Migatronic RCI2 User Manual

ROBOT CONTROL INTERFACE - RCI

USER GUIDE

2

50115001 C1 Valid from 2019 week 24

Table of contents

Specifications .............................................................................................. 3 - 4

How it works .................................................................................................... 5

Connection to a robot and welding machine ................................................ 6

How to connect the installation ................................................................ 7 - 8

How to do the first configuration and setup ................................................ 9

Jumper settings ............................................................................................. 10

Fieldbus serial communication setup .......................................................... 11

Status menu ............................................................................................ 12 - 14

Setup menu ............................................................................................. 15 - 31

Robot / PLC setup ........................................................................................... 32

Analog Configuration file - PI ................................................................ 33 - 38

Fieldbus Configuration file - PI and PI PLASMA ................................... 39 - 46

Fieldbus Configuration file - PI and PI PLASMA - Std. Motoman ....... 47 - 49

Analog Configuration file - Sigma Galaxy ............................................ 50 - 57

Fieldbus Configuration file - Sigma Galaxy - Standard .......................58 - 60

Fieldbus Configuration file - Sigma Galaxy - Standard Motoman ......61 - 64

Detailed Interface layout .............................................................................. 65

Software upgrade .......................................................................................... 66

Troubleshooting ............................................................................................. 67

Error List .................................................................................................. 68 - 70

ANYBUS - Error List ................................................................................. 71 - 75

Electric Diagram ............................................................................................. 76

SIGMA Robot interface basic setup .............................................................. 77

Spare parts list ............................................................................................... 78

2 3

Specifications

SUPPORTED POWER SOURCES

Migatronic power sources: SIGMA GALAXY with control unit 76113597,

PI 350/500 and PI PLASMA

ANALOG PART OF INTERFACE

ANALOG INPUTS

Galvanic isolated differential inputs: 3

Common mode range: ± 20 VDC

Max differential voltage: 10 VDC

Differential Input impedance: 100K Ohm

Sampling frequency: 100 Hz

Max. pulse frequency (square wave): 10 Hz

Digital resolution: 10 Bit

Error: ± 2 % of reading ± 2 digits(20mV)

ANALOG OUTPUTS

Galvanic isolated differential outputs: 2

Maximum load: 2K Ohm

Output voltage: 0-10 V

Digital resolution: 12 Bit

Sampling frequency: 97 Hz

Error: ± 2 % of reading ± 5 digits(50mV)

Remarks: cannot be used for certification of the welding process

DIGITAL INPUTS

Galvanic isolated inputs: 16

HIGH level (H): 10-26 VDC

LOW level (L): 0-3 VDC

Input impedance: 5K Ohm

Response time to input changes: 100 ms

DIGITAL OUTPUTS

Galvanic isolated outputs: 16

LOW level: 0 V

HIGH level: +20V from internal supply (JMP2 1-2) or

+24V from external supply (JPM2 2-3)

Max load: 50 mA

Response time: 100 ms

GENERAL DATA

Operating temperature: -10 to 40°C (14 to 104°F)

Specifications

FIELDBUS PART OF INTERFACE

Supported Fieldbus communication interface

General Technical Data

Certification UL, cUL File number E214107

CE - Declaration of Pre-Conformity

Emission EN 61000-6-4

EN55011 Radiated emission

EN55011 Conducted emission

Immunity EN 61000-6-2 EN61000-4-2 Electrostatic discharge

EN61000-4-3 Radiated immunity

EN61000-4-4 Fast transients/burst

EN61000-4-5 Surge immunity

EN61000-4-6 Conducted immunity

DeviceNet

Vendor ID / Name: 90 (005Ah) / (HMS Industrial Networks)

Product Name: ‘Anybus-CompactCom DeviceNet’

ProdTypStr: Generic Device

Device Type: 0 (0000h)

Product Code: 98 (0062h) (Anybus-CompactCom DeviceNet)

Baud rates: 125kbps – 250kbps - 500kbps

Major Revision: 2

Minor Revision: 1

The Anybus CompactCom DeviceNet module accepts 11-25 V on the industrial network side of the module. Maximum current

consumption at 11-25 V is 36-38 mA/module.

Ethernet IP

Vendor ID / Name: 90 (005Ah) / (HMS Industrial Networks)

Product Name: ‘Anybus-CC EtherNet/IP’

ProdTypStr: Generic Device

Device Type: 0 (0000h) (Generic Device)

Product Code: 99 (0063h) (Anybus-CompactCom EtherNet/IP)

Assembly instance input: 100 (0064h)

Assembly instance output: 150 (0096h)

Configuration instance: 1 (0001h)

Major Revision: 2 (0002h)

Minor Revision: 11 (000Bh)

The Ethernet interface supports 10/100Mbit, full or half duplex operation.

ProfiNET

Vendor ID: 268 (010Ch) (HMS Industrial Networks)

Device Type: 7 (0007h) (Anybus-CompactCom PROFINET IO)

Station Type: ‘ABCC-PRT’

ProfiBus

IM Manufacturer ID: 268 (010Ch) (HMS Industrial Networks)

IM Order ID: ‘ABCC-DPV1’

IM Profile ID: 62976 (F600h) (Generic Device)

IM Profile Specific Type: 4 (0004h) (Communication Module)

IM Version: 257 (0101h)

IM Supported: 30 (001Eh) (IMO..4 supported)

EtherCAT

Vendor ID E000 001Bha (HMS Industrial Networks Secondary Vendor ID, has to be replaced by Vendor ID of end product vendor.)

a. For firmware revision 1.02 and later.

Product Code 0000 0034h (Anybus CompactCom EtherCAT)

Device Name ‘Anybus-CC EtherCAT’

Serial Number (Assigned during manufacturing)

4 5

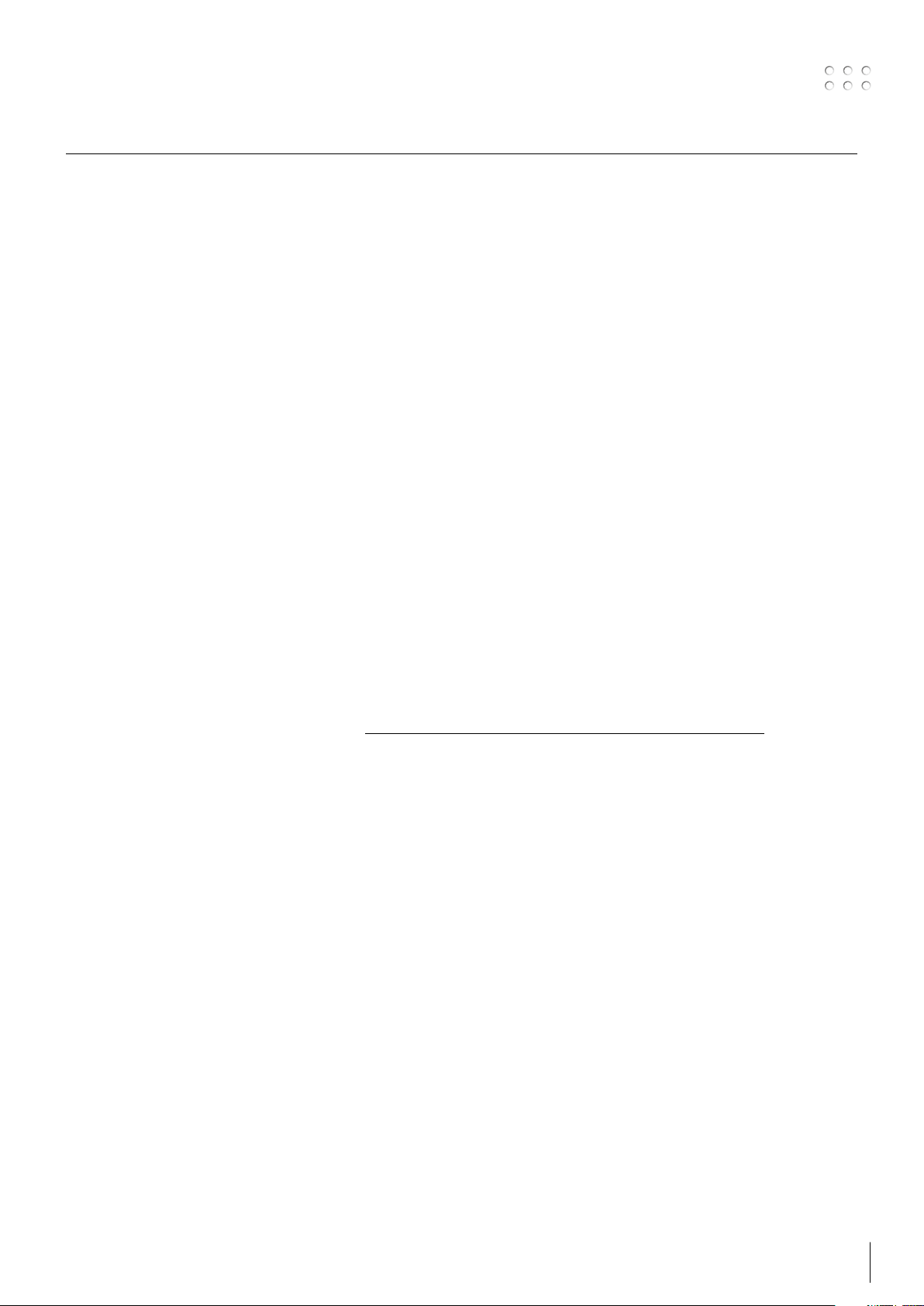

How it works

Robot Control Interface (RCI2)

The Robot Control Interface is a flexible I/O

interface system designed for controlling

different Migatronic machines and devices by

means of robots controllers and PLCs.

2

The Robot Control Interface (RCI

) acts as

“translator” between MIGANET and the

connected robot controller.

Interface concept

Several machine parameters like program

selection, secondary functions, internal alarms

etc. are fully accessible, and thus creation

of both sophisticated and simple custom

applications is possible.

There are two possible ways to control the

welding machine, of which only one can be

active at a time:

1: Serial communication:

Serial communication through Fieldbus

and industrial Ethernet via ANYBUS

communication modules. (Referred to as

Fieldbus in the rest of this manual.)

Configuration

2

RCI

has to be setup for the desired way of

communication, by loading a configuration file

directly into RCI2.

There are four different groups of configuration

files.

Pi/Pi Plasma – Analog communication

Pi/Pi Plasma – Fieldbus serial communication

Sigma Galaxy – Analog communication

Sigma Galaxy – Fieldbus serial communication

Each group can contain more configuration files

with special functionality.

See list on page 33-64.

SD card

The SD card contains the configurations files that

are needed by RCI

2

.

It also contains documentation and setup files

that are needed by the robot/PLC controller.

2: Analog communication:

A set of analog inputs and outputs can

control the welding machine.

ROBOT

CONTROLLER

ANALOG/DIGITAL

I/O INTERFACE

PLC

CONFIGURATION

FILE

Analog

communication

MIGANET

(CANBUS)

Fieldbus

communication

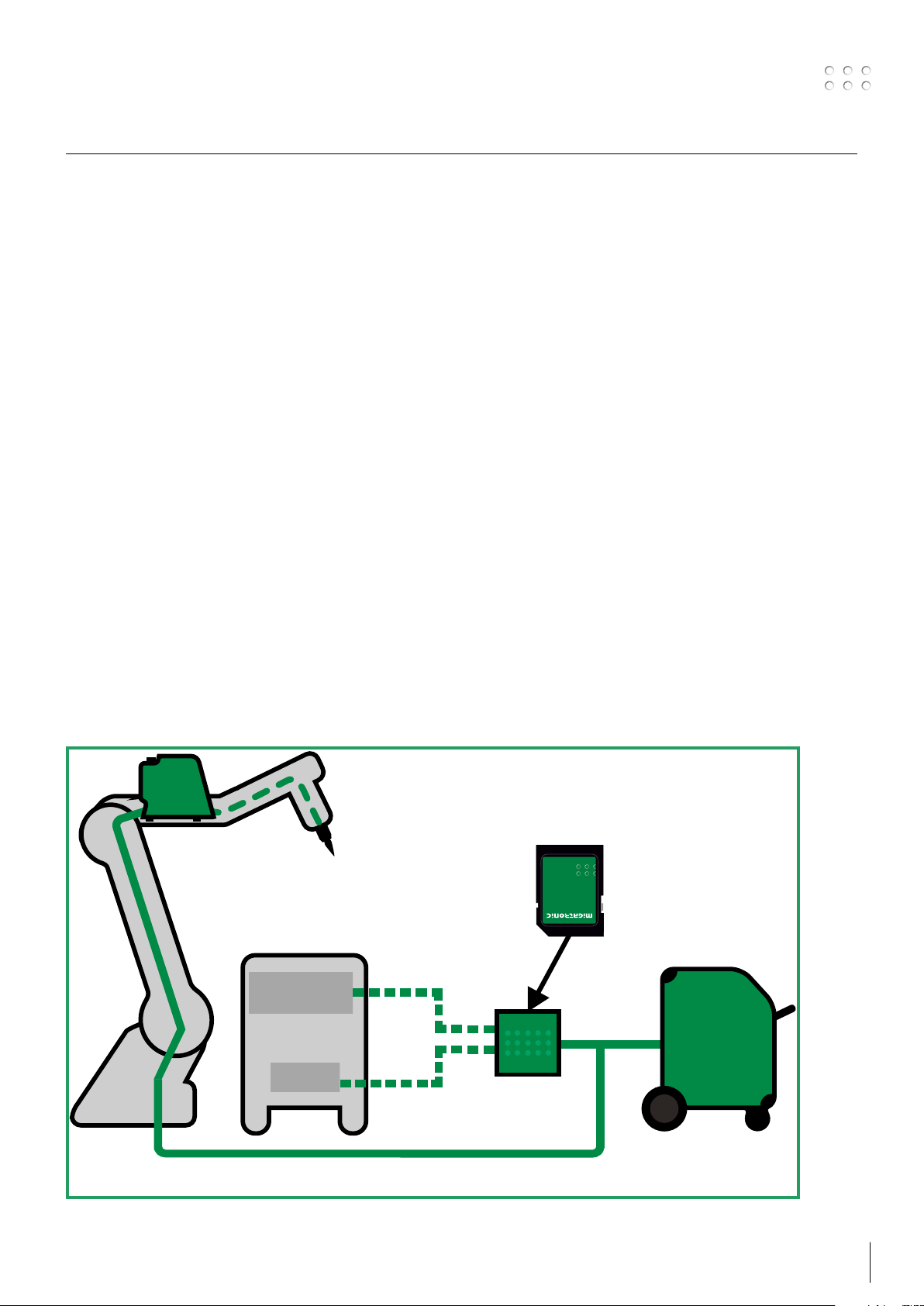

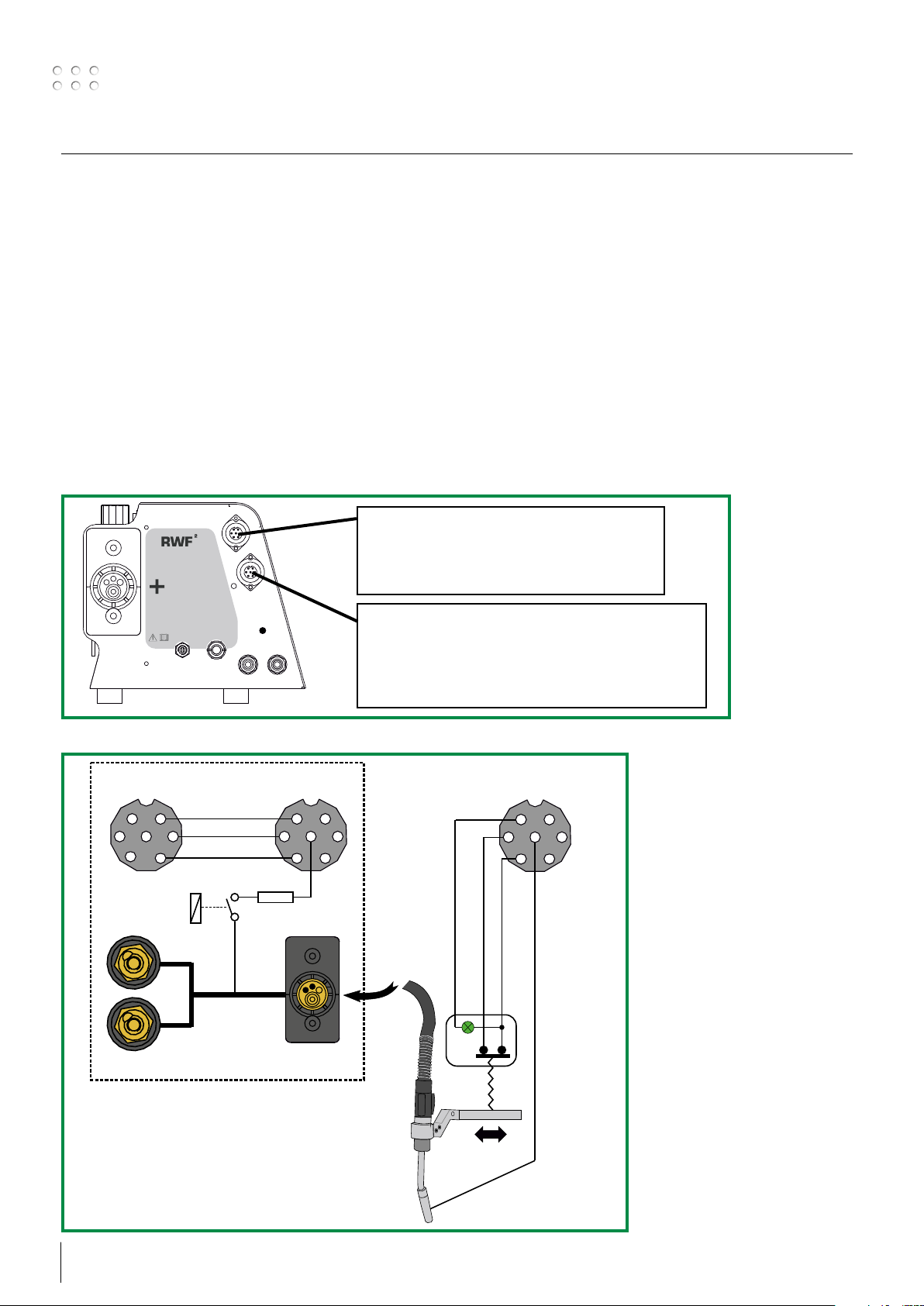

Connection to robot and welding machine

2

RCI

Fieldbus connection

to robot

CANBUS connection

to welding machine

Analog connection

to robot

Fieldbus communication

One of the following Anybus modules is installed when RCI2 is intended for serial communication.

ETHERNET/IP DEVICENET PROFINET PROFIBUS EtherCAT

Analog communication

The analog communication is accessible through

the 37 pin military plug.

The configuration file is defining the function of

each pin.

Setup for analog communication. See page 9

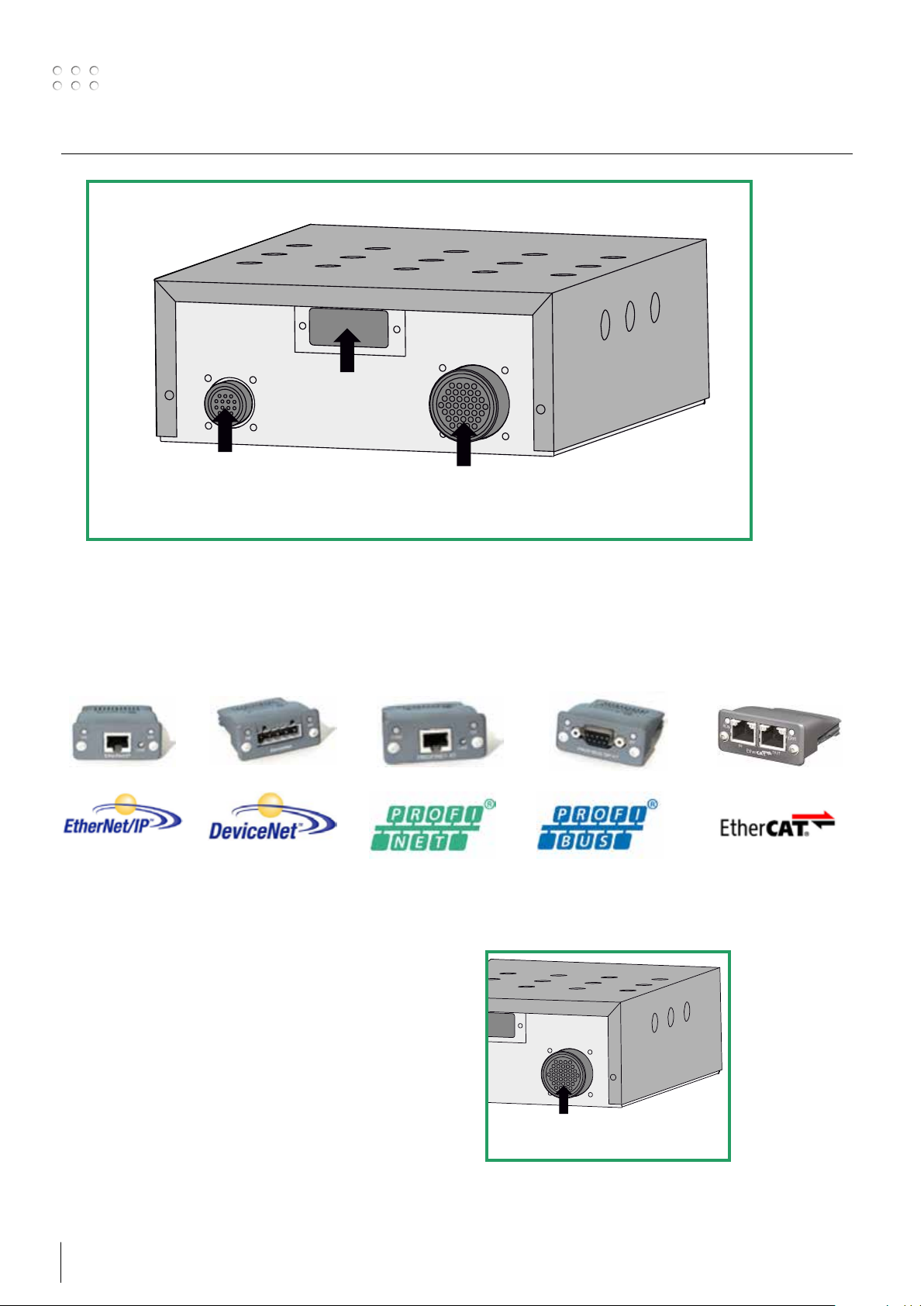

6 7

Analog connection

to robot

How to connect the installation

MIG installation

RWF²

3

c

TIG installation

CWF²

f

ROBOT / PLC

CONTROLLER

ANALOG/DIGITAL

ANALOG/DIGITAL

I/O INTERFACE

I/O INTERFACE

CONTROLLER

3

f

Analog

communication

1

max. 3 m

Fieldbus

communication

1

3 windings

through core

17440005

e

RCI²

1

3 windings

through core

17440005

REMOTE²

MIGANET

(CANBUS)

b

4

b

SIGMA GALAXY

2

g

EXT. COOLER

REMOTE²

4

6

ROBOT / PLC

CONTROLLER

ANALOG/DIGITAL

ANALOG/DIGITAL

I/O INTERFACE

I/O INTERFACE

CONTROLLER

Note:

Keep distance

of 5 cm

d

h

Main components:

1. Interface - RCI

2

I/O

2. Welding inverter - MIG /TIG/Plasma TIG

3. Wire feed unit - RWF2/CWF

4. Remote2 control

5. CAN connector box

6. Ext. cooler - option for Plasma TIG

Analog

communication

a

max. 3 m

Fieldbus

communication

a

b

RCI²

1

e

CONNECTION

BOX

b

Cables and fittings:

a. Signal cable for robot controller fieldbus or analog

b. CAN communication cable for welding inverter

c. Interconnection, water hose, gas and 2xwelding cable and CAN

d. Highly flexible interconnection for robot

e. Earth connection

f. Welding torch

b

PI & PLASMA TIG

b

2

g. Welding return cable

h. Interconnection, water hose, gas and welding cable

Welding process Distance to work piece

c

( + + )

f

h

Total cable length in welding circuit

c g

( + + + )

f

h

Total length of CAN cable

( + + )

b

MIG – IAC and pulse 10 m 20 m 30 m

MIG – non pulse 30 m 60 m 30 m

TIG 10 m 20 m 30 m

g

c

d

How to connect the installation

Touch sensing

For exact positioning of the welding torch, it is possible to use the Touch Sensing signal.

This option is available when using Fieldbus communication only.

When the welding wire has contact to the work piece, the robot/controller is told so by changing the

status of an output bit. Touch sensing can also be connected to the gas nozzle.

N.B. Gas nozzle sensing is automatically enabled through a relay when activating touch sensing. The relay

will, for safety reasons, disconnect the gas nozzle sense signal during welding.

Activate Touch sensing by enabling the Touch sensing input bit.

E.x. For Sigma Galaxy this is input Bit # 123. See Fieldbus configuration file for more details.

Read the Touch sensing status output bit.

When the welding wire (or optional the gas nozzle) has contact to work piece, while not welding:

E.x. For Sigma Galaxy output Bit # 147 is ON when there is contact, and OFF when no contact.

See Fieldbus configuration file for more details.

Collision protection signal to robot controller

Pin 1: 0V from robot controller

Pin 2: +24V from robot controller

Pin 3: Collision signal to robot controller

RWF

AIR Clean

Max.8 bar

2

To robot controller To collision sensor &

Male

1

3

Torch gas

nozzle sense

relay

Welding +

from power source

2

0V

24V

Collision signal

1K 50WΩ

touch sensor

Female

1

2

7

3

ZA

Collision protection signal and touch sense to torch

Pin 1: 0V to collision sensor

Pin 2: +24V to collision sensor

Pin 3: Collision signal from collision sensor

Pin 7: Touch sense connection to gas nozzle

To RWF² collision

sensor & touch sensor

Male

1

2

7

3

Collision

sensor

Torch gas

nozzle sense

signal

8 9

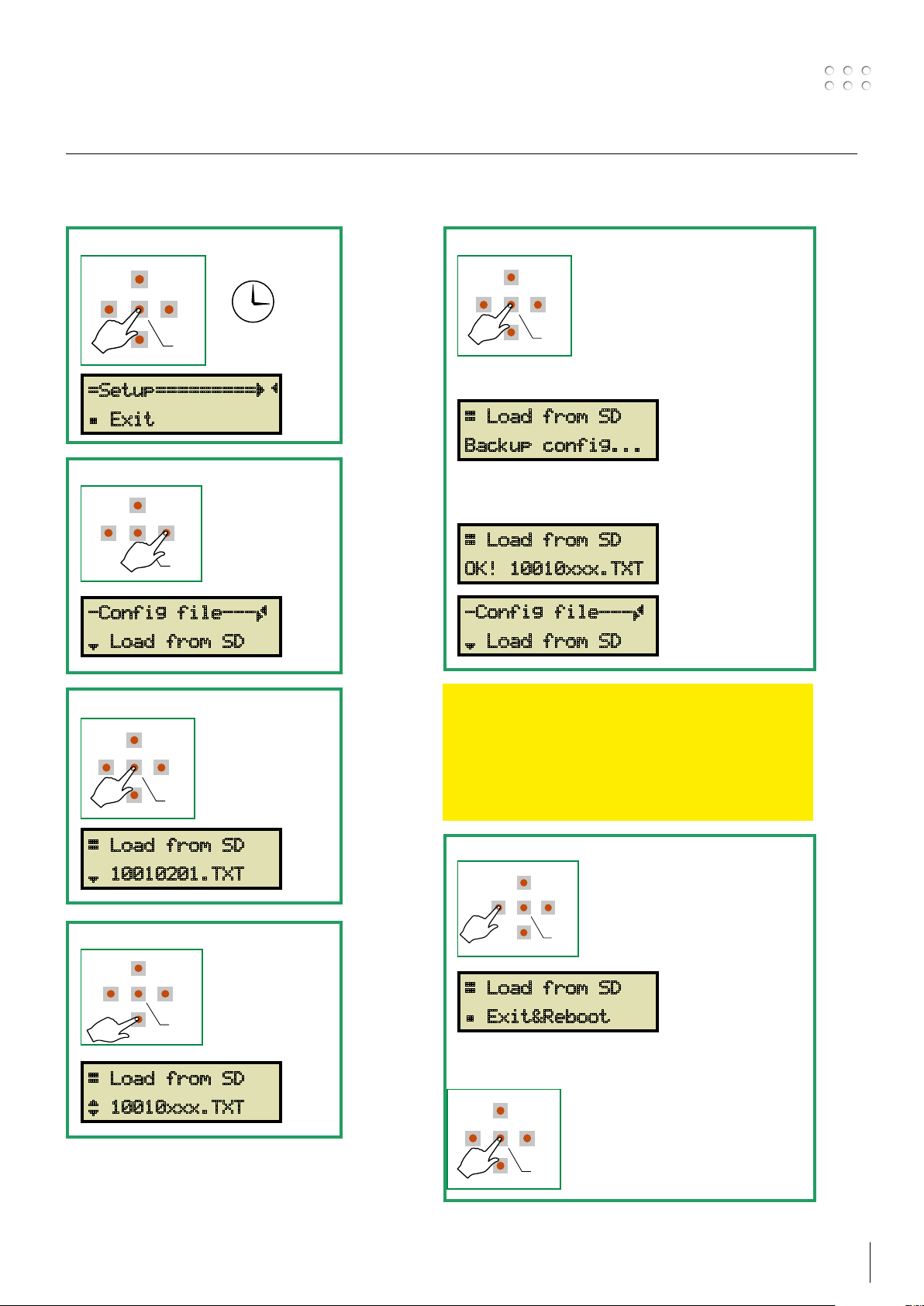

How to do the first configuration and setup

RIGHT

DOWN

ENTER

LEFT

UP

3 SECS

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

Choose the configuration file suitable for your selection of communication method, from the list on page

33-64. The configuration file is placed on the preinstalled SD card.

Enter Setup menu

1

=Setup=========ÇÄ

Á Exit

Choose Config file setting

2

-Config file---Ã

¾ Load from SD

Select With eNteR

5

During loading process the display will indicate

that a backup file is being saved on the SD card.

Æ Load from SD

Backup config...

Indication of successful loading

Æ Load from SD

OK! 10010xxx.TXT

-Config file---Ã

¾ Load from SD

Enter Load menu

3

Æ Load from SD

¾ 10010201.TXT

Scroll to the desired file

4

Æ Load from SD

¿ 10010xxx.TXT

IMPORTANT

Fieldbus serial communication:

Continue to page 11 without leaving the Setup menu.

Analog communication:

Continue on this and the next page to complete setup.

Leave the Setup menu

6

Æ Load from SD

Á Exit&Reboot

Confirm with ENTER

Setup for Analog communication is finished

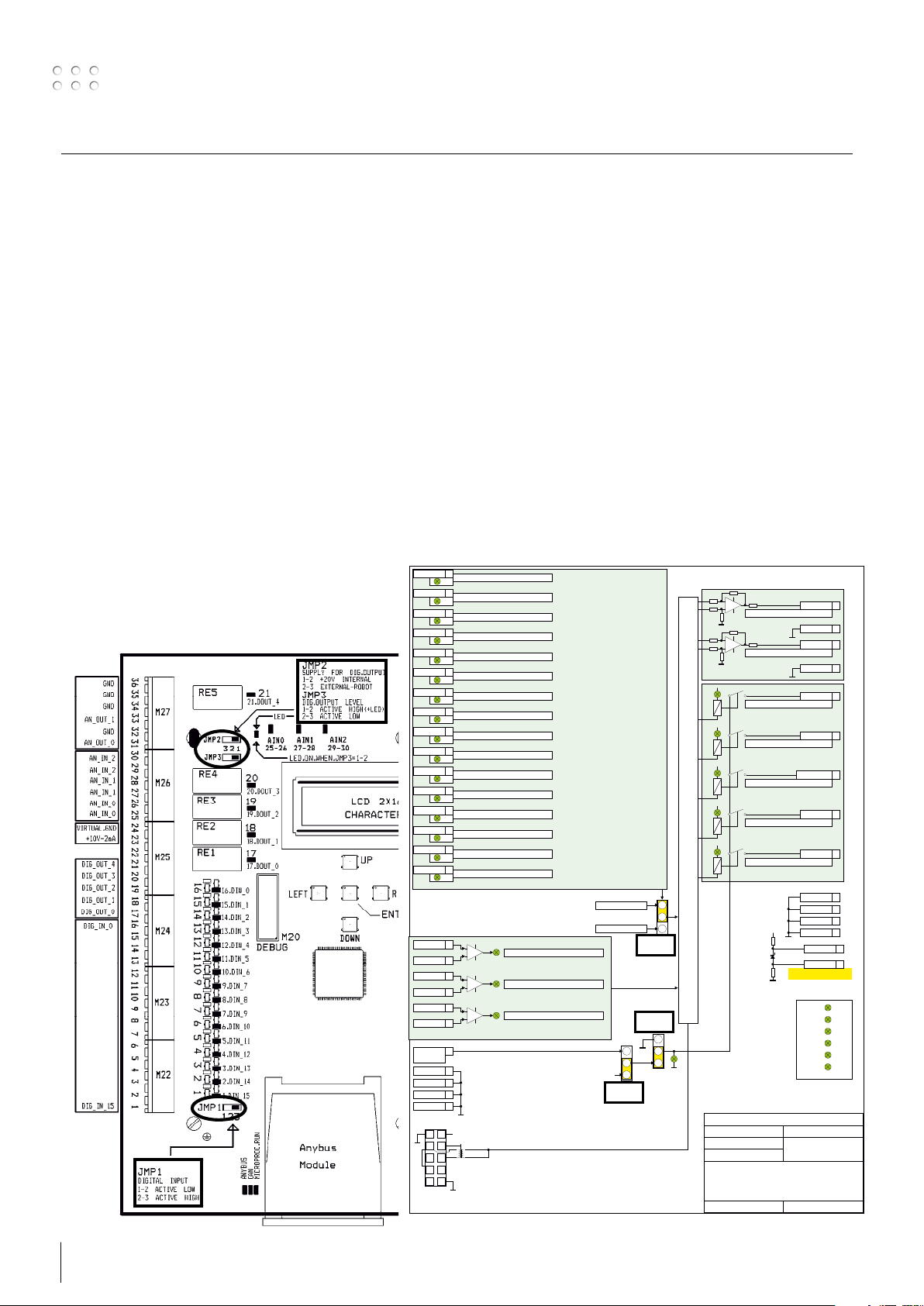

Jumper settings

DiGitAl iNPUtS leVel - JMP1

The active input level for all inputs is determined by positioning of jumper JMP1.

JMP1 position 1-2 = Active LOW

JMP1 position 2-3 = Active HIGH – (default)

DiGitAl OUtPUtS leVel – JMP3

The active output level on all outputs is determined by positioning of jumper JMP3.

JMP3 position 1-2 = Active HIGH – (default)

JMP3 position 2-3 = Active LOW

DiGitAl OUtPUtS VOltAGe SOURce – JMP2

Another jumper (JMP2) is provided to configure the voltage level of all the digital outputs.

JMP2 position 1-2 = +20VDC supplied by RCI – (default)

JMP2 position 2-3 = +24VDC supplied by external power supply from robot or custom hardware

XX function 16

Function defined by the configurations file

D16

XX function 15

Function defined by the configurations file

XX function 14

XX function 13

XX function 12

XX function 11

XX function 10

XX function 09

XX function 08

XX function 07

XX function 06

XX function 05

XX function 04

XX function 03

XX function 02

XX function 01

Digital input

Analog input

Robot supply

+ 24 VDC

GND 32

GND 34

GND 35

GND 36

Connect to

welding machine

6

10

D28

Function defined by the configurations file

D40

Function defined by the configurations file

D52

Function defined by the configurations file

D17

Function defined by the configurations file

D29

Function defined by the configurations file

D41

Function defined by the configurations file

D53

Function defined by the configurations file

D18

Function defined by the configurations file

D30

Function defined by the configurations file

D42

Function defined by the configurations file

D54

Function defined by the configurations file

D19

Function defined by the configurations file

D31

Function defined by the configurations file

D43

Function defined by the configurations file

D55

25XX function +

26XX function -

27XX function +

28XX function -

29XX function +

30XX function -

22

1

+ 55V

+ 11V

Can-bus

5

M18

Function defined by the configurations file

D1

Function defined by the configurations file

D3

Function defined by the configurations file

D2

Digital input: Active High

Digital input: Active Low

Jumper 2

3

2

+ 20 VDC

1

JMP2

Jumper 1

JMP1

JMP3

Jumper 3

3

2

1

Output active

high

Function

Function

Processor

+

D56

RE1

Function

+

D57

RE2

Function

+

D58

RE3

Function

+

D59

RE4

Function

+

D60

RE5

Function

3

Analog

2

Input

1

Digital

Input

Can-Bus

D61

Arthur Nielsen

Robotinterface mk3

Basic setup

Rev: 0 15-01-2014

Function defined by the configurations file

Function defined by the configurations file

Function defined by the configurations file

Function defined by the configurations file

Function defined by the configurations file

Function defined by the configurations file

Function defined by the configurations file

50

50

+ 15

200 200

10VDC

2mA

Potentiometer supply

Migatronic A/S

XX function 31

GND 32

XX function 33

GND 34

Analog output

XX function 17

XX function 18

XX function 19

XX function 20

XX function 21

Digital output

GND 32

GND 34

GND 35

GND 36

10 VDC 23

Virtuel Gnd 24

This is NOT GND!

5V

D74

3.3V

D75

-15V

D67

D66

15V

D65

20V

Powersupply

5V can-bus

D7

10 11

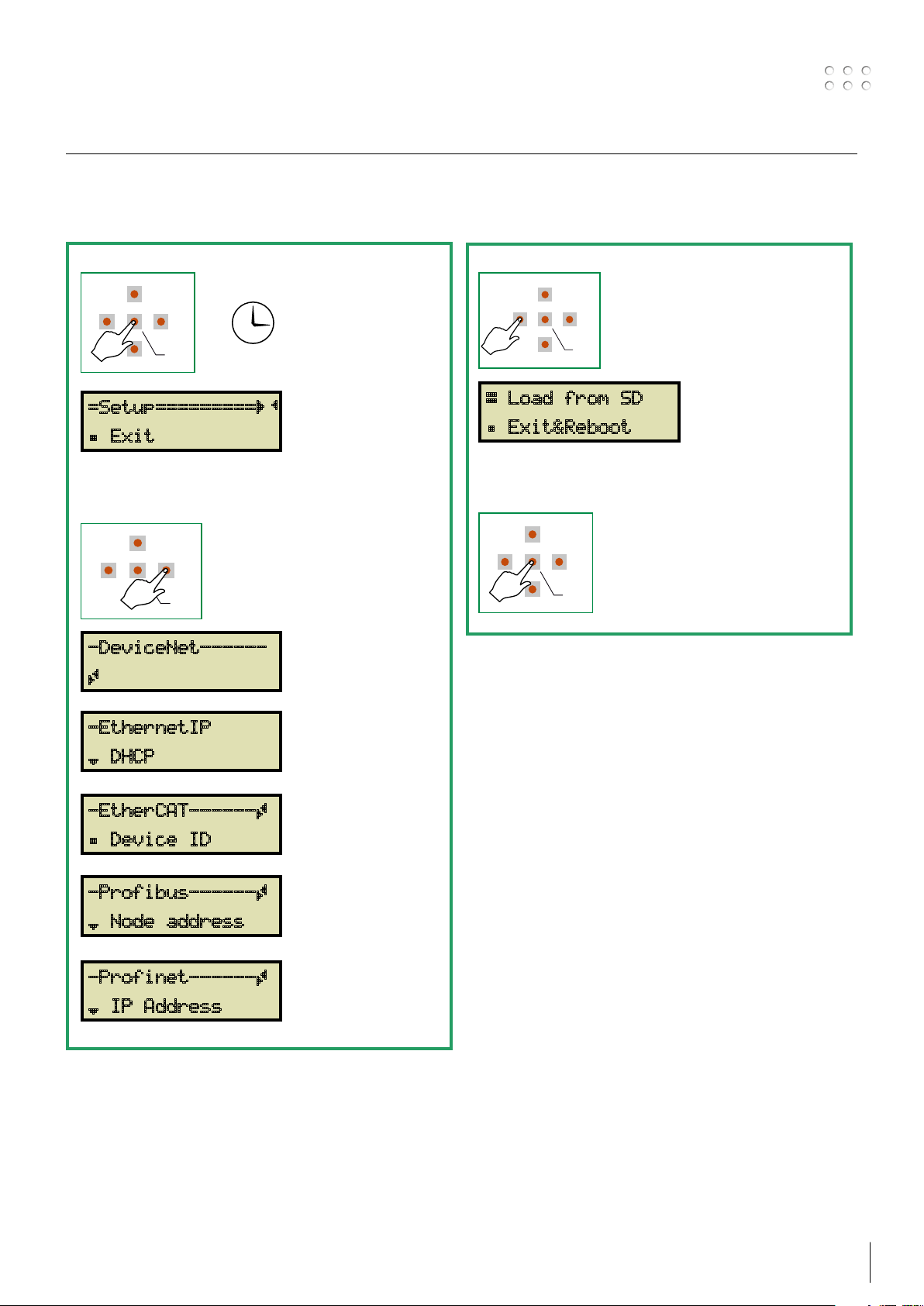

Fieldbus serial communication setup

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

3 SECS

RIGHT

DOWN

ENTER

LEFT

UP

The communication address information needed by the installed Anybus module depends on the type of

installed Anybus module. See the page corresponding to your network type.

Enter Setup menu

1

=Setup=========ÇÄ

Á Exit

Press RIGHT until the display shows the

name of your Anybus module.

-DeviceNet------

Continue on page 20

Ã

Leave the Setup menu

2

Æ Load from SD

Á Exit&Reboot

Confirm with ENTER

-EthernetIP

Continue on page 21

¾ DHCP

-EtherCAT------Ã

Continue on page 22

Á Device ID

-Profibus------Ã

Continue on page 23

¾ Node address

-Profinet------Ã

Continue on page 24

¾ IP Address

Status menu

The initial menu is showing the status of the interface.

No changes of configurations are possible, from here.

For setup see page 15.

È SETUP MENU is LOCKED – NEED PASSWORD

Status: É

1

----->

2

Software ver.:

NOT CONFIGURED

INITIALIZATION

ERROR

RUNNING

DEVICE ERROR

The version code of the installed software is shown

RCI2 1.00

3

Config.name:

12345678.TXT

The file name of the installed configuration file is shown.

The configuration file holds all information needed for correct communication between

robot and welding machine.

UP

LEFT

DOWN

Interface is not configured. Please load a configuration file.

At turn-ON of interface.

An error is present. Check the error log and the error list on page

68-70

The interface is working properly without problems.

An error is present on one of the connected devices, welding

machine or RWF

68-70

2

. Check the error log and the error list on page

RIGHT

ENTER

4

Config.descr:

STANDARD CONFIG#1

5

Anybus Status:

(Not Present)

A text description of the installed configuration file is shown.

The configuration file holds all information needed for correct communication between

robot and welding machine.

When an Anybus module is installed and the correct configuration file is loaded, this menu

is indicating the status of the serial communication and Anybus module status.

Anybus Status: Description

Setup

Network init

Wait process

Idle

Process active

Error

Exception

(not present)

Anybus Setup in progress.

The Anybus module is currently performing network-related

initialization tasks.

Telegrams now contains Process Data (if such data is mapped),

however the network Process Data channel is not yet active.

Communication between robot and Anybus module is missing.

Check cable between robot and RCI

Check network setup.

The network interface is idle. The exact interpretation of this

state is network specific.

Depending on the network type, the Read Process Data may be

either updated or static (unchanged).

The network Process Data channel is active and error free

There is at least one serious network error.

Enter setup menu – Diagnostic, and readout the error code.

The module has ceased all network participation due to a host

application-related error.

This state is unrecoverable, i.e. the module must be restarted

in order to be able to exchange network data. Exchange the

Anybus module if a restart does not solve the problem.

2

RCI

is not configured for use of Anybus module

2

interface.

12 13

Status menu

16 15

141312 11

10 9 8

7 6

5

4

3

2 1

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

D

I

G

_

I

N

_

1

5

D

I

G

_

I

N

_

0

1

0

.

D

I

N

_

6

6

.

D

I

N

_

1

0

5

.

D

I

N

_

1

1

8

.

D

I

N

_

8

4

.

D

I

N

_

1

2

7

.

D

I

N

_

9

1

.

D

I

N

_

1

5

3

.

D

I

N

_

1

3

1

4

.

D

I

N

_

2

1

5

.

D

I

N

_

1

1

3

.

D

I

N

_

3

1

1

.

D

I

N

_

5

1

2

.

D

I

N

_

4

9

.

D

I

N

_

7

2

.

D

I

N

_

1

4

1

6

.

D

I

N

_

0

0 1 2 3 4 5 6 7 8 9 A B C D E F

21 20 19 18 17

D

I

G

_

O

U

T

_

0

1

9

.

D

O

U

T

_

2

2

0

.

D

O

U

T

_

3

1

8

.

D

O

U

T

_

1

2

1

.

D

O

U

T

_

4

01234

D

I

G

_

O

U

T

_

1

D

I

G

_

O

U

T

_

2

D

I

G

_

O

U

T

_

4

D

I

G

_

O

U

T

_

3

R

E

1

R

E

2

R

E

3

R

E

4

R

E

5

2

0

1

9

1

8

1

7

2

1

1

7

.

D

O

U

T

_

0

Digital Inputs:

6

__2___67_9AB___F

Indication of activity on the digital inputs when RCI2 is setup for “analog”

use. The displayed number is referring to the digital input number.

See example below.

Displayed numbers

Connector numbers

Digital input numbers

Digital Outputs:

7

0__3_

Indication of activity on the digital output

when RCI2 is setup for “analog” use

The displayed number is referring to the digital output number.

See example below

Displayed numbers

Connector numbers

Digital output numbers

Status menu

29 28 27 26 25

AIN0

25-26

RE2

RE3

RE4

RE5

30

AN_ IN_ 2

AN_ IN_ 2

AN_ IN_ 1

AN_ IN_ 1

AN_ IN_ 0

AN_ IN_ 0

LCD

CHARA

AIN1

27-28

AIN2

29-30

DOWN

Analog Inputs:

8

0=7.53V 1=10.00V

Analog Outputs:

9

0=00.00V 1=7.89V

The 3 analog inputs can be monitored in this menu.

The LED brightness will vary according to the analog voltage

LEFT

Analog Inputs:

2=0.00V

The 2 analog outputs, AN_OUT_1 and AN_OUT_0

can be monitored in this menu.

UP

RIGHT

ENTER

Clock: 09:35:47

10

FRI 2013-11-08

36 35 34 33 32

GND

GND

GND

AN_OUT_1

GND

AN_OUT_0

M27

31

Local time and date, used in ERROR LOG reports,

and indication of when BACKUP files were stored.

14 15

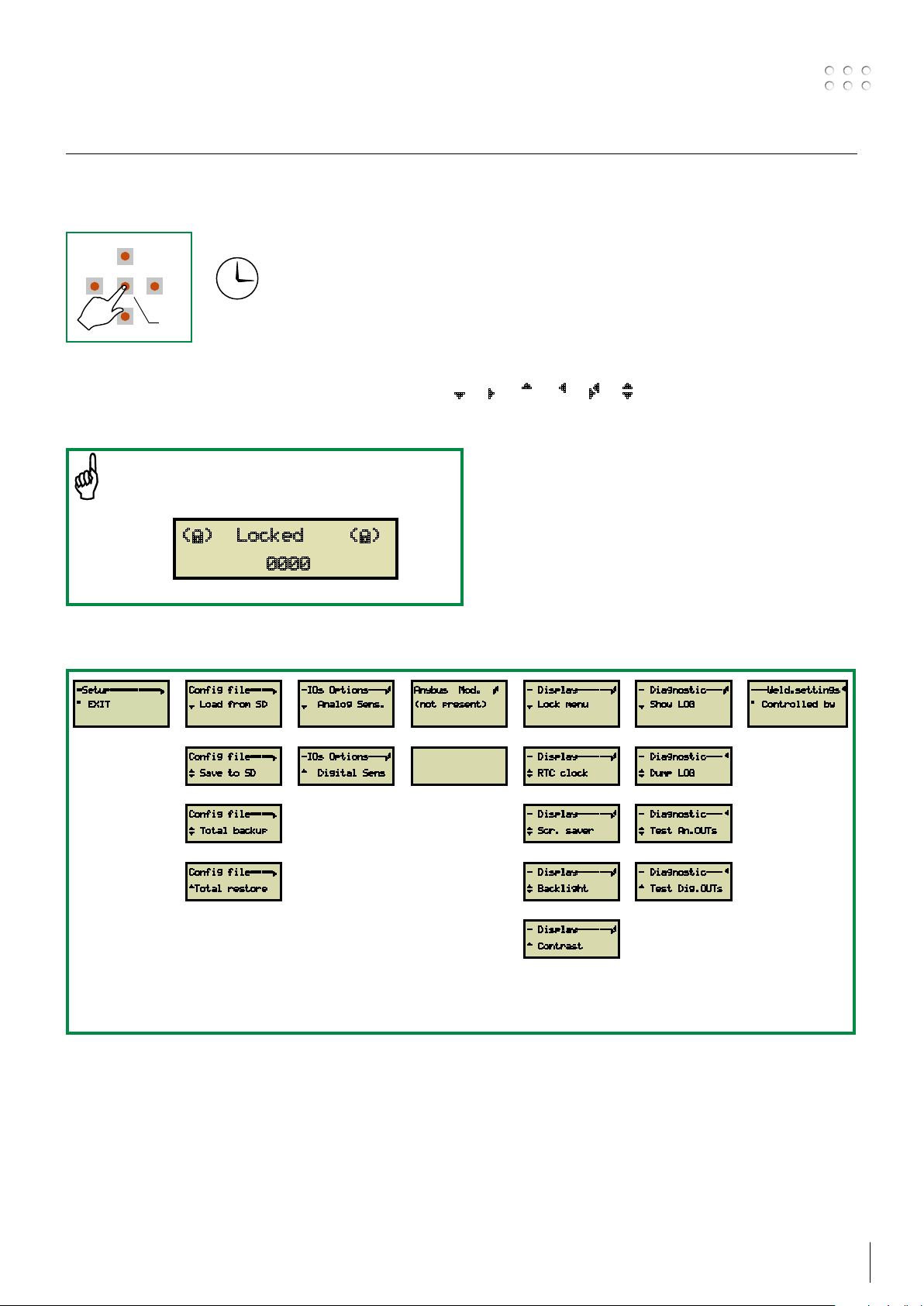

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

3 SECS

This page is showing the structure of SETUP MENU for the interface.

In this area it is possible to CONFIGURE different parameters of the interface

Follow the navigation arrows as shown in the display ¾ Â À Ä Ã ¿

Enter the unlock code and press ENTER

if this information is shown

(È) Locked (È)

0000

Menu structure

=Setup=========Â

° EXIT

(1)

Config file====Â

¾ Load from SD

(2)

Config file====Â

¿ Save to SD

-IOs Options---Ã

¾ Analog Sens.

(3)

-IOs Options---Ã

À Digital Sens

Config file====Â

¿ Total backup

Config file====Â

ÀTotal restore

See the following pages for menu description

Anybus Mod. Ã

(not present)

(4)

Depending on

installed module.

See description

- Display------Ã

¾ Lock menu

(5)

- Display------Ã

¿ RTC clock

- Display------Ã

¿ Scr. saver

- Display------Ã

¿ Backlight

- Display------Ã

À Contrast

- Diagnostic---Ã

¾ Show LOG

(6)

- Diagnostic---Ä

¿ Dump LOG

- Diagnostic---Ä

¿ Test An.OUTs

- Diagnostic---Ä

À Test Dig.OUTs

---Weld.settingsÄ

° Controlled by

(7)

Setup menu

MIGA_CFG

ROBOT

1000xxxx.txt

1000xxxx.PDF

(configuration file description)

(configuration file)

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

UP

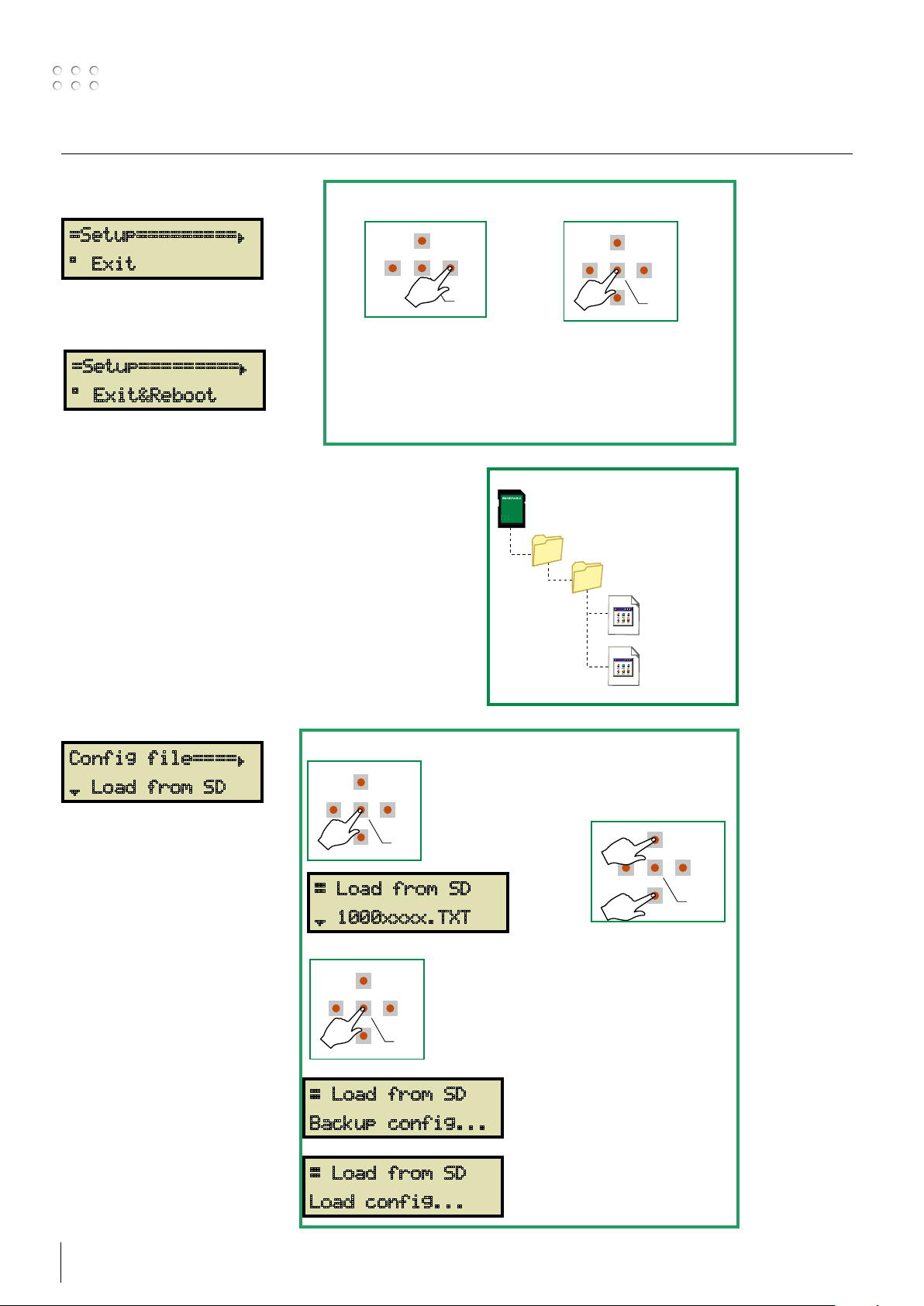

(1) – Setup Exit

Next menu Leave the menu with ENTER

=Setup=========Â

° Exit

Exit&Reboot is shown when changes have been made

=Setup=========Â

° Exit&Reboot

to settings in other menus, and the interface needs

to reboot to become active again. Not all changes to

parameters will force the REBOOT

(2) – Config file

A configuration file, holding information on input and

output setting, must be loaded into RCI2. Take care that

the inserted SD card holds the configuration files in a file

structure as shown to the right.

List of available configuration files see page 33-64.

Customized configuration files can be produced on

request.

Config file====Â

Enter Load menu

¾ Load from SD

Press ENTER Select file

RIGHT

ENTER

Æ Load from SD

¾ 1000xxxx.TXT

LEFT

DOWN

Confirm with ENTER

A backup file is saved

automatically on the SD

card, every time a new file is

Backup file name is

Æ Load from SD

BACK00.TXT

BACK01.TXT etc etc.

Backup config...

loaded.

Latest backup file has the

highest number

16 17

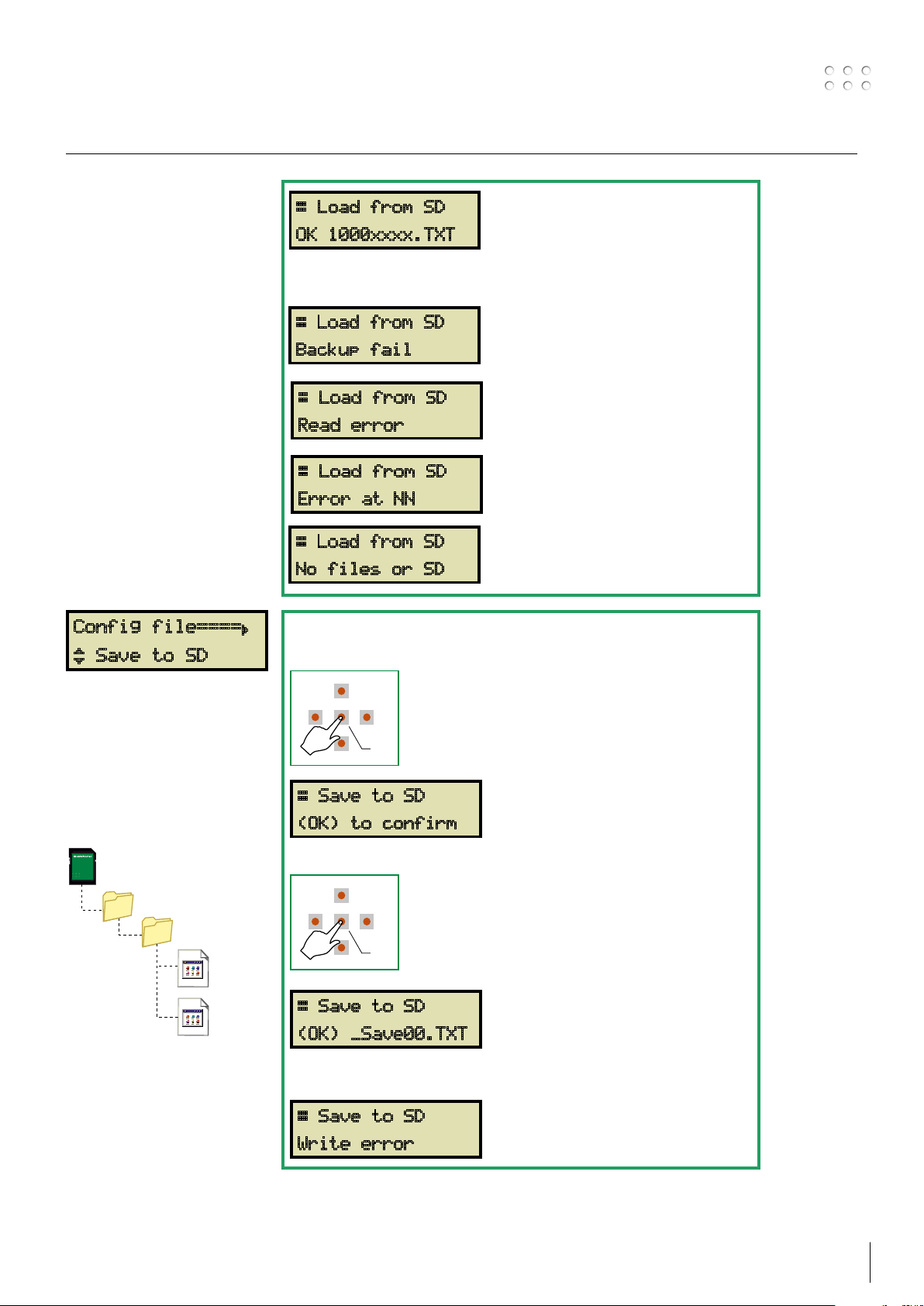

Æ Load from SD

Load config...

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

Configuration file is saved

successfully.

Æ Load from SD

OK 1000xxxx.TXT

Possible errors during reading and saving to SD card

Config file====Â

¿ Save to SD

This function is used when

you want to copy the

installed configuration

file to another SD card.

Configuration file only is

copied.

Æ Load from SD

Backup fail

Æ Load from SD

Check if there is enough space on the

SD card, SD write protected OFF or

SD card is defective.

Impossible to read the selected file or

problems on SD card.

Read error

Æ Load from SD

Syntax error at line NN.

Error at NN

Æ Load from SD

SD card folder or files are missing.

No files or SD

Save a copy of the configuration file to a SD card.

Press Enter

Æ Save to SD

(OK) to confirm

Press Enter

MIGA_CFG

ROBOT

_SAVE00.TXT

Saved file name is

SAVE00.TXT

SAVE01.TXT etc etc.

_SAVE01.TXT

Æ Save to SD

(OK) _Save00.TXT

Possible errors during reading and saving to SD card

Æ Save to SD

SD card or folders are missing or

problems on the SD card

Write error

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

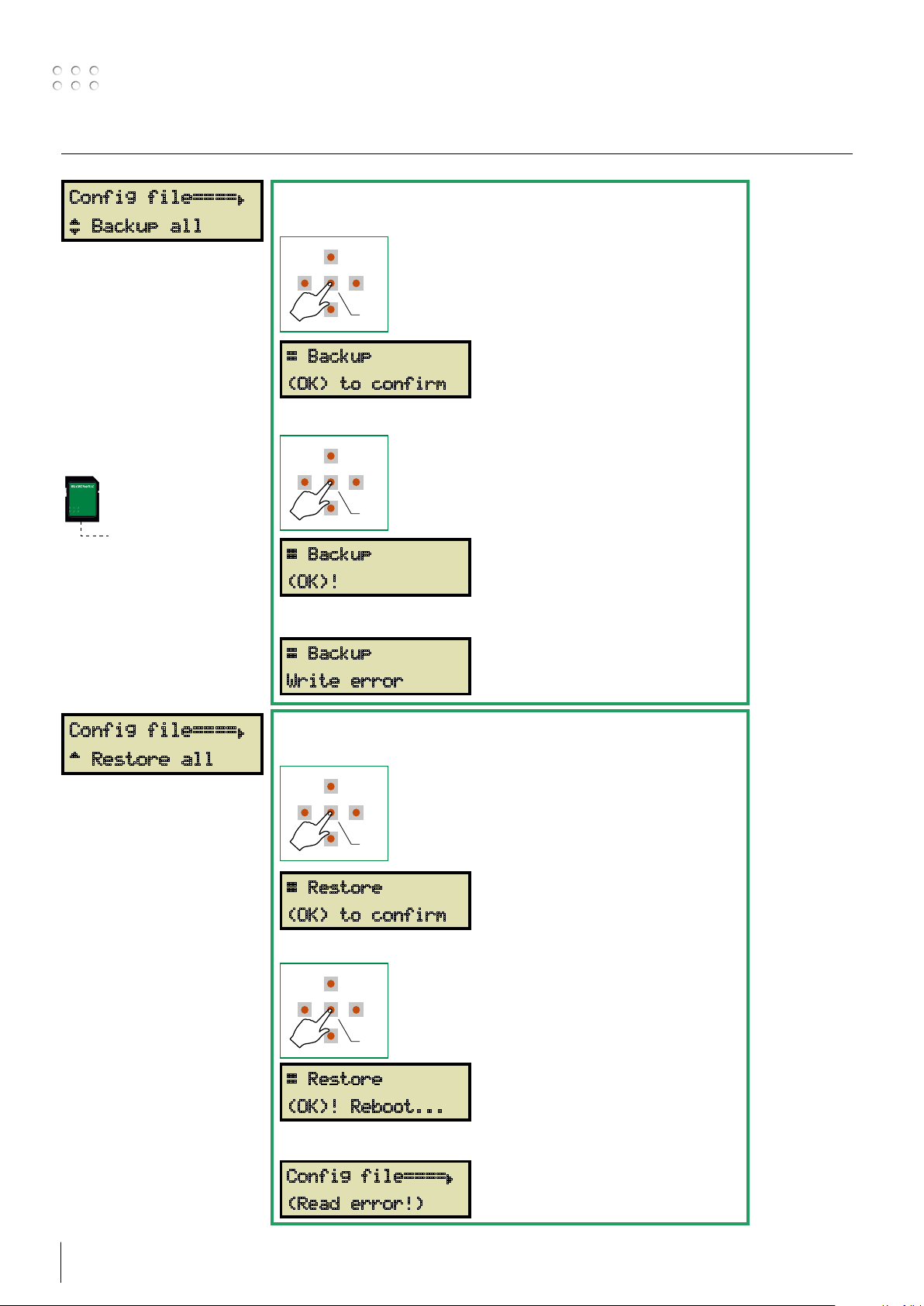

RCI2.BCK

Config file====Â

¿ Backup all

A backup of all

configurations settings and

Anybus network setups are

stored on the SD card.

This function is useful

when replacing the RCI2

after a breakdown, or

when cloning of RCI2 is

needed.

Previous backup file will be

overwritten.

A Total backup of all settings to the SD card.

Press Enter

Æ Backup

(OK) to confirm

Press Enter

Æ Backup

Saved file name is RCI2.BCK

saved at the root of SD card.

(OK)!

Possible errors during backup to SD card

Config file====Â

À Restore all

Upload of backup file

with all configuration

setups and Anybus

network setups stored on

the SD card.

This function is useful

when replacing the RCI2

after a breakdown, or

when cloning the RCI2 is

needed.

Æ Backup

SD card or folders are missing or

problems on the SD card

Write error

Restore settings from backup of all settings to the SD card.

Press Enter

Æ Restore

(OK) to confirm

Press Enter

Æ Restore

(OK)! Reboot...

Read file name

URI_BCK.BIN

from the root of SD card.

Possible errors during restore from SD card

Config file====Â

SD card or folders are missing or

problems on the SD card.

(Read error!)

18 19

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

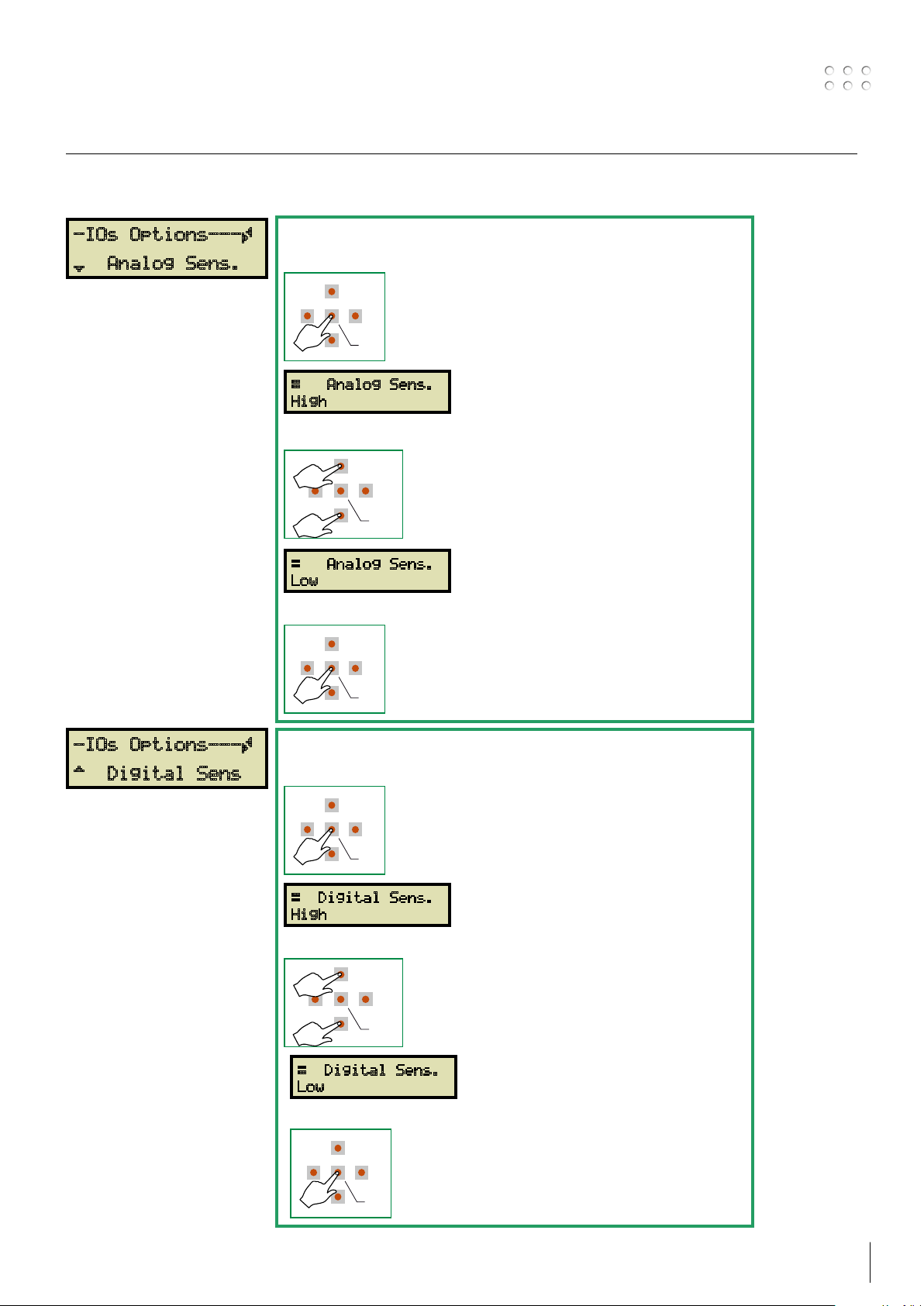

(3) – IOs options

-IOs Options---Ã

¾ Analog Sens.

This filter allows change of

sensitivity to background

noise on all inputs. LOW is

default.

Change the sensitivity for analog inputs

Press Enter

Æ Analog Sens.

High

High sensitivity = no filter

Press Down or Up

UP

DOWN

RIGHT

ENTER

Low sensitivity = active filter

LEFT

Æ Analog Sens.

Low

Press Enter

-IOs Options---Ã

À Digital Sens

This filter allows change of

sensitivity to background

noise on all inputs. LOW is

default.

Change the sensitivity for digital inputs

Press Enter

Æ Digital Sens.

High

High sensitivity = no filter

Press Down or Up

UP

DOWN

RIGHT

ENTER

Low sensitivity = active filter

LEFT

Æ Digital Sens.

Low

Press Enter

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

UP

RIGHT

DOWN

ENTER

LEFT

UP

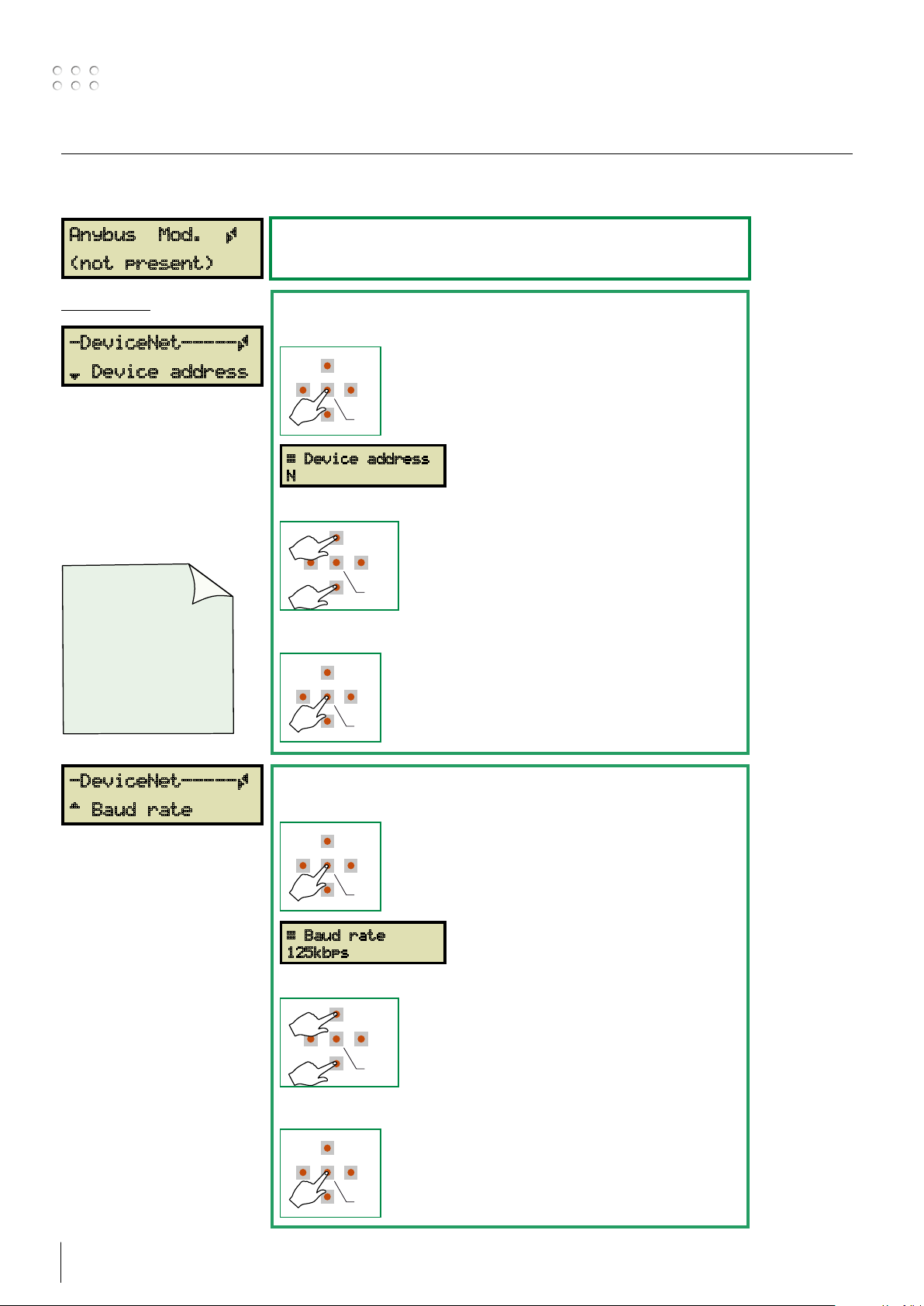

(4) – Anybus module

Anybus Mod. Ã

(not present)

DeviceNet

-DeviceNet-----Ã

¾ Device address

The interface automatically

detects and identifies the

installed Anybus module

and consequently displays

different scenarios,

depending on the

information needed by the

Anybus module.

The EDS file

needed by the

robot controller/PLC

can be found on the

SD card, or

downloaded from

www.migatronic.com

MY MIGATRONIC

No Anybus module is installed or detected.

DeviceNet address setup

Press Enter

Æ Device address

N

Press Down or Up

Press Enter to leave Device address

LEFT

DOWN

UP

Set the network device address.

N is in the range 0 to 255.

RIGHT

ENTER

-DeviceNet-----Ã

À Baud rate

DeviceNet baud rate setup

Press Enter

Æ Baud rate

125kbps

Press Down or Up

Set the network baud rate.

Possible settings.

LEFT

DOWN

RIGHT

ENTER

125 - 250 - 500kbps and Autobaud

Press Enter to leave

20 21

RIGHT

DOWN

ENTER

LEFT

UP

UP

RIGHT

DOWN

ENTER

LEFT

UP

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

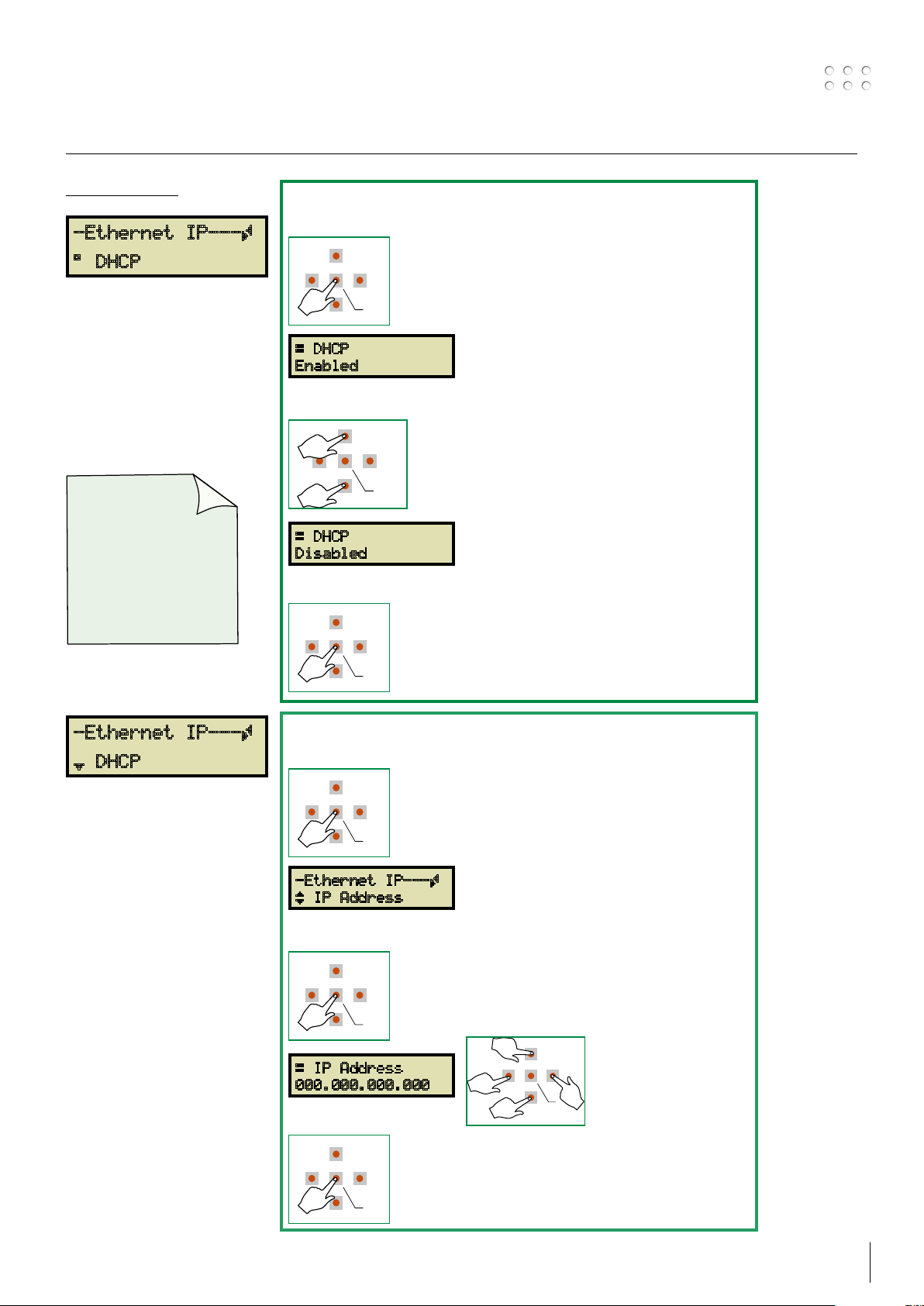

ETHERNET/IP

-Ethernet IP---Ã

° DHCP

The interface automatically

detects and identifies the

installed Anybus module

and consequently displays

different scenarios,

depending on the

information needed by the

Anybus module.

The EDS file

needed by the

robot controller/PLC

can be found on the

SD card, or

downloaded from

www.migatronic.com

MY MIGATRONIC

DHCP setting

Press Enter

Æ DHCP

Enabled

Press Down or Up

DOWN

RIGHT

ENTER

LEFT

Æ DHCP

Disabled

Press Enter to leave

DHCP = Enabled

IP address is issued by the DHCP network

server

DHCP = Disabled

IP address must be configured manually

-Ethernet IP---Ã

¾ DHCP

IP address manual setup

Press Enter

-Ethernet IP---Ã

¿ IP Address

Press Enter

Æ IP Address

000.000.000.000

Press Enter to leave

UP

LEFT

DOWN

Set the IP address as

specified by the robot

RIGHT

or network controller.

E.x. 192.168.000.010

ENTER

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

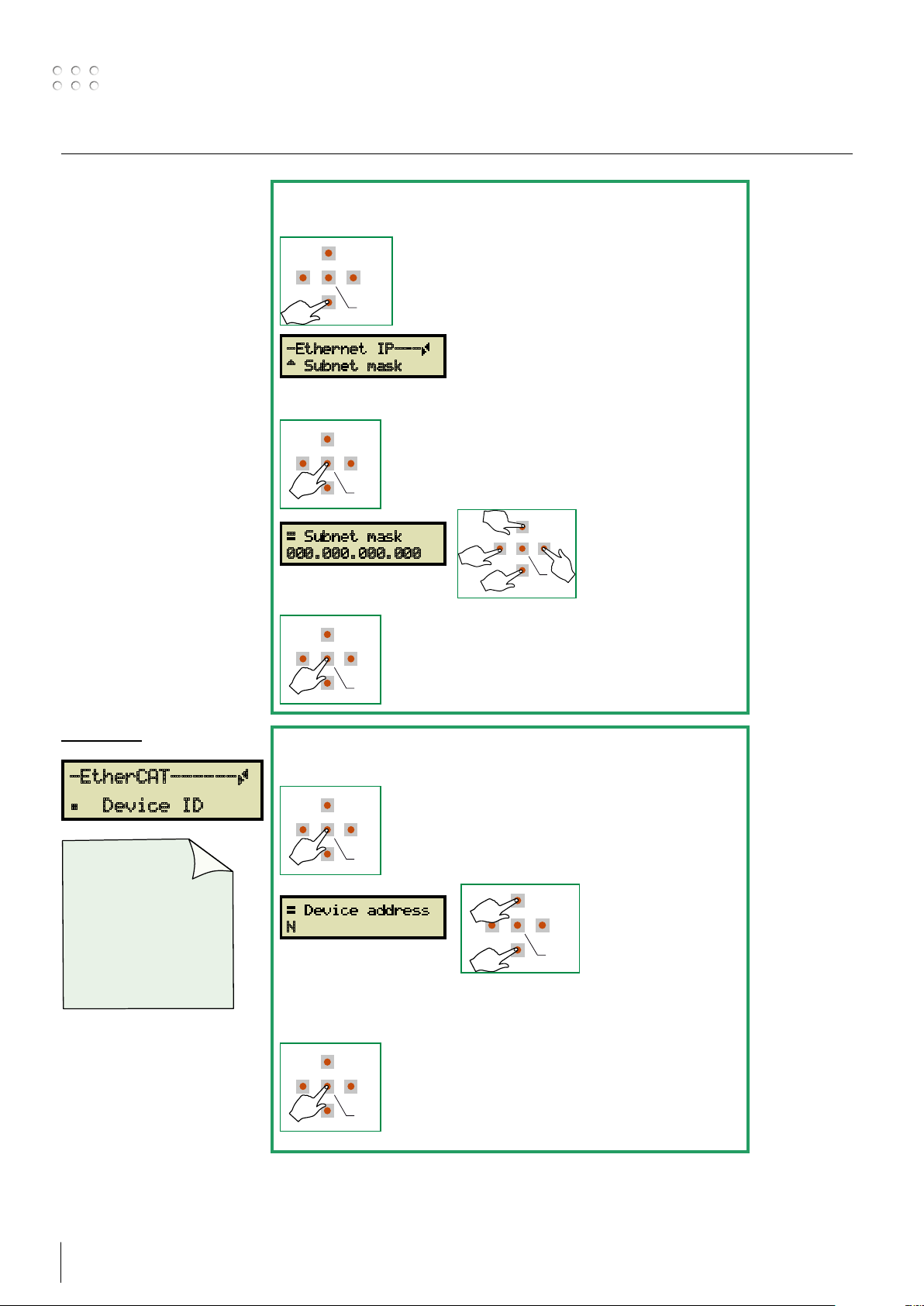

IP address manual setup SUBNET MASK

Press Down

DOWN

RIGHT

ENTER

LEFT

-Ethernet IP---Ã

À Subnet mask

Press Enter

Æ Subnet mask

000.000.000.000

Press Enter to leave

UP

LEFT

DOWN

Set the IP subnet mask

address as specified by

RIGHT

the robot or network

controller.

ENTER

E.x. 255.255.255.000

EtherCAT

-EtherCAT------Ã

Á Device ID

The ESI file

needed by the

robot controller/PLC

can be found on the

SD card, or

downloaded from

www.migatronic.com

MY MIGATRONIC

Device ID setup

Press Enter

Æ Device address

N

Press Enter

LEFT

DOWN

UP

Set the Device ID as

specified by the robot

or network controller.

RIGHT

N is in the range 0 to

ENTER

65535.

22 23

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

UP

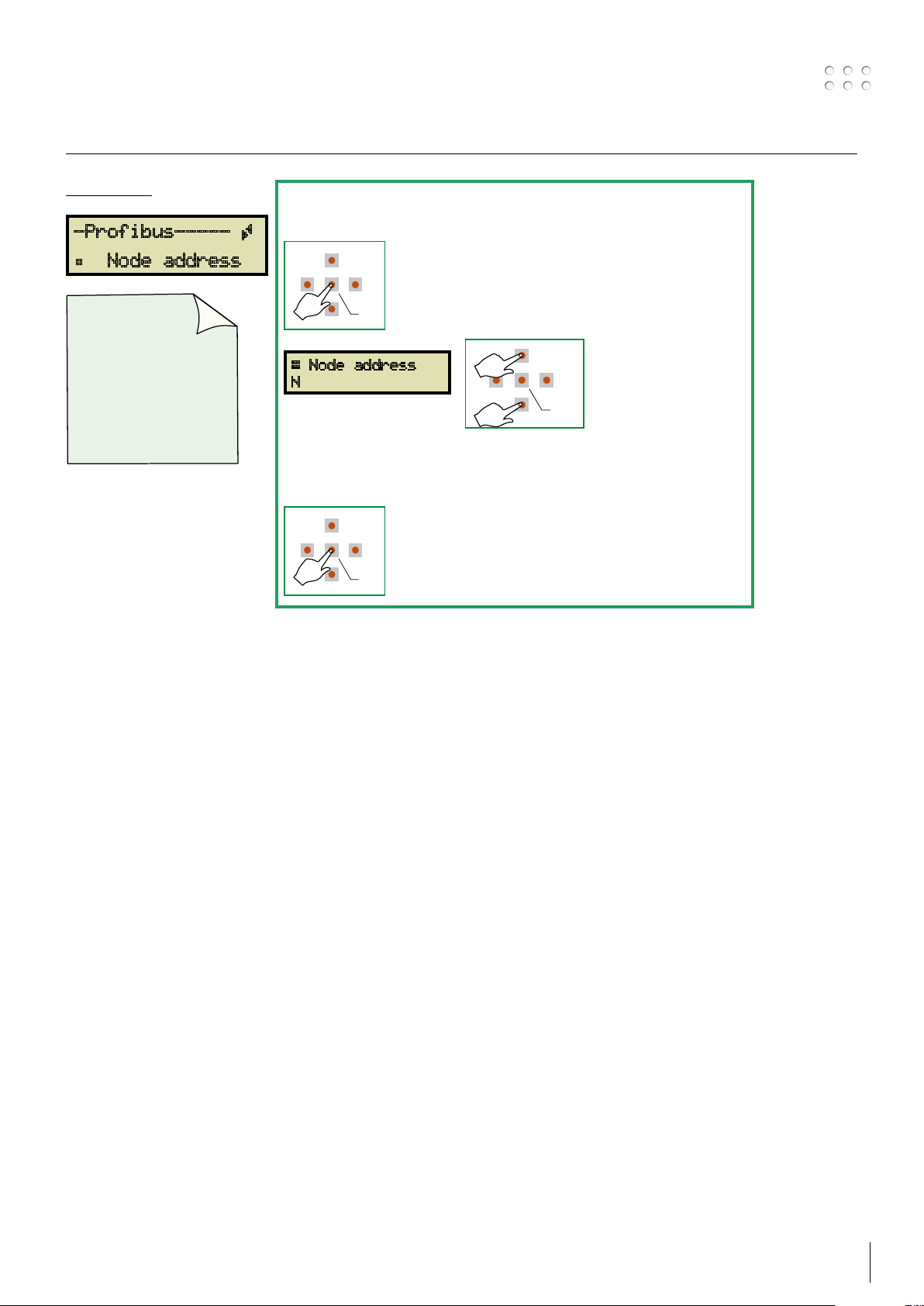

PROFIBUS

-Profibus----- Ã

Á Node address

The GSD/GSE file

needed by the

robot controller/PLC

can be found on the

SD card, or

downloaded from

www.migatronic.com

MY MIGATRONIC

Node address setup

Press Enter

Æ Node address

N

Press Enter

LEFT

DOWN

Set the node address

as specified by the

robot or network

RIGHT

controller.

ENTER

N is in the range 0 to

125 and SSA

(Set Slave Address =

Master is setting the

address)

Setup menu

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

RIGHT

DOWN

ENTER

LEFT

UP

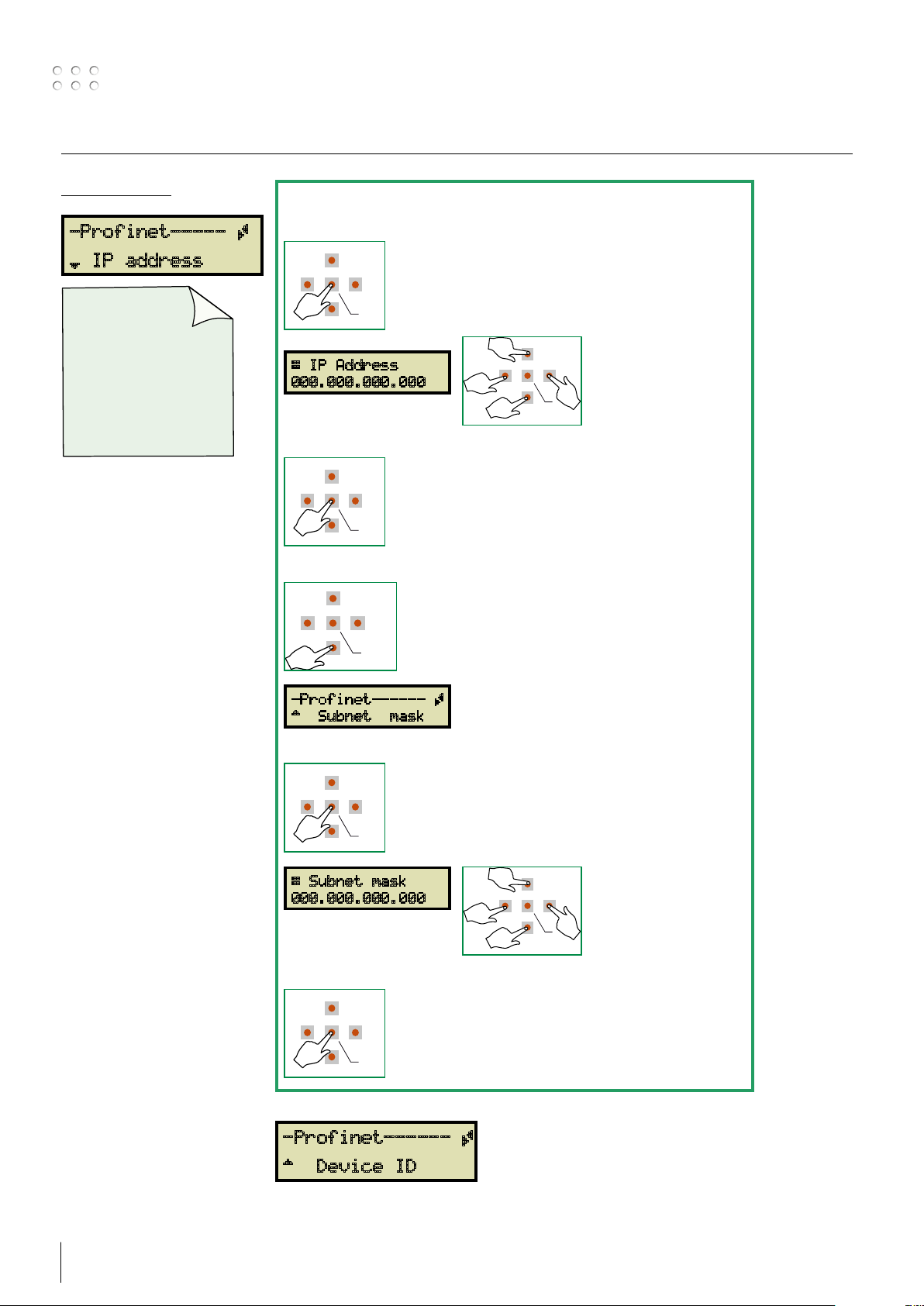

PROFINET IO

-Profinet----- Ã

¾ IP address

The GSDML file

needed by the

robot controller/PLC

can be found on the

SD card, or

downloaded from

www.migatronic.com

MY MIGATRONIC

IP address setup

Press Enter

Æ IP Address

000.000.000.000

Press Enter

Press Down

UP

LEFT

RIGHT

UP

Set the IP address as

specified by the robot

DOWN

RIGHT

or network controller.

E.x. 192.168.000.010

ENTER

LEFT

ENTER

DOWN

-Profinet------ Ã

À Subnet mask

Press Enter

Æ Subnet mask

000.000.000.000

Press Enter to leave

UP

Set the IP subnet mask

address as specified by

DOWN

RIGHT

the robot or network

controller.

ENTER

E.x. 255.255.255.000

LEFT

-Profinet------ Ã

À Device ID

24 25

Loading...

Loading...