MID WEST PRODUCTS GSF-31M-NT Owner's Manual

©2018 Mid West Products, Inc. -1- Form No. M15-1603

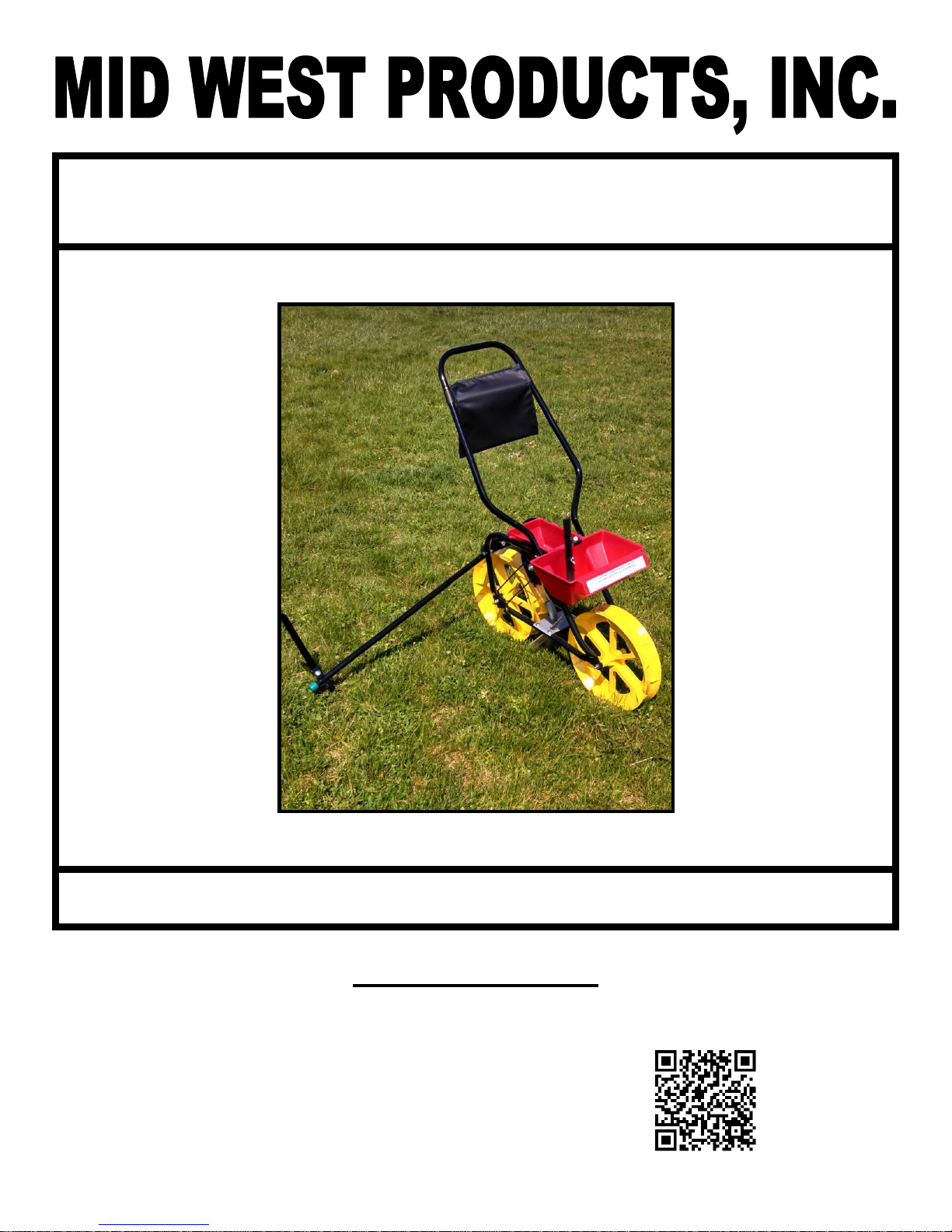

VEGETABLE GARDEN SEED ROW PLANTER

MODEL GSF-31M-NT

No Tools Required Owner’s Manual and Parts List

SAVE THIS MANUAL

You will need this manual for the safety instructions, assembly instructions and parts list. Put it in a

safe, dry place for future reference.

Additional Information/Link to PDF Copy of this Manual:

©2018 Mid West Products, Inc. -2- Form No. M15-1603

VEGETABLE GARDEN SEED ROW PLANTER AND FERTILIZER APPLICATOR

NO TOOLS ASSEMBLY

OPERATING

MAINTENANCE

PARTS LISTING

ASSEMBLY

1. Remove two Wing Nuts (37) from the Hex

Bolts (44) which are located at the top of

Lower Handle Tubes (10). Install the Upper

Handle Tube (11) onto the Hex Bolts (44) in

the Lower Handle Tubes (10) and secure

with previously removed Wing Nuts (37).

2. Remove Wing Nut (37) from Hex Bolt (45) in

the fertilizer section of the Seed/Fertilizer

Hopper (1). Install Fertilizer Lever (19) onto

Hex Bolt (45) and secure with previously

removed Wing Nut (37).

3. Unscrew Plastic Knob (48) from Row Marker

Tube (21).

4. Assemble Row Marker Tube (21) to the Row

Marker Bracket (20) using the Hex Bolt (38)

that is inserted into the end of the Row

Marker Tube (21), with the head of the Hex

Bolt pointing away from the Seed/Fertilizer

Hopper (1).

5. Screw the previously removed Plastic Knob

(48) onto the Hex Bolt (38) to assemble the

Row Marker Tube (21) to the Row Marker

Bracket (20). Do not fully tighten hardware,

allowing row Marker Tube to pivot from side

to side.

OPERATION

1. To install the desired Seed Plate, hold the

Seed Plate at an angle with the bottom

against the straight wall in the Hopper. Line

up the slots in the Seed Plate with the raised

portions of the Hub, hold it firmly against the

inside of the Hopper and rotate it

approximately ½” in the “ON” direction as

indicated by the arrow on the Plate until the

cam action locks the Seed Plate in place on

the Hub. Do Not Force! OFF and ON

directions are indicated on the Seed Plates

with arrows.

2. Next, set the planting depth with the wedgeshaped Furrowing Shoe located directly

under the Hopper. Move Furrowing Shoe

until top edge is in line with desired planting

depth. Retighten Wing Nut (35) after

adjustment is made. Check the depth by

moving the Seeder forward a few inches.

3. Pour seeds in the Seed Hopper. CAUTION:

Do not fill the Hopper above the center of the

Seed Plate.

4. Pour fertilizer into fertilizer hopper.

CAUTION: Do not over fill the Hopper.

Allow 1” from fertilizer to top edge of Hopper.

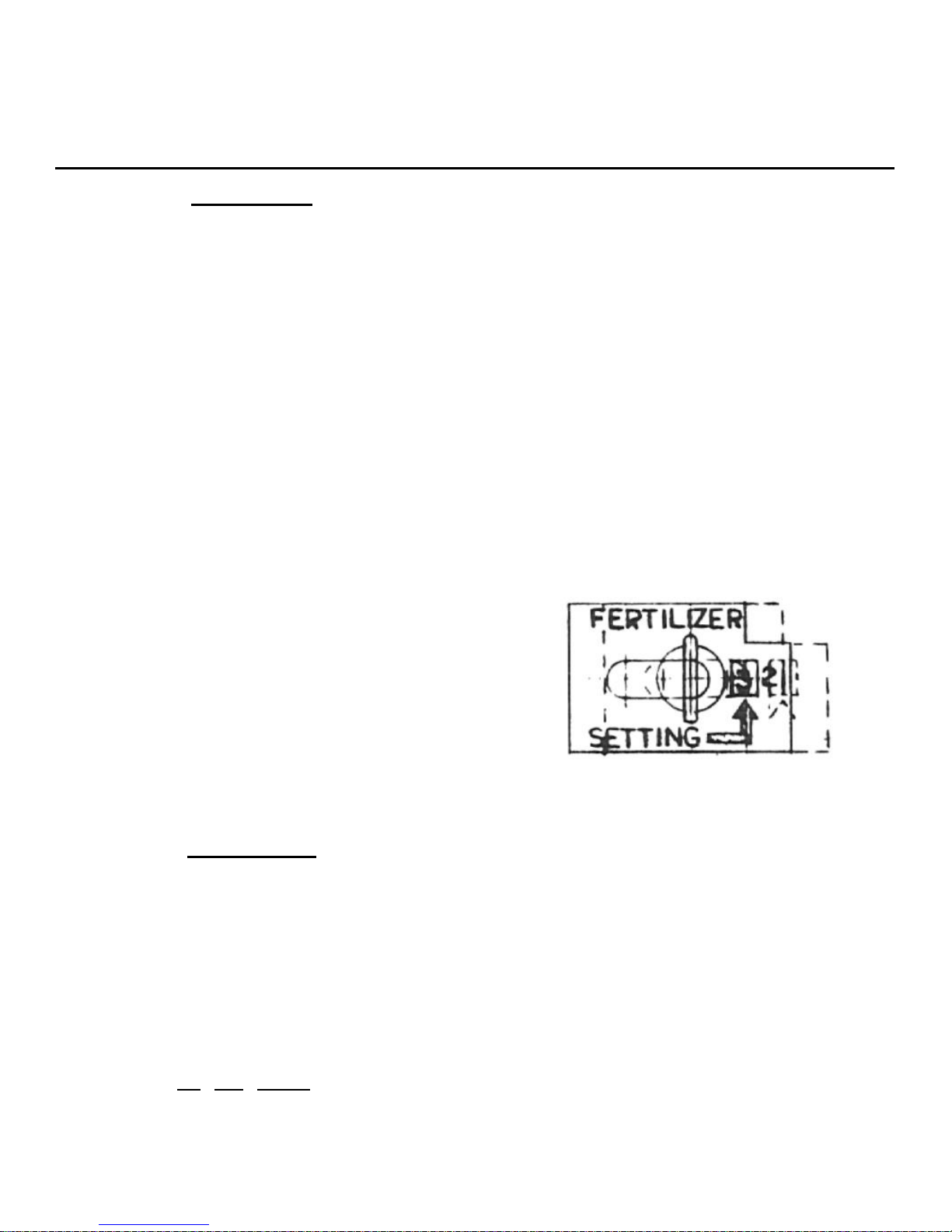

5. Adjust fertilizer flow by loosening Wing Nut

on Fertilizer Hopper. Slide calibrated plate

to desired setting and tighten Wing Nut.

Before filling, shut off Fertilizer Control.

6. Mark out the first row in your garden. Lower

the Row Marker Shaft and adjust the Row

Marker to the proper width for the next row.

You are now ready to plant

7. To empty seeds, remove Plug (2) from Seed

Hopper by simply putting pressure on center

of Plug and push inward. Pour seeds into a

clean container.

8. Empty fertilizer by placing a clean container

under Fertilizer Hose, setting Adjustment

Plate to No. 3 setting and open control,

allowing fertilizer to flow into the container.

9. To remove Seed Plate, hold Pulley and Belt

stationary with one hand and rotate the Seed

Plate approximately ½” in the “OFF”

direction indicated by an arrow on top of the

©2018 Mid West Products, Inc. -3- Form No. M15-1603

Seed Hopper. Push the Seed Plate off the

Hub through the hole just above the Pulley.

It will slip off easily.

NOTICE: Keep your Seed/Fertilizer Hopper

clean and free from sand, grit, and seed

treating materials.

SEED PLATE SELECTION GUIDE

Selection information as to seed size and

spacing are also found on your Seed Plates.

15-1018-1 Has a 9 inch seed drop spacing,

plants corn and sunflowers.

15-1018-2 Has a 3 ½ inch seed drop spacing,

plants small and medium peas

and beans, also similar seeds.

15-1018-3 Has 3 ½ inch seed drop spacing,

plants variety of peas and beans

including baby Lima.

15-1018-4 Has a 3 ½ inch seed drop spacing,

plants beets, extra small peas and

beans, okra, and related seeds.

15-1018-5 Has a 3 inch seed drop spacing,

plants radishes, small beets, and

seed of like size.

15-1018-6 Has 4 inch drop spacing, plants

most small seeds such as turnips,

mustard, lettuce, carrots, kale,

collards, endive, spinach,

rutabaga, parsnips, parsley, and

rhubarb. This plate may also be

used to plant seeds for vegetable

that are sometimes grown from

plants. These include broccoli,

brussel sprouts, cabbage,

cauliflower, celery, onions, and

peppers.

NOTE: When changing Seed Plates, be sure

Hopper is empty.

FERTILIZER ADJUSTMENT SETTINGS

Granular Fertilizer must be free flowing without

lumps.

No. 1 setting – 1 lb per 100 ft.

No. 2 setting – 2 lb per 100 ft.

No. 3 setting – 3 lb per 100 ft.

Consult your fertilizer dealer for further

application data. We recommend that Users

contact their Local Ag Agent with the USDA

(United States Department of Agriculture) for

their recommendations on the proper fertilizers

to use in their particular County.

HELPFUL OPERATING SOLUTIONS

PROBLEM:

1. The Seeder will not go more than a foot or

two . . .

2. The peas, beans, and/or corn fly out of the

hopper . . .

3. The seeds break . . .

SOLUTIONS:

Be extra careful, do not back up the Seeder.

(Lift the Seeder to reposition the GSF 31M)

So, what happens if the Seeder is pulled

backwards?

1. The Seed Plate will come loose, whenever

the rear Wheel of the Seeder is pulled

backwards. If the Seed Plate loosens, even

a little, then seeds get caught between the

Seed Plate and the side of the Seed Hopper.

This causes the Seed Plate to quit turning.

2. As the rear Seeder Wheel is still being

pushed, the plate tightens and seeds that

are caught between the Plate and the

Hopper wall, then get crushed. Once the

seeds are crushed, then the Plate can’t turn

and the seeds are all planted on one spot or

they clog the Seed Chute.

The Upper Pulley and Spindle are too tight:

1. Remove the Belt (Item 16) — it is easiest to

remove the Belt located on the Lower Pulley

(Item 15) — pulling the Belt slightly to one

side and at the same time.

2. Check the Upper Pulley (Item 15) that is

connected to the Spindle (Item 13).

3. If the Pulley/Spindle Assembly does not spin

freely or is tight, then back off the Screw

(Item 40) one-fourth to one-half turn.

Loading...

Loading...