Page 1

DESCRIPTION

The MM1000A is a lower-cost alternative to

the MM1000 DC limit alarm for standard

applications. The MM1000A monitors a DC

input and trips a dpdt, 5 A relay when the

input exceeds the desired level. The alarm

has a green LED to indicate relay status.

Setpoint adjustment is provided by a 25-turn

trimpot, adjustable from below 0% to above

100% of span. Deadband, also a 25-turn

trimpot, is adjustable from below 1% to

above 100% of span. A user-changeable

jumper may be changed to provide high or

low-trip.

The module includes filtering and conditioning

to reduce susceptibility to transients and

noisy operations.

For options or input ranges not provided by

MM1000A, refer to MM1000.

OPTIONS

These instructions cover the following

options on the MM1000A.

H = High alarm.

Relay de-energizes on an

increasing signal.

L = Low alarm.

Relay de-energizes on a

decreasing signal.

CONTROLS

The MM1000A contains setpoint and

deadband adjustments, both accessible from

the top of the module. A user-changeable

jumper on the circuit board may be changed

to provide high or low trip. The MM1000A has

no zero or span adjustment.

CALIBRATION

To change the SETPOINT or DEADBAND

settings proceed as follows.

To calibrate the alarm setpoint, set the input

to the desired setpoint and turn the

DEADBAND control fully ccw. Adjust the

SETPOINT control until the LED turns off (ccw

for a high alarm, cw for low).

Adjust the DEADBAND control for the desired

amount of deadband. Vary the input up and

down to check the level at which the alarm

trips and resets. The setpoint will remain

approximately centered in the middle of the

deadband.

MM1000A

DC INPUT

SINGLE ALARM

FIXED RANGE

DPDT RELAY

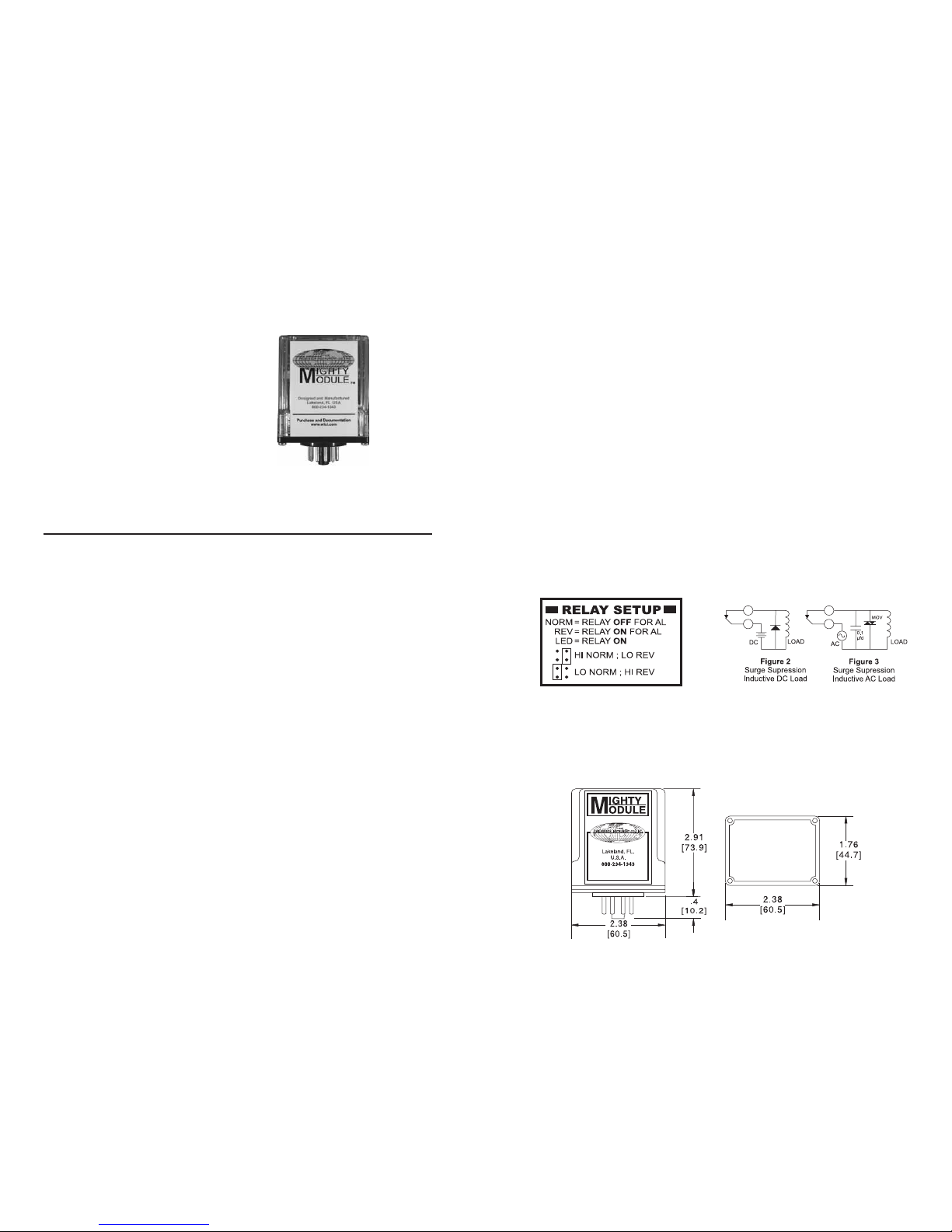

RELAY SETUP

To change the relay setup, unscrew the four

screws holding the cover in place. Remove

the cover to access the relay setup jumper

on the PC board.

Caution: For safety, do not apply power

while the cover is removed.

Caution: The MM1000A’s circuitry is

precise, sensitive and closely spaced.

Circuit board contamination can lead to

errors and instability, especially at high

humidities. Handle the circuit board by

its edge only, or wear clean gloves, to

avoid contamination.

Refer to the relay setup label on the side of

the module’s cover (Figure 1). In the “HI

NORM; LO REV” position the relay will be off

(de-energized) on high inputs. In the “LO

NORM; HI REV” position the relay will be off

(de-energized) on low inputs. In either

position the LED will be on whenever the

relay is energized.

After changing the jumper position recalibrate

as described above.

Figure 1

Jumper Positions for Relay Setup

RELAY CONTACT PROTECTION

When inductive loads such as motors, relays

or transformers are switched, voltage

transients may be generated which exceed

the ratings of the relay contacts. The resulting

arcing can quickly destroy the contacts.

(Refer to the SPECIFICATIONS below for

the relay contact ratings.)

Surge suppression is required across

inductive loads to guard against premature

relay failure. Figure 2 illustrates diode surge

suppression for a DC load. The diode’s

operating (peak inverse) voltage should

exceed the load’s supply voltage by at least

50% and should have a current rating of at

least one ampere.

Figure 3 shows surge suppression for an

AC load, using an MOV (Metal Oxide Varistor)

and a capacitor. The breakdown voltage

ratings of both the MOV and the capacitor

must exceed the peak AC voltage.

With normal sine-wave power, PEAK = 1.414

x RMS voltage. For 115 V AC power a 200

volt peak rating is recommended.

CASE DIMENSIONS INCHES [mm]

1 2

Page 2

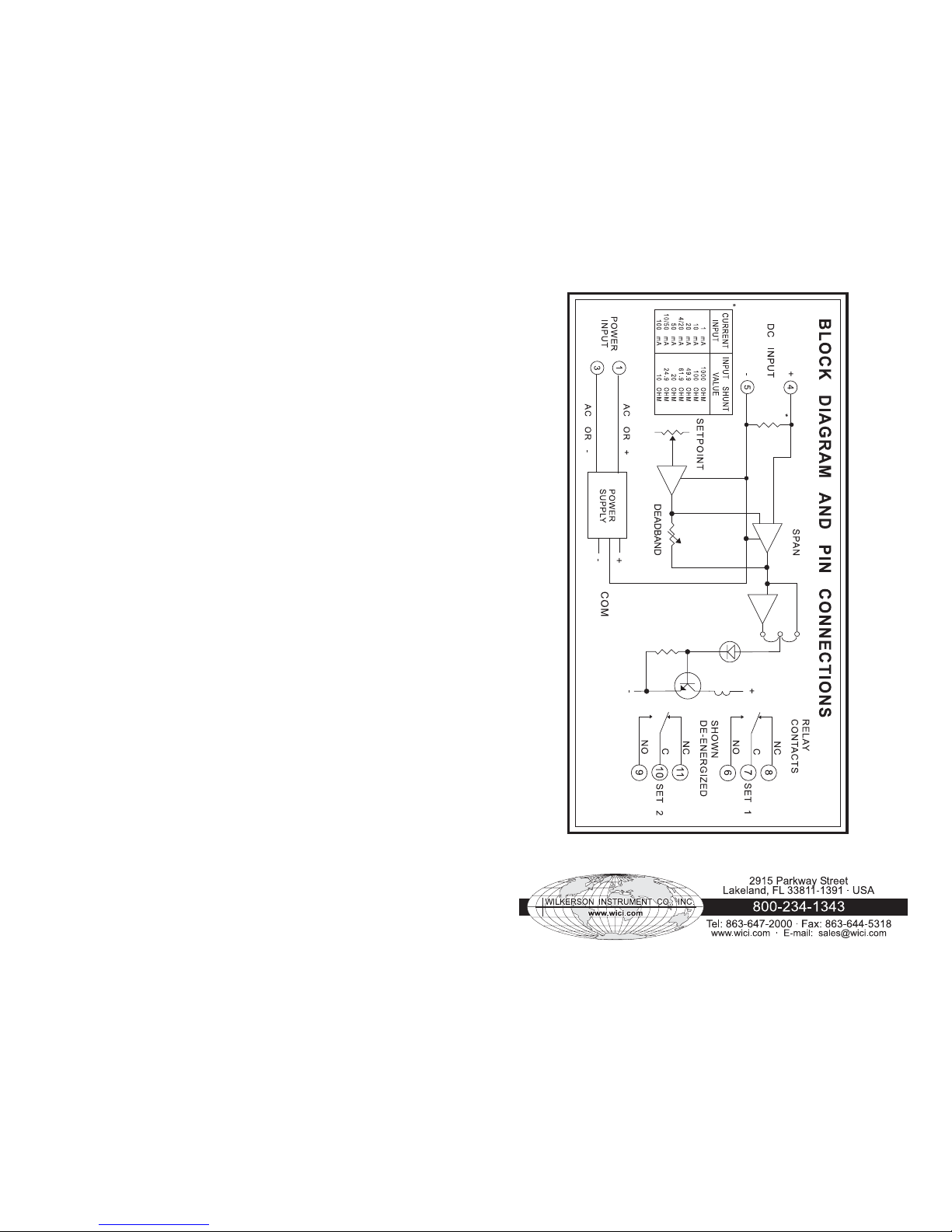

SPECIFICATIONS

INPUT RANGE

Select any input range within the

following limits

Voltage

Min span 1 V, Max input 250 V

Offset 0 V min, +100% of span max

(example, +10/+20 V)

For negative offsets, use MM1000

Current

Min span 1 mA, Max input 100 mA

Offset 0 mA min, 100% of span max

(example, +50/+100 mA)

For negative offsets, use MM1000.

INPUT IMPEDANCE

Voltage 200 kilohms

Current see table in block diagram

SETPOINT

0 to 100% of span, min.

DEADBAND

1% to 100 % of span, min.

RESPONSE TIME

20 ms typical

ACCURACY

±0.1% of span

COMMON MODE REJECTION

120 dB, DC to 60 Hz

RELAY CONTACTS

(dpdt)

Resistive Load:

5 A max, 150 W max, 220 VAC max,

30 VDC max

Inductive Load:

(Power factor ³ 0.4):

2.5 A max, 75 W max, 220 VAC max,

30 VDC max

OPERATING TEMPERATURE

14°F to 140°F/-10°C to 60°C

TEMPERATURE STABILITY

±0.02% of span/°C max

POWER (2.5 W max)

115 VAC ±10%, 50 or 60 Hz

230 VAC ±10%, 50 or 60 Hz

(DC Power Option)

12 VDC (limits 10 VDC to 15 VDC)

24 VDC (limits 21 VDC to 32 VDC)

Isolation, DC power supply

to input common: 10 megohms

MOUNTING

The module is designed to plug into a standard 11-pin relay socket. (MP011) is a

molded plastic socket suitable for mounting

on a flat surface or snap into a 2 3/4 inch wide

PVC track (TRK48).

A hold-down clip (CLP1) is available for

installation where vibration may be a problem.

A DIN rail mounted socket (DMP011) is available for 35mm symmetrical DIN rail.

A Killark HK Series explosion-proof housing

with dome and 11 pin socket is available

(HKB-HK2D-11).

WARRANTY

The Mighty Module Series of products carry

a limited warranty of 10 + 5 years. In the

event of a failure due to defective material

or workmanship, during the 10 year period,

the unit will be repaired or replaced at no

charge. For a period of 5 years after the

initial 10 year warranty, the unit will be

repaired, if possible, for a cost of 10 % of

the original purchase price.

Relays are not covered by the warranty.

Specifications are subject to change without notice. © 2007 Wilkerson Instrument Co., Inc. DWG#W102454 3/07

3 4

Loading...

Loading...