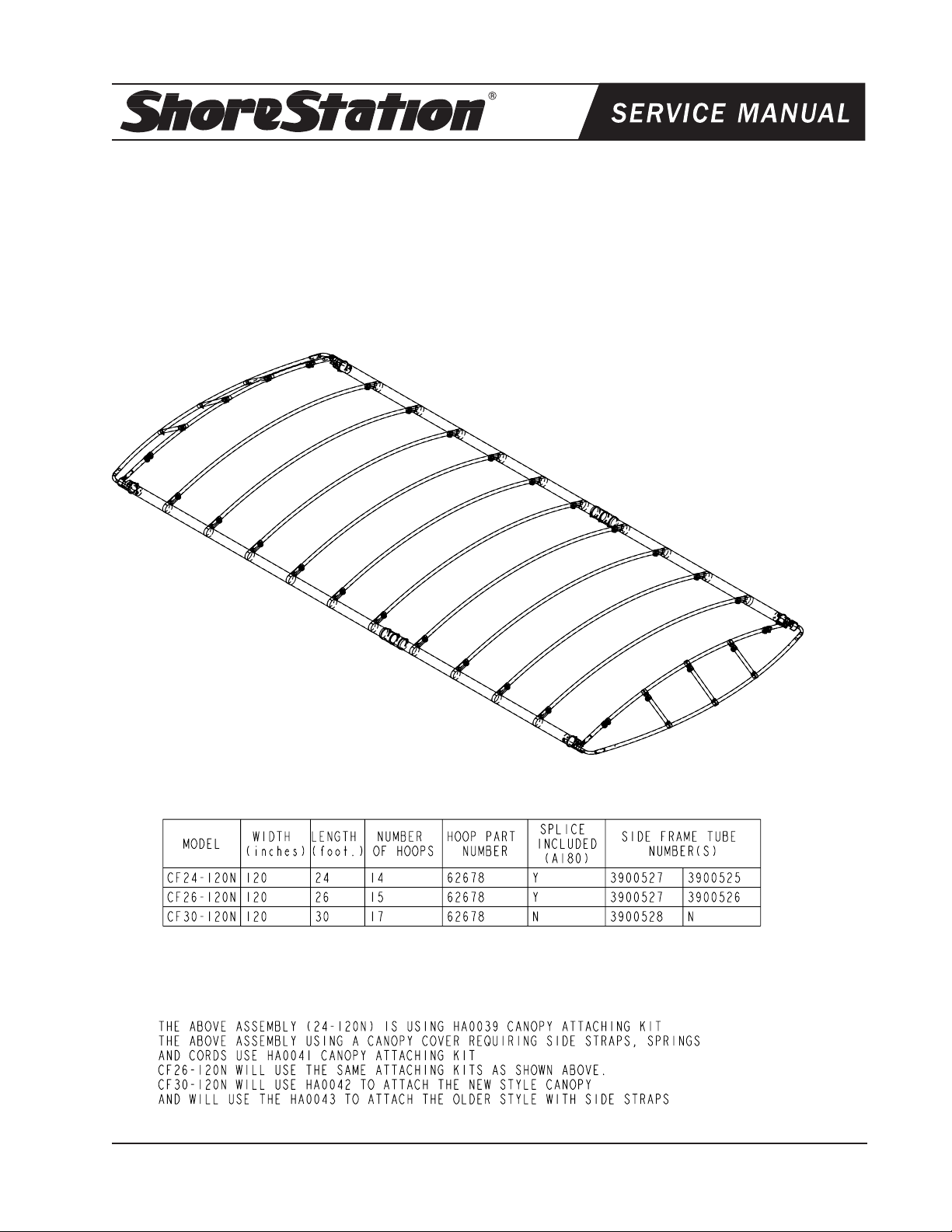

Midwest CF24-120N, CF26-120N, CF30-120N Service Manual

CF24-120N, CF26-120N & CF30-120N Canopy Frames Fitting:

Aluminum Hoist Models: SSV30/40120, SSPV30/40120, SS30/40120 DW,

SSPV30/40120 DW, SSV50120 & SSV50120 DW

Hydraulic Hoist Models: SSV40120 HYD, SSV60120 HYD, SSV40120 HYD DW &

SSV60120 HYD DW

Steel Hoist Model: SSV45120

Diagram A

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003526

Page 1 REV A 4/12/06

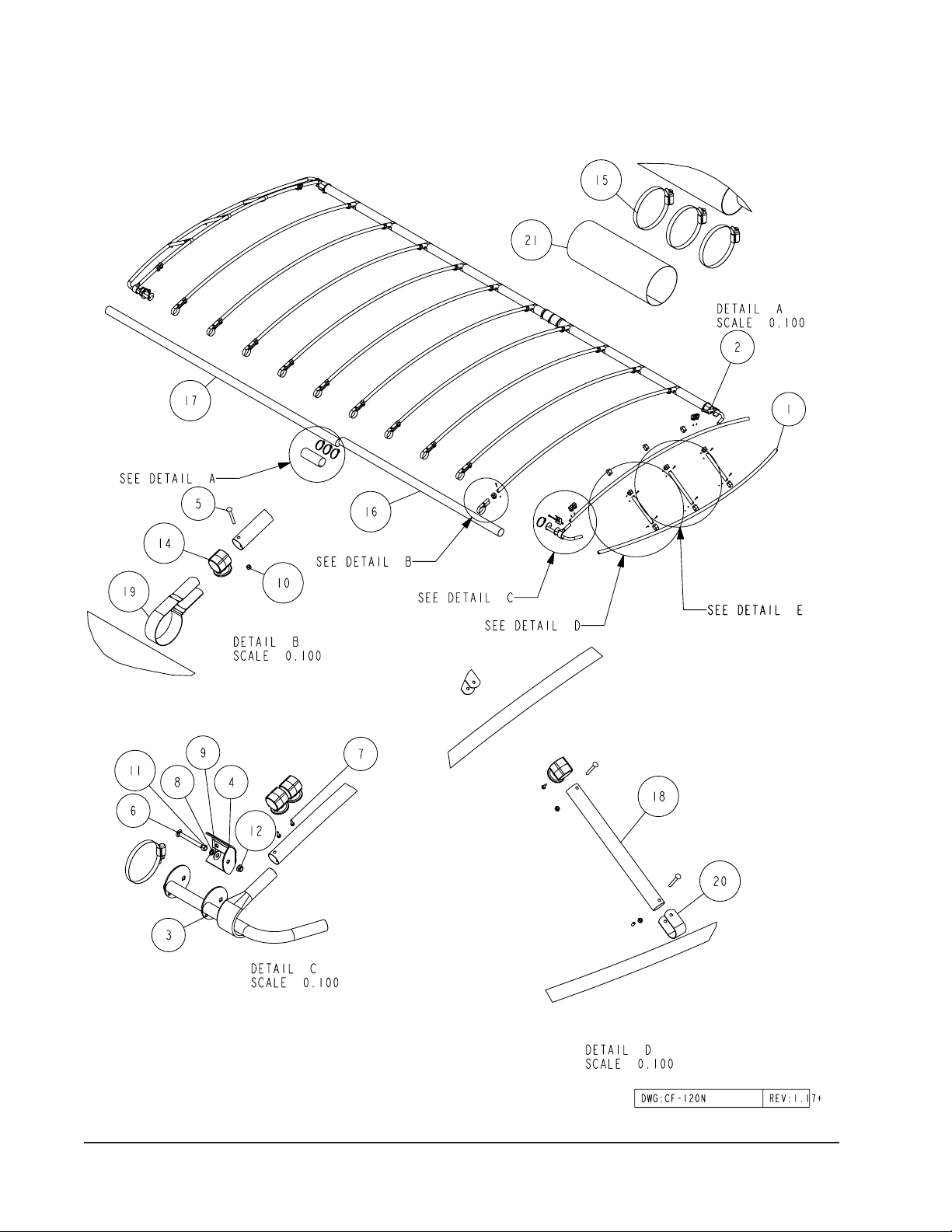

Diagram B

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003526

Page 2 REV A 4/12/06

ASSEMBLY INSTRUCTIONS

Break bundles and hardware box. Sort all parts according to

size. Depending on the model ordered, you may have extra

parts.

END HOOD ASSEMBLY

(Refer to Diagram A for a final assembly view)

The first step will be to assemble the end hoods. Locate

the adjustable canopy end assemblies. Note that there are

two- right and two- left hand assemblies. (See Diagram B,

Detail E.)

Next locate two of the canopy bows and place them on the

floor or ground with one each of the right and left hand assemblies placed at each end of the bows.

Identify the canopy bow that will be installed as the bow that

will form the upper curved portion of the canopy end section.

Slide two (2) each of the plastic canopy cord spool hooks on

each end of this canopy bow. A total of four canopy cord spool

hooks will be placed on this bow.

Insert one end of the two canopy bows over the round tubes

on one of the adjustable canopy end assemblies. Note that

one bow will lay flat on the floor while the other bow with the

canopy cord spool hooks installed will curve upward in the

form of the canopy once it is completely assembled.

Insert the other ends of the canopy bows onto the round tubes

on the second adjustable end assembly. Make sure that the

canopy bows are slid onto the round tubes as far as they can

without jamming or driving them on.

Mark the centers on the two canopy bows. Locate one of the

19” canopy end spacer tubes (Item 22 in Diagram B, Detail

E). Attach it to the canopy bow that is laying flat on the floor

or ground at the center location just marked. Secure together

with an end hood loop using a 1/4” x 2-1/4” carriage bolt and

nut provided as shown. Slip one of the canopy cord spool

hooks onto the 19” canopy end spacer tube. Secure the

other end of the spacer tube to the top bow with a second

end hood loop and 1/4” x 2-1/4” carriage bolt. Secure with a

¼” hex nut. Tighten.

Locate one of the 16” canopy end spacer tubes (Item 18 in

Diagram B, Detail D). Attach it to the canopy bow that is laying

flat on the floor or ground at the ¼ point (center between the

end of the canopy bows and the 19” spacer tube just installed

in the center). Secure together with an end hood loop using

a 1/4” x 2-1/4” carriage bolt and nut provided as shown. Slip

one of the canopy cord spool hooks onto the 16” canopy

end spacer tube. Rotate the spacer tube up and slide either

towards or away from the 19” center spacer tube until it will

fit between the two canopy bows. Secure the other end of the

spacer tube to the top bow with a second end hood loop and

1/4” x 2-1/4” carriage bolt. Secure with a ¼” hex nut. Tighten.

Repeat on the other side of the end hood assembly.

Locate the ½” long black plastic caps supplied in the hardware. Push one of them onto each of the bolts sticking

through the nut securing the spacer tube to the flat canopy

bow. This will protect the vinyl cover from fraying when it

comes in contact with the bolt.

Measure up and place a mark at 7 ½” and 10 ½” from each

end of the upper canopy bow forming the top curve. Place

the mark on the bottom side of the tube.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003526

Page 3 REV A 4/12/06

Locate a No. 10 x ¾” self-drilling screw. Position the bottom

edge of the canopy cord spool hook on the 10 ½” mark. Position so the spool of the molding is pointing directly down.

Secure in this position by placing the self-drilling screw into

the center hole of the spool, then drilling the screw in to attach

it to the canopy bow.

Place the bottom edge of the second canopy cord spool

hook at the 7 ½” mark. Position so the spool of the molding

is pointing directly down. Secure in this position by placing

the self-drilling screw into the center hole of the spool, then

drilling the screw in to attach it to the canopy bow.

Measure and place a mark at 2” from the top of the 19” and

the 16” canopy end spacer tubes. Locate a No. 10 x ¾” selfdrilling screw. Position the top edge of the canopy cord spool

hook on the 2” mark. Position so the spool of the molding is

pointing inward as shown. Secure in this position by placing

the self-drilling screw into the center hole of the spool, then

drilling the screw in to attach it to the canopy bow.

Repeat the above process on the other end hood assembly.

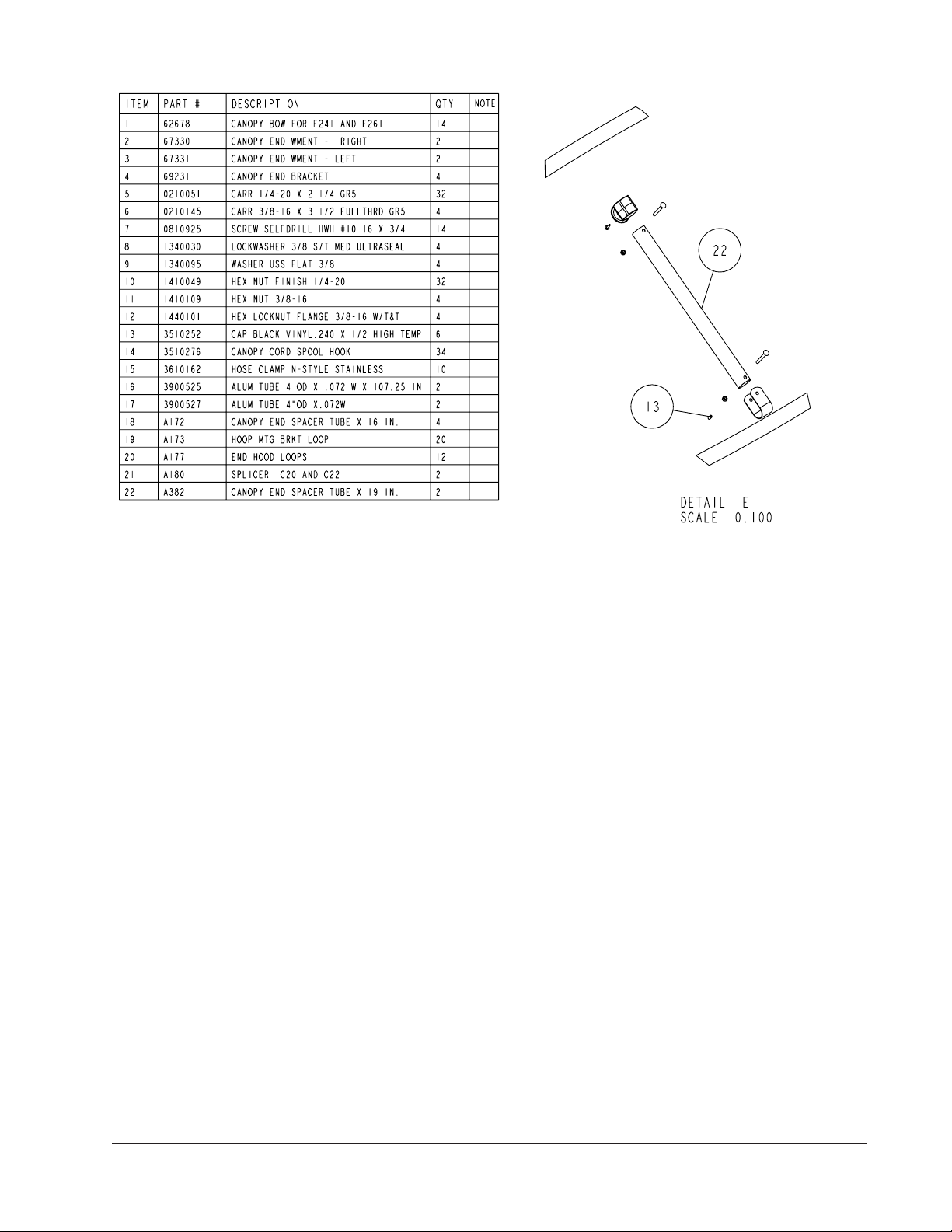

FRAME ASSEMBLY INSTRUCTIONS

Tighten the stainless steel hose clamps evenly and securely

around the side frame splice placing two of the clamps at

the very ends of the side frame splice and one in the center

of the splice where the ends of the side frame tubes meet

inside the splice.

The frame is easiest assembled when it is assembled on

four sawhorses or something of this height. Place the two

sideframe tubes on the sawhorses located at a spacing that

is comparable to the width of the canopy once it is assembled.

Place the two side frame tube assemblies so the splicers are

directly across from each other (long side frame tubes are at

same end of canopy). Insert the two end hood assemblies just

assembled into the ends of the 4” diameter side frame tubes.

This will properly space the tubes and keep them positioned

while the balance of the bows are assembled to the side

frames. Make sure the adjustable end hood assemblies are

slid completely in and against the end of the side frame tube.

Secure in this position by placing a stainless steel hose clamp

around the side frame tube and also around the end hood

tube stop weldment approximately 1” from the end of the side

frame tube. Position the tightening mechanism on the clamp

so it is located on the inside of the side frame tube and in a

position that won’t interfere with the canopy cover when it is

pulled around the side frame tube during installation.

Locate the four 4” side frame tubes. Note that there are two

different lengths. Identify a smooth flat surface that they can

be laid on during assembly because it makes the process

much easier to accomplish. Measure and place a mark at 6”

from one end of each of the side frame tubes. Loosen four

of the stainless steel hose clamps large enough so they will

slide over the side frame splice, Ref. 20 in Detail B. Mate the

marked ends of a short and long side frame tube together.

Slide the splice onto the first side frame tube until it meets

the 6” mark. Place the second side frame tube into the splice

until the ends of the side frame tubes are touching each other.

Note: The side frame tubes nudged together is very important

because it adds considerable strength to the joint once it is

fully assembled and tightened properly. The ends of the side

frame tubes must be centered in the splice.

Repeat the process on the other side frame tube.

The canopy bows are to be spaced on 24” centers. Using

a tape measure, place the first mark at 22”. Then mark The

balance of the side frame 24” intervals the full length of the

side frame tubes.

Locate the balance of the canopy bows. Slide two (2) each

of the canopy cord spool hooks on each bow, then attach

them to the side frames using the hoop mounting bracket

loops provided.

Note that they have to be formed around the side frame tube

when assembling. Align the hole in each end of the hoop

mounting loop with the holes in the end of the canopy bow.

Secure together using 1/4” x 2-1/4” carriage bolts and hex

nuts. Thread on the nuts but do not tighten until instructed.

Repeat the above process on all of the canopy bows. Once

they are all attached to the side frames, relocate them so they

are on the 24” marks identified earlier.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003526

Page 4 REV A 4/12/06

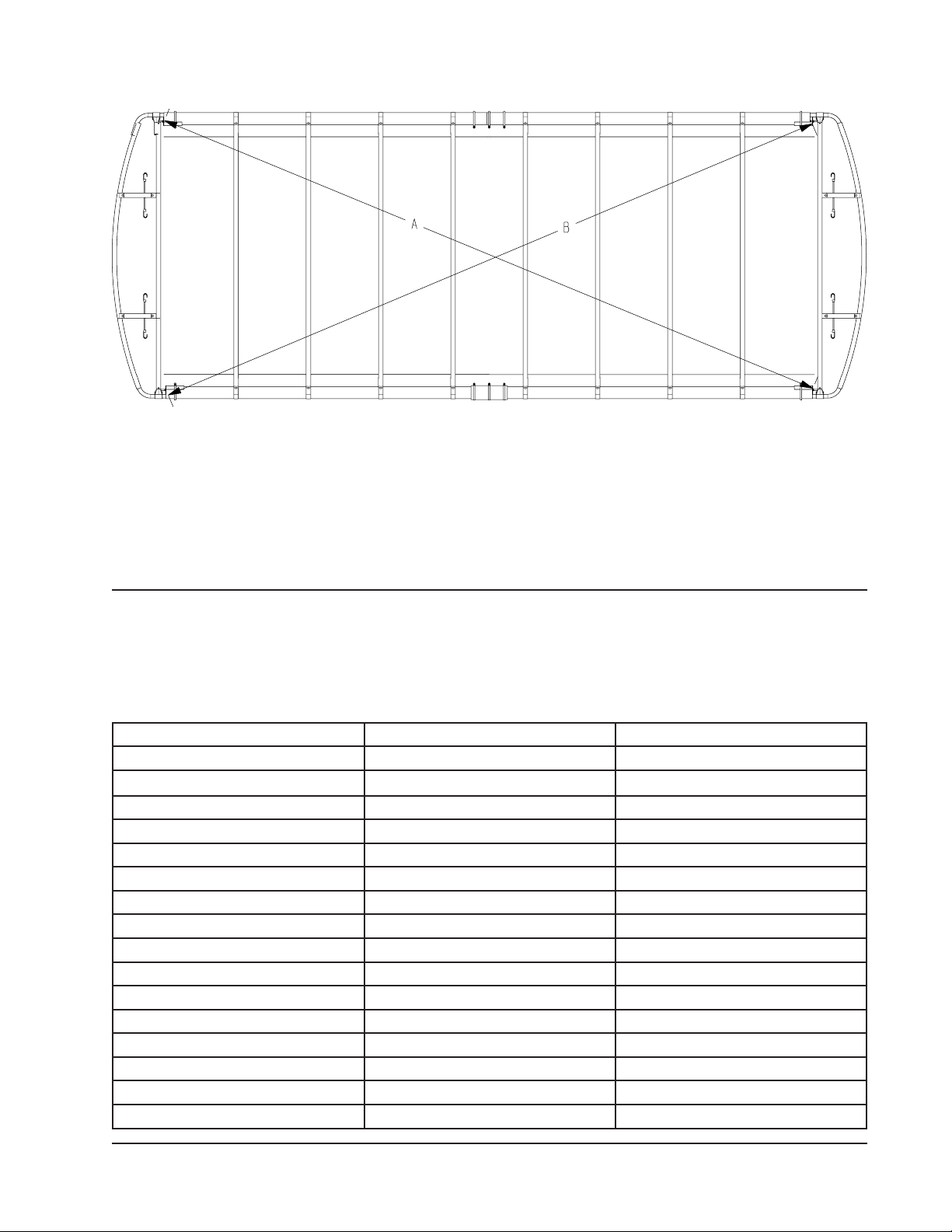

CHECKING FOR CANOPY FRAME SQUARE

Diagram AA

Check for square by using a tape measure or string.

Measure from one end of the side frame tube on one side of

the framework to the other side frame tube on the other side

of the framework.

Pull a tape measure or string from the opposite ends of the

canopy side frames across the framework as shown in the

above diagram.

Measurements A and B must match each other in order for

the framework to be square. If they don’t, slide one side frame

either forward or backward until matching measurements are

achieved. Once achieved, tighten all of the bolts attaching the

canopy bows to the side frames. the framework assembly is

now complete.

The canopy post assembly and installation instructions are supplied with the canopy post bundles and are located in the

support cup box. Use these instructions to attach the canopy posts to your hoist.

The following canopy post bundles are required to fit the following hoist.

Once the canpo y posts have been installed on your hoist continue to attach the cano py frame and vinyl as

follows.

Hoist Model Canopy Post Required Consists of Bundles

SSV30120 CP72D 68318, 68324

SSV40120 CP72D 68318, 68324

SSPV30120 CP72D 68318, 68324

SSPV40120 CP72D 68318, 68324

SSV30120DW CP30D 68318, 68325

SSV40120DW CP30D 68318, 68325

SSPV30120DW CP30D 68318, 68325

SSPV40120DW CP30D 68318, 68325

SSV40120HYD CP72K 68317, 68331

SSV50120 CP72M 68318, 68330

CP90F 68318, 68327

SSV50120DW CP32M 68318, 68329

SSV60120HYD CP72H 68317, 68332

CP90H 68317, 67567

SSV60120HYD DW CP32H 68317, 67320

SSV45120 (Steel Hoist) CP42G 68320, 68328

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003526

Page 5 REV A 4/12/06

Loading...

Loading...