Page 1

MA514302i

R

User ’s Guide

M7 SpeedClave®

Steam Sterilizer

For Models:

M7-020

M7-021

M7-022

003-1417-00 Rev . F (8/15)

SF-1849

Page 2

2

MA511501i

R

1

2

1

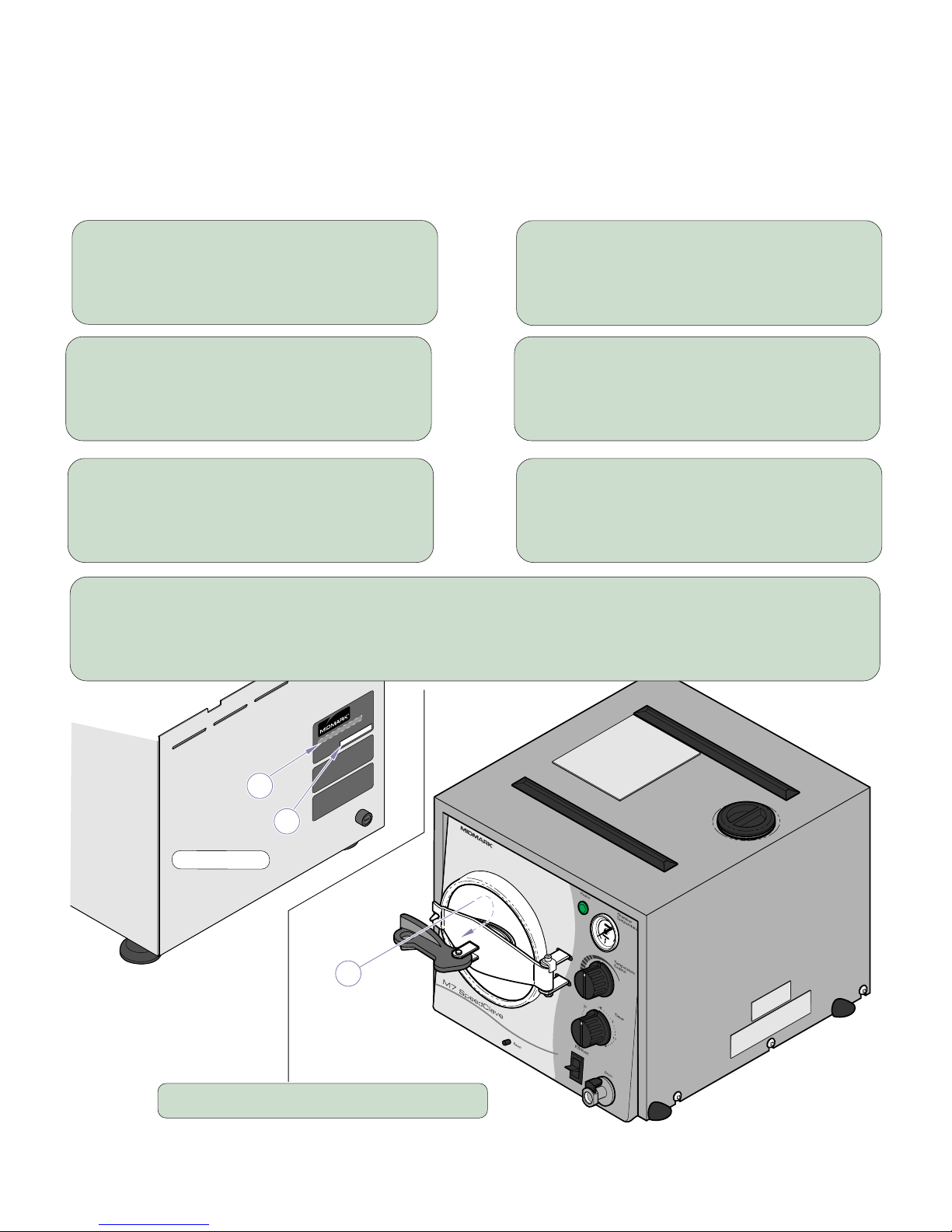

Owner’s Product Identification

(The information below is required when calling for service)

Model Number (2):

Serial Number (1):

Date of Purchase: Name of Owner / Facility:

Name of Dealer: Dealer’s Phone Number:

Midmark Authorized Service Company:

Model / Serial Number Location

Back of Unit

Page 3

1

Table of Contents

Owner’s Product Identification ...................................................................................2

Calling For Service .......................................................................................................2

Important Information

Safety Symbols ...........................................................................................................3

Intended Use ..............................................................................................................4

Electromagnetic Interference...................................................................................... 4

Transportation / Storage Conditions ...........................................................................4

Safety Instructions ......................................................................................................4

Operating Environment Conditions............................................................................. 4

Electrical Requirements .............................................................................................5

Certifications ............................................................................................................... 5

Operation Precautions ................................................................................................ 6

Steam Sterilization Monitoring ....................................................................................6

Location Requirements............................................................................................... 7

Operation

Instrument Cleaning ...................................................................................................8

Loading Trays..............................................................................................................8

Recommended Temperature & Times ........................................................................9

Controls & Indicators ................................................................................................10

Preparation Before Operation ................................................................................... 11

Operation

Opening Door ........................................................................................................12

Filling Chamber .....................................................................................................12

Place Trays Into Chamber .....................................................................................13

Close & Latch Door ...............................................................................................13

Set Time & Temperature ........................................................................................14

Venting ...................................................................................................................15

Drying ....................................................................................................................15

Operator Maintenance

Cleaning ................................................................................................................... 16

Daily .......................................................................................................................16

Weekly ................................................................................................................... 17

Monthly ..................................................................................................................18

Tray Rack

Removal.................................................................................................................19

Installation ............................................................................................................. 19

Troubleshooting .........................................................................................................20

Accessories

List of Authorized Accessories ................................................................................. 21

Specifications............................................................................................................. 21

Warranty Information

Limited Warranty ....................................................................................................... 22

Page 4

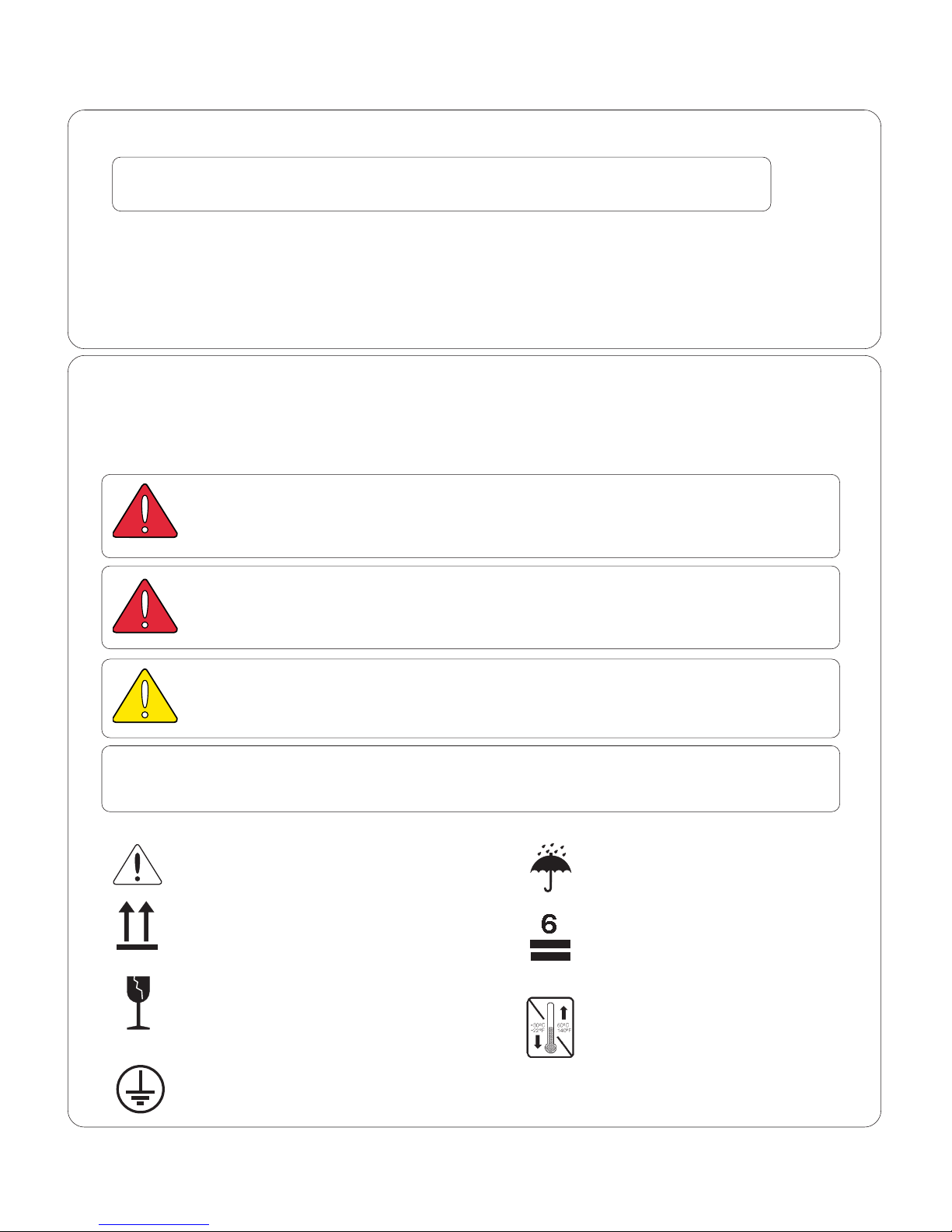

3

Important Information

Consult User Guide Keep dry

for important information.

Proper shipping orientation Maximum stacking height

(palletted units)

Fragile

Minimum and maximum storage

temperature for the unit.

Protective earth ground

Calling For Service

Note

Model / Serial Number information is required when calling for service.

Contact your Midmark Dealer, or log onto www.midmark.com to locate your nearest

service provider. To contact Midmark directly:

1-800-Midmark (1-800-643-6275) or 937-526-3662

8:00 am until 5:00 pm. Monday through Friday (EST)

[excluding standard U.S. holidays]

Safety Symbols

Warning

Indicates a hazardous situation which could result in serious injury if not avoided.

This symbol is used only in the most extreme situations.

Caution

Indicates a potentially hazardous situation which could result in minor injury if not

avoided.

Equipment Alert

Indicates a potentially hazardous situation which could result in equipment damage

if not avoided.

Note

Amplifies a procedure, practice, or condition.

Page 5

4

Intended Use

This product is intended to be used in medical and dental offices, hospitals, clinics, nursing homes,

laboratories, and other facilities to sterilize heat and moisture stable, reusable equipment.

All M7 efficacy testing is exclusive of lumened device sterilization. It is our recommendation that the

end-user contact the device manufacturer to determine the recommended sterilization equipment

procedures and parameters

for the device being sterilized. This is consistent with a Public Health

Notice for Reprocessing of Reusable Ultrasound Transducer Assemblies Used for Biopsy

Procedures issued by the FDA.

Electromagnetic Interference

This Midmark sterilizer is designed and built to minimize electromagnetic interference with other

devices. However, if interference is noticed between another device and this sterilizer, remove

interfering device from room and/or plug sterilizer into an isolated circuit.

Transportation / Storage Conditions

EQUIPMENT ALERT

The water must be drained from the unit’s reservoir before

transporting or storing at 32°F (0°C) or below.

Ambient Temperature Range: ..............................-40°C to +70°C (-40°F to 158°F)

Relative Humidity .................................................10% to 90% (non-condensing)

Atmospheric Pressure ..........................................500hPa to 1060hPa (0.49atm to 1.05atm)

Safety Instructions

Primary concern of Midmark is that this equipment is operated and maintained with safety of patient

and staff in mind. To assure safer and more reliable operation:

• Read and understand this manual before attempting to install or operate sterilizer.

• Assure that appropriate personnel are informed on contents of this manual;

this is the responsibility of the purchaser.

• Assure that this manual is located near sterilizer, or if possible, permanently affixed to sterilizer.

Operating Environment Conditions

EQUIPMENT ALERT

Unit should be allowed to reach room temperature before

operating. Failure to do so could result in damage to the unit.

• Operating Environment

Temperature Range: ........................................ 0° F to 104°F (20°C to 40°C)

• Normal Operating Altitude: ...............................Below 9842 ft. (3000 m) above sea level.

• Device approved for

Indoor Use Only

.

Important Information

Page 6

5

WARNING

Use 207 - 253 VAC, 50 HZ alternating current only for 230 VAC models

and 104 - 126 VAC, 60 HZ alternating current only for 115 VAC models.

Failure to do so could result in electrical shock to personnel and will result in

damage to sterilizer.

Note

Grounding reliability can only be achieved if this unit is connected to a matching three

pronged, grounded, isolated, correctly polarized receptacle.

Unit Ratings:

115 VAC Unit:

115 VAC, 60 Hz, 10 Amp

Dedicated branch circuit: 120 VAC, 60 Hz, 15 Amp

Maximum Power Consumption: 1300 Watts

230 VAC Unit: 230 VAC, 50 Hz, 5 Amp

Dedicated Branch Circuit: 230 VAC, 50 Hz, 10 Amp

Maximum Power Consumption: 1300 Watts

Fuse Ratings:

115 VAC Unit: ....................................... F1, 12 Amp, 250 V, Fast Acting, 1/4” x 1 1/4”

230 VAC Unit: ....................................... F1, 8 Amp, 250 V, Fast Acting, 5 x 20 mm

This product has been evaluated with respect to electrical

shock, fire & mechanical hazards only, in accordance wit h

UL61010A-1, U L61010-2- 041, CAN/CSA C22.2 NO. 1010 an d

CAN/CSA C22.2 NO. 1010.2-041-96.

LA BORATOR

Y

E QUIPMENT

59FM

Equipment not suitable for use in the presence of a flammable

anesthetic mixture with air, or with oxygen, or nitrous oxide.

ISO 9001 Certified

Certifications

Electrical Requirements

• Device to be operated in a relatively dust free environment. An excessive relative humidity

environment should in accordance to IEC664).

• Device should be connected to a power source with over-voltage limits less than 1500 volts from

mains to ground. (Installation Category II in accordance to IEC 664)

Page 7

6

Operation Precautions

EQUIPMENT ALERT

Do not use toweling or packaging which may contain chlorine bleach

residue. Doing so could result in trays and/or chamber rusting or

discoloration. In extreme cases, the life of the chamber may be significantly

shortened.

WARNING

Do not use

this sterilizer in an explosive or oxygen-rich atmosphere, or

where flammable anesthetics are stored. To do so could result in an

explosion or fire.

Do not use

this sterilizer for sterilizing volatile substances or for any purpose

other than its intended design. Burns and toxic or explosive conditions could

result.

Clean and dry instruments

before putting them into the sterilizer. Incomplete

and improper cleaning of instruments will hinder sterilization. This will result in

unsterile instruments which could lead to personal injury or death.

If the sterilizer malfunctions

, immediately unplug it. If it continues to malfunction,

call your nearest factory trained servicer or dealer. Do not attempt to repair the

sterilizer yourself or by an untrained person.

Do not force the door handle

at any time. Chamber pressure may cause the door to

open with extreme force. If door handle does not move freely, allow unit to cool and

depressurize for 40 minutes before attempting to open the door. Failure to comply

to these instructions could result in severe personal injury.

EQUIPMENT ALERT

Processing goods using an incorrect sterilization program could result in

unsterile goods and may damage instruments. Consult with your supply

manufacturer for specific sterilization instructions.

WARNING

Use process monitors with

each sterilization load

rated for use with

Gravity Displacement Steam Sterilizers

. Also, if sterilization cycle terminated

prematurely, reprocess instruments to ensure sterility of load.

Process monitors

(Rated for Gravity Displacement Steam Sterilizers)

• Should be included in each sterilization cycle.

• Detect whether cycle parameters were delivered.

• Cannot establish that a processed item is actually sterile.

• If a failure is detected, the user must determine source of failure.

(Failures could result from improper packaging, loading, or sterilizer malfunction).

• Follow process monitor manufacturer’s instructions for proper selection, storage,

use, and interpretation of their devices.

Steam Sterilization Monitoring

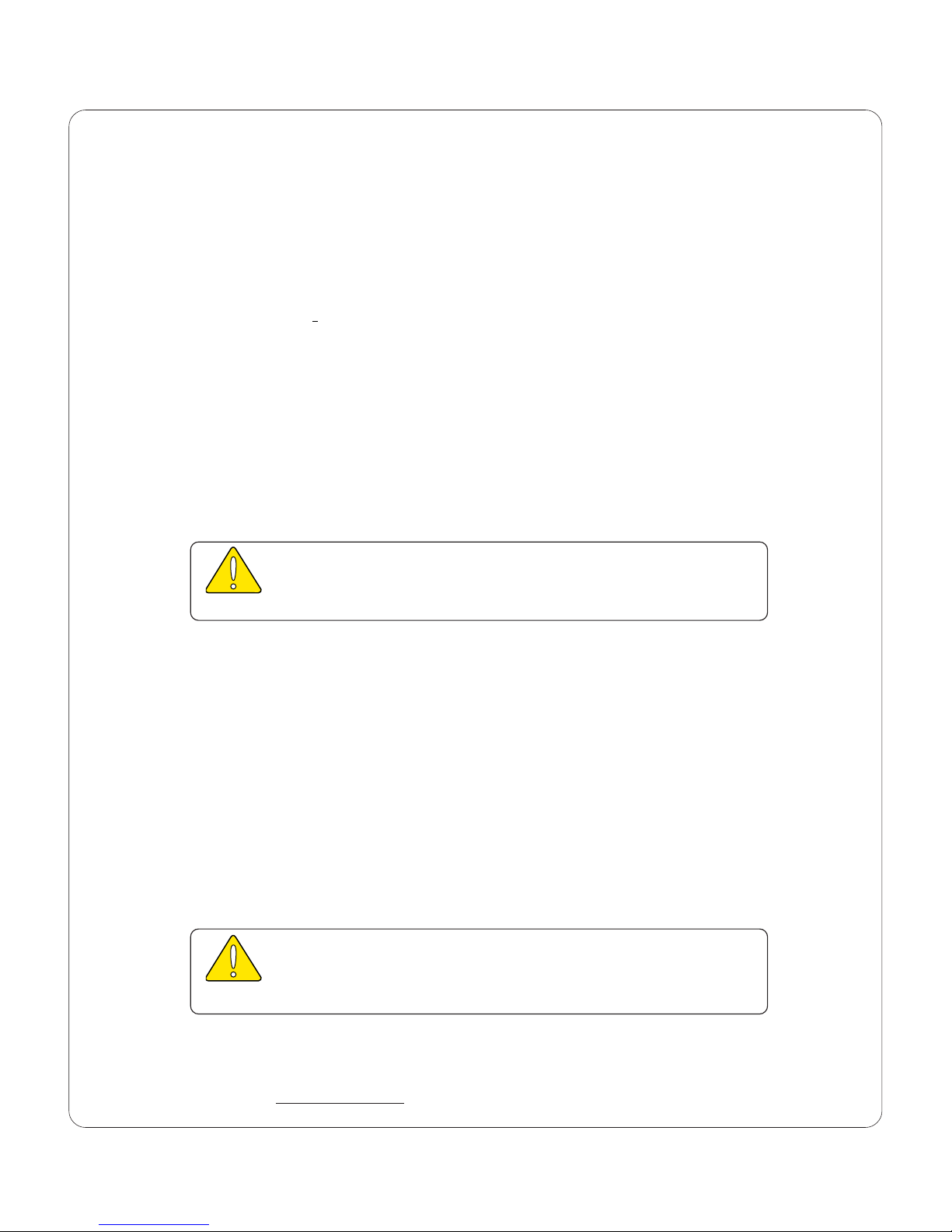

Page 8

7

R

MA512802i

R

Follow appropriate agency

(state dental or medical board) for sterilization monitoring guidelines for

your office. Additional information can also be obtained from CDC, AAMI,

OSAP, and ADA regarding monitoring programs or other sterilization issues.

Steam Sterilization Monitoring

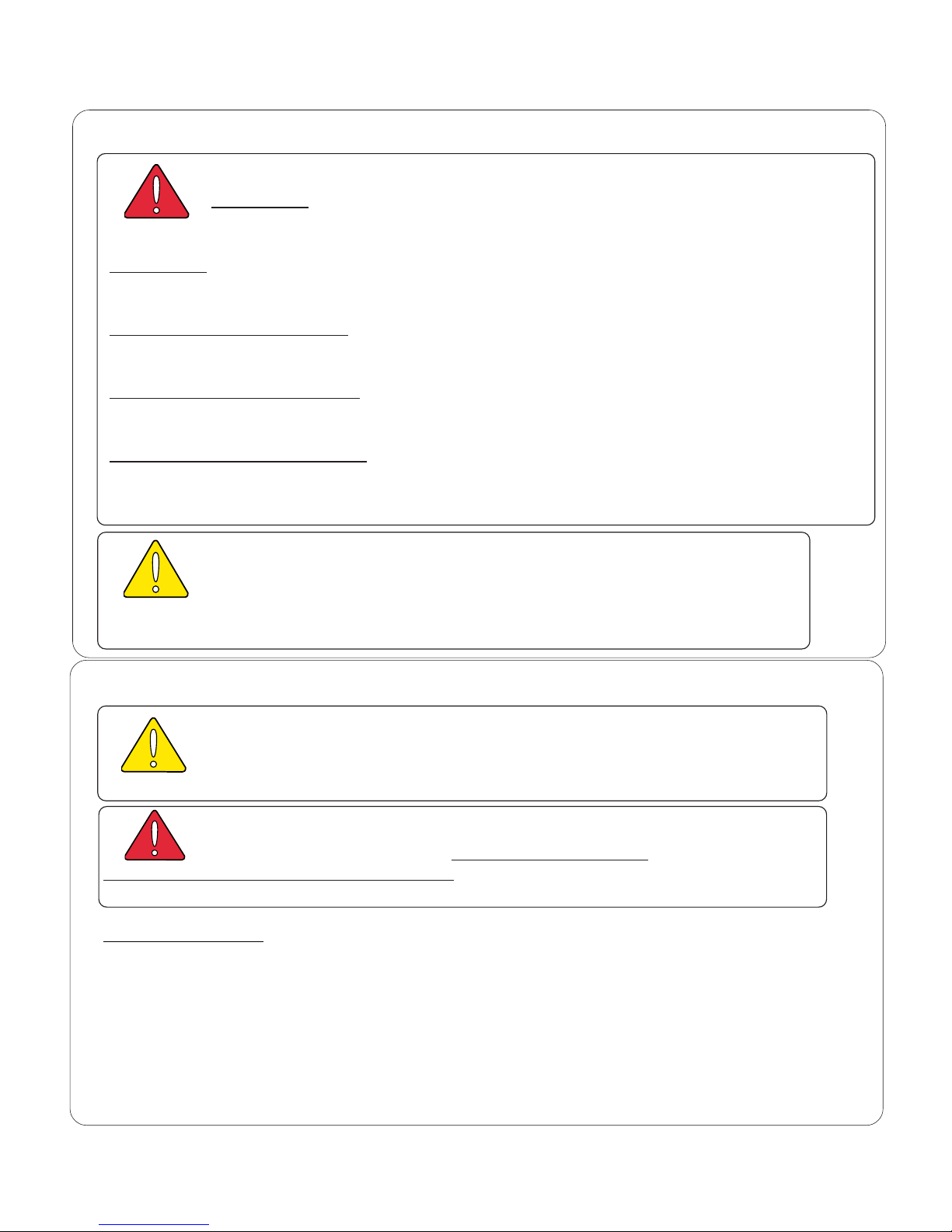

Location Requirements

Overhang

Maximum 15''

(38 cm)

Height

Minimum 25''

(63.5 cm)

for access to

Fill

Clearance

Minimum 2 1/2''

(6.4 cm)

Surface

Must be level,

water and heat

(160°F[71°C])

resistance.

Depth

16 1/2" (42 cm) Minimum

Includes 2'' (5 cm) clearance

behind unit.

WARNING

Do not use

this sterilizer in an explosive or oxygen-

rich atmosphere, or where flammable anesthetics

are stored. To do so could result in an explosion or fire.

Page 9

8

Instrument Cleaning

ï Clean instr uments in accordance with the Manufacturer of the instruments and

OSHAís recommendations.

ï Thoroughly wash instr uments to remove gross debris (either manually or using an

ultrasonic cleaner).

ï Rinse instr uments thoroughly and dry.

ï Ster ilize jointed instruments

in an open position.

Loading T ra ys

ï Place all containers so opening allows steam to

enter and air to leave. Containers are usually

positioned on side with opening tilted slightly down.

ï Pouch or wrap items to preserve

sterility after processing.

Use only coverings designed and

recommended for steam sterilization.

ï Do not wrap items too tightly.

Steam penetration will be affected.

ï Do not stack trays on one another.

Use Midmarkís tray rack trays provided.

ï Position loads on trays with appropriate

spacing between items for proper steam

flow and drying.

ï Place unwrapped items on a towel.

** Packs to have a minimum of 1/4 in. (6.3 mm) space between each other and away from

all sterilizer surfaces.

WARNING

Clean and dry instruments before putting them into

sterilizer. Incomplete or improper cleaning of instruments will hinder sterilization. This will result in unsterile

instruments which could lead to personal injury or death.

seiticapaCmumixaM

epyTdaoLyarTegraL7MyarTllamS7MlatoTreziliretS

smetidiloS

0011-stnemurtsni12

).sbl4.2(smarg ro

007-stnemurtsni41

).sbl6.1(smarg ro

gk9.2-stnemurtsni65

).sbl4.6( ro

)**(skcaP

mc5.2otpumc.uc0801

kciht

)kciht.ni1otpu.ni.uc66(

mc5.2otpumc.uc0801

kciht

)kciht.ni1otpu.ni.uc66(

5.2otpumc.uc0492

pu.ni.uc081(kcihtmc

)kciht.ni1ot

Page 10

9

* Exposure Time is the total time required for sterilization of the load.

This period

begins

when the sterilizer

reaches

the sterilization temperature.

Sterilization temperature

must be held

for the amount of time as recommended in the

above chart.

Not included

in Exposure Time are the time it takes to reach sterilization temperature and the

time it takes to cool back down.

Recommended Temperatures & Times

Suggested Extended Times At Reduced Temperature For Higher Altitudes

Altitudes higher than 1000 ft. (305 m) above sea level, maximum temperature that unit

achieves may be less than 270°F (132°C).

Use the following to process items at the higher altitudes:

• Unwrapped Items 250°F (121°C) for 15 minutes exposure time*.

• Wrapped Items 250°F (121°C) for 20 minutes exposure time*.

*emiTerusopxE/erusserP/.pmeT

)smuminiM(

deziliretSeBoTsmetI

s'rerutcafunammetiehttlusnocsyawlA(

.)noitaziliretsrofnoitadnemmocer

)C°231(F°072

)aPk681(ISP72

setuniM3emiTerusopxE

*

.yartanoesoolstnemurtsnI*

.sretsinaclatemrossalgnepO*

.serudecorplacigrusnidesutongnibuT*

sdnemmocerrerutcafunamsmetI*

.setunim3rof)C°231(F°072taerusopxe

desimorpmocsismetidepparwnufoytiliretS*

noerusopxe .tnemnorivneelirets-nonaot

)C°231(F°072

)aPk681(ISP72

setuniM51emiTerusopxE

*

.yartanoesoolstnemurtsnI*

.stnemurtsnilaudividnidepparwylesooL*

ybdetarapesstnemurtsnidepparwelpitluM*

.cirbaf

.stnemurtsniesoolfosyartdepparW*

.serudecorplacigrusnidesutongnibuT*

sdnemmocerrerutcafunamsmetI*

erusopxe .setunim51rof)C°231(F°072ta

)C°121(F°052

)aPk401(ISP51

setuniM03emiTerusopxE

*

rofdepparwskcaplacigrusdnaselitxeT*

.noitazilirets

rerutcafunam,sdiuqiltpecxe,smetI*

rofsdnemmocererusopxe )C°121(°052ta

.setunim03rof

Page 11

10

MA512902i

R

Controls & Indicators

Cycle Timer

Controls time of cycle.

Timer will buzz at end

of cycle. Graduated in

minutes from 0 to 30

and functions as ON/

OFF switch.

Fill / Vent Valve

Press down and hold to fill

water into chamber before

cycle or to vent chamber

after cycle.

Reset Button

Depress to close

Low Water T-stat

after unit has cooled.

Door

Self-aligning,

spring loaded.

Pilot Light

Illuminates when

heater is energized.

Full Line

Visible thru Fill opening,

shows when reservoir is

at Full capacity.

Temperature Guage

Shows chamber temperature.

170°- 270°F (77°-132°C)

Temperature Regulator

Controls temperature in chamber

(Maximum 270°F)

Drain Coupling

Insert adapter / hose

to open valve and

drain reservoir.

Door

Handle

(See Positions)

Unlatched

Vent

Latched

Page 12

11

Preparation Before Operation

EQUIPMENT ALERT

Assure Sterilizer electrical specifica-

tions, as shown on Model / Serial

Number label, match the electrical supply

before plugging unit into outlet.

1. Plug Unit In

Plug Sterilizer into

an outlet that has a

dedicated circuit.

EQUIPMENT ALERT

Use only distilled or demineralized water.

Do Not use normal tap water as the minerals

and chlorides in the water could adversely affect the

life and reliability of the Sterilizer and articles being

sterilized.

2. Fill Reservoir

Remove cap and fill with

distilled / demineralized

water to Full mark.

Full

Mark

Note

Do

not

overfill reservoir.

Overfilling may cause:

• Water splashing out reservoir.

• Water siphoning back into

chamber during venting.

• Sterilized products could

remain wet.

• Water could run out bottom

of door.

Page 13

12

Operation

Opening Door

Filling Chamber with Water

2. Open Door

While pushing door / cross arm

assembly toward right, pull outward.

1. Fill Chamber

Press down and hold

Fill / Vent Lever until

water is within 1/2''

(1.3 cm) of rim.

1. Unlatch Door

Place handle in

Unlatched position.

EQUIPMENT ALERT

Never run the Sterilizer without

the Tray Rack installed.

Note

Fill may take between 30 to 40

seconds dependent on water

level in reservoir.

1/2''

(1.3 cm)

Page 14

13

Place Trays Into Chamber

Close and Latch Door

1. Close Door

Swing door to left

until it stops.

2. Close Door

Push door to right and swing

inside chamber,then release.

Door should spring back

fitting inside chamber.

3. Latch Door

Swing door handle

all the way to right.

1. Pack Trays

Pack trays (see

Loading Trays) then

load into chamber.

Note

Always include a process

monitor strip with each load.

Use only

Gravity Displacement

Steam Sterilizer

monitor strips.

Page 15

14

MA513603i

R

Set Time & Temperature

1. Set Timer

Turn Timer knob

clockwise to 15

minutes.

2. Set Temperature

Turn Temperature Control

knob Fully to left (counter clockwise).

This is maximum setting

of 270°F (132°C).

Note

Place a mark on front face of

Temperature Control to mark

position of knob for future

reference.

CAUTION

Temperatures set below 250°F

(121°C) should not be used for

sterilization, unless otherwise required by

the device manufacturer. Temperatures

below 250°F (121°C) are provided for

disinfection only.

Note

Refer to “Recommended

Temperatures & Times” or to

chart on top of Sterilizer for

proper settings.

3. Re-Set Temp. Control

When Temperature Gauge

reaches desired tempera ture, immediately turn

Temperature knob slowly

clockwise until pilot light

goes out.

4. Re-Set Timer

After re-setting Temperature

Control re-set Timer to desired

sterilization time.

Note

When Timer is on Pilot

Light illuminates to show

Heater is on.

Temperature

Gauge

Page 16

15

Venting Sterilizer

3. Vent

Hold Fill / Vent lever down

until door “pops” inward.

Leave door in “Vent” position.

Do not open door.

Drying

2. Vent

Swing door handle

to “Vent” position.

1. Vent

Turn Timer off when

buzzer sounds.

1. Drying

Keep door handle in “Vent”

position for 15 minutes.

Do NOT open door.

2. Drying

Remove contents after Dry

time has elapsed.

Trays may be placed on

racks on top of Sterilizer.

EQUIPMENT ALERT

Do NOT turn on heat (Timer)

or open door during 15 minute

drying period.

Note

Allowing Sterilizer to set

without venting

will cause

items to come out wet

CAUTION

The metal door and surronding

metal surfaces are HOT!

Use care when operating door to

prevent burns.

CAUTION

The metal door and surronding

metal surfaces are HOT!

Use care when operating door to

prevent burns.

Page 17

16

Operator Maintenance

Daily

R

MA514400

2. Door Gasket & Surface

Wipe door gasket & mating

surface with a damp cloth.

3. Door Gasket

Examine gasket for damage

and replace if necessary.

1. External Surfaces

Wash with damp cloth and

mild soap solution, then

wipe with soft, dry cloth.

Mating

Surface

Gasket

CAUTION

Make sure that Sterilizer is cool before attempting

to clean to prevent personal injury from burns.

EQUIPMENT ALERT

Never use abrasive or bleaching

agents (steel wool, scouring powder,

bleach, etc. or a wire brush) to clean chamber.

Damage to the chamber or related components

could occur.

Page 18

17

Operator Maintenance

Weekly

Note

Refer to “Tray Rack” for

Removal & Installation

Instructions

MA514001

3. Remove Hose

Press down on release lever

and remove hose assembly.

4. Fill Reservoir

Use only distilled or

demineralized water.

1. Trays & Chamber

Wash with damp cloth and

mild soap solution, then

wipe with soft, dry cloth.

2. Drain Reservoir

Place end of hose in

container and connect

hose adapter to coupling.

Note

If drain coupling leaks after

insertion or removal reinsert

adapter / hose several times

to clean seals, stopping leak.

Release

Lever

Drain

Coupling

Hose /

Adapter

Page 19

18

MA670700i

Fill / Vent

1/2''

(1.3 cm)

Operator Maintenance

Monthly

(Flush The System)

3. Fill Chamber

Press down and hold

Fill / Vent Lever until

water is within 1/2''

(1.3 cm) of rim.

1. Drain & Refill Reservoir

Drain reservoir and refill with

clean distilled or demineralized

water. (Refer to Weekly Cleaning)

4. Run Cycle

Run one 6 Minute cycle

at 270°F (132°C).

7. Run Cycle

Run one 3 Minute cycle

at 270°F (132°C).

8. Drain & Cool

Drain chamber and reservoir

and allow sterilizer to cool,

Remove trays and tray rack

(Refer to Tray Rack Removal).

2. Add Cleaner

Add 1 oz. (29.6 ml) of

Speed-Clean to a cool

chamber.

Note

Never sterilize instruments

while performing cleaning

procedures.

5. Drain & Refill Reservoir

Drain chamber and reservoir

and refill with clean distilled or

demineralized water.

(Refer to Weekly Cleaning)

10 . Refill Reservoir

Refill reservoir with clean distilled

water. Install chamber filter, tray

rack and trays.

9. Clean Chamber, Filter, & Trays

Remove chamber filter, wipe out

chamber and clean trays and tray

rack.

Filter

Full

Mark

6. Fill Chamber

Press down and hold

Fill / Vent Lever until

water is within 1/2''

(1.3 cm) of rim.

Page 20

19

R

Tray Rack

1. Removal

Lift up on left edge of tray

plate until it “pops” free of

wire rack.

Slide tray out of chamber.

2. Removal

Squeeze bottom of wire

rack together and slide

out of chamber.

2. Installation

Gently squeeze bottom of

rack together and insert into

chamber as far as it will go.

1. Installation

Holding tray plate with right

side point down, insert into

chamber.

Note

Offset ends of rack must

be on left side of chamber.

WARNING

Make sure unit is cool before attempting

to remove or install tray rack and plate.

Use care to prevent injury when handling metal

tray rack assembly.

Do NOT run sterilizer without Tray Rack assembly

in place.

3. Installation

Position right side of rack

under bottom wire aligning

straight ends of rack with

notches on plate.

4. Installation

Holding right side of plate

in position, press down left

side of plate until it snaps|

into offsets of wire rack.

Tray

Plate

Offset

Ends

Straight

Ends

Tray

Plate

Left Edge

Right Edge

Wire

Rack

Wire

Rack

Page 21

20

Troubleshooting Guide

melborP esuaCelbissoP noituloS

nOremiT•

thgiLtoliPoN•

taeHoN•

teltuootnideggulptondrocrewoP.teltuootnigulP

.deppirttinuotrekaerbtiucricytilicaF.rekaerbtiucricteseR

.ynapmoCecivreSllacpirtotseunitnoctifI

.nepoesuFreziliretS .)sgnitaResuFees(ezisemashtiwesuFecalpeR

.deppirt)s(tatsomrehTtaehrevO.setunim02-51loocottinuwollA

.yrassecenfirebmahc&riovreserotretawddA

.elcycnurdnanottubteseRsserP

)s(rotinoMssecorP

noitaziliretswohs

.eruliaf

,etadfotuo)s(rotinoMssecorP

rofdetartonsiro,denoitcnuflam

maetStnemecalpsiDytivarG

.sreziliretS

rofrotinomhserfaesU

maetStnemecalpsiDytivarG

sreziliretS

..senilediugs'rerutcafunamwolloF

tonerewsnoitidnocnoitaziliretS

.)s(rotinomfonoitacoltatneserp

repreziliretSdaoleR

"syarTgnidaoL"

wolloF.senilediug

.)s(rotinomfotnemecalps'rerutcafunam

tcatnoc&ecivresfotuotinuekattsisrepmelborpfI

.recivreSrorelaeD

wol,lavomerriatneiciffusnI

.erusserpwolro,erutarepmet

narorelaeDruoytcatnocdnaecivresfotuotinuekaT

.recivreSdezirohtuA

.roodtuoskaelretaW

rebmahcgnillifrevO tnorffo)mc3.1("2/1nihtiwsiretawlitnurebmahclliF

.mirrebmahc

.leveltonreziliretS.reziliretSleveL

retaW.kramLLUFrevoriovreseR

.rebmahcotnigninohpis

.stimilnihtiwsilevellitnuriovreserniarD

.degamadroytridteksagrooD .teksagroodecalperro/dnanaelC

.yrdtonskcaP

.dedaolrevoreziliretSrepreziliretSdaoleR

"syarTgnidaoL"

.senilediug

tcatnoc&ecivresfotuotinuekattsisrepmelborpfI

.recivreSrorelaeD

.leveltonreziliretS.reziliretSleveL

retaW.kramLLUFrevoriovreseR

.rebmahcotnigninohpis

.stimilnihtiwsilevellitnuriovreserniarD

elcyCyrDerofebdenepogniebrooD

.etelpmoc

setunim51tsaeltarofnoitisop"TNEV"niroodevaeL

tinugnitnevretfa

.rebmahcnideggolcneercsretliF.neercsretlifecalperronaelC

.wolootreziliretstoegatlovylppuS aotreziliretstcennocnaicirtceledeifilauqaevaH

.levelegatlovreporphtiwtiucricdetacidedetarapes

otdraheldnaHrooD

.nepo

.eldnahroodnomacyrD

roodstcatnoctahtecafrussimaC(

.)noitisopdehctalninehw

macno)]C°941[F°003(esaergerutarepmethgihaecalP

.eldnahfotrap

Page 22

21

Accessories

Specifications

Physical Dimensions:

Overall Length............................................................................... 48.3 cm (19 in.)

Overall Width................................................................................. 35.6 cm (14 in.)

Overall Height ............................................................................... 33 cm (13 in.)

Shipping Carton ............................................................................ 61 cm x 40.6 cm x 40.6 cm

(24 in. x 16 in. x 16 in.)

Counter Area ................................................................................ 42 cm (D) x 39.4 cm (W)

(16.5 in. x 15.5 in. includes 5 cm [2"]

clearance on one side and back)

Chamber ........................................................................... 19.0 cm Diameter x 36.2 cm depth

(7.5 in. Diameter x 14.25 in. depth)

Door Opening ................................................................................. 16.8 cm (6 5/8 in.)

Large Trays (2) ........................................................................ 30.5 cm x 14.3 cm x 22.2 cm

(12 in. x 5 5/8 in. x 7/8 in.)

Small Trays (1) ........................................................................ 30.5 cm x 10.5 cm x 2.22 cm

(12 in. x 4 1/8 in. x 7/8 in.)

Weight:

Empty Reservoir ........................................................................... 13.6 kg (30 lb.)

Full Reservoir ................................................................................ 19.0 kg (41.8 lb.)

With Shipping Carton .................................................................... 17.7 kg (39 lb.)

Water Reservoir Capacity ..................................................... Approximately 4.96 Liters

to full mark (1.31 gallons).

Chamber Safety Valve ................................................................ set at 214 kPa (31 PSI)

seirosseccA

noitpircseDrebmuNtraPesUdednetnI

®naelC-deepS

elttoB).zo61(1

00-6930-200

ehtnidesunoitulosgninaelcA

.reziliretSehtfossecorpgninaelc

®naelC-deepS

esaC1

)selttoB].zo61[21(

10-6930-200

ehtnidesunoitulosgninaelcA

.reziliretSehtfossecorpgninaelc

looTdnaHlooC 100703A9

morfsyartevomerotdesulooT

.rebmahcreziliretS

Page 23

22

Warranty Information

SCOPE OF WARRANTY

Midmark Corporation (“Midmark”) warrants to the original retail purchaser that it will repair or replace components of the

domestic and international medical products manufactured by Midmark (except for components not warranted under

“Exclusions”) that are defective in material or workmanship under normal use and service. Midmark’s obligation under

this warranty is limited to the repair or replacement, at Midmark’s option, of the applicable components. This limited

warranty shall only apply to defects that are reported to Midmark within the applicable warranty period and which, upon

examination by Midmark, prove to be defective. This warranty extends only to the first retail purchaser of a product and

is not transferable or assignable.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date of delivery to the original user, shall be one (1) year for all

warranted products and components.

OBTAINING WARRANTY SERVICE

Warranty service must be obtained through either Midmark or an authorized dealer in the Midmark product line for

which warranty service is requested. Midmark may be contacted for warranty service inquiries or issues via email at

www.midmark.com; by phone at 1-800-MIDMARK; by facsimile at 1-800-365-8631; or by mail to Midmark Corporation,

60 Vista Drive, Versailles, Ohio 45380.

It is the retail purchaser’s obligation to arrange for delivery of a product to Midmark or one of its authorized dealers for

warranty service, which delivery shall be at retail purchaser’s expense. It is also the retail purchaser’s obligation to

comply with the warranty service instructions provided either by Midmark or its authorized dealer. The retail purchaser

must provide Midmark with completed warranty registration information within thirty (30) days after purchase in order to

obtain the benefits of this warranty.

EXCLUSIONS

This warranty does not cover, and Midmark shall not be liable, for the following:

(1) defects, damage or other conditions caused, in whole or in part, by misuse, abuse, negligence, alteration, accident,

freight damage, tampering or failure to seek and obtain repair or replacement in a timely manner;

(2) products which are not installed, used, and properly cleaned and maintained as required in the Midmark “Installation” and/or “Installation/Operation Manual” for the applicable product;

(3) products considered to be of a consumable nature;

(4) accessories or parts not manufactured by Midmark;

(5) charges by anyone for adjustments, repairs, replacement parts, installation or other work performed upon or in

connection with such products which are not expressly authorized in writing in advance by Midmark;

(6) costs and expenses of routine maintenance and cleaning; and

(7) representations and warranties made by any person or entity other than Midmark.

EXCLUSIVE REMEDY; CONSEQUENTIAL DAMAGES DISCLAIMER:

MIDMARK’S ONLY OBLIGATION UNDER THIS WARRANTY IS THE REPAIR OR REPLACEMENT OF DEFECTIVE

PARTS. MIDMARK SHALL NOT BE LIABLE FOR AND HEREBY DISCLAIMS ANY DIRECT, SPECIAL, INDIRECT,

INCIDENTAL, EXEMPLARY OR CONSEQUENTIAL DAMAGES OR DELAYS, INCLUDING, BUT NOT LIMITED TO,

DAMAGES FOR LOSS OF PROFITS OR INCOME, LOSS OF USE, DOWNTIME, COVER AND EMPLOYEE OR INDEPENDENT CONTRACTOR WAGES, PAYMENTS AND BENEFITS.

NO AUTHORIZATION

No person or firm is authorized to create or approve for Midmark any other obligation or liability in connection with the

products.

WARRANTY DISCLAIMER

THIS WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED. MIDMARK MAKES NO IMPLIED WARRANTIES OF ANY KIND INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY IS LIMITED TO THE REPAIR OR

REPLACEMENT OF DEFECTIVE PARTS.

STATUTE OF LIMITATIONS

No action may be brought against Midmark for breach of this limited warranty, an implied warranty, if any, or for any

other claim arising out of or relating to the products, more than ninety (90) days following expiration of the limited

warranty period.

Page 24

Midmark Corporation

60 Vista Drive

Versailles, OH 45380-0286

937-526-3662

Fax 937-526-5542

midmark.com

Loading...

Loading...