CPX-900

CPX-900 WiFi

Battery & System

Analyzer

October 2018

167-000848EN-B

For testing 6 and 12-volt automotive batteries and

12- and 24-volt charging systems

User Manual

support.cpx900.com

www.midtronics.com

1

blank page behind cover

CPX-900

Contents

1 – Introduction 5

Personal Precautions 5

Symbols Conventions 5

Description 5

Consent to Collection and Use of Data: 5

Controls & Connections 6

Main Menu 6

Additional Screens 6

Main Menu Icons 7

Initial Power Up 7

WiFi Settings 7

BMIS Settings 8

Shop Settings 8

Data Collection Consent 8

Test Preparation 8

Inspecting the Battery 8

Testing Out-of-Vehicle 9

Testing In-Vehicle 9

Connecting To A Battery 9

Setting User Preferences 9

2 – In Vehicle Test 10

Battery Test 10

Battery Test Results 12

System Test 13

System Test Results 13

3 – Out Of Vehicle Test 14

Battery Test 14

Battery Test Results 15

4 – History 16

5 – Messages 17

Accessing Messages 17

6 – Settings 18

Tool 18

Display 18

Date & Time 18

Print Format 19

Work Order 19

Auto Test 19

VIN Entry 19

Version 19

Shop Settings 19

Admin 19

Shop Info 20

Network 20

WiFi 20

BMIS Settings 20

www.midtronics.com

3

CPX-900

7 – Maintenance & Troubleshooting 21

Tester Cables 21

Cleaning Clamps 21

Handling Test Cables 21

Storing Test Cables 21

Printer Paper 22

Replacing The Paper Roll 22

Replacing The Internal Batteries 23

Appendix A: Recommended Scanning Procedure 24

Scanning Tips 24

Appendix B:Test Results Decision Tables 25

Battery Test Results 25

Alternator Test Results 26

4

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

Personal Precautions

1 – Introduction

1 – Introduction

Risk of explosive gases. Never

smoke or allow a spark or ame

in the vicinity of a battery.

Batteries can produce a highly

explosive mix of hydrogen gas and

oxygen, even when the battery is not

in operation. Always work in a wellventilated area.

Wash hands after handling.

REQUIRED BY CALIFORNIA PROP. 65:

posts, terminals, and related accessories contain

lead and lead compounds, chemicals known to

the state of California to cause cancer and birth

defects or other reproductive harm.

Battery

Inspect the battery for damage and check the electrolyte level. If the electrolyte level is too

low, replenish it and fully charge the battery. Always use the necessary safety precautions when

working with batteries to prevent severe injury or death. Follow all manufacturers’ instructions

and BCI (Battery Council International) safety recommendations, which include the following

precautions:

9 Battery acid is highly corrosive. If acid enters your eyes, immediately ush them thoroughly

with cold running water for at least 15 minutes and seek medical attention. If battery acid

gets on your skin or clothing, wash immediately with a mixture of water and baking soda.

9 Always wear proper safety glasses or face shield when working with or around batteries.

9 Keep hair, hands, and clothing as well as the analyzer cords and cables away from moving

engine parts.

9 Remove any jewelry or watches before you start servicing the battery.

9 Use caution when working with metallic tools to prevent sparks or short circuits.

9 Never lean over a battery when testing, charging, or jump starting.

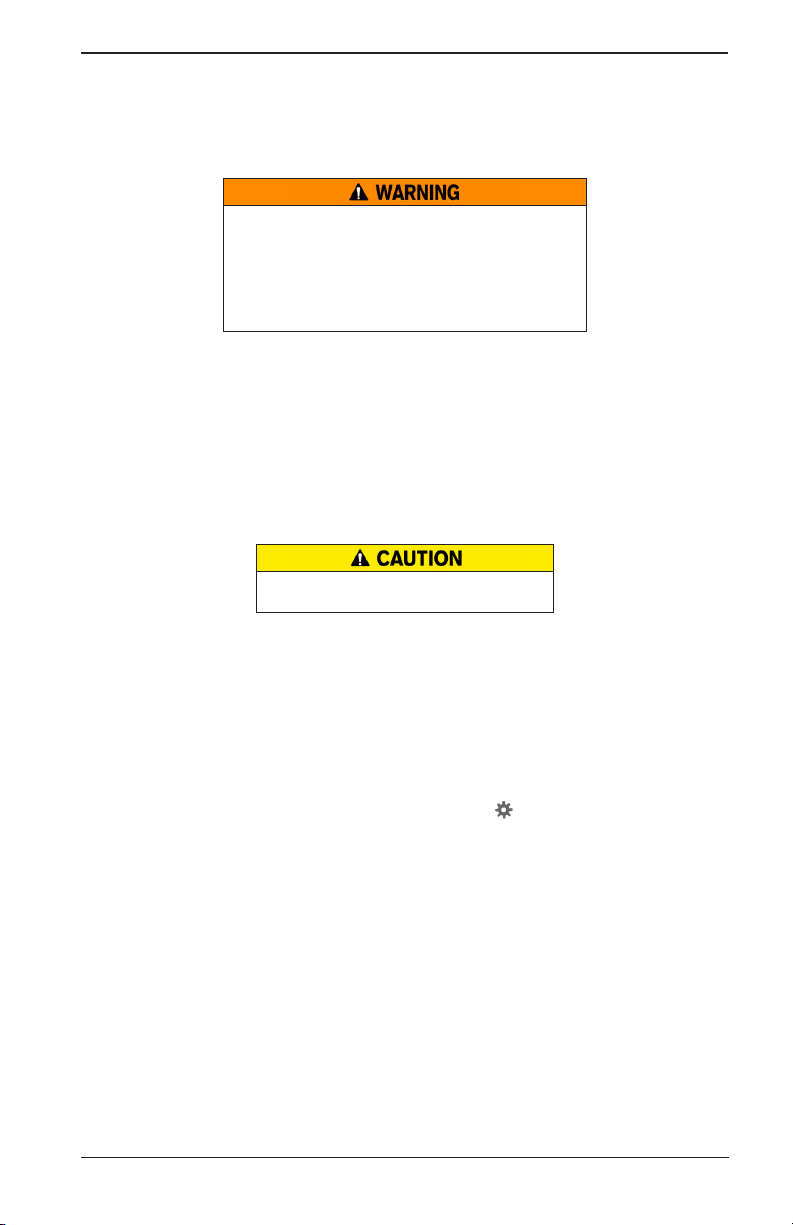

Symbols Conventions Description

Symbol Description

The safety symbol indicates

instructions for avoiding hazardous

conditions and personal injury.

The safety symbol with the

words CAUTION, WARNING, or

!

DANGER indicates instructions for

avoiding hazardous conditions and

personal injury.

The wrench symbol indicates

procedural notes and helpful

information.

The analyzer uses function-specic applications

accessed through a series of menus and icons

to guide users through the battery testing

process for consistent testing implementation

and accuracy. These are accessed using the

tester’s touch screen display. Test results can

be displayed on the full-color screen, printed,

or wirelessly emailed.

Consent to Collection and Use of Data:

You agree that Midtronics, Inc. may collect, store, transmit, and use technical data and related

information, including but not limited to technical information about this device, system and

application software, and accessories, that is gathered periodically to facilitate the provision of

product support, product improvements, product development, and other services related to

use of this device. If electing to collect personal data (such as e-mail addresses) the user is solely

responsible for obtaining any necessary permissions, and agrees to indemnify and hold harmless

Midtronics, Inc. its subsidiaries, ocers, employees and agents from any liability associated with

collecting, storing, and transmitting such personal data.

www.midtronics.com

5

1 – Introduction CPX-900

Controls & Connections

Display Screen

Cooling Vent

Arrow Keys & Power But-

ton

Mini-USB Port

Thermal Printer

(optional)

Temperature Sensor

VIN Barcode Scanner

(optional)

Clamp Tabs

Main Menu

12.74V CPX-900

In Vehicle Test

Messages

Out of Vehicle

Test

Sengs

History

Version

Menu Bar

12.74V

Battery Voltage

(if connected)

WiFi signal strength

Controller internal battery status

Main Menu Selection Area

When displayed, the Screen Arrows show which ARROW key on the keypad to press to

Additional Screens

The dots at the bottom or side of a menu or results screen indicate additional screens are available,

display other icons or screens. When displayed under a list of options, the Screen Arrows

show which keypad arrow to press to highlight a character or item in a list.

Screen 1

Screen 2

Screen 3

Press or

Screen 1

Press or

Screen 2

6

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

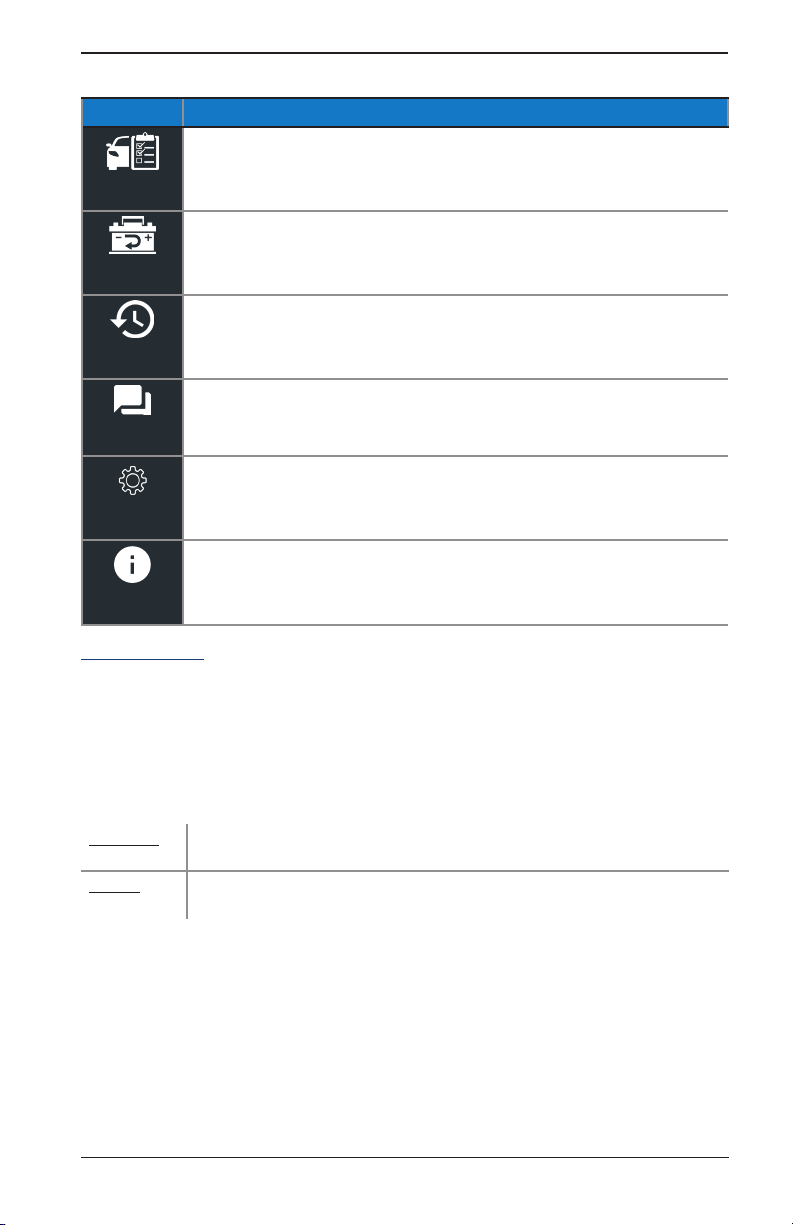

Main Menu Icons

Icon Description

For testing batteries that are connected to and installed in a vehicle. An In Vehicle

Test includes a Battery Test and a System (Starter and Charging) Test.

In Vehicle Test

For testing batteries not connected to or removed from a vehicle.

Out of Vehicle

Test

Access archived test histories or search test history by VIN or by technician.

History

Displays alerts and notications for upcoming tool software updates.

Messages

1 – Introduction

Setup/adjust: WiFi, printer setup,

display and sound settings, BMIS information, and shop information.

email settings, user information, default language,

Sengs

Access to tester software version information.

Version

Initial Power Up

The tester will take a few moments when powered up for the rst time.

BMIS Setup-does not display if Wi not successfully setup (See "BMIS" in Chapter 6: Setup)

WiFi Settings

Set up the tool's WiFi connection. Select Skip to congure WiFi at a later time. See "Network" in

Chapter 6: Setup

Automatic The tester searches for any detectable WiFi networks. Select a displayed

Manual Manually enter Security, SSID, Password, Encryption, and WEP Keys.

network is then displayed on the tester screen.

www.midtronics.com

7

1 – Introduction CPX-900

BMIS Settings

At the User Credentials screen, enter the Midtronics-provided username, password, Client ID, and

Location ID to access BMIS data management.

Use to highlight the numbers on the displayed keyboard and press to select. Press

Skip to move to the next step.

NOTE: If WiFi was not congured in the previous step, the BMIS setup screen is not

displayed.

Username Provided by Midtronics

Password Provided by Midtronics

Client ID Provided by Midtronics

Location ID Provided by Midtronics

Shop Settings

Use to enter information about the shop in which the tester will be used.

Shop Name Country

Shop Address Phone Number

Shop Address 2 Email Address

City Website

State (Blank)

Zipcode (Blank)

Country

With the displayed alphanumeric keypad, u

se to highlight the desired alphanumeric

character. Select to access the lower case and symbol character maps.

Once all of the alphanumeric characters have been entered, select Save or Esc to exit without saving.

Data Collection Consent

Select Accept to acknowledge test data is being collected via BMIS.

Test Preparation

Inspecting the Battery

Before starting the test visually inspect the battery for:

• Cracked, buckled, or leaking case. If you see any of these defects, replace the battery.

• Corroded, loose, or damaged cables and connections. Repair or replace them as needed.

• Corrosion on the battery terminals, and dirt or acid on the case top. Clean the case and termi-

nals using a wire brush and a mixture of water and baking soda.

• Low electrolyte level. If the electrolyte level is too low, add distilled water to ll up to ½ above

the top of the plates and fully charge the battery. Do not overll.

• Corroded or loose battery tray and hold-down xture. Tighten or replace as needed.

8

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

1 – Introduction

Testing Out-of-Vehicle

The preferred battery test location is In-Vehicle. However, for testing Out-Of-Vehicle:

• Always disconnect the negative cable from the battery rst and reconnect it last.

• Always use a carry tool or strap to lift and transport the battery.

Failure to properly install lead terminal adapters,

or using adapters that are dirty or worn, may

cause false test results.

When testing side-post or Group 31 batteries, always use

lead terminal adapters provided with the tester—do not

test at the battery’s steel bolts. To avoid damage, never use

a wrench to tighten the adapters more than ¼ turn.

Testing In-Vehicle

The preferred test position is at the battery posts. If you must test at a remote-post location, it

should have both a positive and negative post. Otherwise, you must remove the battery and

perform an out-of-vehicle test.

At the start of the test, make sure all vehicle accessory loads are o, the key is not in the ignition,

and the doors are closed.

Connecting To A Battery

Do not connect the tester to a voltage source

greater than 30 Vdc.

Connect the clamps to the tester: the red clamp to the positive (+) terminal and the black clamp to

the negative (–) terminal. If the clamps are reversed when connected, the tester displays CLAMPS

REVERSED! Reconnect the clamps.

Make sure both sides of the clamps are gripping the terminals by rocking each clamp back and

forth. A poor connection will prevent testing, and the tester will display a CHECK CONNECTION

message. If the message reappears after reconnecting, clean the terminals and reconnect.

Setting User Preferences

Customize the analyzer by setting preferences in the Settings ( ) Menu, described in Chapter 6.

www.midtronics.com

9

2 – In Vehicle Test CPX-900

2 – In Vehicle Test

Use In Vehicle Test to perform Battery Tests on in-vehicle batteries using test

parameters determined by vehicle VIN or through manual entry of battery

In Vehicle Test

NOTE:When VIN Entry is enabled (See Chapter 6 - Settings), an In Vehicle Test test will

The CPX-900 provides a battery decision along with additional detailed information on battery

cranking and reserve capacity. Press to return to the previous screen, select options and

when necessary, to enter or continue to the next step.

Battery Test

1. Connect the tester clamps to the battery terminals.

2. Auto Test - If enabled, the tool immediately begins testing the battery. (See Chapter 6 - Settings)

parameters. A System Test for Starter and Charging testing is also available.

always associate the in-vehicle battery to the VIN of the vehicle being tested.

IMPORTANT: To expidite the testing procedure, makes sure Auto Test is enabled.

(Chapter 6 - Settings) The testing process begins as soon as the clamps are connected.

NOTE:

3. At the Main Menu select In Vehicle Test.

4. Enter Work Order - If enabled, use the displayed keyboard template to Enter Work Order information. (See Chapter 6 - Settings)

5. Temperature - when prompted, hold the tester temperature sensor 6 to 12 inches over the

top of the battery being tested.

Select Capture to lock in the live temperature reading.

6. VIN Capture - (scanner optional) scan the VIN bar code, usually located in the right corner of

the vehicle's front windshield or on the driver’s side door frame.

Refer to Appendix A for additional scanning tips.

NOTE: VIN scanning is skipped when the CPX-900 is not equipped with an op-

NOTE: Barcode types supported by the CPX-900 include A: 1D: Code 39, Code

The testing process uses Conductance Proling™ technology to determine

battery cranking capability and Reserve Capacity. This additional analysis can take

up to 60 seconds to complete.

Temp Sensor

tional scanner.

128, UPC, Codabar, GS1-Limited; 2D: PDF417, QR Code: Model 2, and Data Matrix

type barcodes. Refer to Appendix A for recommended VIN scanning procedures.

10

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

2 – In Vehicle Test

VIN Barcode

Scanner

Drivers Door Frame

Windshield

Manual Entry - Use the on-screen keypad to manually type the 17-digit VIN and select Next.

1 2 3 4 5 6 7 8 9 0

W E R T Y U P

A S D F G H J K L

Z X C V B N M

ESC Save

The displayed digit counter will count up the alphanumeric characters as they are entered.

7. Battery Test Setup - Edit the displayed battery information. Select Start to begin the testing

process.

Application Automotive

Battery Post Top Post Side Post

Battery Type Flooded

Battery Units CCA

Battery Rating

Rating Description Range

CCA Cold Cranking Amps (specied by SAE): The

CA Cranking Amps: The amount of current a

DIN Deutsche Industrie-Norm 100 to 1000

SAE Society of Automotive Engineers - European

IEC International Electrotechnical Commission 100 to 1000

EN Europa-Norm 100 to 1700

MCA Marine Cranking Amps: The amount of current

EN2 Europa-Norm 100 to 1700

amount of current a battery can provide at 0 ºF

(–17.8 ºC).

battery can provide at 32°F (0 ºC).

labeling of CCA

a battery can provide at 32°F (0 ºC).

4D/8D

AGM Spiral

EFB

DIN

IEC

MCA

Hold down or to increase

scrolling speed.

Group 31

AGM

Gel

CA

SAE

EN

EN2

100 to 3000

100 to 3000

100 to 3000

100 to 3000

www.midtronics.com

11

2 – In Vehicle Test CPX-900

Battery Test Results

Icons are color-coded to indicate status.

Green

Yellow

Battery Test

All test parameters were completed

:

and have passed.

Some test parameters may require

:

further testing.

VIN: 1HGEM225X5Lxxxxxx

Good Baery

Send Results System Test Done

Cranking Health

Rated: 575 CCA

Measured: 599 CCA

Starter Test

Red

Gray

Test Results - Baery

Rated 575 CCA

Voltage 12.72 V

Measured 599 CCA

Temperature: 970 F

The battery has failed the test.

:

Insufcent data to perform the test.

:

Test Results - Baery

Baery meets or exceeds

required standards. Test

again in 90 days.

Alternator Test

Test Results - Baery

Reserve Health

The baery has sucient

reserve capacity to

provide power for the

electronics systems in the

OK

vehicle.

Test Results - Battery Test

NOTE: See Appendix B for complete parameter descriptions.

12

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

Select Send Results displayed at the bottom of the tester screen to send the test results to the

optional built-in printer or via email. Select Done to return to the Main Menu.

Email

Printer

6

2 – In Vehicle Test

System Test

1. Select System Test displayed at the bottom of the screen to continue to the System Test.

2. Start the vehicle's engine and let it idle.

3. Ensure all accessories (High Beam headlights/ventilation blower etc.) are o and select Next.

The alternator output is tested.

4. When prompted, rev and hold the engine to between 2000 to 3000 rpm.

The alternator output is tested.

5. When prompted Idle the engine and and select Next.

6. Turn on the high beam headlights and ventilation blower and select Next.

The alternator output is tested.

7. When prompted, rev and hold the engine to between 2000 to 3000 rpm.

The alternator output is tested.

8. When prompted, turn o all loads and Idle the engine. Select Next.

System Test Results

Test Results - Summary

Good Baery

Cranking Normal

Charging Normal

Send Results Done

Test Results - Summary

T

he Test Results - Summary screen is displayed following a System Test. Select the Battery, Cranking,

or Charging Test to view detailed test results for each part of the test.

NOTE: See Appendix B for complete parameter descriptions.

Select Send Results displayed at the bottom of the tester screen to send the test results to the

optional built-in printer or via email. Select Done to return to the Main Menu.

Email

Printer

6

www.midtronics.com

13

3 – Out Of Vehicle Test CPX-900

3 – Out Of Vehicle Test

Use Out Of Vehicle Test to test and verify the condition of a batteries that is not

connected to a vehicle..

Out Of Vehicle

Test

IMPORTANT: To expidite the testing procedure, makes sure Auto Test is enabled.

(Chapter 6 - Settings) The testing process begins as soon as the clamps are connected.

The CPX-900 provides a battery decision along with additional detailed information on battery

cranking and reserve capacity. Press to return to the previous screen, select options and

when necessary, to enter or continue to the next step.

Battery Test

1. Connect the tester clamps to the battery terminals.

2. Auto Test - If enabled, the tool immediately begins testing the battery. (See Chapter 6 - Settings)

NOTE:

The testing process uses Conductance Proling™ technology to determine

battery cranking capability and Reserve Capacity. This additional analysis can take

up to 60 seconds to complete.

3. At the Main Menu select Out Of Vehicle Test. The Battery Test begins immediately.

4. Enter Work Order - (if enabled) Use displayed template to Enter Work Order information.

5. Battery Test Setup - Edit the displayed battery information. Select Start to begin the testing

process.

Application Automotive

Battery Post Top Post Side Post

Battery Type Flooded

Battery Units CCA

Battery Rating

4D/8D

AGM Spiral

EFB

DIN

IEC

MCA

Hold down or to increase

scrolling speed.

Group 31

AGM

Gel

CA

SAE

EN

EN2

14

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

Rating Description Range

CCA Cold Cranking Amps (specied by SAE): The

CA Cranking Amps: The amount of current a

DIN Deutsche Industrie-Norm 100 to 1000

SAE Society of Automotive Engineers - European

IEC

EN

MCA Marine Cranking Amps: The amount of current

EN2

amount of current a battery can provide at 0 ºF

(–17.8 ºC).

battery can provide at 32°F (0 ºC).

labeling of CCA

International Electrotechnical Commission 100 to 1000

Europa-Norm 100 to 1700

a battery can provide at 32°F (0 ºC).

Europa-Norm 100 to 1700

3 – Out Of Vehicle Test

100 to 3000

100 to 3000

100 to 3000

100 to 3000

6. Temperature - when prompted, hold the tester temperature sensor 6 to 12 inches over the

top of the battery being tested.

Temp Sensor

Select Capture to lock in the live temperature reading.

Battery Test Results

NOTE: See Battery Test Results in Chapter 2 - In Vehicle Test for test result screens

and descriptions.

www.midtronics.com

15

4 – History CPX-900

4 – History

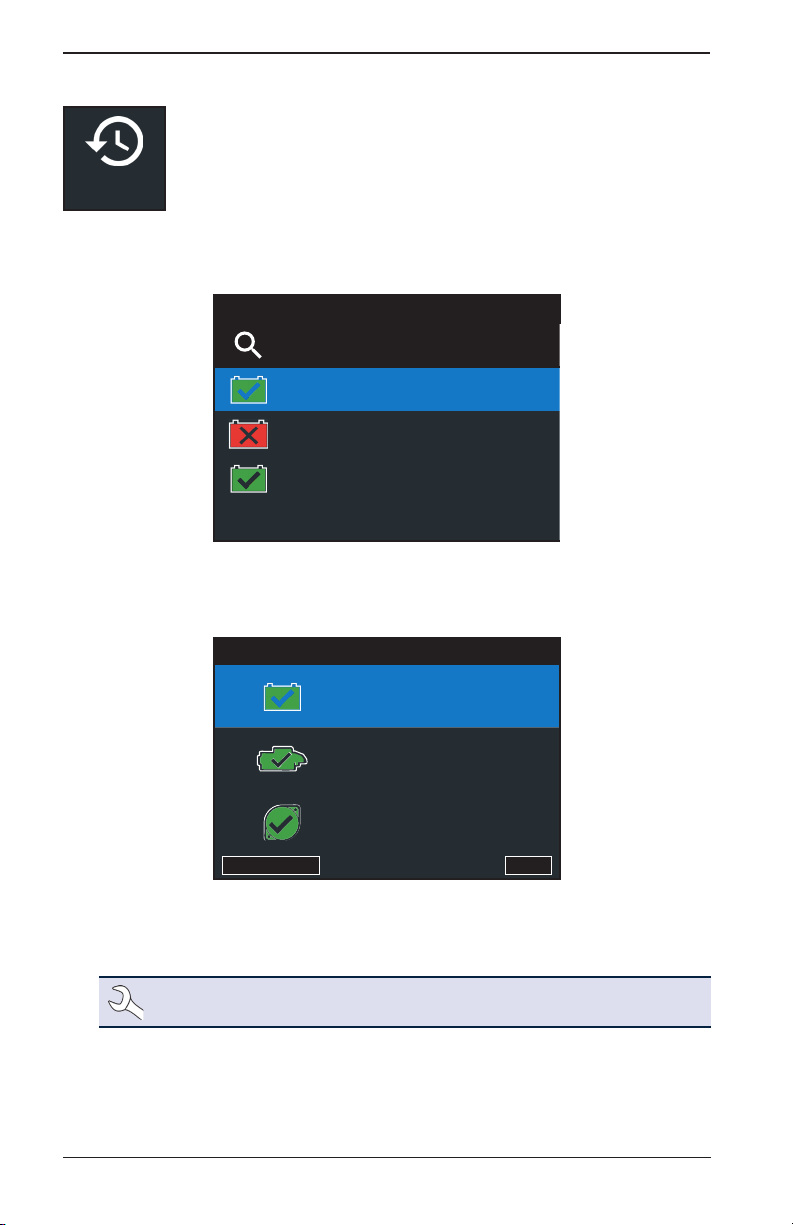

Use History to access the tool usage history, a vehicle history based on VIN, and

user histories. The search function can also be used nd test records for specic

History

Press to return to the previous screen, select options and when necessary, to enter or

continue to the next step.

1. At the Main Menu, select History. The Tool History screen is displayed.

vehicles and technicians.

Search Records

In Vehicle Test 1HGEM225X5Lxxxxxx

06/08/2018 12:09 PM

In Vehicle Test

06/08/2018 8:45 AM

Out of Vehicle

06/07/2018 3:16 PM

Tool History

5UXZV4C50D0xxxxxx

No VIN

1/3

2. Select a vehicle record to view the results or select Search Options to search for records by

manually entering a VIN, scanning a VIN, or by test result decision.

3. For In Vehicle tests, the Summary screen is displayed.

Test Results - Summary

Good Baery

Cranking Normal

Charging Normal

Send Results Done

Test Results - Summary

4. Select the Battery, Cranking, or Alternator Test to view detailed test results for each part of

the test.

NOTE: See Battery Test Results in Chapter 2 - In Vehicle Test for test result screens

and descriptions.

5. To send the test results to a congured printer or via email select Send Results. To return to

the Home Screen, select Done to the Main Menu.

16

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

5 – Messages

The Messages function displays alerts and notications for upcoming tool

software updates.

Messages

Select to return to the previous screen or to return to the Main Menu.

Accessing Messages

A number is displayed next to the Messages icon when the analyzer has

received any critical messages.

Unread Critical Messages

Read Critical Messages

5 – Messages

www.midtronics.com

17

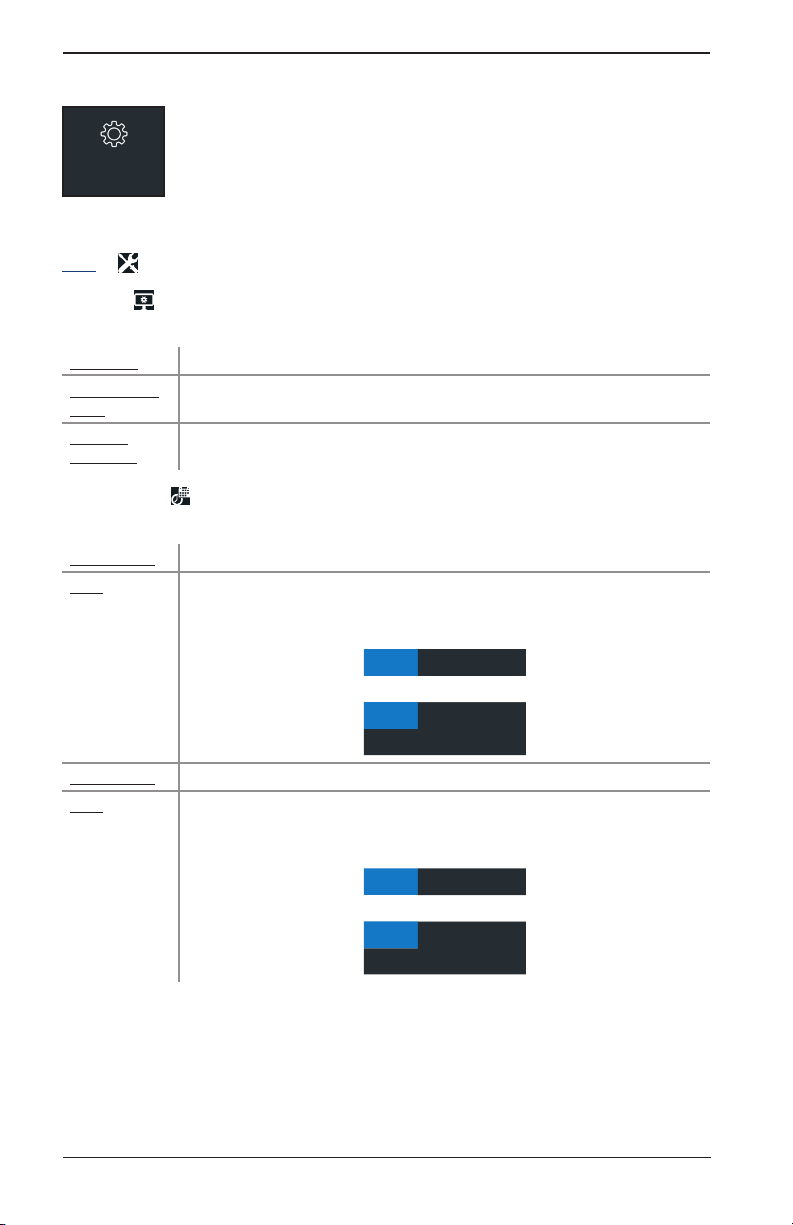

6 – Settings CPX-900

6 – Settings

Use Setup to setup and adjust the tester display and time, shop and

administrative settings, network connectivity, and BMIS settings.

Sengs

Press to return to the previous screen, select options and when necessary, to enter or

continue to the next step.

Tool

Display

Use to return to the Display menu.

Language Select the analyzer default standard language.

Temperature

Units

Number

Separator

Date & Time

Use to return to the Display menu.

Date Format Select Month/Day/Year (MM/DD/YYYY), or Day/Month/Year DD/MM/YYYY.

Date

Select the default temperature units (Fahrenheit/Celsius) used when measuring

battery temperature.

Select the default number display using commas or periods separators.

Use or to advance the month, day, and year. Use or to advance

left or right and move to Cancel or Next. Select Next to save the date or

Cancel to exit without saving.

Time Format Select 12 or 24 Hour Format.

Time

Use or to advance the hours, minutes, and AM/PM setting. Use or

to advance left or right and move to Cancel or Next. Select Next to save the

time or Cancel to exit without saving.

18

June 18 2018

Cancel Next

10 46 AM

Cancel Next

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

6 – Settings

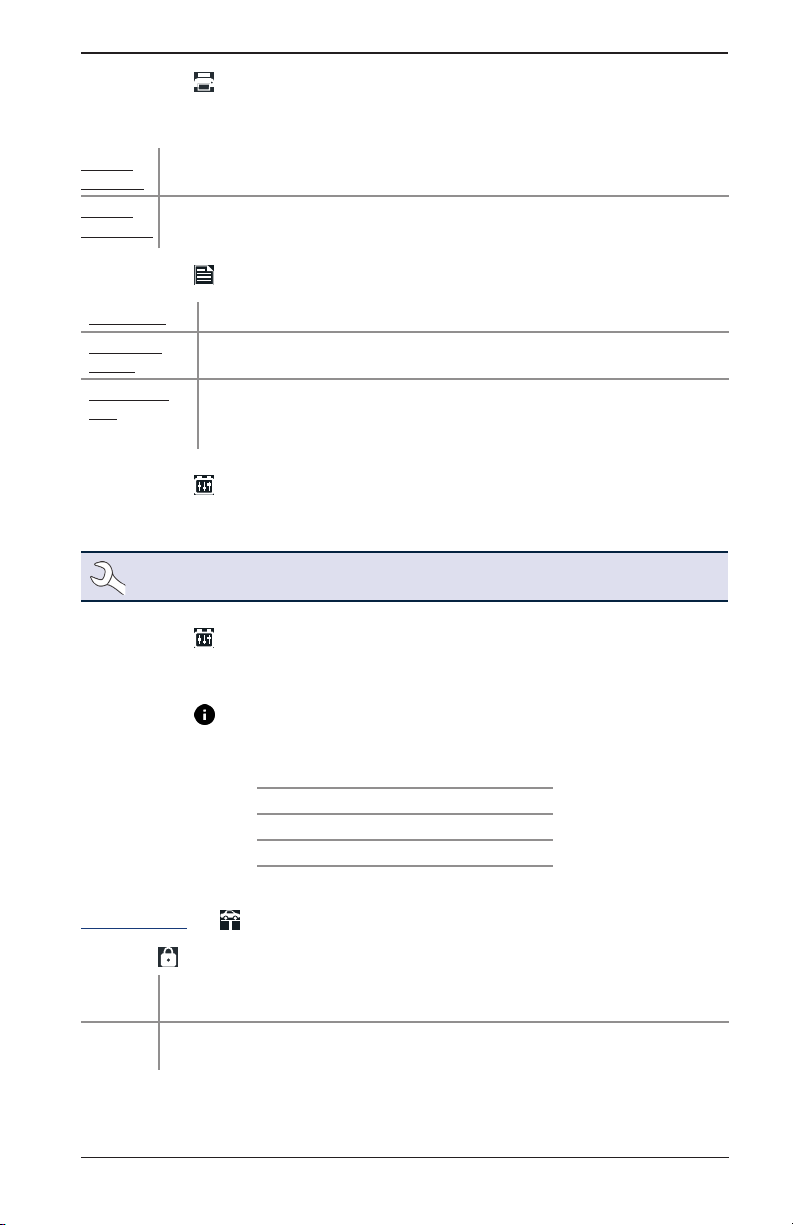

Print Format

Set the default to include Shop Info and State Of Health (SoH) information on test result printouts.

Use to return to the Display menu.

Include

Shop Info

Include

SoH Graph

Press to check and uncheck the box. A checked box indicates the shop

information will be included on printed test results.

Press to check and uncheck the box. A checked box indicates the State Of Health

screen will be included on printed test results.

Work Order

Work Order

Customize

Enable

Work Order

Tex t

Press to check/uncheck the box to enable/disable the function.

Press to check/uncheck the box to enable/disable the ability to customize

Work Order Text.

Use to highlight characters on the displayed keyboard and press

to select. Limit=13 characters. Select Esc to return to the Work Order Settings

screen.

Auto Test

Press to check and uncheck the box. A checked box indicates the tester will immediately begin

testing a battery as soon as it is connected. Use to return to the Tool menu.

NOTE: To expidite the testing procedure, enable the Auto Test function.

VIN Entry

Press to check and uncheck the box. A checked box indicates the VIN Entry option will be

included as part of an In Vehicle Test. Use to return to the Tool menu.

Version

Use to conrm technical information for internal tester software and hardware.

Shop Settings

Admin

Admin

Enable

Admin

Pin

www.midtronics.com

Press to check and uncheck the box. A checked box indicates the Admin

function is enabled.

Use to select a four (4) digit Admin PIN. Select OK to save the PIN or

Cancel to exit without saving. Use to return to the Shop Settings menu.

Cong: Build Number:

Firmware: Serial Number:

Flash: MAC ID:

EEPROM: FCC ID:

Build Date:

19

6 – Settings CPX-900

Shop Info

Use to enter information about the shop in which the tester will be used.

Shop Name Country

Shop Address Phone Number

Shop Address 2 Email Address

City Website

State (Blank)

Zipcode (Blank)

Country (Blank)

With the displayed alphanumeric keypad, u

se to highlight the desired alphanumeric

character.

Select to access the lower case and symbol character maps.

Once all of the alphanumeric characters have been entered, select Save or Esc to exit without saving.

Network

WiFi

Automatic The tester searches for any detectable WiFi networks. A list of detected WiFi

Manual Manually enter Security, SSID, Password, Encryption, and WEP Keys. Select

networks is then displayed on the tester screen. Highlight a displayed network

and press to connect. Press to return to the WiFi Settings screen.

Connect.

BMIS Settings

Username Provided by Midtronics

Password Provided by Midtronics

Client ID Provided by Midtronics

Location ID Provided by Midtronics

20

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

7 – Maintenance & Troubleshooting

7 – Maintenance & Troubleshooting

Tester Cables

The test cables that come with your analyzer are consumable items. Cables are like tires in that

the more you use them and the harder you drive them, the shorter their useful life. Here are a few

things you can do to protect your test cables from damage and premature wear:

Cleaning Clamps

• The grease, dirt, and sulfation that build up on battery terminals are highly corrosive and can

damage the clamps over time. Before connecting the clamps, ensure accurate test readings

and protect the clamps by cleaning the battery case and terminals using a wire brush and a

mixture of water and baking soda.

• Periodically clean the clamps using a mixture of baking soda and water, or a mild hand-soap,

and a small bristle brush.

• To protect the clamps from oil and dirt, clip them to the Clamp Tab on the back of the analyzer.

Clamp Tab

Handling Test Cables

• Always connect and disconnect the clamps to the battery by opening and closing the clamps.

Never pull on the test cables to remove the battery clamps. Pulling can damage the Y-junction, the cables, and the clamps to the extent that the analyzer may produce lower-thanexpected conductance readings or fail completely.

• Never carry the analyzer by the cables. Carrying the analyzer or swinging it by the cables puts

unnecessary strain on the cables and can result in premature failure. Handle the analyzer with

care to get the maximum use from the product.

Storing Test Cables

• Never wrap the cables around the analyzer; this puts unnecessary strain on the test cables.

Because the test cables are the “tires” of the analyzer, they have a certain life expectancy and will

wear out eventually. However, the abuse examples cited above are not covered under warranty. To

ensure the best performance and longest life of the test cables, attach and remove them with care,

and carry the analyzer and cables together.

If an inspection or a change in test results indicate that the test cables need to be replaced, call

Midtronics Customer Service at 1-800-776-1995.

www.midtronics.com

21

7 – Maintenance & Troubleshooting CPX-900

Printer Paper

The internal printer is shipped with a roll of 2¼" wide by 17/8" in diameter thermal printing paper

installed. Replacement rolls are available through Midtronics or online oce supply websites.

NOTE: Due to production variances some paper roll diameters may be too large.

Please remove paper from roll to recommended 17/8" diameter. DO NOT force cover to

close if roll is too large.

NOTE: The analyzer uses only thermal printing paper.

Replacing The Paper Roll

1. Unlock the printer door by gently lifting up on the release.

Release

2. Lift the printer door and remove the spent roll.

3. Place a new roll of paper in the compartment. The paper feeds from the bottom of the roll.

4. Pull the paper forward so that it extends past the serrated edge of the paper slot.

5. Close the door and make sure the lever locks securely. For a clean tear, pull the paper along

the serrated edge. Do not pull the paper straight out of the printer.

22

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

7 – Maintenance & Troubleshooting

Replacing The Internal Batteries

1. Turn the analyzer face down.

2. Use a Phillips screwdriver to remove the screw securing the door to the battery compartment.

Battery

Cover Screw

3. Lift the door at the tab and place it aside.

4. Remove the discharged batteries.

5. Insert new batteries as shown. Make sure the positive and negative terminals are positioned

correctly.

6. Reposition the door on the battery compartment.

7. Reinsert and tighten the screw.

www.midtronics.com

23

Appendix A: Recommended Scanning Procedure CPX-900

Appendix A: Recommended Scanning Procedure

The CPX-900 uses an optional 1D/2D barcode scanner built into the back of the tester to scan the

VIN of the vehicle being tested. This number is then cross referenced with the original equipment

manufacturer's battery specications stored in the tester's database and displayed on the tester

screen.

NOTE:

Barcode types supported by the CPX-900 include A: 1D: Code 39, Code 128, UPC,

Codabar, GS1-Limited; 2D: PDF417, QR Code: Model 2, and Data Matrix type barcodes.

Scanning Tips

• Barcode Scanner: Located in the upper left portion on the back of the tester.

VIN Barcode

Scanner

Drivers Door Frame

Windshield

• Hold Steady: Hold the tester steady when scanning the VIN barcode. This allows the user to

clearly see the barcode and allows the scanner to focus on it.

• Clean Barcode/Windshield: Surface dirt can interfere with the scanning process. If necessary

wipe the VIN barcode with a cloth or your nger remove any surface dirt.

• Lighting/Glare: If sunlight is shining directly onto the VIN barcode, try pivoting the scanner

up or down slightly to reduce any glare.

24

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

Appendix B:Test Results Decision Tables

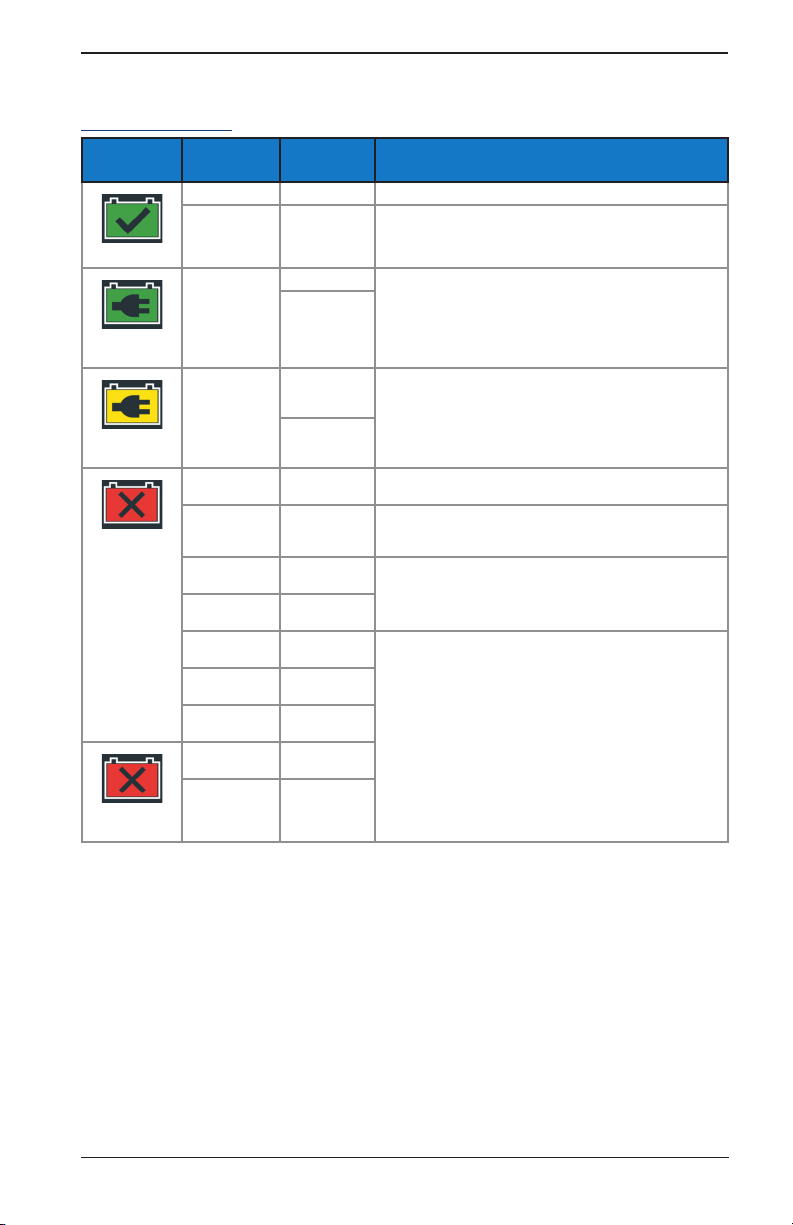

Battery Test Results

Decision

Good Battery

Good

Recharge

Charge &

Retest

Replace

Battery

Badcell Short

Replace

Cranking

Health

Good Battery Good Battery Battery meets or exceeds required standards.

Good Battery Unknown

Good

Recharge

Charge &

Retest

Badcell

Replace Short

Charge &

Retest

Good Battery Replace

Good

Recharge

Replace

Battery

Replace

Battery

Replace

Battery

Badcell

Replace Short

Badcell

Replace Short

Reserve

Capacity

Reserve

Good Battery

Unknown

Reserve

Unknown

Reserve

Charge &

Retest

Replace

Battery

Replace

Battery

Battery

Replace

Battery

Good Battery

Replace

Battery

Unknown

Reserve

Good Battery

Unknown

Reserve

Appendix B:Test Results Decision Tables

Description

Battery meets or exceeds required standards.

Battery is good, but low on charge. Fully charge the battery for

optimal performance and life. Check for causes of low charge.

Battery requires charge to determine condition.

Battery fails to meet industry accepted standards.

Battery is low in charge and shows low reserve capacity. Low

reserve capacity will compromise the battery’s ability to provide

system current and hold a charge.

Battery is good for cranking purpose but shows low reserve

capacity. Low reserve capacity will compromise the battery’s

ability to provide system current and hold a charge.

Battery fails to meet industry accepted standards

www.midtronics.com

25

Appendix B:Test Results Decision Tables CPX-900

Alternator Test Results

Decision Action

The output from the alternator is normal.

Charging

Normal

No Output

Low Output

High

Output

No output detected. Check belts to ensure alternator is rotating when engine is running.

√ Check all alternator connections including to the battery. Clean or replace if necessary and

retest.

√ If the belts and connections are in good working condition, replace alternator or external voltage

regulator.

Alternator not providing enough current to power electrical loads and charge the battery.

√ Check belts to ensure the alternator is rotating with the engine running.

√ Check alternator connections to and from the battery. If loose or heavily corroded, clean or

replace the cable and retest.

Alternator voltage to the battery exceeds normal limits of a functioning regulator.

√ Check for loose and normal ground connections. If no connection problems are found, replace

the regulator.

The normal high limit of a typical automotive regulator is 14.5 volts +/–0.5. Refer to the manufacturer

specications for the correct limit, which may vary by vehicle type.

26

Midtronics Inc. 7000 Monroe Street Willowbrook, IL 60527

CPX-900

Appendix A: Recommended Scanning Procedure

www.midtronics.com

27

PATENTS

This product is made by Midtronics, Inc., and is protected by one or more U.S. and foreign patents.

For specic patent information, contact Midtronics, Inc. at +1 630 323-2800.

Midtronics products are warranted to be free of defects in materials and workmanship for a period

of one (1) year from date of purchase. Midtronics will, at our option, repair or replace the unit with

a re-manufactured unit. This limited warranty applies only to Midtronics products, and does not

cover any other equipment, static damage, water damage, overvoltage damage, dropping the

unit, or damage resulting from extraneous causes including owner misuse. Midtronics is not liable

for any incidental or consequential damages for breach of this warranty. The warranty is void if

owner attempts to disassemble the unit or to modify the cable assembly.

SERVICE

To obtain service, contact Midtronics at 866-592-8052. Have your model and serial numbers ready.

This rst step is critical as we will trouble-shoot the problem(s) over the phone, and many problems

are resolved during this step. If the problem cannot be resolved, then the Customer Service Agent

will issue you a Return Material Authorization (RMA). This number becomes your tracking number.

The nal step is to return the unit to Midtronics freight prepaid (you pay), to the attention of the

RMA number obtained.

In USA:

LIMITED WARRANTY

Midtronics, Inc.

Attn: RMA # xxxxx (this is the RMA number that you must obtain from Midtronics)

7000 Monroe St.

Willowbrook, IL 60527

In Canada:

Midtronics c/o FTN (FTN is Fed-ex Trade Networks –this is NOT a Midtronics facility)

Attn: RMA # xxxxx (this is the RMA number that you must obtain from Midtronics)

7075 Ordan Drive

Mississauga, ON L5T1K6

Midtronics will service and return the unit using the same type of service as received. If Midtronics

determines that the failure was caused by misuse, alteration, accident, or abnormal condition of

operation or handling, purchaser will be billed for the repaired product and it will be returned

freight prepaid with shipping & handling charges added to the invoice. Midtronics products

beyond the warranty period are subject to the repair charges in place at that time. Optional

re-manufacturing service is available to return our products to like-new condition. Out-of-warranty

repairs carry a 3-month warranty. Re-manufactured units purchased from Midtronics are covered

by a 6-month warranty.

www.midtronics.co m

Corporate Headquarters

Willowbrook, IL USA

Phone: 1.630.323.2800

Canadian Inquiries

Toll Free: +1 1 866 592 8052

support.cpx900.com

Midtronics b.v.

European Headquarters

Houten, The Netherlands

Serving Europe, Africa, the Middle

East, and The Netherlands

Phone: +31 306 868 150

Midtronics China

China Operations

Shenzhen, China

Phone: +86 755 2374 1010

167-000848EN-B 10/18 ©2018 Midtronics, Inc. All rights reserved.

Midtronics India

Navi Mumbai, India

Phone: +91 22 2756 4103/1513

Asia/Pacíc (excluding China)

Contact Corporate Headquarters

Phone: +1.630.323.2800

Loading...

Loading...