Page 1

Working Instructions

for MIHM-VOGT Laboratory Furnaces

with Controller M1

Version 1.0 01/2013

Page 2

- 2 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Page 3

- 3 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Working instructions

for

MIHM-VOGT laboratory furnace

with controller M1

Table of contents:

1. Delivery form 4

2. Use area 4

3. Technical data 5

4. Safety warning 5

5. Installation and electrical connection 6

6. Operation 6

6.1 Start-up 6

6.2 Loading 6

6.3 Operation of the electronics 6

6.3.1 Basic keys 7

6.3.2 Display functions 7

6.3.3 Setting temperature and holding time / delay 7

6.3.4 Starting a program with the casting time / finishing time feature 9

7. Special functions 9

7.1 Display at the beginning when switching on 9

7.2 Setting the actual time 9

7.3 Programming of exhaust blowers, catalyzers and/or fume extraction hoods 10

7.4 Industrial function 11

7.5 Service function 11

7.6 Controller initialization 12

7.7 How to connect exhaust blowers, catalyzers and/or fume extraction hoods 12

8. Error signals 13

8.1 Error messages of the electronics 13

8.2 Miscellaneous errors and their causes 14

9. Maintenance and care 14

9.1 Care 14

9.2 Maintenance 15

9.2.1 How to change the thermocouple 15

9.2.2 How to change the heating chamber 15

9.2.3 How to change the door stone 16

9.2.4 How to replace the controller 16

9.2.5 How to replace the power element of the 2nd heating circuit

(only for furnace types: BL, TL) 16

9.2.6 How to change the air circulation fan 16

9.3 Warranty 17

9.4 Circuit diagrams 18

Index 19

Page 4

- 4 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Dear customer,

We thank you for your decision to buy a high-quality MIHM-VOGT furnace. It will support you

with your work for many years, as it was developed and built using the latest technology.

Nevertheless, improper use and handling can cause damage, therefore we ask you to

carefully read through these working instructions and to follow it.

The CE-sign confirms that MIHM-VOGT laboratory furnaces correspond to the

governing regulations of the EC guidelines.

1. Delivery form

Each laboratory furnace is delivered with a M1 microprocessor controller, a refractory

ceramic tray, a PtRh-Pt thermocouple, and an escape pipe.

Instead of the escape pipe, the furnace can also be equipped with the following

accessories:

Exhaust fan DG2 (Art. N° 7202)

Catalyzer KN1 (Art. N° 7300)

Catalyzer for shock-heat investments KN2 (Art. N° 7320)

Spare parts

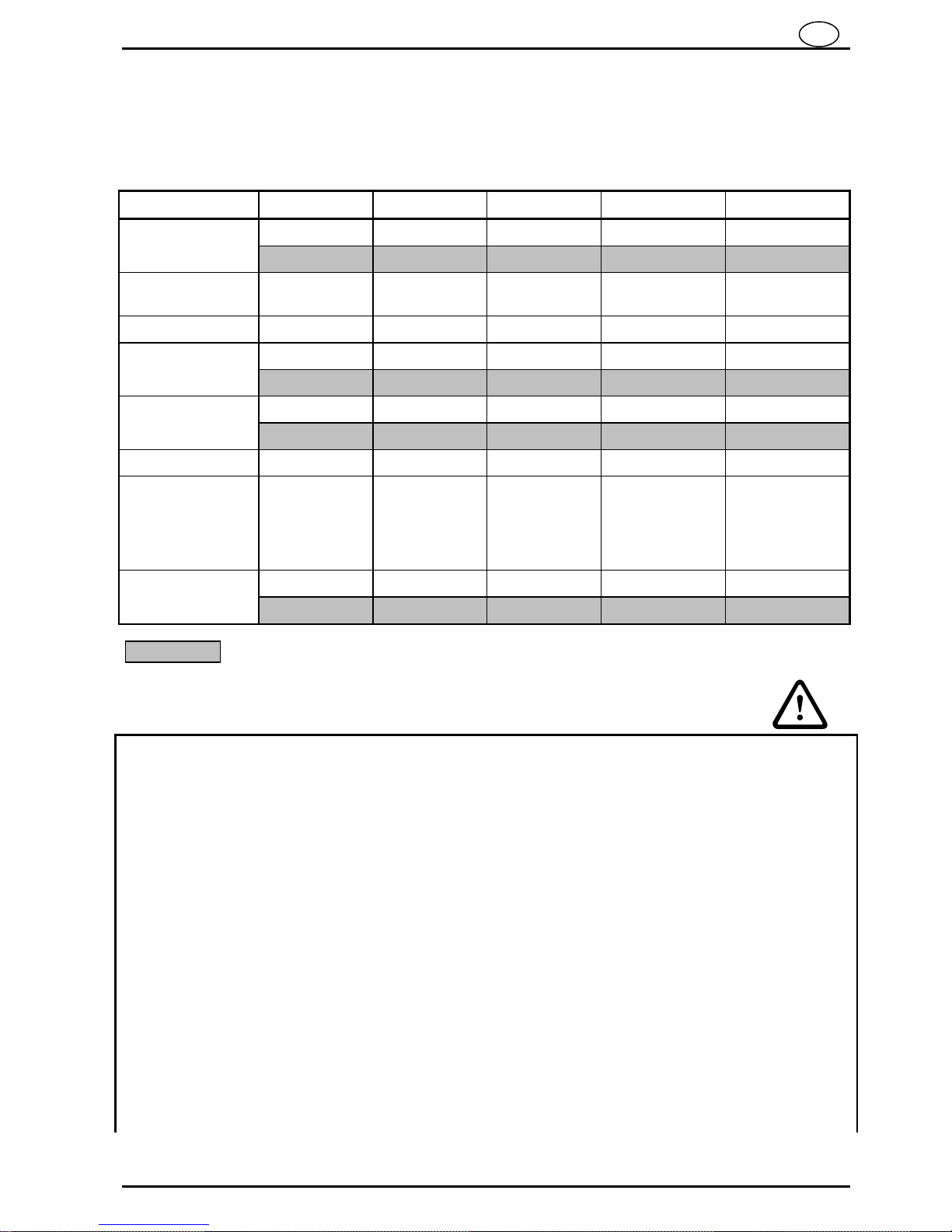

Item n°:

Furnace type:

KM

SL

GL

BL

TL

Ceramic tray

20020

30020

40020

50020

50020

Thermocouple

20100

30110

40110

50110

60110

Door filling

20351

30301

30301

30301

30301

Heating muffle (without ventil.)

20010

30010

40010

50010

60010

Heating muffle (with ventilator)

20015

30015

40015

50015

60015

2. Use area

The laboratory furnace is used for the elimination of wax and for preheating of dental

casting rings. The heating muffle is made of a high-quality ceramic and is heated evenly

on four sides. The low electric load guarantees a high lifespan of the heating wire. A

high-quality internal insulation ensures a long lifetime.

At the rear of the furnace, two sockets are provided for the connection of an exhaust fan

or a catalyzer and a ventilating air hood.

The furnace door is equipped with a safety switch, which interrupts the heating current

when opening the door. The M1 controller includes a thermocouple circuit breaker so

Page 5

- 5 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

that the furnace does not overheat if the thermocouple is defective. The type of the

furnace is listed on an identification plate at the rear of the furnace.

3. Technical data

Furnace type:

KM

SL

GL

BL

TL

Outside dimensions

40 x 48 x 40

43 x 58 x 45

48 x 58 x 52

54 x 60 x 55

54 x 65 x 55

w x h x d (cm)

40 x 48 x 45

43 x 58 x 51

48 x 58 x 59

54 x 60 x 62

54 x 65 x 62

Heating chamber:

w x h x d (cm)

15 x 10 x 17

18 x 11 x 19

20 x 11 x 25

25 x 11 x 28

25 x 17 x 28

Capacity:

4 pcs. 6x

4 pcs. Ø 8 cm

6 pcs. Ø 8 cm

9 pcs. Ø 8 cm

18 pcs. Ø 8 cm

Max. temperature

1150 °C

1150 °C

1150 °C

1150 °C

1150 °C

1100 °C

1100 °C

1100 °C

1100 °C

1100 °C

Power rating:

1.6 kilowatts

1.8 kilowatts

2.3 kilowatts

3.5 kilowatts

4.5 kilowatts

1.6 kilowatts

2.1 kilowatts

2.6 kilowatts

3.7 kilowatts

4.8 kilowatts

Tension:

230 V~

230 V~

230 V~

230/400 V~ (2/N)

230/400 V~ (2/N)

Preheating times:

60 min.

900 °C

90 min.s

1050 °C

60 min.

800 °C

90 min.

1100 °C

60 min.

800 °C

90 min.

1100 °C

60 min.

800 °C

90 min.

1100 °C

60 min.

800 °C

90 min.

1100 °C

Weight:

32 kg

63 kg

75 kg

90 kg

100 kg

36 kg

70 kg

80 kg

95 kg

105 kg

furnaces with circulating air (not recommended for speed investments)

4. Safety warning

The MIHM-VOGT laboratory furnace is exclusively made for the elimination of wax and

for the preheating of casting rings. We are not liable for damages due to another use.

The sockets on the rear are to be used exclusively for MIHM-VOGT ventilating air hood,

a MIHM-VOGT exhaust fan or a MIHM-VOGT catalyzer.

The MIHM-VOGT laboratory furnace must be operated exclusively by technicians, who

know the content of this manual. Labels and stickers on the laboratory furnace must

always be maintained in legible condition. They must not be removed.

The MIHM-VOGT laboratory furnace should be set up only in dry areas and should not

be in contact with liquids. In the area of the furnace, furniture and other objects cannot

consist of explosive, combustible or easily inflammable materials. In the installation area

of the furnace, no easily inflammable or combustible gases or liquids are allowed to be

stored.

Modifications of the MIHM-VOGT laboratory furnace can only be made after prior

written agreement from us. We are not liable for damages caused by your

Page 6

- 6 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

modifications. Before every maintenance, the appliance is to be turned off and the

power-supply plug is to be pulled out.

The furnaces type KM, SL, GL must always be connected to a plug protected by a 16

Amp fuse. The furnaces type BL and TL are to be connected to a CEKON plug (230 /

400 V, AC).

The hot furnace door should only be touched at the grip, the hot muffles should only be

grabbed with sufficiently long tongs. Because of the wax fumes and the steam from the

investments, the furnace should be equipped with an exhaust fan or catalyzer and

placed under a ventilating air hood. The fumes are to be extracted outside.

The ceramic tray should always be used to protect the heating muffle.

The transportation protection from the heating muffle must be taken off before the first

use.

5. Installation and electrical connection

The laboratory furnace is to be positioned in a dry area in accordance with the safety

warnings and is to be connected to a separate circuit secured with 16 Amp. The

transportation protection must be removed from the heating muffle. The laboratory

furnaces type KM, SL and GL are to be connected to an earthed plug 230 V. The

laboratory furnaces type BL and TL are to be connected to a CEKON plug 230/400 V

AC. If required, the exhaust fan DG2 or the catalyzer KN / KN2 are installed at the

furnace rear (see point 7.7). For their connection, the socket marked "Gebläse" is used.

6. Operation

6.1 Start-up

Prior to the first use, the muffle must be heated up to 1050°C. Hold this temperature for

1.5 hours (= 90 minutes). This way, the necessary oxide layer is formed on the heating

wire.

6.2 Loading

The casting muffles are to be put on the ceramic tray. Metallic muffle rings should not

come in contact with the heating chamber walls.

6.3 Operation of the electronics

The regulator is equipped with the most modern electronics allowing that the heating

process goes through the heating curves with high precision. The furnace is

Page 7

- 7 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

programmed on a menu-driven keyboard with LED indicators. The following functions

are available:

hh:mm

M1

FF

6.3.1 Basic keys

increases / decreases the value

starts / stops the current program

Function key

6.3.2 Display functions

is illuminated when the temperature (°C) is indicated in the display

hh:mm

is illuminated when the holding time / delay is indicated in the display

is illuminated when the night time clock / casting time clock is activated

is illuminated when the furnaces heats up

6.3.3 Setting temperature and holding time / delay

After switching on, the display shows the actual temperature of the furnace, and the

temperature sign lights up. The or keys are used to enter the temperature

desired. Confirm this value by pressing the key. Then, the holding time / delay

(hh:mm) can be entered by means of the and keys and is confirmed by pressing

the key. Now the furnace is started with the key.

! Attention:

Display

Keys

On/Off switch

Status

Display

Page 8

- 8 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

When setting the temperature ( ) or the holding time / delay (hh:mm), the

corresponding LED is blinking.

When the actual temperature ( ) or the actual holding time / delay (hh:mm) is

indicated, the corresponding LED is illuminated.

The heating mode is started and stopped with the key. When the furnace is in

the heating mode, the corresponding LED ( ) is illuminated.

Example: Setting temperature and delay :

Temperature: 850 °C

Delay: 30 minutes

After switching on, the actual temperature is indicated:

21

hh:mm

Now the temperature desired (850°C) can be set by means of the keys and :

8 5 0

hh:mm

While setting the temperature, the display and the LED are blinking. Use the key

to confirm the value entered. If no other settings are made within 10 seconds, the

controller automatically takes over the value given.

By pressing the key, the display also switches over to the delay field:

00 : 00

hh:mm

The delay desired is set by means of the keys and :

00 : 30

hh:mm

While setting the delay, the display and the LED hh:mm are blinking. Use the key

to confirm the value entered. If no other settings are made within 10 seconds, the

controller automatically takes over the value given.

Zeit

°C

850

time

Page 9

- 9 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

The furnace starts heating up as soon as the key is pressed. The LED is

illuminated. The display indicates the actual temperature and delay, respectively. An

acoustic signal indicates that the heating process is finished. Opening the door stops

the sound.

The heating mode is quit by pressing the key.

6.3.4 Starting a program with the casting time / finishing time feature

A long push on the key activates the casting time / finishing time feature. At first,

the day of casting (Monday = 1, Tuesday = 2, ... Sunday = 7) is chosen by means of the

and keys (example: Wednesday = 3):

3

hh:mm

Pressing the key confirms the setting and changes over to the time field where first

the hour (hh:--) is entered, and after another push of the key, the minutes (--:mm) of

the desired casting time / finish time are entered (example: 08:30 am):

08:30

hh:mm

Another push of the key completes the settings of the delay start feature. The

controller automatically calculates the starting time of the furnace.

This function can be deactivated by a long push on the key.

7. Special functions

7.1 Display at the beginning when switching on

When switching on the furnace, the display indicates the version number of the

software for 3 seconds.

7.2 Setting the actual time

The electronics needs to know the actual day and the actual time to correctly calculate

the starting time of the furnace for the casting time / finish time feature. The time is

preset at the factory but must be adapted if used in a different time zone or when the

summer time / winter time changes. Pressing the key and switching on the main

Page 10

- 10 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

switch at the same time opens the actual time field. First enter the actual day (1 =

Monday, 2 = Tuesday, ... 7 = Sunday) (example: Thursday = 4):

4

hh:mm

Then press the key to enter the actual hour. After another push of the key, the

actual minute can be entered (example: 16:53 - use the 24-hour clock!):

16 : 53

hh:mm

Press the key to complete the settings and to save the actual time in the electronics.

7.3 Programming of exhaust blowers, catalyzers and/or fume extraction hoods

The sockets for an exhaust blower, a catalyzer, or a fume extraction hood are located

on the rear of the furnace. They were programmed at the factory to shut off at a

temperature of 600 °C. It is required, however, to reprogramm them especially, when

using shock-heat investments. Pressing the key and switching on the main switch at

the same time activates the programming mode of the sockets.

16 0 0

hh:mm

The first figure shows the socket used. Figure "1" stands for the socket named

"Gebläse" (blower or catalyzer), and figure "2" stands for the socket named "Dunst"

(fume hood). At the factory, the turn-off temperature is set to 600 °C. This temperature

can be changed to a temperature between 200 °C and 999 °C by pressing the and

keys. If the socket needs to run throughout the complete process, it has to be set to

the following indication by pressing the or keys:

1 0n

hh:mm

1 = socket for blower/catalyzer

2 = socket for fume hood

shut-off temperature

of the sockets

Page 11

- 11 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Then press the key to switch over to socket "2" which is reprogrammed in the same

way. Leave the programming mode of the sockets by another push of the key.

! ATTENTION: If a blower, a catalyzer, or a fume extraction hood are connected and

used together with shock-heat investments, please set the shut-off temperatures of

socket 1 ("Gebläse") and socket 2 ("Dunst") to a 20 °C higher temperature than the final

temperature of the shock-heat investments or let them run permanently (= 0n).

7.4 Industrial function

In case the furnace is not used in the dental field, it might be necessary that the furnace

shuts off directly after the holding time. If so, bring the DIP switch No. 1 on the circuit

board in ON position.

Therefore, remove the operating electronics (6 screws). The DIP switch is located on

the rear in the area of the processor (see picture above).

7.5 Service function

In case the furnace does not heat up although the program has been entered correctly,

a control function of the heating may be added by means of DIP switch No. 2 (see

picture in chapter 7.4). The colon in the center of the display shows the following

functions:

lower point: is lit when the heating is activated

upper point: is lit when the heating is activated and electrical power reaches the

heating.

Both points lit but the furnace remains cold means that the heating is defective and has

to be replaced. Otherwise the electronics must be replaced. Please call the customer

service if necessary.

DIP switch:

1: industrial function

2: service function

3: free

4: free

Page 12

- 12 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

7.6 Controller initialization

In order to guarantee an optimal performance with the various laboratory furnaces,

different parameters are preset. The controller is reset to factory settings with the

following keystroke, and the respective parameters are activated:

+ + SWITCHING ON control parameters for furnace types KM1

+ + SWITCHING ON control parameters for furnace types SLM1 ... TLM1

! ATTENTION: The controller parameters may not be altered without agreement of

MIHM-VOGT in Stutensee/Germany!

7.7 How to connect exhaust blowers, catalyzers and/or fume extraction hoods

a.) Connection of an exhaust blower:

The exhaust blower type DG2 is inserted into the designated space at the back and

fixed at the rear sheet metal with the corresponding screws. If an exhaust pipe is

connected, this has to be removed. Connect the plug at the rear socket marked

'Gebläse'.

If required, the exhaust blower can be extended up to approx. 3 - 5 m using

conventional metal pipes (with a diameter of 80 mm at least). Please see to it that the

air resistance is kept low (make only a few angles and do not use flaps) since otherwise

the air flow in the blower might change its direction and, thus, suction stops.

In case of shock-heat investments, please ensure that the blower runs throughout the

complete preheating process of the casting muffles. If required, the shut-off temperature

of the sockets have to be changed (see point 7.3)

b.) Connection of a catalyzer:

The adapter supplied for the catalyzer type KN or KN2 is inserted into the designated

space at the back and fixed at the rear sheet metal using the according screws. If an

exhaust pipe is connected, this has to be removed. The suction pipe of the catalyzer

has to be attached to the adapter and secured with the counter screw. Connect the plug

at the rear socket marked 'Gebläse'.

It is recommendable to operate the catalyzer under a fume extraction hood exhausting

the fumes either into a chimney or to the outside. The catalyzer may be extended in the

same way as a blower; then an additional ventilator (type ZL, order No. 73010, or type

ZL2, order No. 73210) must be installed on top of the catalzer. With this measure, the

catalyzer's pipe may be extended up to approx. 3 - 5 m (diameter for KN 120 mm at

least, diameter for KN2 150 mm at least). Please see to it that the air resistance is kept

low (make only a few angles and do not use flaps) since otherwise the air flow in the

blower may change its direction.

Page 13

- 13 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

In case of shock-heat investments, please ensure that the blower runs continuously

throughout the complete preheating process of the casting muffles. If required, the

shutoff temperature of the sockets has to be changed (see point 7.3)

In dental technology, gases of burnt wax (= organic hydrocarbons) are the main

components which are emitted when heating investments or casting muffles. These

gases are burnt again in the catalyzer and split into carbon dioxide (CO2) and water

steam (H2O). In case of higher temperatures, some investments may release also

ammonia gases which the catalyzer transforms into different nitrogen oxides (NOx). As

not all manufacturers of investments and waxes give complete information on additional

components, it is impossible to name all remainders of other contents released and

their composition.

c.) Connection of a fume extraction hood:

A fume extraction hood used together with the laboratory furnace can be controlled via

the socket marked 'Dunst'. Using shock-heat investments requires continuous operation

of the fume extraction hood during the complete preheating process of the casting

muffles. The shut-off temperature of the rear sockets might have to be altered (see

point 7.3).

If the fume extraction hood is controlled by several furnaces, a furnace adapter / relay

connection must be used:

MIHM-VOGT furnace adapter:

furnace control only

with switch:

furnace control / mains control

Connection of up to 3 furnaces:

OA3, Art. No.: 7453

OA31, Art. No.: 7455

Connection of up to 4 furnaces:

OA4, Art. No.: 7454

OA41, Art. No.: 7456

8. Error signals

8.1 Error messages of the electronics

Error signals:

Cause:

Elimination:

Er01

Thermocouple defective,

loose connection of the

thermocouple,

booster electronics for the

thermocouple defective.

Replace thermocouple,

tighten thermocouple connections,

exchange controller, call customer

service if required.

Er04

Thermocouple is incorrectly

attached (connected the wrong

way round).

Shift thermocouple connections.

Er08

Temperature surrounding the

furnace is too cold or too hot

(-20°C … +75 °C).

Install furnace in another place. Call

customer service if required.

Page 14

- 14 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

8.2 Miscellaneous errors and their causes

Error:

Cause:

Elimination:

Controller shows wrong

time.

Controller was set to a wrong

time.

Correct time in accordance with point

7.2

Heating has not started

although autostart was

programmed.

Long power failure during the

night.

Check power connection, if required,

and make sure that it is not connected

to an external time switch.

Controller shows "--:--" in

the time display (door open)

when door is shut.

Door switch sticks or is defective.

Check door switch. Call customer

service if necessary.

Light-emitting diode at the

controller indicates heating,

but furnace does not heat.

Heating muffle is defective

(check the electrical power at the

heating muffle - see point 7.5 - or

measure the resistance with an

ohmmeter).

[R

o.k.

=18 .. 30 ]

Heating muffle is defective. Replace it.

Call customer service if necessary.

Controller is defective.

Replace the controller. Call customer

service if necessary.

Power element (Type: BLM1,

TLM1) is defective.

Replace the power element. Call

customer service if necessary..

Controller "forgets" the

heating data stored.

Controller is defective.

Replace the controller. Call customer

service if necessary.

Controller "forgets" the time

Controller is defective.

Replace the controller. Call customer

service if necessary.

Display does not work.

Yellow pilot light of On/Off

switch is on.

Protection fuse of the furnace is

defective.

Turn off the furnace, wait for 30

seconds, switch on again. If this does

not help, replace the controller. Call

customer service if necessary.

Display is not working.

Yellow pilot light of On/Off

switch is off.

No mains voltage.

Check fuses in the circuit breaker box,

check connection management. Call

customer service if necessary.

9. Maintenance and care

9.1 Care

The chamber area should be kept clean. The ceramic tray must be used .

The muffles are to be put into the furnace so that no contact with the walls exists.

The furnace is to be heated up empty on 1050 °C before the first use; this

temperature is to be held for 1.5 hours (= 90 minutes). This process should be

repeated, especially if the furnace is used to burn out wax, every 2 weeks in the

first three months of operation. Later, repeat this process every four weeks.

If the furnace is used to burn out wax, we recommend to use an exhaust unit or a

catalyzer to evacuate the wax steams.

Page 15

- 15 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

9.2 Maintenance

Warning:

Turn off the furnace and pull out the power-supply plug before doing maintenance work!

Attention:

The laboratory furnace insulation (lining) contains ceramic fibre / aluminium silicate fibre particles.

According to the EU classification of December 5, 1997, this fibre must be declared as “carcinogen

category 2 according to EU Directive 97/69/EC” (substances to be regarded as carcinogenic for humans).

Animal experiments have shown that high exposure to dust can cause diseases of the lung or pleura in

the form of fibrosis or cancer. These findings have not been confirmed in human studies. Critical health

impairment is unlikely if the recommended instructions for use and valid limits are observed.

Examples for European limits:

Country Limit Origin

Germany 0.5 F/ml TRGS 900

France 0.6 F/ml Circulare DRT nr. 95-4 du 12.01.95

Great Britain 2.0 F/ml HSE - EH40, maximum exposure limit

It is unlikely that these limit values will be reached during servicing of the laboratory furnace. It is

nevertheless recommended that respiratory masks type FFP2 are worn on a voluntary basis.

9.2.1 How to change the thermocouple

Pull the power-supply plug out!

Only for furnaces with circulating air: unscrew the protection covering the motor of

the ventilator.

Loosen the connections of the thermocouple head. Unscrew the thermocouple

from the rear wall and take it out.

Insert the new thermocouple and fix it with screws on the rear wall. Connect the

new thermocouple correctly: red cable at +, white cable at -!

9.2.2 How to change the heating chamber

Pull the power-supply plug out!

For furnaces with circulating air only: unscrew the protection covering the motor of

the ventilator. Remove the air circulation fan as described in chapter 9.2.6.

Unscrew the upper and lower rear panels. Loosen the connection of the heating

wires in the lower switchbox.

Page 16

- 16 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Remove the insulation at rear with care. Carefully pull out the heating chamber

backwards.

Put in the new heating muffle (IMPORTANT: for furnace type BL, put the ceramic

tray in the heating chamber before inserting the heating chamber!). Connect the

new heating chamber.

Put the insulation material back and fix the upper and lower wall again.

For furnaces with circulating air only: install the air circulation fan as described

under 9.2.6. Screw on the protective cover of the ventilator motor.

9.2.3 How to change the door stone

Loosen the cross-recessed screw and remove the hold sheet metal. Take out the

door-stone.

9.2.4 How to replace the controller

Pull the power-supply plug out!

Loosen the cross-recessed screws from the front electronic (controller component)

and remove the controller.

Remove plugs and plug-in strips at the controller. Loosen the thermocouple

connection wire. Proceed accordingly in reverse order to put in the new front

electronic unit. Do not mix up the thermocouple connections

(red = "+", white = "-").

9.2.5 How to replace the power element of the 2nd heating circuit

(only for furnace types: BL, TL)

Pull the power-supply plug out!

Take the ceramic tray out of the heating chamber or safe it, respectively (BL), put

the furnace on its side, unscrew the metalplate at the bottom.

Remove the plug-in strips from the power element and unscrew it.

Proceed accordingly in reverse order for reassembly.

9.2.6 How to change the air circulation fan

Pull the power-supply plug out!

Laboratory furnace type KM:

Unscrew the cover of the fan.

Unscrew the mounting sheet metal with the fan motor from the rear wall. Take

those and the heating chamber out.

Reverse the procedure to reassemble the air circulation fan. Propeller should not

be overtightened; it must be able to run freely. File the aperture if necessary.

Laboratory furnace type SL... TL:

Page 17

- 17 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Unscrew the cover of the ventilator. Extract the protection basket in the heating

chamber.

Hold tightly the motor of the ventilator and unscrew the propeller in the heating

muffle from the motor axle. WARNING: anti-clockwise threads! If Propeller axle

should be stuck, spray it with penetrating oil and let work. Call customer service if

necessary.

Unscrew the ventilator motor at rear.

Reverse the procedure to reassemble the air circulation fan. Propeller should not

be overtightened. It must be able to run freely. File the aperture if necessary.

9.3 Warranty

1. Mihm-Vogt guarantees, under the following conditions, that its dental appliances are free of defects in

accordance with the latest technological findings for the appliance in question for a period of 12 months

from delivery of the appliance by the specialist dealer, provided that this occurs no later than six months

after delivery from the factory.

2. The warranty covers only the repair of the dental appliance free of charge by a Mihm-Vogt specialist

dealer. The parts incorporated in the appliance during the repair will be subject to the same warranty as

that of the appliance itself until expiry of said warranty in accordance with No. 1. Replaced parts will

become the property of Mihm-Vogt.

3. Guarantee claims are to be submitted with the invoice to a Mihm-Vogt specialist dealer who will carry out

the repair.

4. Wear and tear, particularly to wear parts such as heating elements, bulbs, fans, and thermo-elements,

are not covered by the warranty.

5. Guarantee claims will not be accepted if a defect is connected with

a) the effect of external mechanical or chemical influences on the appliance

b) improper or excessive use of the appliance

c) repair, maintenance or servicing by a third party whom the end user knows not to be a Mihm-Vogt

specialist

d) incorporation in the appliance of parts whose use has not been approved by Mihm-Vogt or which

change the appliance in a way not approved by Mihm-Vogt

e) failure to observe the instructions by Mihm-Vogt on the handling, servicing and care of the

appliance (e.g. operating instructions), in particular if the scheduled services are not carried out

f) failure by the end user to notify a defect and have it repaired as described in No. 3 immediately in

the case of defects that were apparent at the time of delivery of the appliance or immediately on

detection in the case of defects that became apparent later.

6. Recommendations for use, irrespective of whether they are given orally, in writing or during practical

instruction, are based on experience and tests by Mihm-Vogt and can therefore be regarded as

guidelines only. Mihm-Vogt products are subject to further development. Mihm-Vogt therefore reserves

the right to make changes in design and composition.

7. All guarantee claims expire at the end of the warranty period defined in No. 1. For claims made but not

rectified during the warranty period, the expiry date is extended until the defect has been rectified. In this

case the warranty expires two months at the latest after the last repair or statement by the Mihm-Vogt

specialist dealer that the defect has been remedied or did not exist.

8. Claims by the purchaser against the supplying dealer are unaffected by this warranty.

MIHM-VOGT GmbH & Co. KG

October 2008

Page 18

- 18 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

9.4 Circuit diagrams

thermocouple

thermocouple

heating

heating

circulating air*)

fume extraction hood

fume hood

motor for air circulation*)

exhaust blower

door

door switch

exhaust blower

lower switchbox

*) Only furnace types ending with '-U' provide the

circulating air feature.

mains

Protective note as per DIN 034

Circuit diagram for furnace types

KM, SL, GL either with M1controller

M1-controller

upper box

Distributor:

Date:

Name: last amendment

released:

July 25, 2005

Gräbe H

checked:

July 25, 2005

Gräbe H

drawn up:

July 25, 2005

Gräbe D

thermocouple

heating 1

circulating air*)

fume extraction hood

exhaust blower

door

mains

M1-controller

heating 1

heating 2

thermocouple

reserve

Protective note as per DIN 034

Circuit diagram for furnace types

BL and TL with M1-controller

circulating air*)

fume extraction hood

exhaust blower

A-terminal

2nd power element

flat cable

lower switchbox

upper box

*) Only furnace types ending with '-U' provide the

circulating air feature.

Distributor:

Date:

Name: last amendment

released:

July 25, 2005

Gräbe H

checked:

July 25, 2005

Gräbe H

drawn up:

July 25, 2005

Gräbe D

Page 19

- 19 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Index

A

actual time 8

adapter 11

additional ventilator 11

air circulation 3

air circulation fan 15

aluminum silicate fibre 13

annealing 13

autostart 7

B

blower 9

C

care 13

catalyzer 2, 4, 9, 11

ceramic fibre 13

ceramic tray 13

CE-sign 2

change

air circulation fan 15

controller 14

door stone 14

heating chamber 14

power element 15

thermocouple 14

circuit diagrams 17

circulating air 3

colon 10

connection

catalyzer 10

catalyzer 11

exhaust blower 10

fume extraction hood 10, 11

control mode 10

controller 14

controller initialization 10

D

day 7

delay start feature 7

delivery form 2

DG2 2, 4, 10

DIP switch 9

display at the beginning 8

display functions 6

door stone 14

E

electrical connection 4

error 12

Error

Time 12

error messages 12

error signals 12

example 6

exhaust blower 10

exhaust fan 2, 4

F

fume extraction hood 9, 11

function keys 5

furnace adapter 11

H

health 13

heating 10, 12

heating chamber 14

heating wire 2

I

identification plate 3

industrial function 9

installation 4

K

key

+/- 5

F 5

start/stop 5

keyboard 5

keys 5

KN 11

KN2 11

L

limit values 13

loading 5

M

maintenance 13

O

operation 5

operation of the electronics 5

P

pipe 11

power element 15

programming

catalyzer 8

exhaust blower 8

fume extraction hood 8

R

relay connection 11

reset 10

S

safety switch 2

safety warning 4

service function 10

setting

delay 6

holding time 6

temperature 6

shock-heat investments 10, 11

shutoff function see industrial function

shutoff temperature 8

spareparts 2

special functions 8

summer time 8

Page 20

- 20 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

T

technical data 3

thermocouple 12, 14

thermocouple circuit breaker 2

time zone 8

U

use area 2

V

ventilating air hood 2

W

warranty 16

wax-out 13

winter time 8

Z

ZL 11

ZL2 11

Loading...

Loading...