Migatronic RALLY MIG 161i User Manual

RALLY MIG 161i

BRUGSVEJLEDNING

USER GUIDE

BETRIEBSANLEITUNG

GUIDE DE L’UTILISATEUR

BRUKSANVISNING

GUIDA PER L’UTILIZZATORE

GEBRUIKERSHANDLEIDING

KÄYTTÖOHJE

GUÍA DE USUARIO

KEZELÉSI ÚTMUTATÓ

PODRĘCZNIK UŻYTKOWNIKA

NÁVOD K OBSLUZE

РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

50115018 B2 Valid from 2018 week 21

Dansk ..................................................................3

English ................................................................9

Deutsch .............................................................15

Français .............................................................21

Svenska .............................................................27

Italiano .............................................................33

Nederlands .......................................................39

Suomi ................................................................45

Español .............................................................51

Magyar ..............................................................57

Polski .................................................................63

Česky .................................................................69

Русский ...........................................................75

2

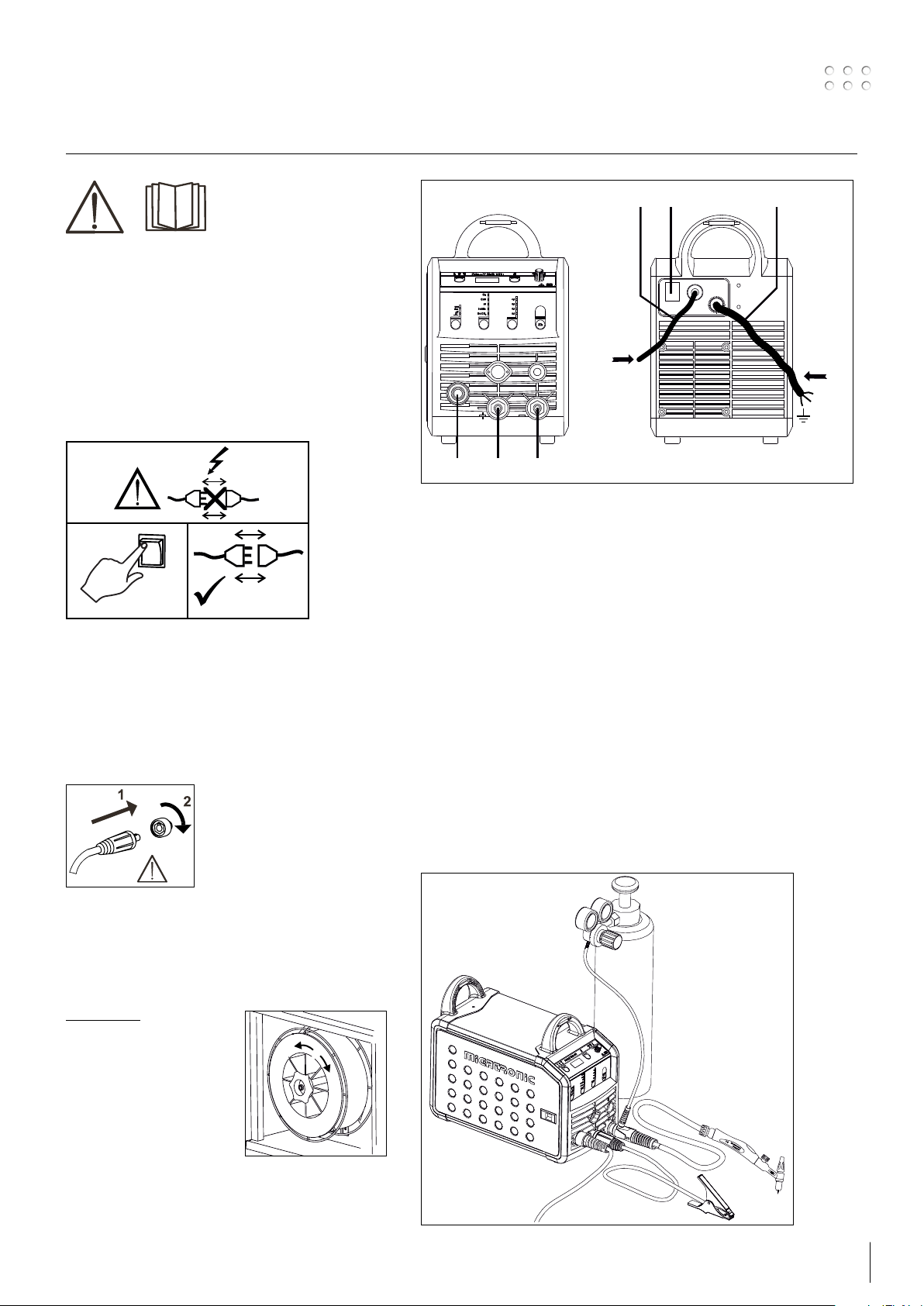

Connection and operation

Warning

Read warning notice and

instruction manual carefully

prior to initial operation and

save the information for later

use.

Permissible installation

Mains connection

Connect the machine to the correct mains supply. Please

read the type plate (U1) on the rear side of the machine.

0

l

1

2

3

GAS

max. 8 Bar

4

65

1. Mains connection

2. Power switch

3. Connection of shielding gas

4. Connection of earth clamp or

electrode holder/TIG torch

5. Connection of welding hose

6. Connection of earth clamp or electrode holder

12

Power

N

F

Connection of shielding gas

Connect the gas hose, which branches off from the

back panel of the welding machine (3), to a gas supply

with pressure regulator (0-8 bar). (Note: Some types of

pressure regulators require an output pressure of more

than 2 bar to function optimally).

Important!

In order to avoid destruction

of plugs and cables, good

electric contact is required when

connecting earth cables and

welding hoses to the machine.

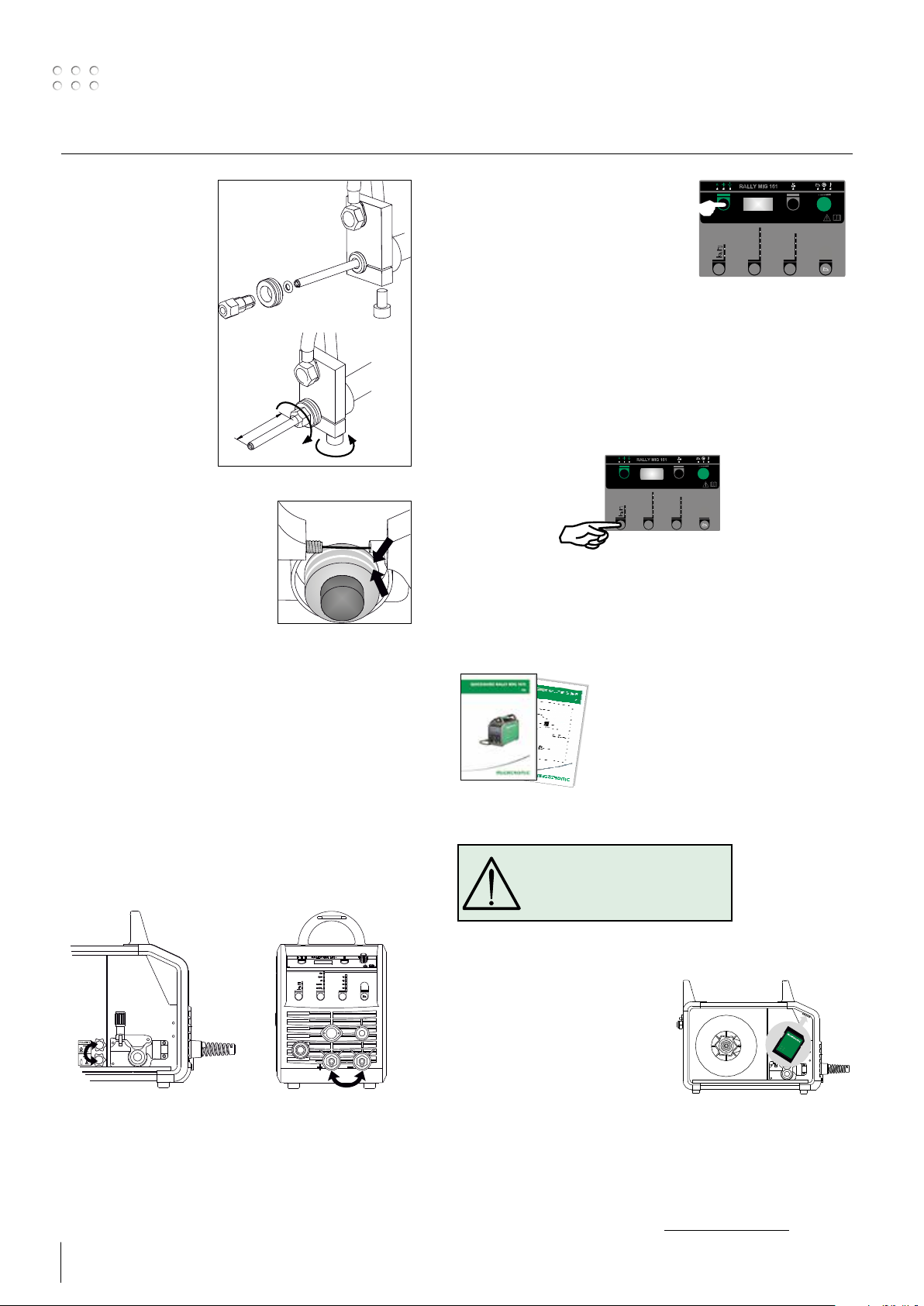

Adjustment of wire drive rolls

The wire brake must ensure that the wire reel brakes

sufficiently before the welding wire runs over the edge

of the reel. The brake force is dependent on the weight

of the wire reel and wire feed speed.

Adjustment:

• Adjust the wire brake by

fastening or loosening

the self-locking nut on

the axle of the wire hub.

Torch adjustment (Dialog torch)

The current size can be adjusted both from the machine

and the welding torch if a welding hose with Dialog

torch is in use. The torch adjustment is passive without

Dialog torch.

Connection of electrode holder for MMA

The electrode holder and earth cable are connected to

plus connection (6) and minus connection (4). Observe

the instructions from the electrode supplier when

selecting polarity.

Installing the TIG torch

9

Connection and operation

Change of wire liner

Welding in aluminium

and MIG brazing requires

a special teflon liner.

Use article no. 81100137

to order kit for

aluminium and MIG

brazing in 1.0 mm wire

with wire liner and inlet

guide.

43

Wire drive rolls

The welding machine is supplied

with turnable wire drive rolls with

V-groove.

For aluminium welding and MIG

brazing, we recommend U-groove/

article no. 82046232.

Selecting welding polarity

Polarity reversal is recommended for certain types of

welding wire, in particular Innershield welding wire. For

recommended polarity, please refer to the welding wire

packaging.

Change of polarity:

1. Disconnect the machine from the mains supply.

2. Dismount the milled nuts at the poles (fig. 1).

3. Reverse the cables (fig. 1).

4. Mount the milled nuts (fig. 1).

5. Exchange earth cable from minus to plus (fig. 2).

6. Connect the machine to the mains supply.

1

2

Inching

The function is used for wire inching

e.g. after change of wire. Wire inching

starts by pressing the green key pad and

simultaneously triggering the torch trigger.

CrNi

Fe

Mix

Fe CO

Wire inching continues even though the

green key pad has been released. It does

not stop until the torch trigger has been released again.

Switch on, press, weld

Welding program setting

• Switch on the welding machine on the main switch (2)

• Select process

• Select type of material and wire diameter

• Set one of the following parameters:

welding current, wire feed speed or thickness of material

• Trim the arc length, if required

• Adjust secondary parameters.

Please read your quickguide

• The machine is now ready to weld

WARNING

Voltage is present on the welding

wire when pressing the welding

hose trigger.

i

Cu

CrNi

1.0

Al

0.9

Fe

Mix

0.8

Fe CO

0.6

2

i

Cu

1.0

Al

0.9

0.8

0.6

2

Change of polarity

10

Software reading

• Insert the SD-card (<2 GB) in

the slide in the right side of the

machine.

• Turn on the machine.

• The display flashes shortly with three

lines.

• Wait until the set current is

displayed.

• Turn off the machine and remove the SD card.

• The machine is now ready for use.

It is necessary to read software inside the new control unit by means of

a SD card, if the control unit has been exchanged.

The software can be downloaded from www.migatronic.com

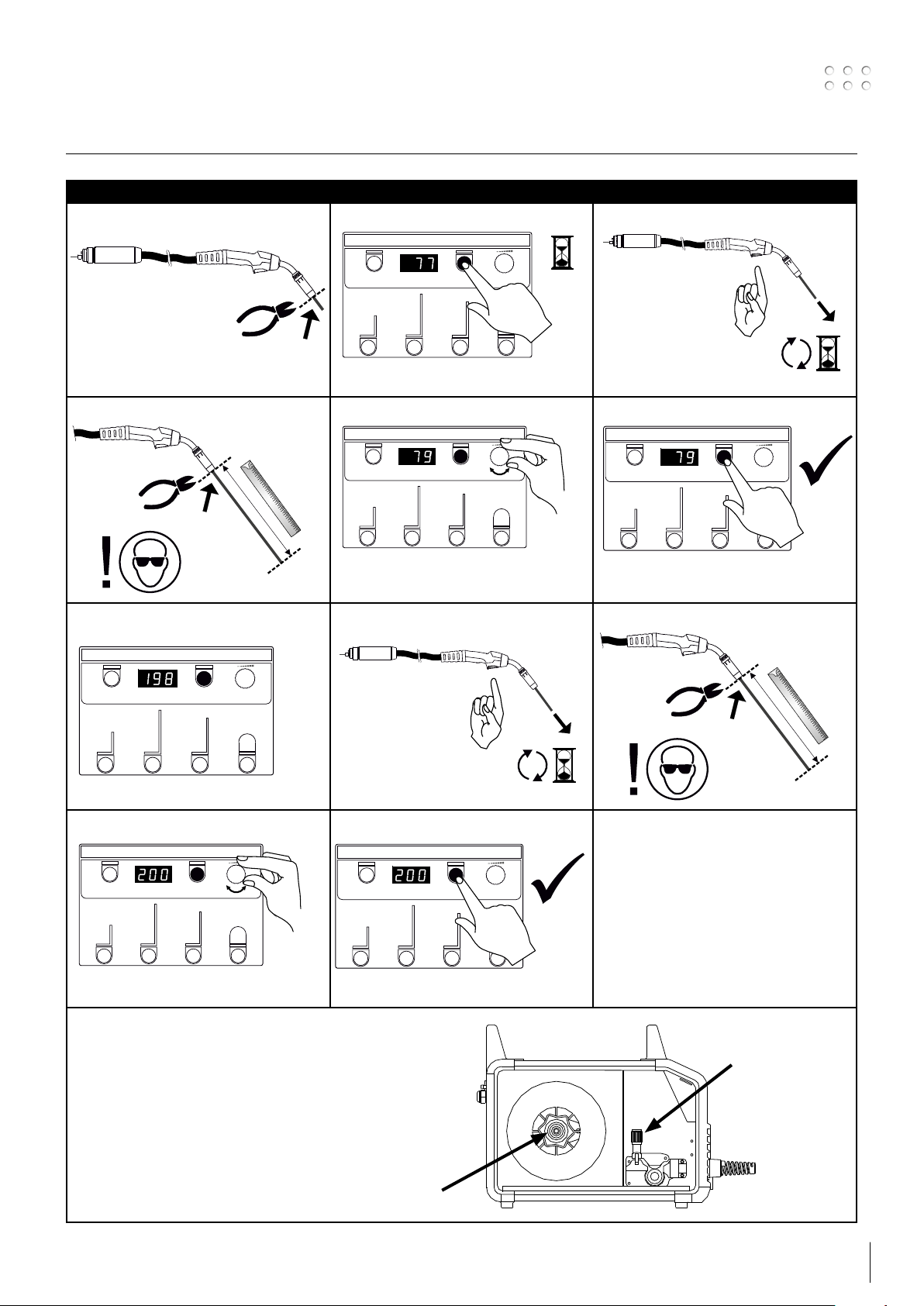

Special functions

10 secs

Calibration of wire feed speed

I II III

IV V VI

e.g. 79 cm

VII VIII IX

X XI

Note:

Adjustment of the pressure on the wire drive rolls and/or

adjustment of the wire brake may influence the wire feed speed

and make it necessary to carry out calibration

e.g. 200 cm

Tightening device for

wire drive rolls

Wire brake

11

Loading...

Loading...