Mifab MHY-35 Installation Manual

®

MIFAB Hydrant Selection Guide

MPB-2018-USA

MPB-2019-USA

MIFAB HYDRANT SELECTION GUIDE

MIFAB hydrants are engineered to control the supply of water in various types of applications. Due to a wide

range of uses, careful consideration should be taken when selecting and specifying the hydrants. The

information provided below will aid the specifier in selecting the correct hydrant for the application considering

such issues as temperature, recessed boxes, vacuum breaker / backflow preventer and optional variations.

WALL HYDRANTS

The most common installation area for hydrants is in the wall. They may be installed either inside or outside of

commercial buildings and serve numerous purposes including watering plants and shrubs and washing floors

or parking areas. Non-freeze wall hydrants are available in various lengths to accommodate different wall thick nesses to ensure that the inlet connection is inside the heated building to prevent freezing. Sometimes, nonfreeze wall hydrants must be concealed entirely within the wall. In these instances, an overall dimension can be

specified. This dimension measures from the back of the face of the hydrant to the end of the inlet connection.

Extra precautions must be taken to properly insulate the valve body to protect against freezing. In addition to

the hydrant that allows connection to standard wall hydrant, MIFAB offers a combination hot and cold water

both hot and cold supplies. It is used to supply tempered water. See MIFAB MHY-45.

NARROW WALL HYDRANTS

Narrow wall hydrants are installed in areas where the entire product must fit within a 4" thick wall. A unique

feature on the inlet supply of the MIFAB hydrant permits the installer to rotate the connection to any position to

connect to the water supply line. The narrow wall hydrant may also be encased to gain all of the advantages of

installing the hydrant in a recessed box. MIFAB's MHY-55 encased narrow wall hydrant has an overall length of

3 5/8" to ensure that it will still fit within a 4" thick wall.

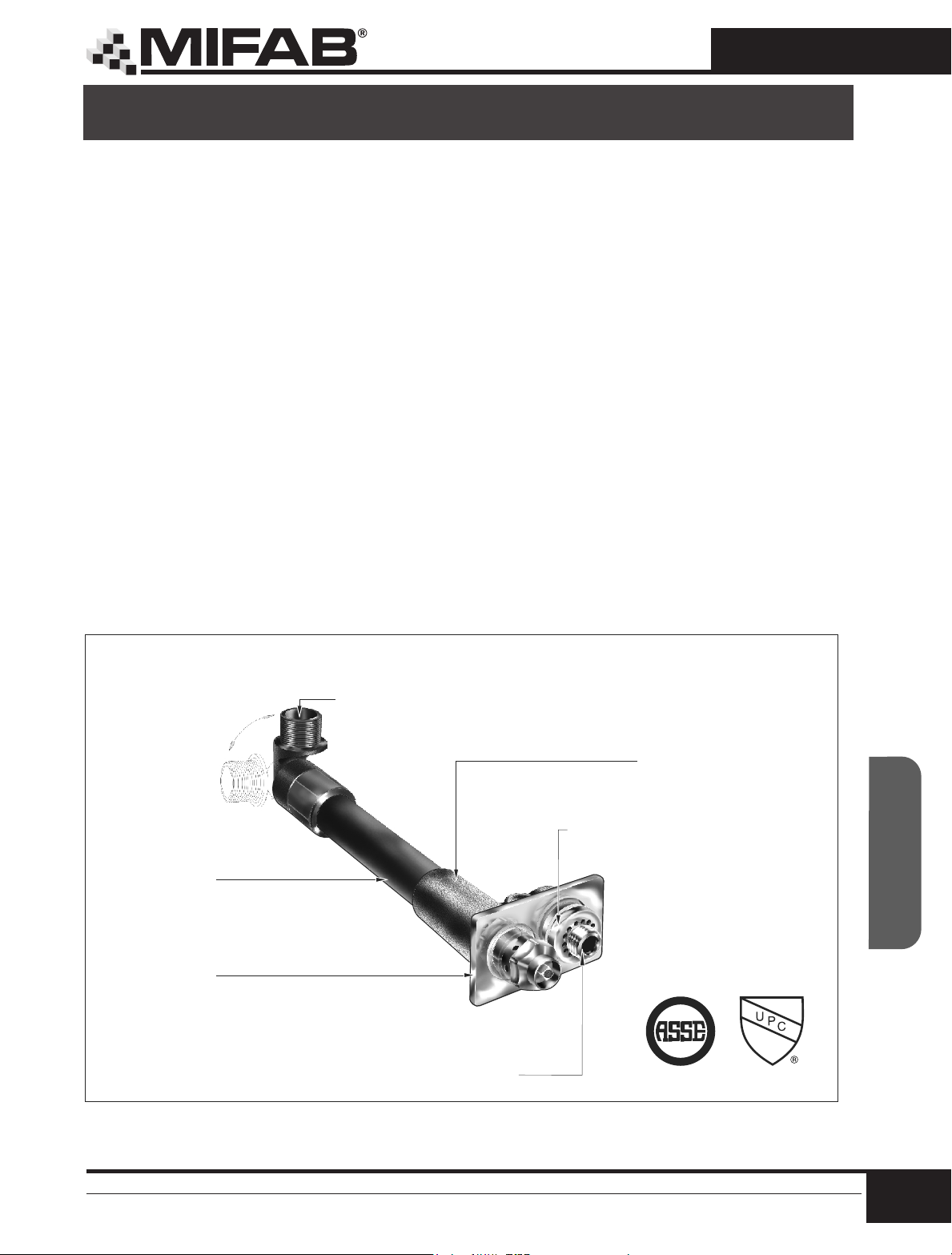

HEAVY DUTY

CASING

POLISHED

CHROME PLATED

FACE PLATE

COMBINATION 3/4” SWT. OR 1” M.I.P. 360 DEGREE SWIVEL INLET

CONNECTION THAT CAN BE REMOVED FOR A STRAIGHT BACK

3/4” SWT. INLET CONNECTION

HEAVY DUTY CHROME

PLATED BRONZE HEAD

CASTING

VANDAL RESISTANT

INTEGRAL VACUUM

BREAKER

SHYDRANT

STANDARD 3/4” (19) MALE HOSE CONNECTION

sales@mifab.com • Canada Toll Free: 1-800-387-3880

Design and dimensions are subject to modication. Prices do not include applicabl e t a x e s . Visit www.mifab.com for the most recent product information.

MIFAB®, Inc., 1321 West 119th Street, Chicago, Illinois 60643-5109, USA Toll Free: 1-800-465-2736 • Fax: 1-773-341-3049

All sales subject to MIFAB’s® Terms and Warranties. Please refer to inside front cover.

265

MPB-2019-USA

®

MPB-2018-USA

MIFAB Hydrant Selection Guide Cont’d.

RECESSED BOXES

MIFAB's recessed hydrant boxes are made with a flange that covers the rough opening and is installed flush

against the exterior wall surface. The hinged locking cover conceals the hose nozzle and all of the operating

parts. The advantages of the flush recessed box:

• Arecessed box provides roughing in the box flush with the exterior wall for a pleasing appearance.

• The hose connection and operating mechanism are concealed within the box instead of protruding from

the wall surface.

• The box has a locking hinged cover that will prevent unauthorized access and vandalism of the operating

mechanism and hose nozzle. The same key that operates the hydrant also unlocks the box. This key is a

special 3-3/4" long to ensure that the operator's fingers are outside of the hydrant box while operating the

hydrant. Typically, short keys are provided by others that result in the operator's fingers being scraped or

cut by the inside of the hydrant box.

MIFAB hydrant boxes are standard in a satin finished nickel bronze material. Polished chrome plated and cast

stainless steel, are also available. The open face hydrant should be specified when the operating mechanism

and hose nozzle is preferred to be exposed and may extend beyond the finished wall. This hydrant should

be installed in a concealed location or where security is provided. MIFAB's MHY-10 and MHY-30 hydrants can

be easily attached to the hydrant box. The hydrant is inserted through the front of the box until the back

of the faceplate rests flush against the inside of the box. Two set screws on the top and bottom of the back of

the box are used to tighten the hydrant securely into the box.

MIFAB has engineered several unique features into its' wall hydrant boxes.

• A"drip lip" on the exterior of the hydrant box accumulates water that results from the closing of the hydrant.

This residual water drips from the lip onto the ground clear of the wall. Standard competitive designs cause

unsightly oxide stains on the wall.

• The bottom of MIFAB's hydrant boxes are solid. There are no slots or grooves for water to drain back into the

wall and cause damage.

• The boxes are also available with four /" x 1" slots (suffix -S) (one at each side and two on the top of the box)

and three mounting brackets (suffix -BR) for easy installation by the contractor into the frame or ladder

system. Too often, contractors have difficulty installing hydrant boxes into walls because nothing is provided

to secure the box to the wall. Many contractors go to considerable expense to fabricate their own hydrant box

mounting devices. MIFAB's hydrant boxes eliminate these extra costs and ensure that the installation and

operation of the hydrant box is simple.

HYDRANTS

266

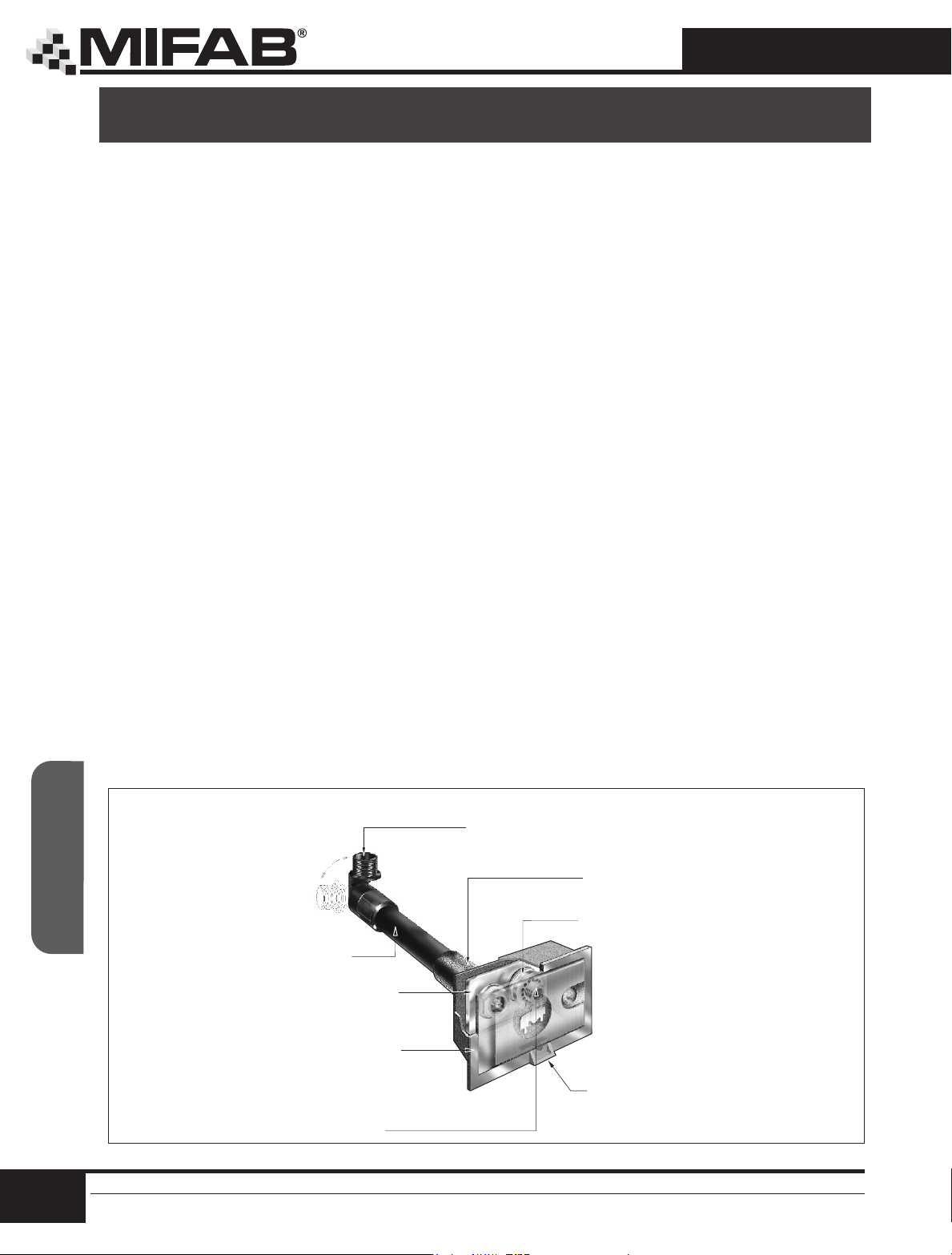

COMBINATION 3/4” SWT. OR 1” MALE THREADED 360 DEGREE

SWIVEL INLET CONNECTION THAT CAN BE REMOVED FOR A

HEAVY DUTY

CASING

POLISHED

CHROME PLATED

FACE PLATE

NICKEL BRONZE BOX

WITH HINGED

LOCKING COVER

STANDARD

3/4” MALE HOSE

CONNECTION

Design and dimensions are subject to modication. Prices do not include applicabl e t a x e s . Visit www.mifab.com for the most recent product information.

MIFAB®, Inc., 1321 West 119th Street, Chicago, Illinois 60643-5109, USA Toll Free: 1-800-465-2736 • Fax: 1-773-341-3049

All sales subject to MIFAB’s® Terms and Warranties. Please refer to inside front cover.

STRAIGHT BACK 3/4” SWT.

INLET CONNECTION

HEAVY DUTY CHROME

PLATED BRONZE HEAD

VANDAL RESISTANT

INTEGRAL VACUUM

CASTING

BREAKER

DRIP LIP

sales@mifab.com • Canada Toll Free: 1-800-387-3880

Loading...

Loading...