For testing 6- and 12-volt

automotive and marine

batteries, and for testing

12- and 24-volt

charging systems.

INSTRUCTION MANUAL

TABLE OF CONTENTS

BATTERY TEST ....................................................................................3

SELECTING A LANGUAGE...........................................................3

PRIOR TO TESTING .....................................................................3

If testing out-of-vehicle ...........................................................3

If testing in-vehicle..................................................................3

CONNECTING THE ANALYZER ...................................................3

KEYPAD.........................................................................................4

IN-VEHICLE OR OUT-OF-VEHICLE TEST ...................................4

BATTERY RATING SYSTEMS ......................................................4

RATING VALUE .............................................................................5

ADDITIONAL TEST FEATURES....................................................5

Surface charge removal .........................................................5

Temperature compensation....................................................5

BEFORE or AFTER CHARGE tests .......................................5

BATTERY TEST RESULTS ...........................................................5

STARTER SYSTEM TEST .................................................................... 6

STARTER SYSTEM TEST RESULTS ...........................................6

STARTER SYSTEM PROBLEMS ..................................................7

With the vehicle lights on........................................................7

With the vehicle lights off........................................................7

CHARGING SYSTEM TEST..................................................................7

CHARGING SYSTEM TEST RESULTS.........................................8

VOLTMETER ....................................................................................... 10

PRINT/VIEW CAPABILITY.................................................................. 11

TROUBLESHOOTING......................................................................... 12

DISPLAY PROBLEMS .................................................................12

PRINTING PROBLEMS ...............................................................12

Status LED ........................................................................... 12

Solutions ............................................................................... 13

• 1 •

REPLACING THE MICRO500 BATTERY ........................................... 14

PATENTS, LIMITED WARRANTY, SERVICE .................................... 15

• 2 •

CAUTION: Because of the possibility of personal injury,

!

always use extreme caution when working with batteries. Follow all BCI (Battery Council International) safety

recommendations.

BATTERY TEST

SELECTING A LANGUAGE

Press and hold down both ARROW buttons while connecting to a

battery. Scroll to the desired language, then press ENTER to select.

PRIOR TO TESTING

If testing out-of-vehicle

• Clean battery terminals with a wire brush before testing.

• For group 31 or side-terminal batteries, install and tighten the lead

terminal adapters provided with this analyzer. Do not use steel

bolts. Failure to properly install terminal adapters, or using

terminal adapters that are dirty or worn may result in false test

results.

If testing in-vehicle

• The preferred test position is at the battery terminals. If the battery is

not accessible, you may test at the jumper post, however the available power value could be lower than actual. If you get a REPLACE

BATTERY result, retest at the battery terminals before replacing the

battery.

• At the beginning of a test sequence, make sure all vehicle accessory

loads are off and the ignition is in the off position.

CONNECTING THE ANALYZER

• Connect red clamp to positive (+) terminal.

• Connect black clamp to negative (–) terminal.

• To ensure a proper connection, rock the clamps back and forth. The

analyzer requires both sides of the clamp to be firmly connected prior

to testing. A poor connection will prevent testing and a CHECK

CONNECTION message will appear. If this occurs, clean the terminals and reconnect.

• 3 •

KEYPAD

Use the ARROW buttons to scroll to menu choices.

Use the ENTER button to make selections.

Press the BACK button to move backwards to the

previous step.

Press the PRINT/VIEW button to enable print/view

capability.

IN-VEHICLE OR OUT-OF-VEHICLE TEST

The analyzer will ask if the battery is connected in a vehicle or if it is

out of a vehicle. At the prompt, make your selection by pressing the

ARROW buttons, then press ENTER.

BATTERY RATING SYSTEMS

You will be prompted to choose the battery’s rating system. The available

rating systems are:

CCA: Cold Cranking Amps

The most common rating for cranking batteries at 0º F.

CA: Cranking Amps

Used for some batteries in southern climates rated at 32º F.

MCA: Marine Cranking Amps

For testing marine batteries rated at 32º F.

JIS: Japanese Industrial Standard

Shown on a battery as a combination of numbers and letters. For example: 80D26.

• 4 •

RATING VALUE

At the prompt scroll to the battery’s rating value and press ENTER.

ADDITIONAL TEST FEATURES

SURFACE CHARGE REMOVAL

If surface charge is detected while testing in the vehicle, the analyzer will

prompt you to turn on the headlights to remove the surface charge.

Follow the instructions on the display. After detecting the removal of the

surface charge, the analyzer will automatically resume testing.

TEMPERA TURE COMPENSATION

If necessary, the analyzer will prompt the user to choose if the battery

temperature is above or below 32°F. Choose the appropriate selection by

pressing the up or down arrow button, then press the enter button to

make the selection.

BEFORE or AFTER CHARGE TEST

If necessary, the analyzer will ask the user if the battery has just been

charged. Choose the appropriate selection by pressing the up or down

arrow button then press the enter button to make the selection.

Note: When testing a battery installed in a vehicle that has recently

been driven, use the BEFORE CHARGE test.

BATTERY TEST RESULTS

GOOD BATTERY Return to service.

GOOD-RECHARGE Fully charge battery and return to service.

CHARGE & RETEST Fully charge battery and retest. Failure to fully

charge the battery before retesting may

cause false readings.

REPLACE BATTERY Replace the battery and retest to perform a

complete charging system analysis. (See note

below.)

BAD CELL-REPLACE Replace the battery and retest to perform a

complete system analysis.

• 5 •

NOTE: A REPLACE BATTERY result may mean a poor connection

between the vehicle’s cables and the battery. After disconnecting the

vehicle’s battery cables from the battery, retest the battery using the outof-vehicle test before replacing.

STARTER SYSTEM TEST

IMPORTANT: When testing older model diesel engines in cold weather,

preheating and post heating of the glow plug may skew test results.

Warm up the engine for 5 minutes then test the vehicle.

Following the battery test, you will be prompted to press enter for the

starter test. After pressing the enter key you will be prompted to start the

engine.

At the conclusion of the test, the Micro500 will display one of the following results:

STARTER SYSTEM TEST RESULTS

CRANKING VOLTAGE NORMAL

The system is showing normal starter draw. Press enter to perform the

charging system test.

CRANKING VOLTAGE LOW

The cranking voltage is below normal limits, troubleshoot the starter with

manufacturers recommended procedure.

CHARGE BATTERY

The battery state-of-charge was too low to perform a starter test. The

battery must be charged before testing the starter. Press enter to perform the charging system test, or charge the battery and retest.

REPLACE BATTERY

The battery must be replaced before testing the starter. Press enter to

perform the charging system test.

If the battery is good and fully charged and the vehicle will not start,

perform the steps below for further diagnosis.

• 6 •

STARTER SYSTEM PROBLEMS

With the vehicle lights on

If the engine does not crank and the lights dim heavily, check the connections to ensure the wiring is clean and in good condition. If the wiring

is in good condition, repair or replace the starter.

If the engine does not crank and the lights go out, there is probably a

poor connection. Check the connection to the battery and ground and

ensure they are clean and tight.

If the starter does not crank and the lights do not turn on, check for an open

circuit and retest the battery to ensure it is good and fully charged. Replace

any defective wiring and clean and tighten all wiring connections.

With the vehicle lights off

If the engine cranks slowly but will not start, check all wiring to ensure it

is in good condition. Make sure the cables from the starter to the battery

are sized according to the manufacturer’s specifications. If the engine is

operating properly and the wiring is in good condition, repair or replace

the starter.

If the engine cranks but does not start, check the ignition system and fuel

system for other problems. If the engine does not crank and a clicking

noise is heard, check the solenoid.

CHARGING SYSTEM TEST

IMPORTANT: When testing older model diesel engines in cold weather,

preheating and post heating of the glow plug may skew test results.

Warm up the engine for 5 minutes then test the vehicle.

The Micro500 walks you through the steps to perform a charging system

analysis. With the vehicle running, you will be asked to perform tasks for

the Micro500 to do the analysis.

Step 1: The Micro500 will display live alternator output voltage.

Press ENTER to begin the charging system test.

Step 2: Testing at rev

The Micro500 will prompt you to rev the engine for 5 seconds. When the

Micro500 has detected the rev, data is collected and the analyzer will

show that it detected the rev. If the Micro500 does not detect that the rev

occurred, it will continue to prompt you to rev the engine for 5 seconds.

Once detected, press enter to continue.

• 7 •

Note: Some 8 cylinder vehicles and older vehicles idle at a high level

after starting. This can allow the analyzer to detect a rev without any

action being taken. If this occurs, continue on with the test process. The

final test results will not be affected.

Step 3: Testing at idle

The Micro500 will analyze the charging system output at idle for comparison to other readings.

Step 4: Diode/Ripple test

The Micro500 will look for the amount of ripple from the charging system

to the battery. Excessive ripple usually means one or more diodes have

failed in the alternator or there is stator damage.

Step 5: Testing with accessory loads

The Micro500 will prompt you to turn on accessory loads, then test at

idle, then prompt you to rev the engine for 5 seconds.

The analyzer will determine if the charging system is able to provide

sufficient current for the demands of the vehicle’s electrical system.

Note: When asked to turn on the accessory loads, turn on the blower to

high (heat), high-beam headlights, and rear defogger.

Do not use cyclical loads such as air conditioning or windshield

wipers.

Step 6: Analyzing Data

The Micro 500 will analyze all readings to provide the results of the

charging system test.

CHARGING SYSTEM TEST RESULTS

At the conclusion of the test, the Micro500 will output one of the following

results and, the idle voltage and load voltage:

CHARGING SYSTEM NORMAL\DIODE RIPPLE NORMAL

No problem detected. The system is showing normal output from the

alternator.

CHARGING SYSTEM PROBLEM

A problem was detected in the charging system. The potential cause of

the problems are listed below:

• 8 •

NO CHARGING VOLTAGE

The alternator is not providing charging current to the battery. Check the

belts to ensure the alternator is rotating with the engine running. If the

belts are slipping or broken, replace the belts and retest. Check all

connections to and from the alternator especially the connection to the

battery. If the connection is loose or heavily corroded, clean or replace

the cable and retest. If the belts and connections are in good working

condition, replace the alternator. (In older vehicles, external voltage

regulators were utilized. In these instances, only replacement of the

voltage regulator may be required.)

LOW CHARGING VOLTAGE

The alternator is not providing sufficient current for the system’s electrical loads and the charging current for the battery. Check the belts to ensure

the alternator is rotating with the engine running.

If the belts are slipping or

broken, replace the belts and retest. Check the connections from the

alternator to the battery. If the connection is loose or heavily corroded,

clean or replace the cable and retest. If the belts and connections are in

good working condition, replace the alternator. (In older vehicles, external voltage regulators were utilized. In these instances, only replacement

of the voltage regulator may be required.)

HIGH CHARGING VOLTAGE

This means the voltage output from the alternator to the battery exceeds

the normal limits of a functioning regulator. Check to ensure there are no

loose connections and that the ground connection is normal. If there are

no connection issues, replace the regulator. Since most alternators have

the regulator built-in, this will require you to replace the alternator. (In

older vehicles, external voltage regulators were utilized. In these

instances, only replacement of the voltage regulator may be required.)

The regulator is designed to control voltage output based on the battery

voltage, underhood temperature, and vehicle loads being used. In other

words, it controls the maximum voltage the system can produce based

upon the current needs and amount of current that can be produced by

the spinning of the rotor in the alternator. The normal high limit of a

typical automotive regulator is 14.7 volts +/– 0.5. Check manufacturer

specifications for the correct limit, as it will vary by vehicle type and

manufacturer.

A high charging rate will overcharge the battery which may decrease its

life and cause it to fail. If the battery test decision is REPLACE and the

charging system test shows a HIGH CHARGING VOLTAGE, check the

levels of the electrolyte in the battery. A battery condition symptom of

overcharging is fluid spewing through the vent caps which causes low

electrolyte levels and will harm the battery.

• 9 •

EXCESS RIPPLE DETECTED

One or more diodes in the alternator are not functioning or there is stator

damage, which is shown by an excessive amount of AC or ripple current

supplied to the battery. Check to ensure the alternator mounting is sturdy

and that the belts are in good shape and functioning properly. If the

mounting and belts are good, replace the alternator.

An alternator is designed to create the electrical energy necessary to

charge the battery and provide for the vehicle’s electrical system load.

Since the alternator creates AC, (alternating current), it must be rectified

into DC, (direct current), to charge the battery and supply power to the

rest of the system. To accomplish this, the alternator uses diodes which

allow current flow in only one direction, changing AC current to DC

current. When one or more of the diodes fail, the AC ripple current from

the alternator to the battery will exceed normally acceptable limits.

VOLTMETER

The Micro500 can also function as a voltmeter. The operating range of

the voltmeter is 0 through 30 Vdc.

IMPORTANT: If the Micro500 is connected above 30 Vdc, the circuit

board may be damaged.

To use the voltmeter function, press the PRINT/VIEW button. Then use

the blue arrow buttons to scroll to the appropriate selection, then press

the enter button to make the selection.

Use the red and black clamps as probes. The analyzer cannot detect

negative voltage. If the analyzer is connected in reverse polarity, the

analyzer will shut off.

To turn off the voltmeter, disconnect the analyzer and press the PRINT/

VIEW button. The analyzer will automatically shut off if 0 Vdc is detected

for 1 minute.

• 10 •

PRINT/VIEW CAPABILITY

IMPORTANT: When you start a new test by reconnecting to the battery,

all the previous test data in the analyzer’s memory will be erased.

By pressing and holding the PRINT/VIEW button after completing a test

and disconnecting from the battery, you will be given the option of

viewing the last test or printing the last test result. If you choose to view

the last test, use the ENTER and BACK buttons to scroll through the

last result.

The Micro500 also has the ability to print the last test result using the IR

output at the top of the analyzer and the IR receiver at the bottom of the

Midtronics printer (below the MODE button). With the printer on, align

the IR output from the Micro500 with the receiver on the printer and

press and hold the PRINT/VIEW button. Select PRINT from the option

menu by pressing the up or down ARROW button then press the

ENTER button to make the selection.

HINTS:

1. The analyzer will continue to send data once the print button is

pressed. If the analyzer output and the printer input are not aligned,

all the data may not print. If data has not printed, press the PRINT/

VIEW button a second time to cancel the print job. Verify alignment

between the analyzer and printer, then press the print button. The

printer will begin printing.

2. It takes approximately 30 seconds to print the full test results. The

test results are displayed on the screen while they are printed.

Refer to the enclosed printer manual for more information.

• 11 •

TROUBLESHOOTING

DISPLAY PROBLEMS

If the display does not illuminate

• Check connection to the battery.

• Battery may be too low to power the analyzer (below 1 volt). Fully

charge the battery and retest.

• Internal 9-volt battery may need to be replaced. Replace the 9-volt

battery and retest.

• If the analyzer detects computer or ignition noise, a SYSTEM NOISE

message will appear on the display. Verify that all vehicle accessory

loads are off and the ignition switch is in the off position. The analyzer will automatically retest when the system noise is no longer

detected. If the SYSTEM NOISE message continues after several

retest attempts, disconnect the battery cables and retest.

• If the analyzer does not power up when the PRINT/VIEW button is

pressed, replace the 9-volt battery.

PRINTING PROBLEMS

Status LED

When a printer fault occurs, the STATUS LED will flash. You can identify

the fault by the number of sequential flashes:

Sequence Condition Solution

* * *

** ** **

*** *** ***

Paper out

Thermal head too hot

Battery low

• 12 •

Fit new paper

Allow head to cool

Recharge printer

battery for 16 hours

Solutions

• If the IR transmitter and receiver are not aligned, all the data may not

print. The infrared ports on the top of the Micro500 and on the front

of the printer (below the MODE button) should be pointed directly at

each other. The maximum distance for reliable transmission between

the ports is 18 inches (45 cm). To realign, press PRINT/VIEW to

cancel the print job. Verify alignment between the analyzer and

printer; then try to print the test results again.

• If the analyzer displays PRINTING RESULTS, but the test results are

not printing, press PRINT/VIEW to cancel. Turn off the printer and

charge the printer battery for at least 15 minutes before attempting to

print again.

• Make sure the printer is on. The printer shuts off after 2 minutes of

inactivity to conserve the battery. To turn the printer on, briefly press

the MODE button. The green STATUS light should turn on. Make

sure you are using the Midtronics printer provided with the Micro500.

Other printers may not be compatible.

• Direct sunlight interferes with infrared data transmission/receiving.

If the printer is not receiving data, remove the printer and Micro500

from direct sunlight. If the printed characters are not clear or are

partially missing, recharge the battery and reprint.

• Verify that the correct printer is selected. Press and hold the PRINT/

VIEW button, use the ARROW buttons to scroll to SELECT

PRINTER, and press ENTER. Use the ARROW buttons to scroll to

HP 82240B, and press ENTER.

• Verify that a compatible communications protocol is selected in the

printer’s setup. The printer’s HPIR mode (Infrared 33 kHz encoded)

is compatible with the analyzer’s HP 82240B printer option. Refer to

the printer manual for more information.

• If you are unable to print after ensuring the analyzer is functioning,

the printer is on, the battery is good, and the IR transmitter and

receiver are aligned, check the printer manual for further instructions

or call Midtronics at 800-776-1995 for assistance.

• 13 •

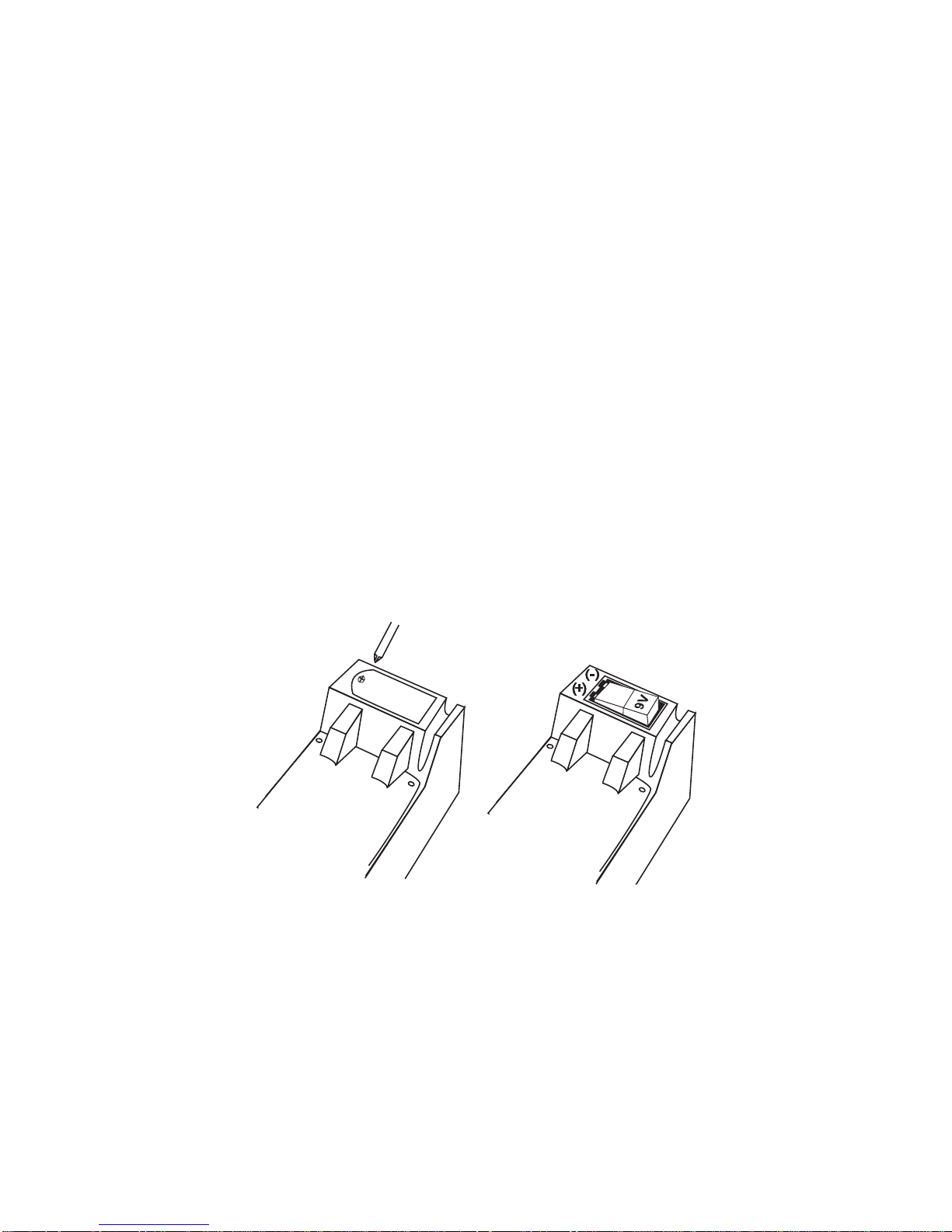

REPLACING THE MICRO500 BATTERY

The Micro500 uses a 9-volt battery to allow testing batteries down to 1

volt. When the battery requires replacing, the display shows “Low

Internal Battery, Replace” when you connect to a battery.

You should change the battery as soon after the message is displayed

as possible.

NOTE: The analyzer will retain setup information while you change the

9-volt battery.

IMPORTANT: The Micro500 can test down to 5.5 volts when the internal

9-volt battery is not functioning.

1. Remove the cover to the battery compartment using a small

screwdriver.

2. Insert a 9-volt battery as shown below, making sure the positive

and negative terminals are positioned correctly.

3. Put the cover onto the compartment and tighten the screw.

• 14 •

PATENTS

Made in the U.S.A. by Midtronics, Inc. and is protected by one or more of the

following U.S. Patents: 6,469,511; 6,456,045; 6,445,158; 6,441,585; 6,392,414;

6,323,650; 6,316,914; 6,310,481; 6,304,087; 6,249,124; 6,225,808; 6,163,156;

6,091,245; 6,051,976; 5,831,435; 5,821,756; 5,757,192; 5,592,093; 5,585,728;

5,572,136; 4,912,416; 4,881,038; 4,825,170; 4,816,768; 4,322,685. Canadian

Patents: 1,295,680; 1,280,164. United Kingdom Patents: 0,672,248; 0,417,173.

German Patents: 693 25 388.6; 689 23 281.0-08; 93 21 638.6. European patents: C382.13-0040 WO; C382.13-0033 EP; C382.13-0018 EP. And other U.S.

and Foreign patents issued and pending. This product may utilize technology

exclusively licensed to Midtronics, Inc. by Johnson Controls, Inc. and /or Motorola,

Inc.

LIMITED WARRANTY

This battery analyzer is warranted to be free of defects in materials and

workmanship for a period of one year from date of purchase. Midtronics will, at

our option, repair the unit or replace the unit with a remanufactured analyzer.

This limited warranty applies only to Midtronics battery analyzer and does not

cover any other equipment, static damage, water damage, overvoltage, dropping

the unit or damage resulting from extraneous causes including owner misuse.

Midtronics is not liable for any incidental or consequential damages for breach

of this warranty. The warranty is void if owner attempts to disassemble the unit,

or to modify the cable assembly.

SERVICE

To obtain service, purchaser should contact Midtronics for a Return Authorization

number, and return the unit to Midtronics, attention: Service Department. If

Midtronics determines that the failure was caused by misuse, alteration,

accident, or abnormal condition of operation or handling, you will be billed for the

repaired product and it will be returned to you freight prepaid. Battery analyzers

beyond the warranty period are subject to the repair charges in effect at that

time. Optional remanufacturing service is available to return the analyzer to like

new condition.

• 15 •

NOTES

• 16 •

PN 168-100D 5/03 ©2003 Midtronics, Inc.

Loading...

Loading...