Battery Management Innovation

Expandable Electrical

Diagnostic Platform

For testing 6 and 12-volt automotive batteries

and 12- and 24-volt charging systems

INSTRUCTION MANUAL

Contents

Contents

Chapter 1: Before You Begin ............................................................................. 7

Safety ..............................................................................................................................7

General Precautions ............................................................................................................. 7

Conventions Used in This Manual ...................................................................................7

Registering Your Analyzer ...............................................................................................8

Chapter 2: Description ....................................................................................... 9

Test Leads, Connectors, and Data Ports ......................................................................10

Display and Keypad ...................................................................................................... 11

Data Entry Methods .......................................................................................................12

Menu icons .......................................................................................................................... 12

Option Buttons .................................................................................................................... 12

Scrolling Lists ...................................................................................................................... 12

Alphanumeric Entry ............................................................................................................. 12

Menu Maps ....................................................................................................................13

Main Menu .......................................................................................................................... 13

DMM Menu .......................................................................................................................... 14

Info Menu ............................................................................................................................ 15

Print/View Menu .................................................................................................................. 15

Utilities Menu ....................................................................................................................... 16

Chapter 3: Test Preparation ............................................................................. 17

Inspecting the Battery ....................................................................................................17

Testing Out-of-Vehicle ...................................................................................................17

Testing In-Vehicle ..........................................................................................................17

Connecting the Battery Test Cable ................................................................................17

Connecting an Accessory Cable ...................................................................................18

• 3 •

Contents

Setting User Preferences ..............................................................................................18

Chapter 4: Battery Test .................................................................................... 19

Additional Test Requirements ........................................................................................20

Temperature Compensation ................................................................................................ 20

Surface Noise/Unstable Battery .......................................................................................... 20

Deep Scan Test ................................................................................................................... 21

Battery Test Results ......................................................................................................22

Chapter 5: 5-Minute Discharged Battery Test ................................................ 23

Test Routine ..................................................................................................................23

Chapter 6: System Test .................................................................................... 25

Battery Test ...................................................................................................................25

Starter Test ....................................................................................................................25

Starter System Test Results ................................................................................................ 26

Alternator Test ...............................................................................................................27

Alternator Test Results ........................................................................................................ 28

Chapter 7: Cable Drop Test ............................................................................. 31

Battery Ground Test ......................................................................................................32

Battery Ground Test Results ............................................................................................... 32

Starter Circuit ................................................................................................................33

Starter Circuit Test Results .................................................................................................. 33

Alternator Circuit ............................................................................................................34

Alternator Circuit Test Results ............................................................................................. 34

Other Circuit ..................................................................................................................35

Other Circuit Test Results.................................................................................................... 35

• 4 •

Contents

Chapter 8: Jump Start (System Test) .............................................................. 36

Chapter 9: DMM (Digital Multimeter) ............................................................... 37

DC Volts ........................................................................................................................37

AC Volts .........................................................................................................................38

Scope ............................................................................................................................38

DC AMP (requires the optional amp clamp) .......................................................................39

AC AMP (requires the optional amp clamp) .......................................................................39

Temp ..............................................................................................................................40

Ohm Meter ....................................................................................................................40

Diode .............................................................................................................................40

Volts/Amp (requires the optional amp clamp) ....................................................................41

Chapter 10: Utilities .......................................................................................... 43

Clock .............................................................................................................................43

Shop ..............................................................................................................................44

Display ...........................................................................................................................45

Coupon ..........................................................................................................................46

Edit Coupon ...................................................................................................................46

Temp ..............................................................................................................................47

Language ......................................................................................................................47

Format Disk ...................................................................................................................47

Update ...........................................................................................................................47

Chapter 11: Info Menu ...................................................................................... 48

Totals .............................................................................................................................48

Transfer .........................................................................................................................48

Version ..........................................................................................................................48

• 5 •

Contents

Chapter 12: Print/View ..................................................................................... 49

View Test .......................................................................................................................49

View Cable Test .............................................................................................................49

Chapter 13: Troubleshooting ........................................................................... 50

The Display Does Not Turn On .....................................................................................50

The STATUS LED Flashes (Midtronics Printer) ............................................................50

Data Will Not Print .........................................................................................................50

Chapter 14: EXP Internal Batteries ................................................................. 52

Battery Power Indicator .................................................................................................52

Replacing the EXP Batteries .........................................................................................52

Patents, Limited Warranty, Service ................................................................. 53

• 6 •

Chapter 1: Before You Start

Chapter 1: Before You Begin

Safety

!

Because of the possibility of personal injury, always use extreme caution when working with

batteries. Follow all manufacturers’ instructions and BCI (Battery Council International) safety

recommendations.

General Precautions

• DANGER—RISK OF EXPLOSIVE GASES: Batteries can produce a highly explosive mix

of hydrogen gas and oxygen, even when the battery is not in operation. Always work in a

well-ventilated area. Never smoke or allow a spark or flame in the vicinity of a battery.

• WARNING—REQUIRED BY CALIFORNIA PROP. 65: Battery posts, terminals, and

related accessories contain lead and lead compounds, chemicals known to the state of

California to cause cancer and birth defects or other reproductive harm. Wash hands

after handling.

• Battery acid is highly corrosive. If acid enters your eyes, immediately flush them thoroughly

with running cold water for at least 15 minutes and seek medical attention. If battery acid

gets on your skin or clothing, wash immediately with water and baking soda.

• Always wear proper safety glasses or face shield when working with or around

batteries.

• Keep hair, hands, and clothing as well as the analyzer cords and cables away from

moving engine parts.

• Remove any jewelry or watches before you start servicing the battery.

• Use caution when working with metallic tools to prevent sparks or short circuits.

• Never lean over a battery when testing, charging or jump starting it.

Conventions Used in This Manual

To help you learn how to use your EXP analyzer, the manual uses these symbols and typographical

conventions:

The safety symbol followed by the word WARNING or CAUTION indicates

!

CAUTION

instructions for avoiding hazardous conditions and personal injury.

The word CAUTION without the safety symbol indicates instructions for

avoiding equipment damage.

The wrench symbol indicates procedural notes and helpful information.

UP ARROW

POST TYPE

The text for keypad buttons and soft-key functions are in bold capital letters.

The text for screen options are in regular capital letters.

• 7 •

Chapter 1: Before You Begin

Registering Your Analyzer

Before using your EXP, we recommend that you register it online

to activate your warranty. Registration will also make it faster and

easier for you to obtain technical support and service, and order

parts and accessories. In addition, you’ll be alerted to any important

information, like product updates and special offers.

To register, log on at www.midtronics.com/warranty.html and have

your serial number ready. The number is at the bottom of the label

on the back of the analyzer (Figure 1).

If your analyzer needs repair, call Midtronics Customer Service.

Servicing the analyzer yourself may void your warranty. Refer to the

Limited Warranty section of this manual.

Figure 1:

Serial Number Location

• 8 •

Chapter 2: Description

Chapter 2: Description

Every inTELLECT™ EXP model includes a handy, hard-sided, molded carrying case, as shown in

Figure 2.

with room for future options, so you can add to your EXP at any time.

Regardless of which conguration you choose, the carrying case will hold all accessories,

Printer batteries

Cable storage

Side-post

stud adapters

Amp clamp

Battery

test cable

Printer paper

Printer charger

Group 31

stud adapters

IR printer

inTELLECT EXP

Figure 2: Model EXP-1000 AMP KIT

• 9 •

Chapter 2: Description

Test Leads, Connectors, and Data Ports

For the cable test leads (Figure 5), there are two connectors on the top of the EXP (Figure 3).

• For the battery test cable, the EXP has a 6-pin connector with a locking ring.

• For the amp clamp and the multimeter test cables, the EXP has an accessories port, which

is a RJ45 connector with a release lever.

Figure 3: Top of EXP Figure 4: Bottom of EXP

IR data

transmitter

SD card slot

for future

upgrades

Accessories

port

6-pin

connector

IR temperature

sensor

DB-9

connector

for future

expandability

DMM cable with

clamps

Figure 5: Test Leads

Amp clamp

DMM cable

with probes

Battery

test cable

There are two IR data ports on the top of

the EXP (Figure 3).

• An IR data transmitter, w hich

transmits test results to the optional

IR printer.

• An IR temperature measurement

sensor.

The EXP also has a DB-9 connector for

future expandability and an SD card slot

for future software upgrades or data

logging. (Figure 4).

The EXP ships with an unprogrammable

card to protect the slot from dust and

debris.

• 10 •

Chapter 2: Description

Display and Keypad

The EXP keypad and display work together to help you quickly nd and use the right tools at the right

time. The display also keeps you on track with on-screen navigation aids, directions and messages.

Figure 6 shows how the elements on the screen relate to the keypad.

T h e I n t e r n a l B a t t e r i e s

Status Indicator, which appears

in the screen’s top left

corner, lets you know the

status and charge level

of the analyzer’s 6 1.5 V batter-

ies. The X shown in the gure

shows that the EXP is powered

by the battery you’re testing to

conserve the internal batteries.

Press the two Soft Keys linked

to the bottom of the screen to

perform the functions displayed

above them. The functions

change depending on the menu

or test process. So it may be

helpful to think of the words

appearing above them as part

of the keys. Some of the more

common soft-key functions are

SELECT, BACK, and END.

When you rst connect the EXP

to a battery it functions as a

voltmeter. The voltage reading appe ars

above the left

soft key until you move to other

menus or functions.

In some cases, you can use

the Alphanumeric Keypad to

enter numerical test parameters

instead of scrolling to them with

the ARROW keys.

You’ll also use the Alphanumeric Keys to create and edit

customer coupons. The keypad

includes characters for punctuation. To add a space, press the

RIGHT and LEFT ARROW keys

simultaneously.

The Title Bar shows you the

name of the current menu, test

tool, utility, or function.

Press the POWER button to

turn the EXP on and off. The

EXP also turns on automatically

when you connect its test leads

to a battery.

Whichever way you turn on the

EXP, it always highlights the icon

and setting you last used for

your convenience.

The Selection Area below the

Title Bar contains items you select or into which you enter information. The area also displays

instructions and warnings.

The Directional Arrows on the

display show you which Arrow

Keys to press to move to other

icons or screens. The Up

and Down Directional

Arrows, for example, let

you know to press the

UP and DOWN ARROW

keys to display the screens that

are above and below the current

screen.

The Left and Right Directional

Arrows let you know to use the

LEFT or RIGHT ARROW keys

to highlight an icon for selection.

Another navigational aid is the

Scroll Bar along the right side

of the screen. The position of its

scroll box tells you which menu

screen you’re viewing.

Scroll Bar

Scroll

Box

Top

or only

screen

Middle

screen

Last

screen

Figure 6: Main Menu and Keypad

• 11 •

Chapter 2: Description

Data Entry Methods

To perform a particular test or function, the EXP will ask for different types of information. This means

that the methods you use to enter information will change depending on the type of information requested. The four types of entry methods are described below.

Typically, the soft key below the right half of the screen conrms your choice, although the word above

it may vary. In Figure 7, for example, the word is SELECT; in Figures 8 and 9, NEXT; and in Figure 10,

SAVE. In a similar fashion, the soft key below the left half of the screen cancels your choice or returns

you to the previous screen, although the word above it may also vary.

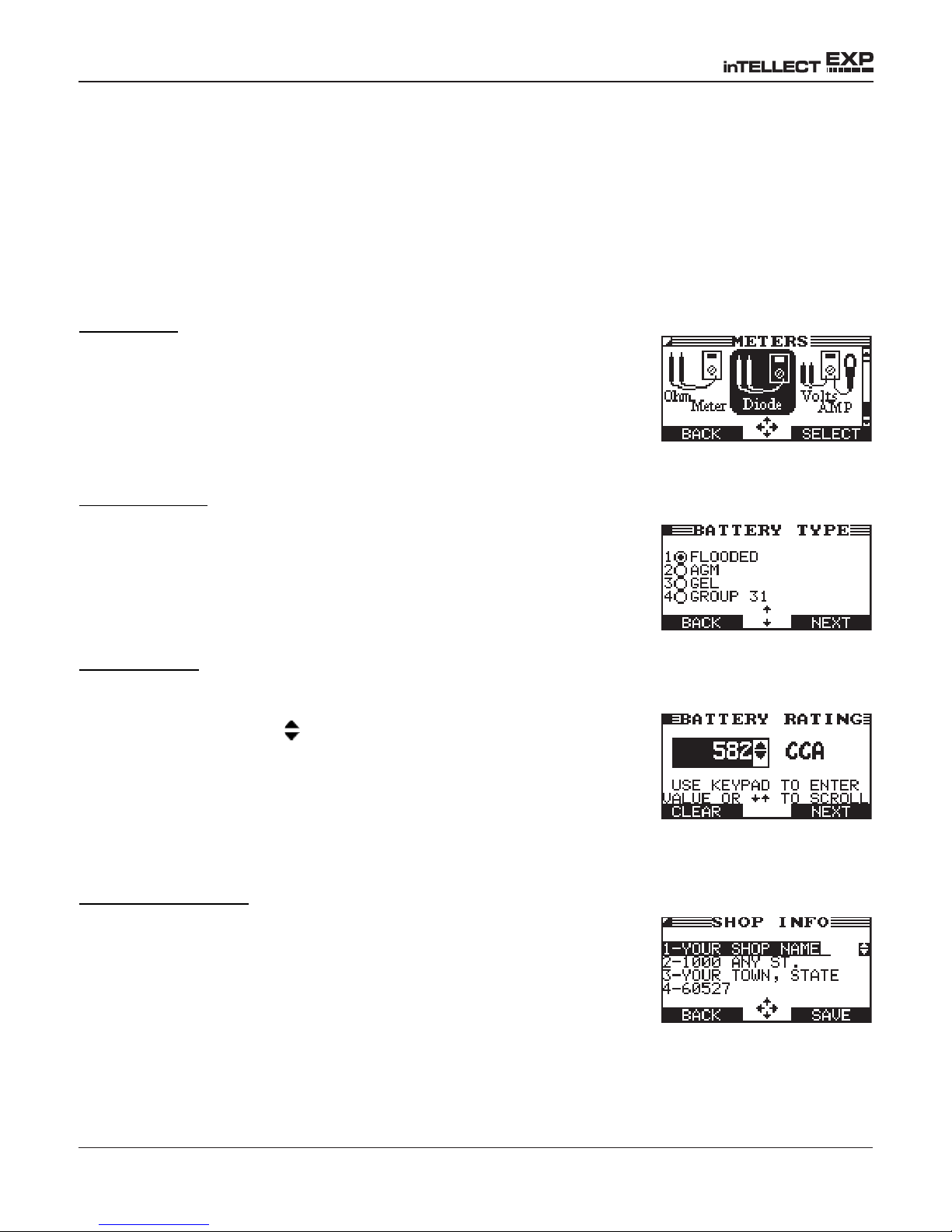

Menu icons

A menu icon is a graphical representation of a function you can select,

such as the Diode Icon in the DMM Menu. To select an icon, use the

LEFT or RIGHT ARROW key to highlight it. Highlighting changes the

icon to a white picture on a black background as shown in Figure 7. To

conrm your selection, press the appropriate soft key.

Figure 7: Highlighted Icon

Option Buttons

Some lists have option buttons before each item. To select an item, use

the UP/DOWN ARROW keys to move the dot into the button next to the

item you want. You can also use the alphanumeric keypad to enter the

number preceding the option button. To conrm your selection, press

the appropriate soft key.

Scrolling Lists

Scrolling lists contain items that extend above and below the screen

or the selection box that contains them. To indicate that there are

more items, the symbols appear to the right of the rst visible or

highlighted item on the list.

To select from this type of list, use the UP/DOWN ARROW keys to

scroll to the item, or use the keypad to enter your choice, and press

the appropriate soft key.

Alphanumeric Entry

Some selections require you to use the alphanumeric keypad. These

“user-dened” selections have a blinking horizontal line (cursor) to the

right of the last character (Figure 10).

Figure 8: Option Buttons

Figure 9: Scrolling List

Use the UP/DOWN ARROW keys to highlight a line for editing. Display

the character, symbol, or number you want by rapidly pressing its key

as many times as needed. If you pause, the cursor moves to the right.

To backspace, press the LEFT ARROW key. Use the RIGHT ARROW

key to add a space. Use the UP/DOWN ARROW keys to highlight a

line for editing. When nished, press the appropriate soft key to save

your settings.

Figure 10:

Alphanumeric Entry

• 12 •

Chapter 2: Description

Menu Maps

This section will help you get to your destination while letting you know what test leads you may need

when you arrive. The test leads are represented by symbols for their connectors.

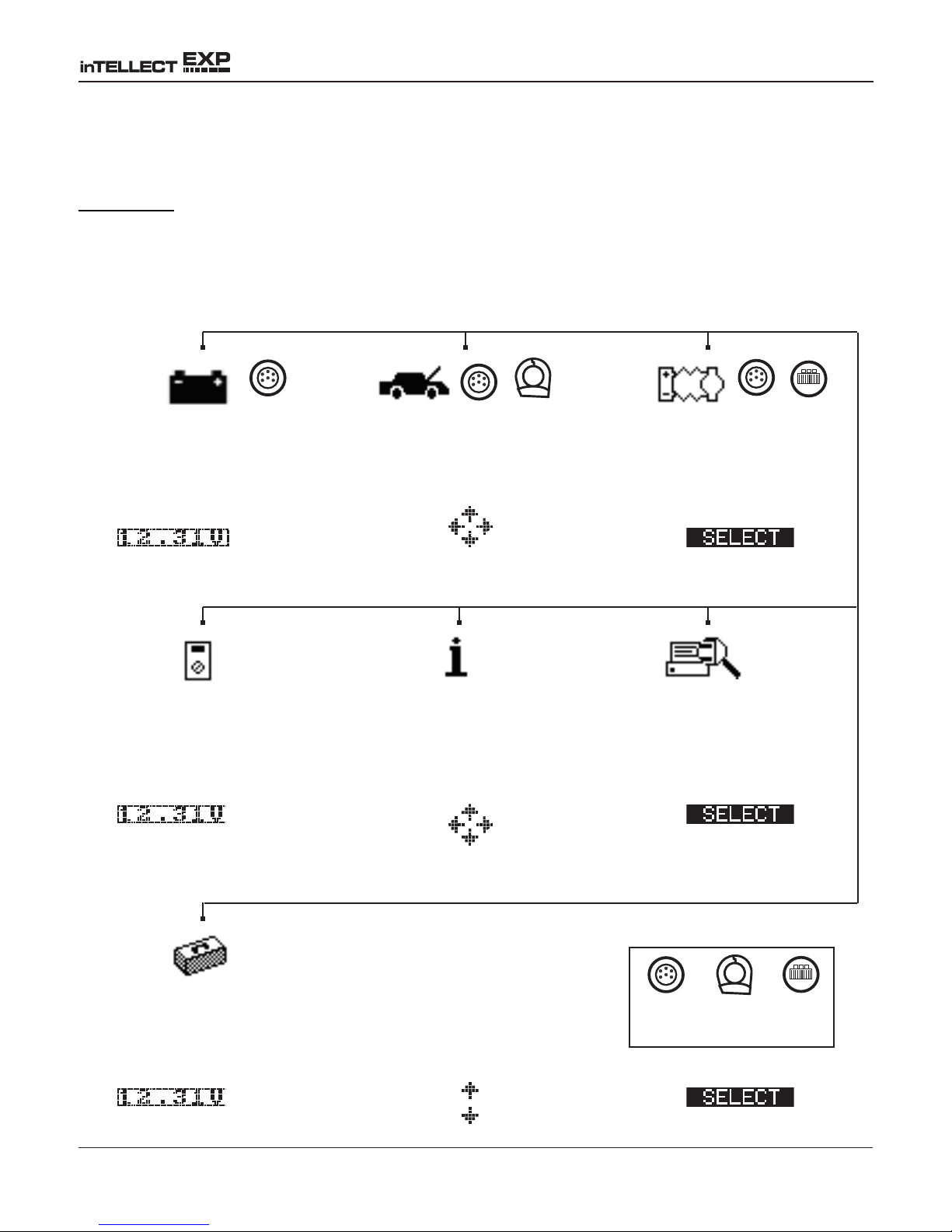

Main Menu

The Main Menu is the starting point for all tools and utilities, which are depicted as icons. Some icons

lead directly to the function they represent, while others are menu icons that lead to two or more

functions. Menu icons are marked here with an asterisk (*) and are mapped on the following pages.

MAIN MENU (Screen 1)

Optional

Tests a battery using

the battery information

you select in a series of

screens.

(voltmeter reading)

*

Digital multimeter with

8 test meters, a temperature sensor, and options

for clamps and probes.

(voltmeter reading) an icon

Tests a battery, and the

starting and charging

systems.

MAIN MENU (Screen 2)

* *

Includes a test counter,

data transfer utility, the

EXP software version

and serial number.

Tests both sides of a

circuit simultaneously

for voltage. Three preset

tests and 1 user-dened.

an icon

Enables you to view your

stored test results and

print them to an optional

IR printer.

Clamps

only

*

Nine utilities, many of

which customize your

user interface.

(voltmeter reading)

MAIN MENU (Screen 3)

• 13 •

Required test leads

Battery

test

Amp

clamp

an icon

Cable

drop

Chapter 2: Description

DMM Menu

The DMM Menu has icons for a temperature sensor and 8 test meters, some of which require different

test leads. The available leads depend on the EXP model purchased. The cable drop leads with

probes is an option that you can purchase separately.

Required test leads

Measures voltage within

a range of 0 to 60 Vdc.

to Main Menu

METERS (Screen 1)

Measures voltage within

a range of 0 to 24 Vac.

METERS (Screen 2)

Battery

test

Amp

clamp

DMM

clamps or

probes

Voltage trace with time

and frequency measurements.

an icon

Tests the strength of

the direct current flow

through a circuit.

to Main Menu

Tests a circuit for continuity and resistance

measured in ohms (Ω).

to Main Menu

Tests the strength of the

alternating current ow

through a circuit.

METERS (Screen 3)

Probes

only

Tests a diode for forward

voltage drop.

• 14 •

Sensor that displays temperature in degrees F

or C (units you can select

in the Utilities Menu.)

an icon

Measures two signals

simultaneously: DC voltage and amperage.

an icon

Chapter 2: Description

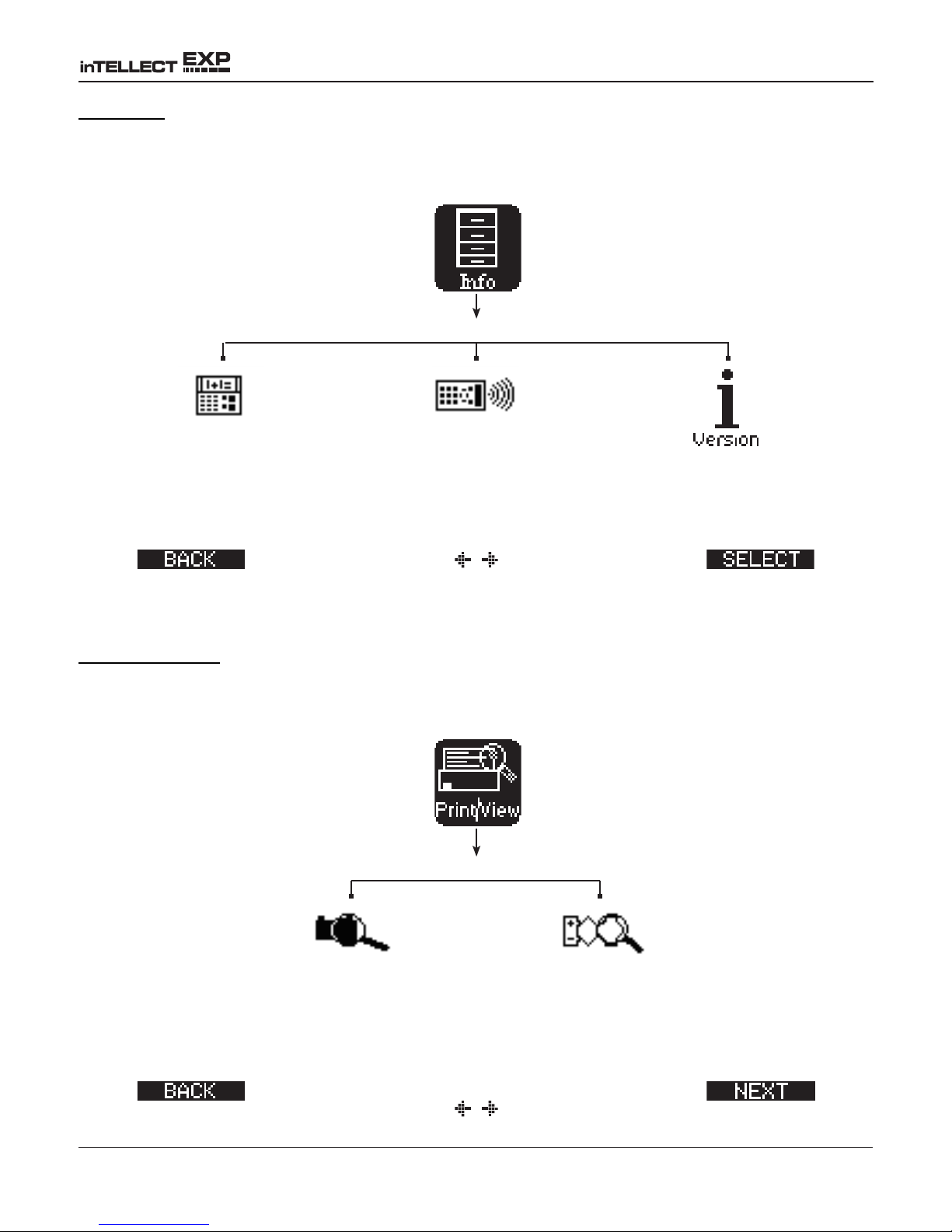

Info Menu

The Info Menu has three utilities to help you manage your test data, and track the usage and history

of your EXP analyzer.

REPORTS

Displays the total Battery and System Tests

performed since the EXP

was rst used.

to Main Menu an icon

An optional IR software

and hardware package

enables you to transfer

test data to a PC.

Displays the software

version, total tests from

rst use, and the serial

number.

Print/View Menu

The EXP stores the last battery, system, and cable test results in its memory until you perform another

test. To review or print results before you retest, select a test type in the Print/View Menu.

REPORTS

Displays the last Battery

and System Test results.

Sends the results to an

optional IR printer.

to Main Menu an icon

Displays the last Cable

Drop Test result. Sends

the result to an optional

IR printer.

• 15 •

Chapter 2: Description

Utilities Menu

The Utilities Menu lets you customize your analyzer to suit your needs. Before testing, check the

default values to see what options you may want to change.

SETUP (Screen 1)

Settings to adjust the

date and time.

Enables you to add a

custom header to printed

test results.

Settings to adjust the

screen contrast an d

backlight time.

to Main Menu an icon

SETUP (Screen 2)

If you’ve created a coupon in the Edit Coupon

utility, use Coupon to

Enables you to create a

coupon at the bottom of

printed test results.

Enables you to select

degrees C or F for temperature measurements.

turn it on and off.

to Main Menu an icon

SETUP (Screen 3)

Sets the language of the

display and printouts.

to Main Menu

Formas the SD card to

receive data. Also erases

all data on the card.

• 16 •

Updates the EXP soft-

ware using les on an

SD card.

an icon

Chapter 3: Test Preparation

Chapter 3: Test Preparation

Inspecting the Battery

Before starting the test visually inspect the battery for:

• Cracked, buckled, or leaking case. If you see any of these defects, replace the battery.

• Corroded, loose, or damaged cables and connections. Repair or replace them as

needed.

• Corrosion on the battery terminals, and dirt or acid on the case top. Clean the case and

terminals using a wire brush and a mixture of water and baking soda.

• Low electrolyte level. If the electrolyte level is too low, add distilled water to fill up to 1/2

above the top of the plates and fully charge the battery. Do not overfill.

• Corroded or loose battery tray and hold-down fixture. Tighten or replace as needed.

Testing Out-of-Vehicle

The preferred battery test location is in the vehicle. However, if you plan to test out of the vehicle:

• Always disconnect the negative cable from the battery first and reconnect it last.

• Always use a carry tool or strap to lift and transport the battery.

CAUTION: When testing side-post or group 31 batteries, always test using lead terminal adapters

provided with the EXP; do not test at the battery’s steel bolts. To avoid damage, never use a wrench

to tighten the adapters more than 1/4 turn. Failure to properly install lead terminal adapters, or using

adapters that are dirty or worn, may cause false test results.

Testing In-Vehicle

The preferred test position is at the battery posts. If you must test at a remote-post location, it should

have both a positive and negative post. Otherwise, you must remove the battery and perform an outof-vehicle test.

At the start of the test, make sure all vehicle accessory loads are off, the key is not in the ignition, and

the doors are closed.

Connecting the Battery Test Cable

CAUTION: Do not connect the EXP to a voltage source greater than 30 Vdc.

Connect the battery test cable to the EXP by rst aligning the cable connector’s 6 pins with the holes

on top of the EXP. Firmly insert the connector and tighten the locking ring.

Connect the clamps to the EXP: the red clamp to the positive (+) terminal and the black clamp to the

negative (–) terminal.

• 17 •

Chapter 3: Test Preparation

If you connect the clamps in the wrong polarity (positive to negative or negative to positive), the EXP

displays CLAMPS REVERSED! Reconnect the clamps.

To make sure both sides of the clamps are gripping the terminals, rock the each clamp back and forth.

A poor connection will prevent testing, and the EXP will display the message CHECK CONNECTION.

If the message reappears after you have correctly reconnected the clamps, clean the terminals and

reconnect.

Connecting an Accessory Cable

If you are using an accessory cable, plug it as you would a phone jack into the accessories port on

top of the EXP. It locks automatically into the port. To remove it after testing, press the lever and pull

the connector out.

Setting User Preferences

Before starting your test you may want to customize the use of your analyzer by setting preferences

in the Utility Menu. The menu has settings for the display’s date and time, the contrast and backlight

time, a utility to customize printouts for the optional IR printer, among others. The utilities are described

in Chapter 10.

To conserve the analyzer’s internal batteries, the EXP will turn off after 30 seconds of

inactivity.

• 18 •

Chapter 4: Battery Test

Chapter 4: Battery Test

The EXP will guide you through the steps of selecting your battery test parameters and interpreting the

results. Before you start the test, review the instructions in Chapter 3: Test Preparation.

1. Select the battery LOCATION.

1 OUT OF VEHICLE

2 IN VEHICLE

Press the NEXT soft key to continue. The BACK soft key returns you to the Main Menu at the

start of the test and to the previous screen as you progress.

2. Select the POST TYPE. The REMOTE option appears for the IN VEHICLE test.

1 TOP

2 SIDE

3 REMOTE

Press the NEXT soft key to continue.

3. Select the BATTERY TYPE.

1 REGULAR/AUTO

2 AGM

3 AGM/SPIRAL

4 GEL

Press the NEXT soft key to continue.

4. Select the battery’s capacity rating standard. The standard, and the rating units required

in step 5, are printed on the battery label. If the information is unreadable, contact the

battery manufacturer.

1 CCA

2 CA

3 MCA

4 JIS

5 DIN

6 SAE

7 IEC

8 EN

Press the NEXT soft key to continue.

• 19 •

Chapter 4: Battery Test

5. Press the UP/DOWN ARROW keys or use the numeric keys to select the

RATING UNITS or in the case of JIS, the part number. To increase your

scrolling speed, hold down the UP or DOWN ARROW key.

The default selection is 500 for all rating standards except JIS, which consists of part

numbers. The entry range is 100 to 3000 except for DIN and IEC, which has a range of

100 to 1000. If you scroll the values they increase and decrease by 5 units.

Press the NEXT soft key to start the test.

For the next few seconds the EXP will display the word TESTING and a stopwatch while

it evaluates the battery. The analyzer will also display your selected rating standard and

units or JIS part number.

Additional Test Requirements

For a more decisive result the EXP may ask for additional information or probe deeper into the

battery’s condition. The following messages and instructions may appear before the analyzer displays

the results of your test.

Temperature Compensation

Figure 11: Temperature Message

If the analyzer detects that the temperature of the battery

may make a difference in the result, it will ask you to

measure the battery’s temperature with the analyzer’s

built-in temperature sensor.

The sensor is located in the top left corner of the EXP.

An arrow moving diagonally across the display will show

you how to angle the EXP so that the sensor is pointed

directly at the battery.

Press the NEXT soft key to continue.

Battery Case

(Top)

Sensor

Aim the EXP

2 inches (5 cm)

from the sides

or top of the

battery case.

Figure 12:

Aiming the Temperature Sensor

Surface Noise/Unstable Battery

The battery will hold a surface charge if the engine has been running or after the battery has been

charged. The analyzer may prompt you to remove the surface charge before it begins testing.

1. Follow the EXP’s instructions indicating when to turn the headlights on and off.

2. The analyzer will resume testing after it detects that the surface charge is removed.

• 20 •

Chapter 4: Battery Test

Deep Scan Test

In some cases the EXP may need to further analyze the battery to determine whether the battery

should be replaced or it has a signicant chance to be recovered. It will then conduct a Deep Scan

Test of the battery for a few seconds.

TESTING

DEEP SCAN TECHNOLOGY

PLEASE WAIT . . . . . . . . . .

After the Deep Scan Test the EXP will either display the results or give you the option to perform the

5-Minute Discharged Battery Test. Although this test takes several minutes, it gives a more precise

result for difcult-to-diagnose batteries. The decision tree of the test is shown below.

RESULTS

DO YOU WANT TO RUN

THE 5 MINUTE

DISCHARGED BATTEY

TEST?

YESNO

BATTERY CHARGE

1 BEFORE CHARGING

2 AFTER CHARGING

PERFORM TEST

( S e e C h a p t e r 6 :

5 Minute Discharged

Battery Test)

NEXT

For a more decisive result,

the analyzer may ask if you

are testing the battery before

TESTING

or after charging.

If the vehicle has just been

driven, select BEFORE

CHARGE. Press the NEXT

soft key to continue.

BATTERY

TEST

RESULTS

Figure 13: Deep Scan Test and Decision Tree

The next section describes the battery test decisions and suggests actions to take.

• 21 •

Chapter 4: Battery Test

Battery Test Results

After the test the EXP will display one of ve battery decisions with the complete results in a series of

screens as shown in Figure 14. Use the UP/DOWN ARROW keys to scroll through each result. To send

the results to an IR printer, press the PRINT soft key. To return to the Main Menu, press the END soft

key, or to continue testing if you’ve selected the system text, press the NEXT soft key. You’ll have the

opportunity to print all the results at the end of the system test.

Measured voltage

Battery decision

A temperature measurement is

displayed here if the EXP has

required you to measure battery

temperature

General health of the battery

and its ability to deliver its

specified performance compared with a new battery

Measured c a p a c i t y

rating units

Ra t i ng un i t s you

selected for the test

Battery’s state of charge

Figure 14: Good Battery Result

Table 1: Battery Decisions and Recommendations

Decision Recommended Action

GOOD BATTERY Return the battery to service.

GOOD–RECHARGE Fully charge the battery and return it to service.

CHARGE & RETEST * Fully charge the battery and retest. Failure to fully charge the battery

before retesting may cause false readings. If CHARGE & RETEST

appears again after you fully charge the battery, replace the battery.

REPLACE BATTERY ** Replace the battery and retest. A REPLACE BATTERY result may also

mean a poor connection between the battery cables and the battery.

After disconnecting the battery cables, retest the battery using the outof-vehicle test before replacing it.

BAD CELL–REPLACE ** Replace the battery and retest.

* If the result is CHARGE & RETEST, the EXP will calculate and display the time needed to

charge the battery at 10, 20, and 40 A.

** When testing at the remote posts, the EXP may need to verify the result. It will give you the

option of retesting at the battery posts.

• 22 •

Chapter 5: 5-Minute Discharged Battery Test

Chapter 5: 5-Minute Discharged Battery Test

This test is an out-of-vehicle dynamic response test in which a deeply-discharged battery can be

diagnosed in minutes instead of the hours needed to charge it. The EXP displays the option to perform

the test after a deep scan and before it arrives at the battery decision. You can also perform a dynamic

response test during the in-vehicle System Test using the vehicle’s charging system to apply the

charging current.

The test requires an:

• External high-current charger

• Amp clamp

Test Routine

1. Have your amp clamp ready and select AMP CLAMP AVAILABLE.

1 AVAILABLE

2 NOT AVAILABLE

Press the NEXT soft key to continue.

2. Select charge current rate of the battery charger you will use for this test.

15 (10–60)

Press the NEXT soft key to continue.

3. Disconnect the analyzer’s clamps from the battery posts.

4. Make sure the charger’s power cord is disconnected and the power switch in the OFF

position.

5. Connect the charger’s clamps to the battery posts: red lead to the positive (+) terminal,

black lead to the negative (–) terminal.

6. Reconnect the analyzer’s clamps to the battery posts. Rock them back and forth so they

make good contact.

7. Connect the amp clamp to the EXP, and remove the clamp from any cables or wires.

8. Press the NEXT soft key to zero out the clamp.

9. Place the amp clamp around the negative (–) battery cable of the charger.

10. Plug in the charger’s power cord and turn on the charger.

• 23 •

Chapter 5: 5-Minute Discharged Battery Test

The EXP will begin testing while the charger applies the charge current to the battery. After the

initial boost charge, the EXP will count down the test time in minutes and seconds.

CAUTION: Do not leave the battery unattended while the charger is in operation.

!

11. When the test is finished, the EXP will ask you to turn off the charger and disconnect

the charger and analyzer clamps.

12. Reconnect the EXP clamps to the battery posts and press the NEXT softkey to display

the battery results (Table 1).

• 24 •

Chapter 6: System Test

Chapter 6: System Test

Before starting the test, inspect the alternator drive belt. A belt that is glazed or worn, or lacks the

proper tension, will prevent the engine from achieving the rpm levels needed for the test.

The System Test includes 3 tests that provide a complete diagnosis of the vehicle’s electrical system:

• BATTERY TEST

• STARTER TEST

• ALTERNATOR TEST

The System Test includes the option of using an amp clamp.

You also have the option of viewing or printing the results at the end of each test, or at the end of the

entire test sequence.

Battery Test

The System Test includes a test of the battery to eliminate it as the cause of starting or charging

problems. See Chapter 4 for the Battery Test procedure.

If the EXP determines that the battery needs assistance to start the vehicle, it will prompt you to begin

the Jump Start routine described in Chapter 8.

Starter Test

If you are using the amp clamp, keep it clamped around the negative (–) battery cable.

1. Start the engine at the prompt.

2. The EXP will display one of 1 of 7 starter decisions (Table 2) with the complete results in

a series of screens as shown in Figure 15. Use the UP/DOWN ARROW keys to scroll to

each screen.

To send the results to an IR printer, press the PRINT soft key. To continue testing, press

the NEXT soft key.

NOTE: In some cases, the EXP may not detect the vehicle’s starting prole. It will dis-

play the soft key options STARTED and NO START. If you select STARTED, the EXP will

skip to the alternator test. If you select NO START, the test process ends.

• 25 •

Chapter 6: System Test

Starter System Test Results

Average cranking voltage

Loop ohms (starter

lo o p res i s tan c e )

displa y ed if a m p

clamp used

Y axis = System performance: cranking

voltage

Y axis = System performance: Cranking

current is displayed if

amp clamp is used

Average cranking current if

amp clamp is used

Cranking time in

milliseconds

X axis = Time

X axis = Time

Figure 15: Normal Cranking Result

Table 2: Starter System Decisions and Recommendations

Decision Action

CRANKING NORMAL The starter voltage is normal and the battery is fully charged.

LOW VOLTAGE The starter voltage is low and the battery is fully charged.

CHARGE BATTERY The starter voltage is low and the battery is discharged. Fully charge the

battery and repeat the starter system test.

REPLACE BATTERY (If the battery test result was (REPLACE or BAD CELL.) The battery must

be replaced before testing the starter.

LOW CRANKING AMPS The starter voltage is high but the cranking amps are low.

NO START The engine didn’t start and the test was aborted.

CRANKING SKIPPED The EXP didn’t detect the vehicle’s starting prole and skipped the Starter

Test.

• 26 •

Chapter 6: System Test

Alternator Test

1. ANALYZING CHARGING SYSTEM DATA: After you press the NEXT soft key to begin the

alternator test, the EXP will immediately begin testing for alternator voltage.

2. TURN ALL VEHICLE LOADS OFF, IDLE ENGINE: Turn off vehicle loads (blowers, interior

light, radio, etc.) and idle the engine. Press the NEXT soft key to continue.

NOTE: If necessary the analyzer will ask if you are testing a diesel engine. It will

resume testing after you make your selection.

3.

REV ENGINE WITH LOADS OFF FOR 5 SECONDS: Rev the engine with the loads off.

Gradually increase the rpm until the analyzer tells you to HOLD the rev level as the bar on

the display crosses the rpm target line.

NOTE: Some 8-cylinder and older vehicles idle at a high level after starting, allowing the

analyzer to detect the rev automatically.

4. ACQUIRING DATA....HOLD ENGINE RPM: Continue to hold the rpm while the EXP takes

system measurements.

5. ENGINE REV DETECTED, IDLE ENGINE: The EXP has detected the rev. Press the

NEXT soft key to continue.

6.

TESTING ALTERNATOR AT IDLE, LOADS OFF: The analyzer will next test the engine

at idle for comparison to other readings, and then test the diode ripple. Excessive ripple

usually means one or more diodes have failed in the alternator or there is stator damage.

7.

TURN HIGH BEAMS AND BLOWER MOTOR ON, IDLE ENGINE: After a few seconds, the

EXP will ask you to turn on the accessory loads. It will determine if the charging system is

able to provide enough current for the demands of the electrical system.

IMPORTANT: Turn on the high-beam headlights, the blower to high and the rear defogger.

Don’t use cyclical loads such as air conditioning or windshield wipers.

8. TESTING ALTERNATOR AT IDLE, LOADS ON: The analyzer will determine if the charging

system is able to provide sufficient current for the demands of the vehicle’s electrical

system.

9. REV ENGINE WITH LOADS ON FOR 5 SECONDS: The EXP will test the charging system

with the loads on and prompt you to rev the engine. Gradually increase the rev until the

analyzer tells you to HOLD the rev level as the bar on the display crosses the rpm target

line.

10. ACQUIRING DATA....HOLD ENGINE RPM: Continue to hold the rpm while the EXP takes

system measurements.

• 27 •

Chapter 6: System Test

11. ENGINE REV DETECTED, IDLE ENGINE: The EXP has detected the rev. Press the

NEXT soft key to continue.

12. ANALYZING CHARGING SYSTEM DATA: The EXP is completing its final analysis of

the charging system data.

13. TURN OFF LOADS AND ENGINE: Press the NEXT soft key to display the results.

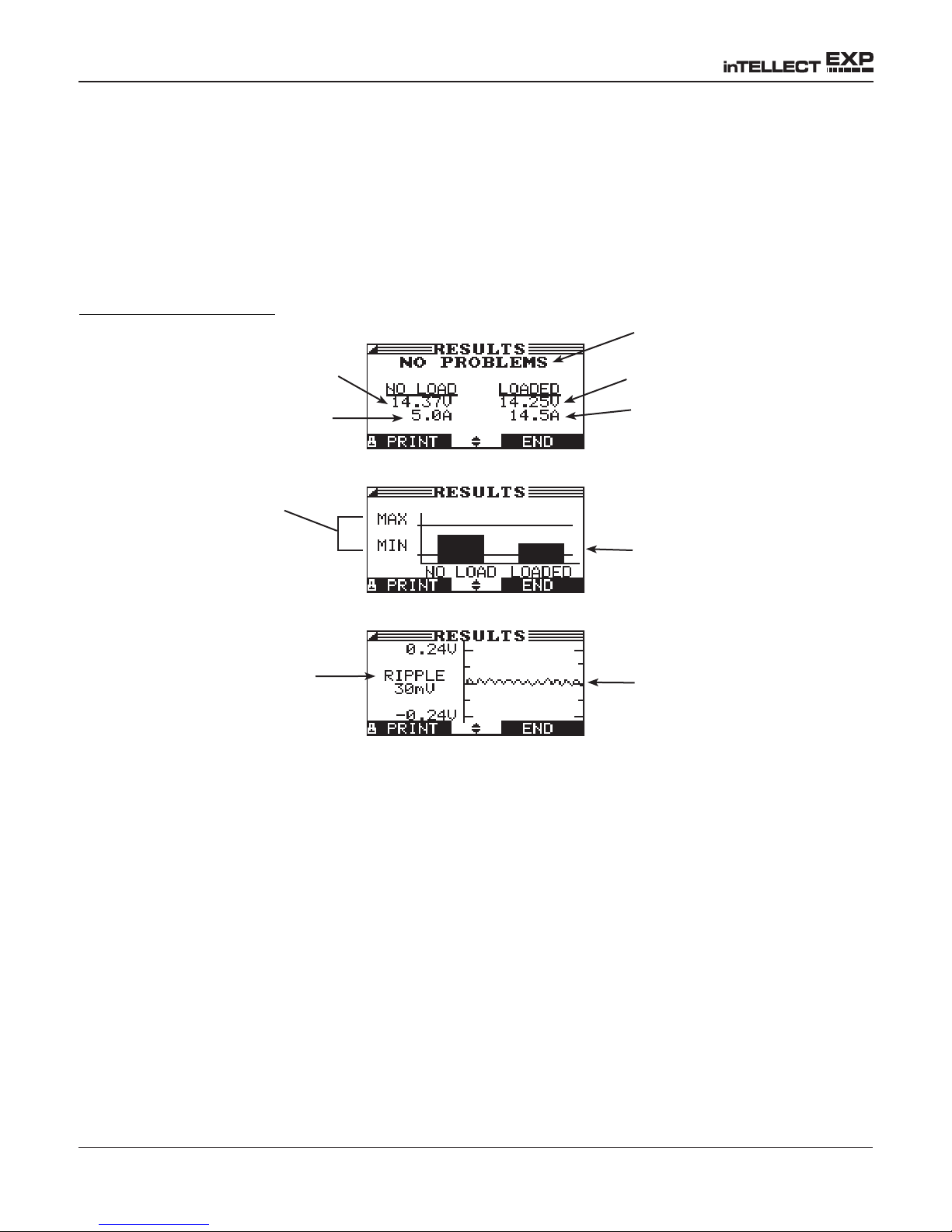

Alternator Test Results

Alternator decision

Loads-off DC voltage at rev

Loads-off current at rev

if amp clamp is used

Normal DC voltage range

Peak-to-peak AC voltage

Figure 16: NO PROBLEMS Alternator Result

Loads-on DC voltage at rev

Loads-on current at rev if amp

clamp is used

Bar graph showing DC

voltage within normal range

with loads on and off

Graph of diode waveform

• 28 •

Chapter 6: System Test

Table 3: Alternator Decisions and Recommendations

Decision Action

NO PROBLEMS The system is showing normal output from the alternator. No problem detected.

NO OUTPUT The alternator is not providing charging current to the battery.

√ Check the belts to ensure the alternator is rotating with the engine running.

Replace broken or slipping belts and retest.

√ Check all connections to and from the alternator, especially the connection

to the battery. If the connection is loose or heavily corroded, clean or replace

the cable and retest.

√ If the belts and connections are in good working condition, replace the alterna-

tor. (Older vehicles use external voltage regulators, which may require only

replacement of the voltage regulator.)

LOW OUTPUT The alternator is not providing enough current to power the system’s electrical

loads and charge the battery.

√ Check the belts to ensure the alternator is rotating with the engine running.

Replace broken or slipping belts and retest.

√ Check the connections from the alternator to the battery. If the connection is

loose or heavily corroded, clean or replace the cable and retest.

HIGH OUTPUT The voltage output from the alternator to the battery exceeds the normal

limits of a functioning regulator.

√ Check to ensure there are no loose connections and that the ground connection

is normal. If there are no connection problems, replace the regulator. (Most

alternators have a built-in regulator requiring you to replace the alternator. In

older vehicles that use external voltage regulators, you may need to replace

only the voltage regulator.)

The regulator controls voltage output based on the battery voltage, underhood temperature, and vehicle loads used. In other words, it controls the

maximum voltage the system can produce based on the current needs and

amount of current that can be produced by the spinning of the rotor in the

alternator. The normal high limit of a typical automotive regulator is 14.5

volts +/–0.5. Refer to the manufacturer specifications for the correct limit,

which may vary by vehicle type.

A high charging rate will overcharge the battery and may decrease its life and

cause it to fail. If the battery test decision is REPLACE and the charging system

test shows a HIGH OUTPUT, check the battery’s electrolyte levels. A symptom

of overcharging is battery uid spewing through the vent caps, which causes low

electrolyte levels and will harm the battery.

• 29 •

Chapter 6: System Test

Table 4: Diode Decisions and Recommendations

Decision Action

EXCESSIVE RIPPLE One or more diodes in the alternator aren’t functioning or there’s stator

damage, which is shown by an excessive amount of AC ripple current

supplied to the battery.

√ Make sure the alternator mounting is sturdy and that the belts are in

good shape and functioning properly. If the mounting and belts are

good, replace the alternator.

OPEN PHASE The EXP has detected an open phase within the alternator. Replace the

alternator.

OPEN DIODE The EXP has detected a open diode within the alternator. Replace the

alternator.

SHORTED DIODE The EXP has detected an shorted diode within the alternator. Replace the

alternator.

• 30 •

R

Battery

Battery Test Lead

DMM Test Lead

Component

Under

Test

1

R

2

+

–

Red Red

Black Black

Chapter 7: Cable Drop Test

Chapter 7: Cable Drop Test

If the test results for the starter or charging systems indicate that there may be a problem, you may want

to perform the Cable Drop Test to determine if it is due to worn cables or bad connections between the

battery and the alternator or starter. Worn cables or bad connections create higher resistance, which

causes a drop across the circuit. The voltage drop reduces current carrying capability that displays the

same symptoms as a weak alternator or starter and causes premature battery failure.

There’s no need to run the engine. The Cable Drop Test uses Midtronics’ conductance technology to

send a signal through the circuit at the component under test. The EXP then simultaneously calculates

voltage drop on the positive (+) and negative (–) sides of any circuit as well as the total voltage drop.

The amperage range for each of the four tests is 0 to 1000 A. When you change the setting from the

factory defaults, the EXP will store your setting in memory for your next test.

There are three preset tests:

• BATTERY GROUND

• STARTER CIRCUIT

• ALTERNATOR CIRCUIT

A fourth test, OTHER CIRCUIT, tests other grounds and circuits against your specied amperage

capacity.

The test requires two test lead connections, as shown in Figure 17:

• Battery test leads at the component’s output lead (the B+ or output screw on the

alternator) and the component’s housing as ground

• DMM test leads at the battery terminals

NOTE: The test requires a complete circuit. If you’re testing a system with a remote

solenoid, you can test from the battery to the solenoid, but not from the battery to the

starter.

Figure 17: Connections for the Cable Drop Test

• 31 •

Chapter 7: Cable Drop Test

To begin, select the Cable Drop Test icon in the Main Menu and follow the instructions on the

display.

IMPORTANT: For accurate results the battery should be good and fully charged before

you perform a test.

Battery Ground Test

The Battery Ground Test measures the voltage drop for the ground strap.

1. SELECT CIRCUIT: Use the UP/DOWN ARROWS or the numerical keypad to select the

Battery Ground Test.

1 BATTERY GROUND

2 STARTER CIRCUIT

3 ALT CIRCUIT

4 OTHER

Press the NEXT soft key to continue.

2. SET AMPS: Use the UP/DOWN ARROWS or the keypad to select the rated amperage of

the circuit you are testing. The default is 80 A.

Press the NEXT soft key to continue.

3. Connect the main clamps (battery test leads) to the battery and ground: positive (+)

clamp to the battery’s positive post; negative (–) clamp to the vehicle chassis.

4. Connect the DMM cable to the battery posts: positive (+) clamp to the positive post;

negative clamp (–) to the negative post.

For the next few seconds the EXP will display the word TESTING and a stopwatch

while it evaluates the battery ground.

Battery Ground Test Results

Total circuit voltage drop

Decision

Figure 18: Battery Ground Test PASS Result

Voltage drop across

positive side of circuit

Voltage drop across

negative side of circuit

If there is a problem, the decision is CLEAN AND RETEST OR REPLACE. To print the results, align

the EXP’s IR transmitter with the printer’s receiver, and select the PRINT soft key. To return to the Main

Menu, press the END key.

• 32 •

Chapter 7: Cable Drop Test

Starter Circuit

The Starter Circuit Test measures the voltage drop of the starter circuit.

1. SELECT CIRCUIT: Use the UP/DOWN ARROWS or the numerical keypad to select

STARTER CIRCUIT.

1 BATTERY GROUND

2 STARTER CIRCUIT

3 ALT CIRCUIT

4 OTHER

Press the NEXT soft key to continue.

2. SET AMPS: Use the UP/DOWN ARROWS or the keypad to select the rated amperage of

the starter circuit. The default is 150 A.

Press the NEXT soft key to continue.

3. Connect the positive (+) clamp of the battery test leads to the starter’s battery terminal

stud. Connect the negative (–) clamp to the starter’s housing.

4. Connect the positive (+) DMM clamp to the battery’s positive (+) post. Connect the

negative clamp (–) to the battery’s (–) negative post.

For the next few seconds the EXP will display the word TESTING and a stopwatch

while it evaluates the battery ground.

Starter Circuit Test Results

Total circuit voltage drop

Decision

Figure 19: Starter Circuit PASS Result

If there is a problem, the decision is CLEAN AND RETEST OR REPLACE. To print the results, align

the EXP’s IR transmitter with the printer’s receiver, and select the PRINT soft key. To return to the Main

Menu, press the END key.

Voltage drop across

positive side of circuit

Voltage drop across

negative side of circuit

• 33 •

Chapter 7: Cable Drop Test

Alternator Circuit

The Alternator Circuit Test measures the voltage drop of the alternator circuit.

1. SELECT CIRCUIT: Use the UP/DOWN ARROWS or the numerical keypad to select ALT

CIRCUIT.

1 BATTERY GROUND

2 STARTER CIRCUIT

3 ALT CIRCUIT

4 OTHER

Press the NEXT soft key to continue.

2. SET AMPS: Use the UP/DOWN ARROWS or the keypad to select the rated amperage of

the alternator circuit. The default is 80 A.

Press the NEXT soft key to continue.

3. Connect the positive (+) clamp of the battery test leads to the alternator’s output stud

(B+). Connect the negative (–) clamp to the alternator’s housing.

4. Connect the positive (+) DMM clamp to the battery’s positive (+) post. Connect the

negative clamp (–) to the battery’s (–) negative post.

For the next few seconds the EXP will display the word TESTING and a stopwatch

while it evaluates the battery ground.

Alternator Circuit Test Results

Total circuit voltage drop

Decision

Figure 20: Alternator Circuit PASS Result

If there is a problem, the decision is CLEAN AND RETEST OR REPLACE. To print the results, align

the EXP’s IR transmitter with the printer’s receiver, and select the PRINT soft key. To return to the Main

Menu, press the END key.

Voltage drop across

positive side of circuit

Voltage drop across

negative side of circuit

• 34 •

Chapter 7: Cable Drop Test

Other Circuit

This test enables you to measure voltage drop across other components.

1. SELECT CIRCUIT: Use the UP/DOWN ARROWS or the numerical keypad to select the

OTHER.

1 BATTERY GROUND

2 STARTER CIRCUIT

3 ALT CIRCUIT

4 OTHER

Press the NEXT soft key to continue.

2. SET AMPS: Use the UP/DOWN ARROWS or the keypad to select the rated amperage of

the circuit you are testing. The default is 10 A.

Press the NEXT soft key to continue.

3. Connect the positive (+) clamp of the battery test leads to the component’s positive

terminal (+). Connect the negative (–) clamp to the component’s negative (–) terminal.

4. Connect the positive (+) DMM clamp to the battery’s positive (+) post. Connect the

negative clamp (–) to the battery’s (–) negative post.

For the next few seconds the EXP will display the word TESTING and a stopwatch

while it evaluates the battery ground.

Other Circuit Test Results

Total circuit voltage drop

Voltage drop across

Decision

Figure 21: Other Circuit PASS Result

If there is a problem, the decision is CLEAN AND RETEST OR REPLACE. To print the results, align

the EXP’s IR transmitter with the printer’s receiver, and select the PRINT soft key. To return to the Main

Menu, press the END key.

positive side of circuit

Voltage drop across

negative side of circuit

• 35 •

Chapter 8: Jump Start (System Test)

Chapter 8: Jump Start (System Test)

The EXP’s Jump Start routine assists a discharged battery so that you can complete the Starter Test

portion of the System Test.

1. When the JUMP START instruction screen is displayed, disconnect the analyzer’s clamps

from the battery posts.

2. Make sure the charger’s power cord is disconnected and the power switch in the OFF

position.

3. Connect the charger’s clamps to the battery posts: red lead to the positive (+) terminal,

black lead to the negative (–) terminal.

4. Reconnect the analyzer’s clamps to the battery posts. Rock them back and forth so they

make good contact.

5. Turn on the booster pack or charger.

6. The EXP will monitor the level of the battery’s voltage for a maximum of 30 seconds.

7. When the time counts down to 0 seconds or the battery voltage is sufficient, the EXP will

instruct you to start the engine.

8. The EXP will display the Starter Test results (See Table 2).

9. Disconnect the booster pack or battery charger.

The EXP will continue with the alternator test.

• 36 •

Chapter 9: Digital Multimeter

Chapter 9: DMM (Digital Multimeter)

The EXP’s 8 digital meters make it versatile enough to test everything from a vehicle’s entire electrical

system to a board-level component:

• DC Voltmeter

• AC Voltmeter

• Scope

• DC Ammeter

• AC Ammeter

• Ohmmeter

• Diode Drop

• Volts/Amp

The DMM’s infrared temperature sensor also enables you to determine the surface temperature of

components before you service them or as a diagnostic aid. Specications for each tool are listed at

the end of this chapter in Table 5.

Select the DMM icon to display its METERS menu. The tools in this menu are available in a series of

three screens.

A measurement that is out of the limit displays as OL. Refer to the manufacturer specications for the

correct limits, which may vary by component or vehicle type.

DC Volts

The DC voltmeter measures voltage between two points in a circuit. The voltmeter is connected in

parallel with the circuit.

1. Connect the DMM test lead to the EXP’s accessories port.

2. Select the meter’s icon.

3. Connect the clamps or probes in the correct polarity: red clamp or probe to positive (+);

black to negative (–).

4. The meter will autorange and display the measurement.

5. To return to the METERS menu, press the END soft key.

• 37 •

Chapter 9: DMM (Digital Multimeter)

AC Volts

The AC voltmeter measures the AC volts between two points in a circuit. The voltmeter is connected

in parallel with the circuit.

1. Connect the DMM test lead to the EXP’s accessories port.

2. Select the meter’s icon.

3. Connect the clamps or probes in the correct polarity: red clamp or probe to positive (+);

black to negative (–).

4. The meter will autorange and display the measurement.

5. To return to the METERS menu, press the END soft key.

Scope

The scope is a voltmeter that provides a graph of voltage difference as it varies over time. After you

select the scope icon, note the instructions in the next screen before proceeding. You’ll need the them

after you press the SELECT soft key to continue:

• Press 1 on the keypad to autoscale the scope.

• Press 3 on the keypad for the time display.

• Press 4 on the keypad for the FFT (frequency) display.

Press the SELECT soft key to continue.

In the time display the horizontal axis is in seconds and the vertical axis is in volts.

In the frequency display the horizontal axis is in hertz and the vertical axis is in volts.

Press the right soft key to alternate between the options to RUN (measure and display the signal) and

HOLD (freeze the signal).

The scope enables you to print the voltage trace to the optional IR printer when you freeze the signal.

Align the EXP’s IR transmitter with the printer’s receiver, and select the PRINT soft key.

To return to the METERS menu, press END.

• 38 •

Chapter 9: Digital Multimeter

DC AMP (requires the optional amp clamp)

The DC ammeter measures DC magnitude and ow of the DC current in a circuit.

1. Connect the amp clamp lead to the EXP’s accessories port.

2. Select the meter’s icon.

3. Select the amp clamp range.

1 70 AMP MAX.

2 700 AMP MAX.

Press the NEXT soft key to continue.

4. The meter will zero itself.

5. Place the clamp’s jaws around the negative (–) cable.

6. The EXP will display the measurement.

7. To return to the METERS menu, press the END soft key.

AC AMP (requires the optional amp clamp)

The DC ammeter measures the magnitude and ow of the AC current through a circuit during normal

operations.

1. Connect the amp clamp lead to the EXP’s accessories port.

2. Select the meter’s icon.

3. Select the amp clamp range.

1 70 AMP MAX.

2 700 AMP MAX.

Press the NEXT soft key to continue.

4. The meter will zero itself.

5. Place the clamp’s jaws around the negative (–) cable.

6. The EXP will display the measurement.

7. To return to the METERS menu, press the END soft key.

• 39 •

Chapter 9: DMM (Digital Multimeter)

Temp

The IR temperature sensor measures surface temperature within a range of –20 to 200 °C. The tool

can be used for checking the transmission for overheating, and the temperature levels of the heater

and air conditioner. Figure 12 shows how to aim the EXP’s temperature sensor at a component you

are testing.

Ohm Meter

The meter is connected in parallel with the circuit under test and uses the power supplied by the EXP’s

internal batteries to detect open or excessive resistance.

CAUTION: Always remove power from the circuit before connecting the ohmeter to avoid damaging

the analyzer.

1. Connect the DMM test lead to the EXP’s accessories port.

2. Select the meter’s icon.

3. Connect the clamps or probes in the correct polarity: red clamp or probe to positive (+);

black to negative (–).

4. The meter will autorange and display the measurement.

5. When finished, press the END soft key.

6. To return to the METERS menu, press the END soft key.

Diode

This test measures the voltage drop across components, such as diodes.

1. Connect the probes test lead to the EXP’s accessories port.

2. Select the meter’s icon.

3. Connect the probes in the correct polarity: red clamp or probe to positive (+); black to

negative (–).

4. The meter will autorange and display the measurement.

5. When finished, press the END soft key.

• 40 •

Volts/Amp (requires the optional amp clamp)

Chapter 9: Digital Multimeter

The volts/amp meter simultaneously

measures charging voltage and charging current.

1. Connect the amp clamp lead to the EXP’s accessories port.

2. Select the meter’s icon.

3. Select the amp clamp range.

1 70 AMP MAX.

2 700 AMP MAX.

Press the NEXT soft key to continue.

4. The meter will zero itself and display the amperage and voltage measurements.

5. Place the clamp’s jaws around the negative (–) cable.

6. Connect the battery test cable to the EXP.

7. Connect the battery test clamps in the correct polarity: red clamp or probe to positive (+);

black to negative (–).

8. The EXP will display the measurement.

9. To return to the METERS menu, press the END soft key.

• 41 •

Chapter 9: DMM (Digital Multimeter)

Table 5: EXP Multimeter Specications

The accuracy specication is dened as ± (n% reading + [count

resolution]) at 77 °F.

*

Vdc

Range Resolution Accuracy Overload Protection

0–60 V 0.01 V 0.05% + 2 120 Vrms

Accuracies are specied from 2% to 100% of range.

Vac

Range Resolution Accuracy Overload Protection

0–24 Vac rms 0.01 Vac 0.1% + 3 120 Vrms

Accuracies are specied from 2% to 100% of range.

Adc

Range Resolution Accuracy Overload Protection

0–70 A 0.01 A ± 3% of reading ± 1A 1000 Arms

0–700 A 0.1 A ± 3% of reading ± 1A 1000 Arms

Accuracies are specied from 2% to 100% of range.

Aac

Range Resolution Accuracy Overload Protection

0–70 A 0.01 A ± 3% of reading ± 1A 1000 Arms

0–700 A 0.1A ± 3% of reading ± 1A 1000 Arms

Accuracies are specied from 2% to 100% of range.

Ohm

Range Resolution Accuracy Overload Protection

10Ω–2 MΩ 1 Ω 2.0% + 4 120 Vrms

Continuity

Range Resolution Accuracy Overload Protection

< 10 Ω 1 Ω 2.0% + 4 120 Vrms

Diode

Range Resolution Accuracy Overload Protection

0–1.5 V 0.01 V 0.05% + 2 120 Vrms

Temperature

Range Resolution Accuracy Overload Protection

-20–200 °F 1 °F 1.0% + 5 --------

• 42 •

Chapter 10: Utilities

Chapter 10: Utilities

The EXP’s Utility Menu has nine utilities that you can easily set up to customize your analyzer:

• Language (English, French or Spanish)

• Format (memory disk)

• Update (software)

• Clock (adjustments to date and time)

• Shop (create an contact informnation header on test results printouts)

• Display (contrast and backlight time adjustments)

• Coupon (turn off the coupon option on test results printouts)

• Edit Coupon (create a promotional coupon on test results printouts)

Each utility described in this section is listed in order by its icon title.

Clock

The CLOCK ADJUST utility has four settings. Use the UP/DOWN ARROW keys to highlight the setting

you want to change.

MODE : AM/PM

TIME : 9:07 PM

FORMAT : MMM/DD/YYY

DATE : 6/17/6/17/2005

Mode

Use the UP/DOWN ARROWS to move the dot to the option button of your choice.

1. Select the 24-hour or AM/PM mode

1 24 HOUR

2 AM/PM

2. Press the SAVE soft key to save your setting or the BACK soft key to return to the

CLOCK ADJUST screen without saving the changes.

Time

1. Use the LEFT/RIGHT ARROWS to highlight the hour, minutes, or AM or PM. To rapidly

scroll, hold down an ARROW key.

9 : 19 PM

• 43 •

Chapter 10: Utilities

2. Press the SAVE soft key to save your setting or BACK to return to the CLOCK ADJUST

screen.

Format

Use the UP/DOWN ARROWS or press the corresponding numerical key to move the dot to the option

button of your choice or enter its number.

1. Select the 24-hour or AM/PM mode

1 MM/DD/YYY (month/day/year)

2 DD/MM/YYY (day/month/year)

2. Press the SAVE soft key to save your setting or the BACK soft key to return to the CLOCK

ADJUST screen without saving the changes.

Date

1. Use the LEFT/RIGHT ARROWS to highlight the hour, minutes, or AM or PM. To rapidly

scroll, hold down an ARROW key.

6 / 17 / 2005

2. Press the SAVE soft key to save your setting or the BACK soft key to return to the CLOCK

ADJUST screen without saving the changes.

Shop

The SHOP INFO utility enables you to create a header for your printed test results showing your

business location information. Its two information screens contain eight lines of text with up to 16

characters on each line.

Screen 1

1–YOUR SHOP NAME

2–1000 ANY STREET

3–YOUR TOWN, STATE

4–YOUR POSTAL CODE

—

Screen 2

5–YOUR COUNTRY

6–YOUR PHONE NUMBER

7–WWW.WEBSITE.COM

8–YOUR SHOP ID NUMBER

—

Blinking cursor

shows the starting

location for editing

• 44 •

Chapter 10: Utilities

To create or overwrite a header:

1. Press the UP or DOWN ARROW to highlight the line you want to change. The cursor will

be blinking to the right of the last character in the line.

2. To move the cursor backward to erase a character, press the LEFT ARROW key; to move

the cursor forward, press the RIGHT ARROW key.

3. Insert a character by pressing the key associated with the character as many times as

needed.

4. You can center text by selecting blank spaces before and after lines of text or insert

spaces between words.

5. Press the SAVE soft key to save your setting or the BACK soft key to return to the SHOP

INFO screen without saving the changes.

Display

The LCD OPTIONS utility enables you to adjust the contrast of the text on the display and the backlight

time.

Contrast Level

The contrast level is 0 (lightest) to 10 (darkest). To change it:

1. Press the UP or DOWN ARROW to highlight the option.

CONTRAST LEVEL 10

BACKLIGHT TIME 60

2. Press the ADJUST soft key to display the option’s numerical scroll box.

10

(1-10)

3. Press the UP/DOWN ARROW keys or the corresponding numerical key to select your

preference.

4. Press the SAVE soft key to save your setting or the BACK soft key to return to the

CONTRAST LEVEL screen without saving the changes.

Current settings

• 45 •

Chapter 10: Utilities

Backlight Time

Backlight time is from 0 to 60 seconds. To change it:

1. Press the UP or DOWN ARROW to highlight the option.

CONTRAST LEVEL 10

BACKLIGHT TIME 60

2. Press the ADJUST soft key to display the option’s numerical scroll box.

Current settings

60

SEC

3. Press the UP/DOWN ARROW keys or the corresponding numerical key to select your

preference.

4. Press the SAVE soft key to save your setting or the BACK soft key to return to the

BACKLIGHT screen without saving the changes.

Coupon

The COUPON SELECT utility enables and disables the printing of the custom coupon you’ve created

in the EDIT COUPON utility.

1. Use the UP/DOWN ARROWS or press the corresponding numerical key to move the dot

to the option button of your choice.

1 NO USER COUPON PRINTED

2 USER COUPON

2. Press the SAVE soft key to save your setting or the BACK soft key to return to the

COUPON SELECT screen without saving the changes.

Edit Coupon

The EDIT COUPON utility enables you to create a promotional coupon for your customers that prints

at the bottom of every test result. Its two information screens contain eight lines of text with up to 16

characters each.

The editing process is the same as when you create a header for your test results printouts. See the

SHOP utility for more information.

• 46 •

Chapter 10: Utilities

Temp

The TEMP. UNITS utility enables you to set the units of measure to either Celsius or Fahrenheit.

To set your preference:

1. Use the UP/DOWN ARROWS or press the corresponding numerical key to move the dot

to the option button of your choice.

1 DEGREES F

2 DEGREES C

2. Press the SAVE soft key to save your setting.

Language

The LANGUAGE utility enables you to select a language for the display and printouts. To set your

preference:

1. Use the UP/DOWN ARROWS or press the corresponding numerical key to move the dot

to the option button of your choice.

1 ENGLISH

2 ESPAÑOL

3 FRANÇAIS

2. Press the SAVE soft key to save your setting.

Format Disk

Select this utility to format an SD card to receive data or erase all data on the card. The EXP will warn

you before formatting the disk and ask you if you want to continue.

Update

As software updates become available you’ll be able to use this utility to update the EXP software

using les on an SD card.

• 47 •

Chapter 11: Info Menu

Chapter 11: Info Menu

The Info Menu has 3 utilities to help you manage your test data and track the usage and history of

your analyzer.

Totals

The TOTALS report displays the total number of battery tests performed since the EXP was rst used.

Press the LEFT and RIGHT ARROW keys simultaneously to clear the total and reset the starting date.

Transfer

The TRANSFER utility lets you transfer test data to a PC using an optional IR receiver/software

package.

Version

Version displays the EXP’s software version, the date the software was released, and the serial

number of the analyzer. The utility keeps a permant count of the number of battery tests performed

since the analyzer was rst used.

• 48 •

Chapter 12: Print/View

Chapter 12: Print/View

The Print/View Menu enables you to view and print the results of the Battery, System, and Cable Drop

Tests before you perform another test and overwrite the results in memory.

View Test

VIEW TEST gives you the option of viewing and printing the results of the Battery and System Tests.

To print the results, align the analyzer’s IR transmitter with the printer’s receiver, and select the PRINT

soft key. To return to the Main Menu, press the END key.

View Cable Test

VIEW TEST gives you the option of viewing and printing the results of the Cable Drop Test. To print

the results, align the analyzer’s IR transmitter with the printer’s receiver, and select the PRINT soft key.

To return to the Main Menu, press the END key.

• 49 •

Chapter 13: Troubleshooting

Chapter 13: Troubleshooting

If you have problems with the display or the Midtronics printer, try these troubleshooting suggestions:

The Display Does Not Turn On

• Check the connection to the vehicle battery.

• Press the POWER button.

• The vehicle’s battery may be too low to power the analyzer (below 1 volt). Fully charge

the battery and retest.

• The analyzer’s 6 AA batteries may need to be replaced. Follow the directions in

Chapter 14: EXP Internal Batteries and replace the batteries (alkaline recommended).

• If troubleshooting does not solve the problem, contact Midtronics at 1-800-776-1995 to

obtain service. See “Patents, Limited Warranty, Service” for more information.

The STATUS LED Flashes (Midtronics Printer)

When a printer fault occurs, the STATUS LED ashes. You can identify the fault by the number of

sequential ashes:

Table 6: Printer STATUS LED

Sequence Condition Solution

* * *

** ** **

*** *** ***

No paper Insert new paper

Thermal head too hot Allow head to cool

Batteries weak Recharge printer

batteries for 16 hours

Data Will Not Print

• If the IR transmitter and receiver are not aligned, all the data may not print. The infrared

ports on the top of the analyzer and on the printer below the MODE button should be

pointed directly at each other. The maximum distance for reliable transmission between

the ports is 17 in (45 cm).

To realign, press the END button to cancel the print job. Verify alignment between the

analyzer and printer; then try to print the test results again.

• Make sure the printer is on. The printer shuts off after 2 minutes of inactivity to conserve

the batteries. To turn the printer on, briefly press the MODE button. The green STATUS

light should turn on. Make sure you are using the Midtronics printer. Other printers may

not be compatible.

• 50 •

Chapter 13: Troubleshooting

• Direct sunlight interferes with infrared data transmission and receiving. If the printer is

not receiving data, remove the printer and EXP from direct sunlight. If the printed characters are not clear or are partially missing, recharge the battery and reprint.

• If you are unable to print after ensuring the analyzer is functioning, the printer is on, the

batteries are good, and the IR transmitter and receiver are aligned, check the printer

manual for further instructions or call Midtronics at 800-776-1995 for assistance. (See

“Patents, Limited Warranty, Service” for more information.)

• 51 •

Chapter 14: EXP Internal Batteries

Chapter 14: EXP Internal Batteries