Page 1

DESCRIPTION

The MM1700 monitors a frequency input

signal and trips a dpdt, 5 A relay when the

input exceeds the desired level. Normal

operation has the relay energized for the

non-alarm condition and de-energized for an

alarm condition. This provides a fail-safe

alarm condition for loss of power to the

module. The alarm has a set of red/green

LEDs to indicate alarm status.

A deadband adjustment allows a deadband

of 0.5% to 100% of span to be set into the

module. The deadband is symmetrical about

the setpoint.

With the latching option, the alarm has no

deadband control. Once the limit has been

reached the alarm latches and power to the

module must be momentarily interrupted to

reset the alarm.

The wide range of input sensitivity allows

the MM1700 Series alarms to be driven from

low level magnetic pickups as well as logic

level signals. A threshold adjustment sets

the minimum input amplitude the module will

process. This allows the user to trade off

sensitivity versus noise rejection. An optional

pullup resistor (Option P) permits use with

contact-closure or open-collector inputs.

The module includes filtering and conditioning

to reduce susceptibility to transients and

noisy operations.

MODEL NUMBERS

These instructions cover the following

setpoint styles:

MM1700 Frequency Input Single Alarm

(25 turn screwdriver adjust)

MM1701 Frequency Input Single Alarm

(Single turn dial)

MM1704 Frequency Input Single Alarm

(Ten turn precision dial)

OPTIONS

These instructions cover the following

options on the MM1700 Series. Options

installed are listed on the label attached to the

side of the module.

H/L H = High alarm: Alarm occurs on an

increasing signal

L = Low alarm: Alarm occurs on a

decreasing signal

R The Normal condition for the relay is

energized. It de-energizes for an alarm

condition (Failsafe). Option R (Reverse

Sense) reverses this logic.

P 10 kilohm pullup resistor for use with

open-collector or contact-closure

inputs.

U All circuit boards conformal coated for

protection against moisture.

MM1700, MM1701 and

MM1704

FREQUENCY INPUT

SINGLE ALARMS

CONTROLS

The MM1700, MM1701 and MM1704 modules

contain setpoint, deadband, zero, span and

threshold adjustments. The setpoint control

in the MM1700 is a 25-turn blind trimpot.

MM1701 and MM1704 contain 1-turn and

10-turn calibrated dials, respectively.

CALIBRATION

Modules are shipped with ZERO and SPAN

precalibrated. The THRESHOLD adjustment

also has been set per requirements stated

on the initial order. The user needs only

adjust the SETPOINT for the desired

response.

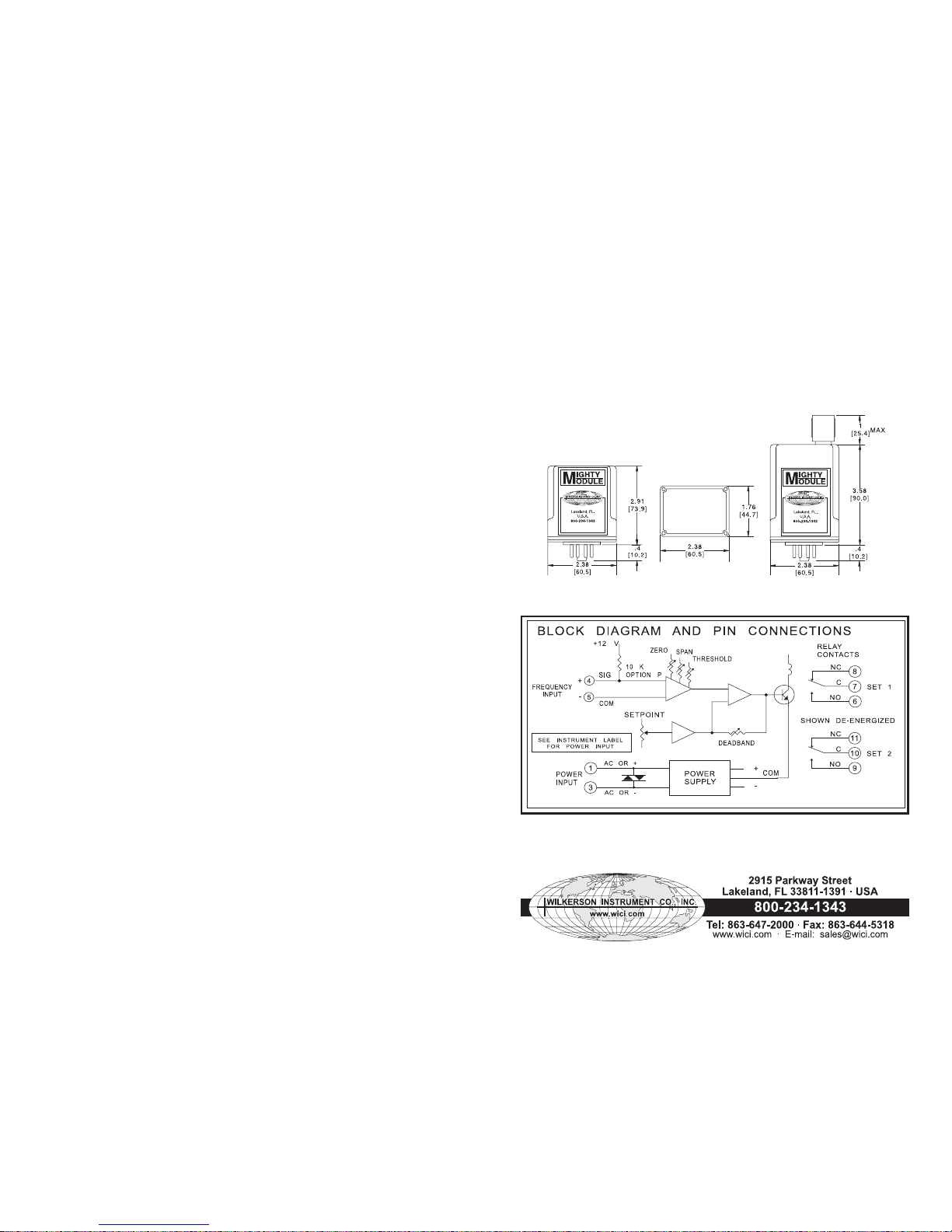

Connect the input to a precision frequency

source covering the desired input range.

Refer to the instrument’s label to determine

your instrument’s supply voltage and input

range. Refer to the “Block Diagram and Pin

Connections” for connections.

To calibrate the alarm setpoint, set the input

to the desired setpoint and turn the

DEADBAND control fully ccw. Adjust the

SETPOINT control until the LED switches to

red (ccw for a high alarm, cw for low).

Adjust the DEADBAND control for the desired

amount of deadband. Vary the input up and

down to check the level at which the alarm

trips and resets. The setpoint will

remainapproximately centered in the middle

of the deadband.

The THRESHOLD adjustment allows the

module to be made insensitive to line

frequency pickup or other noise signals

whose levels are below the threshold

setting. Turning this control fully clockwise

reduces the threshold to zero and makes

the input most sensitive. To adjust, set the

input at about 25% of its normal amplitude.

Set the input frequency to a value slightly

above the trip point. This will cause a high

alarm to trip, or a low alarm to reset.

Start with the THRESHOLD adjustment fully

counterclockwise (minimum sensitivity).

Turn the THRESHOLD adjustment cw until

the alarm changes state. A HIGH alarm will

trip; a LOW alarm will reset.

It is not necessary to recalibrate the setpoint

after changing the threshold setting.

If there is a need to recalibrate ZERO and

SPAN, proceed as follows:

Set the input to the low end of the input range.

Turn the SETPOINT and DEADBAND controls

fully ccw. Adjust the ZERO control until the

LED color changes.

Change the input to the high end of the input

range. Turn the SETPOINT control fully cw.

Adjust the SPAN control until the LED color

changes.

Repeat the ZERO and SPAN adjustments

until both are correct.

After calibration, the SETPOINT and

DEADBAND controls should be reset as

described above.

RELAY CONTACT PROTECTION

When inductive loads such as motors, relays

or transformers are switched, voltage

transients may be generated which exceed

the ratings of the relay contacts. The resulting

arcing can quickly destroy the contacts.

(Refer to the SPECIFICATIONS below for the

relay contact ratings.)

Surge suppression is required across

inductive loads to guard against premature

relay failure. Figure 1 illustrates diode surge

suppression for a DC load. The diode’s

operating (peak inverse) voltage should

exceed the load’s supply voltage by at least

50% and should have a current rating of at

lease one ampere.

Figure 2 shows surge suppression for an

AC load, using an MOV (metal oxide varistor)

and a capacitor. The breakdown voltage

ratings of both the MOV and the capacitor

must exceed the peak AC voltage.

With normal sine-wave power, PEAK = 1.414

x RMS voltage. For 115 VAC power, a 200

volt peak rating is recommended.

1 2

Page 2

SPECIFICATIONS

Input Range

select any range from 0 to 10 Hz min

to 0 to 60 kHz min

Input Sensitivity

any voltage from 50 mV to 100 V peak

Input Impedance

100 kilohms

Option P

Pullup resistor to + input 10 kilohms

Open circuit voltage +12 VDC

Setpoint

0 to 100% of span

Deadband

0.5% to 100% of span

Accuracy

±0.1% of span

Common Mode Rejection

120 dB, DC to 60 Hz

Relay Contacts (dpdt)

Resistive Load:

5 A max, 150 W max,

220 VAC max, 30 VDC max

Inductive Load:

(Power Factor => 0.4)

2.5 A max, 75 W max,

220 VAC max, 30 VDC max

Transistor Output

(Option V)

Relay drive (12 V coil, ±220 ohms)

or open collector outputs sink 100 mA,

30 V supply max

Operating Temperature

14°F to 140°F / -10°C to 60°C

Temperature Stability

±0.2% of span/°C max

Power

115 VAC ±10%, 50/60 Hz (2.5 W max)

230 VAC ±10%, 50/60 Hz (2.5 W max)

(DC Power Option) (2.5 W max)

12 VDC (limits 10 VDC to 15 VDC)

24 VDC (limits 21 VDC to 32 VDC)

Isolation, DC power supply to input

common: 10 megohms

MM1700 MM1701 & MM1704

Specifications are subject to change without notice. © 2008 Wilkerson Instrument Co., Inc. DWG#101717D 3/15

MOUNTING

MM1700, MM1701 and MM1704 are designed

to plug into a standard 11-pin relay socket.

(MP011) is a molded plastic socket suitable

for mounting on a flat surface or

2 3/4 inch wide PVC snap track (TRK48).

Use (CLP1) hold-down clip if needed.

CASE DIMENSIONS INCHES [mm]

A Killark HK Series explosion-proof housing

with dome and 11-pin socket is available

(HKB-HK2D-11). A DIN rail mounted socket

(DMP011) is available for 35mm symmetrical

rail.

3

4

Loading...

Loading...