Clé à chocs

Llave de Impacto Neumática

Use r’s

Manua l

AIR IMPACT WRENCH

Warning

Ear Protection

Safety Goggles

Gloves

3

1.The maximum recommended air pressure during operation must not exceed 90 psi

(6.3bar). Higher air pressure may create unsafe operating conditions for the tool and

the user.

2.The compressed air should be cooled and have a water lter installed at the outlet

end of the compressor. Even with a water filter installed, some water may still

condense in the piping or hose and will enter the tool mechanism causing premature

damage to the tool. Therefore, it is recommended to install an air filter-lubricator

device somewhere between the tool and the compressor.

3.Always use an air compressor of the proper capacity to operate each tool.

4.Clean the hose with a blast of compressed air before connecting the hose to the air

tool. This will prevent both moisture and dust inside the hose from entering the tool

and causing possible rust or malfunction.

1.Using these tools in any potentially explosive environment is strictly prohibited.

2.It is always recommended that these types of tools must be operated when standing

on a solid or rm location.

3.Always use these tools in a well ventilated area.

4.Slipping, stumbling and falling are the major causes of potential serious injury,

therefore, a clean and clutter free surface in the working area before operating the

tools is strongly recommended.

Operation Instruction for Air Impact Wrench

Working environment:

Air supply and connection requirements:

4

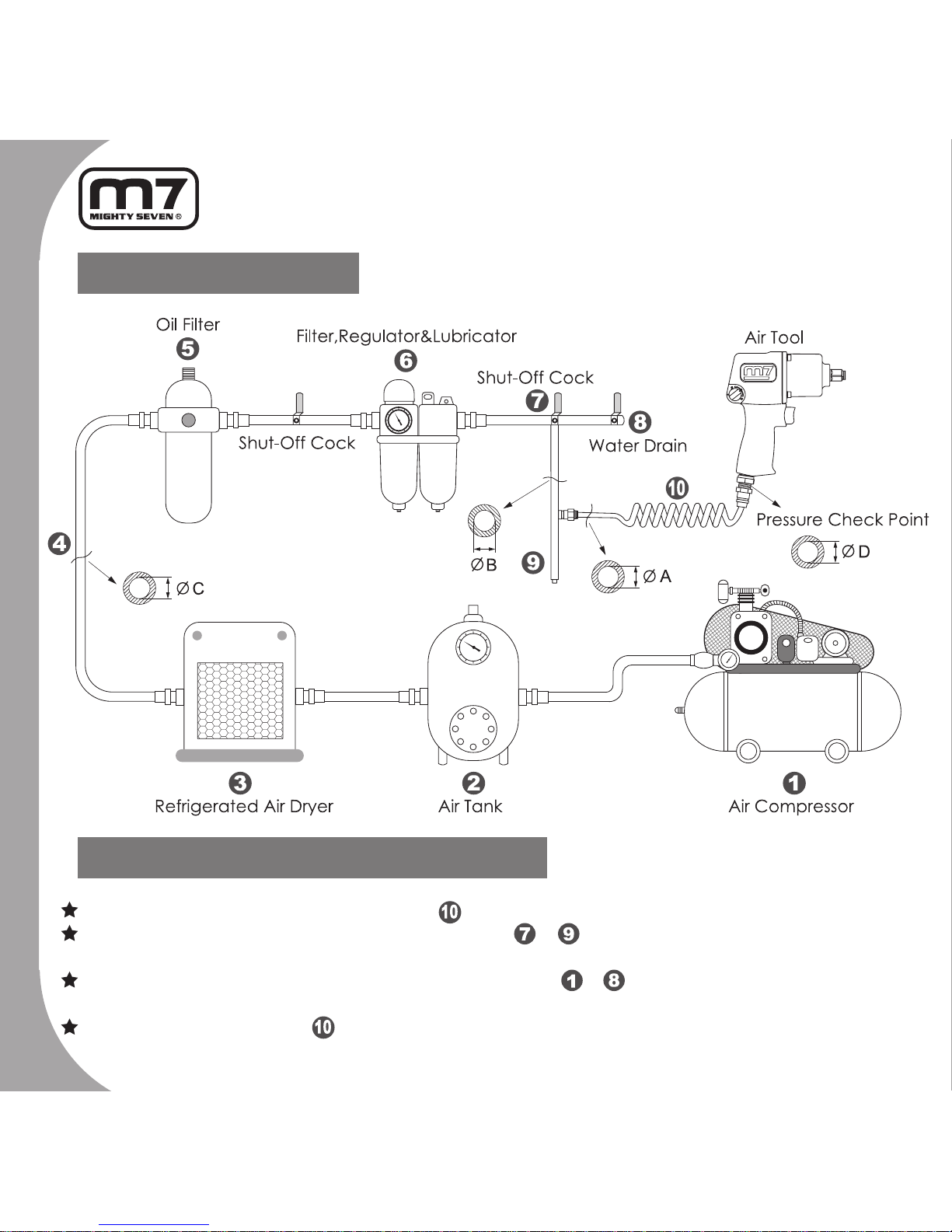

Ideal system connection:

Piping diameters and length requirement:

The diameter ΦA required for the inlet pipe is recommended on the specication table.

The diameter ΦB required for the branch pipe (from to ) should be 2 times as large as ΦA.

ΦB = 2 x ΦA

The diameter ΦC required for the primary air supply (from to ) should be 3 times as large as

ΦA. ΦC = 3 x ΦA

The length for the inlet pipe should be less than 15 feet (4.5m).

5

1. This tool should only be used as a hand operated tool. It is powered by compressed air and is not

insulated against electric shock.

2. This tool is specially designed for tightening or loosening bolts or nuts. Any application or use of this tool

other than what it is designed for is strictly prohibited.

3. Use only pneumatic impact sockets and accessories on this tool. Never use hand sockets or accessories.

4. High sound levels may cause hearing damage. Always wear hearing protection when operating this tool.

5. Wearing eye/face protection can reduce the danger of high-speed socket being ejected from the tool, due

to improper socket insertion during operation.

6. User must wear proper clothing. Loose clothing, long hair, stings, straps, belts and jewelry should not be

worn when operating this tool.

7. Before using these tools, make sure that all couplings and plugs are securely mounted. Air hoses which

are under pressure will cause a whipping action when disconnecting, this can lead to serious injury!

8. Make certain to stand on a solid or rm location and keep body in well-balanced position while operating

this tool.

9. Test run the tool to conrm the rotation direction before practical use. This will reduce the potential hazard

due to unexpected rotating direction.

10.In case of tool insert failure, always keep hands away from rotating socket to reduce the risk of being

injured, especially when working in conned spaces.

11.Always turn off the air supply and disconnect the air hose before changing socket or making adjustments

on the tool.

12.Release the throttle trigger to avoid danger if there is a failure of energy supply and when connecting or

disconnecting the air hose.

13.prolonged use will cause user fatigue. Periodic breaks are recommended for user safety.

14.It is recommended to stop operating the tool whenever the user experiences discomfort, tingling or pain

during use.

15.Beware if the compressed air hose breaks unexpectedly, or is being connected or disconnected

improperly. This whipping action may cause injury.

16.Always use caution when operating this tool to prevent injury.

17.Avoid storing this tool where it is subject to high humidity.

Warning:

6

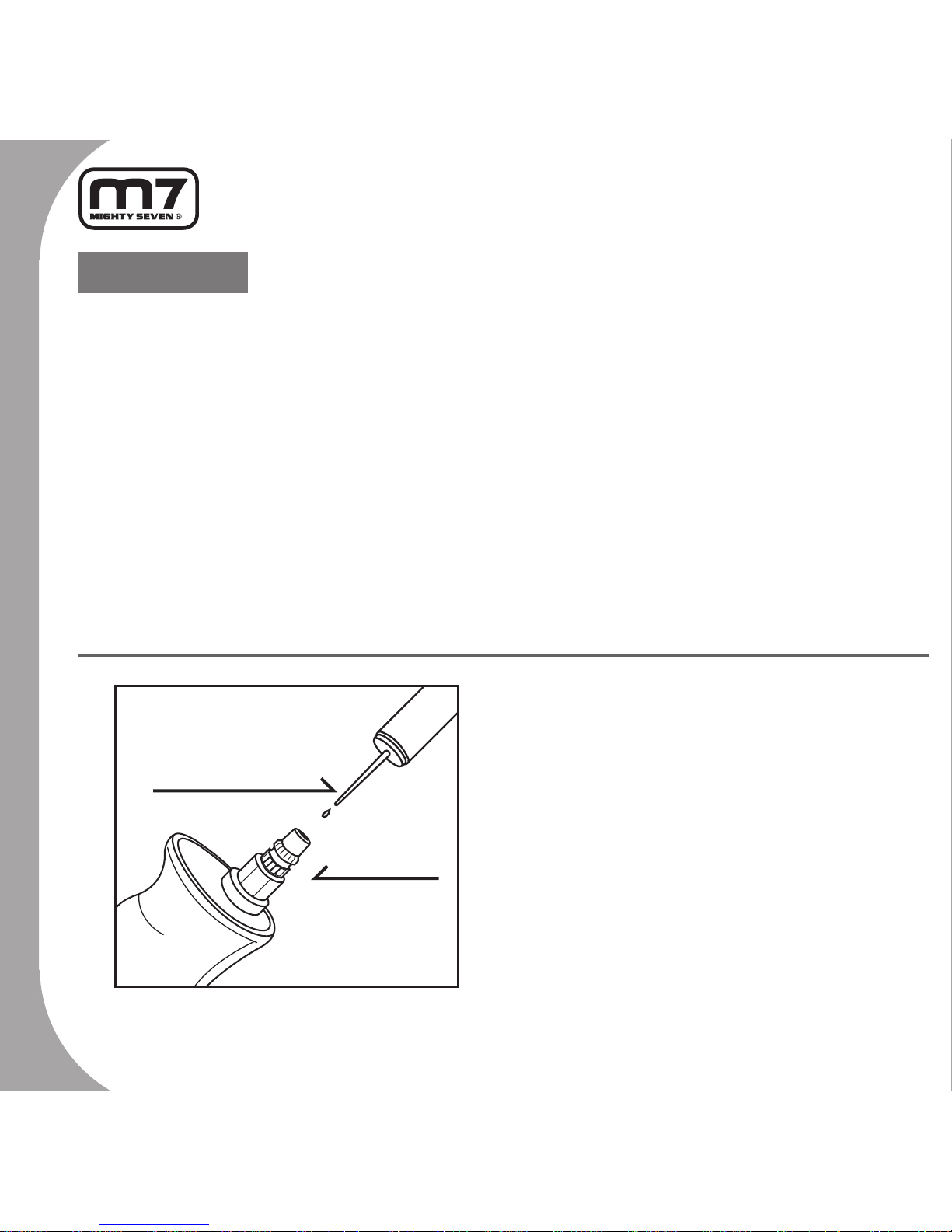

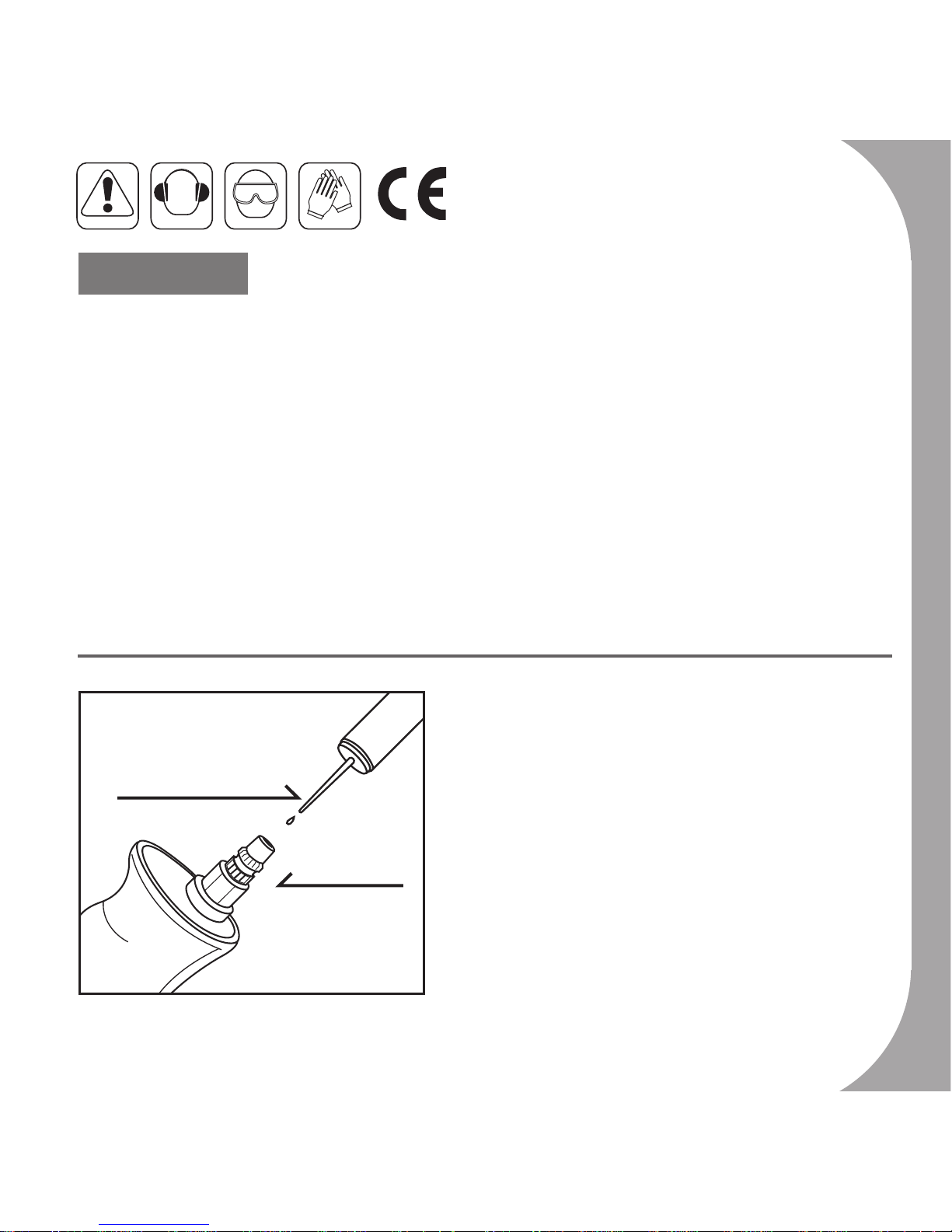

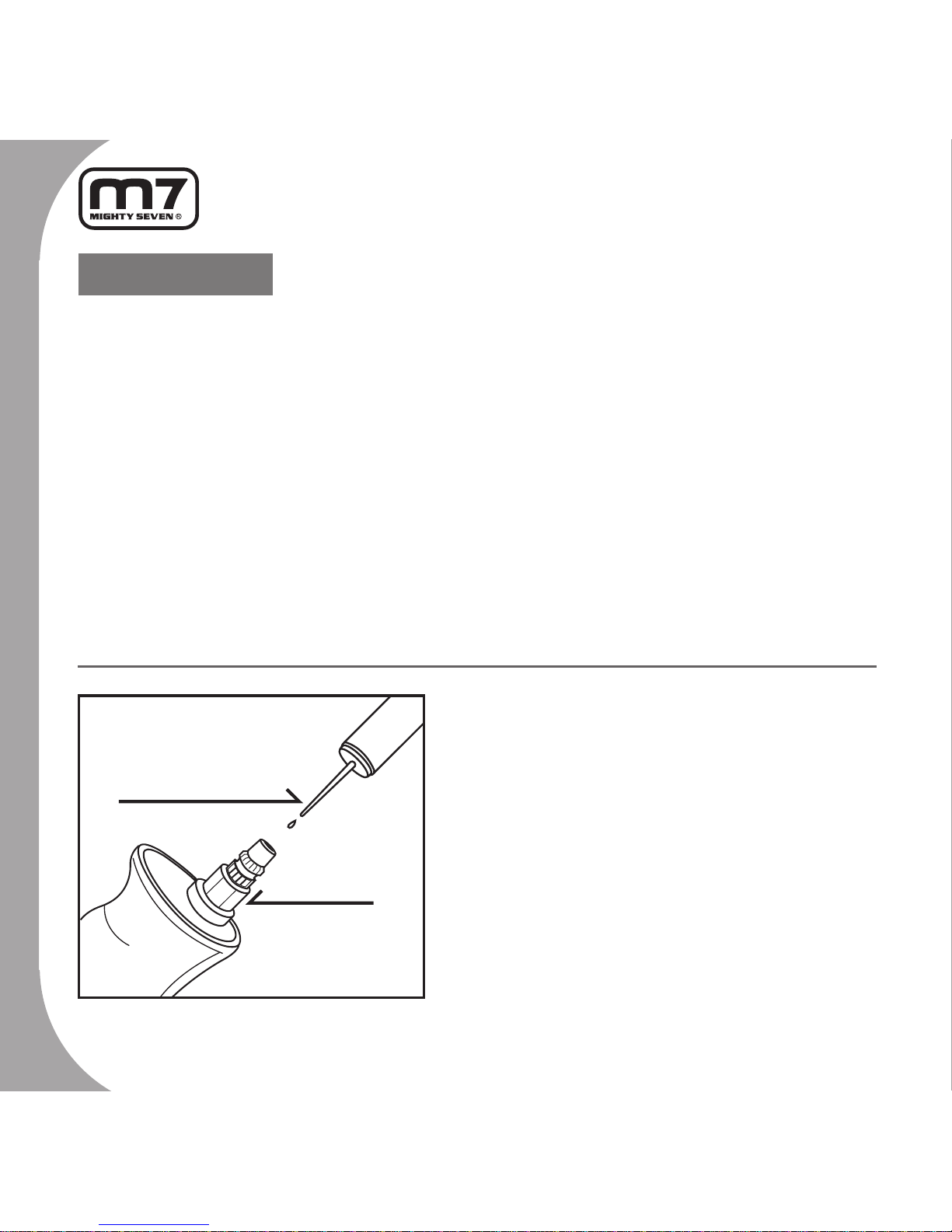

1. Before connecting the air hose to this tool or after operating, apply 4 or 5 drops of

pneumatic oil into the air inlet and run it for several seconds, referring this operation to the

attached illustration No.1.

2. Maintain this tool regularly by performing the same oiling application every 3 to 4 hours of

operation.

3. Do not lubricate tools with flammable or volatile liquids. Use only the lubricant

recommended by Mighty-Seven or authorized dealers. Any other lubricant will lead to

reduce performance of the tool and permanent damage. Whenever any unauthorized

lubricant is used by accident, ush it immediately with recommended pneumatic oil.

4. The impact mechanism also needs to be greased once every 50 hours after practical

operation.

5. Follow all the recycling laws of waste disposal once this tool is no longer usable.

Maintenance:

Pneumatic oil

Air inlet

Regular maintenance

7

Guide d’utilisation - Clé à chocs

1. La pression d'air maximale recommandée ne devrait jamais excéder les 90 psi

(6,3bar). Une utilisation à une pression d'air supérieur peut causer des dommages à

l'outil et/ou pour son utilisateur.

2. L'air à la sorti du compresseur devrait être refroidi et passer à travers un ltre capteur

d'humidité pour éviter les risques de condensation à l'intérieur de l'outil. L'humidité

et la condensation peuvent créer de la rouille et une usure prématurée de l'outil. Pour

cette raison, il est recommandé d'installer un ltre à air/lubricateur quelque part

entre l'outil pneumatique et le compresseur.

3. Utilisez un compresseur avec une capacité adaptée pour chaque outil.

4. Nettoyez le tuyau d'alimentation avec une décharge d'air avant chaque utilisation.

Ceci évitera que de l'humidité et/ou des impuretés ne pénètrent à l'intérieur de l'outil

et ne crée des problèmes de fonctionnement ou une usure prématurée.

1.L’outil ne doit pas être utilisé dans un lieu ayant une atmosphère potentiellement

explosive.

2.Il est fortement conseillé d'utiliser ce genre d'outils avec une prise au sol ferme et solide.

3.Toujours utiliser l'outillage pneumatique dans un endroit bien ventilé.

4.Des installations encombrées et mal organisées sont une des principales causes de

blessures en milieu de travail. Une aire de travail propre et libre de tout obstacle est

requise pour assurer la sécurité au travail.

Environnement de travail:

Pression et alimentation en air :

8

Attention:

1. Tout l'outillage pneumatique devrait être opéré de façon manuelle. Ils sont alimentés par de l'air

comprimé et ne sont pas conçus pour être utilisés dans des milieux sous tension électrique.

2. Cet outil est conçu spéciquement pour le serrage et le desserrage des boulons. Toute autre utilisation

de cet outil est fortement déconseillée.

3. Toujours utiliser des douilles ou des accessoires de type Impact sur cet outil. Ne jamais utiliser de

douilles ou des accessoires à mains.

4. Le niveau sonore élevé de l'outillage pneumatique peut causer des dommages auditifs permanents.

Toujours porter une protection auditive lors de l’utilisation.

5. Il est fortement conseillé de se munir de protection pour les yeux et le visage an d'éviter les blessures

causées par débris ou une douille mal xée éjectée lors de l’utilisation.

6. L'utilisateur se doit de porter des vêtements adéquats. Des vêtements amples, des cheveux longs, des

attaches, sangles, ceintures ou bijoux ne devraient pas être portés lors de l'utilisation de ces outils.

7. Avant d'utiliser ces outils, il faut s'assurer que tous les joints et raccords soient correctement enclenchés.

Les tuyaux d'alimentation sous pression peuvent causer de sérieuses blessures s’ils se déconnectent!

8. Il est fortement conseillé d'utiliser ce genre d'outils avec une prise au sol ferme et solide.

9. Vériez le sens de rotation de l’outil par un test rapide avant chaque utilisation. Ceci pourrait éviter des

blessures dues à un sens de rotation inattendu.

10. En cas d’un bris de la boulonnerie ou d’une douille, toujours tenir les mains éloignées de la partie rotative

de l’outil an d’éviter les risques de blessures, particulièrement dans les endroits connés.

11. Toujours éteindre l’alimentation en air et débrancher les raccords lors d’un changement de douille ou

d’accessoire.

12. Relâchez la gâchette lorsqu’il y a un problème d’alimentation ou lors du débranchement de l’outil.

13 Des périodes d'utilisation prolongée peuvent causer de la fatigue. Des pauses régulières sont conseillées

pour augmenter la sécurité de l’utilisateur.

14. Il est recommandé d'arrêter immédiatement le travail lorsqu'un malaise ou une forte fatigue est ressenti

lors de l'utilisation prolongée de cet outil.

15. Toujours faire attention à un éventuel bris du tuyau d’alimentation en air et lors de son débranchement

intentionnel ou accidentel. Le fouettement du tuyau d’alimentation peut causer des blessures.

16. Toujours être prudent lors de l’utilisation de cet outil pour prévenir les blessures.

17. Évitez de ranger cet outil dans un endroit ou l’air est humide.

9

Maintenance:

Entretien régulier

Huile pneumatique

Entrée d'air

1. Avant l'utilisation ou avant de brancher le tuyau d'alimentation, déposer 4 ou 5 gouttes

d'huile pneumatique par l'admission d'air et faire fonctionner l'outil pendant quelques

secondes. Pour la manipulation, se référer à l’illustration No.1.

2. Procédez à une lubrication régulière de l'outil à toutes les 3 ou 4 heures d'utilisation.

3. Ne pas lubrifier l'outil avec des produits volatile ou inflammable. Seule l'utilisation

de lubrifiants recommandés par M7 ou un revendeur autorisé est permise. Tout autre

lubriant peut réduire la durée de vie de l'outil. Purger avec de l'huile pneumatique tout

outil ayant reçu accidentellement tout autre type de lubriant.

4. Le mécanisme de la clé à choc doit également être graissé à toutes les 50 heures

d’utilisation consécutive.

5. Si l’outil est trop endommagé pour être encore utilisé, déposez-le dans une déchetterie

pour qu’il soit recyclé.

10

1. El uso de estas herramientas en cualquier ambiente potencialmente explosivo está

totalmente prohibido.

2. Es siempre recomendado que este tipo de herramientas sean operadas parándose

sobre un lugar sólido o rme.

3. Siempre usar estas herramientas en un lugar con buena ventilación.

4. Resbalarse, tropezarse y caerse son las mayores causas de daños potencialmente

serios, por lo que se recomienda operar las herramientas en una supercie limpia y

libre de abarrotamiento dentro del área de trabajo.

Ambiente de trabajo:

Requerimientos de surtido de aire y conexiones:

Instrucciones de uso para Llave de Impacto Neumática

1. La presión máxima de operación no debe exceder de 90 psi (6.3bar). Una presión de

aire mayor podría crear condiciones de operación no seguras para la herramienta y el

usuario.

2. El aire comprimido debe ser enfriado y tener un filtro de agua instalado en el lado

de salida del compresor. Aún con el filtro de agua instalado, algo de agua podría

condensarse todavía en las tuberías o la manguera y entrar en el mecanismo de la

herramienta, causando daños prematuros a la misma. Por ello es recomendable

instalar un dispositivo filtro-lubricador de aire en algún punto de la línea entre la

herramienta y el compresor.

3. Siempre usar el compresor de aire de la capacidad apropiada para operar cada

herramienta.

4. Limpiar la manguera con un soplo de aire comprimido antes de conectar la manguera

a la herramienta de aire. Esto evitará que la humedad y la suciedad dentro de la

manguera ingresen a la herramienta causando su oxidación o malfuncionamiento.

11

1. Esta herramienta debe ser usada únicamente como una herramienta operada manualmente. Funciona

con compresora de aire y no está aislada contra choques eléctricos.

2. Esta herramienta está especialmente diseñada para ajustar o soltar tuercas o tornillos. Cualquier otro

uso de esta herramienta ajeno al propósito para el que fue diseñada está estrictamente prohibido.

3. Utilice únicamente dados y accesorios neumáticos para esta herramienta. Nunca use dados o

accesorios de tipo manual.

4. Sonidos de niveles altos podrían causar daños al oído. Use siempre protección de oídos al operar esta

herramienta.

5. El uso de protección de ojos y cara puede reducir el peligro en caso de que el dado sea expulsado a alta

velocidad desde la herramienta a causa de una mala inserción del dado durante el uso.

6. El operario debe usar ropa apropiada. Ropa muy suelta, pelo largo, cordones, tirantes, correas y joyería

no deben ser usados cuando se opere esta herramienta.

7. Antes de usar estas herramientas, asegúrese que todas las piezas de acople y enchufes estén

conectados de forma segura.

8. Asegúrese de pararse sobre una base sólida o rme y mantenga el cuerpo en una posición con buen

balance al operar esta herramienta.

9. Realice una prueba de encendido de la herramienta para conrmar la dirección de rotación antes de

ponerla en uso. Esto reducirá daños potenciales causados por una dirección de rotación inesperada.

10. Siempre mantenga las manos apartadas del dado de rotación para reducir el riesgo de lesionarse en

caso de una falla en la inserción de la herramienta, especialmente cuando se trabaja en espacios

connados.

11. Siempre apague el suministro de aire y desconecte la manguera de aire antes de cambiar el dado o de

hacer ajustes a esta herramienta.

12. Suelte el gatillo de aceleración para evitar peligros si existe una falla en el suministro de energía

eléctrica o cuando conecte o desconecte la manguera de aire.

13. Largos periodos de uso prolongado causan fatiga del usuario. Descansos periódicos son recomendados

para seguridad del usuario.

14. Se recomienda interrumpir el uso de la herramienta en caso de experimentar incomodidad, cosquilleo o

dolor durante su uso.

15. Tenga cuidado si la manguera de aire se rompe inesperadamente, o si se conecta o desconecta de

manera inapropiada. El efecto azote de tal acción podría causar lesiones.

16. Siempre opere esta herramienta con cuidado para prevenir lesiones.

17. Evite almacenar esta herramienta en lugares muy húmedos.

Advertencia:

12

Mantenimiento:

Aceite Neumático

Toma de Aire

1. Antes de conectar la manguera de aire o luego de usarla, aplique 4 ó 5 gotas de aceite

neumático en la entrada de aire y déjela encendida por varios segundos. Ver la ilustración No. 1.

2. Realice un mantenimiento regular de esta herramienta repitiendo la misma operación

lubricación cada 3 ó 4 horas de uso.

3. No utilice líquidos inamables o volátiles para lubricar esta herramienta. Utilice únicamente el

lubricante recomendado por Mighty-Seven o agentes autorizados. Cualquier otro lubricante

producirá una disminución en el desempeño de la herramienta y daño permanente. Si se

utiliza accidentalmente un lubricante no autorizado, quítelo inmediatamente vertiendo encima

aceite neumático recomendado.

4. Engrasar también el mecanismo de impacto luego de cada 50 horas de uso.

5. Respete todas las leyes de reciclaje y desechos una vez que esta herramienta sea descartada.

Mantenimiento regular

13

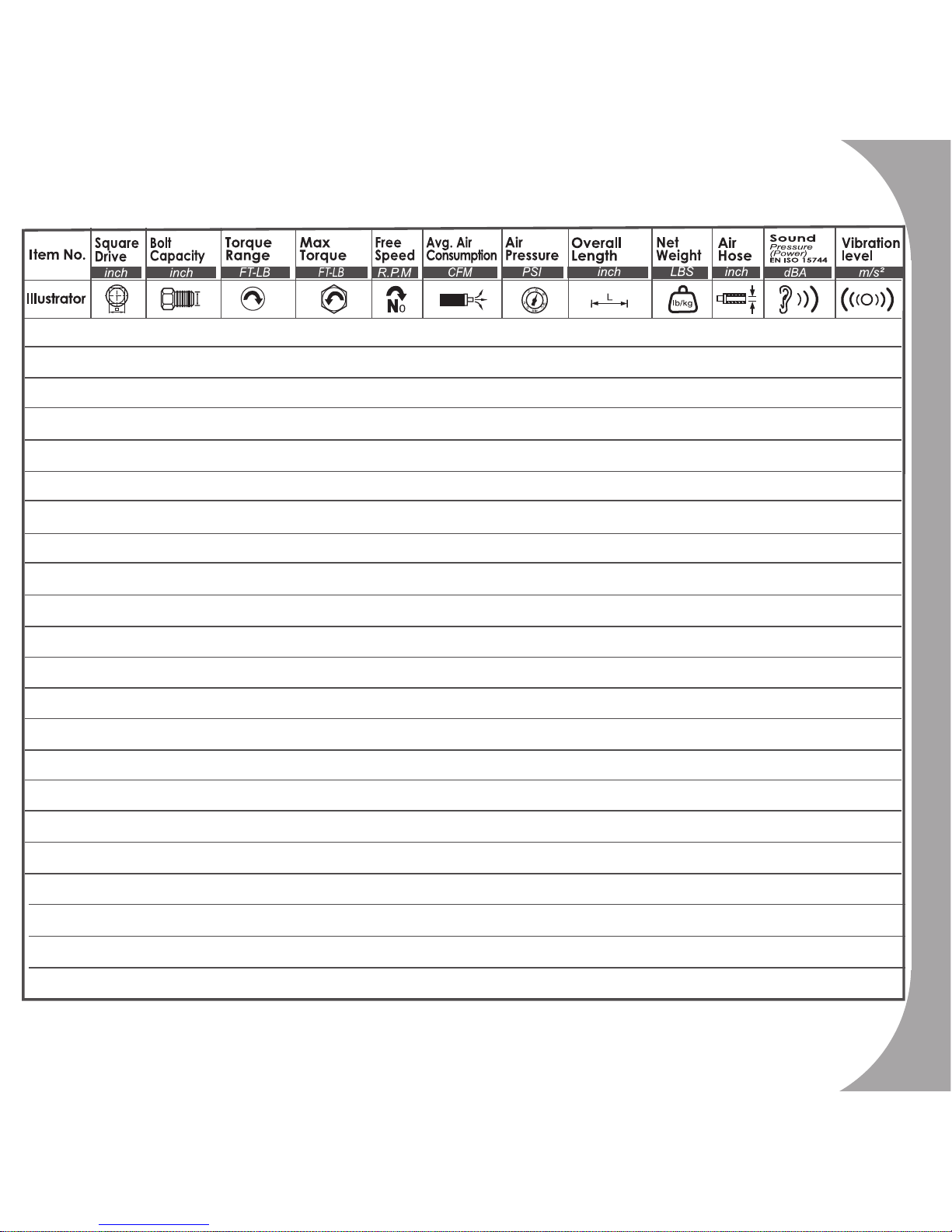

NC-3111 3/8" 1/2" 70-130 175 9000 4.0 90 6-7/16" 3.5 3/8" 93.3 4.1

NC-3210 3/8" 1/2" 100-300 430 10000 4.0 90 5-5/8" 3.3 3/8" 92.1 3.6

NC-3610Q 3/8" 1/2" 100-300 350 8000 4.4 90 4-9/16" 3.3 3/8" 85.0 2.8

NC-3611Q 3/8" 5/8" 100-300 350 10000 4.0 90 4-3/8" 3.3 3/8" 85.0 2.8

NC-4212 1/2" 5/8" 150-300 650 7000 4.0 90 7-13/64" 6.2 3/8" 86.1 3.7

NC-4222 1/2" 5/8" 150-300 650 7000 4.0 90 9-13/64" 6.6 3/8" 86.1 3.7

NC-4216 1/2" 5/8" 180-400 700 9000 4.2 90 7-3/4" 4.4 3/8" 93.9 4.5

NC-4226 1/2" 5/8" 180-400 700 9000 4.2 90 8-7/8" 4.8 3/8" 93.9 4.5

NC-4217 1/2" 5/8" 150-320 600 7000 4.2 90 7-1/4" 5.6 3/8" 92.1 3.7

NC-4230Q 1/2" 3/4" 180-500 700 6500 4.5 90 6-15/32" 5.5 3/8" 85.0 4.5

NC-4236Q 1/2" 1" 200-700 1000 7500 5.5 90 6-45/64" 5.7 3/8" 83.0 4.5

NC-4258 1/2" 5/8" 150-300 580 7000 4.2 90 7-1/4" 5.6 3/8" 93.2 4.4

NC-4610Q 1/2" 5/8" 200-350 500 9000 4.4 90 4-9/16" 3.52 3/8" 85.0 2.8

NC-4620Q 1/2" 5/8"

200-350 500 9000

4.4

90 6-9/16" 3.74 3/8" 85.0 2.8

NC-4611Q 1/2" 5/8" 200-350 450 10000 4.0 90 4-3/8" 3.3 3/8" 85.0 2.8

NC-6210Q 3/4" 3/4" 180-600 1200 6500 4.5 90 6-45/64" 5.61 3/8" 85.0 4.5

NC-6220 3/4" 3/4" 180-600 1200 6500 4.5 90 12-23/32" 5.61 3/8" 85.0 4.5

NC-6216 3/4" 1-1/16" 200-1000 1200 6000 6.0 90 9-1/4" 9.0 1/2" 91.2 5.0

NC-6236Q 3/4" 1" 200-700 1200 7500 6.0 90 6-45/64" 5.7 3/8" 83.0 4.5

NC-8216 1" 1-3/8" 200-1600 1800 6000 9.0 90 19-3/16" 18.48 1/2" 102.0 9.3

NC-8219 1" 1-7/16" 200-1600 1800 4000 11.0 90 12-13/32" 21.69 1/2" 103.4 16.7

NC-8351 1" 1-3/8" 200-1600 2000 4000 11.5 90 20" 27.6 1/2" 101.0 7.3

Uncertainty K=0.5a if a ≤ 5 m/s² or K=0.4a if a>5 m/s²

14

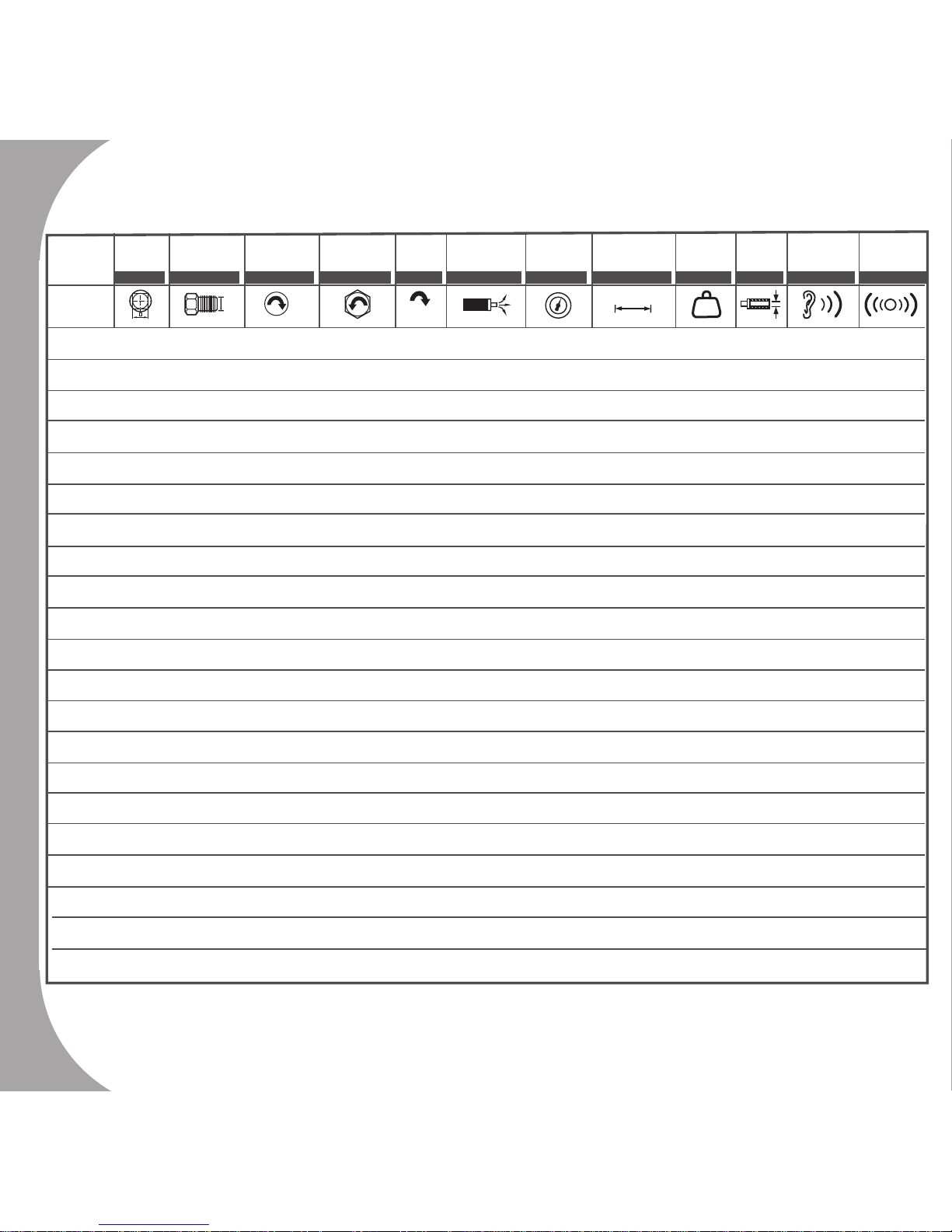

NC-3111 3/8" 13 95-176 237 9000 113 6.3 163 1.6 10 93.3 4.1

NC-3210 3/8" 13 136-407 583 10000 113 6.3 142 1.5 10 92.1 3.6

NC-3610Q 3/8" 13 136-407 474 8000 124 6.3 115.5 1.5 10 85.0 2.8

NC-3611Q 3/8" 13 136-407 474 10000 124 6.3 111 1.5 10 85.0 2.8

NC-4212 1/2" 16 203-407 881 7000 113 6.3 182 2.8 10 86.1 3.7

NC-4222 1/2" 16 203-407 881 7000 113 6.3 233 3.0 10 86.1 3.7

NC-4216 1/2" 16 244-542 949 9000 119 6.3 195 2.0 10 93.9 4.5

NC-4226 1/2" 16 244-542 949 9000 119 6.3 225 2.2 10 93.9 4.5

NC-4217 1/2" 16 203-434 814 7000 119 6.3 184 2.5 10 92.1 3.7

NC-4230Q 1/2" 19 244-678 949 6500 127 6.3 164 2.5 10 85.0 4.5

NC-4236Q 1/2" 25 271-949 1356 7500 155 6.3 171 2.6 10 83.0 4.5

NC-4258 1/2" 16 203-407 786 7000 119 6.3 185 2.5 10 93.2 4.4

NC-4610Q 1/2" 16 271-475 678 9000 124 6.3 115.5 1.6 10 85.0 2.8

NC-4620Q 1/2" 16

271-475 678 9000 124 6.3 166 1.7 10 85.0 2.8

NC-6210Q 3/4" 19 244-810 1627 6500 127 6.3 170 2.55 10 85.0 4.5

NC-6236Q 3/4" 25 271-949 1627 7500 155 6.3 171 2.6 10 83.0 4.5

NC-6220 3/4" 19 244-810 1627 7500 127 6.3 323 3.08 10 87.0 4.5

NC-6216 3/4" 27 271-1356 1627 6000 170 6.3 235 4.1 13 91.2 5.0

NC-8216 1" 33 271-2170 1800 6000 254 6.3 487 8.4 13 102.0 9.3

NC-8219 1" 36 271-2170 2441 4000 311 6.3 315 9.84 13 103.4 16.7

NC-8351 1" 33 200-1600 2712 4000 325 6.3 510 12.5 13 101.0 7.3

Cap.

Boulon

2

2

6

8

10

11

0

bar

Pression

Carré

cond

Tuyau

d'air

Couple

maxi

N

0

Vitesse

à vide

L

Longueur

lb/kg

Poids

Cons. D'air

moyenne

�

Couple

recommandé

DBA

EN ISO 15744

Niveau

sonore

�

Référence

Niveau de

vibration

inch mm Nm Nm R.P.M L/min bar mm kg mm dBA m/s²

Incertitude K=0.5a si a ≤ 5m/s² ou K=0.4a si a>5m/s²

15

2

2

6

8

10

11

0

bar

N

0

L

lb/kg

EN ISO 15744

inch� mm Nm Nm R.P.M L/min bar mm kg mm dBA m/s²

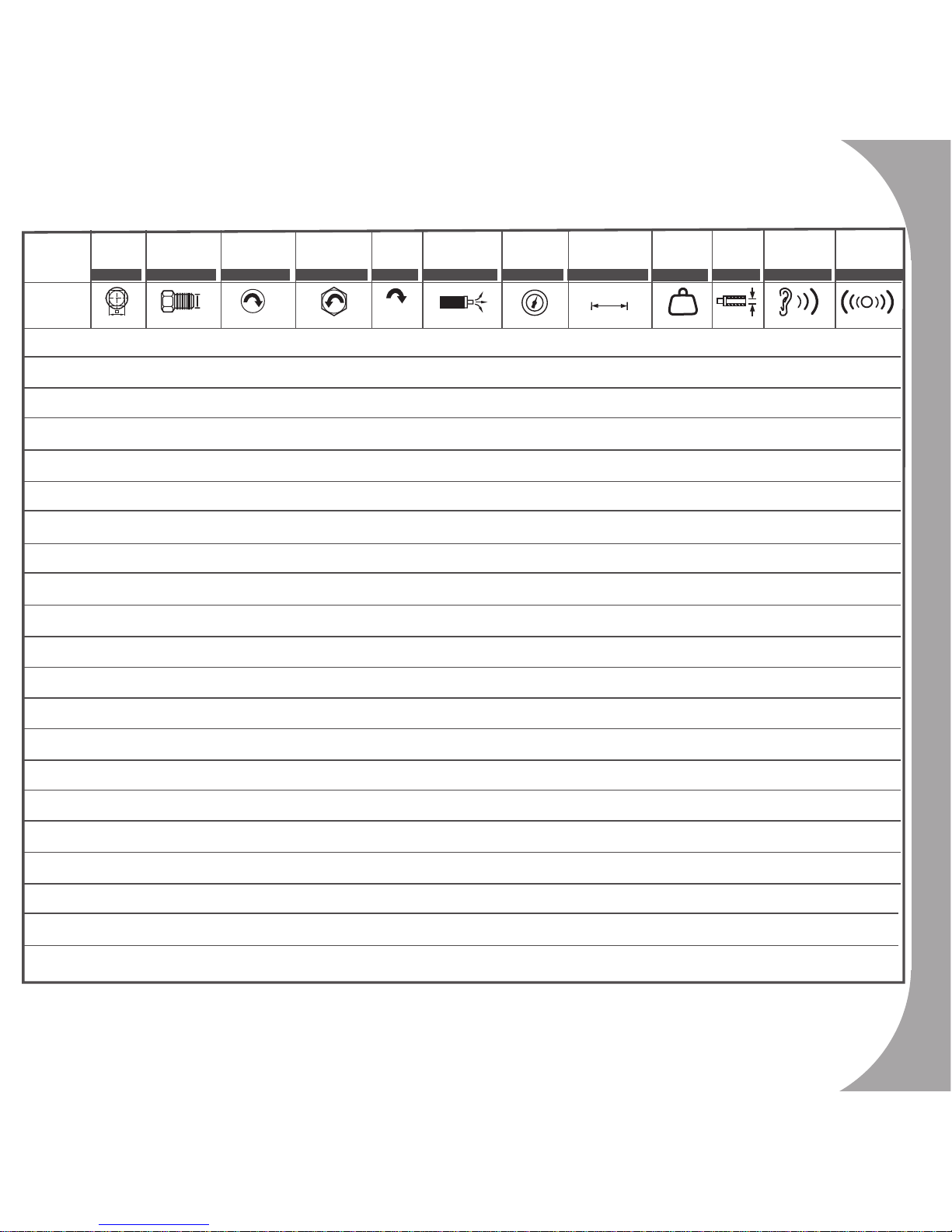

Nivel

de vibración

Modelo

Matriz

Cuadrada

Capacidad

de Perno

Rango

de Torque

Torque

Máximo

Velocidad

libre

Consumo de

Aire Promedio

Presión de

Aire

Longitud Total

Peso Neto

Manguera

de Aire

Presión Sonora

variable K=0.5a si a ≤ 5 m/s² ó K=0.4a si a>5 m/s²

NC-3111 3/8" 13 95-176 237 9000 113 6.3 163 1.6 10 93.3 4.1

NC-3210 3/8" 13 136-407 583 10000 113 6.3 142 1.5 10 92.1 3.6

NC-3610Q 3/8" 13 136-407 474 8000 124 6.3 115.5 1.5 10 85.0 2.8

NC-3611Q 3/8" 13 136-407 474 10000 113 6.3 111 1.5 10 85.0 2.8

NC-4212 1/2" 16 203-407 881 7000 113 6.3 182 2.8 10 86.1 3.7

NC-4222 1/2" 16 203-407 881 7000 113 6.3 233 3.0 10 86.1 3.7

NC-4216 1/2" 16 244-542 949 9000 119 6.3 195 2.0 10 93.9 4.5

NC-4226 1/2" 16 244-542 949 9000 119 6.3 225 2.2 10 93.9 4.5

NC-4217 1/2" 16 203-434 814 7000 119 6.3 184 2.5 10 92.1 3.7

NC-4230Q 1/2" 19 244-678 949 6500 127 6.3 164 2.5 10 85.0 4.5

NC-4236Q 1/2" 25 271-949 1356 7500 155 6.3 171 2.6 10 83.0 4.5

NC-4258 1/2" 16 203-407 786 7000 119 6.3 185 2.5 10 93.2 4.4

NC-4610Q 1/2" 16 271-475 678 9000 124 6.3 115.5 1.6 10 85.0 2.8

NC-4620Q 1/2" 16 271-475 678 9000 124 6.3 166 1.7 10 85.0

2.8

NC-6210Q 3/4" 19 244-810 1627 6500 127 6.3 170 2.55 10 85.0 4.5

NC-6236Q 3/4" 25 271-949 1627 7500 155 6.3 171 2.6 10 83.0 4.5

NC-6220 3/4" 19 244-810 1627 7500 127 6.3 323 3.08 10 87.0 4.5

NC-6216 3/4" 27 271-1356 1627 6000 170 6.3 235 4.1 13 91.2 5.0

NC-8216 1" 33 271-2170 1800 6000 254 6.3 487 8.4 13 102.0 9.3

NC-8219 1" 36 271-2170 2441 4000 311 6.3 315 9.84 13 103.4 16.7

NC-8351 1" 33 200-1600 2712 4000 325 6.3 510 12.5 13 101.0 7.3

16

EC DECLARATION OF CONFORMITY

.

Original Language

Serial Number: Please refer to the tool

Air Impact Wrench

Item No.:

NC-3111 NC-3210 NC-3610Q NC-4212 NC-4222 NC-4216 NC-4226 NC-4217

NC4230Q NC-4236Q NC-4258 NC-4610Q NC-6210Q NC-6220 NC-6236Q NC-6216 NC-8216

NC-8219 NC-8351

We declare under our own responsibility that the above machinery fulls all the

relevant provisions of Machinery Directive 2006/42/EC and its amendment and

is manufactured and tested according to the following standards:

EN ISO 11148-6 / EN ISO 15744 / EN ISO 28927-2

Declared in: Taichung, Taiwan

Dated:2013/06/01

Jonney Chen

Declared by: QA Manager

Manufacturer:

Mighty Seven International Co., Ltd.

No. 70-25, Ching Quang Rd., Wujih Dist.,

Taichung City, 41466 Taiwan

http://www.mighty-seven.com

Authorized contact, to compile the technical les :

King Tony France

3 Rue des imprimeurs ZI République Nord 1.

86000 POITIERS FRANCE

TEL:(+33) 5-49-30-30-90

E-MAIL:christian.aubineau@kingtony.eu

Signature

17

.

traduit de la langue originale

Numéro de série : se référer au numéro inscrit sur la machine

Clé à chocs

Référence:

NC-3111 NC-3210 NC-3610Q NC-4212 NC-4222 NC-4216 NC-4226 NC-4217 NC4230Q

NC-4236Q NC-4258 NC-4610Q NC-6210Q NC-6220 NC-6236Q NC-6216 NC-8216 NC-8219 NC-8351

Nous déclarons sous notre propre responsabilité que les outils sus mentionnés sont

conforme aux provisions relative à la directive outillage 2006/42/EC et ses

amendements

et qu’ils ont été fabriqués et testés selon les standards suivants :

EN ISO 11148-6 / EN ISO 15744 / EN ISO 28927-2

Déclaré à: Taichung, Taiwan

Date: 2013/06/01

Jonney Chen

Declared by: QA Manager

Fabricant:

Mighty Seven International Co., Ltd.

No. 70-25, Ching Quang Rd., Wujih Dist.,

Taichung City, 41466 Taiwan

http://www.mighty-seven.com

Personne autorisée pour établir les ches techniques:

King Tony France

3 Rue des imprimeurs ZI République Nord 1. 86000 POITIERS

FRANCE

TEL:(+33) 5-49-30-30-90

E-MAIL:christian.aubineau@kingtony.eu

Signature

18

.

Traducción del lenguaje original

Número de serie: por favor ver la herramienta

Llave de Impacto Neumática

Modelo :

NC-3111 NC-3210 NC-3610Q NC-4212 NC-4222 NC-4216 NC-4226 NC-4217 NC4230Q

NC-4236Q NC-4258 NC-4610Q NC-6210Q NC-6220 NC-6236Q NC-6216 NC-8216 NC-8219 NC-8351

Declaramos bajo nuestra propia responsabilidad que la maquinaria arriba

mencionada cumple con todas las provisiones relevantes de la Directiva de

Maquinaria 2006/42/EC y sus enmiendas y ha sido fabricado y probado de acuerdo

a los siguientes estándares:

EN ISO 11148-6 / EN ISO 15744 / EN ISO 28927-2

Declarado en: Taichung, Taiwan

Fecha: 2013/06/01

Jonney Chen

Declarado por: Gerente de Control de Calidad

Fabricante:

Mighty Seven International Co., Ltd.

No. 70-25, Ching Quang Rd., Wujih Dist.,

Taichung City, 41466 Taiwan

http://www.mighty-seven.com

Contacto Autorizado, para recopilar los archivos técnicos :

King Tony France

3 Rue des imprimeurs ZI République Nord 1. 86000 POITIERS

FRANCE

TEL:(+33) 5-49-30-30-90

E-MAIL:christian.aubineau@kingtony.eu

Firma

19

Mighty-Seven International Co., LTD, (M7), part of the global King Tony Tool Group,

offers a 12 months limited warranty on all products sold in the US and Canada through

King Tony America. The limited warranty applies to defects in material or workmanship

within the rst 12 months of ownership; it does not apply to products that have been

abused, misused, modied, disassembled or repaired by someone other than an M7

authorized repair center.

King Tony America reserves the right to conduct an inspection of any tool returned

for warranty consideration and will offer the owner of the tool a written evaluation if

warranty is denied for any reason. Specic exclusions to this warranty include certain

consumable (wear) items in every tool. All consumable items are clearly noted in the

parts list for each tool contained in this catalog. Other specific exclusions include

failure to properly oil the tool prior to use and using excessive air pressure to operate

the tool. All implied warranties, including but not limited to the implied warranties of

merchantability or tness for a particular purpose are also specically excluded.

In no event shall King Tony America be liable for consequential, incidental, or specic

damages resulting from or in any manner related to the product, its design, use or

any inability use the same. The sole and exclusive remedy with respect to a defective

product shall be the repair, or replacement of the tool.

For assistance with a warranty claim or for the name of the M7 authorized warranty

repair center nearest you please email: sales@kingtonyamerica.com; or call King Tony

America at +1 561.699.3190 between the hours of 8AM and 5PM, Pacic Time.

Warranty Policy

20

Mighty-Seven International Co., LTD, (M7), membre du groupe King Tony Tools Group, offre

une garantie de 12 mois sur tous les produits vendus aux Etats Unis et au Canada via King

Tony America. Cette garantie s’applique sur les défauts de fonctionnement et de fabrication

pendant les 12 mois suivant l’achat. Cette garantie ne s’applique pas pour les mauvaises

utilisations du produit, ainsi que pour les produits modifiés, démontés ou réparés par un

intervenant autre qu’un centre de réparation agréé par M7.

King Tony America se réserve le droit de procéder à une inspection de chaque produit qui

nous sera retourné an de déterminer si la garantie est applicable, et enverra une évaluation

écrite au propriétaire dans le cas ou la garantie est refusée. Les exceptions spéciques à

cette garantie comprennent l’usure des parties consommables dans chaque outil. Toutes

les parties consommables sont clairement indiquées dans la liste des pièces composant

chaque outil, contenue dans ce catalogue. Les autres exceptions spéciques comprennent

les disfonctionnements liés à l’omission d’huiler correctement l'outil avant utilisation, ainsi

que les disfonctionnements liés à une pression d'air excessive durant l’utilisation. Un produit

défectueux suite à une utilisation contraire à sa fonction ne pourra être pris en garantie.

King Tony America ne peut en aucun cas se tenir responsable des conséquences liées à la

mauvaise utilisation de ses produits. L’unique et exclusive solution en ce qui concerne un

produit défectueux sera la réparation, ou le remplacement de l'outil.

Pour une assistance concernant une demande de garantie dans un centre de réparation

M7 autorisé, veuillez contacter par mail : sales@kingtonyamerica.com ou appeler King Tony

America au +1 561.699.3190 (horaires : 8h-17h, heure Pacique).

Garantie

21

Mighty-Seven International Co., LTD, (M7) parte del Grupo Global de Herramientas de King Tony

ofrece una garantía limitada de 12 meses en todos los productos vendidos en los Estados Unidos y

Canadá a través de King Tony America.

La garantía limitada se aplica a defectos de materiales o a la mano de obra en la manufacturación

dentro de los primeros 12 meses de compra, no se aplica a productos que han sido maltratados,

mal usado, modicados, desarmado o reparado por alguien que no sea un centro de reparación

autorizado M7.

King Tony America se reserva el derecho a realizar una inspección de cualquier herramienta

devuelta a la consideración de garantía y se ofrecera una evaluación por escrita al propietario de la

herramienta si la garantía es negada por cualquier motivo.

Las exclusiones especícas de esta garantía incluyen ciertos respuestos consumibles (desgaste) en

cada herramienta.

Todos los respuestos consumibles se señalan claramente en la lista de piezas para cada

herramienta contenida en este catálogo.

Otras exclusiones especícas incluyen falta de aceite correctamente antes de uso y utilizando la

presión de aire excesivo para operar la herramienta.

Especicamente se excluyen todas las garantias implicitas, incluyendo pero no limitandose a las

garantias implicitas de comerciabilidad o idóneas para un proposito particular estan especicamente

excluidas.

En ningún caso King Tony America será responsable de consecuencias incidentales o daños

especificos resultantes o de cualquier manera relacionada con el producto, su diseño, uso o

cualquier incapacidad de utilizar el mismo.

El unico y exclusivo recurso con respecto al producto defectuoso sera la reparación o sustitución de

la herramienta.

Para obtener asistencia con un reclamación de garantía o para buscar el centro de servicio

autorizado M7 de reparación de garantía más cercano.

envíe un correo electrónico: sales@kingtonyamerica.com,

o llame a King Tony América por teléfono 561.699.3190, 561.699.3190

entre las 8 AM y 17:00 horas, tiempo del Pacíco.

Póliza de Garantía

22

3/8" Air lmpact Wrench

ltem No:NC-3111

The consumable parts The replacement parts The non-replacement parts

23

NC-3111

Pin Clutch Type

No Part No Description Q'ty

1 --- Oil Seal 1

2 NC-3111T02 Cap Bolt (8pcs) 1set

3 NC-3111P03 O-Ring 1

4 --- Clutch Housing 1

5 NC-3111P05 O-Ring 1

6 NC-3111P06 Exhaust Deector 1

7 NC-3111P07 Motor Housing 1

8 --- Anvil Bushing 1

9 NC-3111P09 Set Screw 1

10 NC-3111P10 Spring Pin 1

11 NC-3111P11 Trigger 1

12 NC-3111P12 Push Pin 1

13 NC-3111P13 O-Ring 1

14 NC-3111P14 Pin 1

15 NC-3111P15 Spring 1

16 NC-3111P16 Spring Pin 1

17 NC-3111P17 O-Ring 1

18 NC-3111P18 Speed Regulator 1

22 NC-3111P22 Conical Spring 1

23 NC-3111P23 Air Inlet Bushing 1

24 NC-3111P24 Reverse Valve 1

25 --- O-Ring 1

26 NC-3111P26 Spacer 1

27 --- Retaining Ring 1

No Part No Description Q'ty

28 --- Anvil 1

29 NC-3111P29 Spring 1

30 NC-3111P30 Hammer Cam 1

31 NC-3111P31 Steel Ball 1

32 NC-3111P32 Cam Bolt Pilot 1

33 NC-3111P33 Hammer Cage 1

34 NC-3111T34 Rotor Blade (6pcs) 1set

35 NC-3111P35 Rotor 1

36 NC-3111P36 Ball Bearing 1

37 NC-3111P37 Oil Seal 1

38 NC-3111P38 O-Ring 1

39 NC-3111P39 Cylinder 1

40 NC-3111T40 Spring Pin (2pcs) 1set

41 NC-3111P41 Rear End Plate 1

42 NC-3111P42 Ball Bearing 1

43 NC-3111P43 Rear Gasket 1

47 NC-3111P47 Rear Cover 1

48 NC-3111T48 Hammer Pin (2pcs) 1set

49 NC-3111P49 Front End Plate 1

50 NC-3111P50 Rubber Grip 1

52 NC-3111P52 Valve Stem 1

NC-3111T01 Anvil Ass'y (25.27.28) 1set

NC-3111T03

Clutch Housing Ass'y

(01.04.08)

1set

24

3/8" Air lmpact Wrench

ltem No:NC-3210

The consumable parts The replacement parts The non-replacement parts

33

25

NC-3210

Twin Hammer Type

No Part No Description Q'ty

1 NC-3210T01 Cap Bolt (8pcs) 1set

2 --- Clutch Housing 1

3 --- Anvil Bushing 1

4 NC-3210P04 O-Ring 1

5 --- Retainer Ring 1

6 --- Retainer O-Ring 1

7 --- Anvil 1

8 NC-3210T08 Hammer Pin (2pcs) 1set

9 NC-3210P09 Hammer Cage 1

10 NC-3210T10 Hammer (2pcs) 1set

11 NC-3210P11 Motor Housing 1

12 NC-3210P12 Trigger 1

13 NC-3210P13 Throttle Bushing 1

14 NC-3210P14 Valve Stem 1

15 NC-3210P15 Conical Spring 1

16 NC-3210P16 Exhaust Deector 1

17 NC-3210P17 Spring 1

18 NC-3210P18 Ball Bearing 1

19 NC-3210P19 Front End Plate 1

20 NC-3210P20 Cylinder 1

21 NC-3210P21 Cylinder Dowel 1

22 NC-3210P22 Rotor 1

23 NC-3210T23 Rotor Blade (6pcs) 1set

24 NC-3210P24 Rear End Plate 1

25 NC-3210P25 Ball Bearing 1

26 NC-3210P26 Rear Gasket 1

27 NC-3210P27 Rear Cover 1

28 NC-3210P28 Retainer 1

29 NC-3210P29 O-Ring 1

30 NC-3210P30 Reverse Valve 1

31 NC-3210P31 Spring 1

32 NC-3210P32 Detent Pin 1

NC-3210T02 Clutch Housing Ass'y (02.03) 1set

NC-3210T07 Anvil Ass'y (05.06.07) 1set

33 NC-3210T33 Rubber Grip 1

26

3/8" Air lmpact Wrench

ltem No:NC-3610Q

The consumable parts The replacement parts The non-replacement parts

27

NO. PART NO. DESCRIPTION Q'TY

22 NC-3610P22 Spring 1

23 NC-3610P23 Steel Ball 1

24 NC-3610P24 Throttle Valve Seat 1

25 NC-3610T25

Throttle Valve Assembly

(25-1, 25-2 )

1 set

25-1 --- Throttle Valve Pin 1

25-2 --- Throttle Valve 1

26 NC-3610P26 Spring 1

27 NC-3610P27 Exhaust Deector 1

28 NC-3610P28 Air Inlet 1

29 --- Socket Retainer 1

30 NC-3610P30 Trigger 1

31 NC-3610P31 Trigger Pin 1

32 NC-3610P32 Bushing 1

33 NC-3610T33 Screw (4pcs) 1 set

34 NC-3610T34 Washer (4pcs) 1 set

35 NC-3610T35 Screw (4pcs) 1 set

36 NC-3610T36 Washer (4pcs) 1 set

37 NC-3610P37 O-Ring 1

38 NC-3610T38 Mufer Element (3pcs) 1 set

39 NC-3610P39 Rubber Grip 1

40 --- O-Ring 1

NC-3610T11

Standard Anvil Ass'y

(11, 29, 40)

1 set

NO. PART NO. DESCRIPTION Q'TY

1 NC-3610T01 Housing Ass'y (1, 1-1) 1 set

1-1 --- Screw 1

2 NC-3610P02 Backhead 1

3 NC-3610P03 Cylinder 1

4 NC-3610P04 Rotor 1

5 NC-3610T05 Rotor Blade (6pcs) 1 set

6 NC-3610P06 Rear End Plate 1

7 NC-3610P07 Ball Bearing 1

8 NC-3610P08 Front End Plate 1

9 NC-3610P09 Ball Bearing 1

10 NC-3610P10 Hammer Frame 1

11 --- Standard Anvil 1

12 NC-3610P12 Hammer 1

13 NC-3610T13 Hammer Pin (2 pcs) 1 set

14 NC-3610P14 Gasket 1

15 NC-3610P15 Reverse Valve 1

16 NC-3610P16 Hammer Case 1

17 NC-3610P17 Gasket 1

18 NC-3610P18 Spring Pin 1

19 NC-3610P19 Spring Pin 1

20 NC-3610P20 O-Ring 1

21 NC-3610P21 Retainer 1

NC-3610Q

Jumbo Hammer Type

28

3/8" Air lmpact Wrench

ltem No:NC-3611Q

The consumable parts The replacement parts The non-replacement parts

39

29

NC-3611Q

Jumbo Hammer Type

NO. INDEX NO. DESCRIPTION Q'TY

1 NC-3611P01 Motor Housing 1

2 NC-3611P02 Throttle Valve Seal 1

4 NC-3611P04 Throttle Valve Stem 1

5 NC-3611P05 Spring 1

6 NC-3611P06

1

7 NC-3611P07 Air Inlet Bushing 1

8 NC-3611P08 Spring 1

9 NC-3611P09 Trigger 1

10 NC-3611T10 Screw ( 8pcs ) 1 set

12 NC-3611T12 Hammer Case Assembly ( 12.14 ) 1 set

13 NC-3611P13 O-Ring 1

14 - Bushing 1

15 NC-3611P15 O-Ring 1

16 NC-3611P16 Retaining Ring 1

17 NC-3611T17 Anvil Assembly ( 15.16.17 ) 1 set

18 NC-3611T18 Hammer Pin ( 2pcs ) 1 set

19 NC-3611P19 Hammer 1

20 NC-3611P20 Hammer Cage 1

21 NC-3611P21 Ball Bearing 1

22 NC-3611P22 Front Plate 1

23 NC-3611P23 Rotor 1

24 NC-3611T24 Rotor Blade ( 6pcs ) 1 set

25 NC-3611P25 Cylinder 1

26 NC-3611P26 Cylinder Pin 1

27 NC-3611P27 Rear Plate 1

28 NC-3611P28 Ball Bearing 1

29 NC-3611P29 Gasket 1

30 NC-3611P30 Rear Cover 1

31 NC-3611P31 O-Ring 1

32 NC-3611P32 E-Retaining Ring 1

33 NC-3611P33 Reverse Valve 1

34 NC-3611P34 Spring 1

35 NC-3611P35 Steel Ball 1

37 NC-3611P37 Rubber Grip 1

38 NC-3611T38

1 set

39 NC-3611P39 Washer 1

30

1/2" Air lmpact Wrench

ltem No:NC-4212 NC-4222

The consumable parts The replacement parts The non-replacement parts

31

NC-4212 NC-4222

Twin Hammer Type

No Part No Description Q'ty

1 NC-4212P01 Air Inlet Bushing 1

2 NC-4212P02 Conical Spring 1

3 --- Throttle Valve 1

4 --- Throttle Valve Stem 1

5 NC-4212P05 Throttle Bushing 1

6 --- Trigger Stem 1

7 NC-4212P07 Exhaust Deector 1

8 --- Trigger 1

9 NC-4212P09 Reverse valve Knob 1

10 --- Reverse Valve Bushing 1

11 NC-4212T11 O-Ring (2pcs) 1set

12 --- Motor Housing 1

13 NC-4212P13 Speed Regulator 1

14 NC-4212P14 Screw 1

15 NC-4212P15 Steel Ball 1

16 NC-4212P16 Spring 1

17 --- Grease Inlet 1

18 NC-4212P18 Front Gasket 1

19 NC-4212P19 Retainer 1

20 NC-4212P20 Rear Gasket 1

20A NC-4212P20A O-Ring 1

21 NC-4212T21 Cap Bolt (4pcs) 1set

22 NC-4212P22 Ball Bearing 1

23 NC-4212P23 Rear End Plate 1

24 NC-4212P24 Cylinder 1

25 NC-4212P25 Rotor 1

No Part No Description Q'ty

26 NC-4212T26 Rotor Blade (6pcs) 1set

27 NC-4212P27 Front End Plate 1

28 NC-4212P28 Cylinder Dowel 1

29 NC-4212P29 Ball Bearing 1

31 NC-4212P31 Separator 1

32 NC-4212P32 Hammer Cage 1

33 NC-4212T33 Hammer (2pcs) 1set

34 NC-4212T34 Hammer Pin (2pcs) 1set

35 --- Anvil 1

35A --- 2" Anvil 1

36 --- O-Ring 1

37 --- Retaining Ring 1

38 NC-4212P38 Washer 1

39 NC-4212T39

Motor Clamp Washer

(2pcs)

1set

40 NC-4212P40 Clutch Housing 1

41 NC-4212P41 Anvil Bushing 1

46 --- Speed Indicator Ring 1

48 NC-4212P48 Trigger Retainer 1

49 NC-4212P49 Screw 1

50 --- Heli-Coil (4pcs) 1set

51 NC-4212P51 Mufer Element 1

NC-4212T01

Throttle Valve Ass'y

(03.04)

1set

NC-4212T02 Trigger Ass'y (06.08) 1set

NC-4212T03

Motor Housing Ass'y

(10.12.17.46.50)

1set

NC-4212T04 Anvil Ass'y (35.36.37) 1set

NC-4212T04A

2" Anvil Ass'y (35A.36.37)

(NC-4222)

1set

32

40

1/2" Air lmpact Wrench

ltem No:NC-4216 NC-4226

The consumable parts The replacement parts The non-replacement parts

33

No. Part No. Description Q'ty

22 NC-4216P22 O-Ring 1

23 NC-4216P23 Oil Seal 1

24 NC-4216P24 Cylinder 1

25 NC-4216P25 Spring Pin 1

26 NC-4216P26 Rotor 1

27 NC-4216T27 Rotor Blade (6pcs) 1set

28 NC-4216P28 Rear End Plate 1

29 NC-4216P29 Ball Bearing 1

30 NC-4216T30 Pin (2pcs) 1set

31 NC-4216T31 Spring (2pcs) 1set

32 NC-4216P32 O-Ring 1

33 NC-4216P33 Rear Gasket 1

34 NC-4216P34 Rear Cover 1

35 NC-4216T35 Cap Bolt (4pcs) 1set

36 NC-4216P36 Reverse Valve 1

37 NC-4216P37 O-Ring 1

38 NC-4216P38 Washer 1

39 NC-4216P39 Reverse Lever 1

40 NC-4216P40 Mufer Element 1

NC-4216T01

Clutch Housing Ass'y

(01.02.03)

1set

NC-4216T02 Anvil Ass'y (06.07.08) 1set

NC-4216T02A

2" Anvil Ass'y (06.07.08A)

(NC-4226)

1set

No. Part No. Description Q'ty

01 --- Oil Seal 1

02 --- Clutch Housing 1

03 --- Anvil Bushing 1

04 NC-4216P04 Front Gasket 1

05 NC-4216P05 Motor Housing 1

06 --- O-Ring 1

07 --- Retaining Ring 1

08 --- Anvil 1

08A --- 2" Anvil (NC-4226) 1

09 NC-4216P09 Hammer Cage 1

10 NC-4216T10 Hammer Pin (2pcs) 1set

11 NC-4216P11 Washer 1

12 NC-4216P12 Trigger 1

13 NC-4216P13 O-Ring 1

14 NC-4216T14 Hammers (2pcs) 1set

15 NC-4216P15 Washer 1

16 NC-4216P16 Valve Stem 1

17 NC-4216P17 Conical Spring 1

18 NC-4216P18 Exhaust Deector 1

19 NC-4216P19 O-Ring 1

20 NC-4216P20 Air Inlet Bushing 1

21 NC-4216P21 Ball Bearing 1

NC-4216 NC-4226

Twin Hammer Type

34

1/2" Air lmpact Wrench

ltem No:NC-4217

1

2

3

4

5

6

7

8

9

11

10

12

13

15

14

16

17

18

19

20

21

22

23

24

25

26

28

29

30

31

32

33

35

36

37

38

39

34

The consumable parts The replacement parts The non-replacement parts

40

35

NO. INDEX NO. DESCRIPTION Q'ty

1 NC-4217S01 Screw (3pcs) 1set

2 NC-4217R02 Clutch Housing 1

3 NC-4217R03 Bushing 1

4 NC-4217R04 Front Gasket 1

5 NC-4217R05 Separator 1

6 --- Retaining Ring 1

7 --- O-Ring 1

8 --- Anvil for NC-4217 1

9 NC-4217S09 Hammer Pin(2pcs) 1set

10 NC-4217S10 Hammer(2pcs) 1set

11 NC-4217R11 Hammer Cage 1

12 NC-4217R12 Washer 1

13 NC-4217S13 Motor Clamp Washer(2pcs) 1set

14 NC-4217R14 Cylinder Dowel 1

15 NC-4217R15 Ball Bearing 1

16 NC-4217R16 Front End Plate 1

17 NC-4217R17 Cylinder 1

18 NC-4217R18 Rotor 1

19 NC-4217S19 Rotor Balde(6pcs) 1set

20 NC-4217R20 Rear End Plate 1

21 NC-4217R21 Ball Bearing 1

22 NC-4217R22 Retainer 1

23 NC-4217R23 Rear Gasket 1

24 NC-4217R24 Motor Housing 1

25 NC-4217R25 Screw 1

26 NC-4217R26 Speed Regulator 1

28 NC-4217R28 Reverse Valve Bushing 1

29 NC-4217S29 O-Ring(2pcs) 1set

30 NC-4217R30 Reverse Valve Knob 1

31 NC-4217R31 Spring 1

32 NC-4217R32 Steel Ball 1

33 NC-4217R33 Trigger 1

34 NC-4217R34 Trrigger Retainer 1

35 NC-4217R35 Throttle Valve Seat 1

36 NC-4217R36 Valve Stem 1

37 NC-4217R37 Conical Spring 1

38 NC-4217R38 Exhaust Deector 1

39 NC-4217R39 Air Inlet Bushing 1

NC-4217S08 Anvil Ass'y (06,07,08) 1set

40 NC-4217R40 Rubber Grip 1

NC-4217

Twin Hammer Type

36

1/2" Air lmpact Wrench

ltem No:NC-4230Q NC-4240Q

The consumable parts The replacement parts The non-replacement parts

35

36

37

NC-4230Q NC-4240Q

Twin Hammer Type

No Part No Description Q'ty

1 NC-4230T01 Cap Bolt (8pcs) 1 Set

2 --- Clutch Housing 1

3 --- Anvil Bushing 1

4 NC-4230P04 O-Ring 1

5 --- Retainer Ring 1

6 --- Retainer O-Ring 1

7 --- Anvil 1

8 NC-4230T08 Hammer Pin (2pcs) 1 Set

9 NC-4230P09 Hammer Cage 1

10 NC-4230T10 Hammer Dog (2pcs) 1 Set

11 NC-4230P11 Motor Housing 1

12 NC-4230P12 Trigger 1

13 NC-4230P13 Trigger Retainer 1

14 NC-4230P14 Screw 1

15 NC-4230P15 Throttle Bushing 1

16 NC-4230P16 Valve Stem 1

17 NC-4230P17 Spring 1

18 NC-4230P18 Exhaust Deector 1

19 NC-4230P19 Air Inlet Bushing 1

20 NC-4230P20 Ball Bearing 1

No Part No Description Q'ty

21 NC-4230P21 Front End Plate 1

22 NC-4230P22 Cylinder 1

23 NC-4230P23 Cylinder Pin 1

24 NC-4230P24 Rotor 1

25 NC-4230T25 Rotor Blade (6pcs) 1 Set

26 NC-4230P26 Rear Plate 1

27 NC-4230P27 Ball Bearing 1

28 NC-4230P28 Gasket 1

29 NC-4230P29 Rear Cover 1

30 NC-4230P30 O-Ring 1

31 NC-4230P31 Reverse Valve 1

32 NC-4230P32 Spring 1

33 NC-4230P33 Steel Ball 1

34 NC-4230P34 Retainer 1

35 NC-4230P35 Mufer Element (for 4230Q) 1 pc

36 NC-4230P36 Grip 1

NC-4230T02 Clutch Housing Ass'y (02.03) 1 Set

NC-4230T07 Anvil Ass'y (05.06.07) 1 Set

NC-4230T07A

2" Anvil Ass'y (05.06.07A)

(NC-4240)

1 Set

38

1/2" Air lmpact Wrench

ltem No:NC-4236Q NC-4246Q

The consumable parts The replacement parts The non-replacement parts

1

32

33

31

29

28

34

30

12

11

26

24

27

25

21

20

1

2

3

4

5

6

8

9

10

10

16

17

18

19

13

14

22

23

15

7A

7

35

36

39

NC-4236Q NC-4246Q

Twin Hammer Type

NO. INDEX NO. DESCRIPTION Q'TY

01 NC-4236T01 Cap Bolt (8pcs) 1set

02 - Clutch Housing 1

03 - Anvil Bushing 1

04 NC-4236P04 O-Ring 1

05 - Retainer Ring 1

06 - Retainer O-Ring 1

07 - Anvil 1

08 NC-4236T08 Hammer Pin (2pcs) 1set

09 NC-4236P09 Hammer Cage 1

10 NC-4236T10 Hammer Dog (2pcs) 1set

11 NC-4236P11 Motor Housing 1

12 NC-4236P12 Trigger 1

13 NC-4236P13 Trigger Retainer 1

14 NC-4236P14 Screw 1

15 NC-4236P15 Throttle Bushing 1

16 NC-4236P16 Valve Stem 1

17 NC-4236P17 Spring 1

18 NC-4236P18 Exhaust Deector 1

19 NC-4236P19 Air Inlet Bushing 1

20 NC-4236P20 Ball Bearing 1

21 NC-4236P21 Front End Plate 1

22 NC-4236P22 Cylinder 1

23 NC-4236P23 Cylinder Pin 1

24 NC-4236P24 Rotor 1

25 NC-4236T25 Rotor Blade (6pcs) 1set

26 NC-4236P26 Rear Plate 1

27 NC-4236P27 Ball Bearing 1

28 NC-4236P28 Gasket 1

NO. INDEX NO. DESCRIPTION Q'TY

29 NC-4236P29 Rear Cover 1

30 NC-4236P30 O-Ring 1

31 NC-4236P31 Reverse Valve 1

32 NC-4236P32 Spring 1

33 NC-4236P33 Steel Ball 1

34 NC-4236P34 Retainer 1

35 NC-4236P35

Mufer Element (4236Q)

1pc

36 NC-4236P36

Grip

1

NC-4236T02

Clutch Housing

Assembly (02.03)

1set

NC-4236T07

Anvil Assembly

(05.06.07)

1set

NC-4236T07A

2"Anvil Assembly

(05.06.07A)(NC-4246)

1set

40

1/2" Air lmpact Wrench

ltem No:NC-4258

42

37

34

45

40

44

43A

41

35

24

30

33

36

27

6

39

31

10

38

14

13

12

11

18

26

22

19

9

8

11

23

25

32

7

5

3

4

2

17

15

1

16

29

The consumable parts The replacement parts The non-replacement parts

41

NC-4258

NO. PART NO. DESCRIPTION Q'ty

1 --- Housing 1

2 NC-4258P02 Throttle Valve 1

3 NC-4258P03 O-Ring 1

4 NC-4258P04 Spring 1

5 NC-4258P05 Throttle Valve Plunger 1

6 NC-4258P06 Air Inlet 1

7 --- Throttle Valve Seat 1

8 NC-4258P08 Trigger 1

9 NC-4258P09 Trigger Pin 1

10 --- Reverse Valve Bushing 1

11 NC-4258T11 O-Ring (2PCS) 1 set

12 NC-4258P12 Reverse Valve 1

13 NC-4258P13 Steel Ball 1

14 NC-4258P14 Spring 1

15 NC-4258P15 Reverse Valve Knob 1

16 NC-4258P16 Screw 1

17 --- Grease Fitting 1

18 ---

Reverse Valve Bushing

Gear

1

19 --- Set Screw 1

22 NC-4258P22 Rotor 1

23 NC-4258P23 Ball Bearing 1

24 NC-4258P24 Ball Bearing 1

NO. PART NO. DESCRIPTION Q'ty

25 NC-4258P25 Retainer 1

26 NC-4258P26 Cylinder 1

27 NC-4258P27 Cylinder Dowel 1

29 NC-4258T29 Rotor Blade (6PCS) 1 set

30 NC-4258P30 Front End Plate 1

31 NC-4258P31 Rear End Plate 1

32 NC-4258P32 Gasket 1

33 NC-4258T33

Motor Clamp Washer

(2PCS)

1 set

34 NC-4258P34 Hammer Frame 1

35 NC-4258T35 Hammer Pin (2PCS) 1 set

36 NC-4258P36 Washer 1

37 NC-4258T37 Hammer (2PCS) 1 set

38 NC-4258P38 Hammer Case 1

39 NC-4258P39 Gasket 1

40 NC-4258P40 Bushing 1

41 NC-4258T41 Screw (3PCS) 1 set

42 NC-4258P42 Separator 1

43A ---

Standard Anvil

(for NC-4258)

1

44 --- Socket Retainer 1

45 --- O-Ring 1

NC-4258T01

Housing Assembly

(1,7,10,17,18,19)

1 set

NC-4258T43A

Standard Anvil Ass'y

(43A, 44, 45)

1 set

42

1/2" Air lmpact Wrench

ltem No:NC-4610Q \ NC-4620Q

The consumable parts The replacement parts The non-replacement parts

A

43

NC-4610Q\ NC-4620Q

NO. PART NO. DESCRIPTION Q'ty

1 NC-4610T01 Housing Ass'y (1, 1-1) 1set

1-1 --- Screw 1

2 NC-4610P02 Backhead 1

3 NC-4610P03 Cylinder 1

4 NC-4610P04 Rotor 1

5 NC-4610T05 Rotor Blade (6pcs) 1set

6 NC-4610P06 Rear End Plate 1

7 NC-4610P07 Ball Bearing 1

8 NC-4610P08 Front End Plate 1

9 NC-4610P09 Ball Bearing 1

10 NC-4610P10 Hammer Frame 1

11 NC-4610T11

Standard Anvil Ass'y

(11, 29, 40)

1set

11A

NC-4620HT11A

2" Ext. Anvil Ass'y

(11A, 29, 40)

1 set

12 NC-4610P12 Hammer 1

13 NC-4610T13 Hammer Pin (2 pcs) 1set

14 NC-4610P14 Gasket 1

15 NC-4610P15 Reverse Valve 1

16 NC-4610P16 Hammer Case 1

17 NC-4610P17 Gasket 1

18 NC-4610P18 Spring Pin 1

19 NC-4610P19 Spring Pin 1

20 NC-4610P20 O-Ring 1

21 NC-4610P21 Retainer 1

NO. PART NO. DESCRIPTION Q'ty

22 NC-4610P22 Spring 1

23 NC-4610P23 Steel Ball 1

24 NC-4610P24 Throttle Valve Seat 1

25 NC-4610T25

Throttle Valve

Assembly (25-1, 25-2 )

1set

25-1 --- Throttle Valve Pin 1

25-2 --- Throttle Valve 1

26 NC-4610P26 Spring 1

27 NC-4610P27

1

28 NC-4610P28 Air Inlet 1

29 --- Socket Retainer 1

30 NC-4610P30 Trigger 1

31 NC-4610P31 Trigger Pin 1

32 NC-4610P32 Bushing 1

33 NC-4610T33 Screw (4pcs) 1set

34 NC-4610T34 Washer (4pcs) 1set

35 NC-4610T35 Screw (4pcs) 1set

36 NC-4610T36 Washer (4pcs) 1set

37 NC-4610P37 O-Ring 1

38 NC-4610T38

1set

39 NC-4610P39 Rubber Grip 1

40 --- O-Ring 1

Jumbo Hammer Type

44

39

1/2" Air lmpact Wrench

ltem No:NC-4611Q

The consumable parts The replacement parts The non-replacement parts

6

28

1

9

8

23

17

15

16

13

14

12

27

19

37

18

24

7

5

2

29

30

35

34

33

32

31

10

26

25

22

21

10

20

4

38

45

NC-4611Q

Jumbo Hammer Type

NO. INDEX NO. DESCRIPTION Q'TY

1 NC-4611P01 Motor Housing 1

2 NC-4611P02 Throttle Valve Seal 1

4 NC-4611P04 Throttle Valve Stem 1

5 NC-4611P05 Spring 1

6 NC-4611P06

1

7 NC-4611P07 Air Inlet Bushing 1

8 NC-4611P08 Spring 1

9 NC-4611P09 Trigger 1

10 NC-4611T10 Screw ( 8pcs ) 1 set

12 NC-4611T12 Hammer Case Assembly ( 12.14 ) 1 set

13 NC-4611P13 O-Ring 1

14 - Bushing 1

15 NC-4611P15 O-Ring 1

16 NC-4611P16 Retaining Ring 1

17 NC-4611T17 Anvil Assembly ( 15.16.17 ) 1 set

18 NC-4611T18 Hammer Pin ( 2pcs ) 1 set

19 NC-4611P19 Hammer 1

20 NC-4611P20 Hammer Cage 1

21 NC-4611P21 Ball Bearing 1

22 NC-4611P22 Front Plate 1

23 NC-4611P23 Rotor 1

24 NC-4611T24 Rotor Blade ( 6pcs ) 1 set

25 NC-4611P25 Cylinder 1

26 NC-4611P26 Cylinder Pin 1

27 NC-4611P27 Rear Plate 1

28 NC-4611P28 Ball Bearing 1

29 NC-4611P29 Gasket 1

30 NC-4611P30 Rear Cover 1

31 NC-4611P31 O-Ring 1

32 NC-4611P32 E-Retaining Ring 1

33 NC-4611P33 Reverse Valve 1

34 NC-4611P34 Spring 1

35 NC-4611P35 Steel Ball 1

37 NC-4611P37 Rubber Grip 1

38 NC-4611T38

1 set

39 NC-4611P39 Washer 1

46

3/4" Air lmpact Wrench

ltem No:NC-6210Q NC-6220Q

The consumable parts The replacement parts The non-replacement parts

35

36

47

NC-6210Q NC-6220Q

Twin Hammer Type

No Part No Description Q'ty

1 NC-6210T01 Cap Bolt (8pcs) 1set

2 --- Clutch Housing 1

3 --- Anvil Bushing 1

4 NC-6210P04 O-Ring 1

5 --- Retainer Ring 1

6 --- Retainer O-Ring 1

7 --- Anvil 1

8 NC-6210T08 Hammer Pin (2pcs) 1set

9 NC-6210P09 Hammer Cage 1

10 NC-6210T10 Hammer Dog (2pcs) 1set

11 NC-6210P11 Motor Housing 1

12 NC-6210P12 Trigger 1

13 NC-6210P13 Trigger Retainer 1

14 NC-6210P14 Screw 1

15 NC-6210P15 Throttle Bushing 1

16 NC-6210P16 Valve Stem 1

17 NC-6210P17 Spring 1

18 NC-6210P18 Exhaust Deector 1

19 NC-6210P19 Air Inlet Bushing 1

20 NC-6210P20 Ball Bearing 1

21 NC-6210P21 Front End Plate 1

22 NC-6210P22 Cylinder 1

No Part No Description Q'ty

23 NC-6210P23 Cylinder Pin 1

24 NC-6210P24 Rotor 1

25 NC-6210T25 Rotor Blade (6pcs) 1set

26 NC-6210P26 Rear Plate 1

27 NC-6210P27 Ball Bearing 1

28 NC-6210P28 Gasket 1

29 NC-6210P29 Rear Cover 1

30 NC-6210P30 O-Ring 1

31 NC-6210P31 Reverse Valve 1

32 NC-6210P32 Spring 1

33 NC-6210P33 Steel Ball 1

34 NC-6210P34 Retainer 1

35 NC-6210P35

Mufer Element (NC-6210Q)

1pc

36 NC-6210P36

Grip

1

NC-6210T02 Clutch Housing Ass'y (02.03) 1set

NC-6210T07 Anvil Ass'y (05.06.07) 1set

NC-6210T07A

6" Anvil Ass'y (05.06.07A)

(NC-6220)

1set

48

3/4" Air lmpact Wrench

ltem No:NC-6216 NC-6226

19

18

17

15

16

02

03

04

12

13

14

06

07

09B

09A

10

05

11

20

21

22

23

24

01

26

27

28

25

29

30

31

32

34

36

35

37

38

39

41

42

43A

43

45

46

47

48

40

33

33

08

50

The consumable parts The replacement parts The non-replacement parts

49

NC-6216 NC-6226

New Twin Hammer Type

No Part No Description Q'ty

01 --- Motor Housing 1

02 --- O-Ring 1

03 --- Guide Tube 1

04 NC-6216P04 O-Ring 1

05 NC-6216P05 Retainer 1

06 NC-6216P06 O-Ring 1

07 NC-6216P07 Throttle Valve Seal 1

08 --- Heli Coil 1

09A --- Throttle Valve Pin 1

09B --- Throttle Valve 1

10 NC-6216P10 Spring 1

11 NC-6216P11 Exhaust Deector 1

12 NC-6216P12 O-Ring 1

13 NC-6216P13 O-Ring 1

14 NC-6216P14 Air Inlet 1

15 NC-6216P15 Spring Pin 1

16 NC-6216P16 Spring Pin 1

17 NC-6216P17 O-Ring 1

18 --- Trigger Pin 1

19 --- Trigger 1

20 NC-6216T20 Screw (4pcs) 1set

21 NC-6216P21 Screw 1

22 NC-6216P22 Reverse Valve Knob 1

23 --- Rear Cover 1

24 NC-6216P24 Rear Gasket 1

25 --- Reverse Valve 1

26 --- Spring Pin 1

27 --- Spring 1

28 --- Steel Ball 1

No Part No Description Q'ty

29 --- O-Ring 1

30 --- Ball Bearing 1

31 --- O-Ring 1

32 --- Rear End Plate 1

33 NC-6216T33 Spring Pin (2pcs) 1set

34 NC-6216P34 Cylinder 1

35 NC-6216P35 Rotor 1

36 NC-6216T36 Rotor Blade (6pcs) 1set

37 NC-6216P37 Front End Plate 1

38 NC-6216P38 Ball Bearing 1

39 NC-6216P39 Front Gasket 1

40 NC-6216T40 Hammer Pin (2pcs) 1set

41 NC-6216T41 Hammer (2pcs) 1set

42 NC-6216P42 Hammer Cage 1

43 --- Anvil 1

43A --- 6" Extend Anvil 1

45 --- O-Ring 1

46 --- Socket Retainer 1

47 --- Bushing 1

48 --- Hammer Case 1

50 NC-6216P50 Mufer Element 1

NC-6216T01

Motor Housing Ass'y

(01.02.03)

1set

NC-6216T02 Throttle Valve Ass'y (09A.09B) 1set

NC-6216T03 Trigger Ass'y (18.19) 1set

NC-6216T04

Rear End Plate Ass'y

(08.23.25~32)

1set

NC-6216T05 Hammer Case Ass'y (47.48) 1set

NC-6216T43 Anvil Ass'y (43.45.46) 1set

NC-6216T43A

6" Extend Anvil Ass'y

(43A.45.46) (NC-6226)

1set

50

30

32

38

38

34

35A

36

37

39

4

1

20

21

22

23

25

26

25

27

28

29

5

4

6

7

8

9

10

11

12

19

17

40

41

33

34

42

18

16

15

14

13

13

24

35B

46

48

47

47

45

3

2

3/4" Air lmpact Wrench

ltem No:NC-6218 NC-6228

The consumable parts The replacement parts The non-replacement parts

51

NC-6218 NC-6228

Twin Hammer Type

NO. PART NO. DESCRIPTION Q'TY

1 NC-6218T01

Backhead Assembly

(01.06.14)

1 Set

2 NC-6218P02 Inside Trigger 1

3 NC-6218P03 Outside Trigger 1

4 NC-6218T04 Pin (2 PCS) 1 Set

5 NC-6218T05 Screw (4 PCS) 1 Set

6 --- Bushing 1

7 NC-6218P07 Throttle Valve Plunger 1

8 NC-6218P08 Throttle Valve Seat 1

9 NC-6218P09 Throttle Valve 1

10 NC-6218P10 Spring 1

11 NC-6218P11 O-Ring 1

12 NC-6218P12 Air Inlet 1

13 NC-6218T13 Spring Pin (2 PCS) 1 Set

14 --- Reverse Valve Bushing 1

15 NC-6218P15 O-Ring 1

16 NC-6218T16 Spring Pin (2 PCS) 1 Set

17 NC-6218P17 Reverse Valve 1

18 NC-6218P18 Spring 1

19 NC-6218P19 Steel Ball 1

20 NC-6218P20 Gasket 1

21 NC-6218P21 Ball Bearing 1

22 NC-6218P22 Rear End Plate 1

23 NC-6218P23 Rotor 1

NO. PART NO. DESCRIPTION Q'TY

24 NC-6218T24 Rotor Blade (6 PCS) 1 Set

25 NC-6218T25 Spring Pin (2 PCS) 1 Set

26 NC-6218P26 Cylinder 1

27 NC-6218P27 Front End Plate 1

28 NC-6218P28 Ball Bearing 1

29 NC-6218P29 Washer 1

30 NC-6218P30 Housing 1

32 NC-6218P32 O-Ring 1

33 NC-6218P33 Hammer Frame 1

34 NC-6218T34 Hammer Pin (2 PCS) 1 Set

35A NC-6218T35A Standard Anvil (35A.36.37) 1 Set

35B NC-6218T35B 6" Extend Anvil (35B.36.37) 1 Set

36 --- O-Ring 1

37 --- Socket Retainer 1

38 NC-6218T38 Hammer (2 PCS) 1 Set

39 NC-6218P39 Bushing 1

40 --- Heli-Coil (4 PCS) 1 Set

41 NC-6218T41

Hammer Case Ass'y (40.41)

1 Set

42 NC-6218P42 Side Spade Handle 1

45 NC-6218P45

Rubber Cap

(for inside Trigger)

1

46 NC-6218P46 Hex Key Wrench 1

47 NC-6218T47 Washer (6 PCS) 1 Set

48 NC-6218T48 Screw (2 PCS) 1 Set

52

1

32

33

31

29

28

34

30

12

11

26

24

27

25

21

20

1

2

3

4

5

6

8

9

10

10

16

17

18

19

13

14

22

23

15

7A

7

3/4" Air lmpact Wrench

ltem No:NC-6236Q NC-6246Q

The consumable parts The replacement parts The non-replacement parts

35

36

53

NO. INDEX NO. DESCRIPTION Q'TY

01 NC-6236T01 Cap Bolt (8pcs) 1set

02 - Clutch Housing 1

03 - Anvil Bushing 1

04 NC-6236P04 O-Ring 1

05 - Retainer Ring 1

06 - Retainer O-Ring 1

07 - Anvil 1

08 NC-6236T08 Hammer Pin (2pcs) 1set

09 NC-6236P09 Hammer Cage 1

10 NC-6236T10 Hammer Dog (2pcs) 1set

11 NC-6236P11 Motor Housing 1

12 NC-6236P12 Trigger 1

13 NC-6236P13 Trigger Retainer 1

14 NC-6236P14 Screw 1

15 NC-6236P15 Throttle Bushing 1

16 NC-6236P16 Valve Stem 1

17 NC-6236P17 Spring 1

18 NC-6236P18 Exhaust Deector 1

19 NC-6236P19 Air Inlet Bushing 1

20 NC-6236P20 Ball Bearing 1

21 NC-6236P21 Front End Plate 1

22 NC-6236P22 Cylinder 1

23 NC-6236P23 Cylinder Pin 1

24 NC-6236P24 Rotor 1

25 NC-6236T25 Rotor Blade (6pcs) 1set

26 NC-6236P26 Rear Plate 1

NO. INDEX NO. DESCRIPTION Q'TY

27 NC-6236P27 Ball Bearing 1

28 NC-6236P28 Gasket 1

29 NC-6236P29 Rear Cover 1

30 NC-6236P30 O-Ring 1

31 NC-6236P31 Reverse Valve 1

32 NC-6236P32 Spring 1

33 NC-6236P33 Steel Ball 1

34 NC-6236P34 Retainer 1

35 NC-6236P35

Mufer Element

(6236Q)

1pc

36 NC-6236P36 Grip 1

NC-6236T02

Clutch Housing

Assembly (02.03)

1set

NC-6236T07

Anvil Assembly

(05.06.07)

1set

NC-6236T07A

6"Anvil Assembly

(05.06.07A)(NC-6246)

1set

NC-6236Q NC-6246Q

Twin Hammer Type

54

31

3

3

3

3

3

3

3

3

3

3

1

1

3

1

11

1

1

1

1

33

3

1

1

1

1

13

13

3

3

1" Air lmpact Wrench

ltem No:NC-8216 NC-8226

The consumable parts The replacement parts The non-replacement parts

55

NO. INDEX NO. DESCRIPTION Q'TY

1 NC-8216T01 Backhead Ass'y (1,6,14) 1set

2 NC-8216P02 Inside Trigger 1

3 NC-8216P03 Outside Trigger 1

4 NC-8216T04 Pin (2 PCS) 1set

5 NC-8216T05 Screw (4 PCS) 1set

6 – Bushing 1

7 NC-8216P07 Throttle Valve Plunger 1

8 NC-8216P08 Throttle Valve Seat 1

9 NC-8216P09 Throttle Valve 1

10 NC-8216P10 Spring 1

11 NC-8216P11 O-Ring 1

12 NC-8216P12 Air Inlet 1

13 NC-8216T13 Spring Pin (2 PCS) 1set

14 – Reverse Valve Bushing 1

15 NC-8216P15 O-Ring 1

16 NC-8216T16 Spring Pin (2 PCS) 1set

17 NC-8216P17 Reverse Valve 1

18 NC-8216P18 Steel Ball 1

19 NC-8216P19 Spring 1

20 NC-8216P20 Gasket 1

21 NC-8216P21 Ball Bearing 1

22 NC-8216P22 Rear End Plate 1

23 NC-8216P23 Rotor 1

24 NC-8216T24 Rotor Blade (6 PCS) 1set

NO. INDEX NO. DESCRIPTION Q'TY

25 NC-8216T25 Spring Pin (2 PCS) 1set

26 NC-8216P26 Cylinder 1

27 NC-8216P27 Front End Plate 1

28 NC-8216P28 Ball Bearing 1

29 NC-8216P29 Washer 1

30 NC-8216P30 Housing 1

31 NC-8216P31 Rubber Grip 1

32 NC-8216P32 O-Ring 1

33 NC-8216P33 Hammer Frame 1

34 NC-8216T34 Hammer Pin (2 PCS) 1set

35A – Standard Anvil Ass'y 1

35B –

6" Extended Anvil

for NC-8226

1

36 – O-Ring 1

37 – Socket Retainer 1

38 NC-8216T38 Hammer (2 PCS) 1set

39 – Bushing 1

40 – Heli-Coil (4 PCS) 1set

41 NC-8216T41

Hammer Case Ass'y

(39,40,41)

1set

42 NC-8216T42

Side Spade Handle Ass'y

(42,43)

1set

43 – Strap 1

44 NC-8216T44 Screw (2 PCS) 1set

45 NC-8216P45

Rubber Cap (for Inside

Trigger)

1

46 NC-8216P46 setHex Key Wrench 1

NC-8216T02

Standard Anvil

Ass'y(35A,36,37)

1set

NC-8216T03

6''Extended Anvil Ass'y

(35B,36,37) for NC-8226

1set

NC-8216 NC-8226

Twin Hammer Type

56

1" Air lmpact Wrench

ltem No:NC-8219

The consumable parts The replacement parts The non-replacement parts

57

NC-8219

New Twin Hammer Type

NO. INDEX NO. DESCRIPTION Q'ty

1 NC-8219P01 Backhead 1

2 NC-8219P02 Throttle Valve Seat 1

2A NC-8219P02A O-Ring 1

3 NC-8219P03 Throttle Valve Plunger 1

4 NC-8219P04 Throttle Valve 1

5 NC-8219P05 Spring 1

6 NC-8219P06 O-Ring 1

7 NC-8219P07 Exhaust Deector 1

8 NC-8219P08 Retainer 1

9 NC-8219P09 O-Ring 1

9A NC-8219T09A Screw

(2 pcs)

1set

10 NC-8219P10 Air Inlet 1

12 NC-8219P12 Trigger Pin 1

13 NC-8219P13 Trigger 1

15 --- Reverse Valve Bushing 1

16 NC-8219P16 O-Ring 1

17 NC-8219P17 Reverse Valve 1

18 NC-8219P18 Steel Ball 1

19 NC-8219P19 Spring 1

19A NC-8219P19A Screw 1

21 --- Spring Washer

(4 pcs)

1set

21A NC-8219T21A

Screw Assembly

4pcs(21A,21)

1set

21B NC-8219T21B Screw Assembly (21B,21) 1set

22 NC-8219P22 Gasket 1

23 --- Ball Bearing 1

24 NC-8219T24

Rear End Plate Assembly

(23,24)

1set

26 NC-8219T26 Rotor Blade (6pcs) 1set

27 NC-8219P27 Rotor 1

28 NC-8219P28 Cylinder 1

29 NC-8219P29 Spring Pin 1

NO. INDEX NO. DESCRIPTION Q'ty

29A NC-8219P29A Spring Pin 1

30 NC-8219T30

Front End Plate

Assembly (30,31)

1set

31 --- Ball Bearing 1

32 NC-8219P32 Gasket 1

33 NC-8219T33

Housing Assembly

(15,33,33A,52,63)

1set

33A --- Steel Ball (4pcs) 1set

34 NC-8219P34 Ball Bearing 1

35 NC-8219T35 Hammer Pin (2pcs) 1set

36 NC-8219P36 Hammer Frame 1

37 NC-8219T37 Hammer (2pcs) 1set

38A --- standard Anvil 1

38B --- 6" Anvil 1

40 NC-8219P40 Washer 1

41 NC-8219P41 Bushing 1

42 NC-8219P42 Gasket 1

43 NC-8219P43 Hammer Case 1

44 NC-8219T44

Screw Assembly (4pcs)

(44,44A)

1set

44A - Spring Washer (4pcs) 1set

45 NC-8219P45 Side Spade Handle 1

46 NC-8219T46 Screw (4pcs) (46,46A) 1set

46A --- Spring Washer (4pcs) 1set

47 NC-8219P47 Oil Seal 1

48

---

O-Ring 1

49

---

Socket Retainer 1

52 --- Bushing 1

61 NC-8219P61 Reverse Valve Knob 1

62 NC-8219P62 O-Ring 1

63 --- Heli-Coil (9pcs) 1set

NC-8219T38A

Standard Anvil

38A,48,49

1set

NC-8219T38B 6''Anvil 38B,48,49 1set

58

27

24

23

22

21

25

29

26

28

30

31

32

33

2

3

5

6

7

8

14

12

15

7

20

17

18

19

01

11

51

4

13

33-1

52

34

40

36

37

39

38

42

41

47

43

48

21

45

46

39

34

1" Air lmpact Wrench

ltem No:NC-8311 NC-8351

The consumable parts The replacement parts The non-replacement parts

44

59

NO. PART NO. DESCRIPTION Q'ty

1 --- Backhead 1

2 --- Bushing 1

3 NC-8311P03 Throttle Valve Seat 1

4 NC-8311P04

Throttle Valve Plunger

(For Inside Trigger)

1

5 NC-8311P05 Throttle Valve 1

6 NC-8311P06 Spring 1

7 NC-8311T07 O-Ring (2 PCS) 1set

8 NC-8311P08 Straight Air Inlet 1

11 NC-8311P11

Rubber Cap

(For Inside Trigger)

1

12 NC-8311T12 Pin (2 PCS) 1set

13 NC-8311P13 Inside Trigger 1

14 NC-8311T14 Spring Pin (2 PCS) 1set

15 --- Reverse Valve Bushing 1

17 --- Reverse Valve 1

18 NC-8311P18 Steel Ball 1

19 NC-8311P19 Spring 1

20 --- Spring Pin 1

21 NC-8311T21 Screw (8 PCS) 1set

22 NC-8311P22 Gasket 1

23 --- Ball Bearing 1

24 --- Rear End Plate 1

25 NC-8311P25 Spring Pin 1

26 NC-8311T26 Rotor Blade (6 PCS) 1set

27 NC-8311P27 Rotor 1

28 NC-8311P28 Cylinder 1

29 NC-8311P29 Spring Pin 1

30 --- Front End Plate 1

31 --- Ball Bearing 1

NO. PART NO. DESCRIPTION Q'ty

32 NC-8311P32 Gasket 1

33 --- Housing 1

33-1 --- Steel Ball (4 PCS) 1set

34 --- Heli-Coil (8 PCS) 1set

36 NC-8311P36 Cam 1

37 NC-8311P37 Hammer 1

38 NC-8311P38 Axle Bushing 1

39A --- 8" Extend Anvil for NC-8351 1

39B --- Standard Anvil for NC-8311 1

40 NC-8311P40 Hammer Frame 1

41 --- Socket Retainer 1

42 --- O-Ring 1

43 NC-8311P43 Side Spade Handle 1

44 NC-8311P44 Bushing 1

45 NC-8311P45 Oil Seal 1

46 NC-8311T46 Screw (4 PCS) 1set

47 NC-8311P47 O-Ring 1

48 NC-8311P48 Hammer Case 1

51 NC-8311P51 Outside Trigger 1

52 NC-8311P52 Throttle Valve Plunger 1

NC-8311T01 Backhead Ass'y (1, 2, 15) 1set

NC-8311T02 Reverse Valve Ass'y (17, 20) 1set

NC-8311T03 Rear End Plate Ass'y (23, 24) 1set

NC-8311T04 Front End Plate Ass'y (30, 31) 1set

NC-8311T05

Housing Ass'y

{33, 33-1(4), 34(8)}

1set

NC-8311T06A

8" Extend Anvil Ass'y

(39A, 41, 42) (NC-8351)

1set

NC-8311T06B

Standard Anvil Ass'y

(39B, 41, 42)

1set

NC-8311 NC-8351

Pin Less Type

60

Mighty-Seven International Co., LTD, (M7), part of the global King Tony Tool Group, offers a 12 months limited

warranty on all products sold in the US and Canada through King Tony America. The limited warranty applies to

defects in material or workmanship within the rst 12 months of ownership; it does not apply to products that have

been abused, misused, modied, disassembled or repaired by someone other than an M7 authorized repair center.

King Tony America reserves the right to conduct an inspection of any tool returned for warranty consideration and

will offer the owner of the tool a written evaluation if warranty is denied for any reason. Specic exclusions to this

warranty include certain consumable (wear) items in every tool. All consumable items are clearly noted in the parts

list for each tool contained in this catalog. Other specic exclusions include failure to properly oil the tool prior to

use and using excessive air pressure to operate the tool. All implied warranties, including but not limited to the

implied warranties of merchantability or tness for a particular purpose are also specically excluded.

In no event shall King Tony America be liable for consequential, incidental, or specic damages resulting from or in

any manner related to the product, its design, use or any inability use the same. The sole and exclusive remedy

with respect to a defective product shall be the repair, or replacement of the tool.

For assistance with a warranty claim or for the name of the M7 authorized warranty repair center nearest you

please email: sales@kingtonyamerica.com; or call King Tony America at +1 561.699.3190 between the hours of

8AM and 5PM, Pacic Time.

Date of Purchase

Model No

Distributor Stamp

Warranty Expiration Date Serial No

Warranty Card

61

62

Mighty-Seven International Co., LTD, (M7), membre du groupe King Tony Tools Group, offre une garantie de 12 mois sur

tous les produits vendus aux Etats Unis et au Canada via King Tony America. Cette garantie s’applique sur les défauts de

fonctionnement et de fabrication pendant les 12 mois suivant l’achat. Cette garantie ne s’applique pas pour les mauvaises

utilisations du produit, ainsi que pour les produits modiés, démontés ou réparés par un intervenant autre qu’un centre de

réparation agréé par M7.

King Tony America se réserve le droit de procéder à une inspection de chaque produit qui nous sera retourné afin de

déterminer si la garantie est applicable, et enverra une évaluation écrite au propriétaire dans le cas ou la garantie est refusée.

Les exceptions spécifiques à cette garantie comprennent l’usure des parties consommables dans chaque outil. Toutes

les parties consommables sont clairement indiquées dans la liste des pièces composant chaque outil, contenue dans ce

catalogue. Les autres exceptions spéciques comprennent les disfonctionnements liés à l’omission d’huiler correctement l'outil

avant utilisation, ainsi que les disfonctionnements liés à une pression d'air excessive durant l’utilisation. Un produit défectueux

suite à une utilisation contraire à sa fonction ne pourra être pris en garantie.

King Tony America ne peut en aucun cas se tenir responsable des conséquences liées à la mauvaise utilisation de ses

produits. L’unique et exclusive solution en ce qui concerne un produit défectueux sera la réparation, ou le remplacement de

l'outil.

Pour une assistance concernant une demande de garantie dans un centre de réparation M7 autorisé, veuillez contacter par

mail : sales@kingtonyamerica.com ou appeler King Tony America au +1 561.699.3190 (horaires : 8h-17h, heure Pacique).

Garantie

63

64

Mighty-Seven International Co., LTD, (M7) parte del Grupo Global de Herramientas de King Tony ofrece una garantía limitada de 12 meses en

todos los productos vendidos en los Estados Unidos y Canadá a través de King Tony America.

La garantía limitada se aplica a defectos de materiales o a la mano de obra en la manufacturación dentro de los primeros 12 meses de

compra, no se aplica a productos que han sido maltratados, mal usado, modicados, desarmado o reparado por alguien que no sea un centro

de reparación autorizado M7.

King Tony America se reserva el derecho a realizar una inspección de cualquier herramienta devuelta a la consideración de garantía y se

ofrecera una evaluación por escrita al propietario de la herramienta si la garantía es negada por cualquier motivo.

Las exclusiones especícas de esta garantía incluyen ciertos respuestos consumibles (desgaste) en cada herramienta.

Todos los respuestos consumibles se señalan claramente en la lista de piezas para cada herramienta contenida en este catálogo.

Otras exclusiones especícas incluyen falta de aceite correctamente antes de uso y utilizando la presión de aire excesivo para operar la

herramienta.

Especicamente se excluyen todas las garantias implicitas, incluyendo pero no limitandose a las garantias implicitas de comerciabilidad o

idóneas para un proposito particular estan especicamente excluidas.

En ningún caso King Tony America será responsable de consecuencias incidentales o daños especicos resultantes o de cualquier manera

relacionada con el producto, su diseño, uso o cualquier incapacidad de utilizar el mismo.

El unico y exclusivo recurso con respecto al producto defectuoso sera la reparación o sustitución de la herramienta.

Para obtener asistencia con un reclamación de garantía o para buscar el centro de servicio autorizado M7 de reparación de garantía más cercano.

envíe un correo electrónico: sales@kingtonyamerica.com,

o llame a King Tony América por teléfono 561.699.3190, 561.699.3190

entre las 8 AM y 17:00 horas, tiempo del Pacíco.

Póliza de Garantía

65

Complete air tool solution s

www.mighty-seven.co m

880NC4610QCE

Loading...

Loading...