Page 1

Mobile injector unit E 356/E388

Please read the Warning and Safety instructions in the Operating Instructions for your washer-disinfector as well as any instructions provided by the glassware

,

manufacturer. You should only process laboratory glassware in this mobile unit if it has been declared as suitable for machine processing by the manufacturer. Please

observe their care instructions.

Glass broken during the cleaning process can cause serious injury.

Cleaning results should be tested properly. Do not rely on visual checks only.

Items supplied:

Additonal inserts are available for fitting on the right hand side of

1 mobile unit E 356/E388

1 feed pipe with funnel for the water intake (E 388: with connection for hot-air drying unit)

1 seal

1 jet for flushing out powder dispenser

7 x E 351 jets, 4.0 x 160 mm

7 x E 353 clips for 4.0 x 160 mm jets, consisting of holder + clamp

9 x E 352 jets, 6.0 x 220 mm

the mobile unit:

E 103, E 139, E 149 for test tubes

–

E 109, E 111, E 117, E 144 for beakers

–

E 106 for a variety of laboratory glassware

–

E 134 for slides

–

E 402, E 403 for watch glasses

–

AK12 for funnels and wide necked glassware

–

9 x E 354 clips for 6.0 x 220 mm jets, consisting of holder + clamp

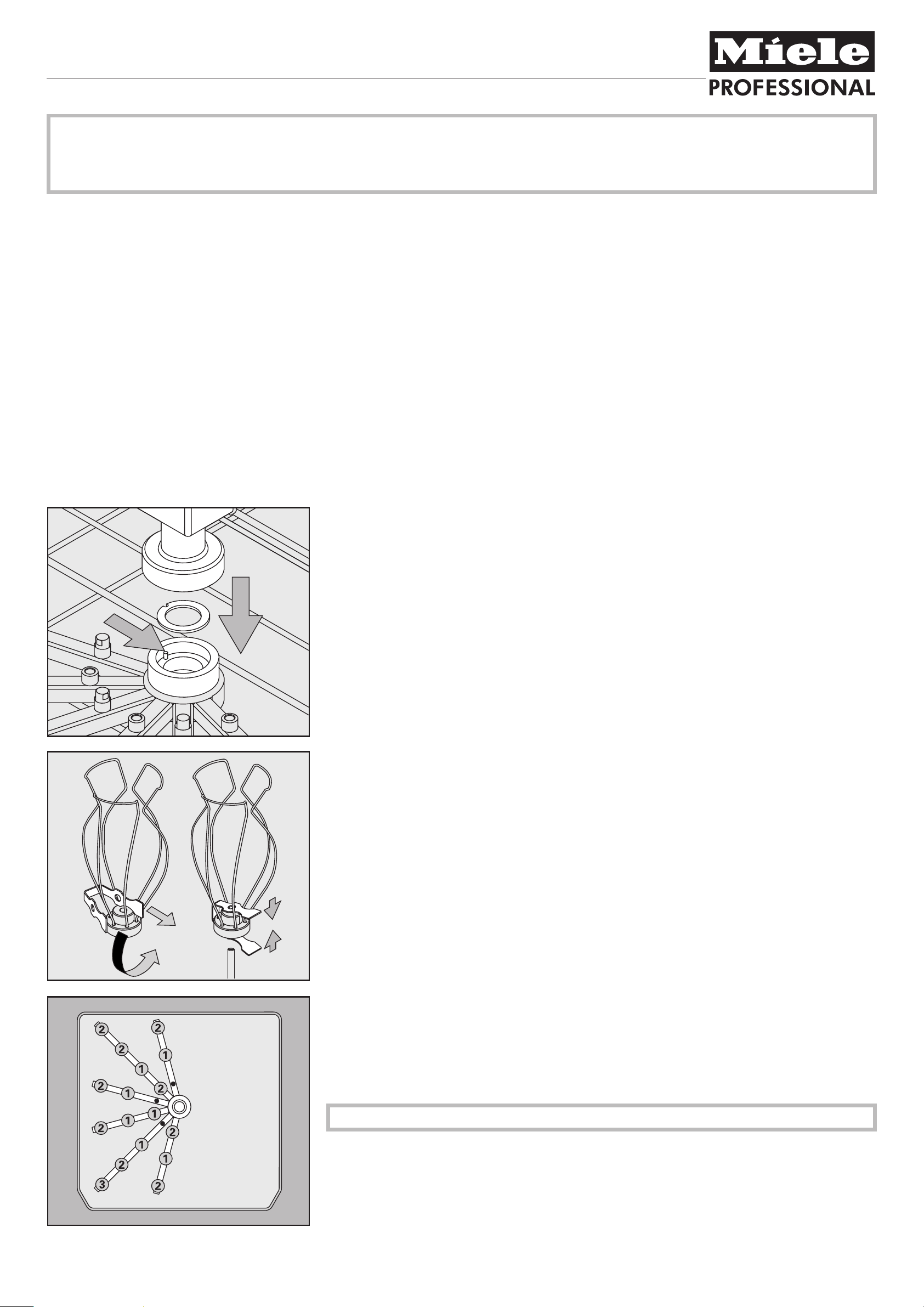

Installation:

Tools required (not supplied):

SW 9 spanner

–

Cross slotted screwdriver

–

Fit the seal in the holder in the mobile unit.

^

Then fit the water feed pipe into the holder.

^

E 388:

When doing so make sure that the groove in the water feed pipe lines up with the notch in the holder. The hot

air drying connection points to the back of the mobile unit.

^ Tighten the nut by hand.

The mobile unit is supplied with two sizes of clamps, holders and jets. Make sure they are put together in the

correct order.

^

Push the clamp through the holder as illustrated.

^

Then squeeze the clamp together and feed the injector jet through the holes in the clamp.

^

Use a spanner to secure the jets into the positions required. The overview gives an example of possible posi

tions. Start from the centre and work your way outwards in ever increasing circles.

a E 351 jets, 4.0 x 160 mm

b E 352 jets, 6.0 x 220 mm

c Position for securing the jet for flushing out the powder dispenser. Secure it to the spray arm with a

cross-slotted screwdriver.

-

To ensure adequate water pressure all positions need to be equipped with jets.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel 0845 365 0555,

Fax 0845 365 0777, Internet: http://www.miele.co.uk / ! Alteration rights reserved / Publication date 15.02.2010

M.-Nr. 07 786 230 / 00 en

Page 2

Mobile injector unit E 356/E388

Areas of application:

The E 356 and E 388 mobile units are suitable for use in the following washer-disinfectors:

G 7804 (E 356 only), G 7835 CD, G 7836 CD, G 7883 (E 356 only), G 7883 CD, G 7893, PG 8535 and PG 8536.

The mobile unit can be used on its own or in combination with an O 195 upper basket.

The 16 injector jets can be used for laboratory glassware.

–

Different volume glassware can be processed, however, the maximum volume per piece is 1 litre.

–

To process pipettes special sleeves are needed, MIBO E 336. These are available to order.

–

Laboratory glassware, which because of its design cannot be flushed through properly, will not be sufficiently

–

processed in this injector module.

This mobile unit should only be used for processing laboratory glassware which has been declared as suit

–

able for machine processing by the glassware manufacturer.

The right hand side of the mobile unit can be used for inserts such as the E 106 for processing laboratory

–

glassware.

-

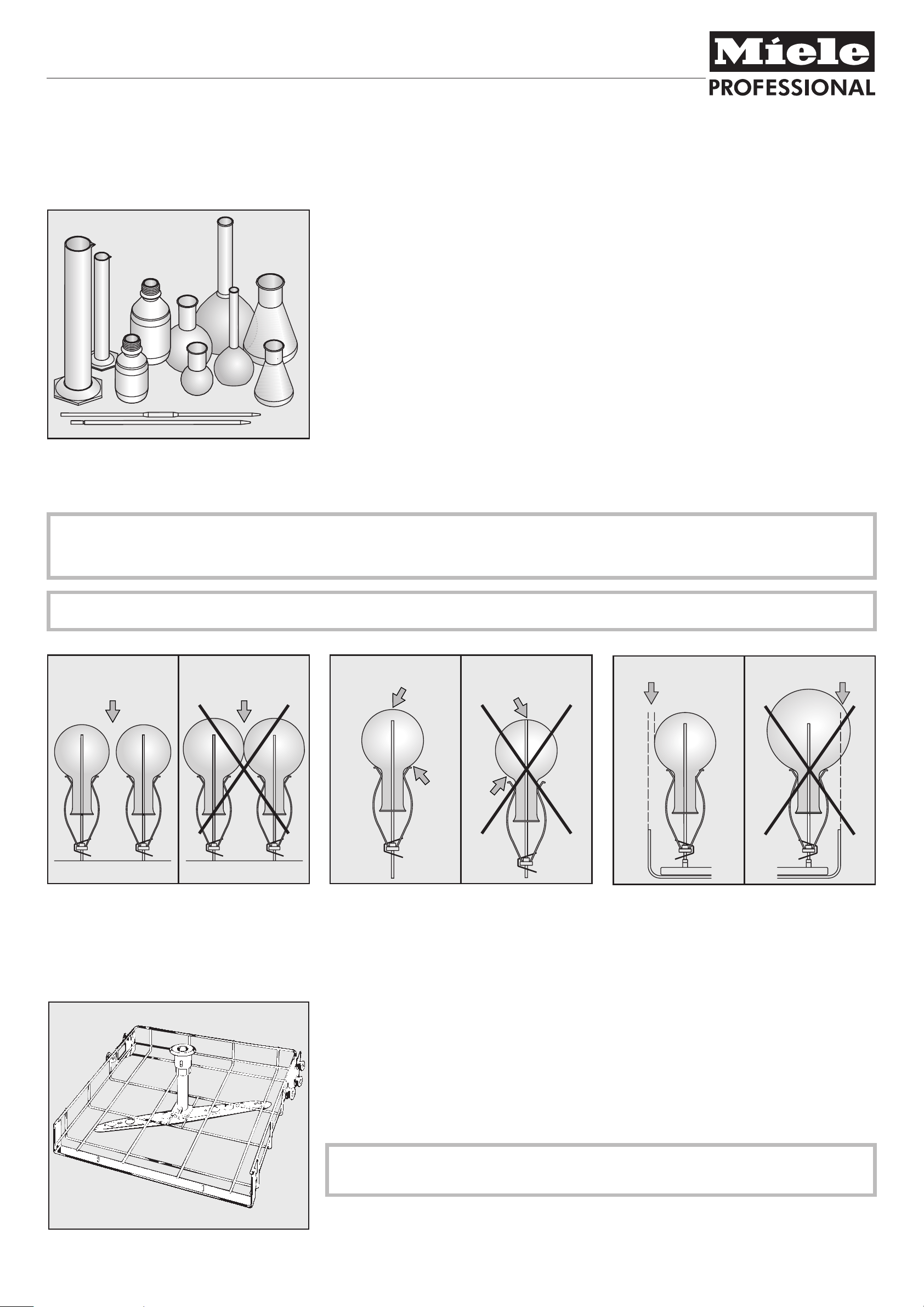

Loading the unit:

The jets are designed for processing narrow necked glassware. Wide necked glassware can be processed in suitable inserts in the right hand side of the unit.

When arranging glassware ensure that the funnel on the inlet pipe and the jet for flushing out the powder dispenser in the door are not obstructed.

The funnel on the intake pipe is used for supplying the mobile unit with water.

The jet for flushing out the powder dispenser is designed to rinse out the powder dispenser in the machine door after use (if applicable to the machine the unit is used

in).

If the mobile unit is used in conjunction with upper basket O 195 make sure that glassware does not extend above the water pipe in the unit. If it does the spray

,

arm in the upper basket will be blocked and this could damage the glassware.

Do not allow individual pieces of glassware to touch

each other.

Upper basket O 195

Push the clips upwards, if necessary, to prevent the

tip of the jet from contacting the bottom of the glass

ware.

Upper basket O 195 can be used for holding glassware in various inserts (optional accessories)

–

E 103 for test tubes

–

E 118 for Petri dishes

–

E 134 for slides

–

AK 12 for funnels and wide necked glassware

The water intake pipe in upper basket O 195 has a spring adapter at the top for the water supply. It has to con

nect properly with the water intake pipe in the washer-disinfector. Otherwise the upper basket spray arm and the

mobile unit will not be supplied with water. Water is supplied to the mobile unit via a water jet underneath the

spray arm in the upper basket.

,

When using the O 195 upper basket make sure that glassware does not extend about the intake pipe in

the upper basket (with the adapter for the water supply pressed down). If this is not done, glassware could

get damaged.

Glassware must not extend beyond the sides of the

mobile unit.

-

-

M.-Nr. 07 786 230 / 00 en

Loading...

Loading...