MidNite Solar Classic 150, Classic 200, Classic 250, Classic 250KS Lite, Classic 150 Lite Owner's Manual

...

MidNite Solar Classic

Owner’s Manual

Standard Classic Classic Lite

This Manual covers models Classic 150, 200, 250 &

250KS as well as the Classic 150, 200, 250 & 250KS LITE

1 | P a g e

The MidNite Solar Classic charge controller conforms to UL 1741, Safety for Inverters, Converters,

Controllers and Interconnection System Equipment for Use With Distributed Energy Resources,

Second Edition, May 7, 1999 with revisions through January 28, 2010 and

CAN/CSA C22.2 No. 107.1: 2001/09/01 Ed: 3 (R2006)

Notice of Copyright

MidNite Solar's Classic charge controller User’s Manual

Copyright ⓒ 2010 all rights reserved.

MidNite Solar Inc. reserves the right to revise this document and to periodically make changes to the

content hereof without obligation or organization of such revisions or changes unless required to do so

by prior arrangement.

Disclaimer

Unless specifically agreed to in writing, MidNite Solar Inc.

(a) Makes no warranty as to the accuracy, sufficiency or suitability of any technical or other

information provided in its manuals or other documentation.

(b) Assumes no responsibility or liability for loss or damage whether direct, indirect, consequential or

incidental, which might arise out of use of such information. The use of any such information will be

entirely at the user's risk.

Contact Information

Telephone: 360.403.7207

Fax: 360.691.6862

Email: customerservice@midnitesolar.com

Web: www.midnitesolar.com

2 | P a g e

YOUR MIDNITE SOLAR DISTRIBUTOR

SOLIGENT

800-967-6917

www.soligent.net

Table of Contents

Glossary of Terms..................................................................................................................................... 5

Scope .......................................................................................................................................................... 7

Introduction .............................................................................................................................................. 7

Classic Power Curves ............................................................................................................................... 9

Unpacking the Classic ............................................................................................................................ 11

Removing and installing the front cover on the Classic ..................................................................... 12

Mounting the Classic ............................................................................................................................. 13

Alternative Mounting .......................................................................................................................... 15

Dimensions...................................................................................................................................... 15

Sealed or Vented .................................................................................................................................. 16

Battery Temperature Compensation .................................................................................................... 16

Classic Stacking Cable Routing and Installation Guidelines ............................................................. 17

Battery Temperature Sensor Installation ............................................................................................. 18

Chassis Grounding ................................................................................................................................. 20

DC System Grounding ........................................................................................................................ 20

DC GFP (Ground Fault Protection) ..................................................................................................... 21

Disabling GFP ..................................................................................................................................... 21

Wiring the Classic .................................................................................................................................. 22

DC Terminal Connector ...................................................................................................................... 25

Over Current Protection and Wire Size Requirements ...................................................................... 25

Current Rating ..................................................................................................................................... 25

Over Current Protection ...................................................................................................................... 26

Long Distance Wire Runs ................................................................................................................... 26

Connecting the Classic to the Clipper ................................................................................................. 26

Maximum and Minimum Wire Size .................................................................................................... 27

Equalization Manual and Auto ............................................................................................................. 28

Equalization with the Classic Lite ...................................................................................................... 28

Equalization with the standard Classic ............................................................................................... 29

Standard Classic programming ............................................................................................................ 30

Commissioning the Classic (Quick Start) ........................................................................................... 30

Battery Charge Stages and Meanings ................................................................................................. 30

Resting ............................................................................................................................................ 30

Mode is OFF ................................................................................................................................... 31

Adjusting Absorb, Equalize and Float Voltages .................................................................................. 31

Current Limit....................................................................................................................................... 31

LED Modes and the “Blinking Red LED”.......................................................................................... 31

Calibrating Battery and PV Voltage .................................................................................................... 32

Configuring DC Input Source ............................................................................................................. 32

Configuring the Classic for Wind Input Source .................................................................................. 34

Setting the Date and Time ................................................................................................................... 35

Setting Longitude and Latitude ........................................................................................................... 35

Configuring Auxiliary Input/Output ................................................................................................... 35

Aux 1 Function................................................................................................................................ 39

Aux 2 Function. Output/Input ......................................................................................................... 40

Setting the MNGP features ................................................................................................................. 41

Navigating the Menu's ........................................................................................................................ 41

3 | P a g e

Viewing Other MidNite Products on the Display ............................................................................... 42

Connecting Classic to Two MNGPs/Network cable ........................................................................... 42

Arc Fault ............................................................................................................................................. 43

View Faults and Warning's .................................................................................................................. 44

View Logged Data .............................................................................................................................. 44

Graphical Logging Display modes ..................................................................................................... 47

Dealer Information Screen .................................................................................................................. 49

Classic Lite Programming ..................................................................................................................... 50

LED explanations ................................................................................................................................ 50

Programming ....................................................................................................................................... 51

Dip Switches ....................................................................................................................................... 51

Section 1 Switch settings explained ................................................................................................. 53

Section 2 Switch settings explained ................................................................................................. 54

Battery voltage and time settings .................................................................................................... 57

Using MNGP Remote to program a Classic Lite ................................................................................ 58

Programming the Lite with a Networked Standard Classic ................................................................ 58

Programming the Lite with the Local App .......................................................................................... 59

Clearing Faults .................................................................................................................................... 59

Notes on the Lite ................................................................................................................................. 59

Explanations of Solar and Legacy ...................................................................................................... 59

Uploading New Firmware to the Classic .............................................................................................. 60

Connecting the Classic to the Internet ................................................................................................. 63

Networking.......................................................................................................................................... 63

Network Setup Through the MNGP ................................................................................................... 64

Web Access ......................................................................................................................................... 66

Local Network..................................................................................................................................... 66

Positive Ground systems ........................................................................................................................ 66

HyperVOC ™ ......................................................................................................................................... 67

Troubleshooting ...................................................................................................................................... 68

Specifications Electrical ......................................................................................................................... 69

Specifications Mechanical ..................................................................................................................... 70

Default Battery charge set points ......................................................................................................... 71

Optional accessories ............................................................................................................................... 71

Regulatory Approval .............................................................................................................................. 71

Warranty ................................................................................................................................................. 72

Appendix ................................................................................................................................................. 73

Aux 1 and Aux 2 Graphs/Jumpers ...................................................................................................... 73

Aux 1 Voltage-Time Relation (Relay/12v) ......................................................................................... 74

............................................................................................................................................................. 74

Aux 2 Voltage-Time Relation (PWM) ................................................................................................ 74

Classic Breaker sizing ......................................................................................................................... 75

Label Set from Classic ........................................................................................................................ 77

MODBUS............................................................................................................................................ 78

RS232 Jack Pin Out .......................................................................................................................... 102

4 | P a g e

Glossary of Terms

Absorb – Constant voltage charge stage to fill the batteries. The controller is regulating so maximum power will

not be seen at this time. The Absorb timer is also counting down to the switch to Float.

A-EQ-R – This will reload the Auto Equalize counters, basically it will start the counters from day 1.

AF – Arc Fault, See page 43 for more info on arc fault protection.

Arc Adjust – This menu is where you adjust the Arc Fault sensitivity. For info on Arc Fault see page 43.

A-RST – Auto reset of the Classic controller, The Classic will reboot around Midnight every night when this is

enabled. This is useful for very remote sites where a loss of internet capability for example would be a hard ship.

Aux – Auxiliary relays. The Classic has 2 relays: Aux 1 can be configured as a 12 volt signal or a dry relay, Aux

2 can be used as a PWM signal output. Refer to page 35 for more Aux info.

BLK – Bulk MPPT Mode. By using the up arrow in Tweaks under BLK you can force the Classic into Bulk

mode.

Bulk MPPT - Maximum current charge stage, the Classic is trying to bring the batteries to the Absorb voltage

set point. We are basically putting all available power into the batteries.

Comm – This Menu allows adjustment of things like Mod Bus port, USB Mode and MNGP address.

DvrtCnt – When enabled, allows the charge stage timers to continue to run when the diversion modes are hold-

ing the battery voltage just below the actual set point.

Equalize - Constant voltage charge stage to equalize the batteries. The controller is regulating so maximum

power will not be seen at this time. The Equalize timer is also counting down to the switch to Float.

EQ MPPT - Maximum current charge stage, the Classic is trying to bring the batteries to the Equalize voltage

set point. We are basically putting all available power into the batteries.

Float – Constant voltage charge stage with a lower voltage than the Absorb charge point. The controller is regu-

lating so maximum power will not be seen at this time.

Float MPPT – Maximum current charge stage, the Classic is trying to bring the batteries to the Float voltage set

point. We are basically putting all available power into the batteries.

FLT – Float mode. By using the up arrow in Tweaks under FLT you can force the Classic into Float mode.

GF – Ground Fault, See page 21 for more info on ground fault protection.

Got Comm – Indicates a lack of communication between the display and the Classic. Consult Troubleshooting

for information page 68.

5 | P a g e

Insomnia – This when enabled, will keep the Classic from going to Resting. This is intended for hydro mode

only where you may need time to open water valves and do not want to wait for the Classic to wake up.

LED-MODE – This selection lets you pick the function of the 6 visible LED’s on a standard Classic.

LMX – LoMax, This enables the Classic to track the input voltage all the way down to Battery voltage. When

disabled the Classic will stop tracking the input around 5 volts above the battery voltage. When the input voltage

is within a couple volts of the battery voltage the inductors can “Sing” this is usually not very loud and will do

no harm.

Local App – Monitoring software included with the Classic for monitoring over the Local Network or Internet.

MNGP – Midnite Graphical interface Panel. This is the graphical display included with the standard Classic

controller.

MNLP – MidNite LED interface Panel. This is the LED display that comes standard with the Classic Lite.

Mode – This menu lets you turn the charging ability of the controller On / Off as well as lets you select the DC

input source. See page 30 for info on the Mode menu.

Mod Bus – a standard protocol used for communications. We have published our protocol to allow users to in-

terface with the Classic. See page 78 for our Mod Bus protocol.

My MidNite – Web based monitoring for the Classic. (Not available yet)

NiteLog – When enabled allows the Classic to log data in the evening when the Classic is Resting.

PV Shading – This indicates the Maximum power point voltage is less than half the open circuit voltage.

Pwr Save – Allows you to adjust the time the Backlight stays on.

Resting – The Classic is not charging the battery due to low light. For reasons Resting will appear please see

page 30.

Shade – When enabled the Classic will show PV Shading on the display when the Maximum power point volt-

age is less than half the open circuit voltage.

T-Comp – Temperature compensation using a temperature sensor to measure the ambient temperature of the

battery bank and will adjust the voltage set points up or down accordingly to ensure a full battery. There are 3

parameters to set Minimum and Maximum adjusted voltage as well as volts per degree C per Cell. Typically this

is -.05 mV but please consult your battery manufacturer. See page 16 for Temperature compensation info.

Tweaks – This menu has all the advanced adjustments for the Classic. For example: Voltage off set adjustments

etc.

VBatt – Battery voltage, measured at the battery terminals of the Classic.

VOC – Open Circuit Voltage, unloaded voltage measurement.

Vpv – Input voltage, measured at the input terminals of the Classic.

6 | P a g e

Web Access – When enabled allows the Classic to send data over the internet to My MidNite’s Server for you to

view when wanted.

Scope

This Manual provides safety guidelines and installation information for the Classic charge controller. It

does not provide brand specific information about photovoltaic panels, batteries etc. Contact the

manufacturer of other components in the system for relevant technical data.

Introduction

The MidNite Classic charge controller is unique in its ability to be used for a great variety of DC input

sources. The Classic is designed to regulate DC input from PV, and Approved Hydro and Wind turbines

for other DC sources please contact MidNite Solar tech support.. The Classic 150, 200 and 250 are

designed to work with 12, 24, 36, 48, 60 and 72 volt battery banks.

The Classic250KS is designed to charge up to a 120V nominal battery bank.

The Classic can be installed stand alone or as a multi-unit networked installation.

Standard features of the Classic charge controller include:

*3 input operating voltage ranges 150, 200 and 250 VDC

*Multiple DC input options (example Solar, Wind or Hydro)

*Wizard driven setup interface including voice and help screens

*Graphical display

*Previous 180 days of operational data logged

*Internet ready

This Manual covers Classic 150, Classic 200 Classic 250 and the Classic 250KS. It covers the

installation, wiring and use of the Classic charge controller.

WARNING Warnings signs identify conditions or practices that could result in personal injury or loss of

life.

CAUTION Cautions identify conditions or practices that could result in damage to the unit or other

equipment.

MIDNITE SOLAR CHARGE CONTROLLER INSTALLATION GUIDELINES AND SAFETY

INSTRUCTIONS

This product is intended to be installed as part of a permanently grounded electrical system as shown in the

system configuration sections. The following important restrictions apply unless superseded by local or national

codes:

7 | P a g e

•The System's DC Negative conductor must not be bonded to earth ground. The Classic does this with its

internal Ground Fault Protection circuitry. The battery negative and ground are not bonded together directly but

are connected together by the Classic’s internal GFP device. All negative conductor connections must be kept

separate from the grounding conductor connections. The equipment ground terminal inside the Classic must be

connected to Earth Ground for the internal DC-GFP to work. Continue

• With the exception of certain telecom applications, the Charge Controller should never be positive grounded.

• The Charge Controller equipment ground is marked with this symbol:

• If damaged or malfunctioning, the Charge Controller should only be disassembled and repaired by a qualified

service center. Please contact your renewable energy dealer/installer for assistance. Incorrect reassembly risks

malfunction, electric shock or fire.

• The Charge Controller is designed for indoor installation or installation inside a weatherproof enclosure. It

must not be exposed to rain and should be installed out of direct sunlight.

For routine, user-approved maintenance:

• Turn off all circuit breakers, including those to the solar modules, batteries and related electrical connections

before performing any maintenance.

Standards and Requirements

All installations must comply with national and local electrical codes; professional installation is recommended.

The NEC in the USA requires a DC ground fault interrupter for all residential PV installations. NEC2011

requires an ARC FAULT detector on all charge controllers and inverters operating above 80VDC. Both of these

devices are built into the Classic.

DC and Battery-Related Installation Requirements:

All DC cables must meet local and national codes.

Shut off all DC breakers before connecting any wiring.

Torque all the Charge Controller’s wire lugs and ground terminals to the specs found on page 19.

Copper wiring must be rated at 75° C or higher.

Keep cables close together (e.g., using a tie-wrap) as much as possible to reduce inductance.

Ensure both cables pass through the same knockout and conduit to allow the inductive currents to

cancel.

DC battery over-current protection must be used as part of the installation on the input and output.

Breakers between the battery and the Classic must meet UL489 standards.

Breakers between the DC source and the Classic must meet UL1077 or UL489 standards.

Design the battery enclosure to prevent accumulation of hydrogen gas at the top of the enclosure. Vent the

battery compartment from the highest point to the outside. A sloped lid can also be used to direct the flow of

hydrogen to the vent opening. Sealed (AGM, Gel etc) batteries do not normally require ventilation. Consult your

battery manufacturer for details.

WARNING: PERSONAL PRECAUTIONS DURING INSTALLATION

WARNING BATTERIES PRESENT RISK OF

8 | P a g e

ELECTRICAL SHOCK, BURN FROM HIGH SHORT CIRCUIT CURRENT, FIRE OR

EXPLOSION FROM VENTED GASES. FOLLOW PROPER PRECAUTIONS.

Someone should be within range of your voice to come to your aid if needed.

Keep plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

Wear complete eye protection. Avoid touching eyes while working near batteries. Wash your hands with

soap and warm water when done.

If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters an eye,

flood the eye with running cool water at once for at least 15 minutes and get medical attention

immediately following.

Baking soda neutralizes lead acid battery electrolyte. Keep a supply on hand in the area of the batteries.

NEVER smoke or allow a spark or flame in vicinity of a battery or generator.

Be cautious to reduce the risk of dropping a metal tool onto batteries. It could short the batteries or other

electrical parts that can result in fire or explosion.

Never wear metal items such as rings, bracelets, necklaces, and watches when working with a battery or

other electrical circuits. A battery can produce a short circuit current high enough to weld a ring or the

like to metal, causing severe burns.

Classic Power Curves

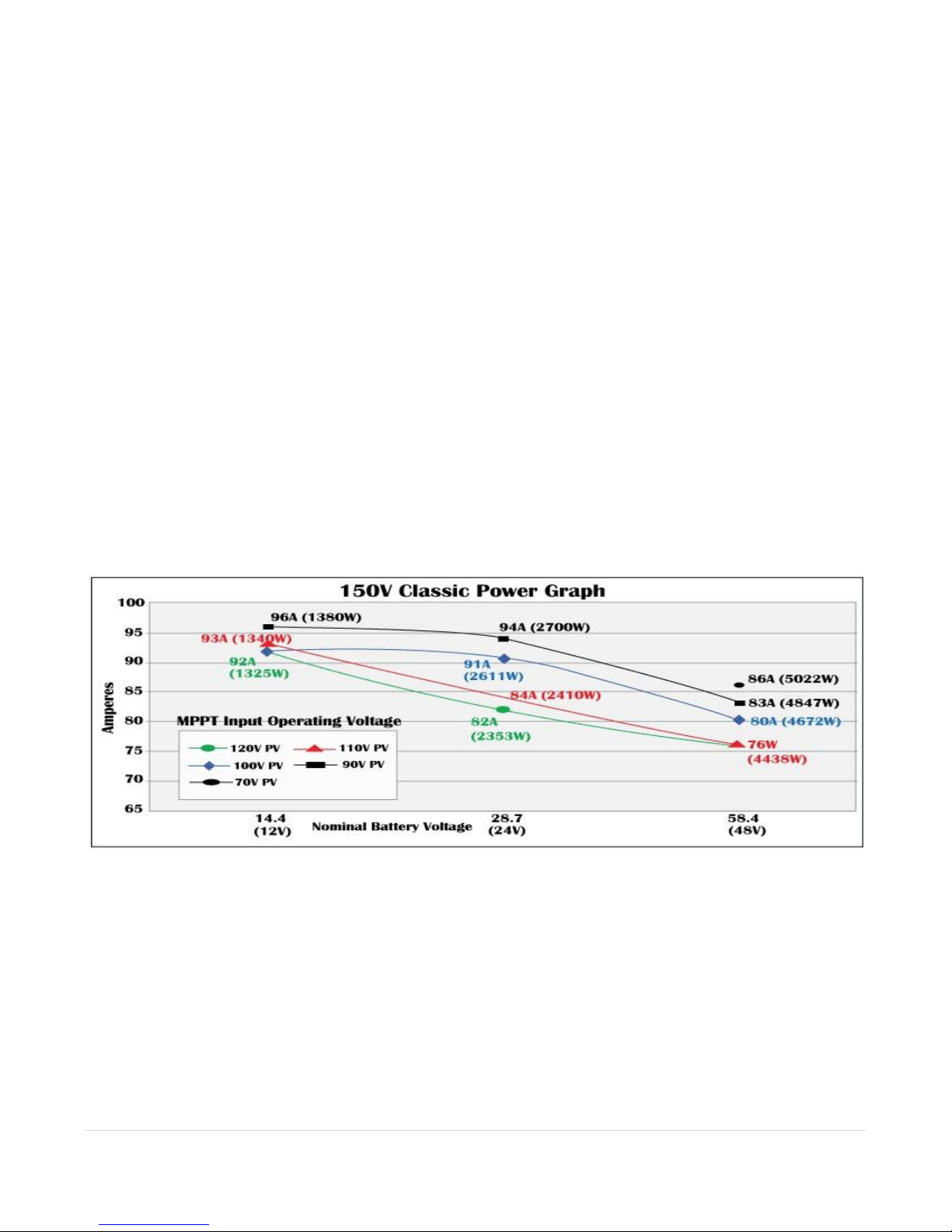

Figure 2.1

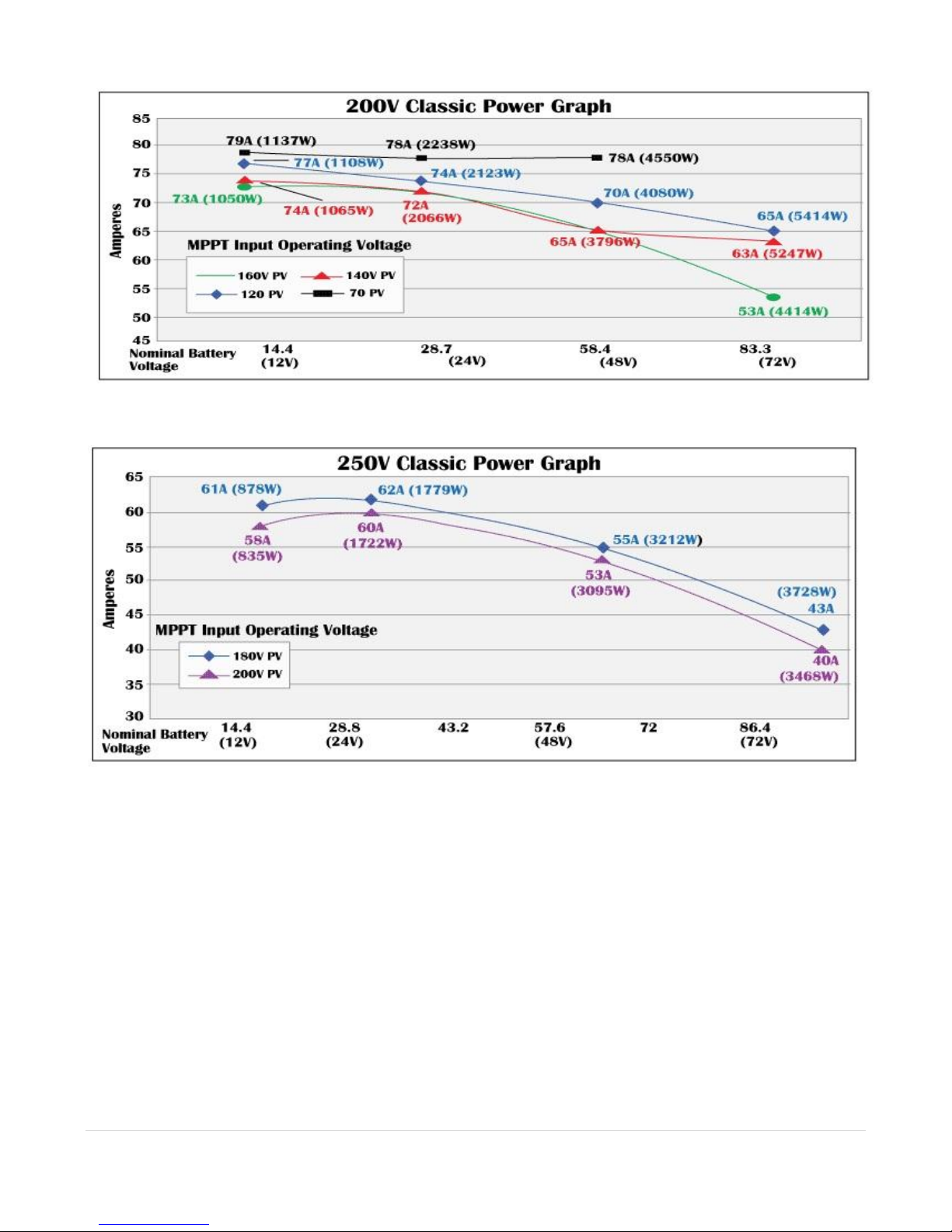

Figure 2.2

9 | P a g e

Figure 2.3

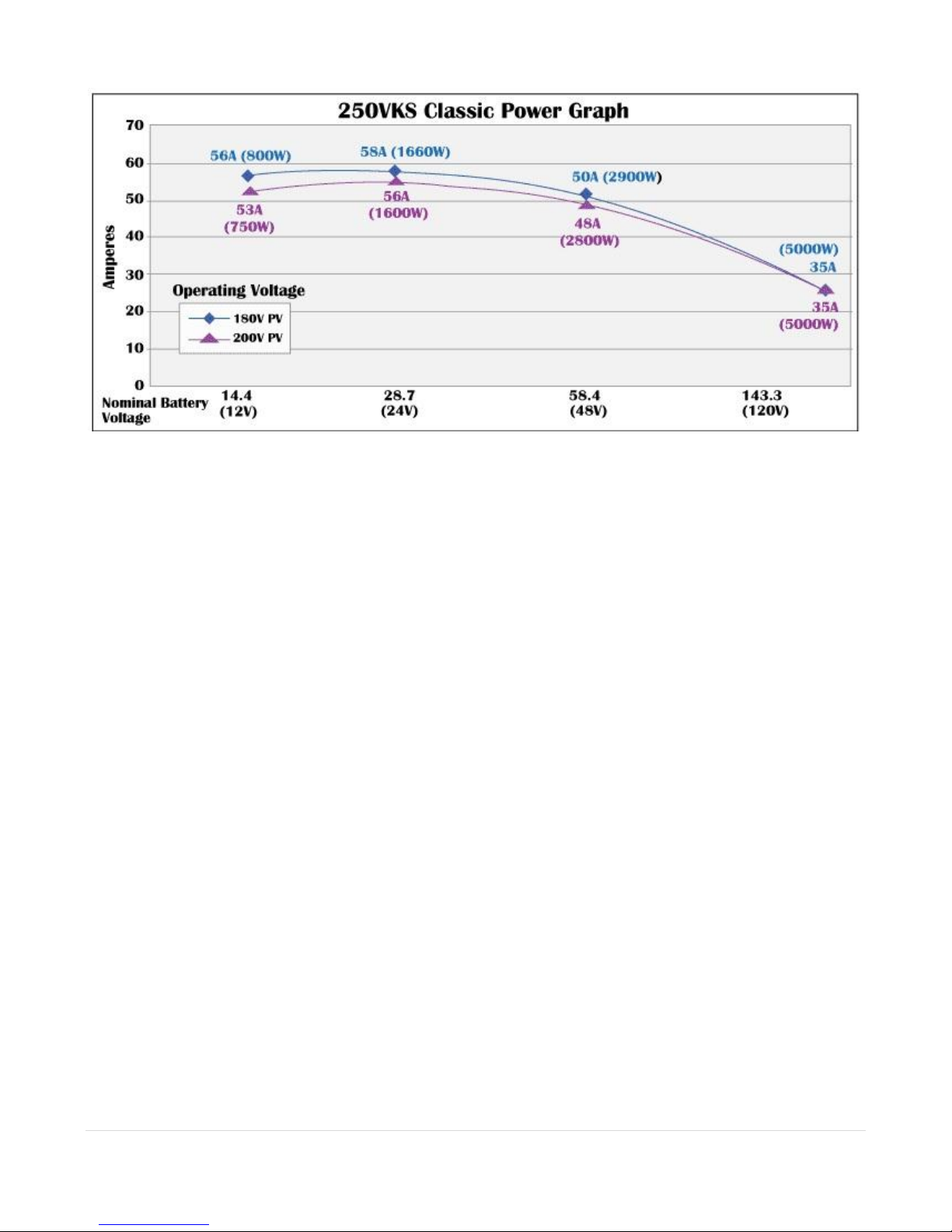

Figure 2.4

10 | P a g e

The graphs above represent the max power output for a given input for each Classic. Using and understanding

these power graphs will help maximize Classic’s output power and aid in selecting wire and breaker/disconnects.

The built in set up wizard also helps select breakers and wire sizes. Notice that lower battery voltages and lower

PV input voltages result in higher continuous output power. The PV voltages listed are for reference and are not

intended to be the only PV voltages supported. The battery voltages listed show the most used battery bank

configurations. Other voltages are also supported. The Classic battery voltage parameters are fully user

adjustable.

For example: if you are using a Classic 250 and 48v battery bank, the maximum continuous output power

based on 25 degree C ambient is 55 amps when using a PV array that yields a Maximum Power Voltage of 180

volts. The same set up using a bit higher voltage modules that result in a 200V Maximum Power voltage will

result in only 53 amps. Although 55 to 53 amps is not a significant change, it does give you the idea that all

things being equal, lower voltages are a bit more efficient.

Unpacking the Classic

When you receive your Classic you will want to unpack it and make sure everything is there and in

good shape. Refer to Figure 1.1. Included in the Classic package should be:

*Classic charge controller

*Battery temperature sensor

*Knock out covers 4 screened

*User’s manual DVD, printed installation instructions

*USB cable for upgrading Firmware

**Snap on upper vent cover

**Knock out covers 4 solid

**Note. These items are optional and do not ship as standard equipment. Email

customerservice@midnitesolar.com for more information or if anything is missing or damaged.

11 | P a g e

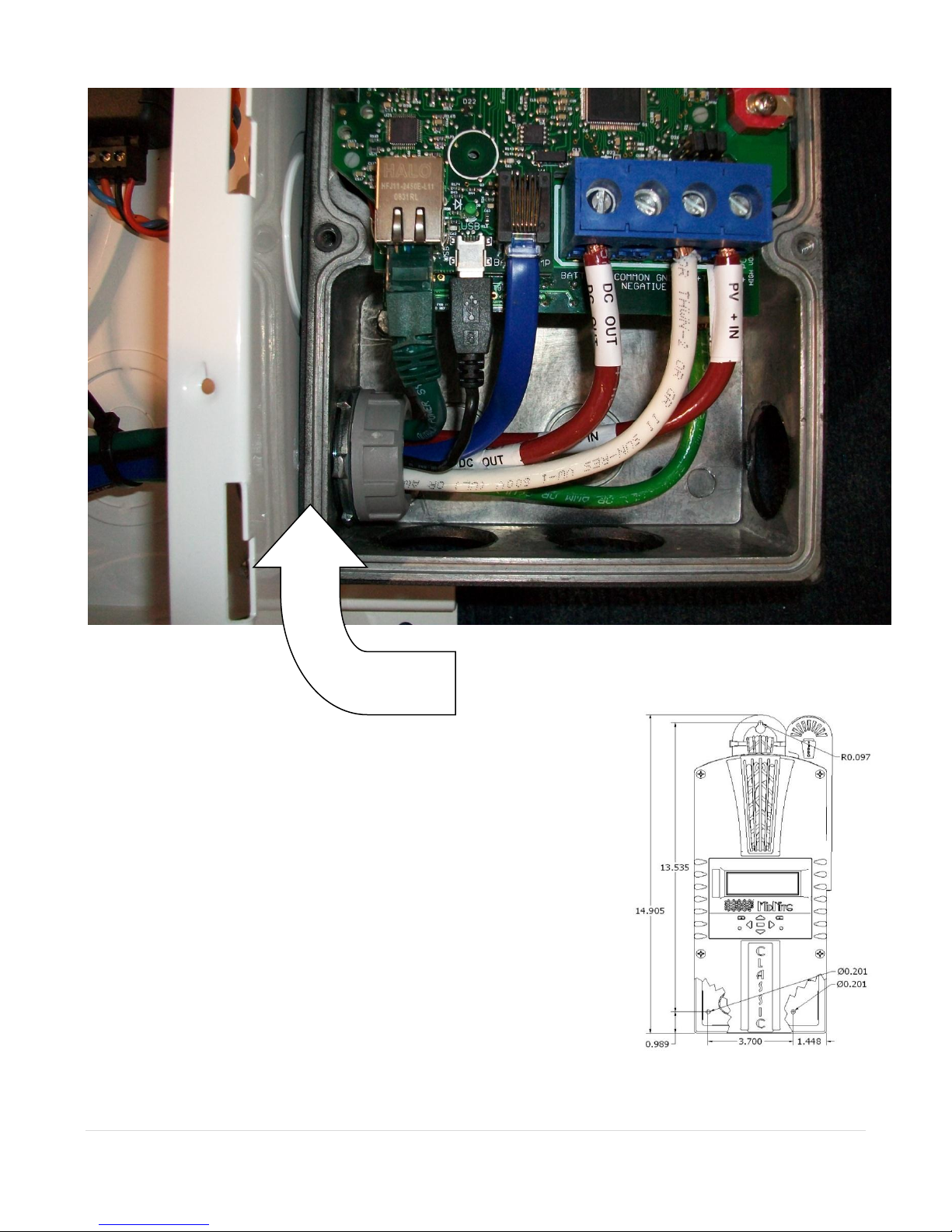

Removing and installing the front cover on the Classic

Removing the front art deco cover is required to gain access to the wiring compartment.

Be aware if this is not the first removal of this cover there is a cable connecting the cover to the

electronics. Do not pull hard or fast as damage could occur.

To remove the front cover of the Classic in preparation for installation, remove the 4 Phillips head

screws with a #2 Phillips screwdriver. Lift the front half of the Classic casting off. You will need to

unplug the display cable. It works the same as any phone cable.

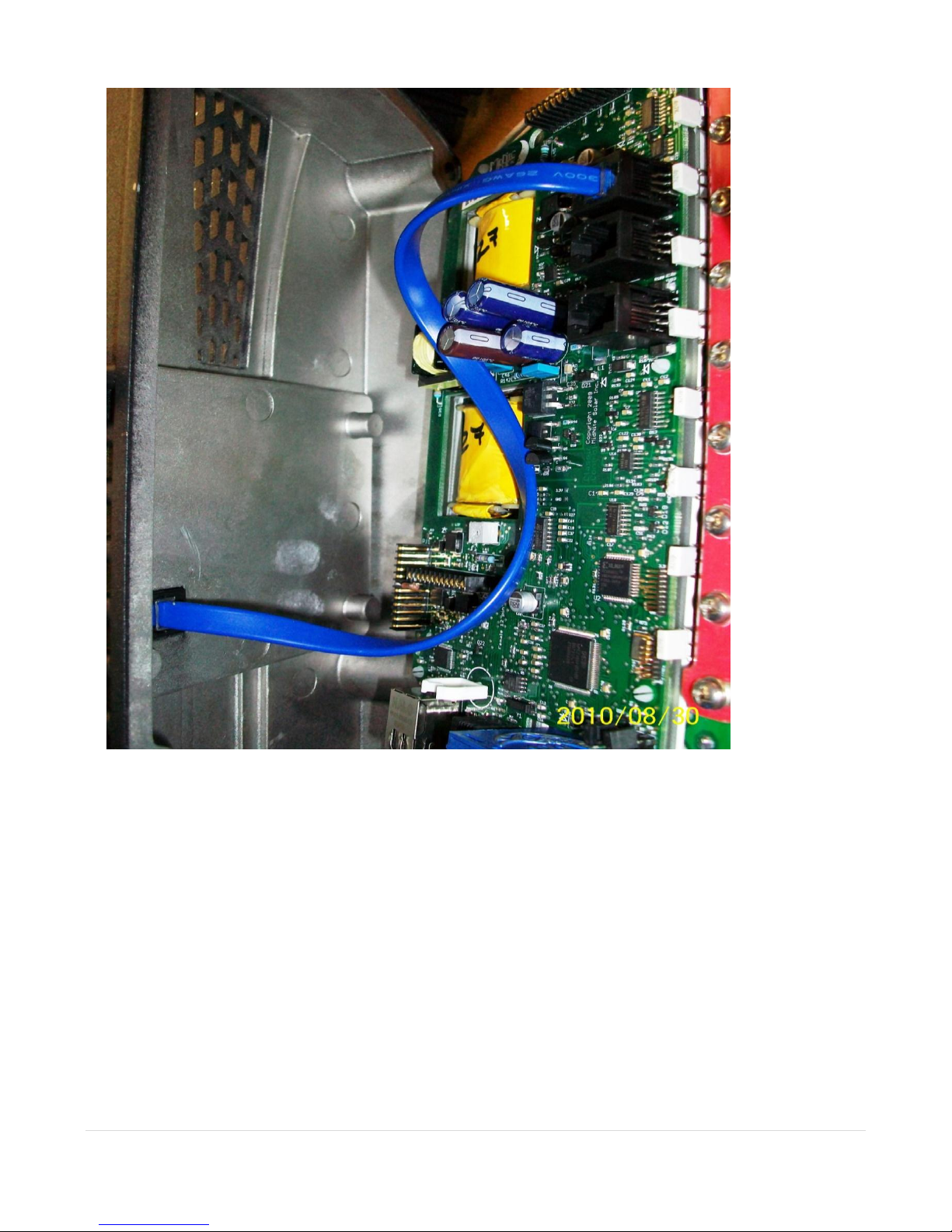

To re-install the front cover of the Classic you will need to plug in the display cable and carefully route

it around the components on the circuit board as you set the cover in place. See Figure 1.2 Do not force

the cover if it does not seat into place easily stop and look for any cables or wires that may be

interfering. With the cover seated in place install the four Phillips screws with a #2 Phillips screwdriver.

Figure 1.2

12 | P a g e

Mounting the Classic

The following section covers typical mounting arrangements. If you require additional details that are

not covered here please contact our technical support team. The Classic is designed to be directly

mounted onto the MidNite Solar E-Panel. The Classic can also accommodate other installation methods

as well. Mount in an upright position out of direct sunlight when possible. For your convenience the

Classic has four one inch knock outs that are pre cast. The Classic has mounting locations and conduit

locations are similar to other brands of charge controllers to facilitate ease of upgrading older

technologies.

Mounting the Classic directly to the E Panel:

*Remove the front cover of the Classic.

*Install the mounting bracket on the E Panel and start the upper mounting screw into the bracket

leaving it about half way out so you can hang the Classic on this screw.

*Install the 1 inch close nipple into the E Panel as shown in the E-Panel directions. The 1” close nipple,

3 locknuts and 2 plastic bushings are included with each E-Panel. One locknut acts as a spacer.

13 | P a g e

*Carefully hang the Classic on the screw in the bracket and slide it over the close nipple see figure 1.3.

Figure 1.3A Charge controller

bracket comes with every E-Panel

*Install the lock nut and bushing on the close nipple and tighten the screw in the mounting bracket.

*Don't install the front cover until you complete the wiring of the Classic.

bracket mounted to the E-Panel. The

Figure 1.3B Classic Mounted to side of E-Panel Figure 1.3C Nipple, locknuts and bushings

that come with every E-Panel

Figure 1.3D Classic mounted to the side of a MidNite Solar E-Panel

14 | P a g e

Install locknut here to act as a spacer.

Alternative Mounting

To mount the Classic to a plywood surface use 1 1/2” wood screws in

the top key hole slot hole and the holes in the wiring compartment.

Taking care to make sure the Classic is Plumb and Level.

Dimensions

See page 70 for more details.

15 | P a g e

Sealed or Vented

The Classic has the ability to be sealed for protection from salt air or dust. It comes from the factory

Vented. If you live in a dusty or salt air environment you may wish to seal the Classic. Sealing the

Classic does not make the unit water resistant. To seal the Classic install the solid plastic knock out

covers into any unused knock outs and snap the upper vent cover onto the Classic as seen in the photo

below. Note that the Classic will be slightly de-rated (puts out less power) by sealing it. Refer to the

specifications page of the owner’s manual for the ratings in the sealed mode. To obtain the parts

necessary to seal the Classic please contact our Technical Support Team. Refer to Figure 1.4 and 1.5

Figure 1.4 Figure 1.5

Battery Temperature Compensation

The Classic comes with a battery temperature sensor (BTS). This sensor raises or lowers charge voltage

based on temperature. Connect BTS to the BATT TEMP jack. (Refer to Battery Temperature Sensor

Installation 18) Battery temperature menu appears as T-Comp in the BATTERY MENU. In this menu

you can change the voltage compensation as needed. If the BTS is disconnected or shorted the Classic

will automatically use the default charge voltages non-compensated.

16 | P a g e

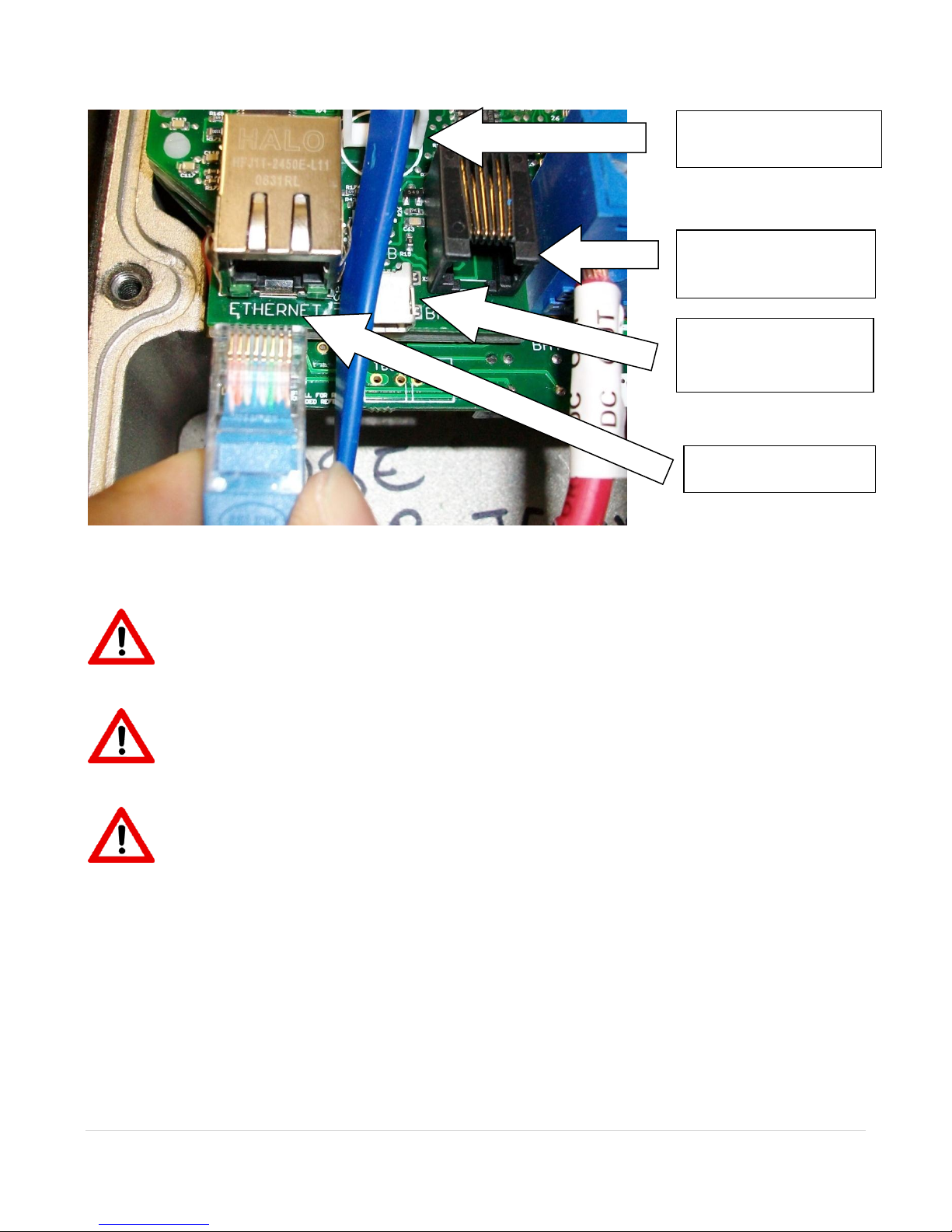

Classic Stacking Cable Routing and Installation Guidelines

Master Classic

Slave Classic

The Classic uses a 4 conductor phone cable to communicate with other Classic's or other MidNite products. This

cable is a standard 4 conductor phone cable and simply plugs into the jack on the Master Classic labeled slave.

Plug the other end into the master jack on the second device (Slave). There is a plastic clamp located on the

circuit board for routing the network cables above the USB jack so they stay tied down and out of the way.

Refer to figure 1.7A and 1.7B

Figure 1.7A Master / Slave hook up

17 | P a g e

Battery Temp Sensor

Cable Clamp for

network cables

USB connector

USB cable is included

Ethernet connector

included

Figure 1.7B

Battery Temperature Sensor Installation

CAUTION - To reduce risk of injury, charge only deep-cycle lead acid, lead antimony, lead calcium,

gel cell or absorbed glass mat type rechargeable batteries. Other types of batteries may burst, causing

personal injury and damage. Never charge a frozen battery.

WARNING: RISK OF INJURY. To reduce the risk of injury, charge only properly rated (such as 6

V 12 V and 24 V ) lead-acid (GEL, AGM, Flooded, or Nickel Cadmium) rechargeable batteries. Other

battery types may burst, causing personal injury and damage.

WARNING: Explosion hazard during equalization, the battery generates explosive gases. Follow all

the battery safety precautions listed in this guide. Ventilate the area around the battery using

ventilators with brushless motors thoroughly and ensure that there are no sources of flame or sparks in the

Vicinity.

The Classic comes with a Battery temperature sensor which plugs into the jack beside the DC Terminal

connector labeled “Battery Temp”. Refer to Figure 1.8 Route the cable through the E-panel into the

battery box. Pick a battery in the middle of the bank and about half way up the side of the battery

thoroughly clean a spot off on the case. Then remove the protective tape from the sensor and adhere the

temperature sensor to the battery. Some manufacturers use a double wall case on the battery. For

mounting a temp sensor to them please refer to the battery manufacturer's recommended procedure.

18 | P a g e

Figure 1.8

Insert BTS to the jack labeled BATTERY TEMP on the control board.

Figure 1.9

19 | P a g e

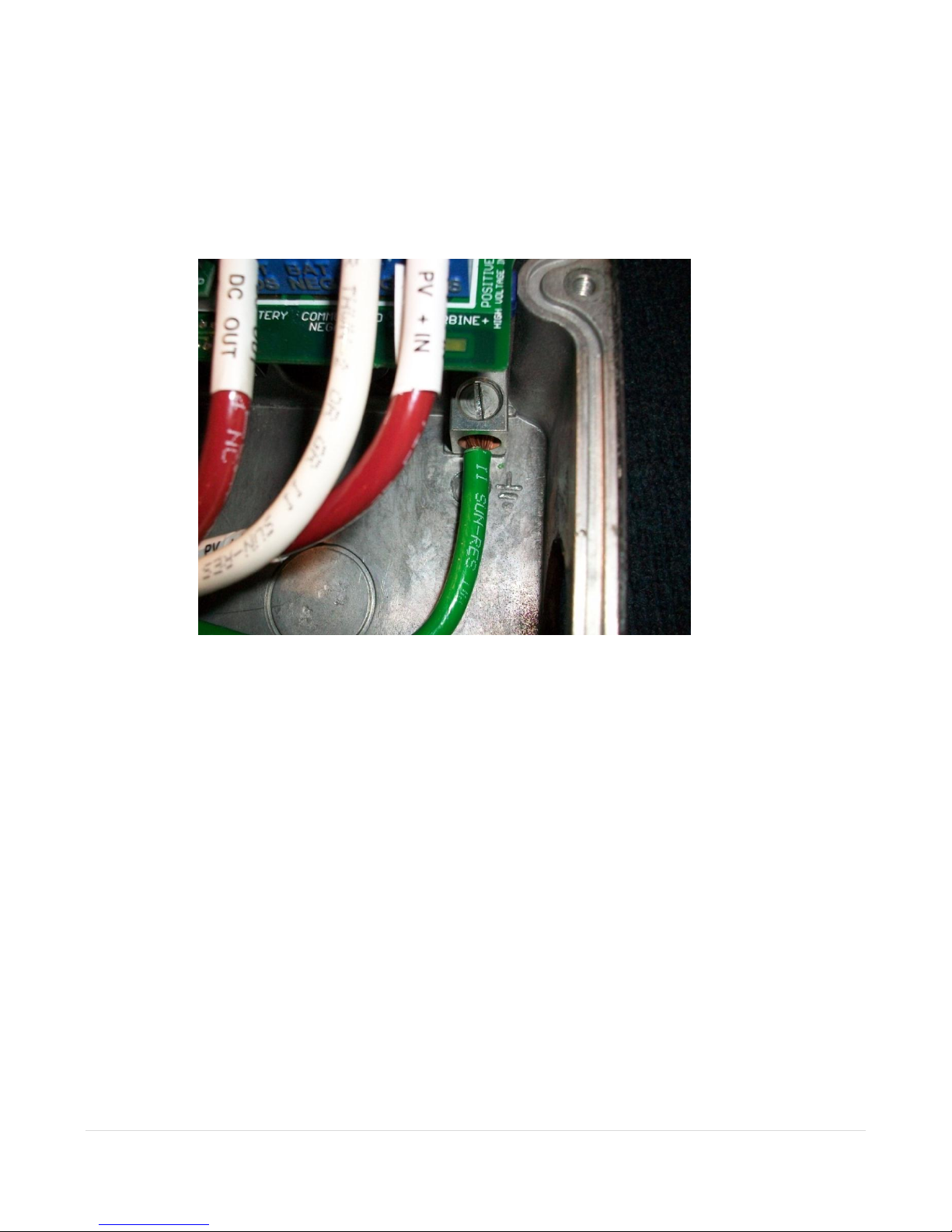

Chassis Grounding

In all installations the Classic chassis should be connected to ground. For systems with a battery

breaker sized 60 amps and smaller 10 AWG (6 mm2) copper is generally sufficient. For systems with a

battery breaker sized 100 amps and smaller 8 AWG (10 mm2) copper is required. For grounding

conductor requirements on your specific installation please consult your local electrical code. The

chassis grounding terminal is in the upper right corner of the electrical connection compartment see

DC System Grounding

The Classic charge controller is designed to work with Negative Ground, Positive Ground or

Ungrounded power systems. In grounded systems, dc negative may be connected to ground either

externally or by using the Classic’s internal grounding jumper, shown on figure 2.1. The internal

grounding jumper should only be installed when the Classic’s GFP is enabled. In a system with

multiple charge controllers the grounding jumper should be installed on every charge controller. In

Positive ground or Ungrounded systems the GFP jumper must be removed. See Figure 2.1 Also note

that with Positive ground there will be items still referenced to battery negative that can complete a

short circuit of the battery bank. These items include but are not limited to the USB Cable and the

Ethernet jack. Please contact Technical support for assistance on Positive ground systems.

20 | P a g e

DC GFP (Ground Fault Protection)

The Classic has internal ground fault protection (GFP) built in. Since 2008 the NEC requires a DC-GFP

on all PV systems in the USA. The built in DC-GFP eliminates the need to purchase and install an

external DC-GFP. If the internal grounding jumper is installed in a Classic, the battery negative and DC

source negative must not be connected to the system grounding conductor anywhere in the system.

Grounding of these circuits will defeat the GFP function. In a network with multiple Classics, all

Classics must have the internal grounding jumper installed and GFP enabled. The factory setting will

make a DC negative to System Ground connection in the Classic charge controller. The GFP function

will need to be disabled for Positive ground or an ungrounded DC system.

Jumper Off (Ground Fault non Active) Jumper On (Ground Fault active)

The Ground fault device is simple to understand and use. The Classic DC-GFP works a bit different

than others. It detects a fault between battery/PV negative and earth ground just like the breaker DC-

GFP system. The difference with the Classic is that it turns off the charge ability and sounds a loud

warning when a ground fault is detected. This is different than disconnecting the PV plus circuit. This

trick of turning off was first pioneered by another charge control company as an alternative to a $100

external circuit breaker assembly. The Classic’s system consists of a PTC that is between the Negative

and Ground internally in the Classic. A PTC is basically a type of resistor with a 1 ohm value that when

loaded to three quarters of an amp will heat up and go to a very high resistance looking like an open

circuit. One of the 3 Classic microprocessors watches the PTC and when it sees a high resistance it will

disable the Classic. The ground fault device will then require a manual reset. The PTC is self-healing

though so there are no fuses to change. This method meets the requirement for DC ground fault

protection in the National Electric Code.

To disable the internal Ground Fault Protection function, the jumper labeled GFP needs to be removed,

and the GFP function must be disabled in the TWEAKS menu. See section below for instructions.

To reset the internal GFP function after detection has occurred; fix the actual ground fault, then turn

OFF the Classic and turn it back ON. Do this by turning the external battery breaker to OFF position

and then to ON position.

Disabling GFP

The GFP feature should only be disabled to operate the Classic in an ungrounded power system or in

systems where GFP is not required.

Press Main Menu

21 | P a g e

Scroll to the right or left until TWEAKS is highlighted and press ENTER

In TWEAKS press the right soft key to get to the MORE menu

In MORE scroll until GFP is highlighted

Use the up and down arrow keys to toggle between on and off

Press ENTER to save

Wiring the Classic

WARNING: Shock hazard. Disconnect the batteries and input power before opening the Classic

front cover

When two or more Classics are paralleled onto one DC Source a blocking diode must be used between

each Classic and the input source to isolate each Classic from the other ones.

The Classic should be wired by a qualified professional and needs to meet all applicable electrical

codes. Always make sure all source and battery circuits are de energized and wait 5 minutes before

working on the wiring in the Classic. The Classic has 2 common neutral (negative) terminals.

Therefore, only one neutral conductor is required to run from the E-Panel and terminate on either (or

both) common neutral terminal. The Positive DC source wire goes to the PV+ Turbine+ screw. The

Positive Battery DC wire goes to battery + terminal. Torque the terminal screws to the specs below.

To connect the wiring to the Classic:

Ensure the DC source and Battery are disconnected

Connect a grounding conductor between the Classic and system ground

Ensure the breaker between the battery and Classic meets UL489 standards.

Ensure the breaker between the dc source and Classic meets UL1077 standards.

Connect the DC source and Battery wire to the Classic

Connect any communications cables or auxiliary input/output wires

Torque terminal connector screws to the following specs

The Torque specs on the DC terminal connector (big blue terminal connector) are:

Up to #10 AWG torque to 25-35 inch pounds.

#8 AWG torque to 30-40 inch pounds.

#6 AWG or above. Torque to 40-50 inch pounds.

22 | P a g e

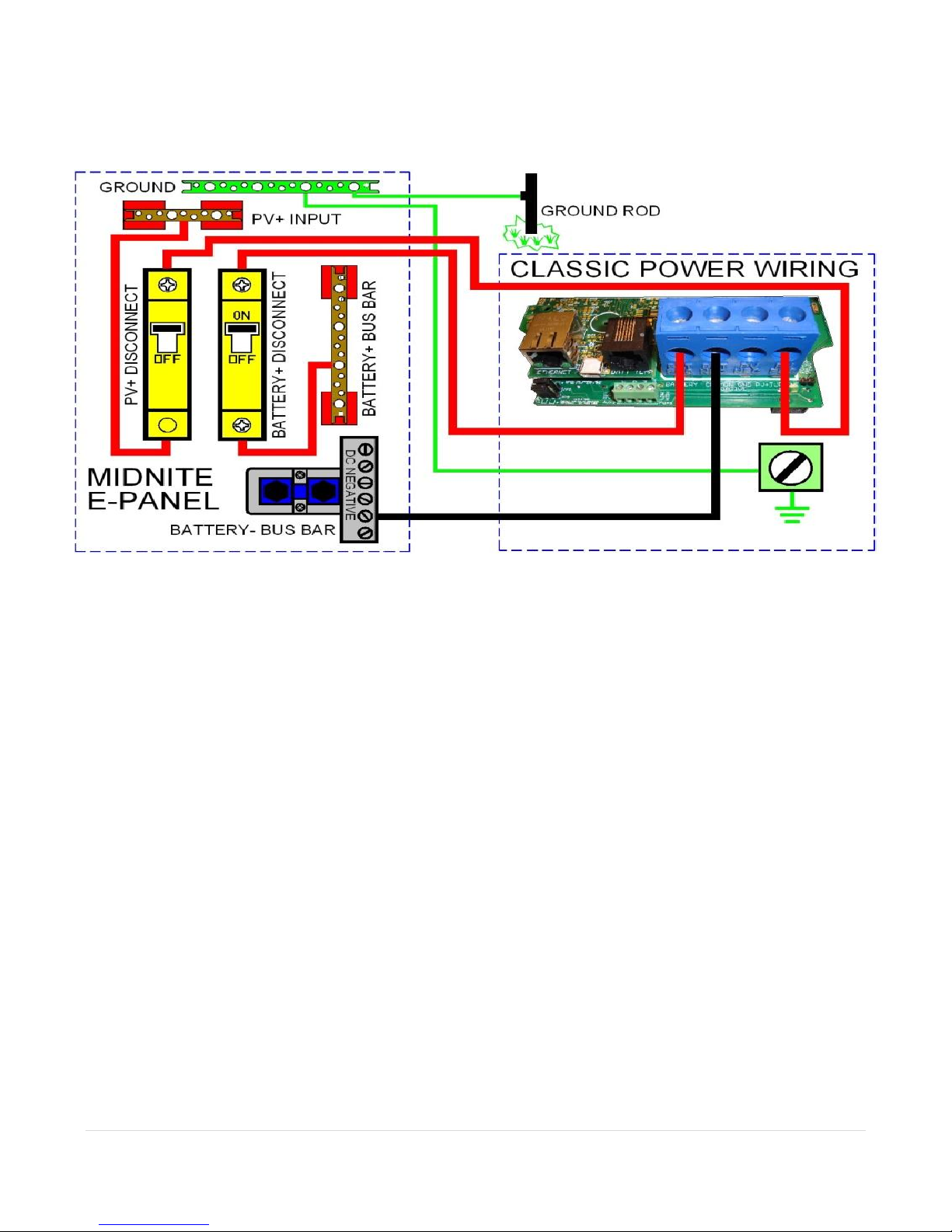

Figure 2.1

23 | P a g e

Figure 2.2

24 | P a g e

DC Terminal Connector

Figure 2.4

The Classic's DC terminal connector is located on the circuit board as shown in. The connector will

take up to a #4 AWG. #4 AWG THHN when installed in the Classic and MidNite E-Panel is rated for

over 100 amps and is therefore suitable for the highest power available from the Classic 150.

Over Current Protection and Wire Size Requirements

The over current devices, wiring, and installation methods used must conform to all electrical codes

applicable to the location of installation. Wiring needs to be protected with proper strain relief clamps

and or conduit. See page 75 for a breaker and wire size chart.

The network cables, USB cable, BTS cable and auxiliary input/output cables should run in a different

conduit to preserve their signal. When installing the Classic in a MidNite E-Panel, it is acceptable to

run all wiring through the same knockout hole. It is legal to run signal and power wires together as long

as all wiring is listed for the highest voltage to be encountered.

Current Rating

The Classic limits the output current based on the model you have.

The Classic current ratings are:

Classic 150 + 150 Lite - 96 amps maximum

Classic 200 + 200 Lite - 79 amps maximum

Classic 250 + 250 Lite - 62 amps maximum

Classic 250ks + 250ks Lite – 58 amps maximum

25 | P a g e

Over Current Protection

The Classic must have over current protection to protect wiring from over current events. A means of

disconnect must be installed on the DC in and DC out of the Classic. Consult your local codes to

determine over current ratings. The breaker between the battery bank and the Classic must conform to

UL489. The breaker between the DC source and the Classic must conform to UL1077 or UL489. The

NEC requires 1.56 times short circuit current for PV over current protection. This is reduced to 1.25

times when using a breaker rated for continuous duty. All MidNite Solar breakers are

hydraulic/magnetic and are rated for continuous duty. No de-rating is required for the output breaker

when using MidNite Solar breakers.

PV in particular will be capable of producing more current than its name plate rating in extreme

situations so the safe minimum wire size should be selected for the PV array maximum short circuit

current. Please consult PV manufacturer for specifications. The US National Electrical Code requires

1.56 times the PV short circuit current for wire size on the PV input. Output wire size follows the NEC

guidelines. Typical wire size for output is 6AWG for the Classic250 and 4AWG for the Classic200 and

150 but check all de-ratings for your wire type and installation method.

Long Distance Wire Runs

The Classic offers some unique opportunities if you are faced with longer than normal wire runs

between the DC source and the Classic. The Classic comes in 3 input voltage ranges letting you design

a DC source at a higher voltage if it is beneficial. For example let’s say you have a 300 ft run from a

PV array to the Classic you could wire for an open circuit voltage close to 250vdc accounting for the

coldest temperature you will encounter. This will allow you to run a smaller gauge wire than with a

lower voltage charge controller. The efficiency of a high voltage Classic is less than the lower voltage

versions, so you need to weigh the benefit. If this sounds too complicated use this rule of thumb in

selecting the proper Classic. PV runs up to 100 feet, use the Classic 150. Runs up to 180 feet, use the

Classic 200. Above 180 feet use the Classic 250.

If the wire size between the DC source and the Classic is larger than the Classic's DC terminal

connector you can use a splicer block or similar connector to reduce down to #4 AWG close to the

Classic. The MidNite E-Panels are supplied with a PV input busbar that accepts up to 2/0 wire.

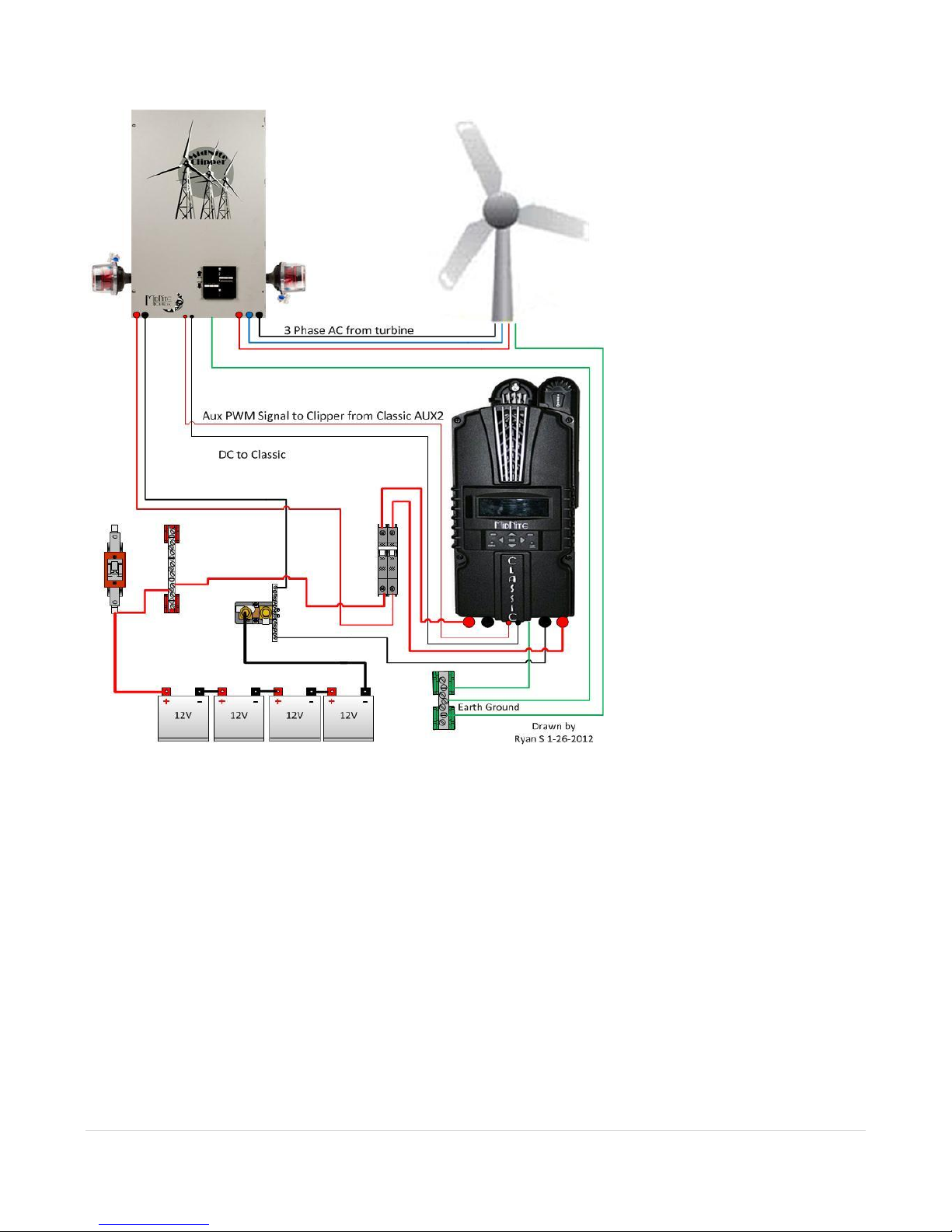

Connecting the Classic to the Clipper

The connections between the Clipper and Classic are fairly basic. There is the DC – and + conductors

from the Clipper to the PV input on the Classic. There is also a smaller set of – and + conductors

connecting Auxiliary 2 to the PWM input on the Clipper. To program the Classic to work with the

Clipper the Aux 2 needs to be programmed. Follow the steps below to program this. (Note: see our

instructional videos at www.midnitesolar.com)

-Enter the Main menu and scroll to Aux and press Enter.

-Scroll to the right to highlight the text under Aux 2 and press the upper right soft key.

-Scroll up or down to find Clipper control and press the right soft key again

-On this screen we need to select AC or DC for the Clipper you have (DC is default)

-Press the right soft key again and here we need to set the absolute voltage we want the clipper to allow

-Press Enter to save this data and press Main Menu until you get back to the Aux 1 and Aux 2 screen

-Set the Text under Aux 2 to say Clipper Control and press Enter.

-Press Status to return to the home screen.

26 | P a g e

Maximum and Minimum Wire Size

The Classics Blue DC terminal connector will accept wire from #14-#4 AWG

The Classics Aux 1 and 2 terminal connector will accept wire up to #18 AWG

27 | P a g e

Equalization Manual and Auto

Equalize

Manual

Off

Auto

On

S1

S2

Mode

System

Voltage

Battery

EQ

DHCP

IP Address

MODBUS

1 2 3 4 5 6 7

8

On

1 2 3 4 5 6 7

8

On

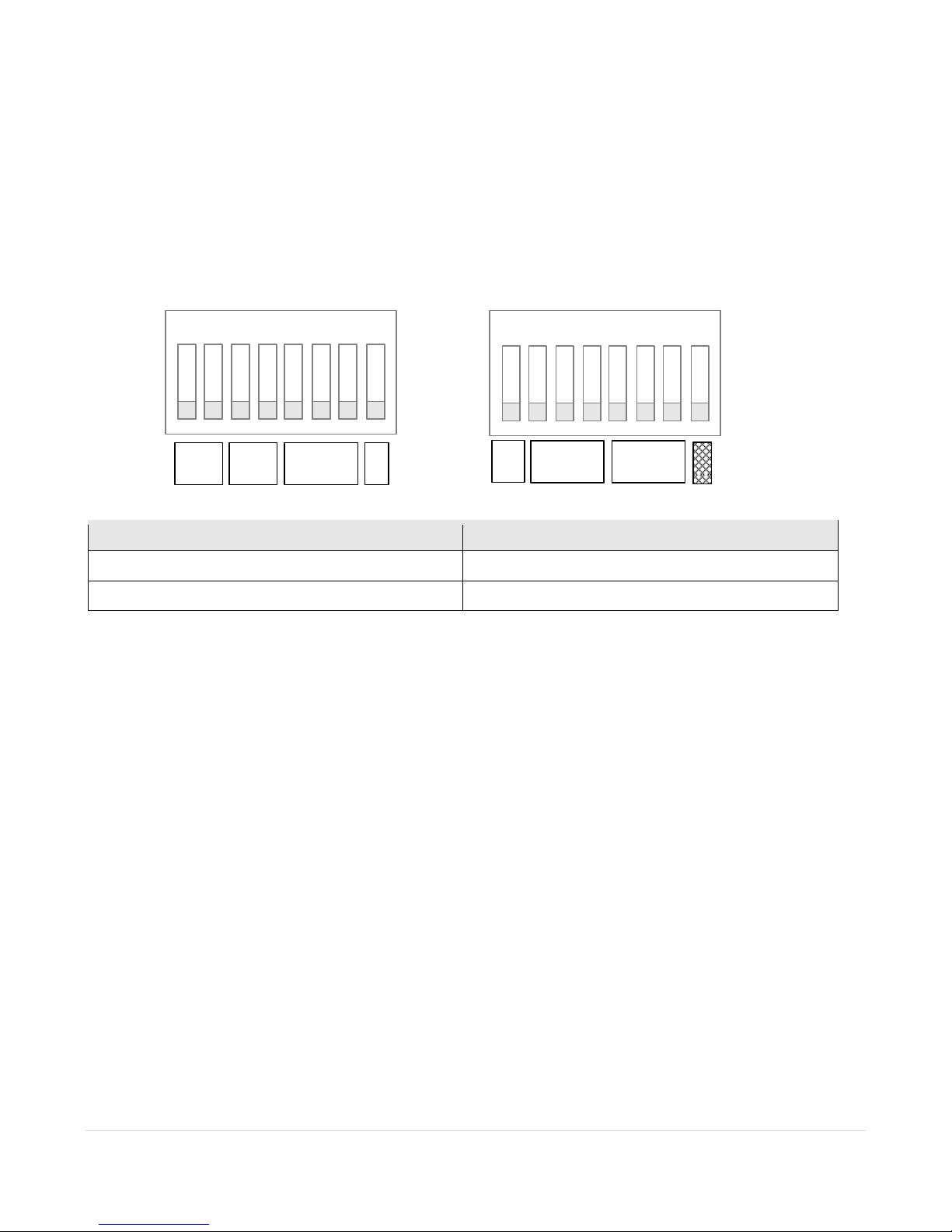

Equalization with the Classic Lite

Auto Equalize Switch 8

Type

port

By setting Auto Equalize to Manual the Equalize intervals in the Battery Settings table are effectively

disabled and Equalization stages will have to be started manually.

Please note that not all manufacturers recommend Equalizing AGM batteries. Check with your

manufacturer and make sure to DISABLE auto Eq on the Lite if your manufacturer does not

recommend Equalizing your AGM batteries

Equlize Button

The Equalize button serves two purposes: the first is to begin an Equalize stage, the second is to clear faults.

Equalization:

An Equalize stage can be scheduled or started at any time by holding the Equalize button down for 2-3 seconds.

Holding the the EQ button down for 2-3 seconds at any point once equalization is activated will cancel the

equalization stage and return back to the most appropriate battery stage.

When the equalize button is pressed, the EQ light will come on solid. Once Equalize proper starts the light will

flash. If Equalization cannot begin immediately then the MNGP Lite will try to engage equalization for 18 hours

and then stop if it can't.

See page 57 for the Voltage and Time parameters of EQ.

28 | P a g e

Equalization with the standard Classic

29 | P a g e

Standard Classic programming

Commissioning the Classic (Quick Start)

The Classic will enter into the Quick Set screens upon initial power up. If the Classic does not enter

into the quick set or you want to restore to Factory Default follow these steps to get initiate a Quick

Set.

With the power off to the Classic Hold the left and right arrow buttons down.

Turn the power on to the Classic and continue to hold the arrow buttons until the setup screen is

displayed.

Answer the questions on the next few screens to complete the Quick Set.

Battery Charge Stages and Meanings

Bulk MPPT

This stage of the Classic means; that the Classic will be putting out as much current as it can to raise the

battery voltage to the absorb voltage set point. This is also known as constant current mode.

Absorb

This stage means that the Classic will maintain the absorb set point voltage until the batteries are charged.

This stage is terminated at the end of the Absorb time or the End Amps set point whichever is reached

first. At this stage the classic is not putting out maximum current, as that would increase the battery

voltage over the Absorb set point. This is also referred to as constant voltage mode.

The absorb time is proportional to the bulk time. (i.e. the time bulk takes to reach the absorb voltage.) The

battery it’s considered “full” at the end of the absorb charge cycle.

Float

A Float cycle follows after the Absorb cycle is completed; Float is displayed on the screen. Battery volt-

age is held at the float voltage set point.

Equalize

Equalization function can be manually initiated or can be set up to Auto Equalize, refer to page 27 for de-

tails on setting up EQ. The intent of an equalization charge is to bring all battery cells to an equal voltage

by a controller deliberate overcharge. The goal is to return each battery cell to its optimum condition

through a series of voltage controlled chemical reactions inside the batteries.

Resting

Resting will show when the Classic is not charging the batteries this is typically do to low light.

30 | P a g e

Loading...

Loading...