MIHM-VOGT KM, GL, BL, SL, TL Working Instructions

Working Instructions

for MIHM-VOGT Laboratory Furnaces

with Controller M1

Version 1.0 01/2013

- 2 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

- 3 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Working instructions

for

MIHM-VOGT laboratory furnace

with controller M1

Table of contents:

1. Delivery form 4

2. Use area 4

3. Technical data 5

4. Safety warning 5

5. Installation and electrical connection 6

6. Operation 6

6.1 Start-up 6

6.2 Loading 6

6.3 Operation of the electronics 6

6.3.1 Basic keys 7

6.3.2 Display functions 7

6.3.3 Setting temperature and holding time / delay 7

6.3.4 Starting a program with the casting time / finishing time feature 9

7. Special functions 9

7.1 Display at the beginning when switching on 9

7.2 Setting the actual time 9

7.3 Programming of exhaust blowers, catalyzers and/or fume extraction hoods 10

7.4 Industrial function 11

7.5 Service function 11

7.6 Controller initialization 12

7.7 How to connect exhaust blowers, catalyzers and/or fume extraction hoods 12

8. Error signals 13

8.1 Error messages of the electronics 13

8.2 Miscellaneous errors and their causes 14

9. Maintenance and care 14

9.1 Care 14

9.2 Maintenance 15

9.2.1 How to change the thermocouple 15

9.2.2 How to change the heating chamber 15

9.2.3 How to change the door stone 16

9.2.4 How to replace the controller 16

9.2.5 How to replace the power element of the 2nd heating circuit

(only for furnace types: BL, TL) 16

9.2.6 How to change the air circulation fan 16

9.3 Warranty 17

9.4 Circuit diagrams 18

Index 19

- 4 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

Dear customer,

We thank you for your decision to buy a high-quality MIHM-VOGT furnace. It will support you

with your work for many years, as it was developed and built using the latest technology.

Nevertheless, improper use and handling can cause damage, therefore we ask you to

carefully read through these working instructions and to follow it.

The CE-sign confirms that MIHM-VOGT laboratory furnaces correspond to the

governing regulations of the EC guidelines.

1. Delivery form

Each laboratory furnace is delivered with a M1 microprocessor controller, a refractory

ceramic tray, a PtRh-Pt thermocouple, and an escape pipe.

Instead of the escape pipe, the furnace can also be equipped with the following

accessories:

Exhaust fan DG2 (Art. N° 7202)

Catalyzer KN1 (Art. N° 7300)

Catalyzer for shock-heat investments KN2 (Art. N° 7320)

Spare parts

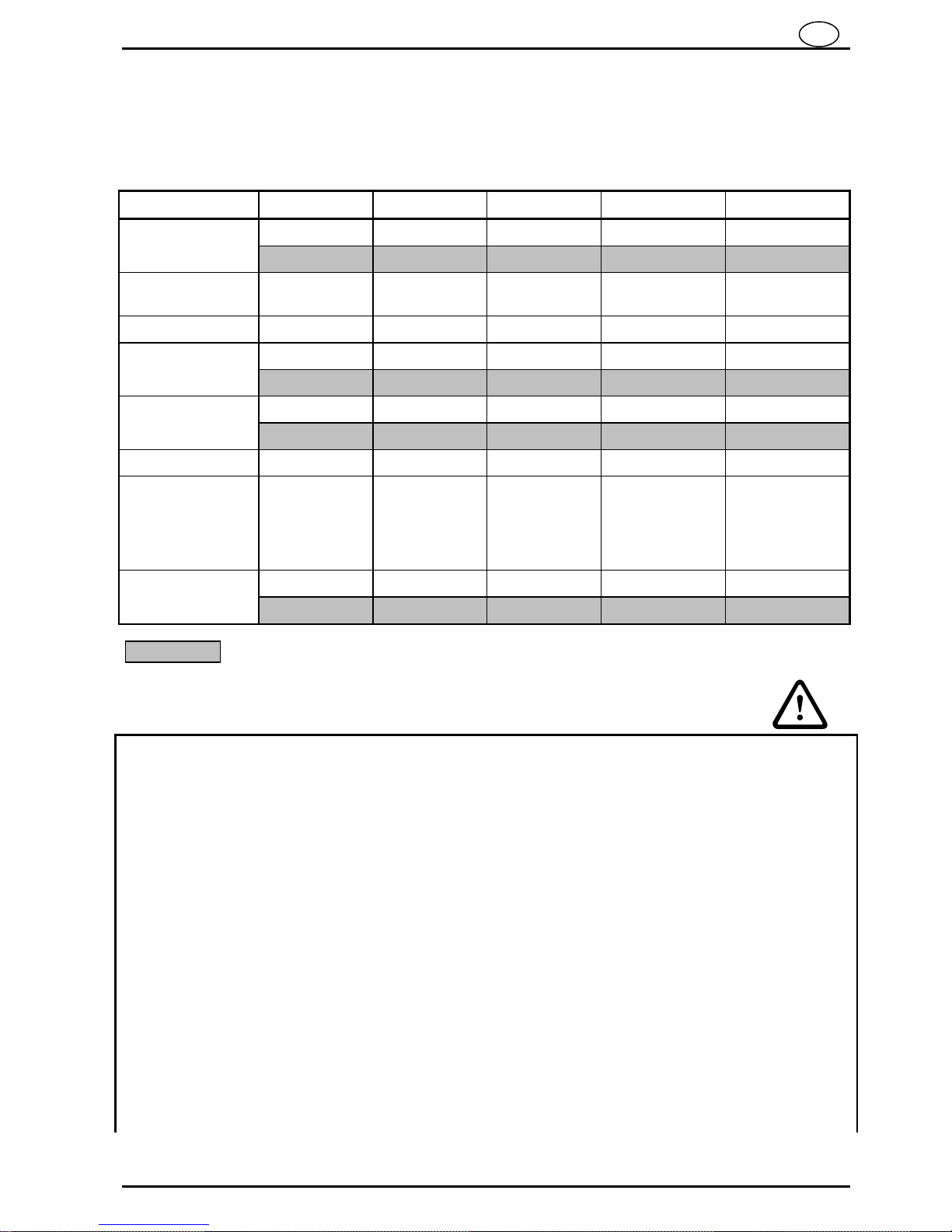

Item n°:

Furnace type:

KM

SL

GL

BL

TL

Ceramic tray

20020

30020

40020

50020

50020

Thermocouple

20100

30110

40110

50110

60110

Door filling

20351

30301

30301

30301

30301

Heating muffle (without ventil.)

20010

30010

40010

50010

60010

Heating muffle (with ventilator)

20015

30015

40015

50015

60015

2. Use area

The laboratory furnace is used for the elimination of wax and for preheating of dental

casting rings. The heating muffle is made of a high-quality ceramic and is heated evenly

on four sides. The low electric load guarantees a high lifespan of the heating wire. A

high-quality internal insulation ensures a long lifetime.

At the rear of the furnace, two sockets are provided for the connection of an exhaust fan

or a catalyzer and a ventilating air hood.

The furnace door is equipped with a safety switch, which interrupts the heating current

when opening the door. The M1 controller includes a thermocouple circuit breaker so

- 5 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

that the furnace does not overheat if the thermocouple is defective. The type of the

furnace is listed on an identification plate at the rear of the furnace.

3. Technical data

Furnace type:

KM

SL

GL

BL

TL

Outside dimensions

40 x 48 x 40

43 x 58 x 45

48 x 58 x 52

54 x 60 x 55

54 x 65 x 55

w x h x d (cm)

40 x 48 x 45

43 x 58 x 51

48 x 58 x 59

54 x 60 x 62

54 x 65 x 62

Heating chamber:

w x h x d (cm)

15 x 10 x 17

18 x 11 x 19

20 x 11 x 25

25 x 11 x 28

25 x 17 x 28

Capacity:

4 pcs. 6x

4 pcs. Ø 8 cm

6 pcs. Ø 8 cm

9 pcs. Ø 8 cm

18 pcs. Ø 8 cm

Max. temperature

1150 °C

1150 °C

1150 °C

1150 °C

1150 °C

1100 °C

1100 °C

1100 °C

1100 °C

1100 °C

Power rating:

1.6 kilowatts

1.8 kilowatts

2.3 kilowatts

3.5 kilowatts

4.5 kilowatts

1.6 kilowatts

2.1 kilowatts

2.6 kilowatts

3.7 kilowatts

4.8 kilowatts

Tension:

230 V~

230 V~

230 V~

230/400 V~ (2/N)

230/400 V~ (2/N)

Preheating times:

60 min.

900 °C

90 min.s

1050 °C

60 min.

800 °C

90 min.

1100 °C

60 min.

800 °C

90 min.

1100 °C

60 min.

800 °C

90 min.

1100 °C

60 min.

800 °C

90 min.

1100 °C

Weight:

32 kg

63 kg

75 kg

90 kg

100 kg

36 kg

70 kg

80 kg

95 kg

105 kg

furnaces with circulating air (not recommended for speed investments)

4. Safety warning

The MIHM-VOGT laboratory furnace is exclusively made for the elimination of wax and

for the preheating of casting rings. We are not liable for damages due to another use.

The sockets on the rear are to be used exclusively for MIHM-VOGT ventilating air hood,

a MIHM-VOGT exhaust fan or a MIHM-VOGT catalyzer.

The MIHM-VOGT laboratory furnace must be operated exclusively by technicians, who

know the content of this manual. Labels and stickers on the laboratory furnace must

always be maintained in legible condition. They must not be removed.

The MIHM-VOGT laboratory furnace should be set up only in dry areas and should not

be in contact with liquids. In the area of the furnace, furniture and other objects cannot

consist of explosive, combustible or easily inflammable materials. In the installation area

of the furnace, no easily inflammable or combustible gases or liquids are allowed to be

stored.

Modifications of the MIHM-VOGT laboratory furnace can only be made after prior

written agreement from us. We are not liable for damages caused by your

- 6 -

MIHM-VOGT GmbH & Co. KG, Friedrich-List-Str. 8, D-76297 Stutensee-Blankenloch, Tel.: +49 7244/70871-0, Fax: +49 7244/70871-20

GB

modifications. Before every maintenance, the appliance is to be turned off and the

power-supply plug is to be pulled out.

The furnaces type KM, SL, GL must always be connected to a plug protected by a 16

Amp fuse. The furnaces type BL and TL are to be connected to a CEKON plug (230 /

400 V, AC).

The hot furnace door should only be touched at the grip, the hot muffles should only be

grabbed with sufficiently long tongs. Because of the wax fumes and the steam from the

investments, the furnace should be equipped with an exhaust fan or catalyzer and

placed under a ventilating air hood. The fumes are to be extracted outside.

The ceramic tray should always be used to protect the heating muffle.

The transportation protection from the heating muffle must be taken off before the first

use.

5. Installation and electrical connection

The laboratory furnace is to be positioned in a dry area in accordance with the safety

warnings and is to be connected to a separate circuit secured with 16 Amp. The

transportation protection must be removed from the heating muffle. The laboratory

furnaces type KM, SL and GL are to be connected to an earthed plug 230 V. The

laboratory furnaces type BL and TL are to be connected to a CEKON plug 230/400 V

AC. If required, the exhaust fan DG2 or the catalyzer KN / KN2 are installed at the

furnace rear (see point 7.7). For their connection, the socket marked "Gebläse" is used.

6. Operation

6.1 Start-up

Prior to the first use, the muffle must be heated up to 1050°C. Hold this temperature for

1.5 hours (= 90 minutes). This way, the necessary oxide layer is formed on the heating

wire.

6.2 Loading

The casting muffles are to be put on the ceramic tray. Metallic muffle rings should not

come in contact with the heating chamber walls.

6.3 Operation of the electronics

The regulator is equipped with the most modern electronics allowing that the heating

process goes through the heating curves with high precision. The furnace is

Loading...

Loading...