MidNite Solar MNE-240, MNE-240 E-panel Owner's Manual

MNE-240 Series E-panel

Owner’s Manual

Important Information

Disclaimer of Liability

MidNite products are not intended for use in connection with Life Support Systems. MidNite Solar

makes no warranty or representation in connection with their products for such uses.

Since the use of this manual and the conditions or methods of installation, operation, use of the

E-Panel are beyond the control of MidNite Solar, this company does not assume responsibility and

expressly disclaims liability for loss, damage or expense, whether direct, indirect, consequential

or incidental, arising out of or anyway connected with such installation, operation, or use.

Important Safety Instructions

This manual contains important safety instructions that must be followed during the installation

and operation of this product.

General Precautions

• Before installing and using this product read all instructions and safety information contained

in this manual and attached to the E-Panel.

• All electrical work must be performed in accordance with local, state and federal electrical

codes.

• This product is designed for indoor/compartment installation. It must not be exposed to rain,

snow, moisture or liquids of any type.

• Use insulated tools to reduce the chance of electrical shock or accidental short circuits.

• Remove all jewelry such as rings, watches, bracelets, etc., when installing or performing

maintenance.

• Always disconnect the batteries or energy source prior to installing or performing maintenance

on the inverter. Live power may be present at more than one point since an inverter utilizes

both batteries and AC.

Battery Safety

• Wear eye protection such as safety glasses when working with batteries.

• For battery installation and maintenance read the instructions provided with the batteries

prior to installing or use.

• Never work alone; always have someone near you when working around batteries.

• Use proper lifting techniques when working with batteries.

• Never use old or untested batteries. Check each battery's label for age, type and date code to

ensure all batteries are identical.

• Batteries are sensitive to changes in temperature. Always install batteries in a stable

environment.

• Install Flooded (Liquid Lead Acid) batteries in a well ventilated area. Theses type of batteries

can produce explosive gasses. For compartment or enclosure installations, always vent batteries

to the outside.

• Provide at least one inch of air space between batteries to provide optimum cooling.

• To prevent a spark at the battery and reduce the chance of explosion, always connect the

cables to the batteries fi rst. Then connect the cables to the inverter.

• Always verify proper polarity and voltage before connecting the batteries to the inverter.

• To reduce the chance of fi re or explosion, do not short-circuit the batteries.

• In the even of accidental exposure to battery acid, wash thoroughly with soap and water. In

the event of exposure to the eyes, fl ood them for at least 15 minutes with running water and seek

immediate medical attention.

MNE-240 Series E-Panel Owner’s Manual

1.0 Introduction

The MNE-240 Series E-Panel enclosure from MidNite Solar provides the basic DC and AC overcurrent protection and disconnects required for a NEC compliant renewable energy system. It is

specifi cally designed to accommodate inverters that provide 120/240VAC in a single unit. The

MNE-240 Series E-Panel can expand to grow as your needs arise and includes the following:

• Powder-coated steel chassis with knockouts to accommodate various install needs.

• Inverter mounts on a unique hinged door to keep a small system foot-print

• E-Panel mounting brackets are included to aid in one person installations

• Inverter battery breaker, inverters cables and snap in grommets included

• 500 amp/50 mV shunt included for battery monitoring systems

• Heavy duty 150 amp bus-bars for AC HOT, NEUTRAL, GROUND, BATT +/- and PV + included

• Dual 50 amp AC input disconnects for generator or utility (prewired)

• Dual 50 amp inverter AC Bypass Switch (prewired)

• Bracket included for mounting optional charge controller (Classic or MX60)

• Inverter, remote control and charge controller mounting hardware included

• One rectangular cut-out for mounting a North American GFCI style AC outlet

• Cut-outs for mounting up to six additional 13mm wide din-rail mount AC and DC breakers (for

circuits such as PV, wind, hydro or AC distribution)

• Conforms to UL508A 1st Edition and CS A C22.2 #14-M95 (Industrial Control Panel)

2.0 Features

Refer to Figure 1 for the following information.

The MNE-240 Series E-Panel incorporates all the AC and DC wiring bus-bars and disconnects

required to connect the Magnum MS-AE Series inverter/charger system.

It also provides additional room to install additional equipment, such as the MidNite Classic Charge

controller (with accompanying solar array breakers/disconnects and battery temp sensors), the

Magnum Battery Monitor, a PV Ground Fault device, and AC branch breakers (that can be used

in lieu of an AC sub-panel to power the inverter’s AC loads). These additional breakers are

installed on a supplied Din-rail mounting bracket that has space for up to six 13mm sized AC or

DC breakers.

The E-Panel includes a DC Breaker used to disconnect the battery bank from the inverter as

required by the National Electric Code (NEC). This breaker is also used as an overcurrent device

to protect against extremely high currents that a battery is capable of producing if any short

circuits occur. A variety of DC Breaker options are available from MidNite Solar.

Next to the DC Breaker is a 500 amp/50 mV shunt with a DC negative bus-bar attached. The

shunt is provided so that a Battery Monitor, which is used to determine the battery bank’s state

of charge, may be easily connected without any rewiring. The DC negative bus-bar provides a DC

negative connection point for any DC loads or PV Panels in the installation.

Located on the right side of the E-Panel system is an AC input disconnect and an inverter bypass

switch. The AC disconnect is used to remove the incoming AC power to the inverter input. The

inverter bypass switch is provided to easily route the incoming AC power around the inverter and

directly to the AC loads in the system - without rewiring or losing power to the AC loads in the

system - in case the inverter needs to be removed.

© 2007 MidNite Solar Page 1

MNE-240 Series E-Panel Owner’s Manual

FRONT SIDE

PWR

ME-RC

Remote

FAULT

CHG

INV

CHARGER

ON/OFF

Control

AC I nput/Output

Bus-bars

Battery

Po siti ve (+)

Bus-bar

Ne gative (-)

Inv e rti ng

SELECT

DC 50.4 5 A

ON/OFF

TECHAGSMETER SETUPSHOREINVERTER

Battery

Bus-bar

500A/50mV

Shunt

PV Po siti ve (+) Bus -b ar

DC

Up p er M o u nting Bracket

Right H i nge Door

(left hinge door is available)

Upper Shield

3030

30

MS-A E

Ground

Bus-bar

Series

Inverter/

Charger

ME-BMK

Battery

ect

Disconn

Monitor

Charge

Controller

Positi ve and Negative I n verter Cab l es

Inverter AC i nput/Output Wires

ME-RC Remote

Mou nting Bracket

(Optional R emote available)

Cutouts for GFCI AC Outlet

Mounting Bracket for

Charge Conroller

Many Knockouts with

vario u s si zes on every side

(not supplied )

Door Grommet (3.5")

AC I nput Di sconnect

INVERTER

ON

ON

OFF

OFF

BYPASS

Inver ter Bypass Swi tch

Cu tou ts for u p to si x 13mm

Din Rai l C ircu i t Breaker s

(breakers no t sup p l ied )

Ba tter y Shu t O ff

(for inverter)

DC Cover

Lower M o u nting Bracket

LEFT

SIDE

Figure 1, MNE-240 Series E-Panel Features

RIGHT

SIDE

© 2007 MidNite SolarPage 2

MNE-240 Series E-Panel Owner’s Manual

3.0 Installation

Before installing, read the entire installation section to determine how you are going to install

your E-Panel. The more thorough you plan in the beginning, the better your ov erall system needs

will be met.

A basic system diagram for the MNE-240 Series E-Panel is shown in Figure 2, MNE-240 Series

E-Panel System Wiring Diagram. This diagram should be reviewed to assist you in planning and

designing your installation.

Info: Installations should be performed by qualifi ed personnel, such as a licensed or

certifi ed electrician. It is the installer’s responsibility to determine which safety codes

apply and to ensure that all applicable installation requirements are followed.

Info: It is easier to install and wire any additional accessories (i.e. breakers for charge

control, the inverter, etc.) while the E-Panel is still lying horizontal on a table. Do as much

as possible before mounting the E-Panel on the wall.

3.1 Door Confi guration

The standard E-Panel ships with breakers on the right side and with a right hand hinge. The

door will open to the right over the breakers. If for some reason you need the breakers on the

right, but the door to open to the left, then you can purchase the left hand door (part number

MNEleftdoorSTM-240).

Info: The circuit-breakers can be moved from the right side and reassembled on the left

side of the chassis. Even though this is possible, it is not advised. Moving the breakers is

very time consuming and the bypass switch will need to be re-positioned and rewired. It

is much more effi cient to so spend the time before the installation to pre-determine and

order the correct side (left hinge or right hinge door).

3.2 Knockout Preparation

Info: See Figure 3 for the location and dimensions for the knock-outs on the MNE-240

Series E-Panel.

Think about all the different wiring required and remove the appropriate knockouts before

mounting the E-Panel. Knockouts for breakers and outlets are best accomplished using a straight

bladed screw driver and hammer. A hacksaw blade is another way to cut them out.

Determine the knockout uses for:

wiring from the E-Panel to an AC sub-panel

•

wire runs from utility and/or a generator to the E-Panel

•

battery cable wiring from the battery bank to the E-Panel

•

additional wiring from any external DC source (PV, Wind or Hydro) to the E-Panel

•

small signal wiring (battery sensors, battery monitoring, auto gen starting)

•

attaching lightning arrestors

•

charge control wiring

•

© 2007 MidNite Solar Page 3

MNE-240 Series E-Panel Owner’s Manual

Utility or Generator

120/240VAC Output

OFF

ON

OFF

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

AC Hot In 1

AC Hot In 2

ON

OFF

15A

AC Neutral

AC Hot Out 1

AC Hot Out 2

Output

120VAC

ON

OFFONOFF

30A 30A

Output

240VAC

ON

OFF

15A

Output

120VAC

From

E-Panel

(AC In)

to

Inverter

(AC In)

Inverter

AC I nput

Disconnect

(30A)

MAGNUM ENERGY

MS-AE Series

Inverter/Charger

AC WI RING

Op t ional Breakers/Disconnects

(6 spaces max @ 13mm)

Battery

Temperature

Sensor

Ba ttery Ban k

(48VDC)

AC Ground

ONON

ONON

OFF

OFF

Bypass

Switch

(50A)

INVERTER

50A50A

BYPASS

ON

OFFONOFF

OFFONOFF

50A50A

ON

120VAC

Outlet

From Inverter

(AC O u t) to

E-Panel (AC Out)

240VAC

Outlet

120VAC

Oulet

Remote Control

PWR

FAU LT

CHG

INV

ON/OFF

CHARGER

ON/OFF

AGS METER SETUPSHO REINVERTER

TECH

SELECT

DC WI RING

DC -

Buss

DC

Shunt

MIDNIGH T S OLA R

Classi c Contr oll er

DC +

ON

Buss

OFF

Shutoff

Main Bat tery

B PVPVB

PV Panels

PVPV

PV +

Buss

12V

12V

DC

Ground

12V 12V

Figure 2, MNE-240 Series E-Panel System Wiring Diagram

ON

OFF

63A

PV Output

PV + Input

ON

ON

OFF

DC-GFP

OFFONOFF

63A 0.5A

63A

© 2007 MidNite SolarPage 4

MNE-240 Series E-Panel Owner’s Manual

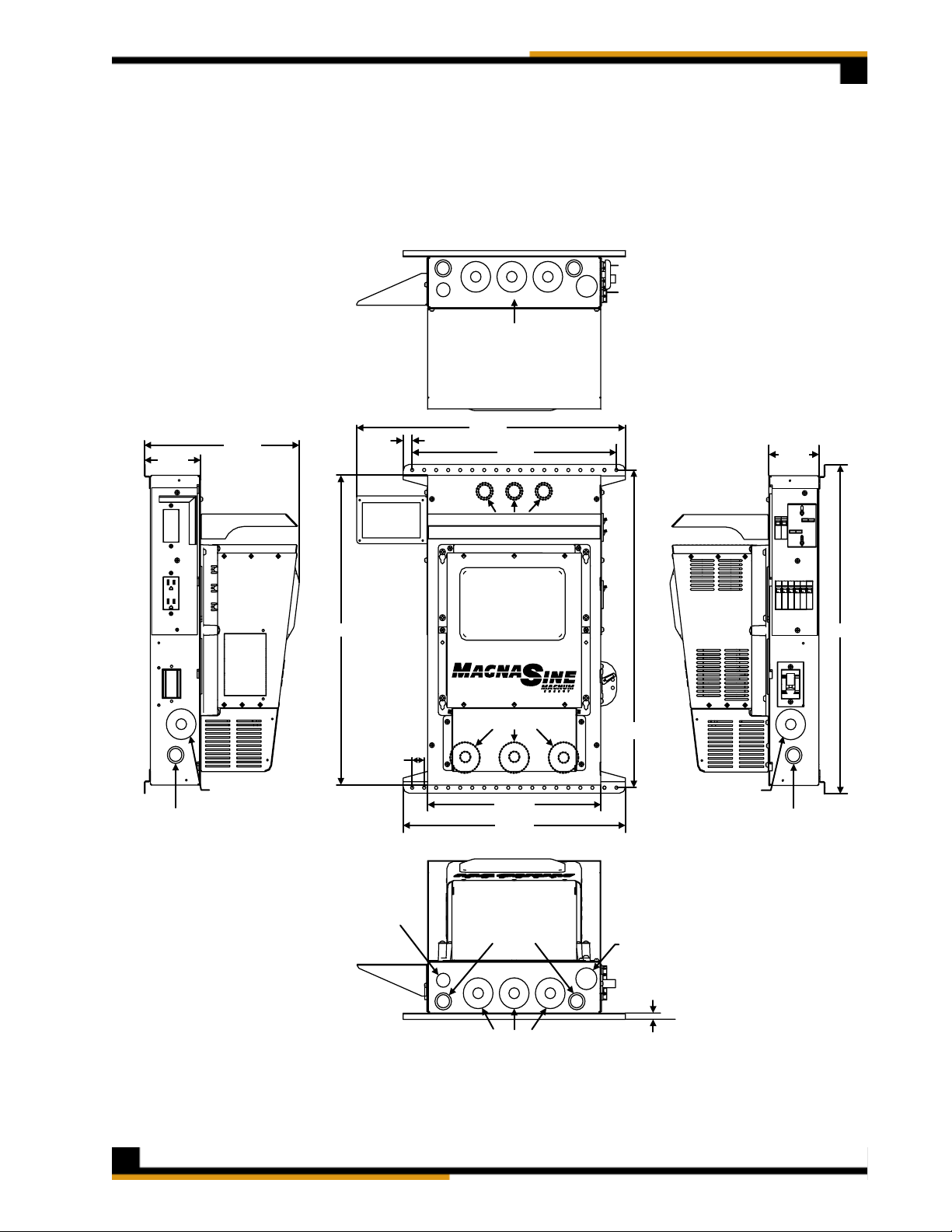

3.3 Knockout sizes and Dimensions

The dimensioned chassis drawing in fi gure 3 shows the location of the conduit knockouts, mounting

holes and mounting brackets.

Knockouts on the top surface are directly in line with ones on the bottom surface for stacking

•

units vertically.

TOP VIEW

UPPER CONDUIT

KNOCKOUTS ARE

MIRROR IMAGE OF

BOTTOM KNOCKOUTS

22.37"

4.67"

12.90"

0.75"

17.00"

4.17"

0.87" (1/2” CONDUIT)

2.47" (2" CONDUIT)

1.13" (3/4 CONDUIT)

1.38" (1" CONDUIT)

LEFT SIDE V I E W

24.91"

1.00"

1.13"

(3/4 CONDUIT)

INSIDE 1.13" (3/4 CONDUIT)

INSIDE 1.38" (1" CONDUIT )

INSIDE 0.87" (1/2” CONDUIT)

INSIDE 2.47" (2" CONDUIT)

14.41"

18.50"

1.13" (3/4 CONDUIT)

1.38" (1" CONDUIT)

26.45"

25.55"

0.87" (1/2” CONDUIT)

2.47" (2" CONDUIT)

1.13" (3/4 CONDUIT)

1.38" (1" CONDUIT)

RIGHT SIDE VIEW

1.75" 1 1/4” CONDUIT)

0.50"

0.87" (1/2” CONDUIT)

2.47" (2" CONDUIT)

BOTTOM VIEW

Figure 3, MNE-240 Series E-Panel Dimensions and Knockout Sizes

© 2007 MidNite Solar Page 5

MNE-240 Series E-Panel Owner’s Manual

3.4 Installing Optional Hardware

Additional Breakers

Additional AC circuit breakers can be installed per the manufacturer’s instructions on the open DIN

Rail in the E-Panel. This DIN Rail has locations available for six additional 13mm wide AC and DC

circuit breakers. These additional circuit breakers can be used for such things as: solar, wind or

hydro charge controllers, DC ground fault protector, AC and/or DC distribution center and more.

Info: MidNite offers 150VDC breakers in 1, 6, 7, 8, 10, 12, 15, 20, 30, 50 and 63 amps.

AC breakers are available in 10, 15 and 20 amp sizes that carry the UL489 and UL489A

branch circuit rating. MidNite also offers 30, 50 and 60 amp sizes that carry the UL1077

listing for supplementary protection but are not branch circuit rated; these breakers are

rated for continuous duty and are usually used as AC disconnects.

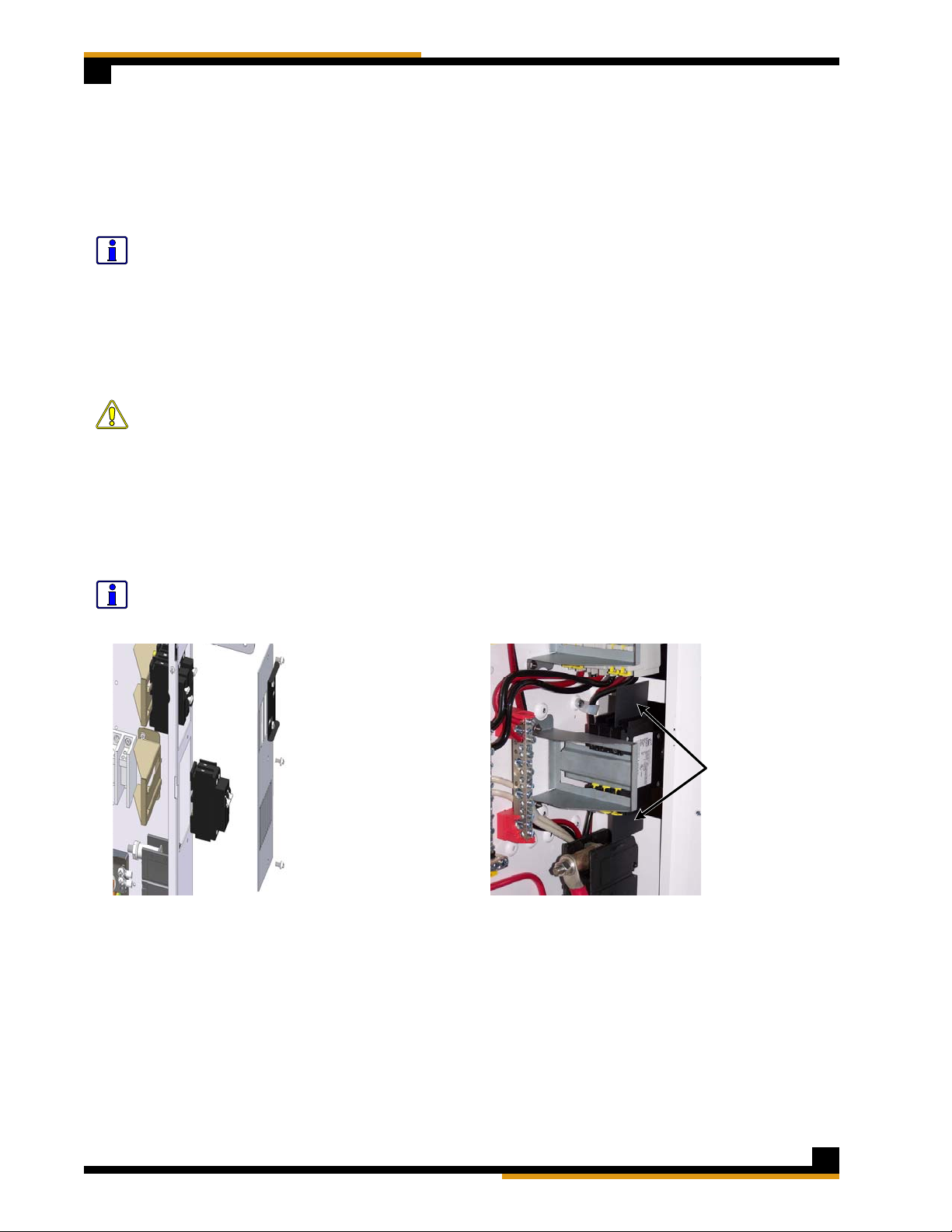

To install additional breakers, remove the side breaker cover with the circuit-breaker cut-outs;

see fi gure 4. Each 13mm wide breaker requires removal of two cut-outs and the 17.5mm wide

breakers require removal of three cut-outs.

Caution: T orque the breaker terminals to 20 in. lbs. using a 1/4” wide fl at-blade screwdriver

(do not use a 3/16” wide or Phillips screwdriver, they can damage the screw terminals

easily). It is highly recommended to recheck all terminations after an hour and also conduct

a pull test. You may be surprised that what you thought was a tight connection actually

pulls out with little effort. Copper is a relatively soft metal and will continue to move under

inadequate clamping pressure; a 20 inch pound of torque takes a lot of strength!

When installing DC and AC breakers together on the same din rail. Some local inspectors will

require physical separation between the AC and DC breakers. There are UL listed plastic 2” x 6”

insulators supplied with this E-Panel to fulfi ll this separation requirements; see fi gure 5.

Info: UL and the NEC allow mixing AC and DC wiring in this installation because the wire

insulation is rated for the highest voltage encountered in the enclosure. Both AC and DC

circuits are considered part of the same Renewable Energy circuit for this installation.

2 x 6" insulators

(placed between the

din-rail mounted DC

and AC breakers)

Figure 4, Removing and replacing

the breaker cover

Figure 5, Insulators between AC and DC

breakers

Charge Controller Bracket

If installing a Charge Controller, secure the charge control bracket to the E-Panel with two #10 x

3/8” sheet metal screws supplied.

Inverter Remote Bracket

If installing the inverter remote control, secure the remote bracket to the upper left hand side

of the E-Panel with two #10 x 3/8” sheet metal screws supplied. When installing the bracket on

the right side, use two sheet metal screws and one machine screw. The remote bracket hides the

space of the AC outlet cut out, but the outlet still can be used with the bracket installed.

© 2007 MidNite SolarPage 6

Loading...

Loading...