MII 52250-2, 52228-B Datasheet

Micropac Industries cannot assume any responsibility for any circuits shown or represent that they are free from patent infringement.

Micropac reserves the right to make changes at any time in order to improve design and to supply the best product possible.

MICROPAC INDUSTRIES, INC. HYBRID MICROELECTRONICS PRODUCTS DIVISION • 905 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 494-2281

www.micropac.com E-MAIL: hybridsales@micropac.com

12/13/01

1

True Hermetically Sealed

Proportionally Controlled Heater Hybrids

Mii

HYBRID MICROELECTRONICS

PRODUCTS DIVISION

Features:

• Self-contained

• Programmable via a single external resistor

• Available from 40 to 50 watts

Applications:

• Microwave Oscillators

• Telecommunications

• Other areas where temperature control is needed

DESCRIPTION

A self-contained hybrid circuit heater that is programmable via a single external resistor. These systems are ideal for

microwave oscillators, telecommunications and other areas where temperature control is needed. Heaters are available

from 40 to 50 watts.

Typical Electrical Characteristics for DC Heater (28V DC Input, 28 Watts (51974))

Operating Voltage Range (See Note 13) …………………………………………………………………………………… 28 ±1 VC

Voltage Limits ……………………………………………………………………………………………… 24 VDC Min, 32 VDC Max

Reverse Voltage Protection …………………………………………………………………………………………….………. To 50 V

Operating Current Range ……………………………………………………………………………….…………....…. .015 to 1.00 A

Turn on Current …………………………………………………………………………………………………..…………… To 1.00 A

Quiescent Current ………………………………………………………………………………………..…………… Less than .019 A

Typical Electrical Characteristics for AC Heaters (115 VAC Input, 28 Watts (52034))

Operating Voltage Range …………………………………………………………………….………. 100 to 125 VAC, 50 to 400 Hz

Voltage Limits ……………………………………………………………………………………………………...……… 0 to 150 VAC

Operating Current, Steady State ……………………………………………………………………………………..… .001 to .280 A

Turn-on Current Range (at 115 VAC) ………………………………………………………………………………………. To .280 A

Quiescent Current ……………………………………………………………………………………………………… Less than 1 mA

Temperature Characteristics

Control Range (See Note 1, 2 & 3) …………………………………………………………………………………. +50°C to +100°C

Variation with Load (See Note 4) ………………………………………………………………………………………...….. 10°C Max

Variation over Operating Range (See Note 5) …………………………………………………………………………………… ±2°C

Maximum Control Temperature (See Note 6) ………………………………………………………………………………… +120°C

Environmental Characteristics

Operating Temperature …………………………………………………………………………………………….… -55°C to +100°C

Altitude ………………………………………………………………………………………………………………...….. 70,000 ft. Max

Shock ……………………………………………………………………………………………………………………….…. 20 G Max

Vibration …………………………………………………………………………………………………………. 50 G at 2,000 Hz Max

Humidity ……………………………………………………………………………………………………………..... Greater than 95%

Micropac Industries cannot assume any responsibility for any circuits shown or represent that they are free from patent infringement.

Micropac reserves the right to make changes at any time in order to improve design and to supply the best product possible.

MICROPAC INDUSTRIES, INC. HYBRID MICROELECTRONICS PRODUCTS DIVISION • 905 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 494-2281

www.micropac.com E-MAIL: hybridsales@micropac.com

12/13/01

2

True Hermetically Sealed

Proportionally Controlled Heater Hybrids

Reliability

Each hybrid circuit is subjected to the following reliability screening per MIL-PRF-38534

• Precap internal visual Method 2017, Condition B

• Temperature cycling, Method 1010, Condition B

• Constant acceleration, Method 2001, Condition B, Y axis only

• Optional Burn-in per Mii specifications

• Fine and Gross leak test, Method 1014, Conditions A & C

• External visual, Method 2009

Notes

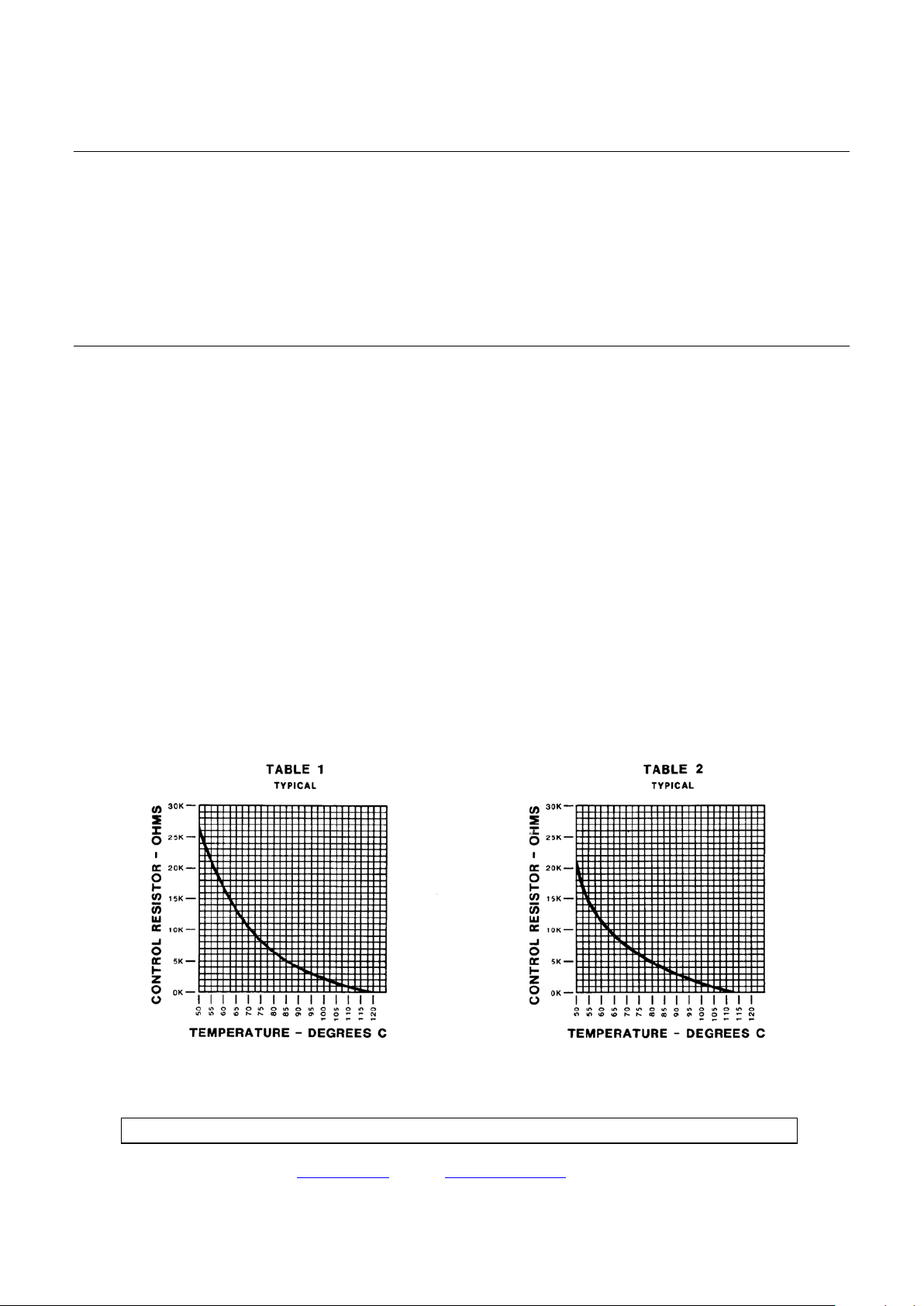

1. DC Heaters (Small Substrate) Use Table 1 for control resistor, and Figure 1 for dimensions.

2. DC Heaters (Large Substrate) Use Table 2 for control resistor, and Figure 3 for dimensions.

3. AC Heaters (Large Substrate) Use Table 2 for control resistor, and Figure 3 for dimensions.

4. Maximum temperature variation for current change from 5% over quiescent to 95% of turn-on current.

5. Maximum temperature variation over operating voltage range when ambient temperature is constant and the supply

current is between 5% over quiescent and 95% of turn-on current.

6. Maximum temperature with any value of control resistor, including 0 ohms.

7. All True hermetically sealed (solder welded) heater modules are leak tested to meet MIL-PRF-38534, Method 1014,

Test Conditions A & C, with a maximum lead rate of 1 X 10

-7

atm-cc/sec, and all hermetically sealed (epoxy) heaters

have a maximum leak rate of 1 X 10

-6

atm-cc/sec.

8. Optimum heat transfer is obtained by using a thermal joint compound such as Dow Corning 340 on the mounting

surface.

9. Operation is possible over +100°C, but electrical performance is not guaranteed. Input current decays to 20mA max

at +120°C without damage to the heater module.

10. All Mii DC heaters are protected against reverse voltage up to 50 V.

11. The standard ceramic heater design has pins for interconnect. The standard Micropac part number with or without

the A suffix will have pins & Micropac can supply the heater without pins and with pad metalization designed for wire

bonding. The version without pins will have a B suffix to the standard Micropac part number.

12. Maximum power rating for control resistor is 1/8 watts. Precise resistor values should be determined by measuring

the surface temperature.

13. The heater is operational from 24 to 32 VDC, however for optimum performance 28 VDC is recommended.

Loading...

Loading...