Mid-West 116 DPI Installation And Operating Instructions Manual

BULLETIN NO. IM116DPI/08

®

Mid-West Instrument

INSPECTION

Before installation carefully check the Model Number on

each instrument against the receiving paperwork and

the intended application. Inspect for shipping damage

and, if damaged, report it immediately. Verify when

the unit is unpacked and in a vertical position that the

pointer is on zero. If the pointer is off zero see

TROUBLE SHOOTING

on zeroing the pointer.

NOTE: BEFORE ATTEMPTING REPAIRS

CONTACT YOUR LOCAL MID-WEST

REPRESENTATIVE OR OUR FACTORY.

FAILURE TO DO SO WILL VOID ANY

WARRANTY.

Installation and Operating Instructions

section 2 for instructions

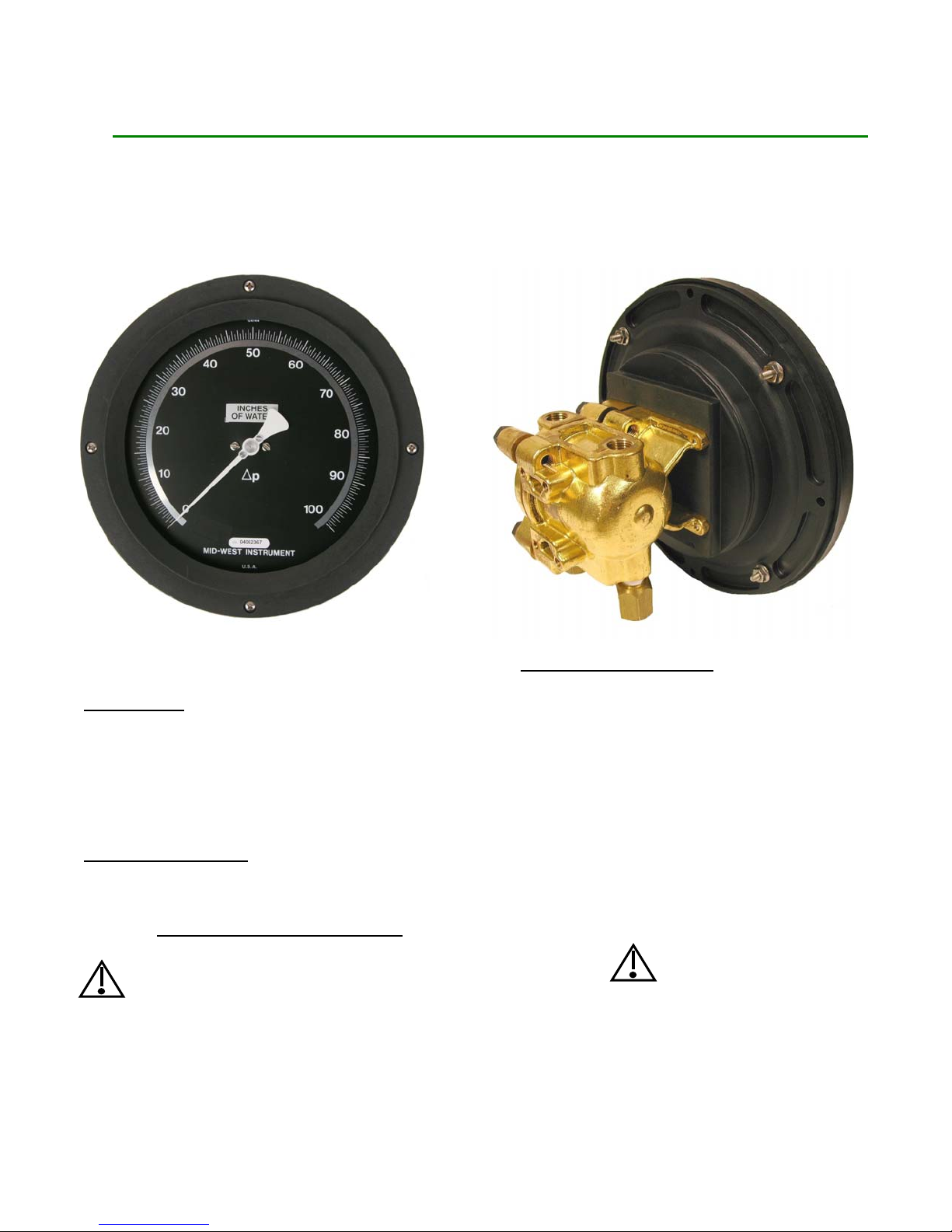

Model 116 DPI

,

PRODUCT DESCRIPTION

The Model 116 design for cryogenic applications are

all-metal differential pressure gauges capable of

operating at low differential pressures for up to 500

PSI of line pressure.

The DPI is equipped with a Bi-directional Over Pressure

Relief Valve (OPV). When the Differential Pressure

exceeds 130% of the range the OPV equalizes the

pressure between the Hi and Lo sides. Dual top and

bottom connections are provided as standard. The DPI

is also equipped with a pointer zero “micro-adjust”. If

necessary the pointer can be re-zeroed.

CAUTION:

Rapid pressurization can cause severe damage

to the sensing element. Rapid pressure change

(either increase or decrease) is a change in

pressure occurring fast enough to drive the

instrument full scale in one (1) second or less.

See installation portion of this I.O.M. for

guidance in how to prevent rapid

pressurization.

INSTALLATION

Model 116 gauges are calibrated and tested prior to

shipment and are ready for immediate installation.

Use of the following installation procedures should

eliminate potential damage and provide optimum

trouble free operation.

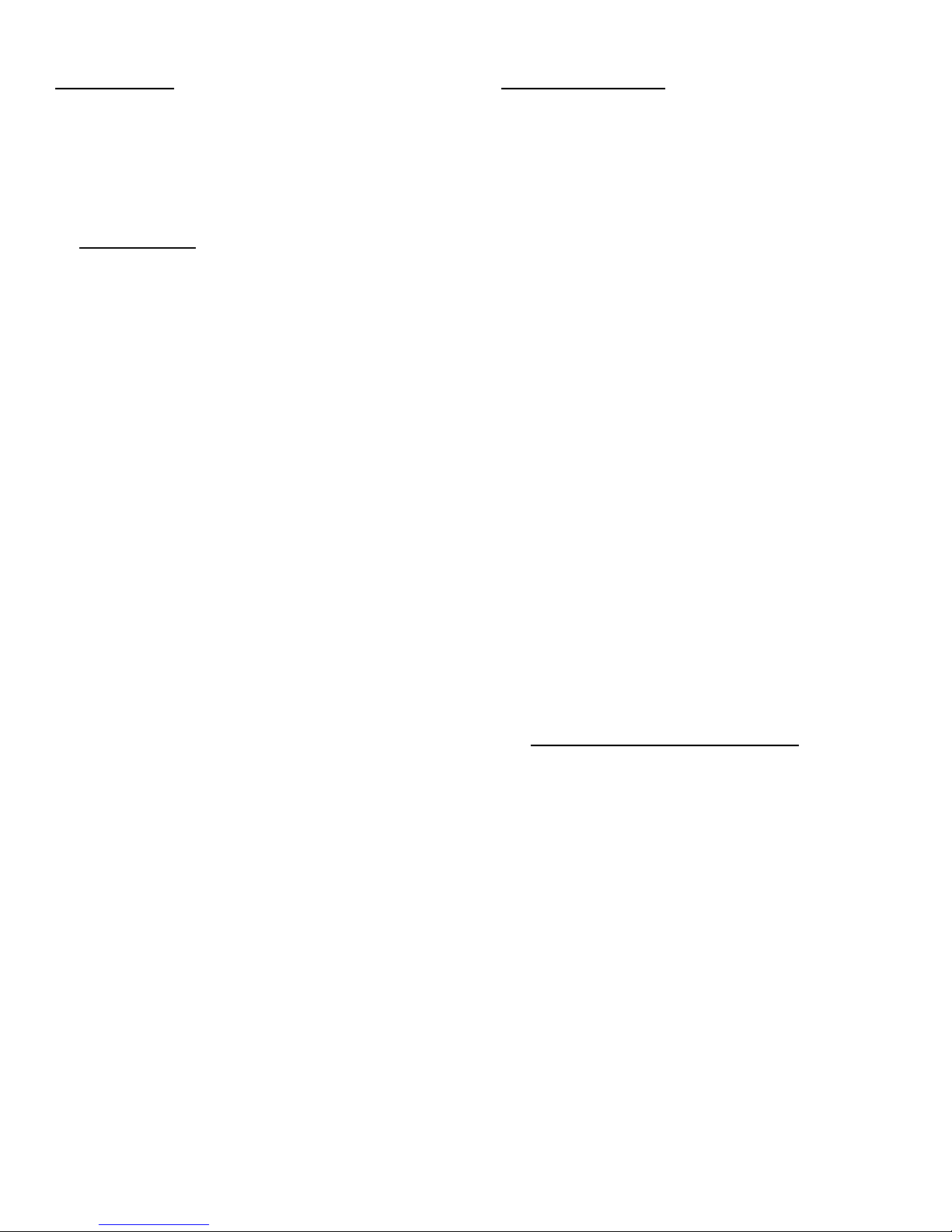

1. CONNECTIONS

Dual ¼” FNPT connections, top and bottom, are provided

as standard but check paperwork for connections

ordered. They are identified “high” and “low”, for high

pressure and low pressure. Be sure that one “high” and

one “low” pressure connection gets plumbed to the

proper connection on your system. The other two ports

should either be plugged or plumbed as drains or bleeds,

depending on whether the service is liquid or gas.

NOTE: It is strongly recommended that a

3-valve manifold be used in plumbing

your model 116 to your system. Properly

used it should insure that your instrument

is not over-ranged or damaged by

pressure shocks during pressurization. It

will facilitate later zeroing, ranging and

calibration checking. It is good practice to

purge or flush the instrument loop prior to

connecting the instrument.

When pressurizing the instrument have

the bypass valve open. Slowly open the

high side and low side isolation valves.

When the unit is pressurized close the

bypass valve to obtain a DP reading.

When removing the instrument open the

bypass valve prior to closing the high side

and low side isolation valves. Leave the

bypass valve open when venting the

instrument.

2. PANEL MOUNTING

The Model 116 is designed for mounting through the

front of the instrument panel and is normally provided

with a panel mounting kit.

Make the cutouts as indicated in (Figure 1). Insert the

gauge through the panel aligning the panel mounting

studs with the holes in the panel. Install the nuts onto

the studs and tighten securely.

TROUBLE SHOOTING

1. Gauge does not indicate differential.

A. Check for proper hook up, high to high and low

to low.

B. Make certain that block valves are open and, if

using a 3-valve manifold, that the equalizer

(balance) valve is closed.

C. If A and B check out correctly, loosen or

disconnect the high pressure line to determine if

there is pressure to the instrument.

D. If there is pressure to the instrumen t, check to

determine that there is a differential across the

unit being monitored. If there is, contact the

factory for assistance and for an “RGA” (returned

goods authorization) number to return the

instrument for repair or replacement.

2. Indicating pointer off zero. (With block valves

closed, equalizer valve open, or no system

differential.)

A. Tap gauge lightly.

B. Make certain block valves are closed and

equalizer valve is open.

C. If A & B do not correct the “off zero” condition,

remove the bezel and lens assembly by removing

the (4) bezel screws. Grasp the pointer hub

between the thumb and forefinger. Using a

straight blade screw driver adjust the screw on

the pointer clockwise to adjust the pointer

upscale or counter clockwise to adjust the pointer

downscale. Tap the gauge lightly to confirm the

pointer is on zero. Reinstall the bezel and lens

assembly.

RECALIBRATION AND/OR REPAIR

1. If recalibration or repair is required, secure an

“RGA” (returned goods authorization) number

from Mid-West Instrument and return the

instrument to the factory.

2. If (1) is not practical, we recommend you discuss

your problem with one of our customer service

representatives and request a “technical service”

manual. Please have both the model and serial

numbers available before calling

Loading...

Loading...