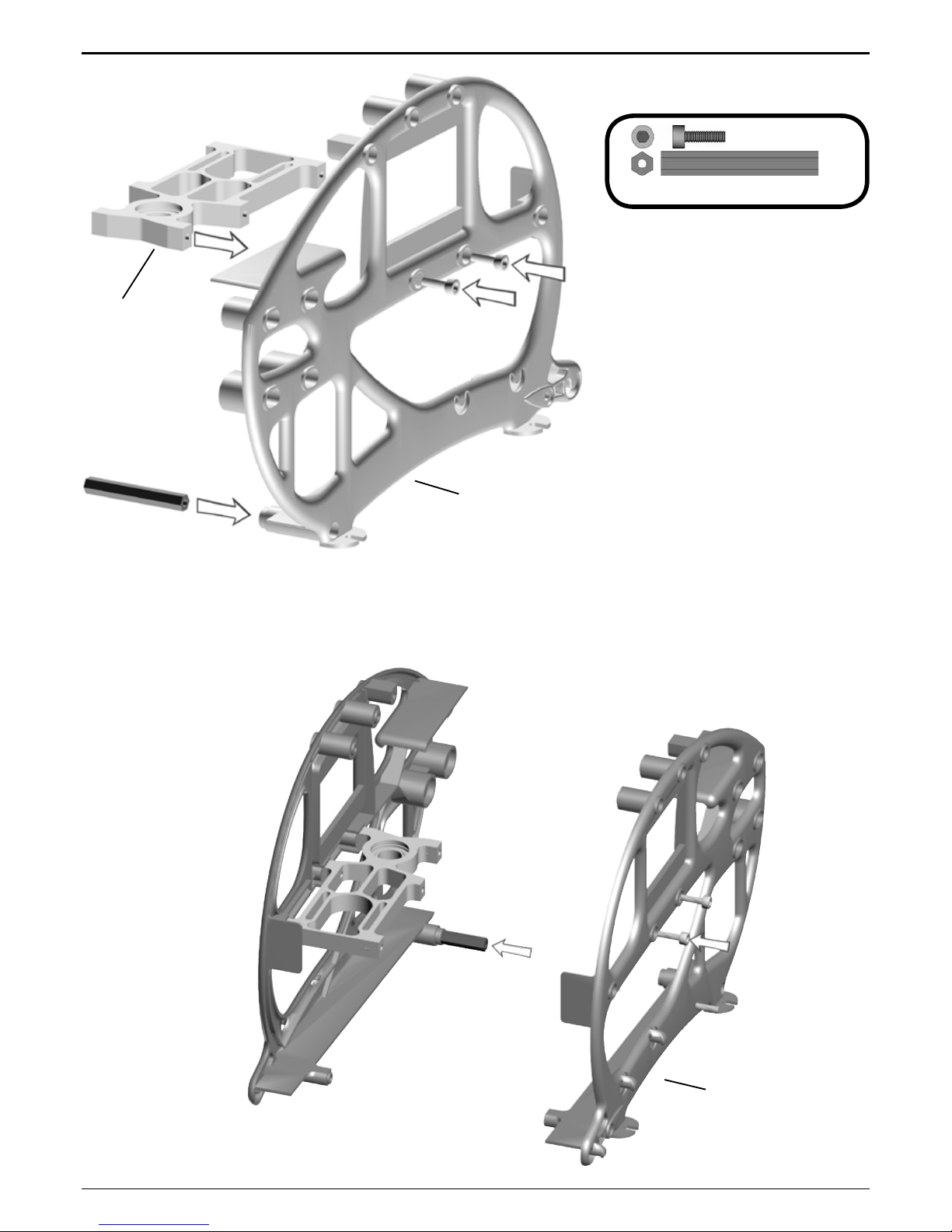

#4187

#4170

#4188

4x M3x10 #1953

1x

38 mm #2371

1 Main Frame

1.1 Main Frame

Bag 1 • Bag 12

Page 5

Manual LOGO 400 SE Page 5 ©Mikado Modellhubschrauber

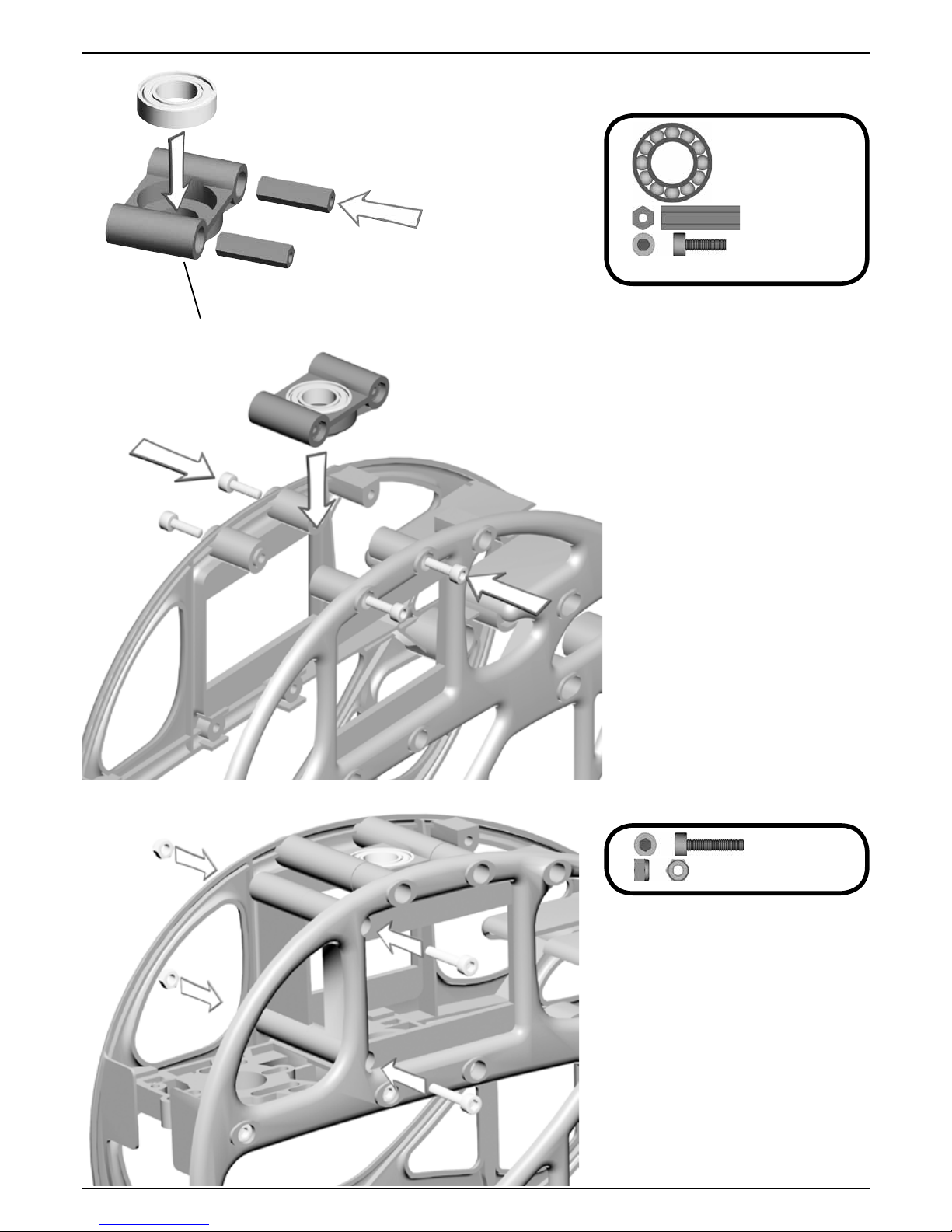

1x 10x19x5 #1329

2x

19 mm #2371

4x

M3x10 #1953

#2380

2x M3x14 #1955

2x

M3 Stopp #2074

1 Main Frame

1.2 Bearing Case

Bag 1 • Bag 10 • Bag 12

Page 6

Manual LOGO 400 SE Page 6 ©Mikado Modellhubschrauber

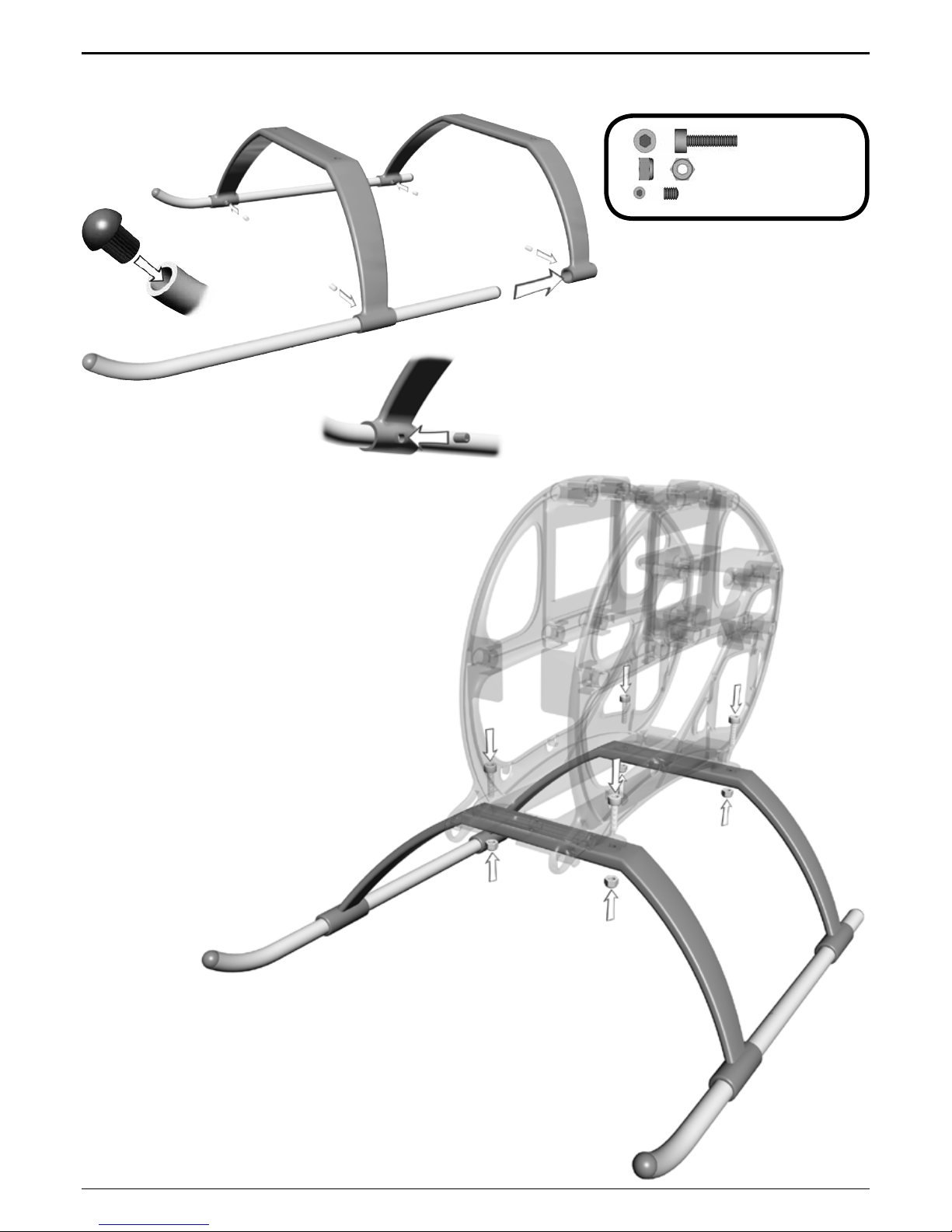

4x M3x12 #1954

4x

M3 #2074

4x

M3x3 #1920

2 Landing Gear

Bag 8 • Bag 12

Page 7

Manual LOGO 400 SE Page 7 ©Mikado Modellhubschrauber

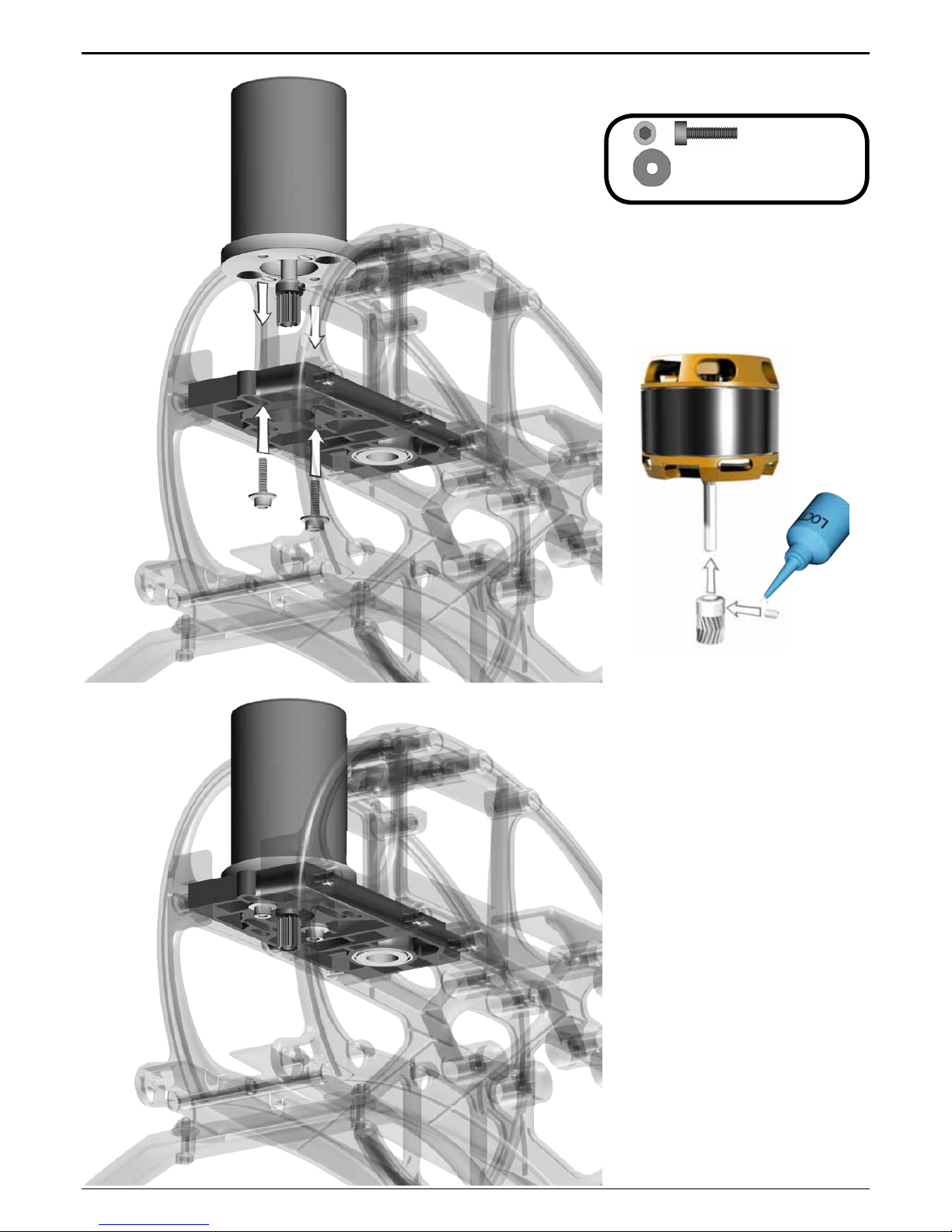

2x M3x12 #1954

2x

3x9x1 #2011

3 Motor Installation

3.1 Motor Attachment

Bag 1 • Bag 12

When installing the motor, tighten

the socket head cap screws only

slightly, making sure that the motor

can still be moved on the motor

plate.

Do not tighten the set screw fully until

the nal position of the pinion on the

motor shaft is determined. This is

done after installing the main gear.

There are two options for attaching

the pinion:

1. For securing the pinion, you may

atten the motor shaft where the set

screw meets the motor shaft - without

making a at surface on the motor

shaft.

2. Alternatively, you may screw the

set screw directly onto the motor

shaft. For this it is required that the

set screw has an appropriate rim for

engaging the motorshaft (all Mikado

pinions have this rim). Note, however,

that after attaching the set screw

once, the rim becomes blunt and may

not be used again.

Page 8

Manual LOGO 400 SE Page 8 ©Mikado Modellhubschrauber

#2731

#2725

4x M3x8 #1915

4x

10x16x0.5 #2010

1x M,5x8 #1940

1x

#1344

#04177

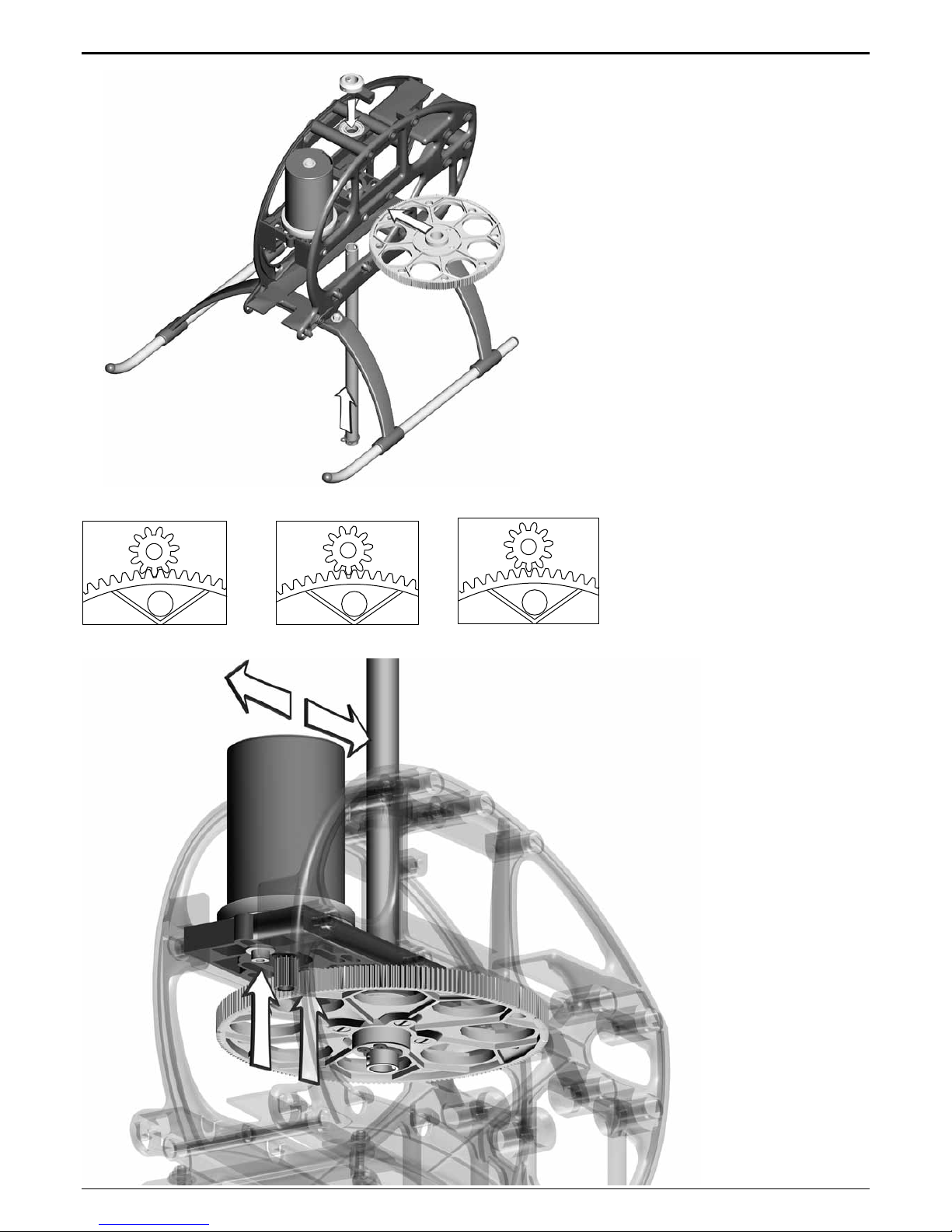

4 Main Gear

4.1 Hub

Bag 2

Page 9

Manual LOGO 400 SE Page 9 ©Mikado Modellhubschrauber

4 Main Gear

After having attached the freeway

hub of the main gear to the rotor

shaft, pull the rotor shaft slightly

upward and simultaneously push

the main shaft collar down onto ball

bearing. Next tighten the set screws.

The rotor shaft should turn easily and

it should not have any axial play.

4.2 Adjusting Gear Backlash

The gear backlash must be adjusted (see drawings). Excess backlash can cause premature wear of

the main gear and will lead to shorter

ight times.

too much backlash correct backlash too little backlash

Page 10

Manual LOGO 400 SE Page 10 ©Mikado Modellhubschrauber

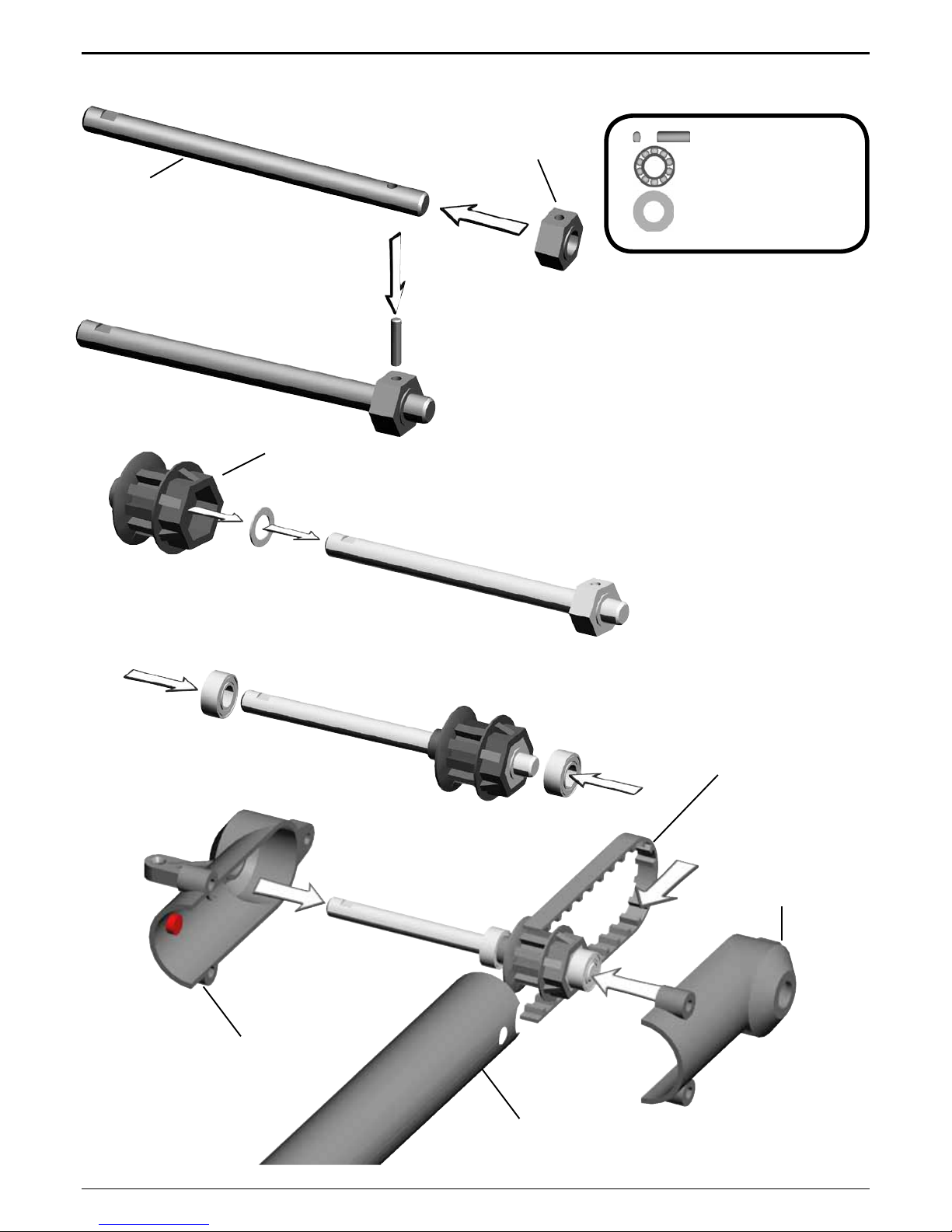

# 4189

# 4181

#2467

#2476

#2466

#2189

#4150

1x 2x10mm #2469

2x

5x10x4 #2470

2x

5x10x0.1 #2004

5 Tail Rotor

5.1 Tail Rotor Shaft

Bag 5 • Bag 10

Should you have difculty mounting

the 2x10 mm pin, carefully tap it with

a rubber hammer, or use a vice. The

5x10x4 bearings can also be mounted on the rotor shaft using a vice and

tapping the shaft softly with a rubber

hammer. If the tail rotor shaft shows

axial play after closing the two halves

of the tail rotor case, use one or two

of the 5x10x0.1 washers which are

included in the bag.

Page 11

Manual LOGO 400 SE Page 11 ©Mikado Modellhubschrauber

#4182

2x M3x25

#1958

1x

M3x10 #1953

3x

M3 #2074

5 Tail Rotor

5.2 Vertical Fin

Bag 5 • Bag 12

Page 12

Manual LOGO 400 SE Page 12 ©Mikado Modellhubschrauber

#2455

#2452

2x 6x10x2,5 #1440

#3030

2x7mm

5 Tail Rotor

5.3 Pitch Slider

Bag 5 • Bag 10

It is important that the tail pitch plate #3030 is aligned properly on the

control sleeve #2455. In the case of

misalignment, the control sleeve may

become deformed.

The mounted tail pitch plate should

be able to move on the tail rotor shaft

with little resistance.

Page 13

Manual LOGO 400 SE Page 13 ©Mikado Modellhubschrauber

#2449

2x 3x6x2,5 #2330

1x

M3x14 #1955

1x

M2x8 #1902

1x

#1570

1x

3x5x5 #2448

1x

3x5x0,5 #2002

5 Tail Rotor

5.4 Tail Rotor Lever

Bag 5 • Bag 12

The mounted tail rotor lever should

be able to move with little resi-

stance.

Page 14

Manual LOGO 400 SE Page 14 ©Mikado Modellhubschrauber

M3x3

M3x16

4x8x3

#2462

4x8x2

#3051

5x8x0,5

M2,5x6

M3 Stopp

2,5x6x0,5

3x M2,5x6

2x

2,5x6x0,5

2x

4x8x3

2x 4x8x2

2x

M3x16

2x 4x8x3,5

2x

M3

1x M3x3

2x

5x8x0,5

5 Tail Rotor

5.5 Tail Rotor Hub

Bag 5 • Bag 10

Small inner

diameter

Large inner

diameter

Apply grease

to bearing

Page 15

Manual LOGO 400 SE Page 15 ©Mikado Modellhubschrauber

#2485

6 Tail Boom

6.1 Tail Boom Holder

Bag 6

Turn the tail drive belt 90° degrees

(clockwise).

Page 16

Manual LOGO 400 SE Page 16 ©Mikado Modellhubschrauber

#2728

1x 4x13x5 #937

1x

4x9x4 #2489

2x 4x8x1 #2013

1x

3x5 #1921

1x

M3x18 #1965

1x

M3 #2074

#2488

!

6 Tail Boom

6.2 Tail Drive Pulley

Bag 6 • Bag 10 • Bag 12

Important: Check belt tension

prior to every ight. Incorrect belt

tension can cause disturbances

for your model R/C system. Incorrect belt tension can lead to a

situation where you lose control of

the tail rotor of your helicopter.

For tightening the belt pull the tail

boom holder toward the front. Belt

tension is xed with the M3x18 sokket head cap screw for tightening the

tail boom holder to the tail boom. The

belt should be tight. When pressing

with your ngers, both sides of the

belt should not come in contact with

each other.

Page 17

Manual LOGO 400 SE Page 17 ©Mikado Modellhubschrauber

#4179

5 Min. Epoxy

1x M2x6 #1901

1x

M2 #2070

2x

M2,5x30#2770

6 Tail Boom

6.3 Tail Control Rod

Bag 6

Screw the two 2 mm ball links onto

the control rods. Their exact positions

are of no importance at this point. The

ball ends are attached to the balls

more easily when the text on them is

pointed away from the helicopter.

Page 18

Manual LOGO 400 SE Page 18 ©Mikado Modellhubschrauber

8x M3 x12 #1954

2x

27,5 mm

#2371

2x

23 mm

#2371

2x

M3x16 #1956

2x

M3 #2074

#4184

#4184

6 Tail Boom

6.4 Installation

Bag 6 • Bag 12

For mounting the tail assembly in

the side-frames, pull the rear ends of

the side-frames apart.

For adjusting the gear backlash,

insert a strip of paper between the

main gear and the drive pulley, then

press the drive pulley against the

main gear.

6.5 Tail Rotor Blades

Bag 5

Tighten the screws holding the

tail rotor blades, but ensure that the

blades move easily in the tail rotor

holders under centrifugal force.

Page 19

Manual LOGO 400 SE Page 19 ©Mikado Modellhubschrauber

2x 2,9x19

2x

M3 #2074

4x

4,8 mm #1574

4x

M2,5x30 #2770

2x

M3x20 #1957

2x

3x5x2 #2463

#4178

#1565

#4182

2,9x19

6 Tail Boom

6.6 Tail Boom Brace

Bag 1 • Bag 6 • Bag 9

5 min epoxy

The ball links should be screwed

onto the control rod such that one is

turned at 90 degrees with respect to

the other.

Page 20

Manual LOGO 400 SE Page 20 ©Mikado Modellhubschrauber

7 Finished Main Frame & Tail Boom

Page 21

Manual LOGO 400 SE Page 21 ©Mikado Modellhubschrauber

2x M2x8 #1902

2x

M2x10 #1903

6x

M2 #2070

4x

4,8 #1570

14-15 mm

16-17 mm 16-17 mm 16-17 mm

(7x)

8 Swashplate

Bag 3

9 Servo Arms

Bag 9

Rudder Servo Elevator Servo Aileron Servo Aileron Servo

Tighten the pivot bolts

very carefully. Do not

overtighten them, as

they will break off.

120° CCPM

Rudder Servo Elevator Servo Aileron Servo left Aileron Servo right

Page 22

Manual LOGO 400 SE Page 22 ©Mikado Modellhubschrauber

14 mm

(.472 in)

#2770

10 Servo Installation

10 .2 Tail Rotor Servo

With LOGO 400 side-frames you

can use two different sizes of tail

rotor servos. A larger standard-size

tail rotor servo can be mounted to the

left side-frame, a smaller mini servo

is mounted to right side-frame.

10.3 Elevator Servo

Linkage measurements for 3D

pitch range (-12° to +12°)

10.1 Linkage

Bag 9

Page 23

Manual LOGO 400 SE Page 23 ©Mikado Modellhubschrauber

#2383

#2384

#2382

10 Servo Installation

10.4 Elevator Linkage/Swashplate

10.5 Canopy Fixing Bolts

Bag 1

Page 24

Manual LOGO 400 SE Page 24 ©Mikado Modellhubschrauber

10 Servo Installation

10.6 Aileron Servo left

10.7 Aileron Servo right

Page 25

Manual LOGO 400 SE Page 25 ©Mikado Modellhubschrauber

10 Servo Installation

10.8 Aileron Linkage

Page 26

Manual LOGO 400 SE Page 26 ©Mikado Modellhubschrauber

5x M3x8

2x

3x7

2x

2,5x7

2x

8x11x4

2x

8x11x1

4x

8x14x4

2x

6x14x5

2x

10x14x1

2x

M3x10

1x

M3x20

2x

M3x22

2x

M4x12

2x

M3x24

2x

4x12x1

3x

M3

2x

Ø4,8x3

2x 3x12

4x

3x7x3

4x

3x6x2,5

2x

3x5x2

2x

M3x14

1x

M3x5

2x

3x5x0,3

M4x12

4x12x1

3x7

2,5x7

8x11x1

8x11x4

10x14x1

(5x)

M3x10

M3x8 (5x)

8x14x4

3x12

3x7x3

3x5x2

3x6x2,5

2x

M3x14

M3x5

3x5x0,3

11 VBar Rotorhead

Bag 7

Large inner

diameter

Small inner

diameter

Apply grease to bearing

Page 27

Manual LOGO 400 SE Page 27 ©Mikado Modellhubschrauber

M3 Stopp

M3x20

37 mm

M3x22

Please adjust the swashplate driver in such a

way that the balls on the inner and outer ring of

the swashplate are positioned exactly on a line

along the longitudinal axis of the heli.

11 VBar Rotorhead

Page 28

Manual LOGO 400 SE Page 28 ©Mikado Modellhubschrauber

1x

M3x40

2x

M3x12 #1954

1x

M3x10 #1953

3x M2,5x10 #1938

3x

M2,5 #2071

#4185

M2,5x10

M3x10

M3x12

M2,5x10

M3x12

M3x40

12 Battery Support

Bag 1 • Bag 12

Page 29

Manual LOGO 400 SE Page 29 ©Mikado Modellhubschrauber

13 Overview

13.1 Chassis

Page 30

Manual LOGO 400 SE Page 30 ©Mikado Modellhubschrauber

13 Overview

13.2 Rotor Head

Page 31

Manual LOGO 400 SE Page 31 ©Mikado Modellhubschrauber

www.mikado-heli.de

Construction & Rendering: Mehran Mahinpour Tirooni • Layout & Realisation: CDT-Berlin

13 Overview

13.3 Tail Boom/Tail Rotor

Loading...

Loading...