Migatronic SIGMA SELECT ROBO User Manual

BRUGSVEJLEDNING

USER GUIDE

BETRIEBSANLEITUNG

GUIDE DE L’UTILISATEUR

BRUKSANVISNING

GUIDA PER L’UTILIZZATORE

GEBRUIKERSHANDLEIDING

NÁVOD K OBSLUZE

PODRĘCZNIK UŻYTKOWNIKA

SIGMA SELECT ROBO

50115056 A Valid from 2018 week 37

2

Dansk ..................................................................3

English ..............................................................17

Deutsch ............................................................. 31

Français ............................................................. 45

Svenska ............................................................. 59

Italiano .............................................................73

Nederlands .......................................................87

Česky ............................................................... 101

Polski ...............................................................115

3

Tilslutning og ibrugtagning

1

0

1

Advarsel

Læs advarsel og brugsanvisning

omhyggeligt igennem inden

installation og ibrugtagning og gem

til senere brug.

Installation

Nettilslutning

Tilslut maskinen til den netspænding den er konstrueret til. Se

typeskiltet (U1) bag på maskinen.

2

Tilslutning af beskyttelsesgas

Gasslangen, som udgår fra bagsiden af maskinen (3), tilsluttes

en gasforsyning med en reduktionsventil (2-6bar).

(Obs. Nogle typer reduktionsventiler kan kræve højere

udgangstryk end 2 bar for at fungere optimalt).

Vigtigt!

Når stelkabel og svejseslange tilsluttes

maskinen, er god elektrisk kontakt

nødvendig, for at undgå at stik og kabler

ødelægges.

ADVARSEL

Når der trykkes på svejseslangens

kontakt/tast er der spænding på

svejsetråden/elektroden.

Tilslutning af svejseslange

Løfteanvisning

(Løftekit varenr.: 78857054)

Anbefalede kabelstørrelser

Svejsestrøm DC PULS

200 A 35 mm² 35 mm²

300 A 50 mm² 70 mm²

400 A 95 mm² / 2x50 mm² 95 mm² / 2x50 mm²

550 A 2x70 mm² 2x70 mm²

Svejseproces Afstand til arbejdsemne

(a+b)

Total kabellængde i

svejsekredsløb (a+b+c)

MIG - IAC og puls 10 m 20 m

MIG - ingen puls 30 m 60 m

c

a

b

L1

L2

L3

N

gul/grøn

brun

sort

grå

3x208-440V (boost)

3x400V

4

Tilslutning og ibrugtagning

11

GAS

2-6 bar

Power

F

F

F

1

2

3

4a

4b

5

5

6

6

7

7

8

9

10

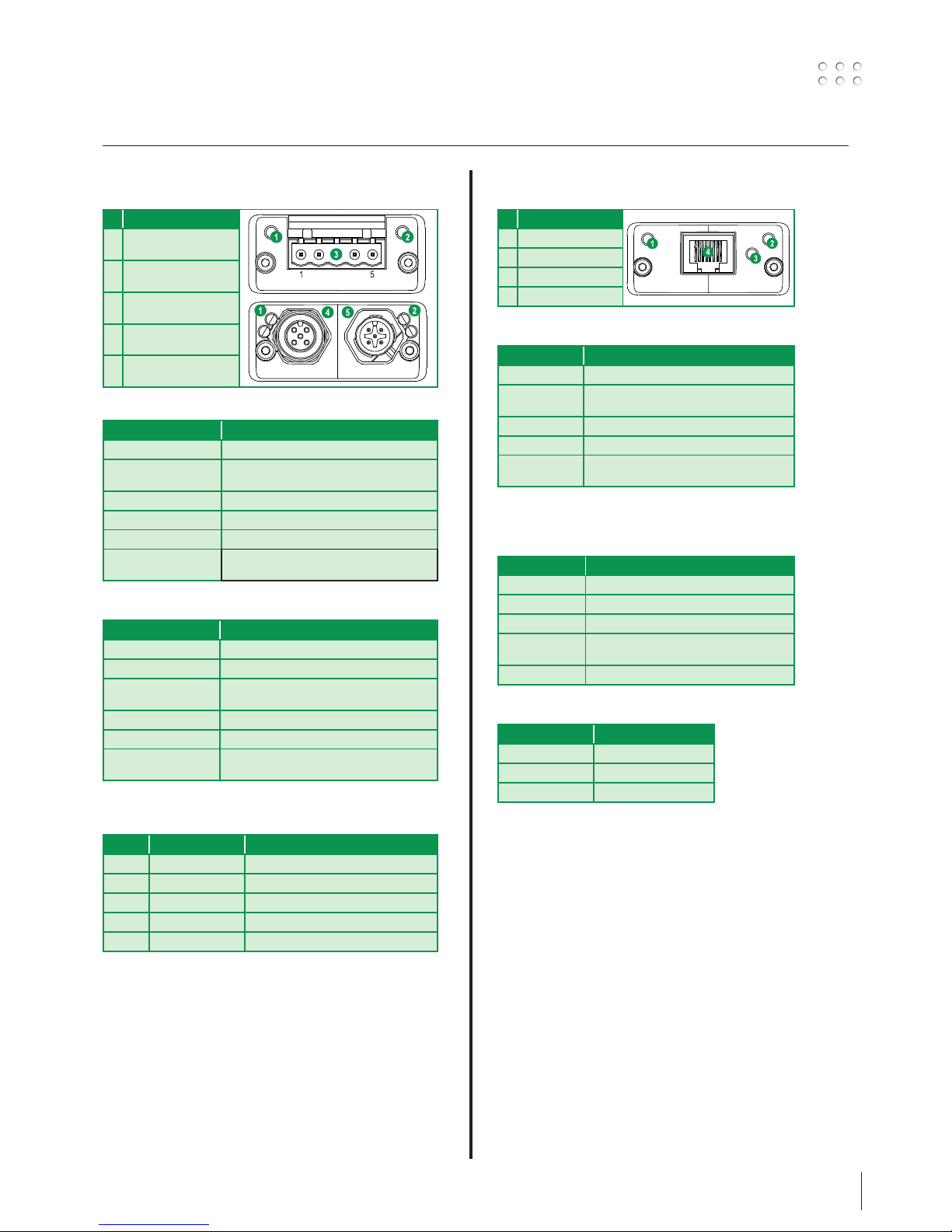

1. Nettilslutning

2. Tænd - sluk knap on/off

3. Tilslutning beskyttelsesgas

4a. Tilslutning køleslange, tilbageløb (rød)

4b. Tilslutning køleslange, fremløb (blå)

5. Dinsetilslutning -

6. Dinsetilslutning +

7. Tilslutning CAN

8. Fieldbusmodul

9. Påfyldning af kølevæske

10. Aflæsning af kølevæskestand (Min/Max)

11. Samlebeslag

MIGA_CFG

DOCUMENTS

Devicenet

EtherCAT

Profibus

Profinet

Ethernet-IP

Config.

Robot-/PLC-opstilling

SIGMA SELECT leveres med Migatronics standard

konfigurationsfil (10010208).

Det medfølgende SD-kort indeholder yderligere

konfigurationsfiler samt diverse opstillingsfiler, der er

påkrævet af nogle robotter og PLC’er.

Indlæs MIGA_CFG/DOCUMENTS folderne på din PC. Hver

folder indeholder EDS- eller GSD-filer, brugsanvisninger,

quickguides og diverse Anybus moduldokumentation til

kommunikationsenheder.

5

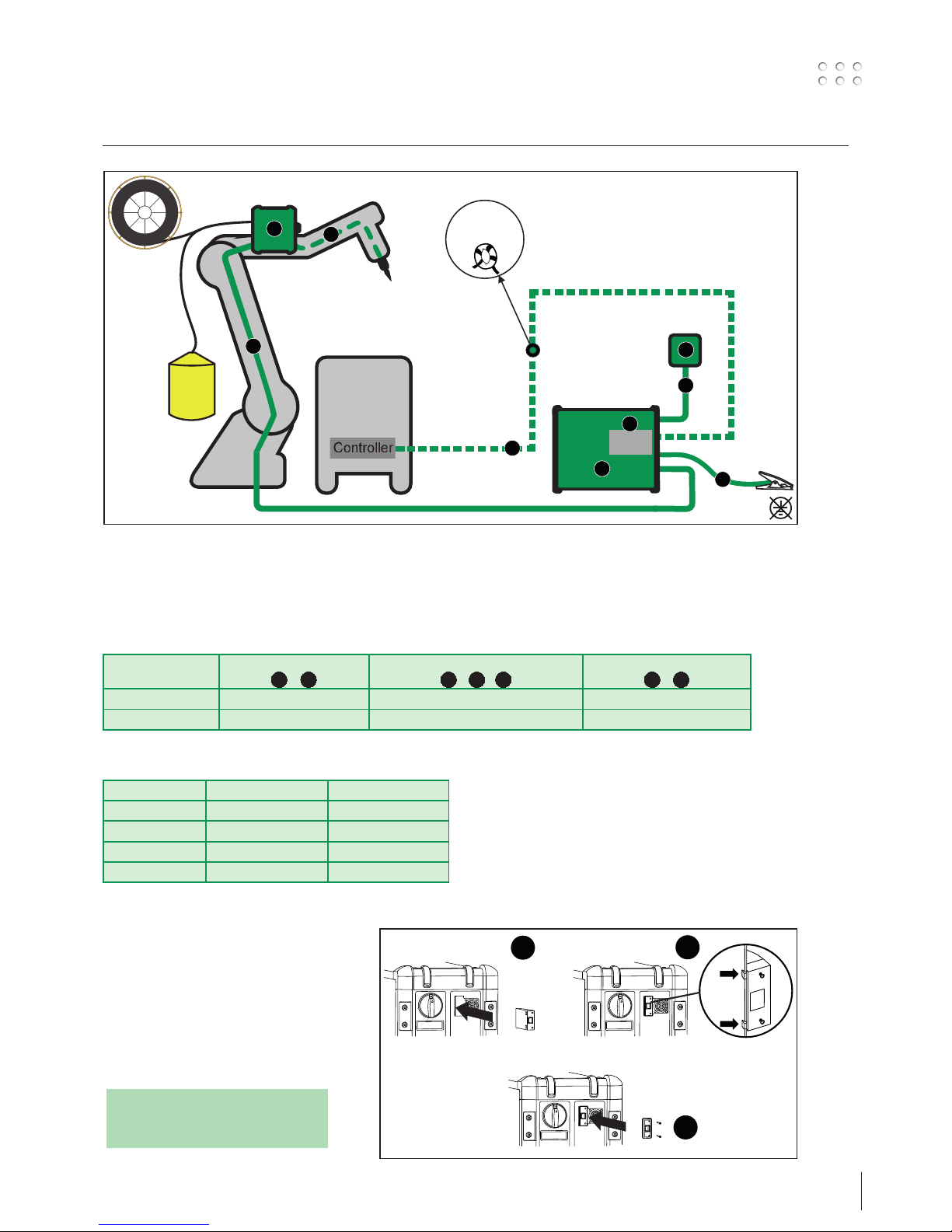

Tilslutning af svejseinstallationen

Controller

d

ROBOT/PLC

controller

3 vindinger

gennem kerne

17440005

RWF 30

SIGMA SELECT ROBO

REMOTE

Anybus

kommunikation

b

4

e

c

a

2

Anybus

interface

1

3

Hovedkomponenter:

1. Interface

2. Svejseinverter

3. Trådboks - RWF 30

4. Remote fjernbetjening

Kabler og fittings:

a. Signalkabel til robot controller

b. CAN kommunikationskabel til svejseinverter

c. Mellemkabel, gas- og 2 x svejsekabel og CAN

d. Svejsebrænder

e. Svejsereturkabel

Svejseproces Afstand til arbejdsemne

( + )

Total kabellængde i svejsekredsløb

( + + )

Total længde af CAN kabel

( + )

MIG – puls 10 m 20 m 30 m

MIG – ingen puls 30 m 60 m 30 m

cc c

b

d d e

Installering af

Anybus-modul

1. Vigtigt! Indsæt stikket lige i hullet, når

Anybus-modulet skal monteres.

2. Skub stikket på plads med forsigtighed.

3. Skru Anybus-modulet fast ved hjælp af

skruerne.

1

2

3

Kabelstørrelser

Svejsestrøm DC PULS

200 A 35 mm² 35 mm²

300 A 50 mm² 70 mm²

400 A 95 mm² / 2x50 mm² 95 mm² / 2x50 mm²

550 A 2x70 mm² 2x70 mm²

BEMÆRK:

DEFEKTE TILSLUTNINGER

DÆKKES IKKE AF GARANTIEN!!!

6

Tilslutning og ibrugtagning

x4

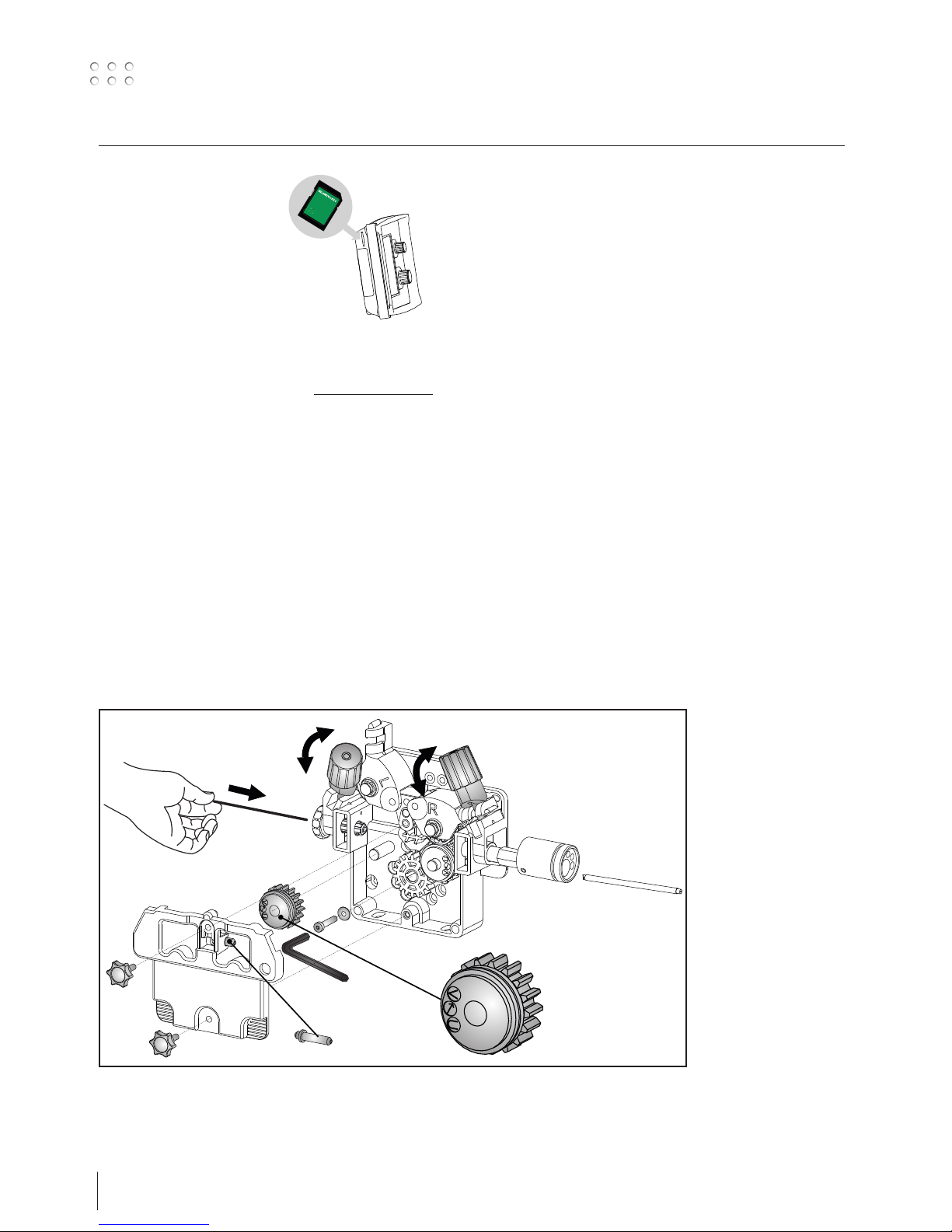

Montering af dele i trådfremføring

Fingerskruens tryk

indstilles, således at

trådtrisserne netop glider

på tråden, når denne

bremses ved kontaktdysen

Software opdatering

• Indsæt SD-kortet

• Tænd maskinen.

• Vent indtil enheden

indikerer, at opdatering er

afsluttet

• Sluk maskinen og tag SDkortet ud.

• Maskinen er nu klar til brug.

Strømkilde og alle tilkoblede enheder får den nye software

indlæst.

Softwaren kan downloades fra http://migatronic.com

Licens SW

Ved tilkøb af ekstra programmer eller særlige funktioner skal

MigaLic.dat filerne indlæses på samme vis som SW-pakker. Husk

at gemme en sikkerhedskopi af filerne.

MigaLic.txt filen indeholder information om maskinens

licensnummer og de gemte licenser på SD-kort.

7

Specielle funktioner

Setup wizard

I II

III

IV V VI

Låsefunktion

I II III

8

Specielle funktioner

Software / Licenser

I II

III

Kabelkompensering (kalibrering af modstand i svejseslange)

I II III

IV V

1

2

Std.

Svejseemnets overflade skal være ren for

at sikre god kontakt med brænderen.

Torch setup

I II

12

- - -

9

Fejlhåndtering

SIGMA Select Robo har et avanceret selvbeskyttelsessystem indbygget. Ved fejl lukker maskinen automatisk for gastilførslen, afbryder

svejsestrømmen og stopper trådfremførelsen.

Udvalgte fejl:

Kølefejl

Kølefejl vises i tilfælde af at kølevandet ikke kan cirkulere som følge af forkert tilslutning eller tilstopning.

Kontroller at køleslangerne er korrekt tilsluttet, efterfyld vandbeholderen og efterse svejseslange og tilslutningsstudser. Kølefejlen

afmeldes med et kort tryk på P-knappen.

Gasfejl (IGC)

Gasfejl kan skyldes for lavt eller for højt tryk på gastilførslen.

Kontroller at trykket på gastilførslen er højere end 2 bar og mindre end 6 bar, svarende til 5 l/min og 27 l/min.

Gasfejl kan sættes ud af funktion ved at indstille manuel gasflow til 27l/min. Gasfejlen afmeldes med et kort tryk på P-knappen.

Fejllog

I II III

Fejllog

Alle fejl gemmes i

maskinens fejllog under

menuen Service.

Fejlloggen kan distribueres,

når der indsættes et

SD-kort og trykkes på

følgende tast:

Fejlloggen er nu gemt på

SD-kortet.

Fejlloggen kan nulstilles,

når der trykkes på tasten ud

for skraldespanden.

10

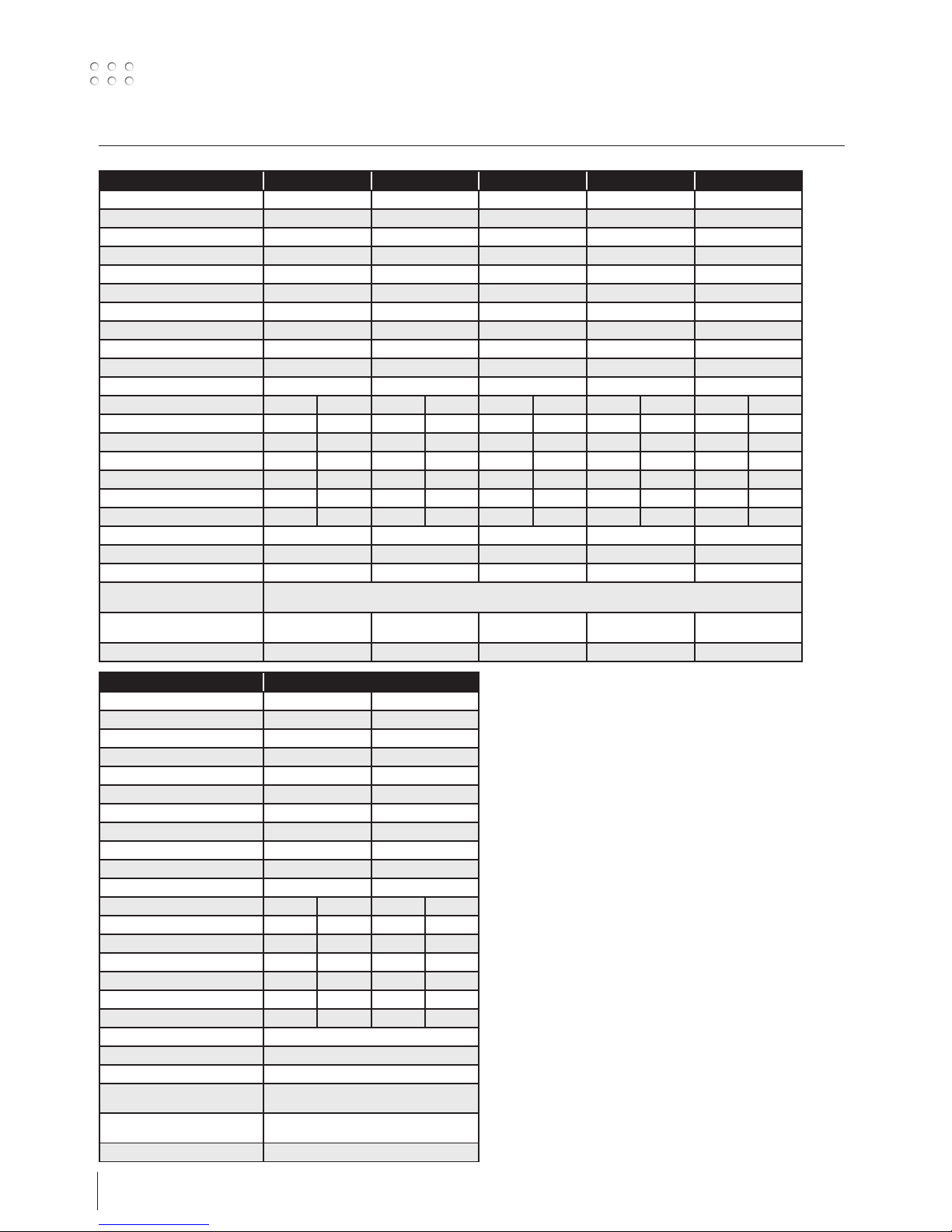

Tekniske data 1

1) Dette udstyr er i overensstemmelse med IEC 61000-3-12, forudsat at nettets

kortslutningseffekt Ssc ved tilslutningsstedet er større end eller lig med

de opgivne data i ovenstående skema. Installatøren eller brugeren af

udstyret er ansvarlig for at sikre, evt. i samråd med forsyningsdistributøren,

at udstyret er tilsluttet til en netforsyning med en kortslutningseffekt Ssc

større end eller lig med de opgivne data i ovenstående skema.

2) S Maskiner opfylder de krav der stilles under anvendelse i områder med

forøget risiko for elektrisk chok

3) Angiver at maskinen er beregnet for såvel indendørs som udendørs

anvendelse

STRØMKILDE 300 300 IAC 400 400 IAC 550

Netspænding ±15% (50-60Hz), V 3x400 3x400 3x400 3x400 3x400

Minimum generatorstørrelse, kVA 16 19 27 29 40

1)

Minimum kortslutningseffekt, MVA TBD 4,3 6,0 6,0 9,5

Sikring, A 16 16 20 20 35

Netstrøm, effektiv, A 11,0 16 17,5 16,5 27,2

Netstrøm, max., A 15,4 18,3 26,0 28,2 39,2

Effekt, 100%, kVA 9,0 11,1 12,1 11,4 18,9

Effekt, max., kVA 10,7 12,7 18,0 19,5 27,1

Effekt, tomgang, W 30 30 30 30 30

Virkningsgrad 0,85 0,85 0,85 0,8 0,90

Powerfaktor 0,90 0,90 0,90 0,90 0,90

MIG MMA MIG MMA MIG MMA MIG MMA MIG MMA

Strømområde, A 15-300 15-250 15-300 15-300 15-400 15-400 15-400 15-400 15-550 15-550

Intermittens, 100% 20°C, A/V 290/28,5 250/30,0 300/29,0 300/32,0 345/31,5 345/33,8 310/29,5 310/32,5 475/37,8 475/39,0

Intermittens, maks. 20°C, A/%/V 400/65/34,0 400/65/36,0 400/60/34,0 400/60/36,0 550/60/41,5 550/60/42,0

Intermittens, 100% 40°C, A/V 220/25,0 220/28,8 270/27,5 270/30,8 300/29,0 300/32,0 280/28,0 280/31,2 430/35,5 430/37,2

Intermittens, 60% 40°C, A/V 240/26,0 230/29,2 370/32,5 370/34,8 350/31,5 350/34,0 510/39,5 510/40,4

Intermittens, maks. 40°C, A/%/V 300/25/29,0 250/40/30,0 300/80/29,0 300/80/32,0 400/50/34,0 400/45/36,0 400/40/34,0 400/40/36,0 550/50/41,5 550/50/42,0

Tomgangsspænding, V 50-60 65-70 65-70 65-70 75-80

2)

Anvendelsesklasse, C / S

S/CE / S/CE S/CE / S/CE S/CE / S/CE S/CE / S/CE S/CE / S/CE

3)

Beskyttelsesklasse IP23S IP23 IP23 IP23 IP23

Normer, C

Normer, S

IEC60974-1, IEC60974-5, IEC60974-10 Cl. A

IEC60974-1, IEC60974-10 Cl. A

Dimensioner C (HxBxL), mm

Dimensioner S (HxBxL), mm

700x260x735

454x260x735

700x260x735

454x260x735

700x260x735

454x260x735

700x260x735

454x260x735

700x260x735

454x260x735

Vægt C / S, kg 36,9 / 26 53 / 36 52 / 35 53 / 53 / 36

STRØMKILDE 300 Boost

Netspænding ±10% (50-60Hz), V 208-380 380-440

Minimum generatorstørrelse, kVA 16 16

1)

Minimum kortslutningseffekt, MVA 3,75

Sikring, A 20 16

Netstrøm, effektiv, A 19,5 10,6

Netstrøm, max., A 31,6 16,2

Effekt, 100%, kVA 7,1 7,0

Effekt, max., kVA 11,0 10,6

Effekt, tomgang, W 45 45

Virkningsgrad 0,81 0,82

Powerfaktor 0,95 0,95

MIG MMA MIG MMA

Strømområde, A 15-300 15-250 15-300 15-250

Intermittens, 100% 20°C, A/V 250/26,5 250/26,5

Intermittens, maks. 20°C, A/%/V 300/40/29,0 300/40/29,0

Intermittens, 100% 40°C, A/V 200/24,0 200/28,0 200/24,0 200/28,0

Intermittens, 60% 40°C, A/V 210/24,5 210/28,4 210/24,5 210/28,4

Intermittens, maks. 40°C, A/%/V 300/25/29,0 250/35/30,0 300/25/29,0 250/35/30,0

Tomgangsspænding, V 50-60

2)

Anvendelsesklasse, C / S

S/CE / S/CE

3)

Beskyttelsesklasse 23S

Normer, C

Normer, S

IEC60974-1, IEC60974-5, IEC60974-10 Cl. A

IEC60974-1, IEC60974-10 Cl. A

Dimensioner C (HxBxL), mm

Dimensioner S (HxBxL), mm

700x260x735

454x260x735

Vægt C / S, kg 45 / 34

11

Tekniske data 2

EU-OVERENSSTEMMELSESERKLÆRING

MIGATRONIC A/S

Aggersundvej 33

9690 Fjerritslev

Danmark

erklærer, at nedennævnte maskine

Type: SIGMA SELECT ROBO

er i overensstemmelse med bestemmelserne i

direktiverne 2014/35/EU

2014/30/EU

2011/65/EU

Europæiske EN/IEC60974-1

standarder: EN/IEC60974-2

EN/IEC60974-5

EN/IEC60974-10 (Class A)

Udfærdiget i Fjerritslev 01.03.2018

Niels Jørn Jakobsen

CEO

BETJENING PROCES VÆRDIOMRÅDE

Valg af tastemetode, 2-takt/4-takt MIG/MAG 2/4

Kontrol af strøm/spænding/trådhastighed - Lokal/brænder/fjernkontrol

Rangering af tråd MIG/MAG

Brænderkøling - Vandkølet/luftkølet

Hotstart % MMA 0,0-100,0

Hotstart-tid, sek. MMA 0,0-20,0

Arc power, % MMA 0,0-150,0

Gasforstrømning, sek. MIG/MAG 0,0-10,0

Krybestart, m/min MIG/MAG 0,5-24,0

Hotstart, % Synergisk -99-(+)99

Hotstart tid, sek. Synergisk 0,0-20,0

Strømsænkningstid, sek. Synergisk 0,0-10,0

Stopstrøm, A Synergisk 0-100

Stopstrømtid, sek. Synergisk 0,0-10,0

Gasefterstrømning, sek. MIG 0,0-20,0

Sekvenstimer / punktsvejsetid, sek. MIG 0,0-50,0

DUO Plus™ effekttrim, % MIG 0-50

DUO Plus™ tid, sek. MIG 0,1-9,9

Elektronisk drossel MIG -5,0-(+)5,0

Sekvens, sekvenstrin MIG 9

KØLEMODUL MCU 1300

Køleeffekt (1 l/min), W 1300

Køleeffekt (1,5 l/min), W 1600

Tankkapacitet, liter 5

Flow, bar - °C - l/min 3,0-60-1,5

Maks. tryk, bar 5

Normer IEC60974-2,

IEC60974-10 CL.A

Dimensioner (HxBxL), mm 207x260x680

Vægt, kg 20

12

Tekniske data Anybus moduler

Supported Anybus communication interface

General Technical Data

Certification UL, cUL File number E214107

CE - Declaration of Pre-Conformity

Emission EN 61000-6-4

EN55011 Radiated emission

EN55011 Conducted emission

Immunity EN 61000-6-2 EN61000-4-2 Electrostatic discharge

EN61000-4-3 Radiated immunity

EN61000-4-4 Fast transients/burst

EN61000-4-5 Surge immunity

EN61000-4-6 Conducted immunity

DeviceNet

Vendor ID / Name: 90 (005Ah) / (HMS Industrial Networks)

Product Name: ‘Anybus-CompactCom DeviceNet’

ProdTypStr: Generic Device

Device Type: 0 (0000h)

Product Code: 98 (0062h) (Anybus-CompactCom DeviceNet)

Baud rates: 125kbps – 250kbps - 500kbps

Major Revision: 2

Minor Revision: 1

The Anybus CompactCom DeviceNet module accepts 11-25 V on the industrial network side of the module. Maximum current

consumption at 11-25 V is 36-38 mA/module.

Ethernet IP

Vendor ID / Name: 90 (005Ah) / (HMS Industrial Networks)

Product Name: ‘Anybus-CC EtherNet/IP’

ProdTypStr: Generic Device

Device Type: 0 (0000h) (Generic Device)

Product Code: 99 (0063h) (Anybus-CompactCom EtherNet/IP)

Assembly instance input: 100 (0064h)

Assembly instance output: 150 (0096h)

Configuration instance: 1 (0001h)

Major Revision: 2 (0002h)

Minor Revision: 11 (000Bh)

The Ethernet interface supports 10/100Mbit, full or half duplex operation.

ProfiNET

Vendor ID: 268 (010Ch) (HMS Industrial Networks)

Device Type: 7 (0007h) (Anybus-CompactCom PROFINET IO)

Station Type: ‘ABCC-PRT’

ProfiBus

IM Manufacturer ID: 268 (010Ch) (HMS Industrial Networks)

IM Order ID: ‘ABCC-DPV1’

IM Profile ID: 62976 (F600h) (Generic Device)

IM Profile Specific Type: 4 (0004h) (Communication Module)

IM Version: 257 (0101h)

IM Supported: 30 (001Eh) (IMO..4 supported)

EtherCAT

Vendor ID E000 001Bha (HMS Industrial Networks Secondary Vendor ID, has to be replaced by Vendor ID of end product vendor.)

a. For firmware revision 1.02 and later.

Product Code 0000 0034h (Anybus CompactCom EtherCAT)

Device Name ‘Anybus-CC EtherCAT’

Serial Number (Assigned during manufacturing)

13

Anybus indikatorer

DeviceNet

# Element

1 Netværksstatus LED

2 Modulstatus LED

3 DeviceNet tilslutning

4 M12 hunstik

5 M12 hanstik

Network Status

Tilstand Indikation

Slukket Ikke online / Ingen strøm

Grøn Online, en eller flere tilslutninger

etableret

Grøn, blinkende (1 Hz) Online, ingen tilslutninger etableret

Rød Kritisk linkfejl

Rød, blinkende (1 Hz) En eller flere tilslutninger på pause

Afvekslende rød/grøn Selvtest

Module Status

Tilstand Indikation

Slukket Ingen strøm

Grøn Normal drift

Grøn, blinkende(1 Hz) Manglende eller ufuldstændig konfigu-

ration, enheden mangler igangsætning

Rød Fejl(ene) kan ikke udbedres

Rød, blinkende (1 Hz) Fejl(ene) kan udbedres

Afvekslende rød/grøn Selvtest

DeviceNet stikforbindelse

Denne stikforbindelse sørger for forbindelse

Pin Signal Beskrivelse

1 V- Negativ bus forsyningsspænding

2 CAN_L CAN lav bus-linje

3 SHIELD Kabelbeskyttelse

4 CAN_H CAN høj bus-linje

5 V+ Positiv bus forsyningsspænding

EtherNet IP

# Element

1 Netværksstatus LED

2 Modulstatus LED

3 Link/Aktivitet

4 Ethernet Interface

Network Status LED

LED tilstand Beskrivelse

Slukket Ingen strøm eller ingen IP-adresse

Grøn Online, en eller flere tilslutninger

etableret (CIP klasse 1 eller 3)

Grøn, blinkende Online, ingen tilslutninger etableret

Rød Dobbelt IP-adresse, FATAL fejl

Rød, blinkende En eller flere tilslutninger på pause (CIP

Klasse 1 eller 3)

Modul Status LED

Bemærk: Der udføres en testsekvens på denne LED

under opstart

LED tilstand Beskrivelse

Slukket Ingen strøm

Grøn Kontrolleret af en scanner i Run tilstand

Grøn, blinkende Ikke konfigureret, eller scanner er ikke

i drift

Rød Alvorlig fejl (EXCEPTION-tilstand, FATAL

fejl etc.)

Rød, blinkende Fejl, der kan udbedres

LINK/Aktivitet LED

LED tilstand Beskrivelse

Off Ingen link, ingen aktivitet

Grøn Link etableret

Grøn, flakkende Aktivitet

1

8

14

Anybus indikatorer

PROFIBUS

# Element

1 Driftsfunktion

2 Status

3 PROFIBUS tilslutning

4 M12 hunstik

5 M12 hanstik

Driftstilstand

Tilstand Indikation

Slukket Ikke online / Ingen strøm

Grøn Dataudveksling

Blinkende grøn Slet

Blinkende rød (1 blink) Parameterfejl

Blinkende rød (2 blink) PROFIBUS konfigurationsfejl

Status

Tilstand Indikation Bemærkninger

Slukket Ikke initialiseret Anybus tilstand = ‘OPSTILLING¨’

eller ‘NW_INIT’

Grøn Initialiseret Anybus modul har forladt

‘NW_INIT’ tilstand

Blinkende grøn Initialiseret, diagnostisk

event(s) til stede

Udvidet diagnostisk bit er

indstillet

Rød Fejltilstand Anybus tilstand = ‘EXCEPTION’

PROFINET IP

# Element

1 Netværksstatus LED

2 Modulstatus LED

3 Link/Aktivitet LED

4 Ethernet Interface

Netværk Status LED

Bemærk: Der udføres en testsekvens på denne LED under

opstart

LED Tilstand Beskrivelse Bemærkninger

Off Offline - Ingen strøm

- Ingen tilslutning med IO Controller

Grøn Online

(RUN)

- Tilslutning med IO Controller

etableret

- IO Controller i RUN tilstand

Grøn,

blinkende

Online

(STOP)

- Tilslutning med IO Controller

etableret

- IO Controller i STOP tilstand

Modul Status LED

Bemærk: Der udføres en testsekvens på denne LED under

opstart

LED Tilstand Beskrivelse Bemærkninger

Off Ikke

Initialiseret

Ingen strøm - eller - Modul i

‘OPSTILLING’ or ‘NW_INIT’ tilstand

Grøn Normal drift Modul har skiftet fra ‘NW_INIT’

tilstand

Grøn,

1 blink

Diagnostiske

event(s)

Diagnostiske event(s) til stede

Grøn,

2 blink

Blink Brugt af engineering værktøjer til

at identificere knude på netværk

Rød Exception-fejl Modul i tilstand ‘EXCEPTION’

Rød, 1 blink Konfigurations-

fejl

Expected Identification varierer

fra Real Identification

Rød,

2 blink

IP Adressefejl IP adresse ikke indstillet

Rød,

3 blink

Fejl i stationsnavn

Stationsnavn ikke indstillet

Rød,

4 blink

Intern fejl Modul er stødt på en større intern

fejl

LINK/Aktivitet LED

LED Tilstand Beskrivelse Bemærkninger

Slukket Ingen link Ingen link, ingen kommunikation

Grøn Link Ethernet link etableret, ingen

kommunikation

Grøn,

flakkende

Aktivitet Ethernet link etableret,

kommunikation til stede

Ethernet Interface

Ethernet interfacet kører ved 100 Mbit, fuld duplex, med

autonegotiation aktiv som standard.

1

8

15

Anybus indikatorer

EtherCAT

EtherCAT Connector

# Element

1 RUN LED

2 FEJL LED

3 EtherCAT (port 1)

4 EtherCAT (port 2)

5 Link/Aktivitet (port 1)

6 Link/Aktivitet (port 2)

RUN LED

Denne LED afspejler status på CoE (CANopen over EtherCAT)

kommunikation

LED Tilstand Indikation Beskrivelse

Slukket INIT CoE enhed i ‘INIT’-tilstand (eller

ingen strøm)

Grøn OPERATIONAL CoE enhed i

‘OPERATIONAL’-tilstand

Grøn,

blinkende

PREOPERATIONAL

CoE enhed i

‘PRE-OPERATIONAL’-tilstand

Grøn,

enkelt blink

SAFEOPERATIONAL

CoE enhed i

‘SAFE-OPERATIONAL’-tilstand

Rød

a

(Fatal Event) -

a. Hvis RUN og ERR bliver rød, indikerer det en fatal event, der

tvinger bus interfacet til fysisk passiv tilstand.

Kontakt HMS teknisk support.

ERR LED

Denne LED indikerer EtherCAT kommunikationsfejl etc.

LED Tilstand Indikation Beskrivelse

Slukket Ingen fejl Ingen fejl (eller ingen strøm)

Rød,

blinkende

Ugyldig

konfiguration

Tilstandsændring modtaget fra

master er ikke mulig på grund af

ugyldige register- eller objektindstillinger.

Rød,

dobbelt

blink

Application

watchdog timeout

Sync manager watchdog timeout

Rød

a

Application

controller failure

Anybus-modul i EXCEPTION

a. Hvis RUN og ERR bliver rød, indikerer det en fatal event, der

tvinger bus interfacet til fysisk passiv tilstand.

Kontakt HMS teknisk support.

LINK/Aktivitet

Disse LED’er indikerer EtherCAT linkstatus og aktivitet.

LED Tilstand Indikation Beskrivelse

Slukket Ingen link Link ikke registreret (eller ingen

strøm)

Grøn Link registreret,

ingen aktivitet

Link registreret, ingen trafik

detekteret

Grøn,

flakkende

Link registreret,

aktivitet detekteret

Link registreret, trafik

detekteret

6

16

17

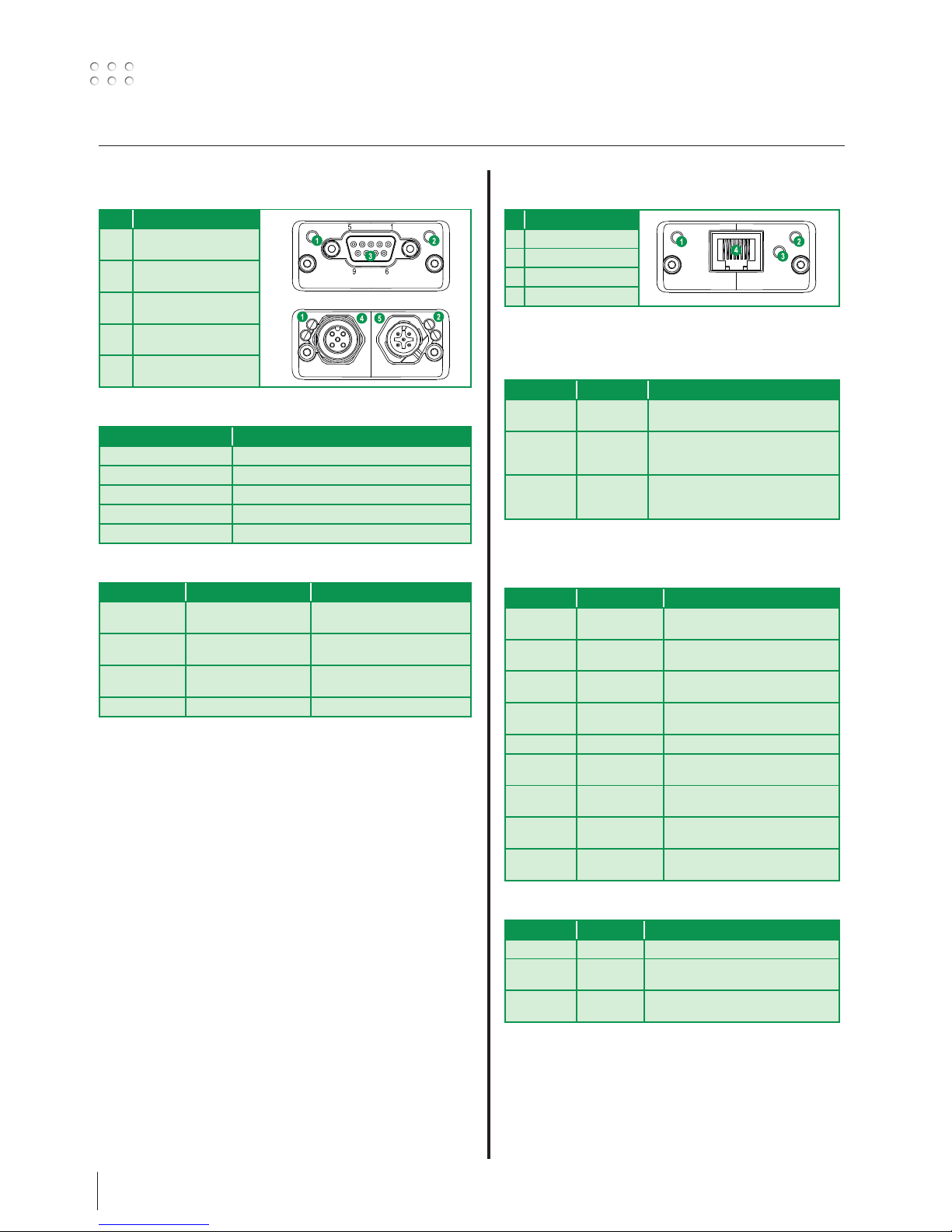

Connection and operation

1

0

1

Warning

Read warning notice and instruction

manual carefully prior to initial

operation and save the information

for later use.

Permissible installation

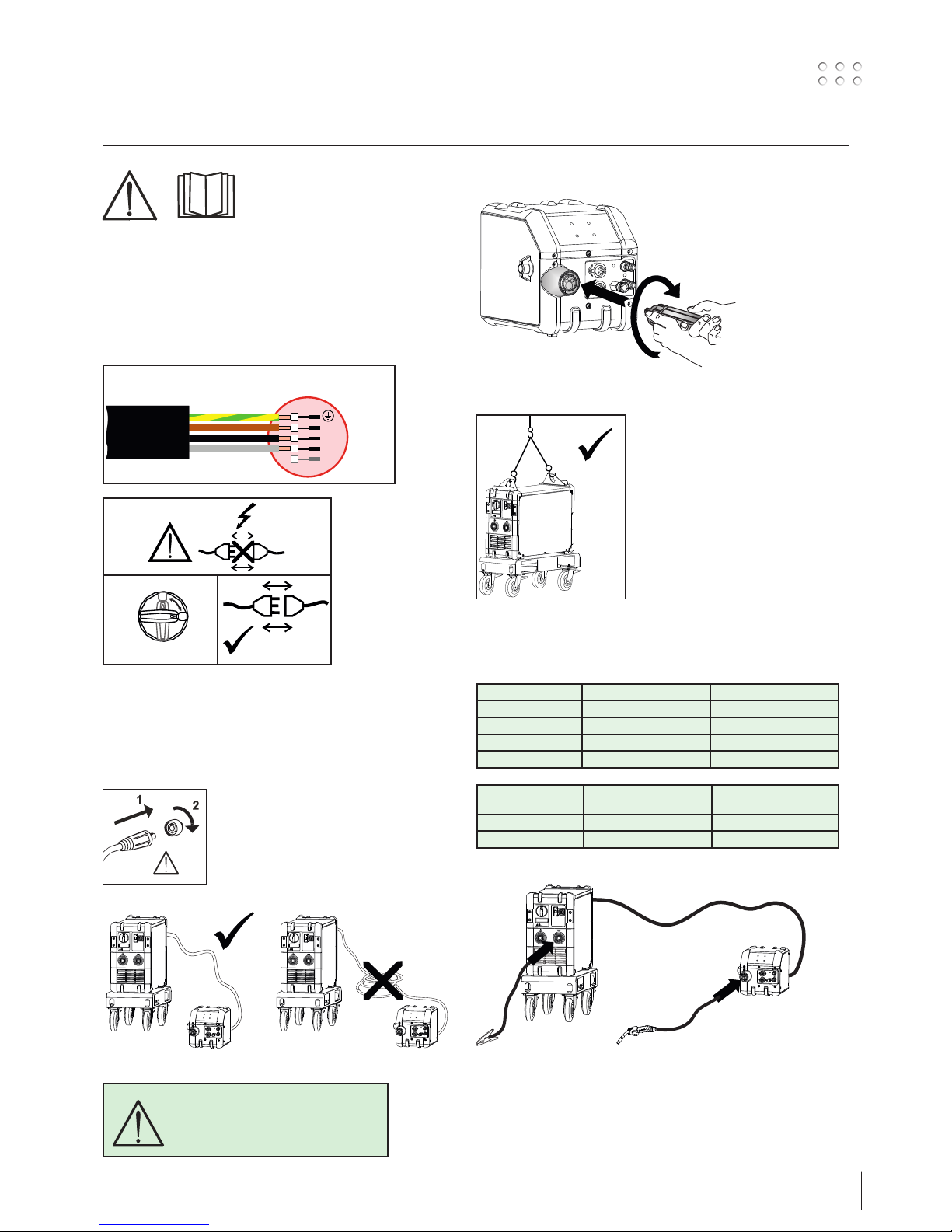

Mains connection

Connect the machine to the correct mains supply. Please read

the type plate (U1) on the rear side of the machine.

2

Connection of shielding gas

Connect the gas hose, which branches off from the back panel

of the welding machine (3), to a gas supply with pressure

regulator (2-6 bar). (Note: Some types of pressure regulators

require an output pressure of more than 2 bar to function

optimally).

Important!

In order to avoid destruction of plugs and

cables, good electric contact is required

when connecting earth cables and welding

hoses to the machine.

WARNING

When you activate the torch trigger,

there is voltage applied to the welding

wire and electrode.

Connection of welding hose

Lift instructions

(Lifting kit no. 78857054)

Recommended cable dimensions

Welding current DC PULSE

200 A 35 mm² 35 mm²

300 A 50 mm² 70 mm²

400 A 95 mm² / 2x50 mm² 95 mm² / 2x50 mm²

550 A 2x70 mm² 2x70 mm²

Welding process Distance to work piece

(a+b)

Total cable length in

welding circuit (a+b+c)

MIG - IAC and pulse 10 m 20 m

MIG - non pulse 30 m 60 m

c

a

b

L1

L2

L3

N

yellow/green

brown

black

grey

3x208-440V (boost)

3x400V

18

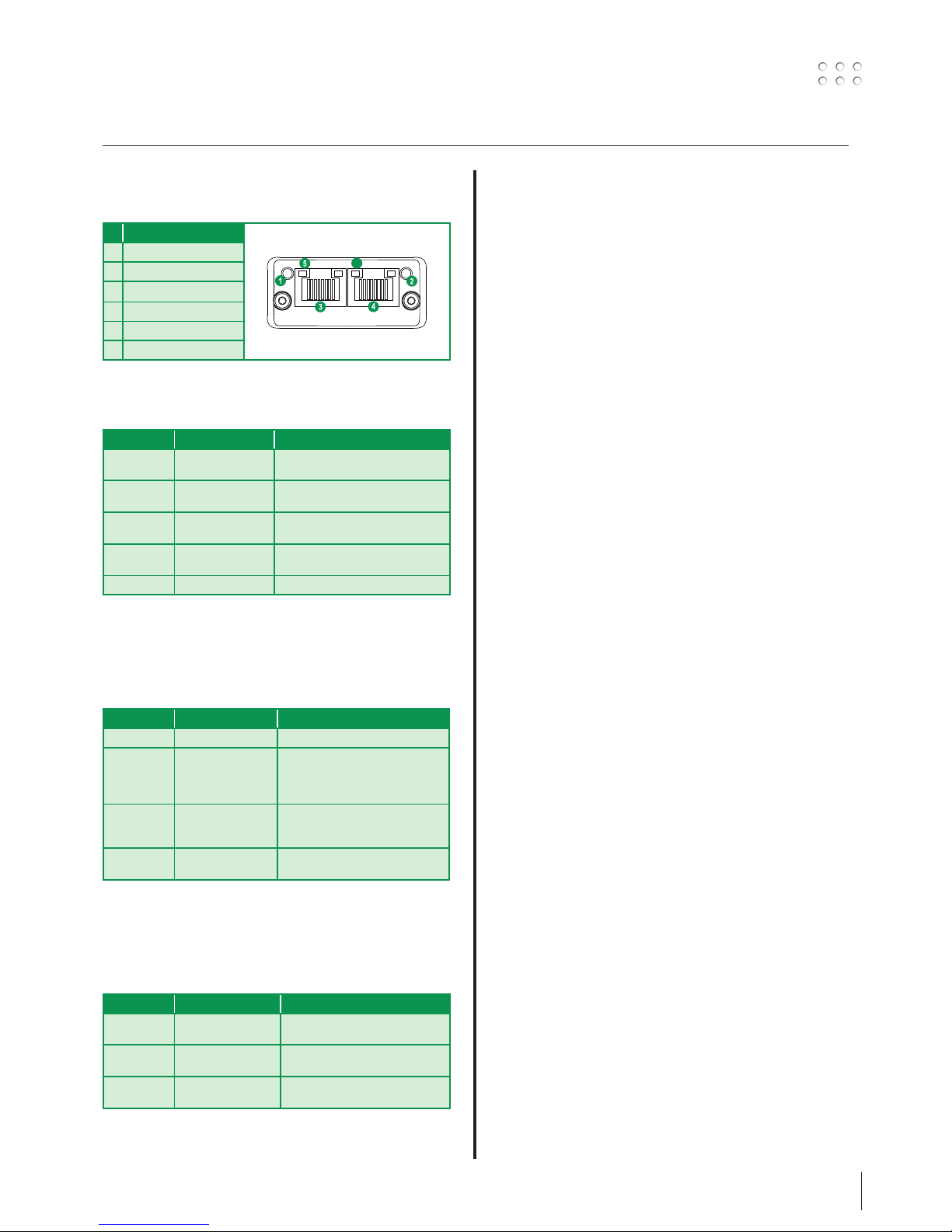

Connection and operation

11

GAS

2-6 bar

Power

F

F

F

1

2

3

4a

4b

5

5

6

6

7

7

8

9

10

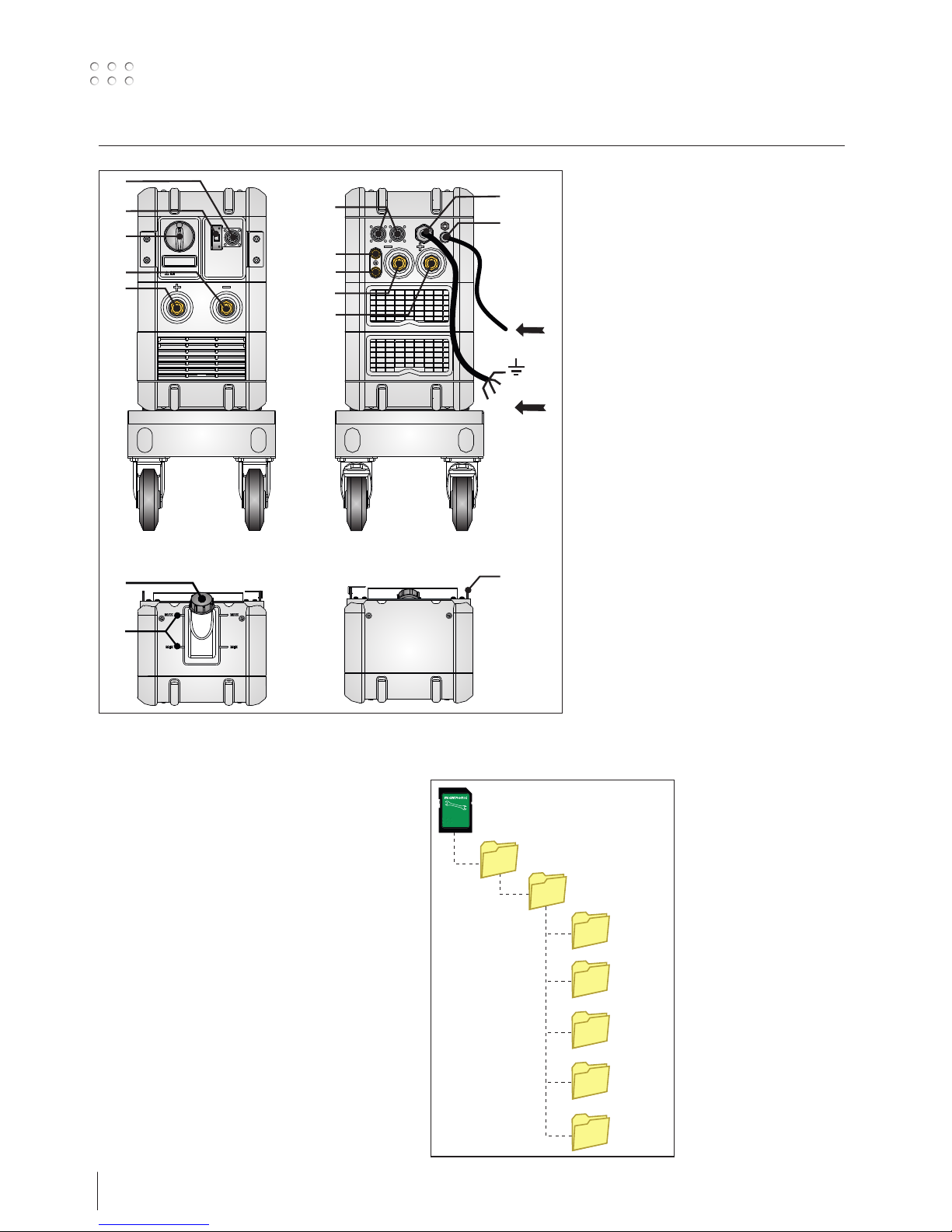

1. Mains connection

2. Power switch on/off

3. Connection of shielding gas

4a. Connection of cooling hose, return (red)

4b. Connection of cooling hose, flow (blue)

5. Dinse connection -

6. Dinse connection +

7. CAN connection

8. Fieldbus module

9. Refill of cooling liquid

10. Cooling liquid level control (Min/Max)

11. Assembly plate

MIGA_CFG

DOCUMENTS

Devicenet

EtherCAT

Profibus

Profinet

Ethernet-IP

Config.

Robot / PLC setup

Migatronic’s standard configuration file (10010208) is

loaded in SIGMA SELECT.

The SD card included in the supply contains additional

configuration files and setup files required by some robots

and PLCs.

Load the MIGA_CFG/DOCUMENTS folders on your PC.

Each folder contains EDS or GSD files, user manuals, quick

guides and various Anybus module documentation for

communication devices.

19

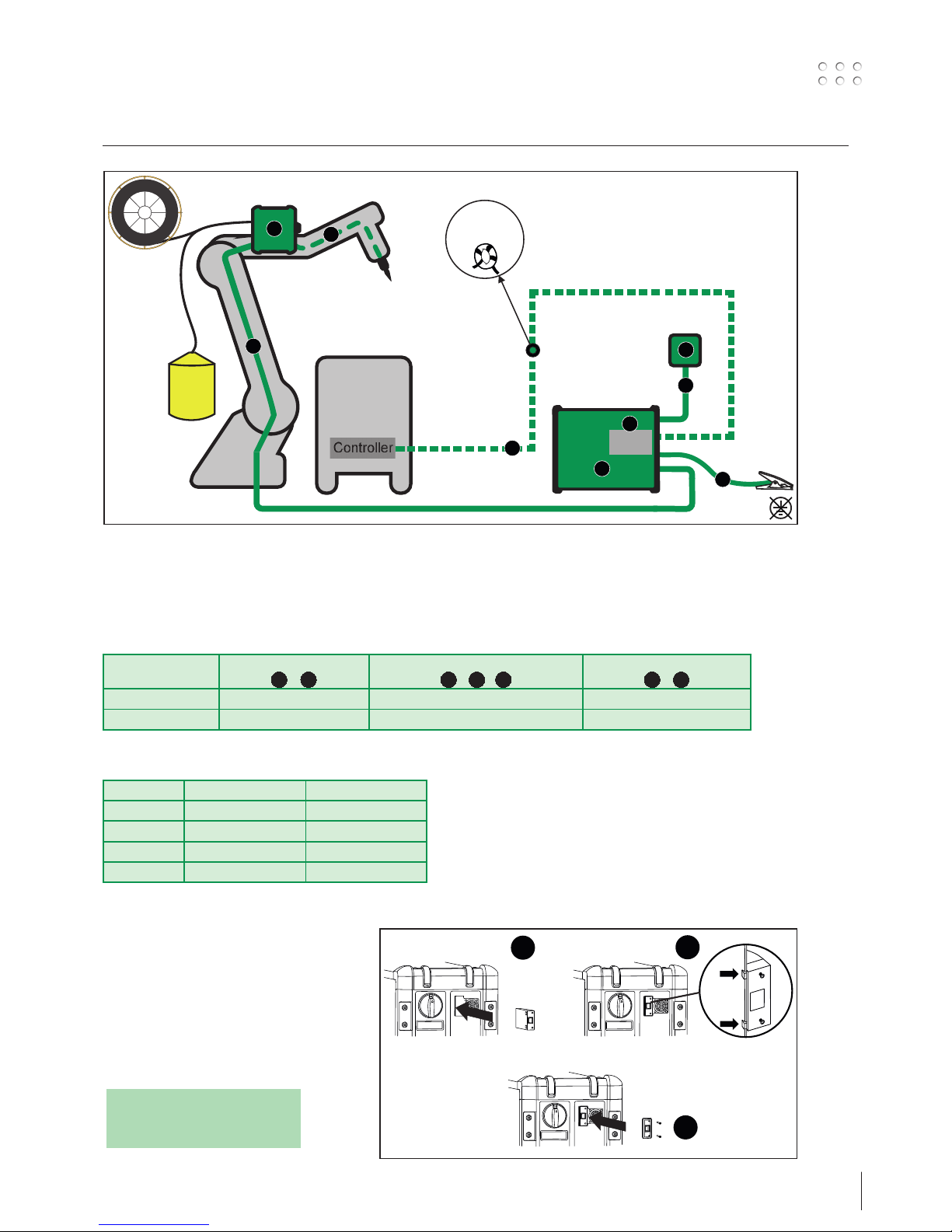

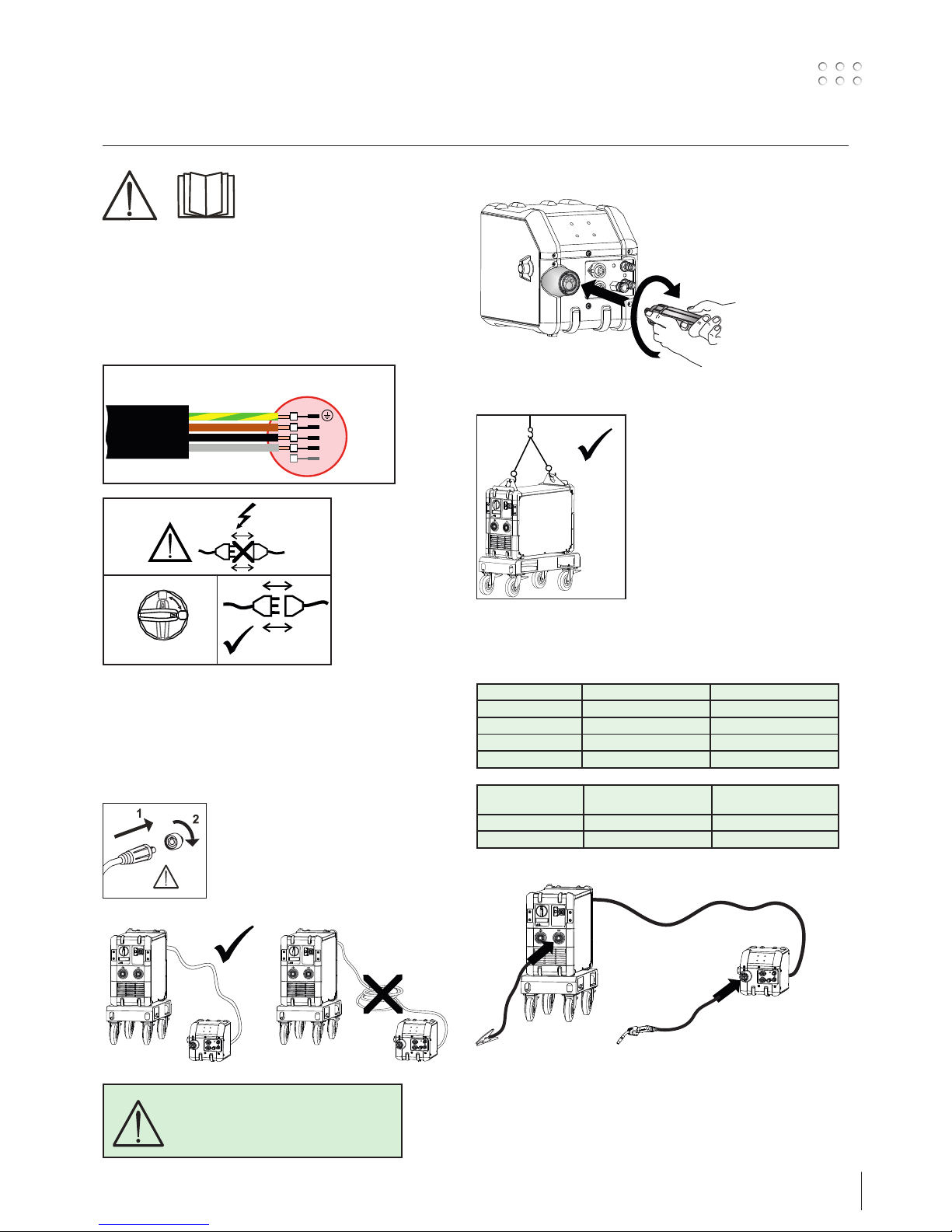

How to connect the installation

Controller

d

ROBOT/PLC

controller

3 windings

through core

17440005

RWF 30

SIGMA SELECT ROBO

REMOTE

Anybus

communication

b

4

e

c

a

2

Anybus

interface

1

3

Main components:

1. Interface

2. Welding inverter

3. Wire feed unit - RWF 30

4. Remote control

Cables and fittings:

a. Signal cable for robot controller

b. CAN communication cable for welding inverter

c. Interconnection, gas and 2xwelding cable and CAN

d. Welding torch

e. Welding return cable

Welding process Distance to work piece

( + )

Total cable length in welding circuit

( + + )

Total length of CAN cable

( + )

MIG – pulse 10 m 20 m 30 m

MIG – non pulse 30 m 60 m 30 m

cc c

b

d d e

Installing

the Anybus module

1. Important! Once you have installed the

Anybus module, insert the plug straight into

the hole.

2. Press the plug slightly into position.

3. Tighten the Anybus module using the screws.

1

2

3

Cable dimensions

Welding current DC PULSE

200 A 35 mm² 35 mm²

300 A 50 mm² 70 mm²

400 A 95 mm² / 2x50 mm² 95 mm² / 2x50 mm²

550 A 2x70 mm² 2x70 mm²

NOTE:

DEFECTIVE CONNECTORS

ARE NOT COVERED BY WARRANTY!!!

20

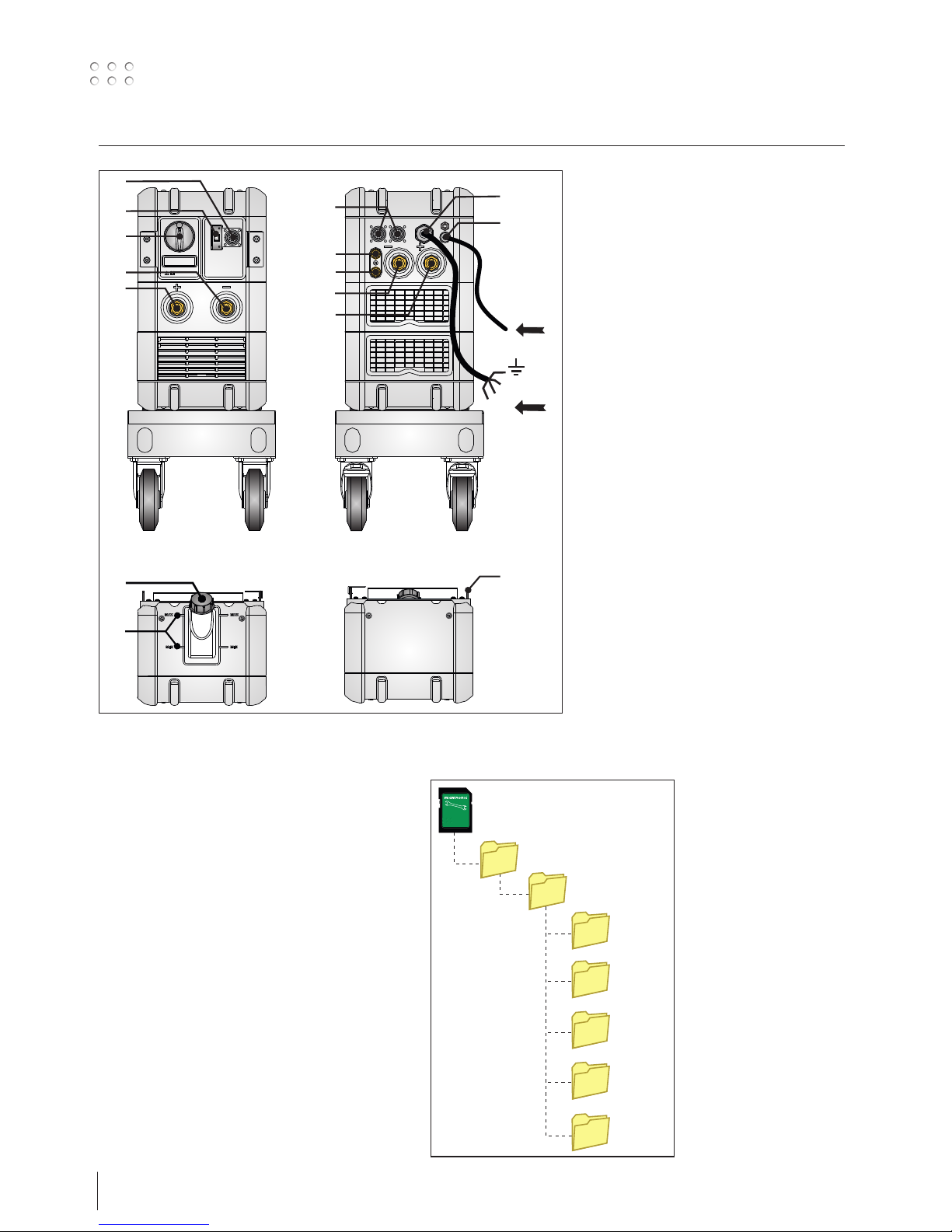

Connection and operation

x4

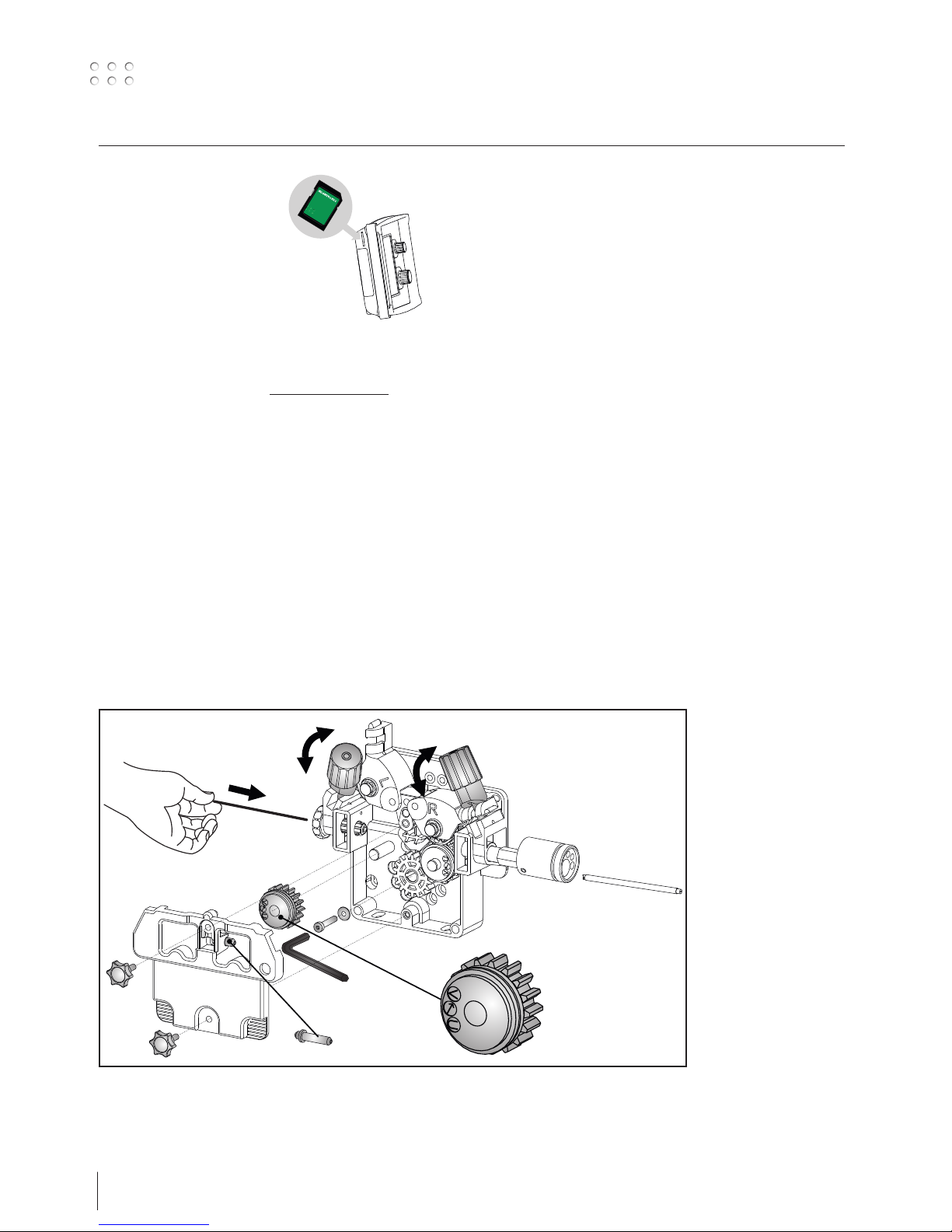

Assembly of parts in wire feed unit

The pressure of the

thumbscrew is adjusted to

allow the wire feed roll

just to slide on the wire

when this is stopped at

the contact tip

Software update

• Insert the SD-card

• Turn on the machine

• Wait until the unit indicates

that the update is complete

• Turn off the machine and

remove the SD card.

• The machine is now ready

for use.

New software will be loaded into power source and all

connected units.

The software can be downloaded from http://migatronic.com

Licence SW

If you purchase additional licences for programs or special

funtions, load the MigaLic.dat files like the software packages.

Note! Create a backup of the files.

The MigaLic.txt file contains information about licence number

and licences saved on SD card.

21

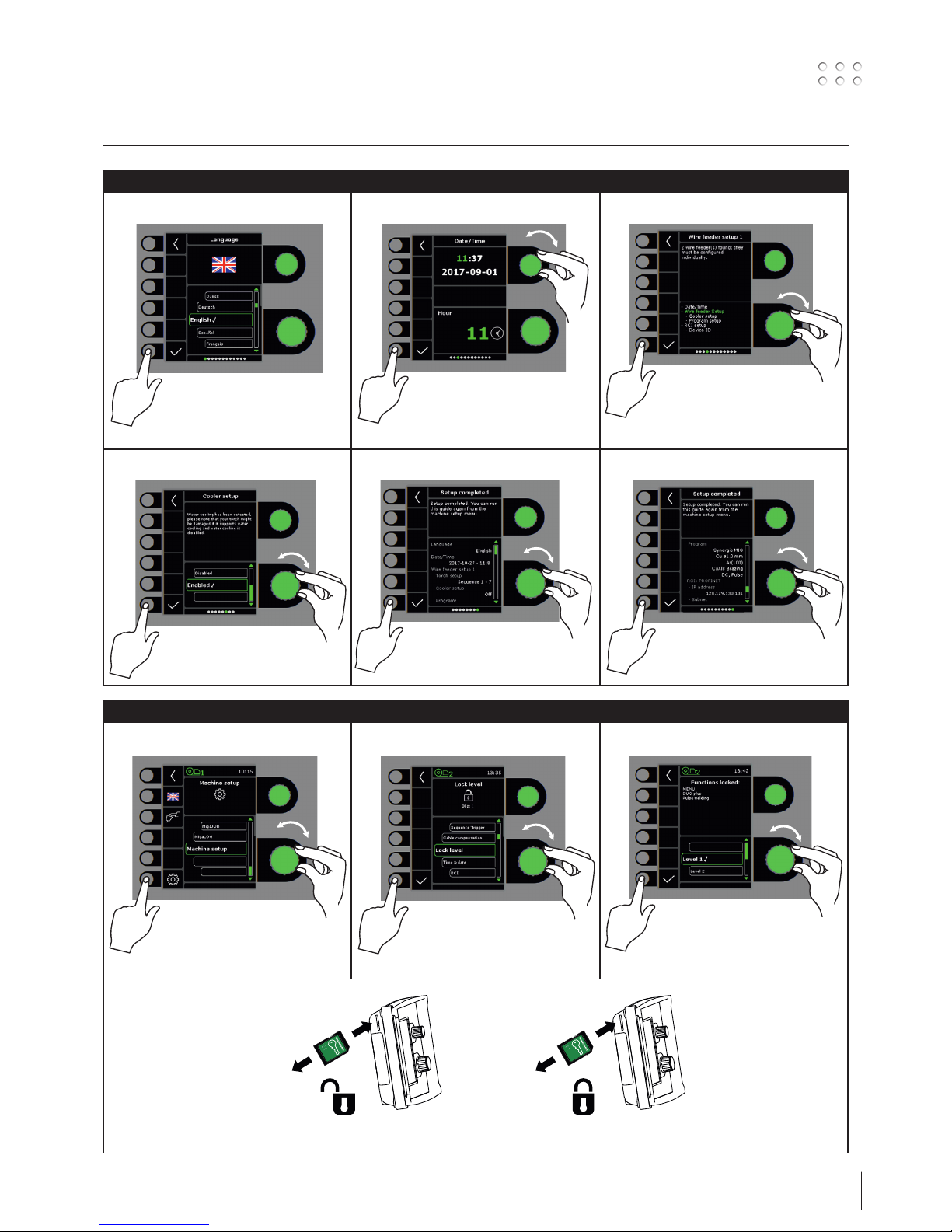

Special functions

Setup wizard

I II

III

IV V VI

Lock function

I II III

22

Special functions

Software / Licences

I II

III

Cable compensation (calibration of resistance in welding hose)

I II III

IV V

1

2

Std.

The surface of the workpiece must be

clean to ensure good contact with the

torch.

Torch setup

I II

12

- - -

23

Error handling

SIGMA Select Robo has a sophisticated built-in self-protection system. The machine automatically stops the gas supply, interrupts the

welding current and stops the wire feeding in case of an error.

Selected errors:

Torch cooling fault

Cooling fault is indicated on machines in case of insufficiant circulation of the cooling liquid due to faulty connection, defective parts or

choking. Check that the cooling hoses are correctly connected, top up the water tank and check welding hose and branches.

The cooling fault is cancelled by pressing shortly on the P-key pad.

Gas control fault (IGC)

Gas fault exists due to a to low or high gas flow.

Make sure that the pressure on the gas flow is higher than 2 bar and less than 6 bar, corresponding to 5 l/min and 27 l/min.

The fault is disconnected by adjusting the manual gas flow to 27 l/min. The gas fault is reset by a short pressure on the P-key pad.

Error log

I II III

Error log

All errors are saved in the

machine error log in the

menu Service.

The error log can be

distributed, when inserting

a SD-card and pressing the

following key:

The error log is now saved

at the SD-card.

The error log can be reset

when pressing the key pad

with the trash bin.

24

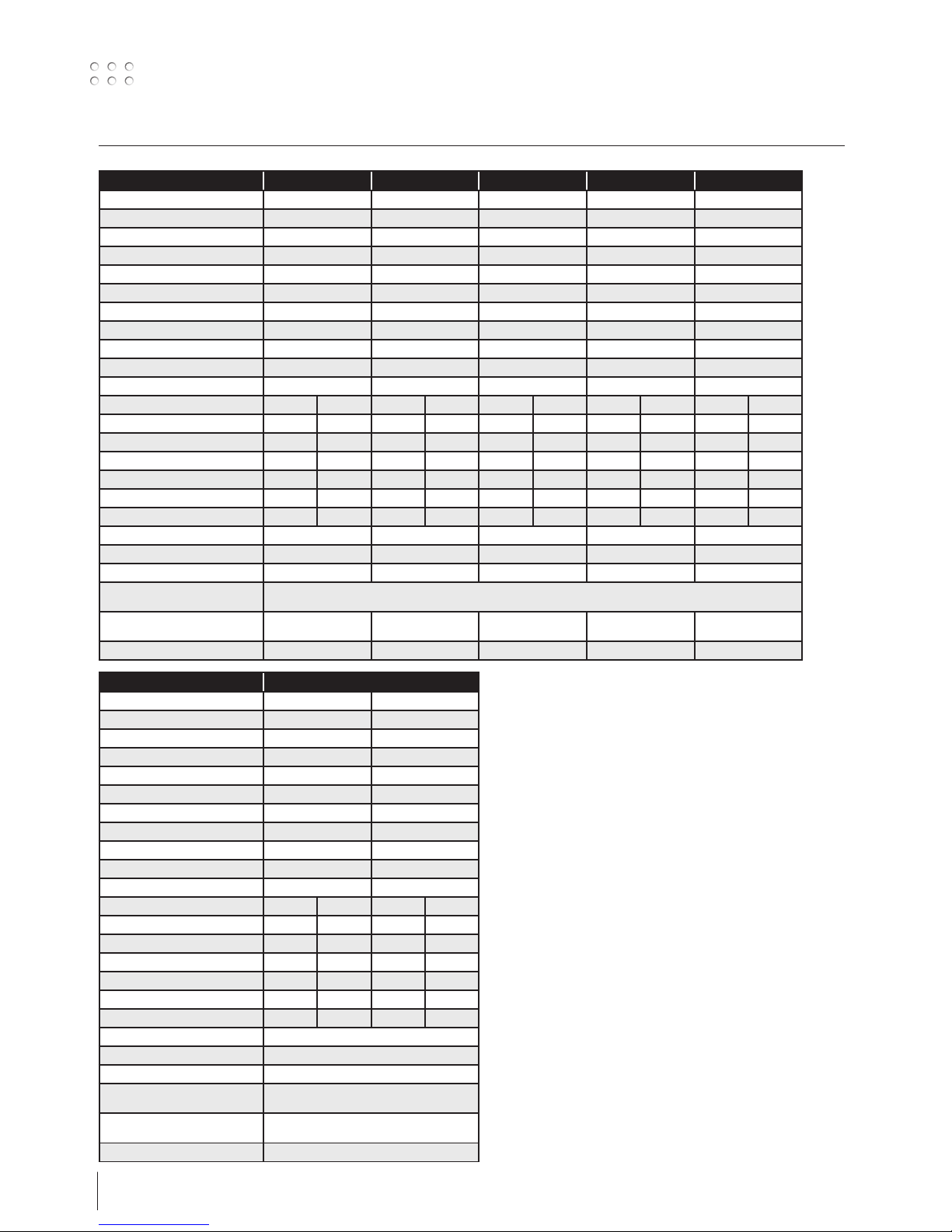

Technical data 1

1) This equipment complies with IEC 61000-3-12 provided that the shortcircuit power Ssc of the grid at the interface point is greater than or equal

to the stated data in the abovementioned table. It is the responsibility

of the installer or user of the equipment to ensure, by consultation with

the distribution network operator if necessary, that the equipment is

connected only to a supply with a short-circuit power Ssc greater than or

equal to the stated data in the abovementioned table.

2) S This machine meets the demand made for machines which are to

operate in areas with increased hazard of electric chocks.

3) Equipment marked IP23/IP23S is designed for indoor and outdoor

applications.

POWER SOURCE 300 300 IAC 400 400 IAC 550

Mains voltage ±15% (50-60Hz), V 3x400 3x400 3x400 3x400 3x400

Minimum generator size, kVA 16 19 27 29 40

1)

Minimum short-circuit power, MVA TBD 4.3 6.0 6.0 9.5

Fuse, A 16 16 20 20 35

Mains current, effective, A 11.0 16 17.5 16.5 27.2

Mains current, max., A 15.4 18.3 26.0 28.2 39.2

Power, 100%, kVA 9.0 11.1 12.1 11.4 18.9

Power, max., kVA 10.7 12.7 18.0 19.5 27.1

Power, open circuit, W 30 30 30 30 30

Efficiency 0.85 0.85 0.85 0.8 0.90

Power factor 0.90 0.90 0.90 0.90 0.90

MIG MMA MIG MMA MIG MMA MIG MMA MIG MMA

Current range, A 15-300 15-250 15-300 15-300 15-400 15-400 15-400 15-400 15-550 15-550

Duty cycle, 100% 20°C (MIG), A 290/28.5 250/30.0 300/29.0 300/32.0 345/31.5 345/33.8 310/29.5 310/32.5 475/37.8 475/39.0

Duty cycle, max. 20°C (MIG), A/%/V 400/65/34.0 400/65/36.0 400/60/34.0 400/60/36.0 550/60/41.5 550/60/42.0

Duty cycle, 100% 40°C (MIG), A/V 220/25.0 220/28.8 270/27.5 270/30.8 300/29.0 300/32.0 280/28.0 280/31.2 430/35.5 430/37.2

Duty cycle, 60% 40°C (MIG), A/V 240/26.0 230/29.2 370/32.5 370/34.8 350/31.5 350/34.0 510/39.5 510/40.4

Duty cycle, max. 40°C (MIG), A/%/V 300/25/29.0 250/40/30.0 300/80/29.0 300/80/32.0 400/50/34.0 400/45/36.0 400/40/34.0 400/40/36.0 550/50/41.5 550/50/42.0

Open circuit voltage, V 50-60 65-70 65-70 65-70 75-80

2)

Sphere of application, C / S

S/CE / S/CE S/CE / S/CE S/CE / S/CE S/CE / S/CE S/CE / S/CE

3)

Protection class IP23S IP23 IP23 IP23 IP23

Standards, C

Standards, S

IEC60974-1. IEC60974-5. IEC60974-10 Cl. A

IEC60974-1. IEC60974-10 Cl. A

Dimensions C (HxWxL), mm

Dimensions S (HxWxL), mm

700x260x735

454x260x735

700x260x735

454x260x735

700x260x735

454x260x735

700x260x735

454x260x735

700x260x735

454x260x735

Weight C / S, kg 36.9 / 26 53 / 36 52 / 35 53 / 53 / 36

POWER SOURCE 300 Boost

Mains voltage ±10% (50-60Hz), V 208-380 380-440

Minimum generator size, kVA 16 16

1)

Minimum short-circuit power, MVA 3.75

Fuse, A 20 16

Mains current, effective, A 19.5 10.6

Mains current, max., A 31.6 16.2

Power, 100%, kVA 7.1 7.0

Power, max., kVA 11.0 10.6

Power, open circuit, W 45 45

Efficiency 0.81 0.82

Power factor 0.95 0.95

MIG MMA MIG MMA

Current range, A 15-300 15-250 15-300 15-250

Duty cycle, 100% 20°C (MIG), A 250/26.5 250/26.5

Duty cycle, max. 20°C (MIG), A/%/V 300/40/29.0 300/40/29.0

Duty cycle, 100% 40°C (MIG), A/V 200/24.0 200/28.0 200/24.0 200/28.0

Duty cycle, 60% 40°C (MIG), A/V 210/24.5 210/28.4 210/24.5 210/28.4

Duty cycle, max. 40°C (MIG), A/%/V 300/25/29.0 250/35/30.0 300/25/29.0 250/35/30.0

Open circuit voltage, V 50-60

2)

Sphere of application, C / S

S/CE / S/CE

3)

Protection class IP23S

Standards, C

Standards, S

IEC60974-1. IEC60974-5. IEC60974-10 Cl. A

IEC60974-1. IEC60974-10 Cl. A

Dimensions C (HxWxL), mm

Dimensions S (HxWxL), mm

700x260x735

454x260x735

Weight C / S, kg 45 / 34

25

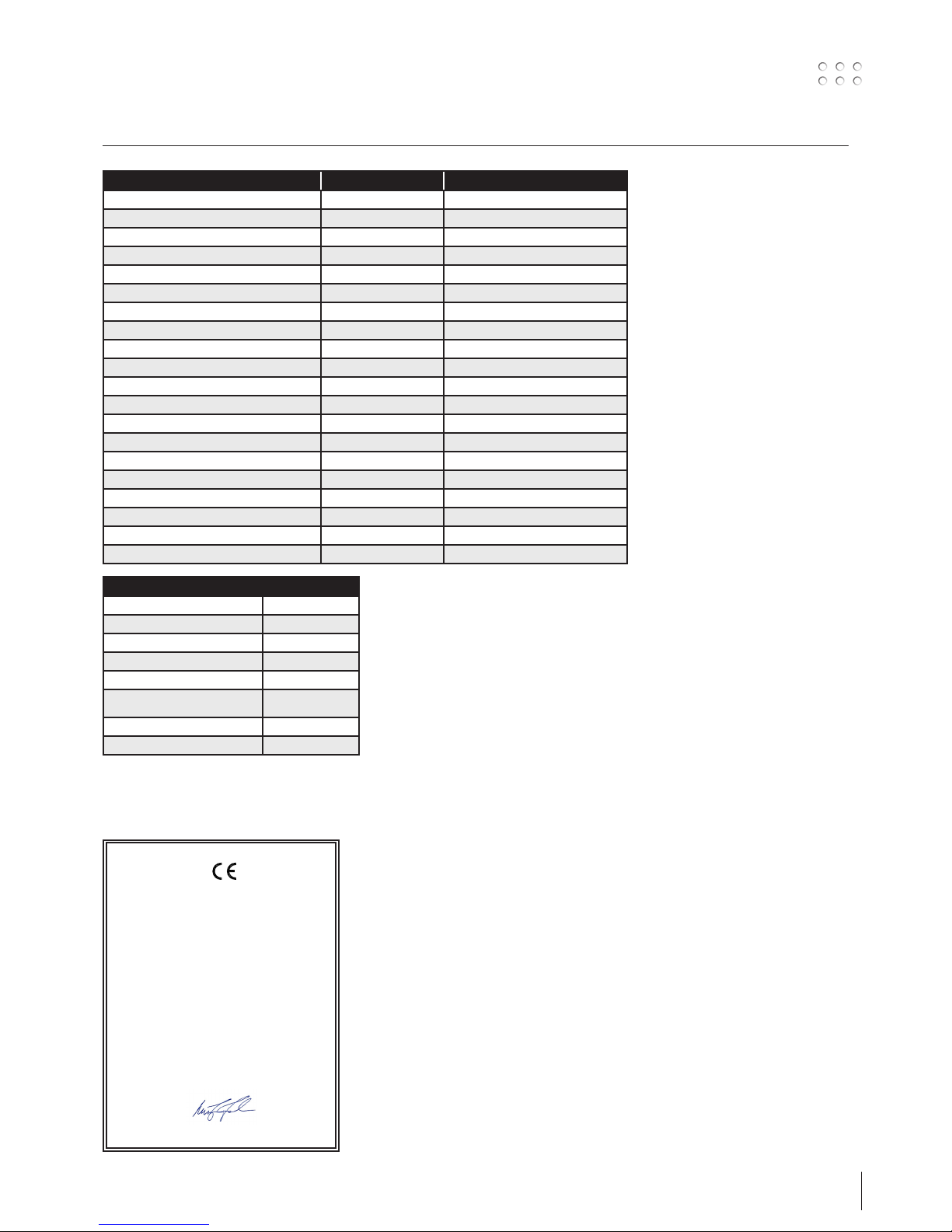

Technical data 2

EC DECLARATION OF CONFORMITY

MIGATRONIC A/S

Aggersundvej 33

9690 Fjerritslev

Denmark

hereby declare that our machine as stated below

Type: SIGMA SELECT ROBO

conforms to directives: 2014/35/EU

2014/30/EU

2011/65/EU

European standards: EN/IEC60974-1

EN/IEC60974-2

EN/IEC60974-5

EN/IEC60974-10 (Class A)

Issued in Fjerritslev 01.03.2018

Niels Jørn Jakobsen

CEO

FUNCTION PROCESS VALUE RANGE

Selection of trigger mode, 2-times / 4-times MIG/MAG 2/4

Control of current/voltage/ wire feed speed - local/torch control/remote control

Wire inching MIG/MAG

Torch cooling - water cooled/air cooled

Hot-start % MMA 0.0-100.0

Hot-start-time, sec. MMA 0.0-20.0

Arc power, % MMA 0.0-150.0

Gas pre-flow, sec. MIG/MAG 0.0-10.0

Soft-start, m/min MIG/MAG 0.5-24.0

Hot-start, % Synergic -99-(+)99

Hot-start-time, sec. Synergic 0.0-20.0

Slope down time, sec. Synergic 0.0-10.0

Stop amp, A Synergic 0-100

Stop Amp time, sec. Synergic 0.0-10.0

Gas post-flow, sec MIG 0.0-20.0

Sequence timer / Spot welding time, sec. MIG 0.0-50.0

DUO Plus™ efficiency, % MIG 0-50

DUO Plus™ time, sec. MIG 0.1-9.9

Electronic choke MIG -5.0-(+)5.0

Sequence, Sequencesteps MIG 9

COOLING UNIT MCU 1300

Cooling efficiency (1 l/min), W 1300

Cooling efficiency (1.5 l/min), W 1600

Tank capacity, liter 5

Flow, bar - °C - l/min 3.0-60-1.5

Pressure max., bar 5

Standards IEC60974-2.

IEC60974-10 CL.A

Dimension s (HxWxL), mm 207x260x680

Weight 20

26

Technical data Anybus modules

Supported Anybus communication interface

General Technical Data

Certification UL, cUL File number E214107

CE - Declaration of Pre-Conformity

Emission EN 61000-6-4

EN55011 Radiated emission

EN55011 Conducted emission

Immunity EN 61000-6-2 EN61000-4-2 Electrostatic discharge

EN61000-4-3 Radiated immunity

EN61000-4-4 Fast transients/burst

EN61000-4-5 Surge immunity

EN61000-4-6 Conducted immunity

DeviceNet

Vendor ID / Name: 90 (005Ah) / (HMS Industrial Networks)

Product Name: ‘Anybus-CompactCom DeviceNet’

ProdTypStr: Generic Device

Device Type: 0 (0000h)

Product Code: 98 (0062h) (Anybus-CompactCom DeviceNet)

Baud rates: 125kbps – 250kbps - 500kbps

Major Revision: 2

Minor Revision: 1

The Anybus CompactCom DeviceNet module accepts 11-25 V on the industrial network side of the module. Maximum current

consumption at 11-25 V is 36-38 mA/module.

Ethernet IP

Vendor ID / Name: 90 (005Ah) / (HMS Industrial Networks)

Product Name: ‘Anybus-CC EtherNet/IP’

ProdTypStr: Generic Device

Device Type: 0 (0000h) (Generic Device)

Product Code: 99 (0063h) (Anybus-CompactCom EtherNet/IP)

Assembly instance input: 100 (0064h)

Assembly instance output: 150 (0096h)

Configuration instance: 1 (0001h)

Major Revision: 2 (0002h)

Minor Revision: 11 (000Bh)

The Ethernet interface supports 10/100Mbit, full or half duplex operation.

ProfiNET

Vendor ID: 268 (010Ch) (HMS Industrial Networks)

Device Type: 7 (0007h) (Anybus-CompactCom PROFINET IO)

Station Type: ‘ABCC-PRT’

ProfiBus

IM Manufacturer ID: 268 (010Ch) (HMS Industrial Networks)

IM Order ID: ‘ABCC-DPV1’

IM Profile ID: 62976 (F600h) (Generic Device)

IM Profile Specific Type: 4 (0004h) (Communication Module)

IM Version: 257 (0101h)

IM Supported: 30 (001Eh) (IMO..4 supported)

EtherCAT

Vendor ID E000 001Bha (HMS Industrial Networks Secondary Vendor ID, has to be replaced by Vendor ID of end product vendor.)

a. For firmware revision 1.02 and later.

Product Code 0000 0034h (Anybus CompactCom EtherCAT)

Device Name ‘Anybus-CC EtherCAT’

Serial Number (Assigned during manufacturing)

27

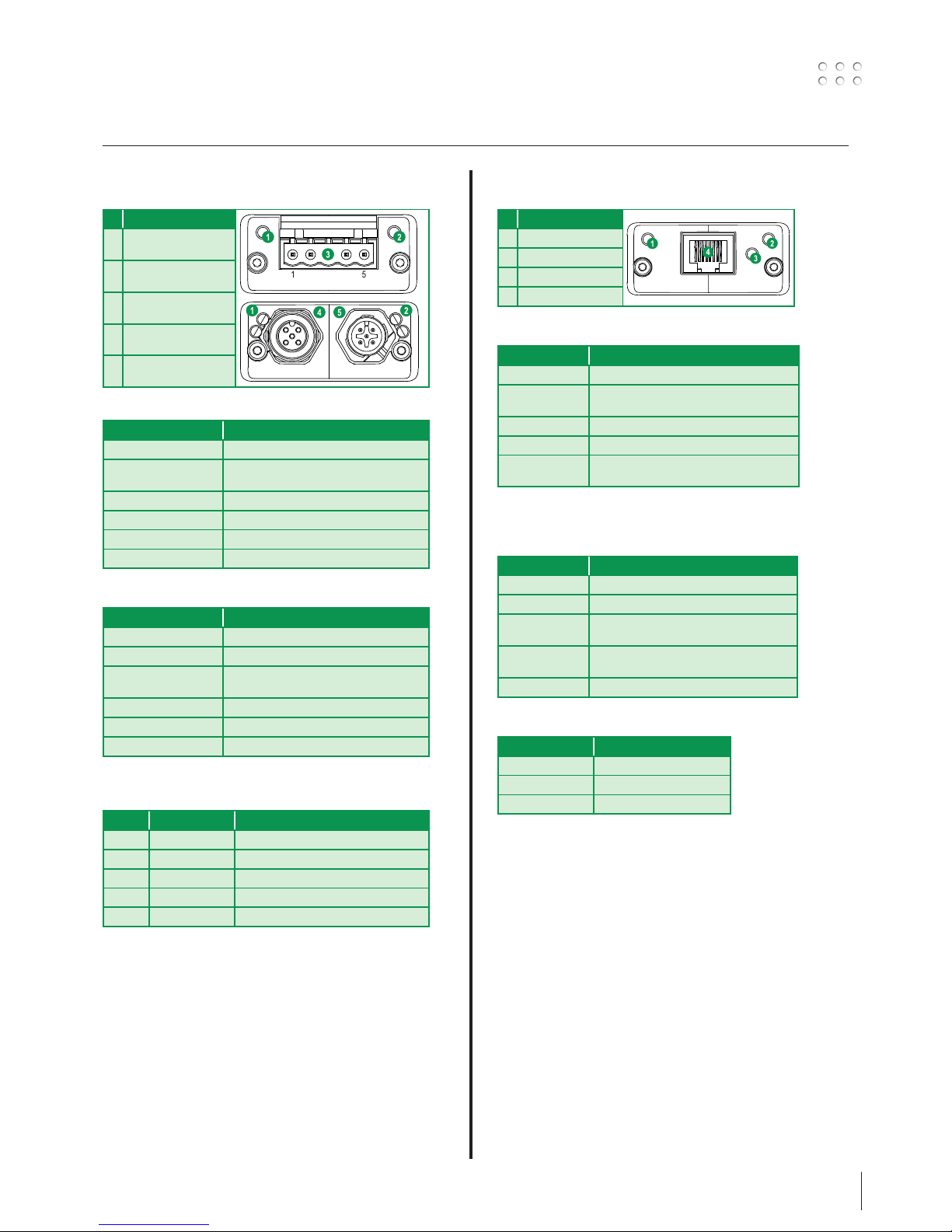

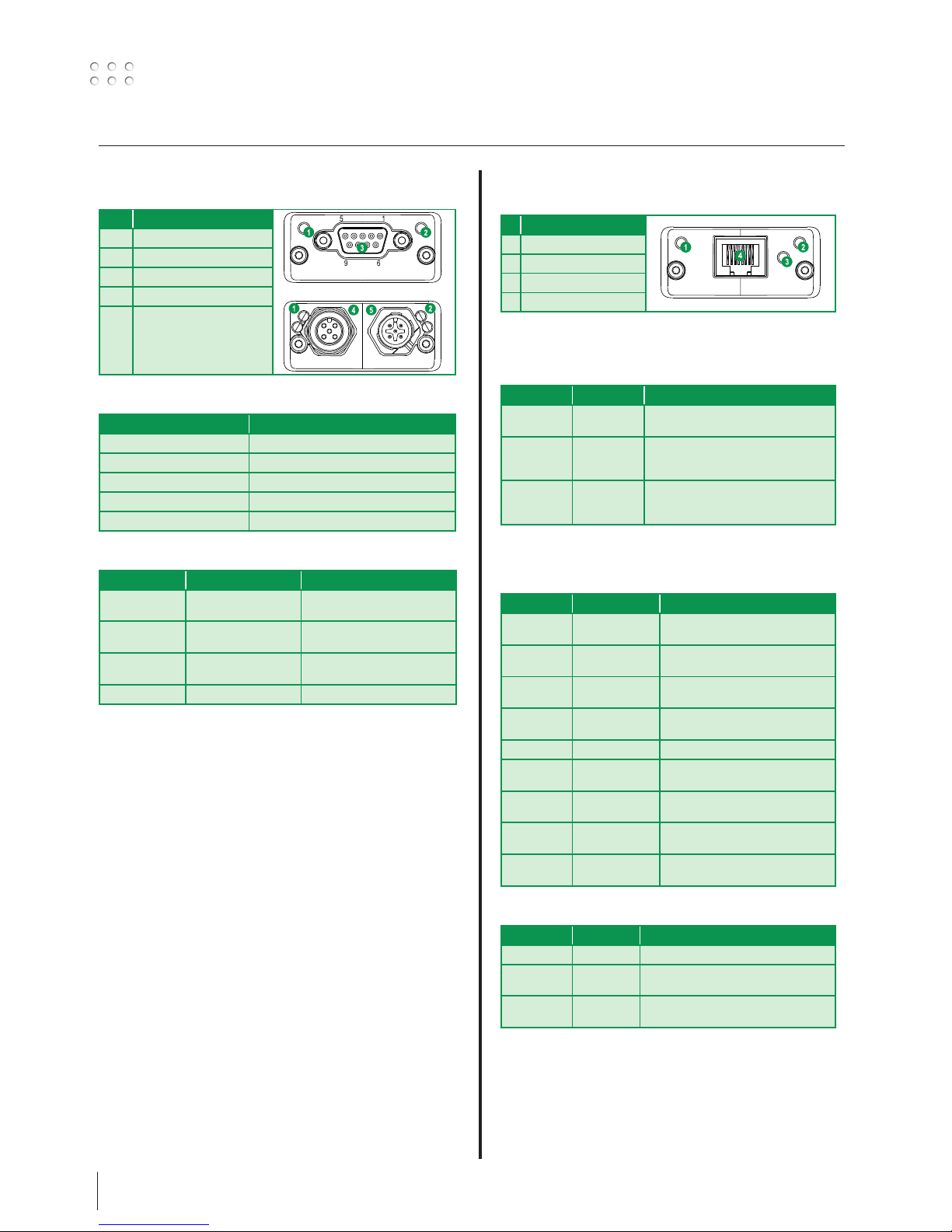

Anybus indicators

EtherNet IP

# Item

1 Network status LED

2 Module status LED

3 Link/Activity

4 Ethernet Interface

Network Status LED

LED State Description

Off No power or no IP address

Green On-line, one or more connections

established (CIP Class 1 or 3)

Green, flashing On-line, no connections established

Red Duplicate IP address, FATAL error

Red, flashing One or more connections timed out (CIP

Class 1 or 3)

Module Status LED

Note: A test sequence is performed on this LED during

startup

LED State Description

Off No power

Green Controlled by a Scanner in Run state

Green, flashing Not configured, or Scanner in Idle state

Red Major fault (EXCEPTION-state, FATAL

error etc.)

Red, flashing Recoverable Fault(s)

LINK/Activity LED

LED State Description

Off No link, no activity

Green Link established

Green, flickering Activity

1

8

DeviceNet

# Item

1 Network status LED

2 Module status LED

3 DeviceNet connector

4 M12 Female connector

5 M12 Male connector

Network Status

State Indication

Off Not online / No power

Green On-line, one or more connections are

established

Flashing Green (1 Hz) On-line, no connections established

Red Critical link failure

Flashing Red (1 Hz) One or more connections timed-out

Alternating

Red/Green

Self test

Module Status

State Indication

Off No power

Green Operating in normal condition

Flashing Green (1 Hz) Missing or incomplete configuration,

device needs commissioning

Red Unrecoverable Fault(s)

Flashing Red (1 Hz) Recoverable Fault(s)

Alternating

Red/Green

Self test

DeviceNet Connector

This connector provides DeviceNet connectivity

Pin Signal Description

1 V- Negative bus supply voltage

2 CAN_L CAN low bus line

3 SHIELD Cable shield

4 CAN_H CAN high bus line

5 V+ Positive bus supply voltage

28

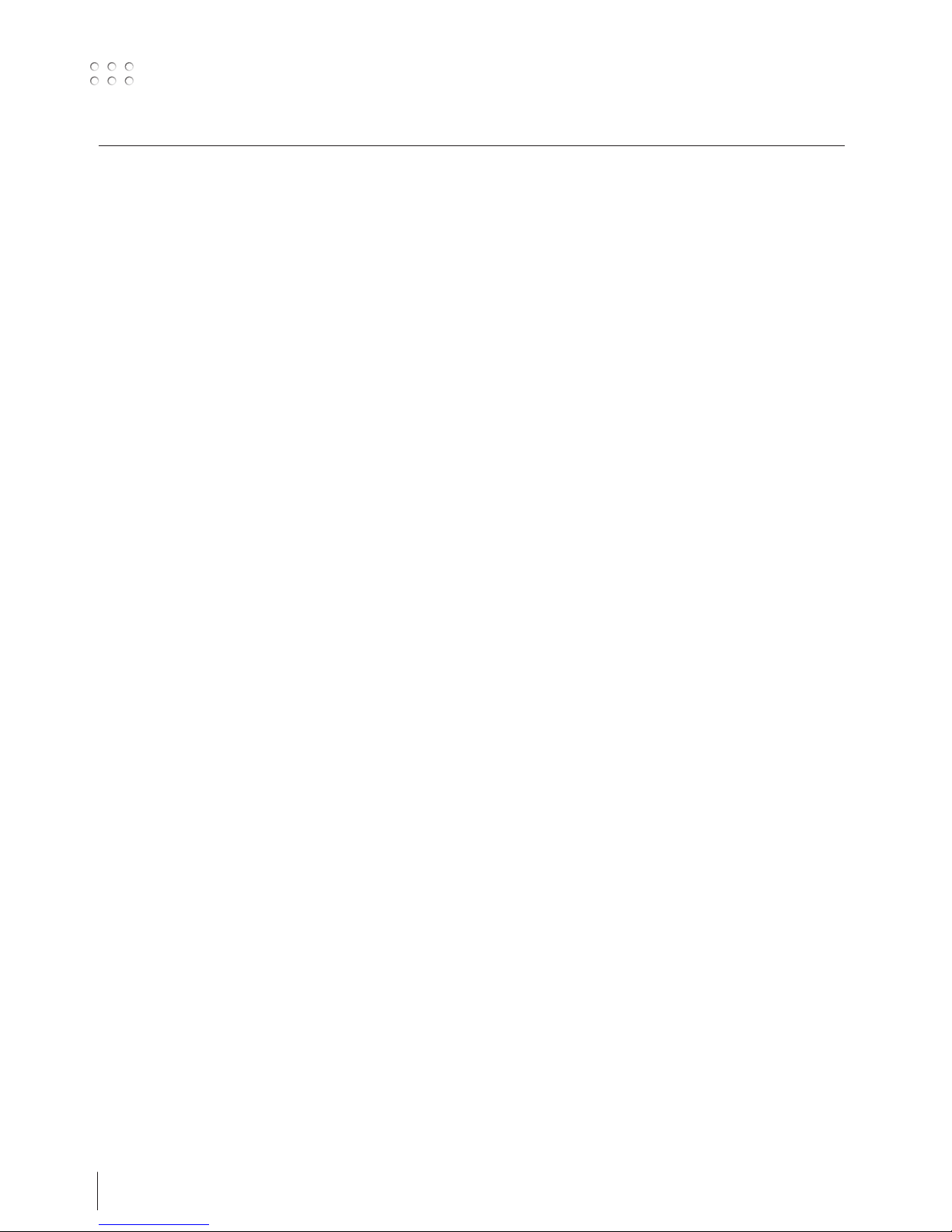

Anybus indicators

PROFIBUS

# Item

1 Operation Mode

2 Status

3 PROFIBUS Connector

4 M12 Female Connector

5 M12 Male connector

Operation Mode

State Indication

Off Not online / No power

Green Data exchange

Flashing Green Clear

Flashing Red (1 flash) Parametrization error

Flashing Red (2 flashes) PROFIBUS Configuration error

Status

State Indication Comments

Off Not initialized Anybus state = ‘SETUP¨’ or

‘NW_INIT’

Green Initialized Anybus module has left the

‘NW_INIT’ state

Flashing Green Initialized, diagnostic

event(s) present

Extended diagnostic bit is set

Red Exception error Anybus state = ‘EXCEPTION’

ProfiNet IP

# Item

1 Network status LED

2 Module status LED

3 Link/Activity LED

4 Ethernet Interface

Network Status LED

Note: A test sequence is performed on this LED during

startup

LED State Description Comments

Off Offline - No power

- No connection with IO Controller

Green Online

(RUN)

- Connection with IO Controller

established

- IO Controller in RUN state

Green,

flashing

Online

(STOP)

- Connection with IO Controller

established

- IO Controller in STOP state

Module Status LED

Note: A test sequence is performed on this LED during

startup

LED State Description Comments

Off Not Initialized No power - or - Module in ‘SETUP’

or ‘NW_INIT’ state

Green Normal

Operation

Module has shifted from the

‘NW_INIT’ state

Green,

1 flash

Diagnostic

Event(s)

Diagnostic event(s) present

Green,

2 flashes

Blink Used by engineering tools to

identify the node on the network

Red Exception Error Module in state ‘EXCEPTION’

Red, 1 flash Configuration

Error

Expected Identification differs

from Real Identification

Red,

2 flashes

IP Address Error IP address not set

Red,

3 flashes

Station Name

Error

Station Name not set

Red,

4 flashes

Internal Error Module has encountered a major

internal error

LINK/Activity LED

LED State Description Comments

Off No link No link, no communication present

Green Link Ethernet link established, no

communication present

Green,

flickering

Activity Ethernet link established,

communication present

Ethernet Interface

The Ethernet interface operates at 100 Mbit, full duplex,

with autonegotiation enabled as default.

1

8

29

Anybus indicators

EtherCAT

EtherCAT Connector

# Item

1 RUN LED

2 ERROR LED

3 EtherCAT (port 1)

4 EtherCAT (port 2)

5 Link/Activity (port 1)

6 Link/Activity (port 2)

RUN LED

This LED reflects the status of the CoE (CANopen over EtherCAT)

communication

LED State Indication Description

Off INIT CoE device in

‘INIT’-state (or no power)

Green OPERATIONAL CoE device in

‘OPERATIONAL’-state

Green,

blinking

PREOPERATIONAL

CoE device in

‘PRE-OPERATIONAL’-state

Green,

single flash

SAFEOPERATIONAL

CoE device in

‘SAFE-OPERATIONAL’-state

Red

a

(Fatal Event) -

a. If RUN and ERR turns red, this indicates a fatal event,

forcing the bus interface to a physically passive state.

Contact HMS technical support

ERR LED

This LED indicates EtherCAT communication errors etc.

LED State Indication Description

Off No error No error (or no power)

Red,

blinking

Invalid

configuration

State change received from

master is not possible due to

invalid register or object settings

Red,

double flash

Application

watchdog

timeout

Sync manager watchdog timeout

Red

a

Application

controller

failure

Anybus module in EXCEPTION

a. If RUN and ERR turns red, this indicates a fatal event,

forcing the bus interface to a physically passive state.

Contact HMS technical support

LINK/Activity

These LEDs indicate the EtherCAT link status and activity

LED State Indication Description

Off No link Link not sensed (or no power)

Green Link sensed, no

activity

Link sensed, no traffic detected

Green,

flickering

Link sensed,

activity detected

Link sensed, traffic detected

6

30

Loading...

Loading...