Miele professional PLW 8617 Operating Instructions Manual

Operating instructions

Washer-disinfector

PLW 8617

To avoid the risk of accidents or damage to the

machine, it is essential to read these instructions

before it is installed and used for the first time.

en-GB

M.-Nr. 11 234 680

2

Contents

Notes about these instructions..........................................................................................6

Intended use ........................................................................................................................7

User profiles.........................................................................................................................8

User administration ............................................................................................................... 8

User profiles .......................................................................................................................... 8

Product description.............................................................................................................9

Appliance overview ............................................................................................................... 9

Infeed and outfeed side.................................................................................................... 9

Infeed and outfeed side without service panel .............................................................. 10

Control elements on the display.......................................................................................... 11

Main menu...................................................................................................................... 11

Programme start display ................................................................................................ 13

Warning and Safety instructions......................................................................................16

Symbols on the machine..................................................................................................... 21

Main menu..........................................................................................................................22

Main menu........................................................................................................................... 22

Actions in theMain menu............................................................................................... 22

Changing the display language .................................................................................. 22

Login ............................................................................................................................ 23

Logout ............................................................................................................................ 24

Printing documentation .................................................................................................. 24

Opening and closing the door........................................................................................ 24

Areas of application ..........................................................................................................25

General information............................................................................................................. 25

Load carriers .................................................................................................................. 25

Preparing the load.......................................................................................................... 26

Preparing the load.......................................................................................................... 27

Before starting a programme ......................................................................................... 29

After the end of a programme ........................................................................................ 29

Laboratory glassware and utensils ...................................................................................... 30

Programme chart................................................................................................................. 31

General programmes ........................................................................................................... 32

Programmes for specific soiling .......................................................................................... 33

Programmes for specific loads............................................................................................ 34

Additional programmes....................................................................................................... 35

Service programme............................................................................................................. 35

Chemical processes and technology ..............................................................................36

Dispensing liquid chemical agents..................................................................................40

Dispensing systems ............................................................................................................ 40

Containers for process chemicals.................................................................................. 41

Filling containers with process chemicals...................................................................... 42

Filling the dispensing system ......................................................................................... 43

Operation............................................................................................................................44

Switching the machine on and off....................................................................................... 44

3

Contents

Selecting a programme ....................................................................................................... 44

Selecting a load carrier................................................................................................... 44

Selecting programmes from Favourites ......................................................................... 45

Starting the programme ...................................................................................................... 46

Programme sequence ......................................................................................................... 47

End of programme............................................................................................................... 47

Cancelling a programme ..................................................................................................... 47

Delay start ........................................................................................................................... 48

Network connection..........................................................................................................49

Network connection ............................................................................................................ 49

Network protocols............................................................................................................... 50

Process documentation ...................................................................................................... 50

System settings .................................................................................................................51

System ................................................................................................................................ 51

Network connections .......................................................................................................... 51

Changing the PIN ........................................................................................................... 52

Pairing ............................................................................................................................ 52

Configuring the printer ................................................................................................... 53

Setting the network ........................................................................................................ 54

Machine functions ............................................................................................................... 55

Carrying out self-disinfection (optional).......................................................................... 55

Starting the continuous programme............................................................................... 55

Filling the dispensing system ......................................................................................... 57

Dispensing system setup ............................................................................................... 57

Calibrating the conductivity meter ................................................................................. 57

Carrying out a programme test ...................................................................................... 58

Restarting ............................................................................................................................ 60

Opening the data plate........................................................................................................ 60

Managing favourites............................................................................................................ 61

Maintenance ......................................................................................................................62

Periodic checks................................................................................................................... 62

Routine checks.................................................................................................................... 63

Cleaning the filters in the wash cabinet .............................................................................. 64

Cleaning the spray arms...................................................................................................... 65

Machine spray arms....................................................................................................... 66

Spray arms on mobile units and modules...................................................................... 66

Cleaning the machine.......................................................................................................... 67

Locking the display ........................................................................................................ 67

Cleaning control elements and the glass door............................................................... 67

Cleaning the front of the machine .................................................................................. 68

Cleaning the wash chamber........................................................................................... 68

Cleaning the door seal ................................................................................................... 68

Built-in printer (optional) ...................................................................................................... 69

Replacing the paper roll ................................................................................................. 69

Thermal paper ................................................................................................................ 70

Error messages and instructions.....................................................................................71

Representation of faults on the display............................................................................... 71

4

Contents

Technical faults on the cleaning machine ........................................................................... 71

List with active messages .............................................................................................. 71

Troubleshooting.............................................................................................................. 72

Technical faults without fault number............................................................................. 72

After sales service.............................................................................................................73

Electrical connection ........................................................................................................74

Electromagnetic compatibility (EMC) .................................................................................. 75

Plumbing ............................................................................................................................76

Technical data....................................................................................................................77

Disposing of your old machine ........................................................................................78

Appendix ............................................................................................................................80

User rights in the Main menu .............................................................................................. 80

User rights in the System menu .......................................................................................... 81

Power levels of the programmes/mobile units/module combinations ................................ 82

Optional extras .................................................................................................................... 85

5

Notes about these instructions

Important warnings

Information which is important for safety is highlighted in a thick

framed box with a warning symbol. This alerts you to the potential

danger of injury to people or damage to property.

Read these warning notes carefully and observe the procedural

instructions and codes of practice they describe.

Notes

Information of particular importance that must be observed is

highlighted in a thick framed box.

Additional information and comments

Additional information and comments are contained in a simple

frame.

Operating steps

Operating steps are indicated by a black square bullet point.

Example:

Select an option using the arrow buttons and save your choice with

OK.

Display

Certain functions are shown in display messages using the same font

as that used for the function itself in the display.

Example:

Settings menu.

6

Intended use

The PLW 8617washer-disinfector is designed to reprocess laboratory

glassware, utensils and similarly categorised components using water-based media.

Appropriate use

Reprocessing encompasses the cleaning, rinsing, and – where necessary – thermal disinfection and drying of the following load:

– Vessels such as beakers, flasks, cylinders and test tubes

– Measuring vessels such as measuring cylinders, volumetric flasks

and pipettes

– Dishes such as petri dishes and watch glasses

– Plates such as slides and sequencing plates

– Small items such as lids, magnetic stirring rods, spatulas and stop-

pers

– Other items such as boxes, plastic flasks and containers, metal

parts, pipe and hose pieces and funnels

The washer-disinfector is generally referred to as “the machine” in

these operating instructions. The term “load” is used wherever the

items to be processed are not defined in any further detail. The term

“wash water” is used for the mixture of water and process chemicals.

Reprocessing is carried out in conjunction with:

– Process chemicals which are tailored to the result of the repro-

cessing

– Load carriers which are tailored to the load

Observe the information issued by the manufacturer of the load.

Inappropriate use

The PLW 8617washer-disinfector may not be used for any purposes

other than the appropriate use described. This applies in particular to:

– Reprocessing of reprocessable medical devices

– Use in the catering industry

– Domestic use

7

User profiles

User administration

Access to the machine is restricted to a certain group of people. Authorised users are entered inUser management via the machine’s

web interface. User managementis described in the programming

manual.

A User IDandPIN are required for the userLogin on the machine.

User actions such as starting a reprocessing programme are saved.

User data is read out on theReprocessing report, for example.

User profiles

Day-to-day use

Service work

Administration

For day-to-day use, operators must be instructed on the basic functions and how to load the machine and must also be trained regularly.

They must have a basic knowledge of machine reprocessing of laboratory glassware and utensils.

Day-to-day work is carried out using the following user levels:

– Without message

– Automatic

– Operator

Adaptations of the machine, e.g. to accessories used or on-site conditions, require additional specific knowledge of the machine.

It is carried out using the following user levels:

– Technician

– Administrator

Changes to the reprocessing process and performance testing also

require specialist knowledge about machine reprocessing of laboratory glassware and utensils and about process technology.

It is carried out using the following user level:

– Administrator

8

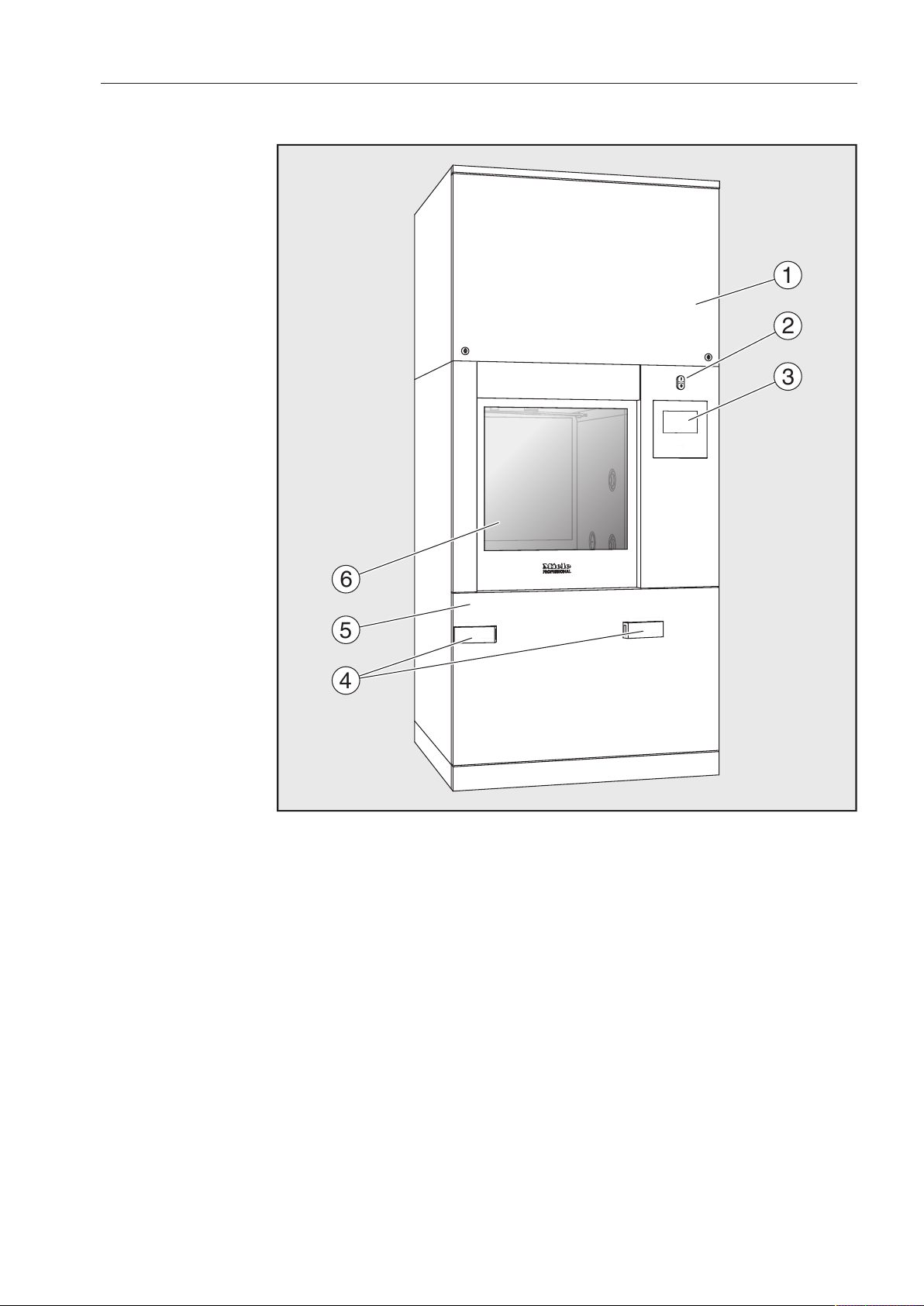

Infeed and out-

1

2

3

5

6

4

feed side

Product description

Appliance overview

a

Service panel for the Customer Service Department

b

I/0 power switch

c

Display

d

Docking system for transfer trolleys,

service panel lock

e

Service panel

f

Door closed

9

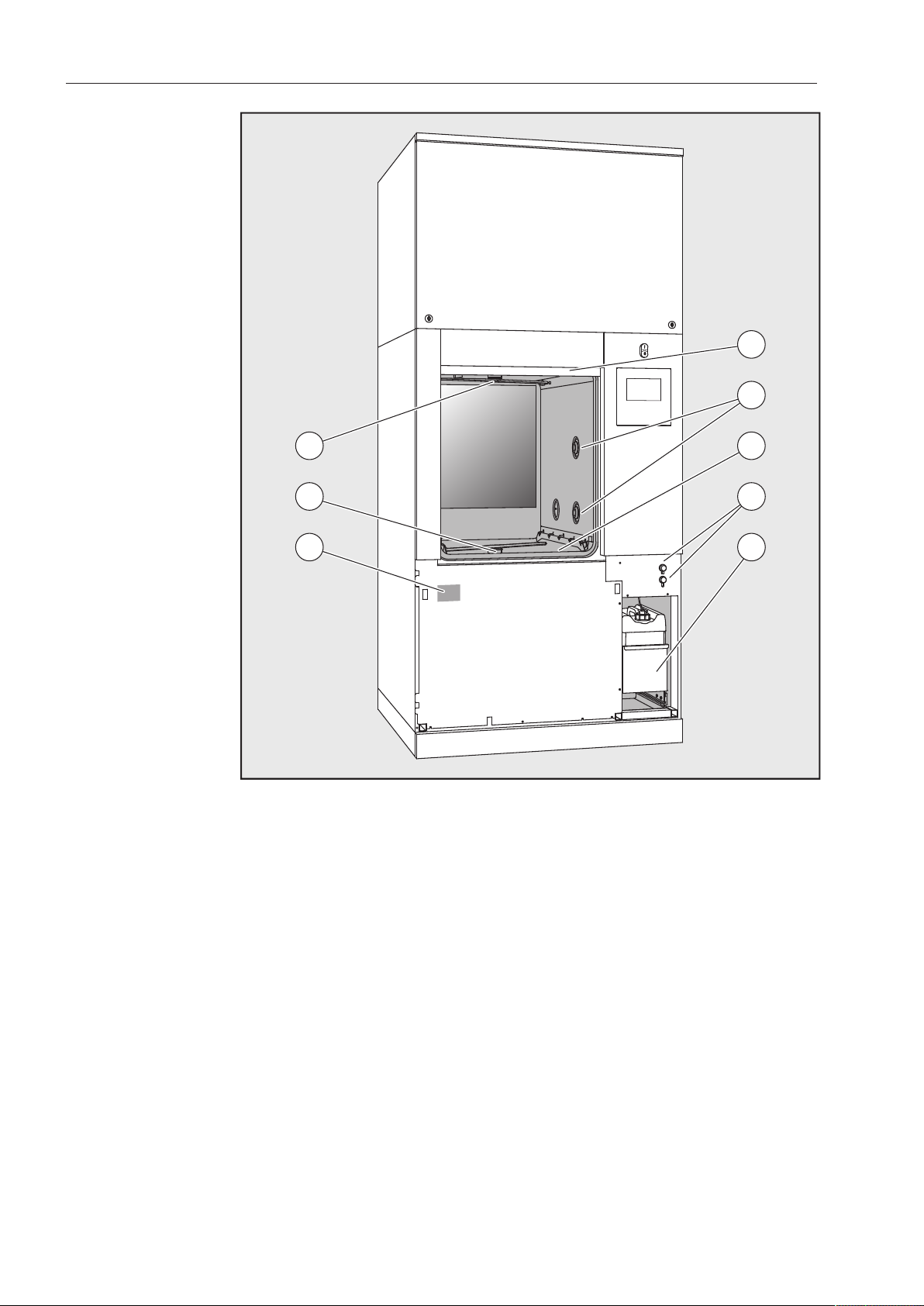

Product description

1

2

3

4

7

8

56

Infeed and outfeed side without

service panel

a

Door open

b

Water supply for load carriers

c

Filter combination

d

Connections for the Customer Service Department

e

Drawer with containers and connections for process chemicals

f

Data plate

g

Lower machine spray arm

h

Upper machine spray arm

10

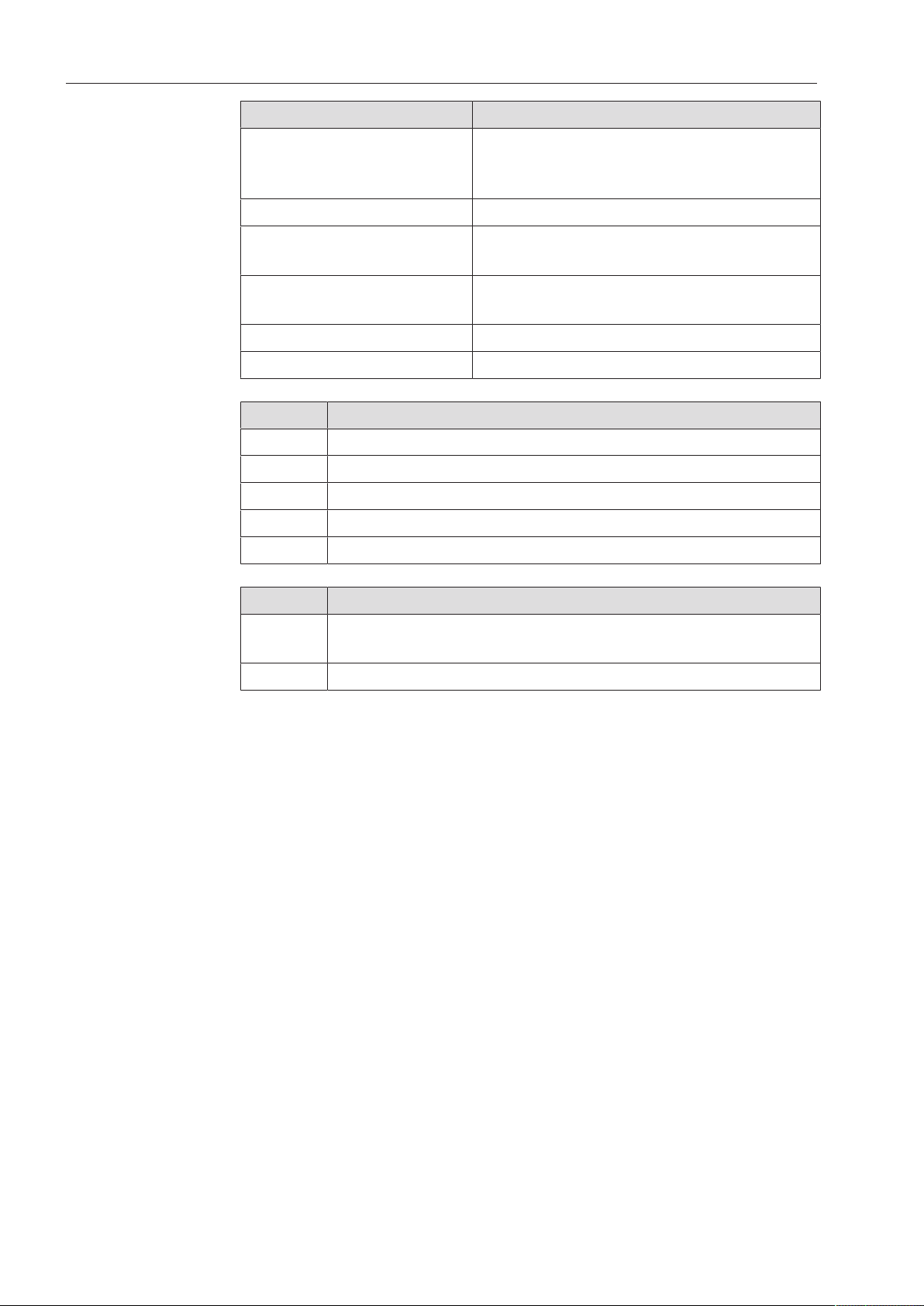

Control elements on the display

Reprocessing

Favourites

Documentation

System

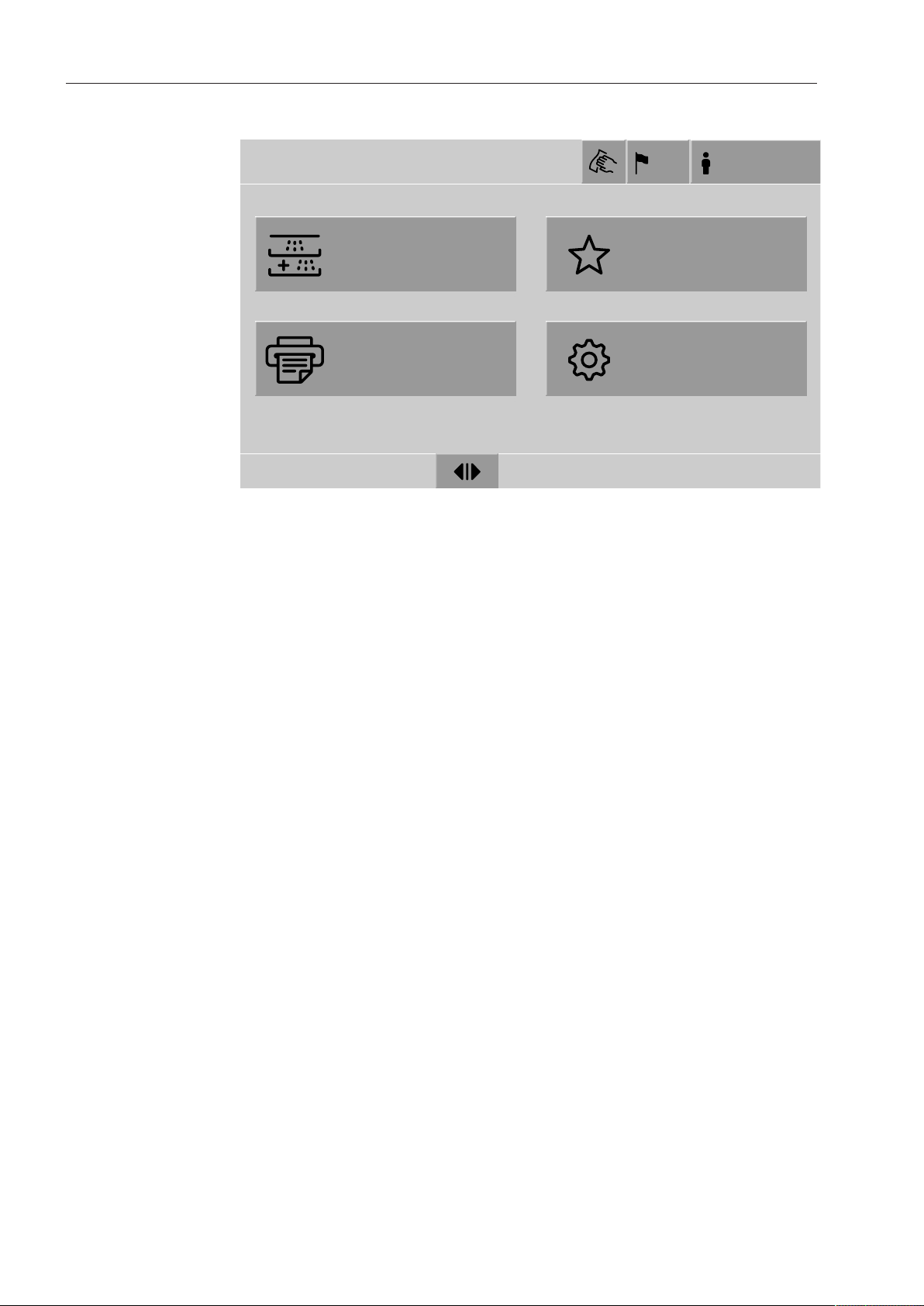

Main menu

GB

Login

18.06.2018 15:05

Product description

Main menu

The machine display shows the control elements light on a black

background. In these operating instructions, the display is shown as

black on a light background in order to improve legibility.

a

Header

b

Display language selected

c

Current user

d

Buttons to call up sub-menus

e

Footer

Buttons in the main menu/ header

Buttons for all enabled actions are displayed in the footer.

If a menu is split across several pages, a scroll bar will be displayed

above the footer. Swipe the display or tap the scroll bar to scroll

between the pages.

Symbol Description/function of the button

Locks the display, e.g. for surface disinfection

Opens the Select display language menu.

Opens the login or logout dialog, e.g. to switch users

The language currently set is indicated behind the symbol,

e.g. GB

11

Product description

Symbols in the

main menu

Buttons in the main menu/ footer

Symbol Description/function of the button

Opens the list of reprocessing pro-

Reprocessing

Favourites Opens the list of favourites

Documentation

System

Information

Please wait, the controls are busy

Symbol Description/function of the button

Warning present, opens the Messages list

Fault present, opens the Messages list

Opens the door

Closes the door

The door is locked

grammes which are assigned to the load

carrier

Opens the list of available reprocessing

reports

Opens the configuration menu, e.g. for

network settings or to change the PIN

Buttons in the submenus/

footer

Symbol Description/function of the button

OK Confirm entries

Leave menu, go back to previous menu level, do not save

entries

12

Product description

0:00

user/

18.06.2018 15:05

GB

USER

Universal

Duration

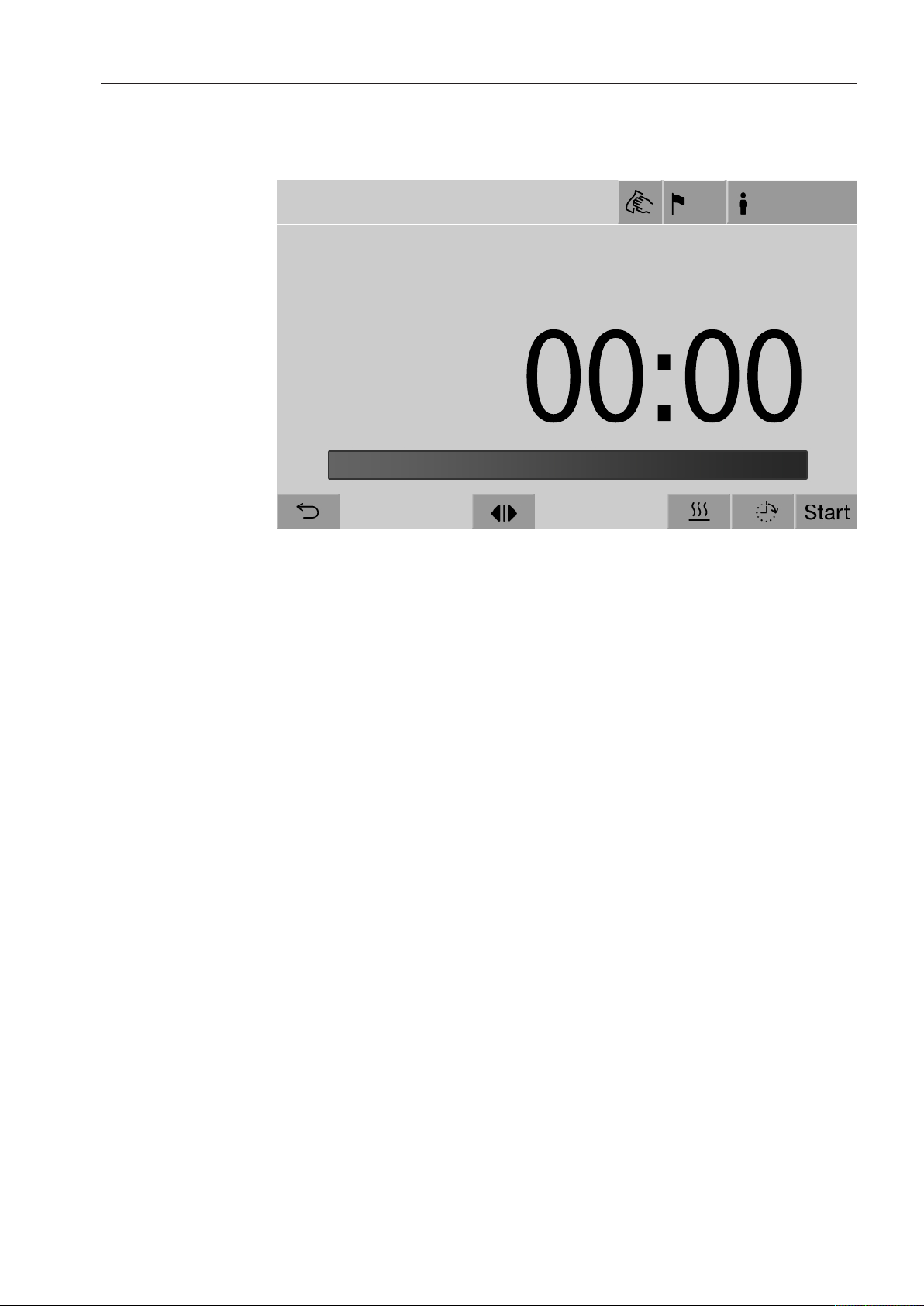

Programme start display

Once the Reprocessingload carrier, for example, has been selected

in the A 500menu and the associated Universalreprocessing programme has been confirmed, the following is displayed:

The pictogram of the load carrier and the selected reprocessing programme are displayed in the header.

The duration and a progress bar are shown on the display.

The colour of the progress bar corresponds to the current machine

status:

– Black for ready for use

– White for an ongoing reprocessing programme

– Green for a reprocessing programme that has been successfully

completed

– Yellow for warnings

– Red for faults

13

Product description

Programme start/

programme sequence buttons/

symbols

Symbol Description/function of the button

Programme start

Programme cancellation

Opens the input screen for selecting the start time

Door locked

In/Out

Displays the programme sequence as a diagram

Selects the steam heating method

Selects the electric heating method

+ Selects the electric and steam heating method

(next to

the pro-

gress

bar)

Shows the programme sequence display in the default

view

Schematic programme sequence display, contains information for the Customer Service Department

Displays the current faults and warnings in the progress

bar

Heat-up

context menu (optional)

This context menu is only available in machines where it is possible

to switch the energy supply from electric to steam.

The energy source for heating can be changed before and during the

programme sequence. The selected setting is used for heating up the

wash water and the demineralised water in the demineralised water

tank.

The selected setting is applied permanently in the machine controls.

Press the button to open the context menu.

14

Product description

0:25

°C

75 °C

Duration

Universal

user/

18.06.2018 15:05

USER

GB

Programme phase

Temperature

Main wash 1

In/Out

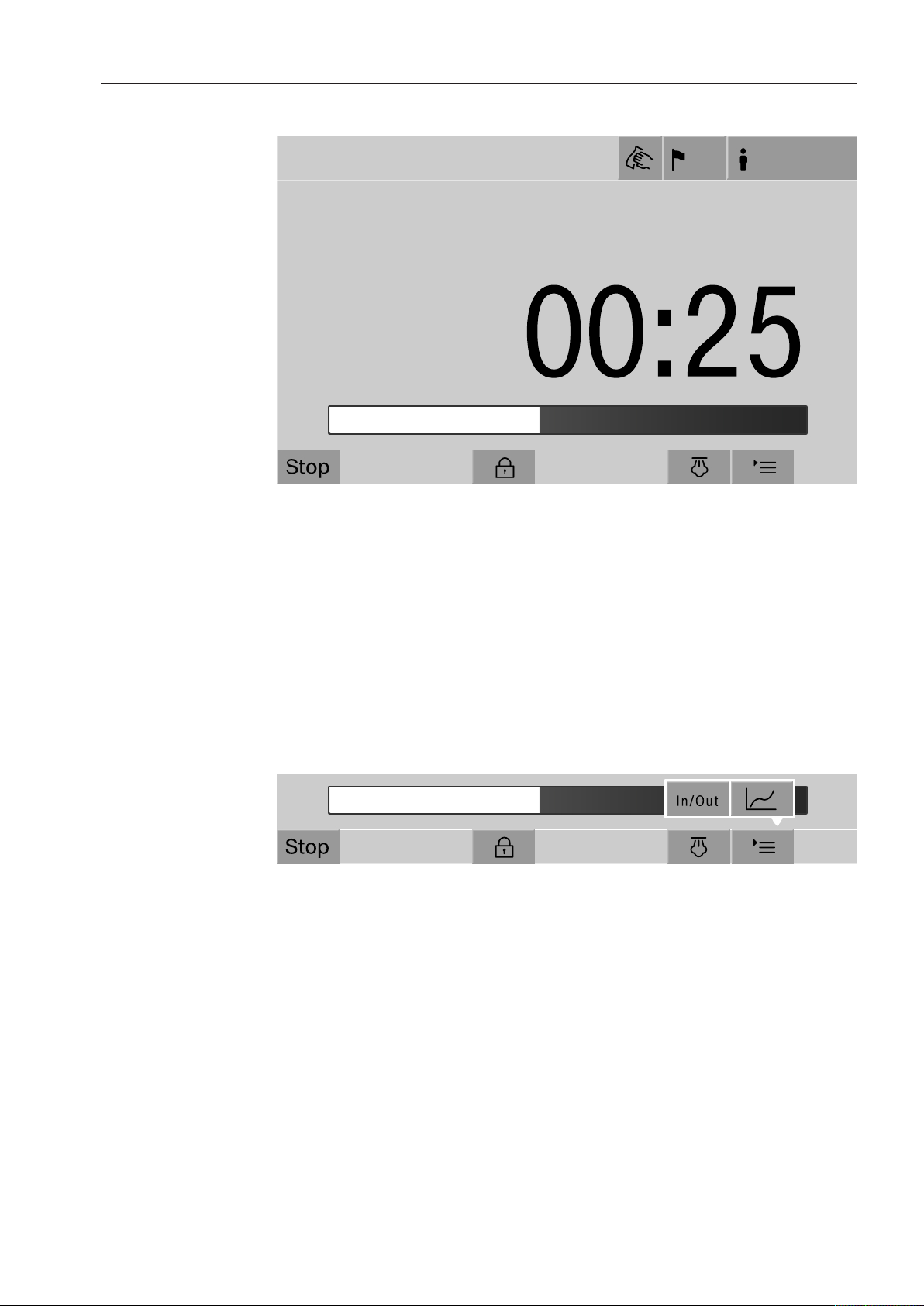

Example of a programme sequence

display

After the programme has started, the following display is shown:

The current programme phase and the temperature reached are also

shown on the display.

The progress bar indicates the ratio between the duration and the

time left.

Programme sequence display

context menu

During the programme sequence, you can choose between 3 views:

– Standard

– In/Out chart – In/Out

– Graphical

The In/Out chart contains information for the Customer Service Department and is not explained in these operating instructions.

Press the button to open the context menu.

Once you have switched to the graphical display using the but-

ton, the following values are displayed as curves:

– Temperature of the wash water [W]

– Temperature of the external drying [EA]

– Temperature of the internal drying [IA]

– Internal wash pressure [P]

15

Warning and Safety instructions

Risk to health and risk of damage if the operating instructions

are not followed.

Failure to follow the operating instructions – and in particular the

safety instructions and warnings they contain – may result in persons being seriously injured or property being seriously damaged.

Read these operating instructions carefully before using the machine. This will prevent both personal injury and damage to the machine.

Keep the operating instructions in a safe place.

Correct application

Use of the machine is only permitted for the applications expressly

approved in the operating instructions. Alterations or conversion of

the machine, or using it for purposes other than those for which it

was intended, are not permitted and could be dangerous.

The cleaning and disinfection processes are only designed for laboratory glassware and utensils which are designated as reprocessable

by the manufacturer. The information provided by the manufacturer of

the load items must be observed.

This washer-disinfector is intended for indoor use only.

The machine is equipped with a special lamp to cope with particu-

lar conditions (e.g. temperature, moisture, chemical resistance, abrasion resistance and vibration). This special lamp must only be used

for the purpose for which it is intended. It is not suitable for room

lighting. Replacement lamps may only be fitted by the Miele Customer Service Department.

Risk of injury

Please pay attention to the following notes to avoid injury

This machine must be commissioned, serviced and repaired by a

Miele authorised and trained service technician only. To ensure compliance with Good Laboratory Practice guidelines, Miele repair and

maintenance contracts are recommended. Unauthorised repairs can

pose considerable risks to the user.

Do not install the machine in an area where there is any risk of ex-

plosion or of freezing conditions.

The electrical safety of the machine can only be guaranteed when

it is correctly earthed. It is essential that this standard safety requirement is observed and regularly tested. If in any doubt, please have

the electrical installation inspected by a qualified electrician.

16

A damaged or leaking machine could be dangerous and comprom-

ise your safety. Disconnect the machine from the mains immediately

and call the Miele Service Department.

Warning and Safety instructions

Label machines which have been taken out of operation and se-

cure them from being switched on again without authorisation. The

machine may only be put back into operation once it has been successfully repaired by the Miele Customer Service Department.

Personnel operating the machine should be trained regularly. Un-

trained personnel must not be allowed access to the machine or its

controls.

Take care when handling chemical agents. These may contain irrit-

ant, corrosive or toxic ingredients.

Please observe the chemical agent manufacturer's safety instructions

and safety data sheets.

Wear protective gloves and goggles.

Only use process chemicals which have been approved by their

manufacturer for the relevant application. The manufacturer of the

process chemicals is liable for any negative influences on the material

of the load and the machine.

The machine is designed for operation with water and recommen-

ded additive chemical agents only. Organic solvents and flammable

liquid agents must not be used in it.

This could cause an explosion, damage rubber or plastic components

in the machine and cause liquids to leak out of it.

The water in the cabinet must not be used as drinking water.

Be careful when sorting items with pointed ends. Position them in

the machine so that you will not hurt yourself or create a danger for

others.

Broken glass can result in serious injury when loading or unload-

ing. Damaged glass items must not be reprocessed in the machine.

When using this machine in the higher temperature ranges, be es-

pecially careful not to scald or burn yourself or come into contact with

irritant substances when opening the door. Where disinfecting agents

are used there is a danger of inhaling toxic fumes.

Where there is a risk of toxic or chemical substances occurring in

or leaking into the suds solution (e.g. aldehyde in the disinfecting

agent), it is essential to regularly check door seals and make sure that

the steam condenser is functioning correctly. Opening the machine

door during a programme interruption carries particular risks in such

circumstances.

Should personnel accidentally come into contact with toxic va-

pours or chemical agents, follow the emergency instructions given in

the manufacturer's safety data sheets.

After using the hot air drying unit, open the door to allow the

everything in the cabinet from the load itself to the mobile units, modules and inserts to cool down.

17

Warning and Safety instructions

Mobile units, modules, inserts and the load must be allowed to

cool down before they are unloaded. Any water remaining in containers could still be very hot. Empty them into the wash cabinet before

taking them out.

Steam heating is permissible up to a pressure of 1000kPa. This

corresponds to a water steam temperature of 180°C.

Never clean the machine or near vicinity with a water hose or a

pressure washer.

The machine must be disconnected from the mains electricity sup-

ply before any maintenance or repair work is carried out.

Quality assurance

The following points should be observed to assist in maintaining

quality standards when processing laboratory glassware and

utensils to avoid damage to the loads being cleaned.

If it is necessary to interrupt a programme in exceptional circum-

stances, this may only be done by authorised personnel.

The standard of cleaning and disinfection must be routinely con-

firmed by the user. The process should be validated on a regular

basis, and checked against documented control results.

For thermal disinfection, use temperatures and temperature holding

times to achieve the required infection prophylaxis in accordance with

current health and safety regulations.

Make sure items being washed are suitable for machine repro-

cessing and are in good condition. Plastic items must be thermally

stable. Nickel plated items and aluminium items can be machine processed using special procedures only.

Items containing iron, and soiling containing residual rust must not be

placed in the cabinet.

Chemical agents can, in certain circumstances, cause damage to

the machine. Always follow the recommendations of the chemical

agent manufacturer.

In case of damage or doubt about compatibility, please contact

Miele.

Cleaning agents containing chlorine can damage the elastomers of

the machine.

If the use of cleaning agents containing chlorine is required, a maximum temperature of 75°C in the “Main wash” programme phases is

recommended (see programme chart).

Cleaning agents containing chlorine must not be used in machines

supplied (ex works) with special oil-resistant elastomers for oil and

grease applications.

18

Warning and Safety instructions

Pre-treatments with cleaning or disinfecting agents can create

foam, as can certain types of soiling and chemical agents. Foam can

have an adverse effect on the cleaning and disinfection result.

Processes must be set up such that foam cannot escape from the

wash cabinet. It would hinder the correct functioning of the machine.

The process used must be monitored on a regular basis by the su-

pervisor to check foaming levels.

To avoid the risk of damage to the machine and any accessories

used with it caused by chemical agents, soiling and any reaction

between the two please read the notes in “Chemical processes and

technology”.

Even when a process chemical, e.g. cleaning agent, is recommen-

ded, the machine manufacturer takes no responsibility for the effect

of such process chemicals on the load.

Please note that changes in product formulation, storage conditions,

etc. which are not announced by manufacturers of process chemicals

may impair the quality of cleaning results.

When using process chemicals, always consult the instructions is-

sued by individual manufacturers. Process chemicals must only be

used for the purpose they are designed for by the manufacturer to

avoid any material damage or the occurrence of very strong chemical

reactions (e.g. oxyhydrogen explosion).

Always follow the relevant manufacturer's instructions on storage

and disposal of chemical agents.

Particles≥200μm are removed by the filters in the wash chamber.

Smaller particles may find their way into the circulation system.

In critical applications where very stringent requirements have to

be met, it is strongly recommended that all the relevant factors for the

process, such as chemical agents, water quality etc. are discussed

with the Miele Application Technology specialists.

If the cleaning result is subject to particularly stringent require-

ments, e.g. in chemical analysis, the operator must carry out regular

quality control to ensure that required standards of cleanliness are

being achieved.

Mobile units, modules and inserts should only be used for the pur-

pose they are designed for.

Hollow instruments must be thoroughly cleaned, internally and externally.

Secure small and light items with cover nets or place in a mesh

tray for small items, so that they do not block the spray arms.

Empty any containers or utensils before loading them.

19

Warning and Safety instructions

The amount of residual solvents and acids on items going into the

cabinet should be minimal.

There should be no more than a trace of any solvents with a flash

point of below 21°C.

Chlorous solutions, in particular hydrochloric acid, must not be

placed in the cabinet.

Ensure that solutions or steam containing chlorides or hydrochloric

acid do not come into contact with the stainless steel outer casing of

the machine in order to avoid any damage through corrosion.

After any plumbing work the water pipework to the machine will

need to be vented. If this is not done, components can be damaged.

Follow the installation instructions in the operating and installation

instructions.

Using accessories

Only Miele accessories should be connected to this machine. They

must be suitable for the application they are required for. Consult

Miele for details on the type of accessories that can be used.

Only use Miele mobile units, baskets and inserts with this washer-

disinfector. Using mobile units and inserts made by other manufacturers, or making modifications to Miele accessories can cause unsatisfactory cleaning results, for which Miele cannot be held liable.

Any resultant damage would not be covered by the guarantee.

Only use process chemicals which have been approved by their

manufacturer for the relevant application. The manufacturer of the

process chemicals is liable for any negative influences on the material

of the load and the machine.

20

Warning and Safety instructions

Symbols on the machine

Warning:

Observe the operating instructions!

Warning:

Danger of electric shock!

Warning: Hot surfaces:

It can be very hot inside the wash cabinet

when the door is opened!

Disposing of your old machine

Please note that, depending on the application, the old machine

may be contaminated with blood and other bodily fluids, pathogens,

facultative pathogens or genetically modified material, etc., and must

be decontaminated before disposal.

For environmental and safety reasons, dispose of all process chemical residues in accordance with safety regulations and the manufacturer’s safety data sheets (wear safety goggles and gloves).

Remove or disable the door so that children cannot become trapped

inside. Then make appropriate arrangements for safe disposal of the

machine.

For machines with a tank system, the water in the tank must be removed beforehand.

Before disposal, all personal data saved in the machine must be

deleted, e.g. user names.

21

Main menu

Reprocessing

Favourites

Documentation

System

Main menu

GB

Login

18.06.2018 15:05

Main menu

Actions in

theMain menu

The main menu of the machine is split into headers and footers and

4menus. The following actions can be performed using the buttons:

– Lock the display, e.g. for surface disinfection (see “Maintenance,

locking machines”)

– Change the display language

– Log a user in and out

– Close popups with messages depending on the user level and the

type of message, warning or error message (see “Error messages

and instructions”)

– Open the list of active messages (see “Error messages and instruc-

tions”)

– Select and start a reprocessing programme depending on the set-

tings in theProgramme management menu in the web interface

(see “Operation”)

– Call up and start reprocessing programmes stored asFavourites

depending on the settings in theSystem, Manage favouritesmenu

(see “Operation”)

– Print outReprocessing reports

– Open theSystem menu to adjust the machine settings depending

on theUser level (see “System settings”)

22

– Open and close the infeed door

– Open and close the outfeed door after the end of a programme de-

pending on the Authentification - End of programmesetting in the

web interface

Main menu

Changing the display language

Login

Manual login

Changing the display language has no impact on the set system language. Reports and printouts are issued in the system language.

Press the button in the header of the display.

The Select display language menu is displayed.

Press the button for the language you want.

The machine controls return to the previous menu; the selected language is set.

Press the button to exit the language selection menu if you do

not want to change the set language.

Access to the machine display is restricted to a certain group of

users. Every user must be entered in the User management in the

web interface (see programming handbook, “User administration”).

Press the button in the header to open the entry window for user

login.

Enter the user ID and press OK to confirm.

Enter the PIN and press OK to confirm.

The functions on the machine display are enabled.

When a user logs in for the first time, they will be prompted to assign

a new PIN.

If the PIN has expired, this prompt will be displayed for the user. The

validity of the PIN can be set in the web interface under “System,

Identification”.

23

Main menu

Logout

Manual logout

Printing documentation

The logged-in user is automatically logged out after 24hours if no

button has been pressed on the display in that time, or if the machine

carries out an automatic restart.

The automatic restart can be set in the web interface under “System,

Automatic restart”.

A user who is logged in can log out manually, e.g. to protect the machine from access without authorisation.

Press the button in the header to log out.

Confirm the confirmation prompt with Yes.

The functions on the machine display are disabled.

The last 200 reprocessing reports saved in the machine controls are

shown on the display. The most recent reprocessing report is the first

on the list. When the number of saved reprocessing reports exceeds

200, the oldest from the list is deleted.

If no external software for process documentation is connected to the

machine, the reprocessing reports can be printed out via an external

printer connected via the network.

Opening and closing the door

Press the Documentation button.

A list of the reprocessing reports is displayed.

Press the button in the Print column to activate the required repro-

cessing reports.

Press the OK button in the footer to start printing.

Press the button in the Print column again to deactivate the selec-

tion.

The reprocessing report is printed out on the external printer.

The status of the machine door is shown in the footer of the display.

– The door has been released and can be opened.

– The door is open and can be closed.

– The door is locked.

Press the button with the symbol to open the door.

24

The door will move up.

Press the button with the symbol to close the door.

The door will move down.

General information

Areas of application

Load carriers

E9xx load carriers

from older model

ranges

Pictograms for manual programme selection

The machine can be fitted with a variety of load carriers, which can

be combined with a variety of modules and inserts depending on the

type and shape of load items requiring cleaning and disinfection.

Select load carriers and other equipment, e.g. irrigation connectors, which are appropriate for the application.

Information on the individual areas of application can be found on the

following pages, as well as in the operating instructions for the load

carriers.

Miele offers suitable load carriers for all areas of application defined

in “Appropriate use”, such as mobile units, modules, inserts and special irrigation connectors. More information can be obtained from

Miele.

Load carriers from older model ranges with the designation E9xx can

be used in the machine.

A857 retrofit kits for the mobile units are available from Miele.

When you select a programme manually on the machine, you must

select the relevant mobile unit first. Pictograms representing the mobile units are shown on the display. The pictograms assigned to the

mobile units in the A5xx model range are listed in the operating instructions for the mobile units.

Mobile unit/module combinations from the A5xx model range

The pictogram and name of the mobile unit can be found on a strut

on the front of the mobile unit. The model shown is the mobile unit

without modules inserted.

For different module combinations in the A500 and A503 mobile

units, several pictograms can be displayed (see operating instructions

for the mobile unit).

Fixed mobile units from the A5xx model range

The pictogram and name of the mobile unit can be found on the front

of the mobile unit.

25

Areas of application

Preparing the load

Only load items which have been declared by their manufacturer as

suitable for machine reprocessing may be processed. The manufacturer’s specific reprocessing instructions must be observed.

Contaminated load items pose a health risk.

Contaminated load items can result in various hazards to the

health, which can lead to infections, poisoning, injuries and more

depending on the type of contamination.

When working with contaminated load items, ensure that all necessary measures are taken to protect personnel.

Wear protective gloves and use suitable aids.

– Arrange the load so that wash water can access all surfaces. This

ensures thorough and proper cleaning.

– Do not place load items inside other items where they may be con-

cealed.

– Do not place load items so close together that cleaning is

hampered.

– Lumened load items must be thoroughly cleaned, internally and ex-

ternally, by the wash water. Depending on the load, special irrigation connectors may be required here, e.g. nozzles, irrigation

sleeves or adapters.

– Ensure that load items with long, narrow, hollow sections can be

flushed through properly before placing them in inserts or connecting them to an irrigation connector.

– Lumened instruments should be inverted and placed in the correct

mobile units, modules and inserts to ensure that wash water can

flow in and out of them unrestricted.

– Deep-sided load items should be placed at an angle to make sure

the wash water runs off them freely.

– Tall, narrow lumened instruments should be placed in the centre of

the mobile units if they are not going to be sprayed directly. This

ensures the insides of the lumened instruments are more easily accessed by the water jets.

– Take apart any load items which can be dismantled according to

the manufacturer’s instructions and reprocess the individual parts

separately from each other.

– Lightweight load items should be secured with a cover net such as

theA 6 to prevent them from spinning around in the wash chamber

and blocking the spray arms.

26

– Only reprocess small items and micro components in special in-

serts, mesh trays with lids or mesh inserts.

– The spray arms must not be blocked by load items which are too

tall or which hang down in their path.

Areas of application

– Broken glass can result in serious injury when loading or unloading.

Damaged glass load items must not be reprocessed in the machine.

– Nickel and chrome-plated load items, and load items made of alu-

minium, require special procedures and are not generally suitable

for machine reprocessing. Special process conditions are required

for these load items.

– With items which are made entirely or partly of plastic, observe the

maximum thermal stability for the items and select an appropriate

programme or adjust the temperature of the programme.

Preparing the load

Danger of explosion due to flammable gases.

Flammable solvents with a flash point below 21°C outgas and can

generate a flammable mix of gases.

Only load the machine with load items which are wetted with traces

of solvents at most.

Start the reprocessing programme as soon as the machine has

been loaded with the wetted load items.

Risk of damage due to solvents.

Solvents with a flash point above 21°C can damage elastomers

and plastics. The machine could leak as a result of this.

Only load the machine with load items which are wetted with traces

of solvents at most.

Start the reprocessing programme as soon as the machine has

been loaded with the wetted load items.

Risk of damage due to corrosion.

Chloride solutions, particularly hydrochloric acid, and ferrous ma-

terials that can rust or corrode cause corrosion on the stainless

steel of the machine and the load carrier.

Do not introduce any chloride solutions into the machine.

Do not introduce any ferrous materials that can rust or corrode into

the machine.

Risk of infection.

Microbiological material, pathogens and facultative pathogens, and

genetically modified material can cause infections or environmental

damage.

Before reprocessing by machine, decide whether the load contaminated in this way needs to be sterilised.

27

Loading...

Loading...