MIDWEST FASTENERS CD 100 Owner's Manual

Ownerʼs Manual

CD 100

Solid State

Capacitor Discharge

Stud Welding System

CD100

Solid State

Capacitor Discharge

Stud Welding System

Owner’s Manual

• Installation

• Operation

• Maintenance

CD50 Stud Welder 0

0 C

MIDWEST FASTENERS, INC.

TABLE OF CONTENTS

GENERAL

INTRODUCTION

INSTALLATION

SETUP& OPERATION

Warranty ......................................................................................... 4

Safety Precautions .......................................................................... 5

What is Stud Welding? ................................................................... 6

How Does CD Stud Welding Differ From ARC Stud Welding? .... 6

CD 100 Overview .......................................................................... 8

CD 100 Installation ........................................................................ 9

CD 100 Setup ............................................................................... 10

Gun Set Ups

Insulation Pins........................................................................ 11

Insulation Pins with Internal Stop.......................................... 11

Weld Studs ............................................................................. 12

Weld Studs with Template Adaptor........................................ 12

Controller Adjustment .................................................................. 13

Making A T est W eld...................................................................... 13

MAINTENANCE

TROUBLESHOOTING

SPECIFICATIONS

Weld Quality ................................................................................. 14

Preventive Maintenance................................................................ 15

Troubleshooting............................................................................ 15

CD 100 Welder Specifications ..................................................... 18

CD 100 Welder Exploded View & Parts List ............................... 19

CD 2P Gun Specifications............................................................ 20

CD 2P Gun Exploded View & Parts List...................................... 21

CD 100 Electrical Schematic........................................................ 22

Notes............................................................................................. 23

MIDWEST FASTENERS, INC.

/or studs approved

SAFETY

PRECAUTIONS

EYE

PROTECTION

• Comply with all electrical, fire and other applicable codes or ordinances

in the installation and use of stud welding systems.

• Remove all combustible or volatile materials from the weld area.

Although weld splatter resulting from stud welding is normally minimal,

proper precautions should be taken when welding near or through

combustible materials to insure that sparks or weld material do not come

in contact with combustible material.

• Recommend wearing of eye protection at all times when welding.

Spectacle type frames with Shade No. 3 absorptive and filter lens and

side shields are suggested. Never look directly at the weld arc without

wearing ey e shields.

• Recommend use of proper ear protection with all CAPACITOR

DISCHARGE stud welding systems. The stud welding operator and

anyone working within five (5) feet of the stud welding operation should

use ear protection devices.

• Use of protective clothing is suggested. Type of clothing will vary as to

application, weld position and stud welding being used; however, in all

cases, it should be fire resistant and sufficient to protect welding

operator from weld splatter and material.

HEARING

PROTECTION

HIGH VOLTAGE

• Keep hands, clothing, etc. away from the weld stud, chuck and all other

parts in contact with them during the weld cycle.

• Keep weld cable and connectors in good condition. Inspect periodically

for broken insulation and/or other electrical hazards.

• Do not operate with worn or poorly connected cables. Inspect all cables

often for bare or exposed wires, broken insulation layers and/or loose

connections. Repair all such connections before welding use.

• Do not stand in water or on damp surfaces while welding. Avoid wearing

wet or sweaty clothes. Do not weld in the rain.

WARNING

Use extreme caution when servicing or troubleshooting

any component of this stud welding system.

If possible, turn all power controls “OFF”

and disconnect all electrical cables.

For other suggested precautions, safe practices, etc.

regarding welding, refer to

“Safety in Welding and Cutting”,

ANSI Z49.1, American National Standards Institute.

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 5

WHAT IS STUD

WELDING?

Stud welding is a welding process where a “stud” (or similar metal part) is

instantaneously end-joined to a metal workpiece. This process involves the

same basic principles and metallurgical aspects as any other welding

process.

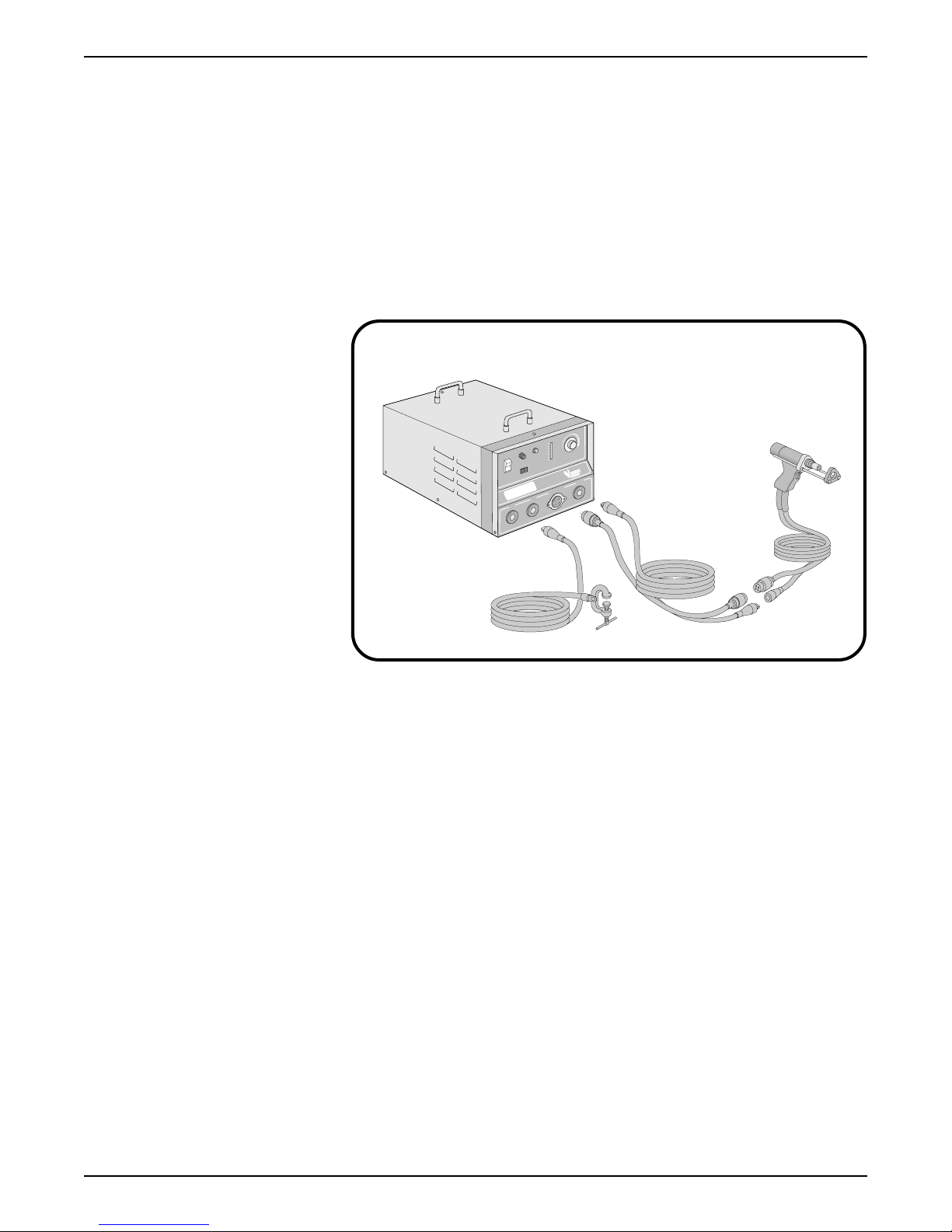

The equipment required to stud weld is composed of a direct current power

supply, a controller, a weld gun and cables to tie the system components

together. In most systems the power supply and controller are combined into

one unit called the “Welder.”

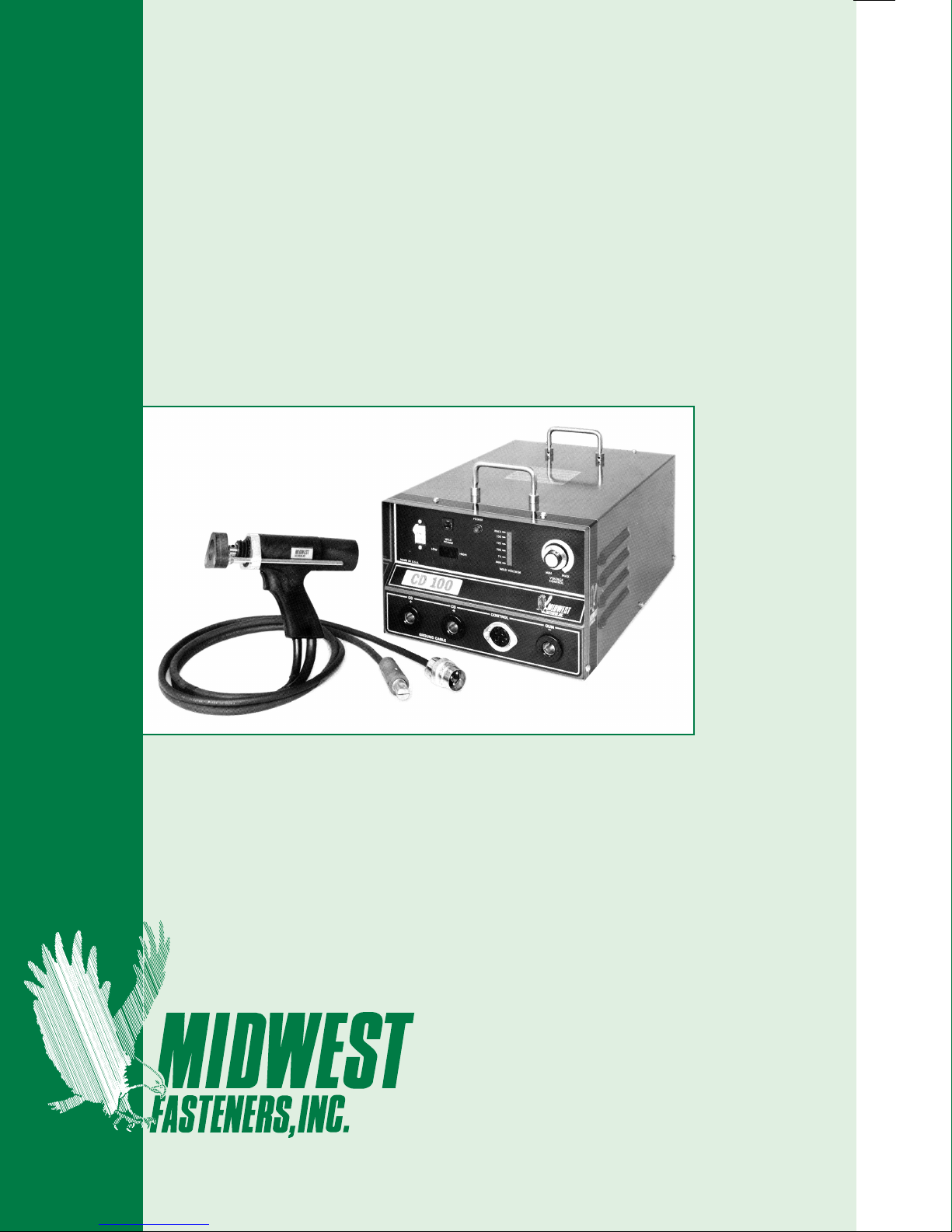

CD 100 STUD WELDING SYSTEM

(P/N: CDSW-100-01)

Controller

N

O

W

O

P

LOW

F

F

O

CD 100

C

D

+

C

+

GROUND CABLE

R

E

W

O

P

D

L

E

R

E

W

W

HIGH

C

D

CDSW-100-00

MIN MAX

E

G

A

T

L

O

L

V

O

R

E

T

G

N

A

O

T

L

C

O

V

D

L

E

N

U

–

L G

O

R

T

N

O

Extension

Cable Set

CDES-201-25

Weld Gun

CDPG-200-06

Ground Cable (2 ea.)

CDGC-201-15

The stud welding process is as follows. The stud is placed

in the collet of the

“Weld Gun” and then positioned against the workpiece. The weld gun trigger

is depressed and t

hrough operation of the stud welding controller and the

design of the stud, an arc is drawn which melts the base of the stud and a

proportionate area of the workpiece. The stud is then forced by the weld gun

into the molten pool and held in place until the metals resolidify. This high

quality fusion weld is completed in milliseconds.

HOW DOES

CD STUD WELDING

DIFFER FROM

ARC STUD WELDING?

6 ©2001

There are two different stud welding processes:

• Capacitor Discharge (called “CD” for brevity) and

• Arc.

The difference between these two methods involves the power source used

to provide the welding current, the workpiece size, base material and the

stud design.

MIDWEST FASTENERS, INC.

—

CD100 Stud Welder

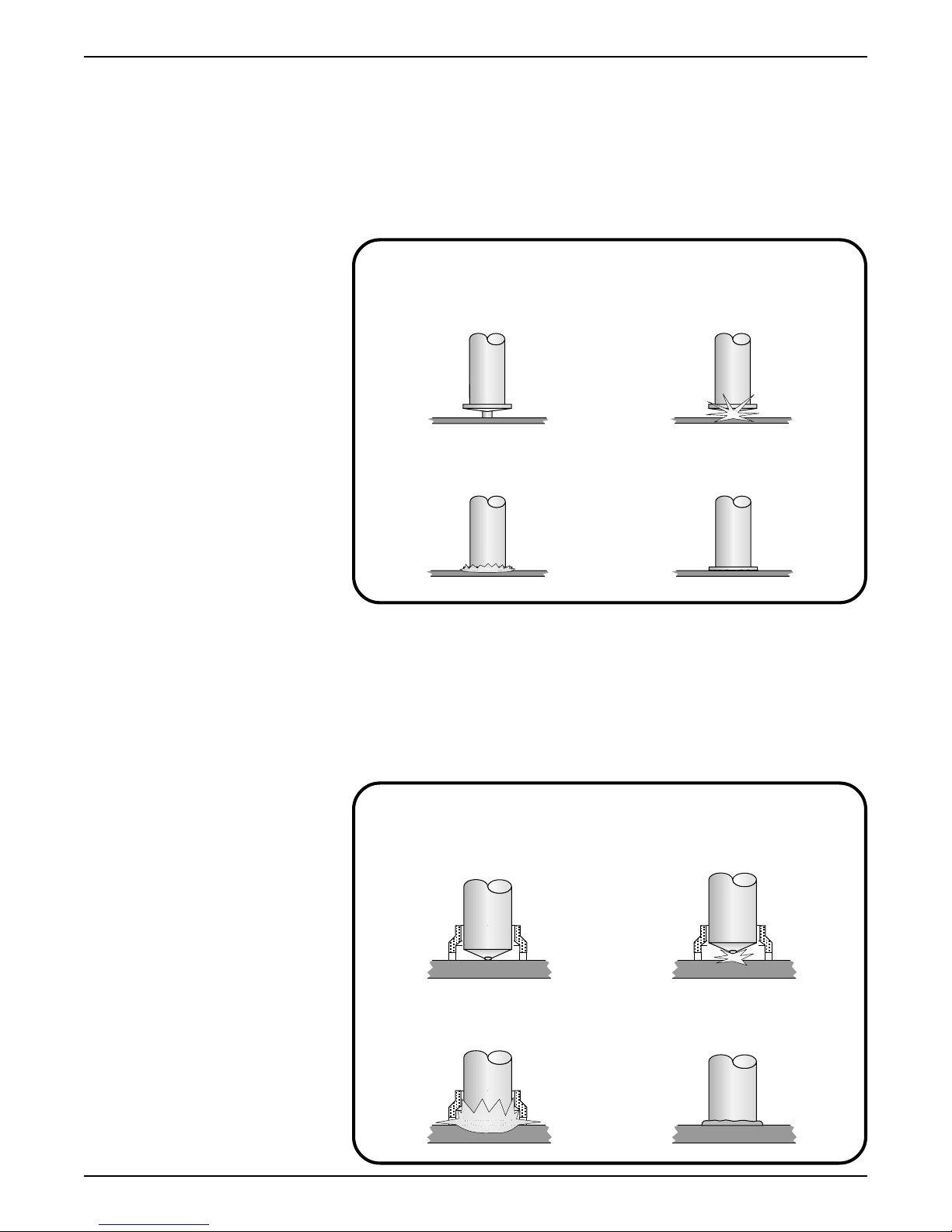

CD STUD WELDING

The CD stud welding process produces weld power through a rapid

discharge of the stored energy from a bank of capacitors. This stored

energy is usually derived from a standard 115 volt AC source. CD stud

welding, as a general rule, is used for studs 5/16" and less in diameter,

(or where thin base metals or dissimilar metals are to be joined.)

“CD” STUD WELDING PROCESS

ARC STUD WELDING

1. Stud is placed against workpiece

and weld gun trigger depressed

3. Weld gun forces stud

into molten metal

2. Stored energy is discharged

through special tip

4. Weld solidifies in

miliseconds

The ARC stud welding process produces weld power through one of three

standard DC welding power sources. These are Transformer-Rectifier type,

Motor/Generator type, or Storage Battery type. A ceramic ferrule is

required in ARC stud welding to maintain the proper atmosphere in the

weld area. ARC stud welding is generally used for studs over 1/4" in

diameter or where heavier base metals are involved.

©2001

MIDWEST FASTENERS, INC.

“ARC” STUD WELDING PROCESS

1. Stud is placed against workpiece

and weld gun trigger depressed

3. Weld gun forces stud

into molten metal

—

CD 100 Stud Welder 7

2. Stud is lifted by weld gun

and initiating arc is drawn

4. Weld solidifies and

ferrule is removed

Loading...

Loading...