Page 1

Mobile unit E 928 for instruments for robotic-assisted surgery

Please read the Warning and Safety instructions in the Operating Instructions for your PG 8527/PG 8528 washer-disinfector carefully. You should only reprocess

,

instruments/medical products in this mobile unit if they have been declared as suitable for machine reprocessing by the manufacturer. Please also observe the

manufacturer's care instructions.

The E 928 mobile unit must only be operated with the ROBOTVARIO programme. This programme is not supplied as standard and must be programmed

retrospectively into the Profitronic unit by Miele.

The setting of the mobile unit will be carried out during commissioning by Miele. The coding must be matched when using automatic mobile unit recognition.

Items supplied:

Mobile unit E 928 with 6 holders for 8 mm shafted instruments for robotic-assisted

surgery, H 560, W 640, D 790 mm with magnetic strip for automatic mobile unit

recognition.

Supplied as separate items:

2 filter plates

–

6 x E 443 injector sleeves with screw thread for instrumentsØ8-8.5mm,

–

121 mm long, Ø 11 mm, cap with Ø 10 mm opening

6 x E 448 silicone hoses, 300 mm, with Luer lock adapters \ for Luer locks ]

–

3 x E 452 injector jets Ø 2.5 mm, 60 mm long

–

Accessory available to order:

E 499, holder for Veress cannulae

–

Areas of application:

8 mm shafted instruments for robotic-assisted surgery can be reprocessed in the

E 928 mobile unit using the ROBOTVARIO programme and Mucapur

ROBOTVARIO cleaning agent.

There are 15 screw connectors in the rear area of the mobile unit for reprocessing

other items used in connection with robotic-assisted surgery.

These are equipped with blanking screws ex-works. Where necessary, the screw

connectors can be fitted with injector jets, injector sleeves or silicone hoses

instead of the blanking screws.

To ensure a suitable standardised spray pressure for all connections, all

,

screw connectors must be fitted with jets, adapters, sleeves or blanking

screws.

Damaged jets, adapters or sleeves etc. must not be used.

Empty jets, etc. do not have to be replaced with blanking screws.

Before loading the machine and before starting a programme, please check

that:

– the mobile unit is correctly fitted into the cabinet and that it has connected

correctly with the water intake of the washer-disinfector.

– the filter plate has been cleaned and is located in the water intake pipe.

For validation purposes please make sure that you follow the loading

instructions given on the template.

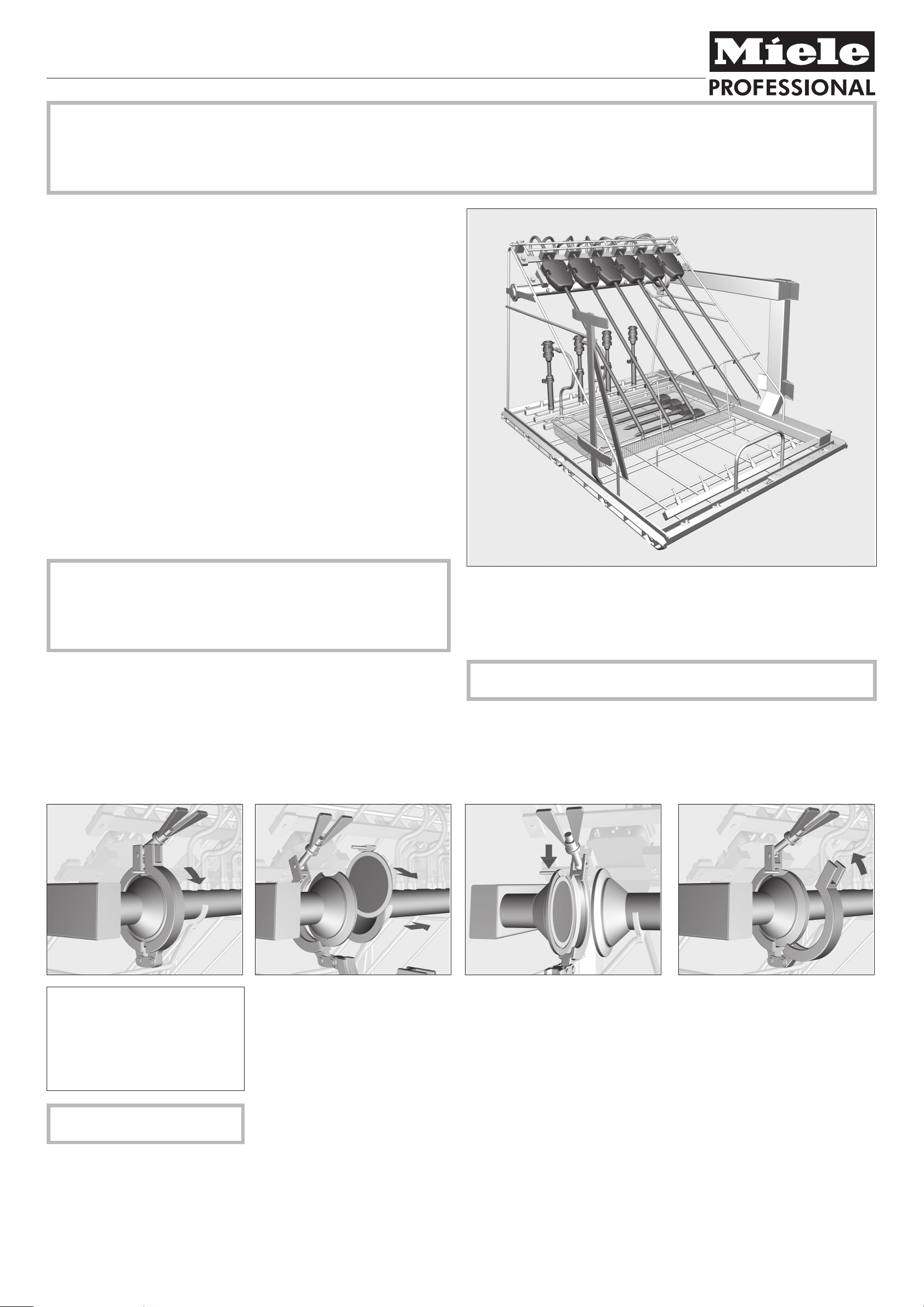

Cleaning the water inlet filter plate

^

A filter plate is located in the water

intake pipe in front of the double pipe

connections for the shafted

instruments.

It prevents residues from other

disciplines getting into the lumen of

the instruments.

,

The filter plate must be cleaned

before every programme.

Pull the right side of the water intake

pipe to the side.

^

Remove the filter plate.

^

Soiling and deposits should be

rinsed off under running water. If

necessary a suitable soft brush can

be used.

^

Blow out the filter plate with

compressed air from the underside

against the flow direction.

^

Place the filter plate in the left side of

the holder and hold it securely at the

top.

^

Push the right side of the water intake

pipe towards the left to close the

holder.

^

Place the clamp around the rim of the

holder and screw it down with the

wing nut.

^

Unscrew the wing nut on the clamp

around the filter plate holder and

open the clamp.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel 0845 365 0555, Fax 0845 365 0777,

Internet: http://www.miele.co.uk /

! 0366 Alteration rights reserved / Publication date: 2013-06-17

M.-Nr. 09 507 430 / 00 en

Page 2

Mobile unit E 928 for instruments for robotic-assisted surgery

Manual pre-cleaning

Pre-treatment at the place of use

,

as well as preparation for machine

reprocessing must be carried out in

accordance with the instrument

manufacturer's instructions.

In addition, immediately after arrival

in the CSSD of instruments which

have been filled with solution in the

operating room:

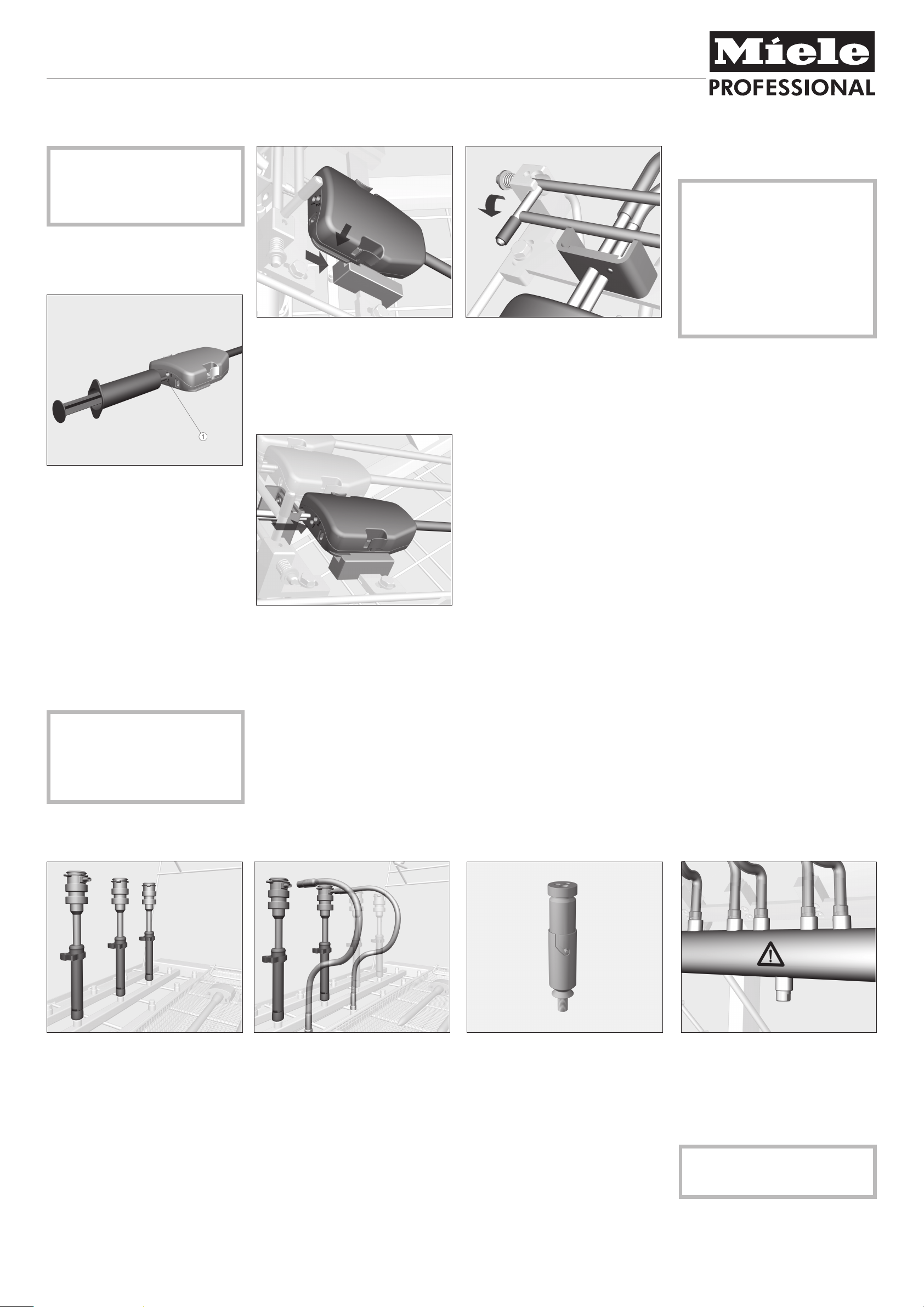

Arranging and connecting the shafted instruments

Place the instrument into the holder

^

from above.

The shaft should be positioned in the

recess of the lower strut.

Open the functional ends of the in

^

strument.

-

When all instruments have been loa

^

ded, move the connector retaining

bar and click it into position.

The retaining plates for the water con

nectors will be held in place by the bar.

Any unused water connectors must also

be positioned underneath the bar.

Routine checks for consistency of

cleaning performance

Instruments should be dismantled at

random after their last operative use

and machine reprocessing. Cap the

Bowden cables at the sprocket and

remove the distal functional part.

Examine the inner distal cylinder,

through which the Bowden cables

pass to the functional end, under a

microscope and use protein analysis

for residual soil in accordance with

current guidelines.

-

-

Remove the solution from the

^

instruments.

Refill the instruments with 3%

^

Mucapur ROBOTVARIO solution and

leave to take effect for 30 minutes.

During this 30 minute activation time:

Empty the Mucapur ROBOTVARIO

^

solution out of the instruments and

replace with fresh solution.

^ Wait for an activation time of

5 minutes.

^ Repeat the procedure as described

five more times.

^ After this prepare the instruments in

accordance with the manufacturer's

recommendations.

A visual check of the instruments,

particularly the distal functional ends,

to ensure that they appear clean,

must be carried out before the

instruments are arranged in the

E 928 mobile unit.

^ Plug the double pipe connection into

the instrument's rinsing attachment.

Trocar sleeves Veress cannulae Test point for cleaning pressure mea

surement

^

Insert the trocar sleeves into the

injector sleeves.

^

Connect the trocar sleeve at the side

with an E 448 hose adapter.

^

Screw the hose adapter to the rinsing

channel.

An E 499 holder is required in order to

reprocess Veress cannulae (available to

order).

The holder comes with its own

instructions.

Cleaning pressure for performance

checks and validation according to DIN

EN ISO 15883 can be measured using

this test point.

^

To measure cleaning pressure,

replace the sealing screw with a Luer

lock adapter, e.g. E 447.

-

Ensure that no instruments, rinsing

channels etc. are connected to the

test point.

Loading...

Loading...