Page 1

Manual

LOGO 20

www.mikado-heli.de

Mikado Modellhubschrauber • Friedrich-Klausing-Straße 2 • 14469 Potsdam • Germany

Phone +49 (0)331 23749-0 • Fax +49 (0)331 23749-11 • www.mikado-heli.de

© Mikado Modellhubschrauber, V2.0

Page 2

Index

1 Main Frame .........................................5

1.1 Motorplate 5

1.2 Elevator Lever 6

1.3 Motorplate 6

1.4 Bearing Case for Main Shaft 7

2 Landing Gear ...................................... 8

3 Motor Installation ............................... 9

4 Main Gear ..........................................10

4.1 Main Gear Hub 10

4.2 Main Rotor Shaft 11

4.3 Adjusting Gear Backlash 13

5 RC Support .......................................14

5.1 Battery Fixing Rings14

5.2 RC Support14

5.3 Servo Tray 15

5.4 Front Battery Fixing Rings 15

5.5 Frame 16

6 Wash-Out...........................................1 7

7 Swashplate .......................................18

8 Preparation for Servo Installation .19

8.1 Servo Arms 19

8.2 Servo Centering 19

8.3 Elevator and Aileron Servos (2x) 20

8.4 Tail Servo 20

9 Aileron Lever .................................... 21

10 Control Rods ..................................22

10.1 Length of Control Rods 22

10.2 Elevator and Aileron Linkages 22

11 Swashplate Guide Bracket ...........24

12 Installation of Wash-Out Hub ....... 2 4

13 Main Frame without Rotor Head .. 2 5

14 Tail Rotor .........................................26

14.1 Tail Rotor Shaft 26

14.2 Vertical Fin 27

14.3 Tail Pitch Slider 28

14.4 Tail Rotor Lever 29

14.5 Tail Rotor Hub 30

15 Tail ....................................................31

15.1 Tail Boom Assembly 31

15.2 Tail Boom Holder 32

15.3 Tail Dr ive Pulley 33

15.4 Control Rods 34

15.5 Tail Assembly 35

15.6 Tail Rotor Blades 36

15.7 Horizontal Fin 36

15.8 Tail Support 37

16 Finished Main Frame ..................... 38

17 Main Rotor Head ............................ 39

17.1 Blade Grips 39

17.2 Mixing Arms 39

17.3 Yoke 40

17.4 Seesaw 41

17.5 Flybar Control Bridge 42

17.6 Flybar 43

17.7 Flybar Paddles 4 4

17.8 Final Assembly 45

17.9 Rotor Head Linkage 46

17.10 LOGO 20 Finished 48

18 RC Installation ................................49

19 Decals ..............................................51

20 How to Avoid Interference............ 5 2

21 RC Programming ...........................53

22 Rotor Blades ...................................60

22.1 Balancing of Rotor Blades 60

22.2 Static Balancing 60

23 Final Pre-Flight Check ..................61

23.1 Direction of Main and Tail Rotation 61

23.2 Blade Tracking Adjustment 61

24 Control Movements.......................62

24.1 Pitch/Throttle 62

24.2 Rotor Head 62

24.3 Elevator 63

24.4 Aileron 63

25 Overview .........................................64

25.1 Chassis 64

25.2 Rotor Head 65

25.3 Tail Boom/Tail Rotor 65

26 Tuning/Accessories.......................66

Manual

All parts shown in the boxes are displayed in real size.

LOGO 20

Page 2 ©Mikado Modellhubschrauber

Page 3

Safety Instructions

OPERATING YOUR MODEL SAFELY

Operate the helicopter in spacious areas with no people nearby.

!Warning: Do NOT operate the helicopter in the following places and situations

(or else you risk severe accidents):

• in places where children gather or people pass through

• in residential areas and parks

• indoors and in limited space

• in windy weather or when there is any rain, snow, fog or other precipitation

If you do not observe these instructions you may be held reliable for personal injury or property damage!

Always check the R/C system prior to operating your helicopter.

When the R/C system batteries get weaker, the operational range of the R/C system decreases. Note that you

may lose control of your model when operating it under such conditions.

Keep in mind that other people around you might also be operating a R/C model.

Never use a frequency which someone else is using at the same time. Radio signals will be mixed and you will

lose control of your model.

If the model shows irregular behavior, bring the model to a halt immediately. Turn off all power switches and

disconnect the batteries. Investigate the reason and fix the problem. Do not operate the model again as long as the

problem is not solved, as this may lead to further trouble and unforeseen accidents.

!Warning: In order to prevent accidents and personal injury, be sure to observe the following:

Before flying the helicopter , ensure that all screws are tightened. A single loose screw may cause a major accident.

Replace all broken or defective parts with new ones, as damaged parts lead to crashes.

Never approach a spinning rotor. Keep at least 10 meters/yards away from a spinning rotor blades.

Do not touch the motor immediately after use. It may be hot enough to cause burns.

Perform all necessary maintenance.

PRIOR TO ADJUSTING AND OPERATING YOUR MODEL, OBSERVE THE FOLLOWING

!Warning: Operate the helicopter only outdoors and out of people’ s reach as the main rotor operates at high rpm!

!Warning: While adjusting, stand at least 10 meters/yards away from the helicopter!

Novice R/C helicopter pilots should always seek advice from experienced pilots to obtain hints with assembly

and for pre-flight adjustments. Note that a badly assembled or insufficiently adjusted helicopter is a safety hazard!

In the beginning, novice R/C helicopter pilots should always be assisted by an experienced pilot and never fly

alone!

Throttle channel should be in motor OFF position while powering up.

When switching the R/C system ON or OFF, always proceed in the following order:

When switching ON:

• Position the throttle control stick (on transmitter) to a position where the LOGO 10 motor does not operate.

• Turn on the transmitter.

• Turn on the receiver.

• Connect the motor battery .

• Operate your model.

When switching OFF:

• Turn off the motor (move throttle control to a position where motor does not operate).

• Wait until the rotor head has stopped spinning.

• Disconnect the motor battery.

• Turn off receiver.

• Turn off transmitter.

Manual

LOGO 20

Page 3 ©Mikado Modellhubschrauber

Page 4

Tools for Assembly & R/C Equipment

Rubber Hammer

Drill with

1.5mm bit

(.059 in)

Marker

Screwdrivers

(plus and minus)

Hex Wrenches

1.5/2.0/2.5/3.0 mm

(.055/.079/.098/.118 in)

Threadlock

Ball link pliers

Scissors

Pitch Gauge

Alle shown products are examples. You may use different brands.

Motor + Speed Controller (check the Mikado

webpages for recommended motors)

Fast Charger (Schulze isl 6-330d or isl 6-636+)

Receiver (Graupner DS 19

or SMC 19 SPCM)

Radio with Heli-Software

Manual

LOGO 20

Battery (Sanyo RC2400 or Sanyo 3000 NiMH)

Receiver Battery

(Sanyo AR500)

Gyro (Futaba GY240

or GY401)

Page 4 ©Mikado Modellhubschrauber

4x Servos

Page 5

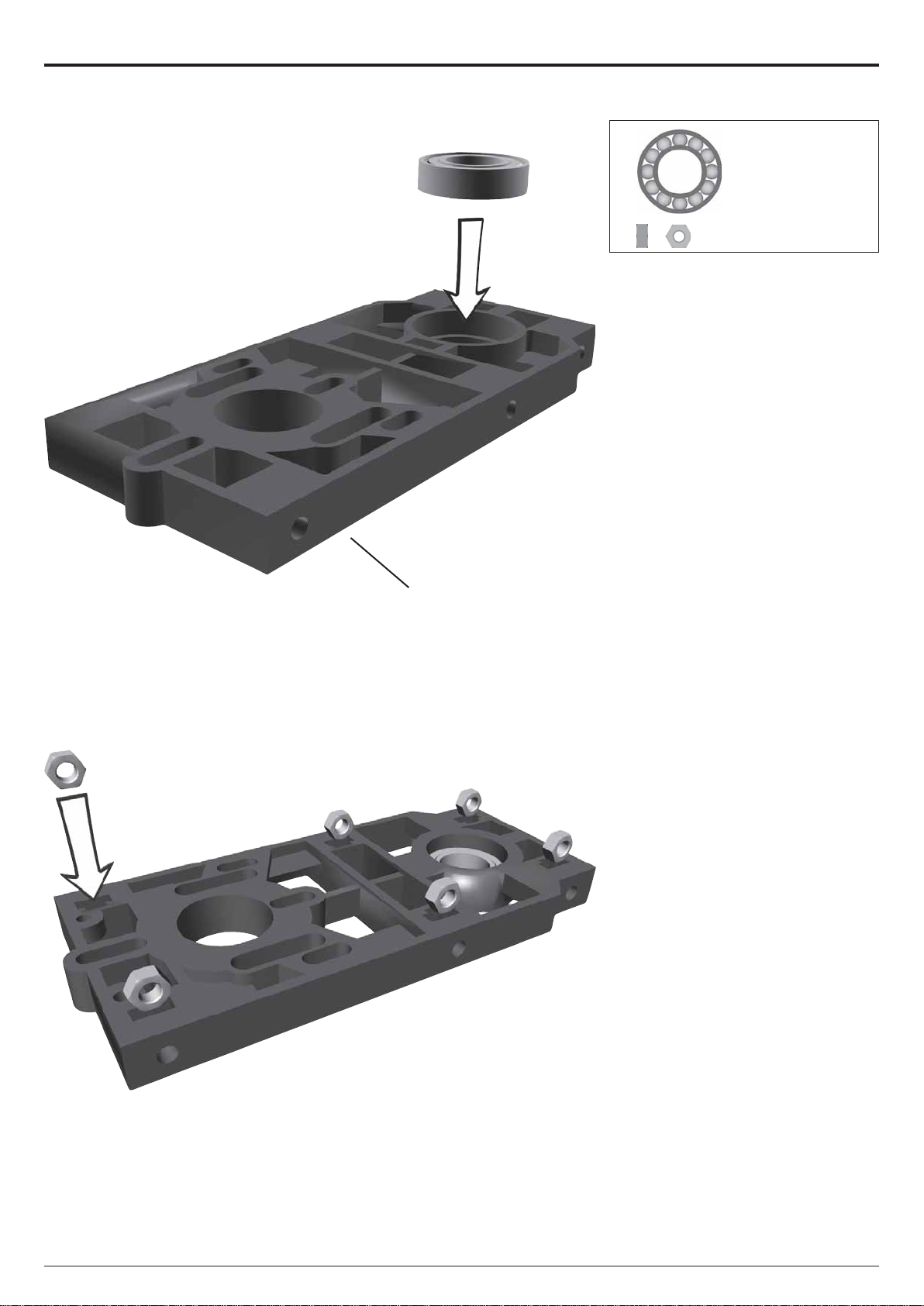

1 Main Frame

1.1 Motorplate

Bag 1 • Bag 10

1x 10x19x5 #1329

#2379

6x

M3 #2072

Manual

LOGO 20

Page 5 ©Mikado Modellhubschrauber

Page 6

#1570

1 Main Frame

1.2 Elevator Lever

Bag 1 • Bag 10 • Bag 12

2x 4x8x3 mm #2397

Choose correct

countersunk screw

#2394

#1570

2x

1x

1x

Ø4,8 mm #1570

M2x8 #1902

M2x10 #1911

1.3 Motor Plate

Bag 1 • Bag 12

4x M3x10 #1953

2x

M3x14 #1955

#2375

#2379

#2376

Manual

LOGO 20

Page 6 ©Mikado Modellhubschrauber

Page 7

1 Main Frame

1.3 Bearing Case for Main Shaft

Bag 1 • Bag 12

2x 19 mm #2370

#2381

4x

M3x12 #1954

Manual

LOGO 20

Page 7 ©Mikado Modellhubschrauber

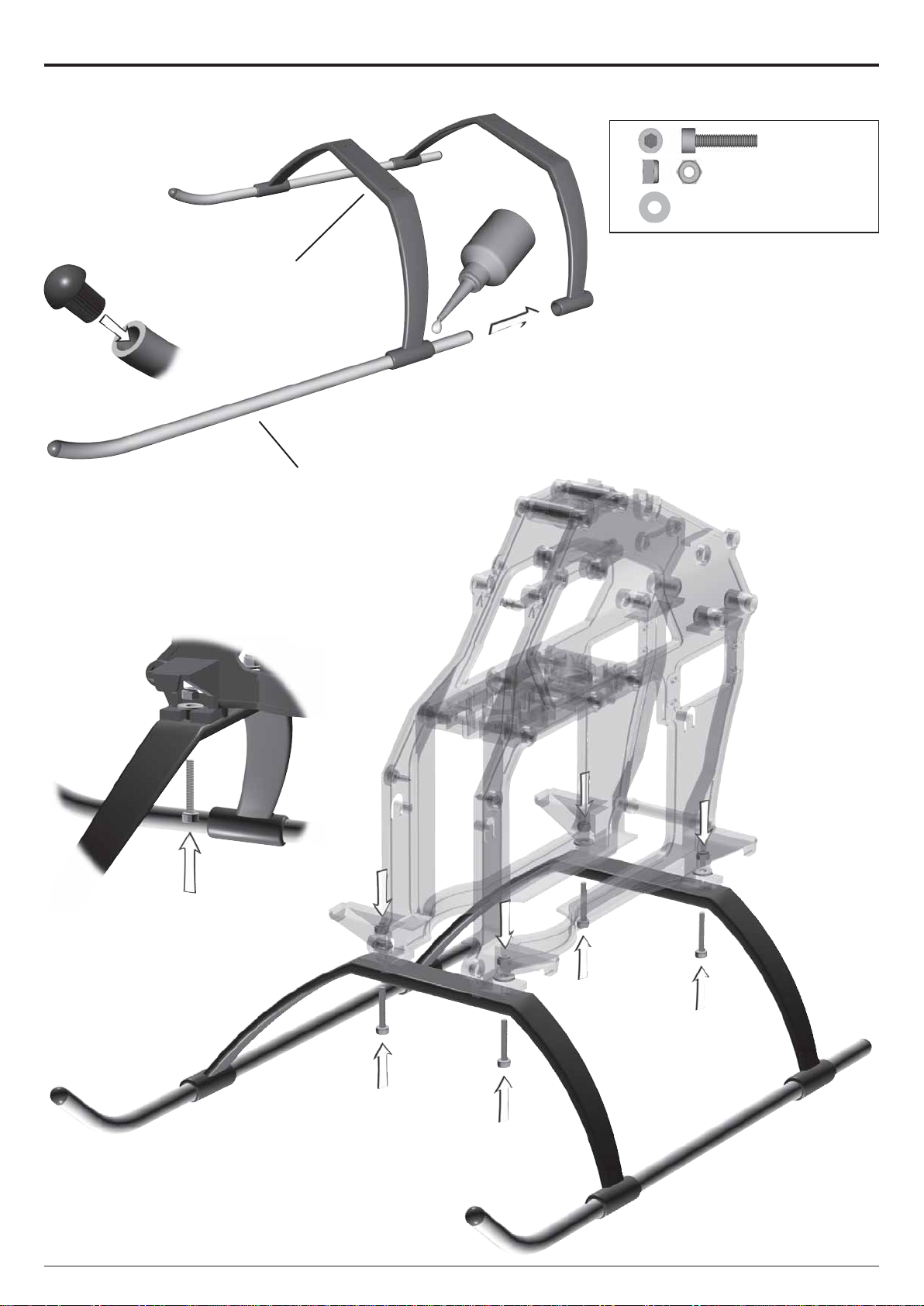

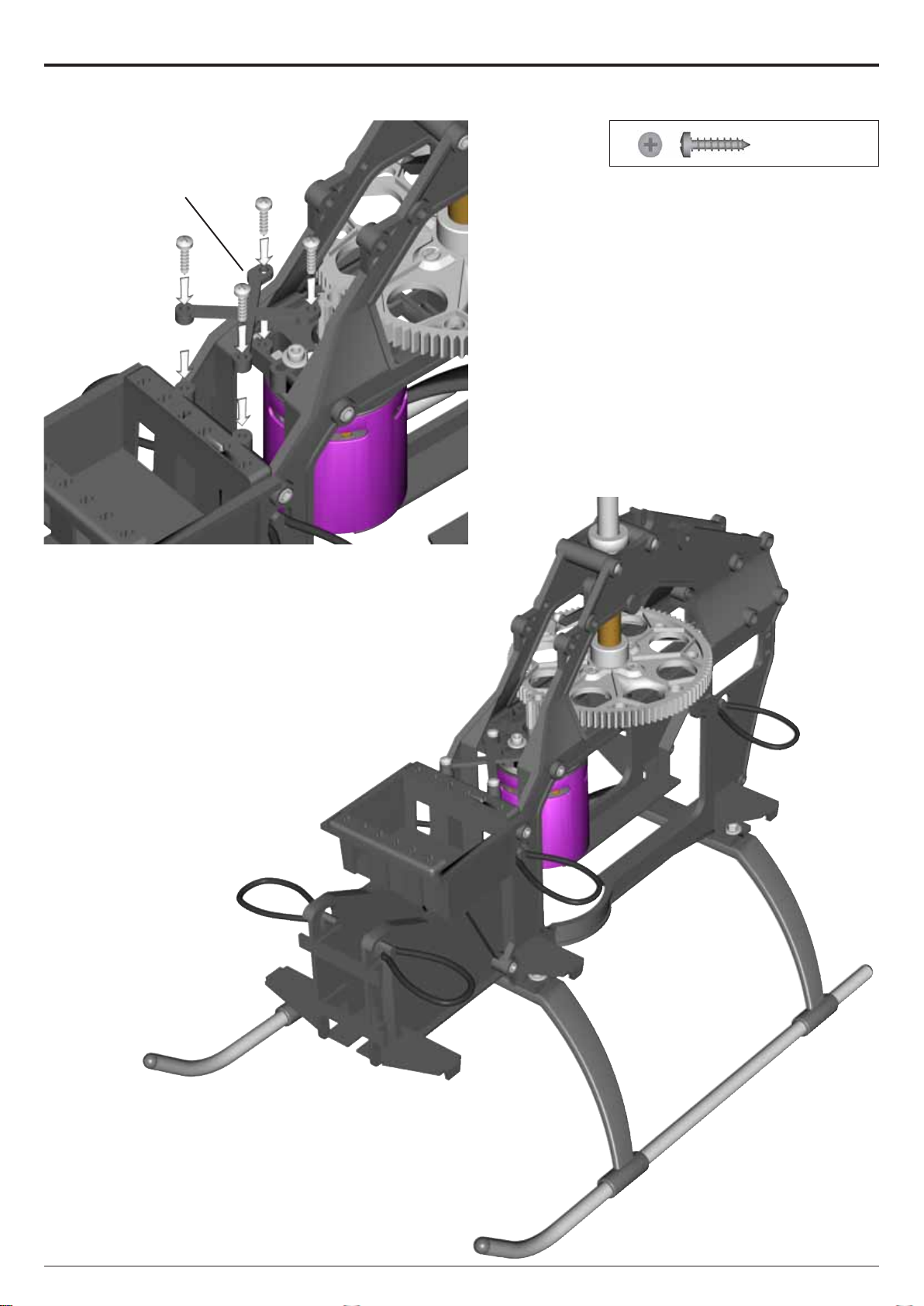

Page 8

2 Landing Gear

Bag 8 • Bag 12

4x M3x14 #1955

#2495

#2496

4x

4x

Align the skids and secure them

with superglue.

M3 #2074

3x7x0,5 #2012

Manual

LOGO 20

Page 8 ©Mikado Modellhubschrauber

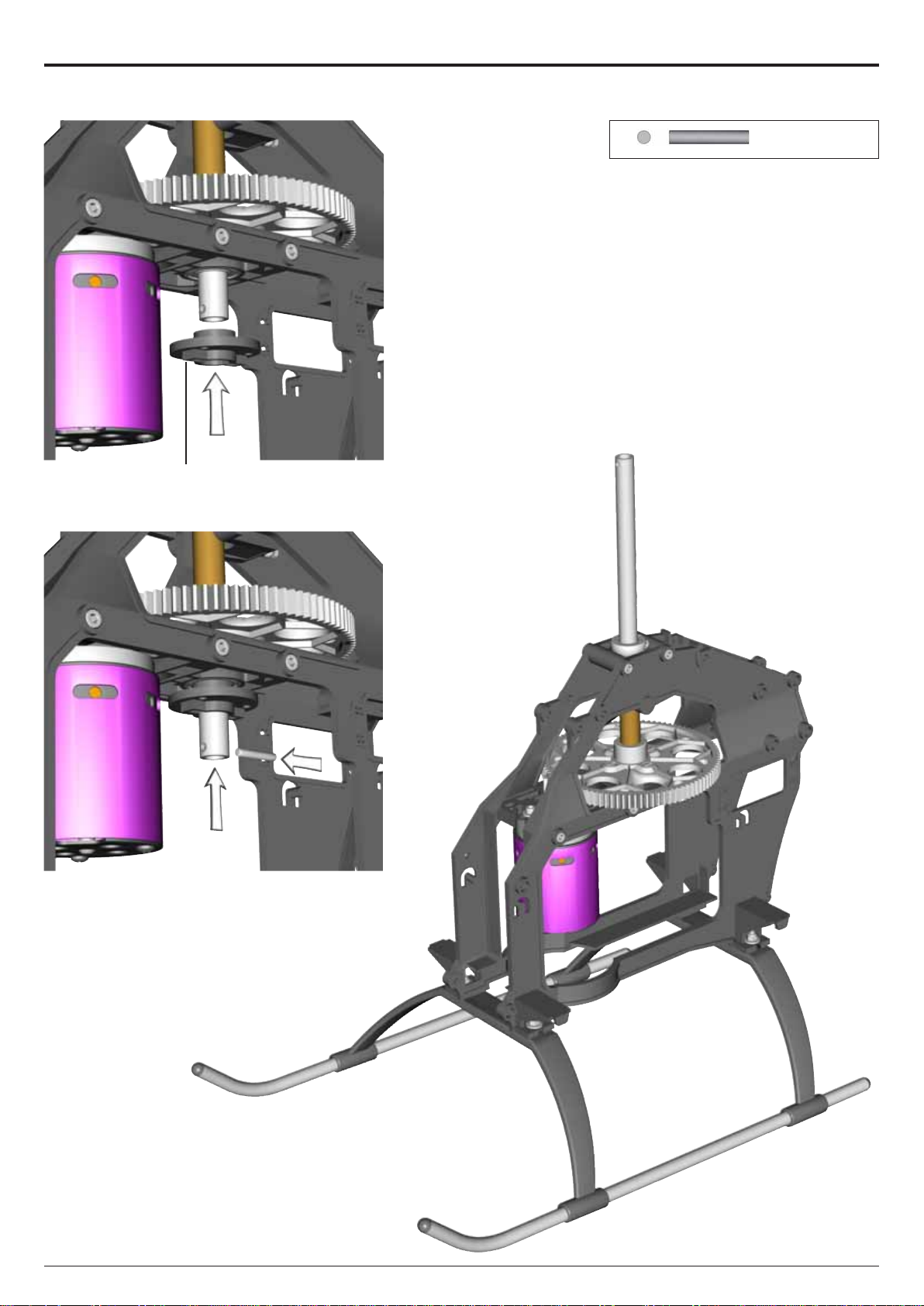

Page 9

3 Motor Installation

3 Motor Installation

Bag 1• Bag 12

2x M3 #2072

Pinion not

included in kit

#2499

2x

2x

2x

Some electric motors are constructed such that they cannot be moved

along the motor plate. If you are using

one of these motors, please use the

motor adaptor plate #2499. The plate

is not needed for Hacker motors.

Please check from the Mikado

website which pinion works best with

the motorset you have (on the Mikado webpage go to LOGO 10 and click

“Motorization”). When a wrong pinion is used, the performance of your

electric helicopter will deteriorate and

the motor or speed controller can be

damaged.

M3x8 #1915

M3x12 #1964

3x7x0,5 #2012

Do not tighten the set screw fully

until the final position of the pinion on

the motor shaft is determined. This is

done after installing the main gear.

There are two options for attaching

the pinion:

1. For securing the pinion, you may

flatten the motor shaft where the set

screw meets the motor shaft - without

making a flat surface on the motor

shaft.

2. Alternatively, you may screw the

set screw directly onto the motor

shaft. For this it is required that the

set screw has an appropriate rim for

engaging in the motorshaft (all Mikado pinions have this rim). Note,

however, that after attaching the set

screw once, this rim becomes blunt

so that the screw may not be used

again.

Manual

LOGO 20

Page 9 ©Mikado Modellhubschrauber

Page 10

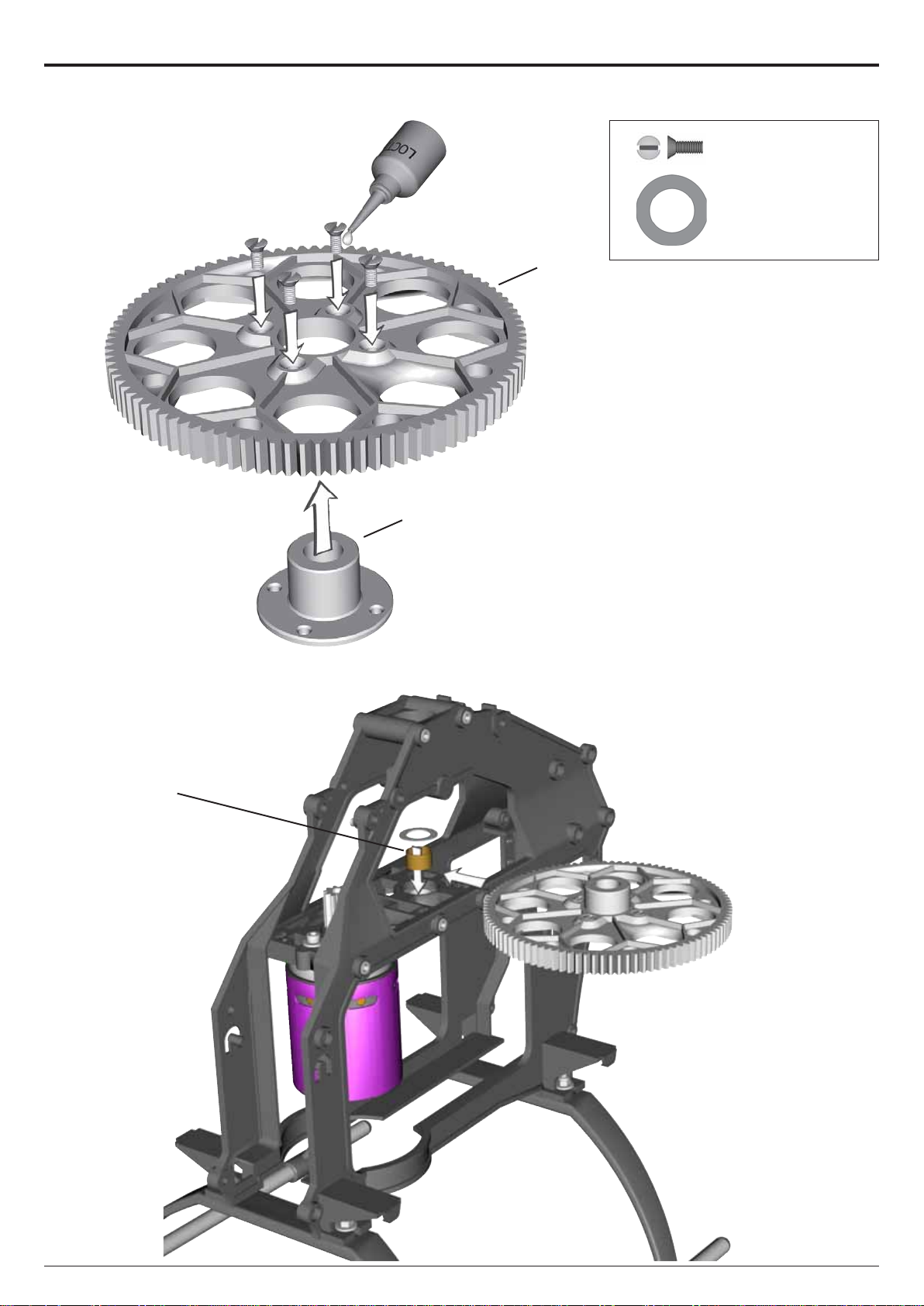

4 Main Gear

4.1 Hub

Bag 2

4x M3x8 #1915

#2410

#3000

1x

10x16x0,5 mm #2010

#2414

Manual

LOGO 20

Page 10 ©Mikado Modellhubschrauber

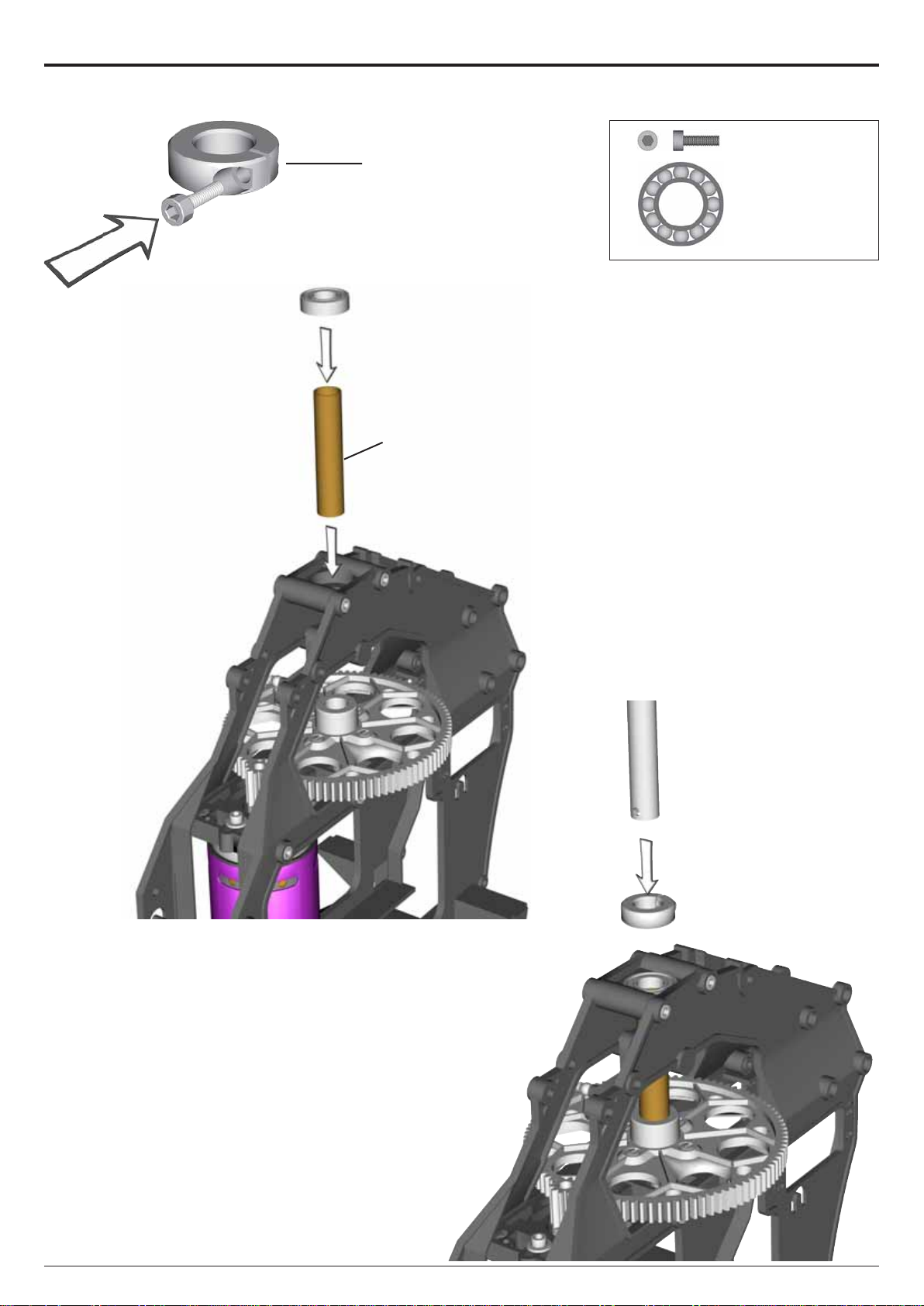

Page 11

#2385

4 Main Gear

4.2 Rotor Shaft

Bag 2 • Bag 12

1x M2,5x8 #1940

#2414

1x

10x19x5 #1329

Manual

LOGO 20

Page 11 ©Mikado Modellhubschrauber

Page 12

#2389

4 Main Gear

4.2 Rotor Shaft

Bag 2 • Bag 12

1x 3x18 #2388

Manual

LOGO 20

Page 12 ©Mikado Modellhubschrauber

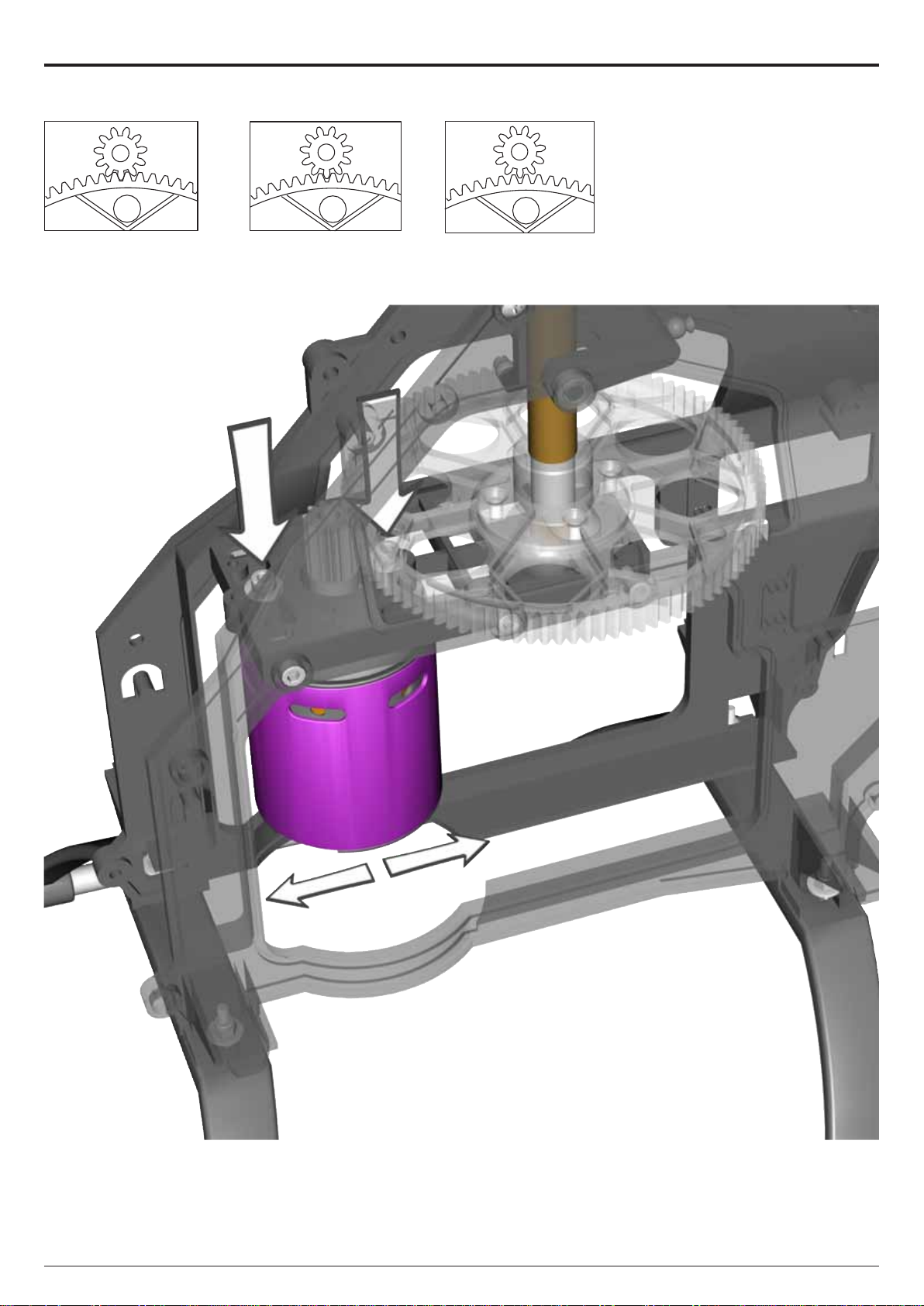

Page 13

4.3 Adjusting Gear Backlash

too little backlash correct backlash too much backlash

4 Main Gear

The gear backlash must be adjusted (see drawings). Excess backlash can cause premature wear of the

main gear and will lead to shorter flight

times.

Manual

LOGO 20

Page 13 ©Mikado Modellhubschrauber

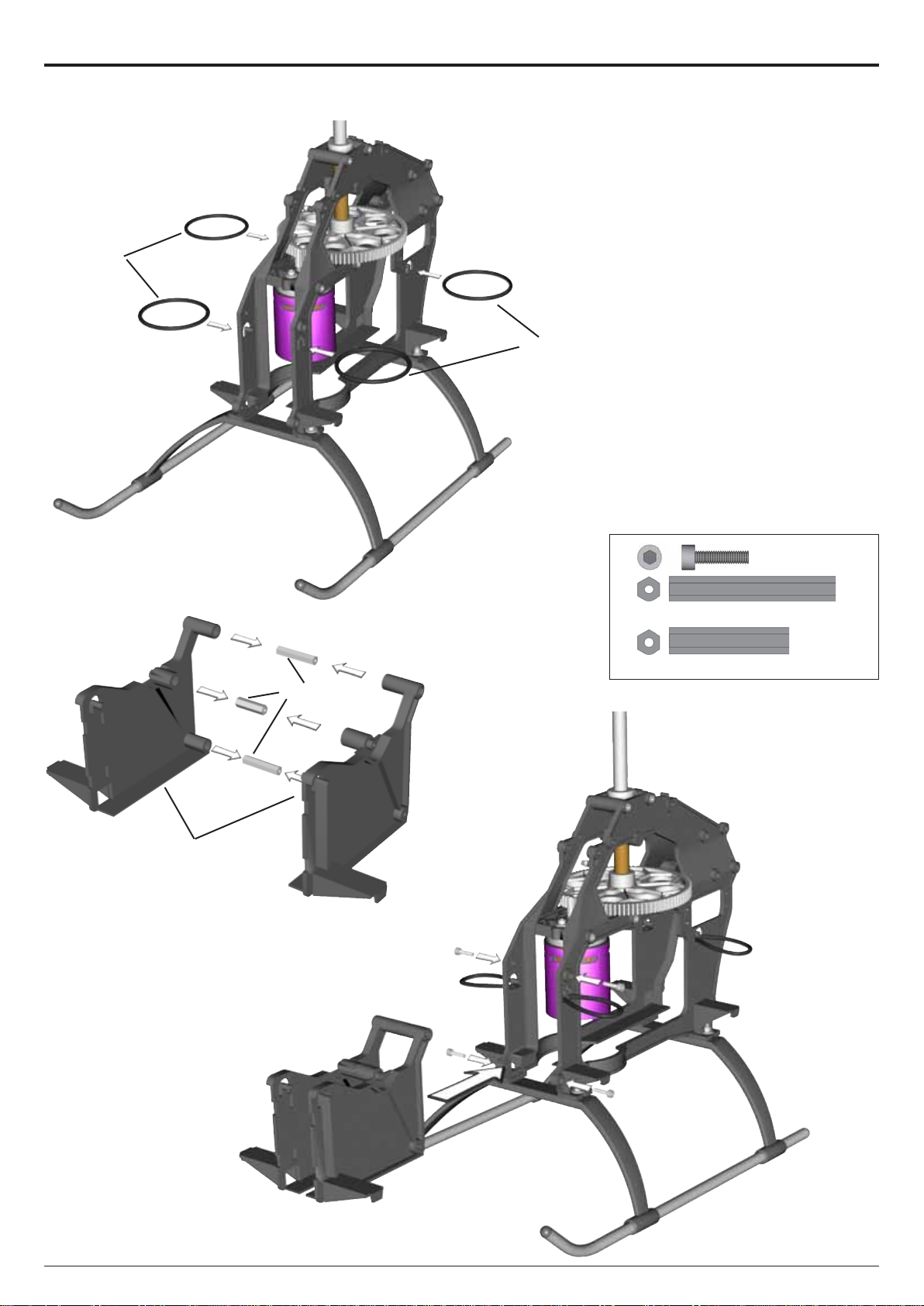

Page 14

#2425

5 RC Support

5.1 Battery Fixing Rings

Bag 4

#2425

#2420

5.2 RC Support

Bag 4 • Bag 12

4x M3x12 #1954

2x

38mm #2370

1x

27,5mm #2370

#2370

Manual

LOGO 20

Page 14 ©Mikado Modellhubschrauber

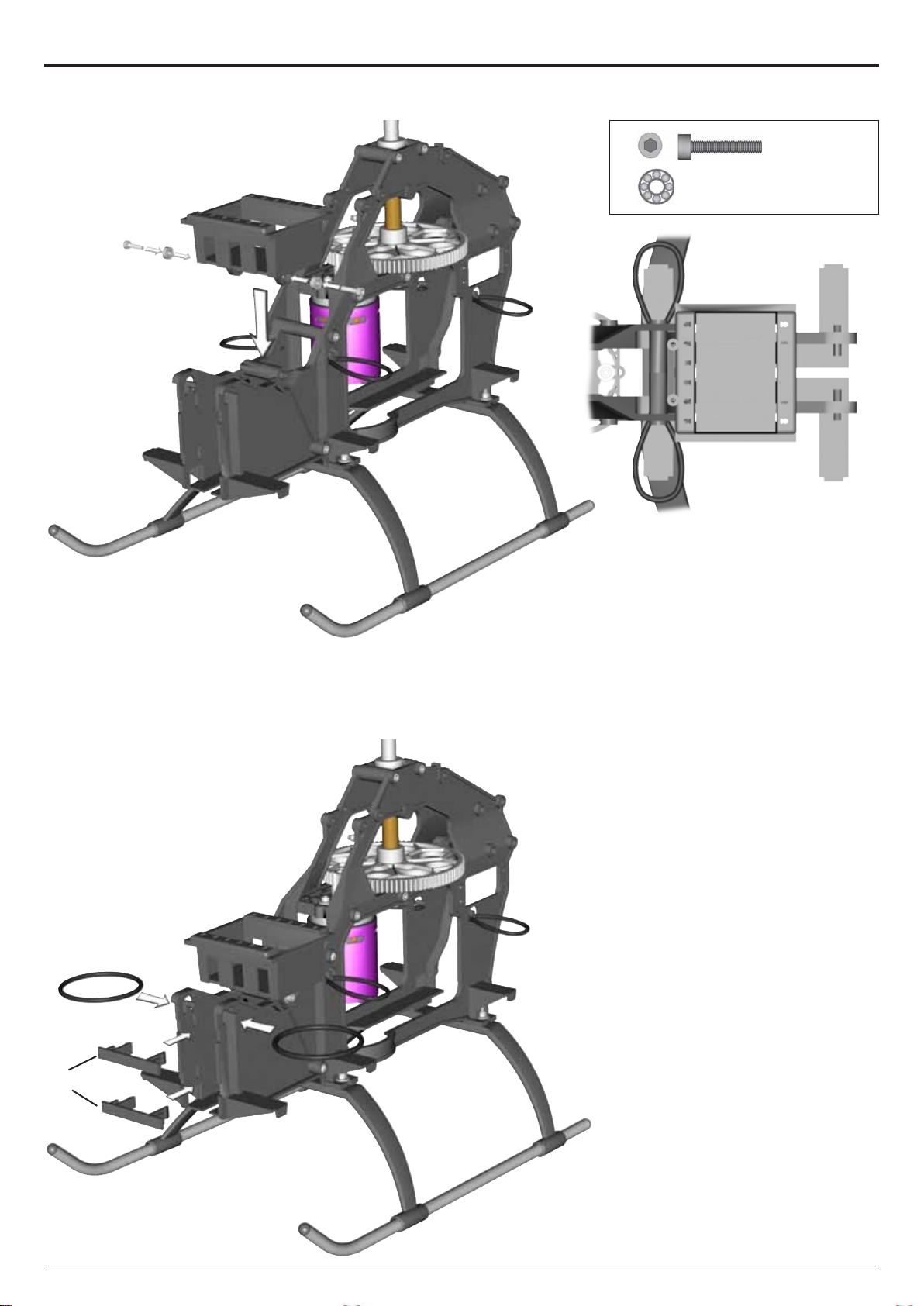

Page 15

5 RC Support

5.3 Servo Trays

Bag 4 • Bag 10 • Bag 12

2x M3x16 #1956

2x

3x8x3 #2397

#2425

5.4 Front Battery Fixing Rings

Manual

LOGO 20

Page 15 ©Mikado Modellhubschrauber

Page 16

#2424

5 RC Support

5.5 Frame

Bag 4 • Bag 12

4x 2,9x13 #2062

Manual

LOGO 20

Page 16 ©Mikado Modellhubschrauber

Page 17

#981

#979

6 Wash-Out

Assembly

Bag 3 • Bag 10 • Bag 12

2x 2x8mm #980

2x M2x8 #1902

2x

4x 3x7x3 #930

2x

Ø4,8 mm #1570

3x5x2,1 #2463

#1570

2x

2x

move easily on the wash-out.

3x5x0,5 #2002

The Y-rods #981 must be able to

#972

M3x14 #1955

Manual

LOGO 20

Page 17 ©Mikado Modellhubschrauber

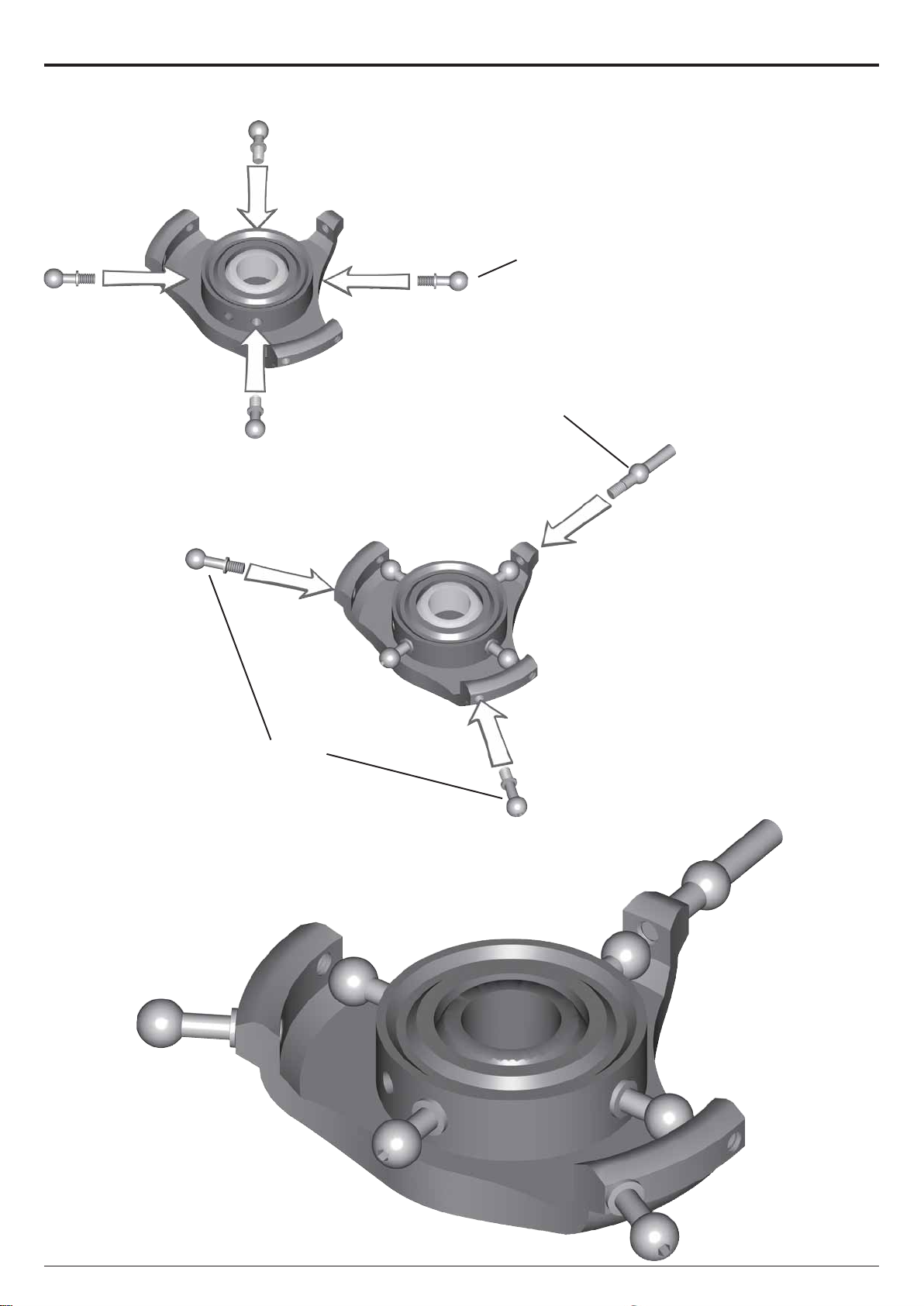

Page 18

#1004

#997

7 Swashplate

Assembly

Bag 3

Secure all pivot bolts with

threadlock.

Important: T ighten the pivot bolts

carefully . Do not overtighten them,

as they will break off.

#1005

Manual

LOGO 20

Page 18 ©Mikado Modellhubschrauber

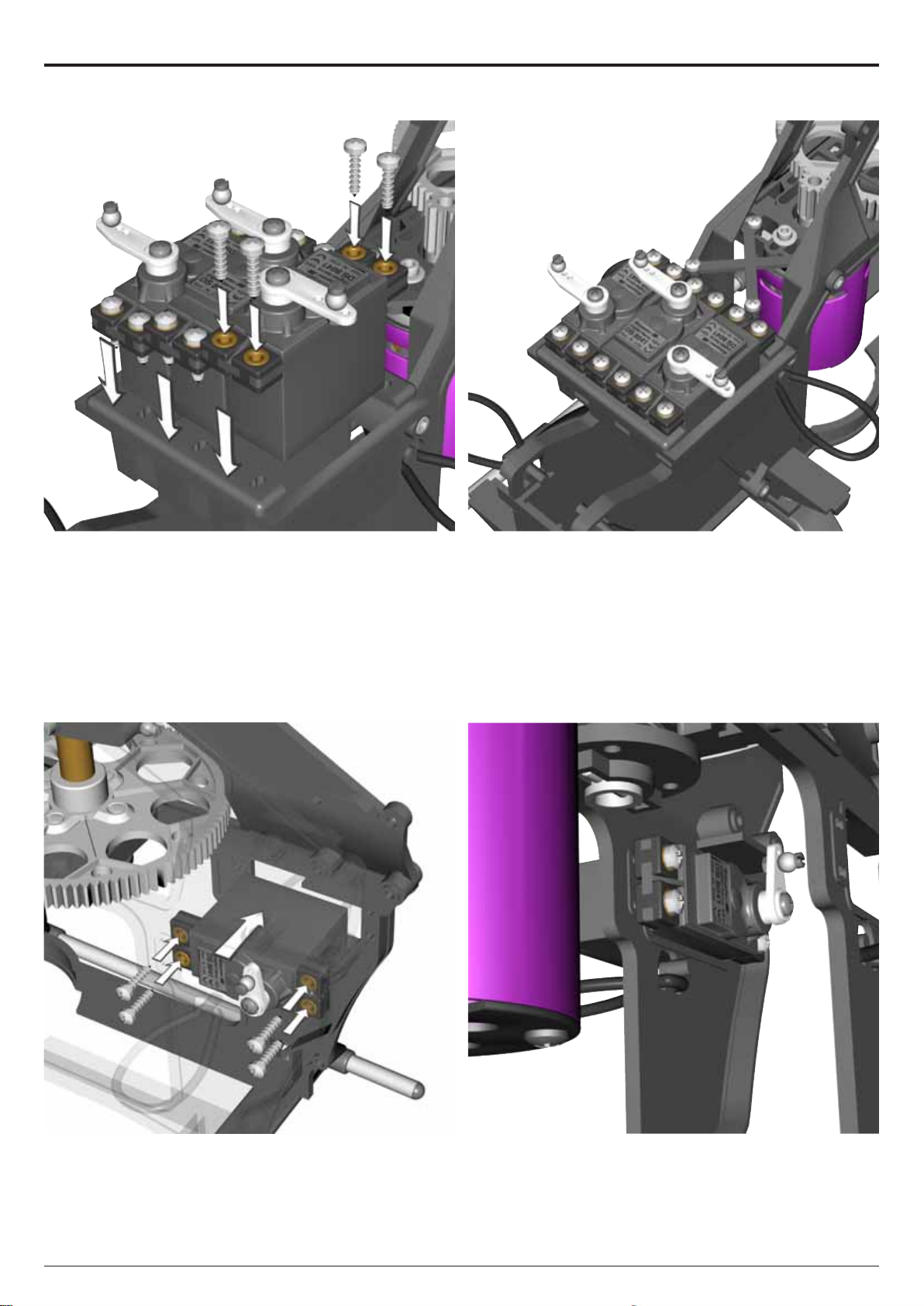

Page 19

8 Preparation for Servo Installation

4x M2 x8 #1902

4x Ø4,8 mm #1570

4x

Rudder Servo

14-15 mm

.551-.591 in

M2 #2070

Standard Pitch 3D Pitch

18 mm

.709 in

>20 mm

>.787 in

#1570

8.1 Servo Arms

Bag 1 • Bag 12

Now you must decide which pitch

range you wish to use. For different

flying styles, different pitch ranges

must be used. For normal flight with

some aerobatics, choose the standard settings and connect the push

rod at the 18 mm hole on the servo

arm. For 3D flight use 20 mm distance

instead. The ball f or the tail-rotor servo arm should be attached with a distance of 14-15 mm from the servo

arm center.

8.2 Servo Centering

Connect the servo wires to the receiver and set all channels in your

transmitter to neutral. Now attach the

servo arms perpendicular to the servos.

Manual

LOGO 20

Page 19 ©Mikado Modellhubschrauber

Page 20

8 Preparation for Servo Installation

8.3 Elevator and Aileron Servos (2x)

8.4 Tail Servo

The use of Futaba servos requires that you take

away a bit of material from the chassis.

Manual

LOGO 20

Page 20 ©Mikado Modellhubschrauber

Page 21

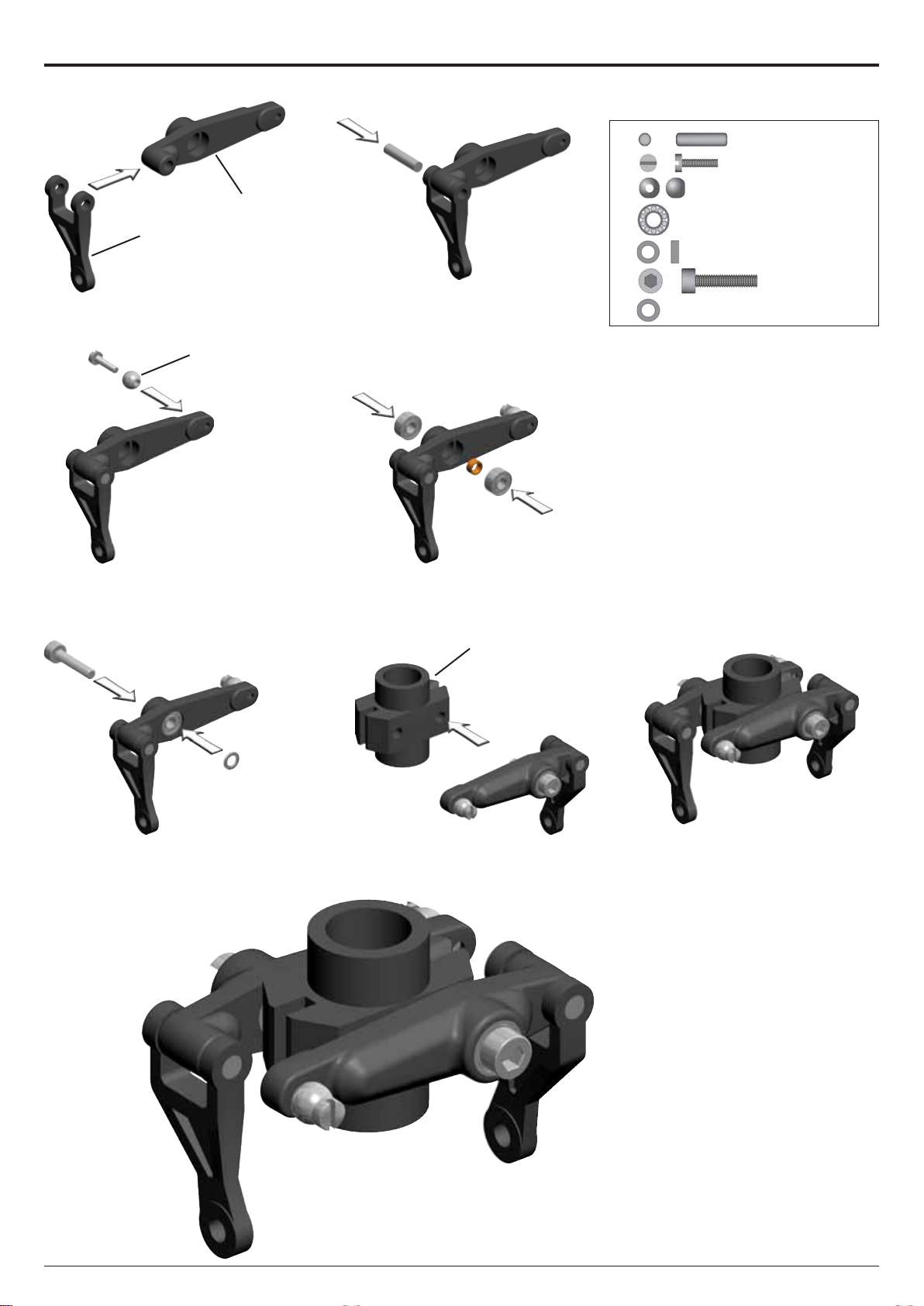

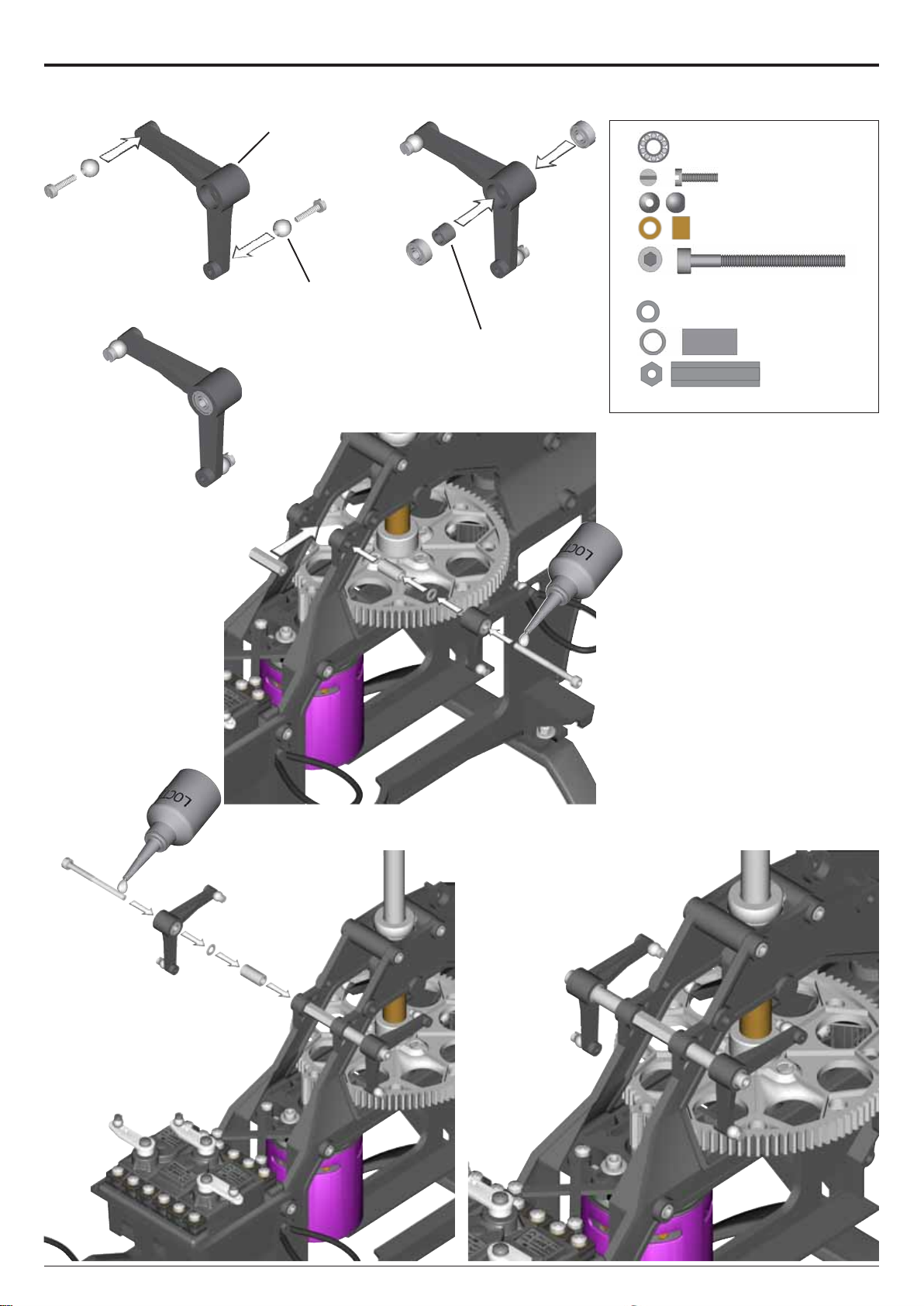

#2401

9 Aileron Lever

9 Aileron Lever

Bag 1 • Bag 10 • Bag 12

4x 3x7x3 #930

#1570

#924

4x

4x

2x

2x

2x

2x

1x

Important: The levers f or the left and

right side are different from each

other.

3x5x0,5 #2001

M2x8 #1905

Ø4,8 mm #1570

3x5x4 #924

M3x35 #1961

Ø6x12 #2413

SW5,5x20 #2390

Manual

LOGO 20

Page 21 ©Mikado Modellhubschrauber

Page 22

21 mm

#1588

10 Control Rods

10.1 Length of Control Rods

Bag 1 • Bag 12

84 mm

#1584

56 mm

2x

#1585

3x

10.2 Elevator and Aileron Linkages

Elevator

Elevator

Elevator

Aileron right

Manual

LOGO 20

Page 22 ©Mikado Modellhubschrauber

Page 23

10 Control Rods

10.1 Elevator and Aileron Linkages

Aileron left

Aileron right

Aileron right

Aileron left

Manual

LOGO 20

Aileron right

Elevator

Page 23 ©Mikado Modellhubschrauber

Page 24

11 Swashplate Guide Bracket

Bag 1 • Bag 12

#2383

#2188

#2384

12 Installation of Wash-Out Hub

The wash-out hub must be able to

move up/down easily on the rotor

shaft.

Manual

LOGO 20

Page 24 ©Mikado Modellhubschrauber

Page 25

13 Main Frame without Rotor Head

Manual

LOGO 20

Page 25 ©Mikado Modellhubschrauber

Page 26

14 Tail Rotor

14.1 Tail Rotor Shaft

Bag 5 • Bag 10

#2475

#2466

#2465

1x 2x8mm #2468

2x

2x

Should you have difficulty mounting

the 2x8 mm pin, carefully tap it with a

rubber hammer, or use a vice. The

5x10x4 bearings can likewise be

mounted on the rotor shaft using a

vice and tapping the shaft softly with

a rubber hammer. If the tail rotor shaft

shows axial play after closing the two

halves of the tail rotor case, use one

or two of the 5x10x0.1 washers

which are included in the bag.

5x10x4 #2470

5x10x0.1 #2004

Manual

LOGO 20

#2442

# 2442

#2445

Page 26 ©Mikado Modellhubschrauber

Page 27

14 Tail Rotor

14.2 Vertical Fin

Bag 5 • Bag 12

2x M3x25

#1958

#2490

1x

3x

M3x20 #1957

M3 #2074

Manual

LOGO 20

Page 27 ©Mikado Modellhubschrauber

Page 28

#2455

#2452

14 Tail Rotor

14.3 Pitch Slider

Bag 5 • Bag 10

2x 6x10x2,5 #1440

It is important that the tail pitch plate #2450 is aligned properly on the

control sleeve #2455. In the case of

misalignment, the control sleeve may

be deformed. The mounted tail pitch

plate should be able to move on the

tail rotor shaft with little resistance.

#3030

2x7mm

Manual

LOGO 20

Page 28 ©Mikado Modellhubschrauber

Page 29

14 Tail Rotor

14.4 Tail Rotor Lever

Bag 5 • Bag 10 • Bag 12

2x 3x6x2,5 #2330

#2449

1x

1x

1x

1x

1x

The mounted tail rotor lever should

be able to move with little resistance.

Ø4,8 mm #1570

3x5x5 #2448

3x5x0,5 #2002

M3x14 #1955

M2x8 #1902

Manual

LOGO 20

Page 29 ©Mikado Modellhubschrauber

Page 30

14 Tail Rotor

14.5 Tail Rotor Hub

Bag 5 • Bag 10 • Bag 12

2x M3x12 #1954

2x

3x5x2 #2463

#2458

#2462

4x

1x

3x8x3 #2423

M3x3 #1920

Manual

LOGO 20

Page 30 ©Mikado Modellhubschrauber

Page 31

#2481

#2482

15 Tail

15.1 Tail Boom Assembly

Bag 6 • Bag 11

short

long

Note:There are two different sizes

of tail rotor pushrods: Two are shorter in height than the third.

#2481

The tail boom has two round cutouts on one end. These should be fitted into the matching shapes in the

tail rotor case.

Manual

LOGO 20

Page 31 ©Mikado Modellhubschrauber

Page 32

#2485

15 Tail

15.2 Tail Boom Holder

Bag 6

Manual

LOGO 20

Tur n the tail drive belt 90 degrees

(clockwise).

Page 32 ©Mikado Modellhubschrauber

Page 33

15 Tail

15.3 Tail Drive Pulley

Bag 6 • Bag 10 • Bag 12

1x 4x13x5 #937

1x 4x9x4 #2489

#3001

#2488

2x

1x

1x

1x

4x8x1 #2013

3x5 #1921

M3x18#1965

M3 #2074

Important: Check belt tension

prior to every flight. Incorrect belt

tension can cause disturbances

for your model R/C system.

Incorrect belt tension can lead to

a situation where you lose control

of the tail rotor of your helicopter .

For tightening the belt, pull the tail

boom holder toward the front. Belt

tension is fixed with the M3x18

socket head cap screw for tightening

the tail boom holder to the tail boom.

The belt should be tight. When pressing with your fingers, both sides of

the belt should not come in contact

with each other.

!

Manual

LOGO 20

Page 33 ©Mikado Modellhubschrauber

Page 34

#1560

#2484

15 Tail

15.4 Tail Control Rods

Bag 11 • Bag 12

Screw the two 2 mm ball links onto

the control rods. Their exact positions are of no importance at this point.

The ball ends are attached to the balls

more easily when the text on them is

pointed awa y from the helicopter.

Manual

LOGO 20

Page 34 ©Mikado Modellhubschrauber

Page 35

15 Tail Boom

15.5 Tail Assembly

Bag 6 • Bag 12

4x M3x12 #1954

4x

2x

2x 19 mm #2370

M3x18 #1965

27,5 mm #2370

If you wish to use longer servo arms, it is necessary

that you take away some material from the bottom surface

of the tail boom holder.

Manual

LOGO 20

Page 35 ©Mikado Modellhubschrauber

Page 36

15 Tail

15.6 Tail Rotor Blades

Bag 5 • Bag 12

#2461

Tighten the screws holding the tail

rotor blades, but ensure that the blades move easily in the tail rotor holders under centrifugal force.

2x

2x

M3x14 #1955

M3 #2074

#2491

Manual

#2441

LOGO 20

#2471

15.7 Horizontal Fin

Bag 6 • Bag 12

2x

M3x25 #1958

2x

Avoid overtightening the M3x18

mm socket head cap screws when

drilling them into the plastic frame.

Mount the horizontal stablilizer perpendicular to the vertical fin.

Page 36 ©Mikado Modellhubschrauber

M3 #2074

Page 37

15 Tail

15.8 Tail Boom Brace

Bag 6 • Bag 11 • Bag 12

#2191#2189

2x M3x12 #1954

#1573

#2369

Manual

LOGO 20

Page 37 ©Mikado Modellhubschrauber

Page 38

16 Finished Main Frame & Tail Boom

Manual

LOGO 20

Page 38 ©Mikado Modellhubschrauber

Page 39

#915

2x

17 Main Rotor Head

17.1 Blade Grips

Bag 7 • Bag 10

2x

4x 8x16x5 #954

#3082

17.2 Mixing Arms

Bag 7 • Bag 12

2x

4x

2x

4x

4x

2x

4x

3x7x3 #930

3x5x12 #3090

Ø4,8 mm #1570

M2x8 #1902

M3x35 #1961

M3 Stopp #2074

Manual

LOGO 20

2x

Page 39 ©Mikado Modellhubschrauber

Page 40

#845

17 Main Rotor Head

11.3 Yoke

Bag 7 • Bag 10

4x 8x3 mm #950

2x

8x11 mm #952

Please tighten the M6

capscrew only gently to avoid

unnecessary widening of the

spindle shaft. (If the spindle

shaft widens, it will be difficult

to slide the ball bearings

onto the spindle shaft).

#910

small

inner Ø

2x

2x

2x

2x

11,5x16,8x0,8 mm

#841

8x16 #840

6x12 #2016

M6x12 #1981

#2016

apply grease

#841

large

inner Ø

Manual

LOGO 20

Page 40 ©Mikado Modellhubschrauber

Page 41

17 Main Rotor Head

17.4 Seesaw

Bag 7 • Bag 10 • Bag 12

#935

2x 4x13x5 #937

2x

4x

2x

4x10x4 #726

M2x8 #1902

M2x3 #1900

#939

Manual

LOGO 20

Page 41 ©Mikado Modellhubschrauber

Page 42

#935

17 Main Rotor Head

#3037

17.5 Flybar Control Bridge

Bag 7 • Bag 10

4x M2x10 #1939

4x

M2 #2070

Manual

LOGO 20

Page 42 ©Mikado Modellhubschrauber

Page 43

#965

17 Main Rotor Head

17.6 Flybar

Bag 7 • Bag 11

#856

#3098

2x M3x3 #1920

Manual

LOGO 20

Page 43 ©Mikado Modellhubschrauber

Page 44

17 Main Rotor Head

A

A=B

B

#958

0°

17.7 FlybarPaddles

Bag 7

0°

Manual

LOGO 20

A

Page 44 ©Mikado Modellhubschrauber

A=B

B

Page 45

17 Main Rotor Head

17.8 Final Assembly

Bag 7 • Bag 12

2x

M4x35 #1974

2x

2x

1x M3x18 #1965

1x

M4 #2076

2x30 mm

#912

M3 #2072

Manual

LOGO 20

Page 45 ©Mikado Modellhubschrauber

Page 46

41 mm

#1565

17 Main Rotor Head

17.9 Rotor Head Linkage

Bag 7 • Bag 12

#1569

45 mm

#1586 #1586

Next mount the length-adjusted flybar control linkages. The ball links are

attached to the balls more easily when

the text on them points away from the

helicopter.

Manual

LOGO 20

Page 46 ©Mikado Modellhubschrauber

Page 47

17 Main Rotor Head

2x M2x12 #1942

1x

1x

4,8 #1571

2x4,5x0,5 #2018

Manual

LOGO 20

Page 47 ©Mikado Modellhubschrauber

Page 48

17.10 Logo 10 assembled

Manual

LOGO 20

Page 48 ©Mikado Modellhubschrauber

Page 49

18 RC Installation

Receiver

Receiver Battery

Speed Controller

Manual

LOGO 20

Mounting of 20 cells Mounting of 24 cells

Page 49 ©Mikado Modellhubschrauber

Page 50

18 RC Installation

18.1 Gyro Support Plate

Bag 6 • Bag 12

2x

M3x35 #1961

#2441

#3044

2x

2x

M3 Stopp #2074

3x5x9mm #3043

Manual

LOGO 20

Page 50 ©Mikado Modellhubschrauber

Page 51

19 Decals

Manual

LOGO 20

Page 51 ©Mikado Modellhubschrauber

Page 52

20 How to avoid interference

Please read these guidelines carefully in order to fly safely and without electrical interference.

Flying an electric helicopter means putting several electric components to use. It is essential to avoid that these

components create disturbances for one another . The following guidelines tell you how this is achie ved.

1. Placement of cables

• The wires connecting the motor with the speed controller should be as short as possible. How ever: Do NO T cut

the motor cables (you won’t be able to re-solder the connectors properly). But DO shorten the speed controller

wires.

• Do not place any wires (servo wire, gyro wire, or antenna wire) in the neighborhood of the speed controller or

close to the wires which lead from the speed controller to the motor.

• All wires leading to the receiver should be shortened in such a way that the wires from the servos, gyro and the

on/off switch lead to the receiver f ollowing the shortest distance possible. Any e xcess wire will be a source for

electrical interference.

• The wires connecting the speed controller with the receiver should be placed at as far away from the motor and

from all other electric leads as possible. If you use a Kontronik T ango motor you must use the K ontronik ferrite

ring. This is because this motor is operated at a high frequency . If you use any other motor, the use of the f errite

ring is recommended.

• Never place any wires in the direct neighborhood of the tooth belt or the drive pulley .

2. Gyro

• Comparison of several gyros has shown that the y react differently to the fields generated by the speed controller.

Many piezo gyros, in particular the less expensive ones, are quite likely to pick up disturbances. This may result

in continuous wiggling or sudden turns of tail. At MIKADO we have found that the new Futaba gyros GY240 and

GY401 do not show these problems and that they also work excellent in all other respects.

• Gyros will be sensitive to electric fields when they are placed in the neighborhood of the speed controller, or

when the gyro cables are close to the motor or speed controller. It is therefore recommended that y ou place the

gyro on top of the tail boom holder. You may order a special gyro mounting plate from MIKADO (part no. 2486).

The GY401, and GY240, due to their smaller size, may also be placed within the RC-frame below the servos.

• As with all cables, place gyro cables away from motor and speed controller .

• Note that if your helicopter appears shaky this is not necessarily due to disturbances. Another source could be

that tail pitch slider can’t move freely . Check regularly (ev ery 10 flights).

3. Antenna (very important!)

• The receiver must be placed in the front of the chassis. The antenna leads through the canopy in a line leading

forward (drill small hole through canopy). Get a wire tube and attach it to the landing-bow on one side. Lead the

antenna back through the tube. The front part of the tube will stick out in front of the landing bow at least 10

inches. Of the antenna, when it comes out of the tube, only 2 to 3 inches will stick out. In other words, if any part

of the antenna is hanging lose, it hangs in front of the nose.

• It is best to attach the atenna tube at the lower antenna holders on the landing bow. Such placement of the

antenna will increase the distance between the antenna and other electrical components such as motor, controller

and batteries. In this wa y , reliable perf ormance of the helicopter in all flight positions is ensured.

4. Receiver

• Use up-to-date and first-rate dual conversion receivers. Here at MIKADO we use the Graupner JR receiver

type DS19 (FM/PPM) or SMC19 DS or SMC20 DS (both SPCM).

• On choice of PCM or PPM: In general, we suggest to use PCM receivers. They ha ve optimal range and they

allow for flight without disturbances when all of the abov e guidelines have been f ollowed. If you are uncertain

whether your heli is disturbance-free, it is recommended that you fly PPM first. This allows y ou to diagnose any

potential disturbances.

5. Battery packs

General rule: The more voltage, the more potential for disturbances. Thus, the more cells you fly , the more prev entive

care should be taken against disturbances. Y ou should use inline battery packs (soldered or connected), because

they have both cables in the back (which avoids excess wiring in the front of the helicopter).

Manual

LOGO 20

Page 52 ©Mikado Modellhubschrauber

Page 53

21 RC Programming

120° Swashplate Mixing (120° CCPM)

The LOGO 10 swashplate is designed to be controlled via electronic CCPM. Thus the corect control

inputs of the three swashplate servos are automatically mixed by the R/C transmitter. If you have never

programmed 120° CCPM before, please read this introductory text carefully.

Collective (Pitch)

Pitch function is used to control the lift or sink of the helicopter. When pitch input is given, all three s washplate servos travel together in the same direction and the same amount. As a result the swash-plate

moves up or down on an even level.

We strongly recommend to use a pitch gauge for adjusting the pitch values. If you do not wish to use the

full pitch range (-12° to +12°), you may set the pitch values for minimum and maximum pitch separately

in the R/C transmitter. If you are new to the hobby, we recommend to set minimum pitch at 3°.

Minimum Pitch

Manual

LOGO 20

Page 53 ©Mikado Modellhubschrauber

Page 54

Neutral Pitch (0°)

21 RC Programming

Maximum Pitch

Manual

LOGO 20

Page 54 ©Mikado Modellhubschrauber

Page 55

21 RC Programming

Programming 120° CCPM Programming 120° CCPM

As the programming procedure varies with different types of R/C systems, it is necessary for you to

refer to the instruction manual of your R/C system. Here are only a few general guidelines which apply

to most systems.

Servo Centering with Sub-Trim Function

As indicated in the above sections on mounting the servos, it is important that the servo arms are

exactly centered. You should use the servo sub-trim function of your R/C system for this purpose.

Activating 120° CCPM

Likely, the 120° CCPM function is initially disabled in your R/C transmitter software and needs to be

separately activated. Please refer to your R/C system manual, where you will also find information on

which channels should be used for the elevator servo and the two roll servos. It is important that you

stick with the requirements stated in the manual. Otherwise the 120° CCPM will not function properly.

Your R/C may support various different CCPM mixings. For Logo 20 choose the 120° mixing with two

roll servos in the front and one elevator servo in the back.

Use the relevant menus for setting the mixing proportions for roll, elevator and pitch functions. Begin

by setting the mix values to 50% each. Higher mix values give higher servo travel for that function

This can have the unwanted result that the swashplate reaches its limits and causes damage to the

servos or rods or to the swash-plate itself.

If necessary , you may use the CCPM menu to reverse the direction of the function. This is necessary,

for example, if the swash-plate tilts to the wrong side or the pitch function is inverted. The menu for

reversing servo functions can be used for reversing the movements of individual servo arms, but not

for reversing the entire control function and of all the involved servos.

Aileron and Elevator Travel

The travel range of the aileron and elevator servos are limited by the swashplate’s mechanical limits.

Please take care that the sw ashplate does not hit the maximum of its trav el. This can have the unwanted

result that the swashplte reachies its mechanical limits and causes damage to the servos or rods or to

the swashplate itself. e Gestänge und die Taumelscheibe.

If you desire more agility for your helicopter, use lighter flybar paddles.

Manual

LOGO 20

Page 55 ©Mikado Modellhubschrauber

Page 56

21 RC Programming

Aileron (Roll)

Aileron (roll) is used to control the helicopter’s movements around its longitudinal axis. When aileron

(roll) input is given, the two roll servos (in the front of the swashplate) travel in opposite directions. As a

result the swash-plate tilts to the right or to the left.

Manual

LOGO 20

Page 56 ©Mikado Modellhubschrauber

Page 57

21 RC Programming

Elevator (Tilt)

For tilting the helicopter , use the ele v ator function. F or tilting f orward, the two aileron servos mov e do wnward and the backward elevator servo moves upward. The elevator servo moves twice as much as the

two aileron servos.

Manual

LOGO 20

Page 57 ©Mikado Modellhubschrauber

Page 58

21RC Programming

Aileron and Elevator Travel

The travel range of the aileron and elevator servos are limited by the swash-plate’s mechanical limits.

Please take care that the sw ash-plate does not hit the maximum of its travel. This can ha ve the unwanted

result that the swashplate reaches its mechanical limits and causes damage to the servos or rods to the

swash-plate itself. If you desire more agility for your helicopter, use lighter flybar paddles.

Tail rotor settings

When the servo arm of the tail rotor servo is in the center , the tail rotor lev er and the servo arm should be

perpendicular with respect to each other. The tail rotor pitch lever should never reach its mechanical

limits.

In case the servo travel is too large, you have the following options for correcting this:

1. Move the ball end of the tail rotor servo closer to the center of the servo arm.

2. Reduce the servo travel in your R/C system using ATV.

3. Reduce the servo travel in your gyro (not all gyros have this option).

In case the servo travel is too small, you have the following options for correcting this:

1. Mov e the ball end of the tail rotor servo further awa y from the center of the servo arm.

2. Increase the servo travel in your R/C system using ATV.

3. Increase the servo travel in your gyro (not all gyros have this option).

Ensure that the tail rotor servo turns in the correct direction. If necessary , re v erse the direction of the tail

rotor servo function in your R/C system.

Adjust the tail rotor linkage in

length such that the tail rotor servo

arm and the tail rotor lever are at

90 with respect to each other.

All parts serving the tail rotor

movements must move smoothly.

When there is too much resistance, the tail rotor will not react

to subtle input and the gyro’s

maximum sensitivity cannot be

fully exploited.

Revo-Mix/Gyro

It is necessary to compensate for the torque created by the motor during flight (but not during autorotation).

This compensation is done by adjusting the tail rotor pitch. There are two options for achieving this:

1. Using normal gyro mode

Please refer to your R/C system manual for activating the revolution mixing function and for setting all

parameters correctly. Final settings should be trimmed during test flights.

Manual

LOGO 20

Page 58 ©Mikado Modellhubschrauber

Page 59

RC Programming

2. Using a gyro in Heading-Hold mode

The Heading-Hold gyro mode compensates automatically the deviation caused by the motor torque.

Therefore, if Heading-Hold mode is used, revo-mix should not be programmed additionally.

Important: Check to ensure that the tail rotor assembly mov es smoothly and without play. Otherwise the

gyro and servo will not compensate the torque properly .

Rotor Head RPM control

LOGO 20 is designed to be flown with constant rotor head speed. Irrespective of flight attitude (ascending,

descending, hovering), rotor speed should be kept roughly constant. There are two different methods for

obtaining constant rotor speed:

Rotor speed control with speed controller

All speed controllers can be used in this mode. With speed controller it is necessary to program a throttle

curve (see manual). Programming of throttle curve requires that you associate a given throttle value with

a particular pitch value. In this way, the rotor speed is held almost constant with all pitch values.

Throttle curve programming depends on the type and quality of the R/C system. Simpler , ine xpensiv e R/

C systems designed for model helicopters usually have a 3-point throttle curve. High-end R/C systems

typically have throttle curves with more configurable points (up to 9). Fine tuning of throttle curves will be

necessary during test flights.

Note that an incorrectly programmed throttle curve reduces performance and can lead to overheating of

the motor and the speed controller.

Rotor speed control with governor (RPM regulation mode)

A speed controller with governor function keeps the rotor head speed constant, independent of flight

attitude (ascending, descending, hovering). It is not necessary to program a throttle curve. The head

speed is simply controlled on the radio transmitter using a switch or lever.

Important:

1) Governor mode must be activated in the speed controller first (see manual of the speed controller)

2) In governor mode, the servo wire of the speed controller must not be connected to the throttle channel.

Use a free channel in your radio to connect the servo wire.

Manual

LOGO 20

Page 59 ©Mikado Modellhubschrauber

Page 60

22 Rotor Blades

22.1 Balancing of Rotor Blades

(Center of Gravity)

Place each rotor blade over an

edge as shown in picture (1). Adjust

the blades so that they are in equilibrium. If the center of gravity is not in

the same place in each blade, this

needs to be corrected using tape.

Apply as much tape as necessary

until both blades show their center of

gravity in the same place.

23.2 Static balancing

Screw the rotor blades together as

shown in picture (2). The rotor blades are properly balanced when they

are suspended exactly horizontally.

If one of the rotorblades is not exactly horizontal, the blades are not in

equilibrium.

This is corrected by applying tape

to lighter blade.

When mounting the rotor blades to

the blade holders, note the proper direction (clockwise rotation). Tighten

the cap screws holding the rotor blades, so that the blades cannot move

easily in the blade holders.

Manual

LOGO 20

Page 60 ©Mikado Modellhubschrauber

Page 61

23 Final Pre-Flight Check

23.1 Direction of Main and Tail Rotation

Prior to the first flight double-check

the direction of rotation of the main

rotor head and the tail rotor. For this ,

turn the main gear clock-wise.

23.2 Blade Tracking Adjustment

OKFalse

Prior to the first flight the tracking

of the rotor blades needs to be adjusted. If the tracking is not adjusted

properly, this can cause vibrations

and lead to instability of the helicopter.

Apply colored tape to the tip of one

of the rotor blades. Apply tape of a

different color to the tip of the other

rotor blade. When you are ready for

your first flight, increase the rotor

speed to just before lift-off. From a

safe distance, check the rotor disk

at eye-lev el. V e ry likely , one rotor blade will move below the other.

Make a note of the color of the lowmoving blade. Then turn off the motor and wait until the rotor head has

come to a halt. Lengthen the linkage

(1) of the rotor blade which was moving low by unscrewing the ball links

somewhat. Repeat the checking procedure until both rotor blades move

on the same level.

Manual

LOGO 20

Page 61 ©Mikado Modellhubschrauber

Page 62

2 4 Control Movements

24.1 Pitch/Throttle

You may want to program a different stick mode than the one shown.

Please check which stick mode is

used by other local pilots. Use the

same one, so fellow pilots can assist

you on the field.

Important: Flying a model helicopter requires many hours of training.

During your first attempts, while familiarizing yourself with the different

control movements, keep the helicopter low above the ground (just a

few centimeters/a couple of inches.)

24.2 Rudder

Manual

LOGO 20

Page 62 ©Mikado Modellhubschrauber

Page 63

24 Control Movements

24.3 Elevator

Manual

LOGO 20

24.4 Aileron

Page 63 ©Mikado Modellhubschrauber

Page 64

25 Overview

25.1 Chassis

Manual

LOGO 20

Page 64 ©Mikado Modellhubschrauber

Page 65

25 Overview

25.2 Rotor Head

25.3 Tail Boom/Tail Rotor

Manual

LOGO 20

Page 65 ©Mikado Modellhubschrauber

Page 66

26 Tuning/Accessories

carbon main frame up-grade set

#850

Alu washout unit #973 Carbon tail rotor upgrade

canopy LOGO 24 #852 (must be

used with LOGO 24 main frame #850)

set #3062

carbon servo

holder for tailboom #828

Alu motorplate #3061

light paddles #2357Rotor disk #932 carbon tail boom #832

hollow spindle shaft #846 Carbon rotor blades 600 mm #1050 semi-symmetrical glass-fibre rotor

blades 600mm #1048

Manual

LOGO 20

Page 66 ©Mikado Modellhubschrauber

Page 67

26 Tuning/Accessories

Carbon horizontal fin #2494

carbon elevator lever #2396

carbon vertical fin #2493

alu hex bolts #2372

carbon base plate #2378

Tail boom for 600 mm

rotor blades #2479

Manual

LOGO 20

Page 67 ©Mikado Modellhubschrauber

Page 68

www.Mikado-Heli.de

Construction & Rendering: Mehran Mahinpour Tirooni • Layout & Realisation: CDT-Berlin

Loading...

Loading...