Midmark M7-020, M7-021, M7-022 Parts Manual

®

Go To Table Of Contents

Style B

SpeedClave

Steam Sterilizers

Model Numbers:

M7

-020 thru -022

Serial Number Prefixes:

V

Service and

Parts Manual

SF-1855 Part No. 004-0454-00 (10/3/2017)

"NO LONGER IN PRODUCTION"

Some service parts may not be available for this product.

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

GENERAL INFORMATION

Next

Back

Symbols ....................................i

Ordering Parts .......................... i

Model / Serial Number

Location .................................. i

Weights, Dimensions,

Electrical Specifications ....... ii

Model Identification /

Compliance Chart .................. iii

Special Tools ............................ iv

Warranty Information............... iv

General Information

ACCESS PROCEDURES

Removing & Installing:

Covers / Panels ........................ C-2

Tray Plate / Rack ...................... C-3

Draining / Filling Reservoir .....C-4

Section C

WIRING DIAGRAMS & SCHEMATICS

115 VAC models

M7 (-020 / -022) .............................

:

D-2

230 VAC models

OPERATION &

TROUBLESHOOTING

Electrical System:

M7 (-020 thru -022) ........................

Filling the Chamber ................. A-6

Heat-Up / Sterilization ............. A-10

Venting the Chamber ............... A-16

Section A

TESTING & REPAIR

Checking for

Pressure Leaks ...................... B-2

Fuse........................................... B-3

Bellows ..................................... B-4

Fill / Vent Valve: ........................ B-6

Temperature Regulator Assy .. B-10

Section B

Heating Element ....................... B-16

Overheat Thermostats ............. B-20

Pressure Relief Valve ............... B-23

Timer ......................................... B-24

Timer Buzzer ............................ B-28

Temperature Gauge ................. B-29

Door Assembly ........................ B-30

Table Of Contents

Reservoir Tank.......................... B-32

Chamber Assembly ................. B-34

A-3

M7 (-021) .......................................

Section D

EXPLODED VIEWS / PARTS LISTS

M7

Section E

Section E

:

(-020 thru -022)

D-3

: ................... E-2

Symbols

Go To Table Of Contents

Next

Back

General Information

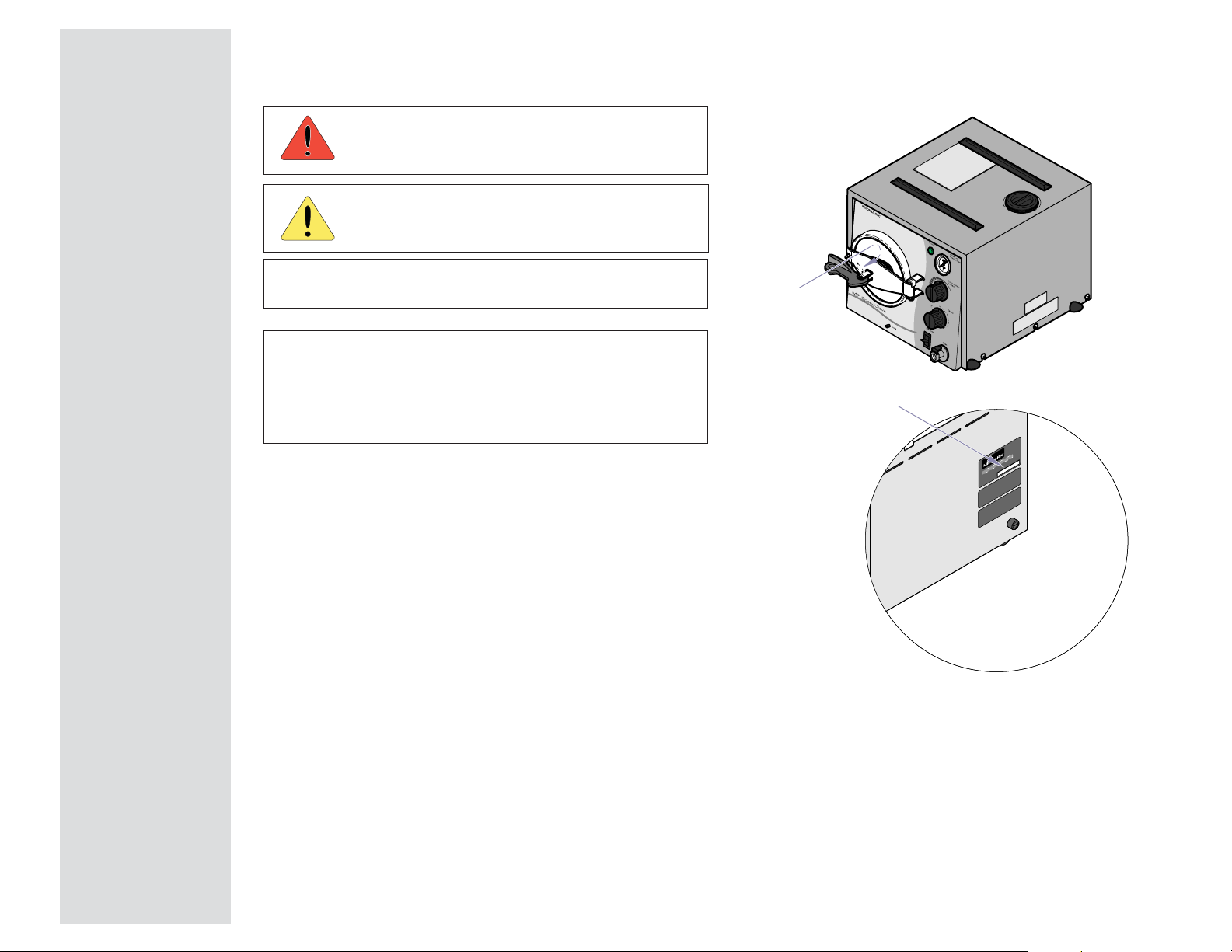

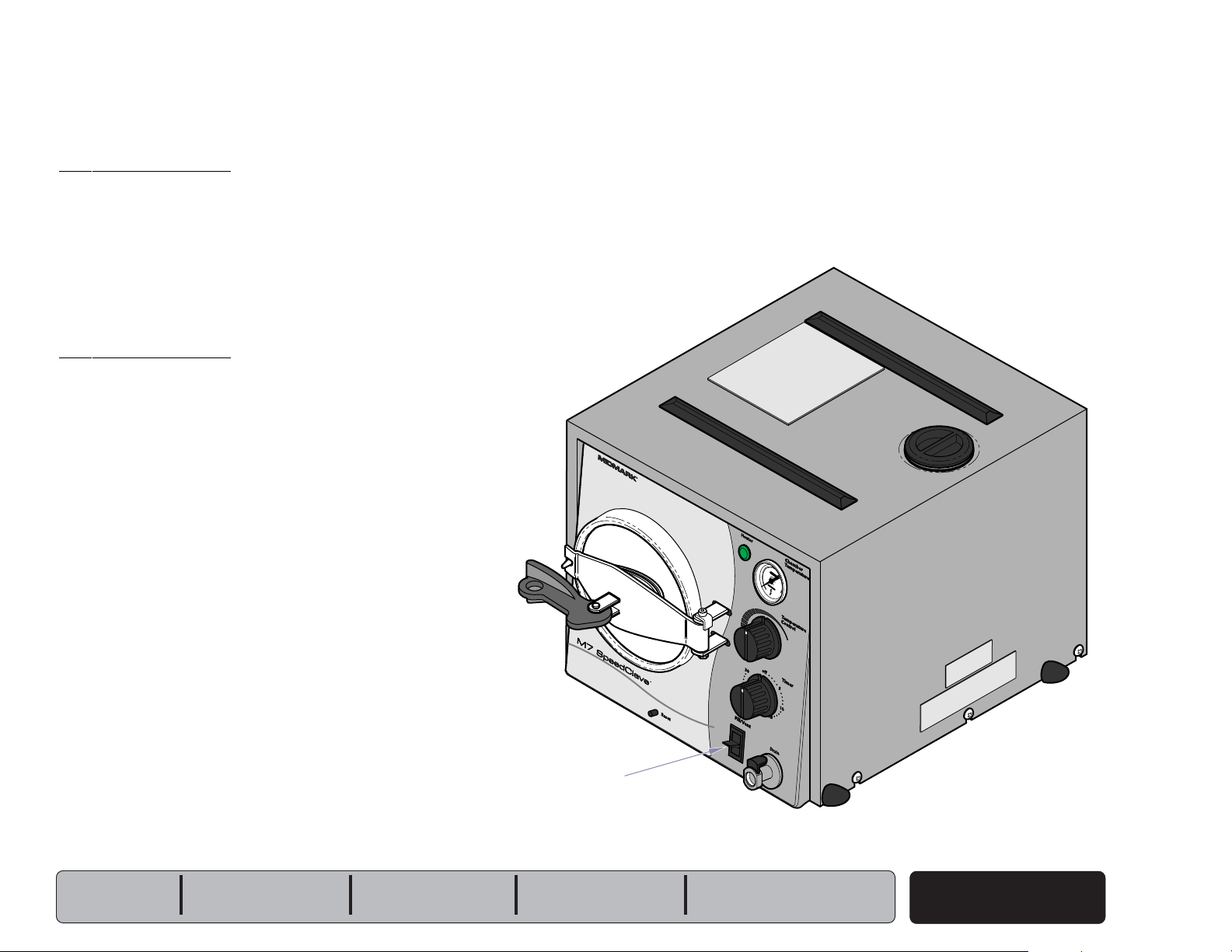

Model / Serial Number Location

Caution

Indicates a potentially hazardous situation

which could result in injury if not avoided.

Equipment Alert

Indicates a potentially hazardous situation

which could result in equipment damage if not avoided.

Note

Amplifies a procedure, practice, or condition.

Indicates that the component the check mark appears

beside should be tested before replacing it.

In Section A, test the components in the order indicated.

(ex.

1st

then,

Refer to Section B for component testing procedures.

2nd

)

Ordering Parts

The following information is required when ordering parts:

• Serial number & model number

• Part number for desired part.

[Refer to Section E: Exploded Views / Parts Lists]

Non-warranty parts orders may be faxed to Midmark using

the Fax Order Form in the back of this manual.

For warranty parts orders, call Midmark's Technical Service

Department with the required information.

Hours: 8:00 am until 5:00 pm EST [Monday - Friday]

Phone: 1-(800)-Midmark

R

Serial Number

(all models)

Model & Serial Number

M7 (-020 thru -022)

Location: back of unit

MA511503i

General Information

© Midmark Corporation 2004 SF-1854

i

General Information

Go To Table Of Contents

Next

Back

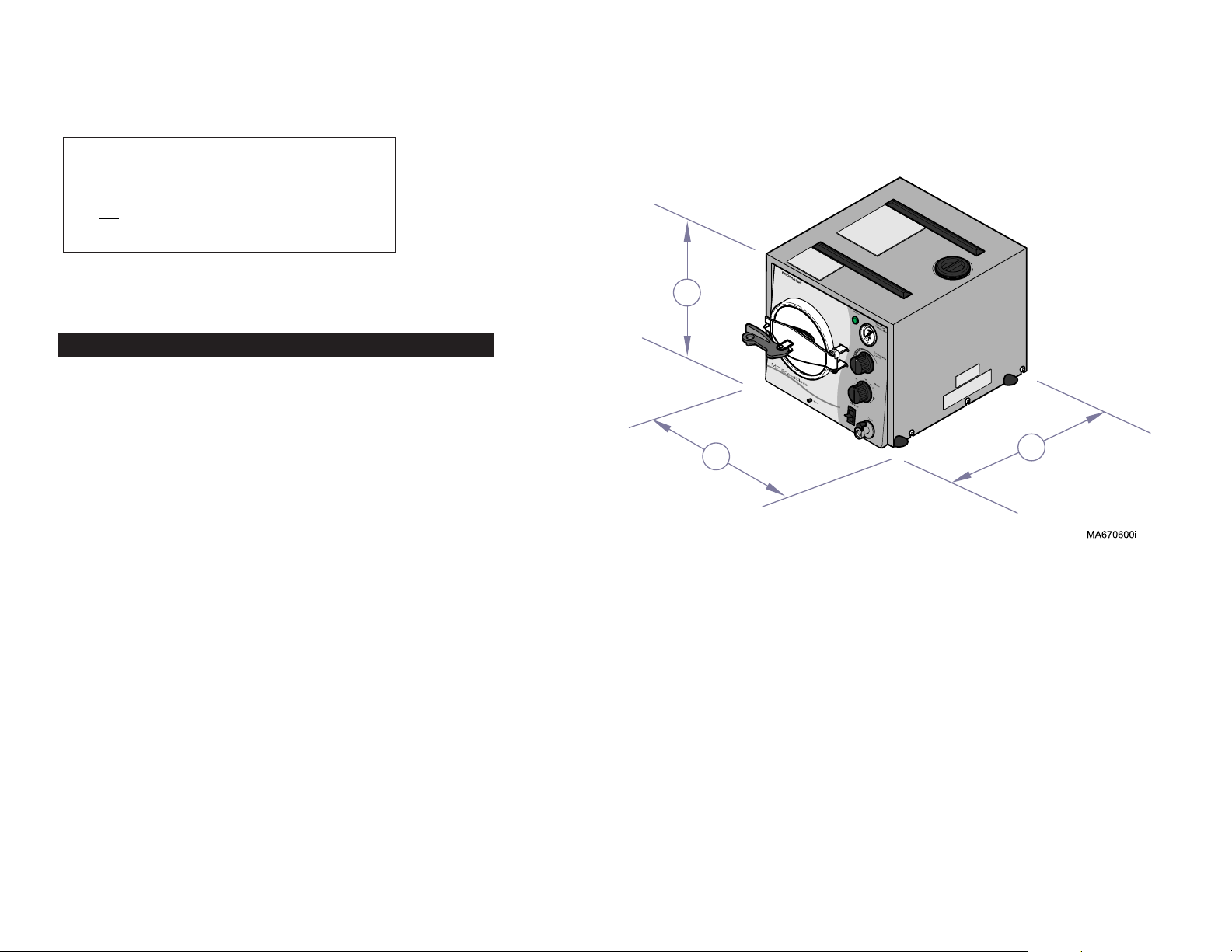

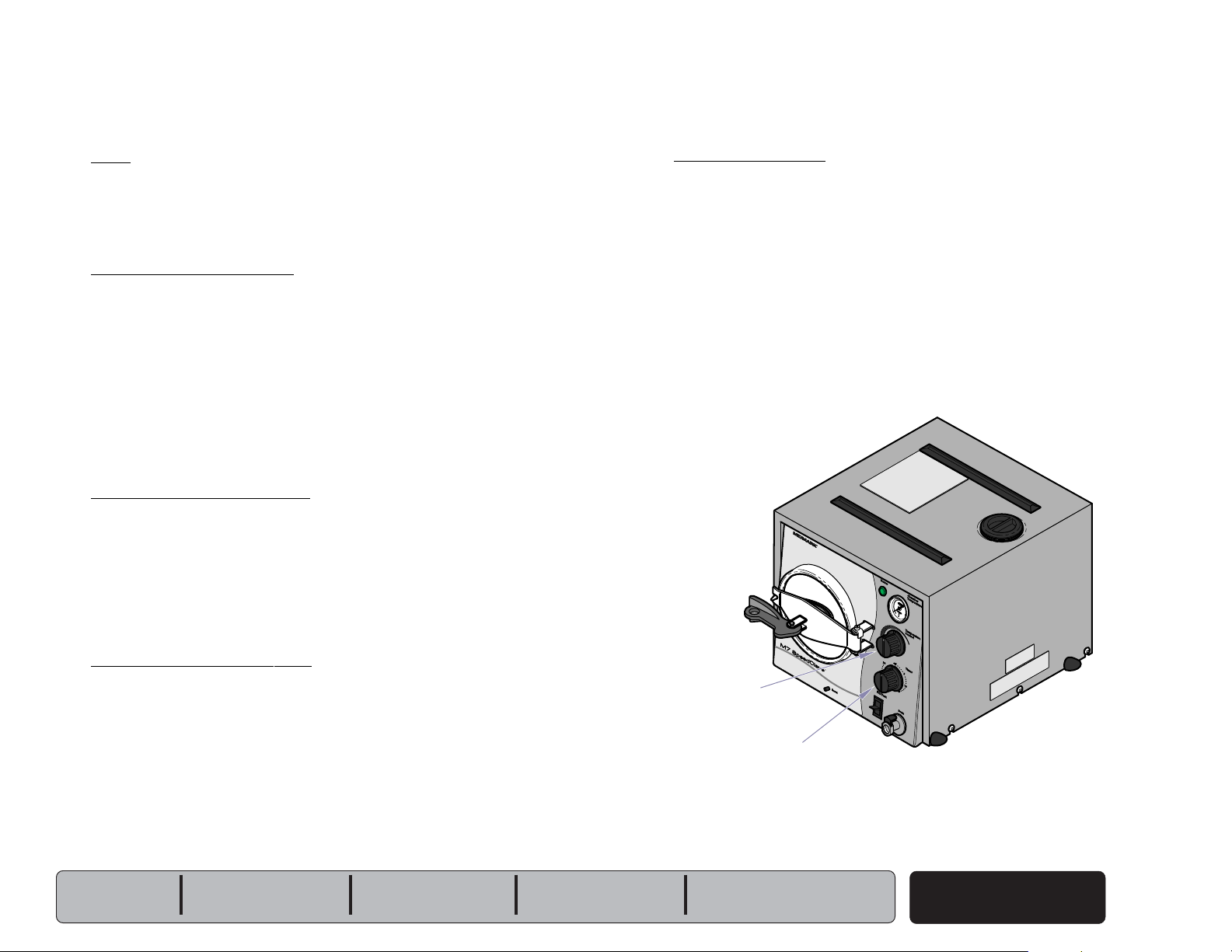

Weights, Dimensions, Electrical Specifications

ATTENTION

A separate (dedicated) electrical circuit is

recommended for all models.

Do not connect to a circuit with other devices,

unless the circuit is rated for the additional load.

M7 (-020 thru -022)

R

A

Dimensions

Height

Width

Depth

Chamber Size: ..................................... Diameter: 7.5 in. (19 cm)

Depth: 14.25 in. (36.2 cm)

Shipping Carton:

(Length x Width x Height) ..................

(61 cm x 40.6 cm x 40.6 cm)

Weight:

Shipping Weight ................................. 39 lbs (17.7 kg)

w/reservoir empty .............................. 30 lbs (13.6 kg)

w/reservoir full ................................... 41.8 lbs (19 kg)

Reservoir Capacity: ............................ Approx. 1.3 gallon (4.9 liters)

at FULL mark

Pressure Relief Valve:

opens at approximately: ....................

Electrical Requirements: ....................

Compliance Chart]

Power Consumption:

115 VAC models ................................

230 VAC models ................................

Fuse

(back of unit)

115 VAC models ................................

230 VAC models ................................

[Refer to illustration]:

(A) ...........................................

(B) ............................................

(C) ...........................................

:

13 in. (33 cm)

14 in. (35.6 cm)

19 in. (48.3 cm)

24 in. x 16 in. x 16 in.

34 psi (234 kPa)

[See Model Identification /

1300 watts, 10 amps @ 115 VAC

1300 watts, 5 amps @ 230 VAC

12 amp, 250 V, Fast-Acting, 1/4" x 1-1/4"

8 amp, 250 V, Fast-Acting, 5 x 20 mm

B

C

ii

© Midmark Corporation 2004 SF-1854

Rev.12/04

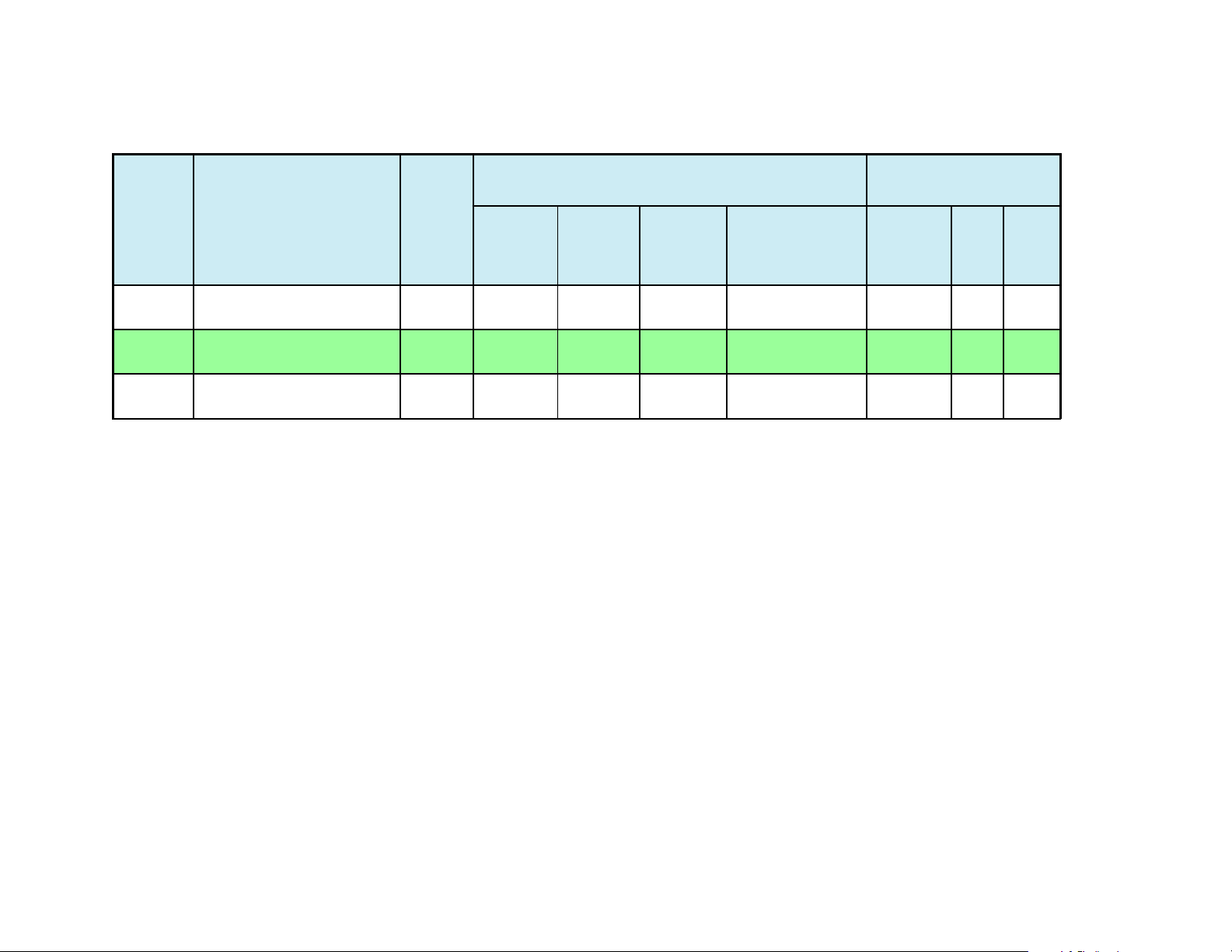

Model Identification / Compliance Chart

Go To Table Of Contents

Next

Back

Serial

Model Description

Number

Prefixes

UL

544

UL

61010A-1

61010-2-041

General Information

Complies To: Electrical Ratings:

CAN/CSA

C22.2,

#151

CAN/CSA

C22.2,

#1010

#1010.2-041-96

Cycles

VAC Amps

(Hz)

M7-020

M7-021

M7-022

Midmark M7 Sterilizer

(115 VAC)

Midmark M7 Sterilizer

(230 VAC)

Ritter M7 Sterilizer

(115 VAC)

V

V

V

xx

x x

xx

115 10 60

230 5 50

115 10 60

© Midmark Corporation 2004 SF-1854

iii

General Information

Go To Table Of Contents

Next

Back

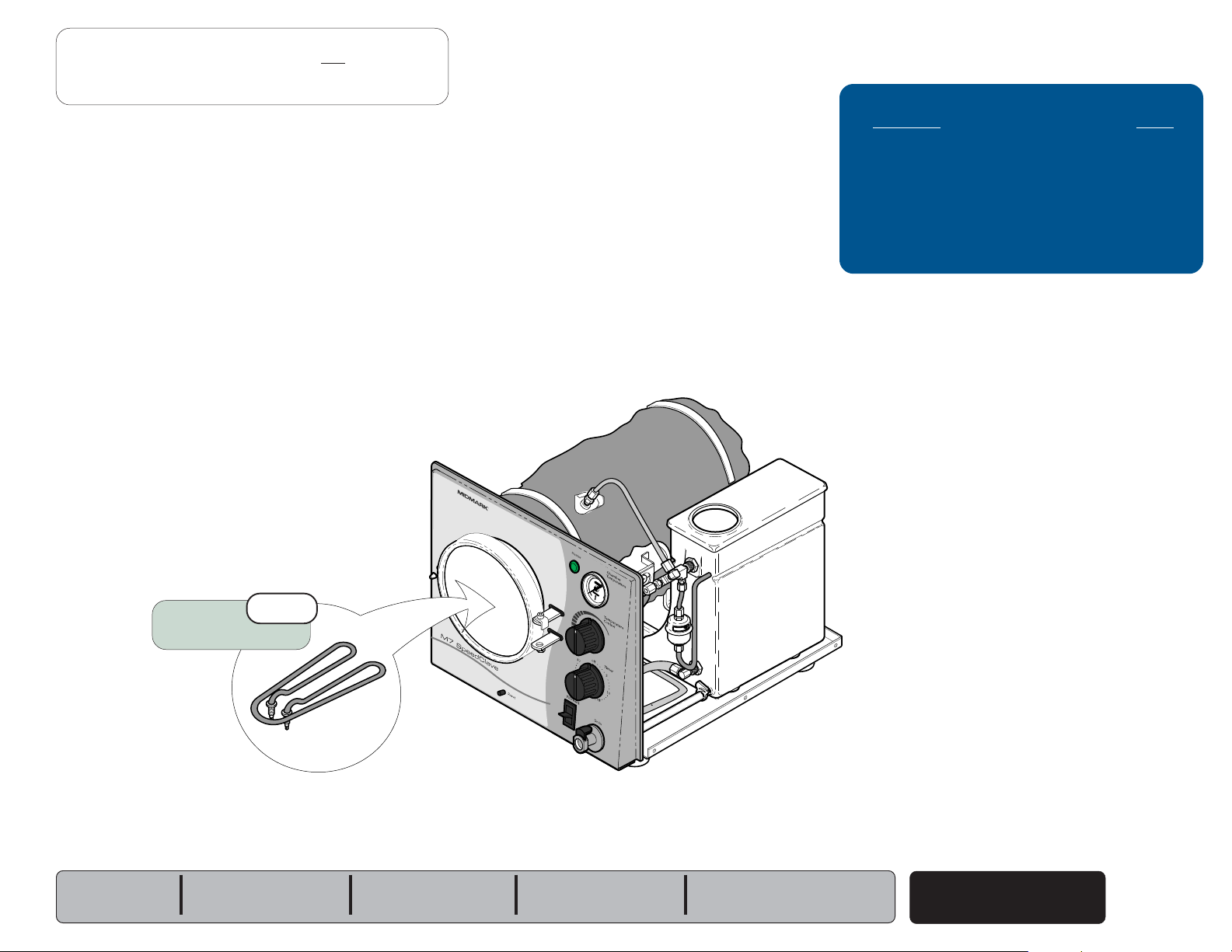

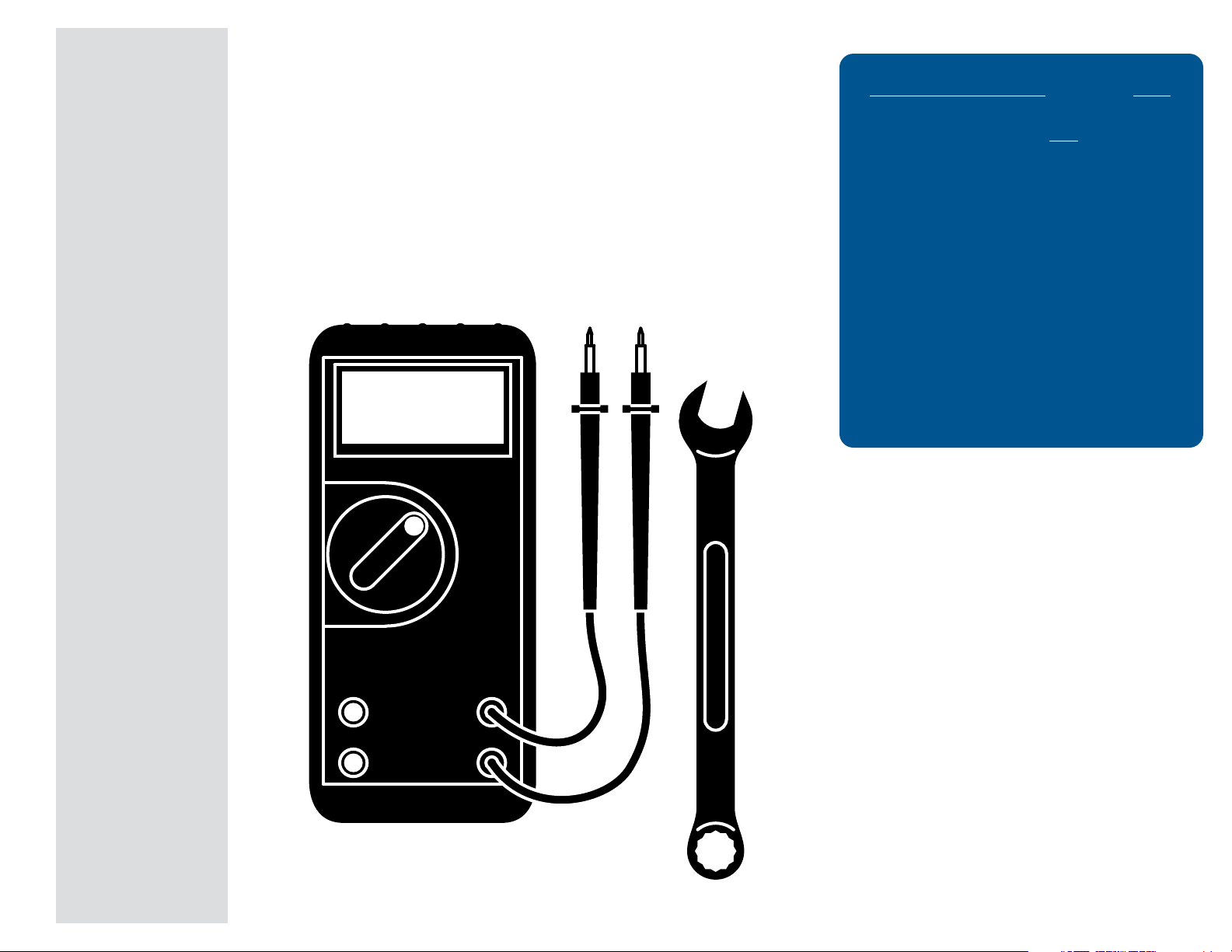

Special Tools

This table lists all special tools needed to diagnose and repair the sterilizer.

looTlaicepS rerutcafnaM rebmuNtraP looTfoesopruP

retemitluMlatigiD

retemomrehTlatigiD

elbaliavayllaicremmoCepytynaskcehcegatlov/ytiunitnocmrofrepoT

elbaliavayllaicremmoC epytyna erutarepmetrebmahcyfirevoT

Warranty Information

SCOPE OF WARRANTY

Midmark Corporation (“Midmark”) warrants to the original purchaser its new Alternate Care

products and components (except for components not warranted under “Exclusions”) manufactured by Midmark to be free from defects in material and workmanship under normal use and

service. Midmark’s obligation under this warranty is limited to the repair or replacement, at

Midmark’s option, of the parts or the products the defects of which are reported to Midmark

within the applicable warranty period and which, upon examination by Midmark, prove to be

defective.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date of delivery to the original user, shall be

one (1) year for all warranted products and components.

EXCLUSIONS

This warranty does not cover and Midmark shall not be liable for the following: (1) repairs and

replacements because of misuse, abuse, negligence, alteration, accident, freight damage, or

tampering; (2) products which are not installed, used, and properly cleaned as required in the

Midmark “Installation” and or “Installation / Operation Manual for this applicable product. (3)

products considered to be of a consumable nature; (4) accessories or parts not manufactured

by Midmark; (5) charges by anyone for adjustments, repairs, replacement parts, installation, or

other work performed upon or in connection with such products which is not expressly

authorized in writing in advance by Midmark.

EXCLUSIVE REMEDY

Midmark’s only obligation under this warranty is the repair or replacement of defective parts.

Midmark shall not be liable for any direct, special, indirect, incidental, exemplary, or consequen

tial damages or delay, including, but not limited to, damages for loss of profits or loss of use.

NO AUTHORIZATION

No person or firm is authorized to create for Midmark any other obligation or liability in

connection with the products.

ADDITIONAL INFORMATION

Failure to follow the guidelines listed below will void the

warranty and/or render the table unsafe for use.

• If a malfunction is detected, do not use the table

until necessary repairs are made.

• Do not attempt to disassemble table, replace

components, or perform adjustments unless you are

a Midmark authorized service technician.

• Do not use another manufacturer's parts to replace

malfunctioning components. Use only Midmark

replacement parts

THIS WARRANTY IS MIDMARK’S ONLY WARRANTY

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES NO IMPLIED

WARRANTIES OF ANY KIND INCLUDING ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE. THIS WARRANTY IS

LIMITED TO THE REPAIR OR REPLACEMENT OF

DEFECTIVE PARTS.

SF-1487 REV. A1

iv

© Midmark Corporation 2004 SF-1854

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Operation &

Troubleshooting

Mode Page

Electrical System:

Filling the Chamber ............................... A-6

Heat Up / Sterilization ........................... A-10

Venting the Chamber ............................ A-16

M7 (-020 thru -022) ..

A-3

Models:

Serial Numbers:

Section A

© Midmark Corporation 2004 SF-1854

A-1

Operation & Troubleshooting

Go To Table Of Contents

Back

Next

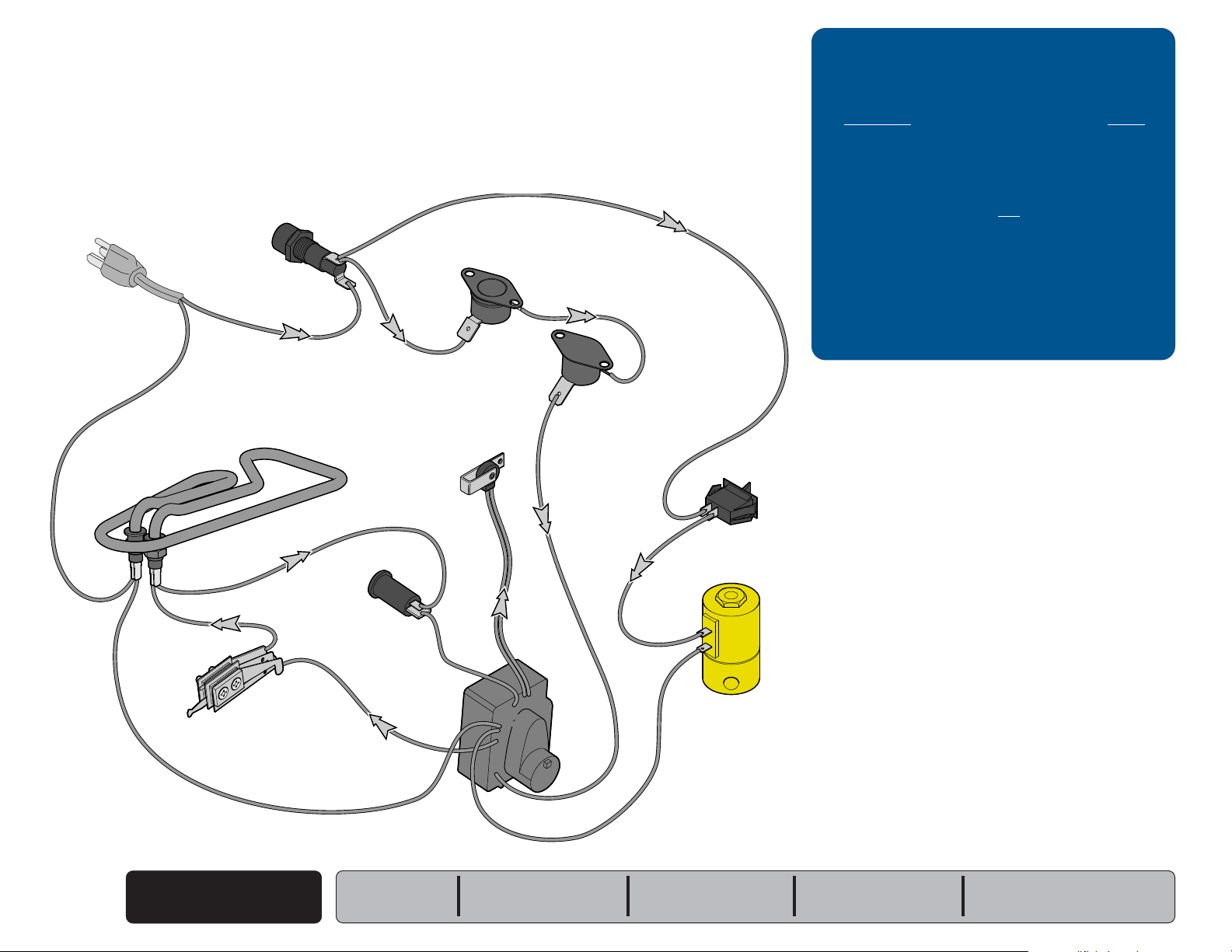

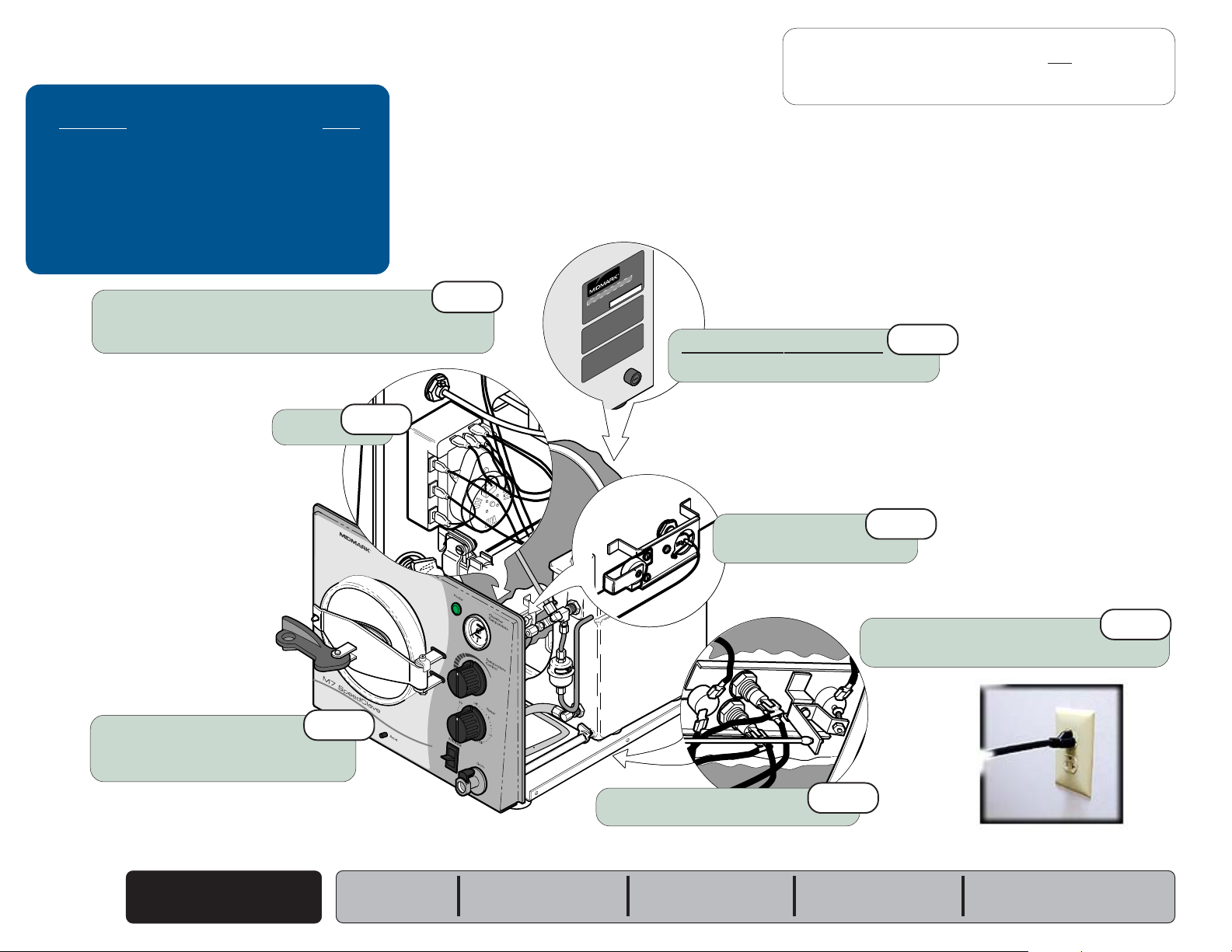

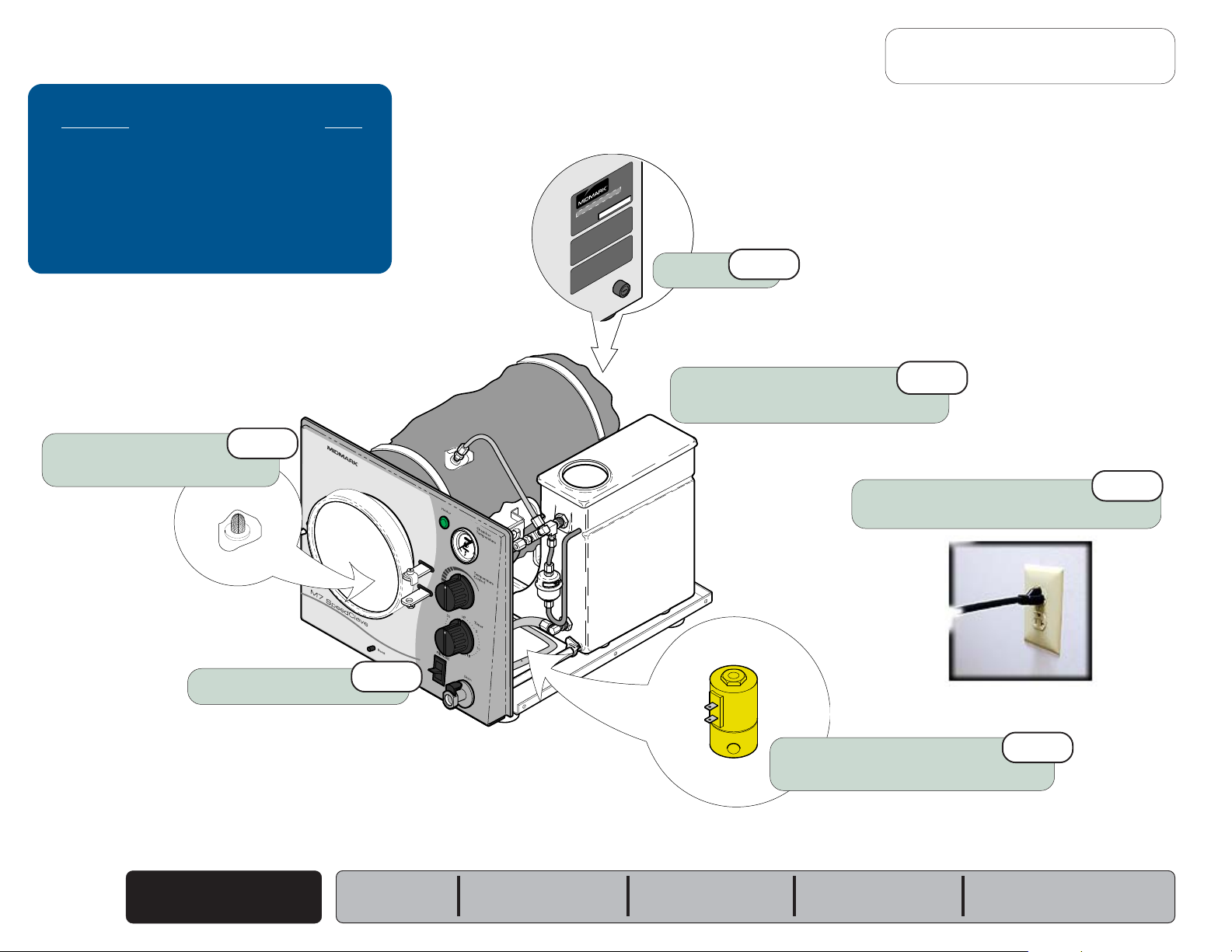

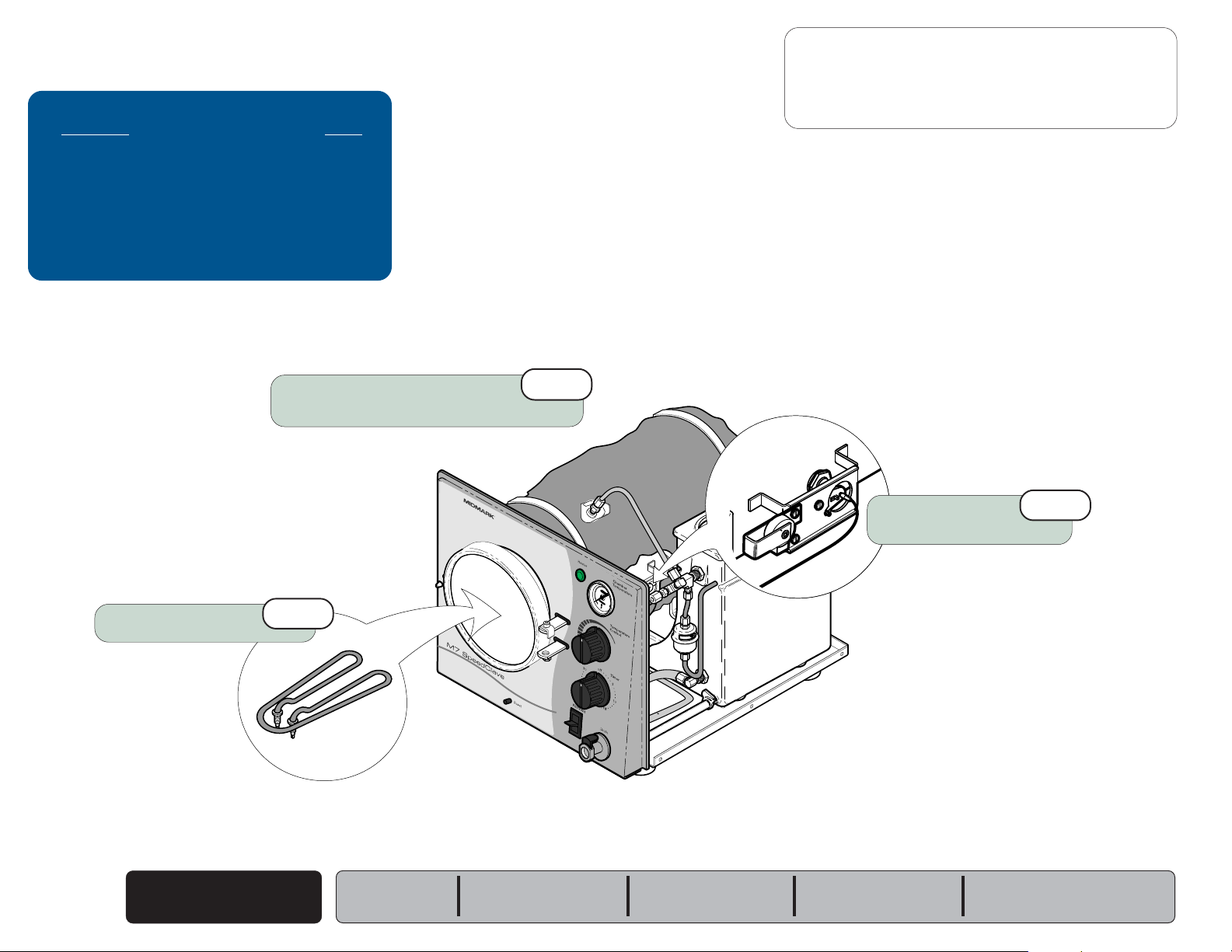

Electrical System - [M7 (-020 thru -022)]

The illustration shows all of the electrical components of the sterilzer.

Refer to the following page for a detailed description of current flow.

Fuse

Overheat

Thermostat

(Manual-Reset)

Troubleshooting

[Electrical System]

Problem: Page

When Fill/Vent Switch is pressed:

- Chamber does not FILL .......................

- Chamber does not VENT .....................

Heating element does not turn ON:

- Heater light is OFF ...............................

- Heater light is ON

.............................

Sterilizer shuts down before

timer setting expires .........................

Timer buzzer does not function ............

A-8

A-18

A-4

A-5

A-13

A-15

Com.

Heating

Element

Com.

Temperature

Regulator

Relay

Heater

Light

Timer

Buzzer

Com.

Overheat

Thermostat

(Auto-Reset)

Fill / Vent

Switch

Fill / Vent

Valve

Timer

MA670900i

Electrical System

A-2

© Midmark Corporation 2004 SF-1854

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Electrical System - [M7 (-020 thru -022)]

With the power cord properly connected...

Fuse

Current

back of the unit. This current supplies power to the fill / vent switch and

the overheat thermostats.

Fill / Vent Switch

Current is supplied to the fill / vent switch thru the fuse.

Overheat Thermostats & Timer

Current is supplied to the two overheat thermostats thru the fuse.

Current continuously flows thru the thermostats to the timer.

If either thermostat opens

from the timer until the thermostat is reset or replaced.

NOTE

The Manual-Reset Thermostat contacts open at approximately 285°F (140°C).

To reset, allow unit to cool, then press RESET button on front of unit.

The Auto-Reset Thermostat contacts open at approximately 295°F (146°C).

This thermostat automatically resets when the unit cools to approx. 265°F (129°C).

(115 / 230 VAC)

continuously flows thru the fuse located in the

(overheat or malfunction),

voltage is removed

When the timer is turned ON (continued)...

Temperature Regulator Relay

Current is supplied to the temperature regulator relay thru the timer. If the

chamber temperature is lower than the temperature knob setting*, the relay

contacts are closed. When these contacts are closed, current flows thru the

relay to the heating element and the heater light.

[* The minimum temperature knob setting is approx. 220°F (104°C)]

The diaphragm cup of the relay expands as the temperature & pressure

inside the chamber increase. When the chamber temperature reaches the

temperature knob setting, the relay contacts open, and voltage is removed

from the heating element & heater light.

Heater Light & Heating Element

When the contacts of the temperature regulator relay are closed,

current is supplied to the heater light and the heating element.

As the relay contacts open and close, the heating element cycles

ON / OFF. This continues until the timer setting expires.

The heater light is illuminated whenever the heating element is ON.

When the timer setting expires...

Timer & Timer Buzzer

The contacts to the temperature regulator relay open, stopping the current

flow to the heater light & heating element.

When filling the chamber (pressing the fill/vent switch)...

Fill / Vent Switch

The contacts of the

switch are closed, current is supplied to the fill / vent valve.

Fill / Vent Valve

When current is applied to the

When the valve is open, water flows into the chamber.

When the Timer is turned ON...

Timer

The

(normally open)

timer motor and the temperature regulator relay. The timer motor runs, and

begins to count down the time it was set for.

(The contacts to the timer buzzer remain open).

Models:

Serial Numbers:

(normally open)

timer contacts close, and voltage is supplied to the

switch close. When the contacts of the

(normally closed)

valve, the valve opens.

M7 (-020 thru -022)

all

The contacts to the timer buzzer close and current flows to the timer buzzer.

When voltage is applied, the buzzer emits an audible signal.

The contacts to the timer motor remain closed for one minute. After one

minute the contacts to the timer motor & the timer buzzer open, stopping the

current flow to these two components.

When pressing the Fill / Vent Switch (to VENT the chamber)...

Fill / Vent Switch

The contacts of the

switch are closed, current is supplied to the fill / vent valve.

(normally open)

switch close. When the contacts of the

Fill / Vent Valve

When current is applied to the

When the valve is open, steam is released thru the condensing coil & the

water is returned to the reservoir .

(normally closed)

Electrical System

© Midmark Corporation 2004 SF-1854

valve, the valve opens.

A-3

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

4th

Loose / Damaged Wire Connections

Check all wiring connections.

(Power cord, overheat thermostats, etc.)

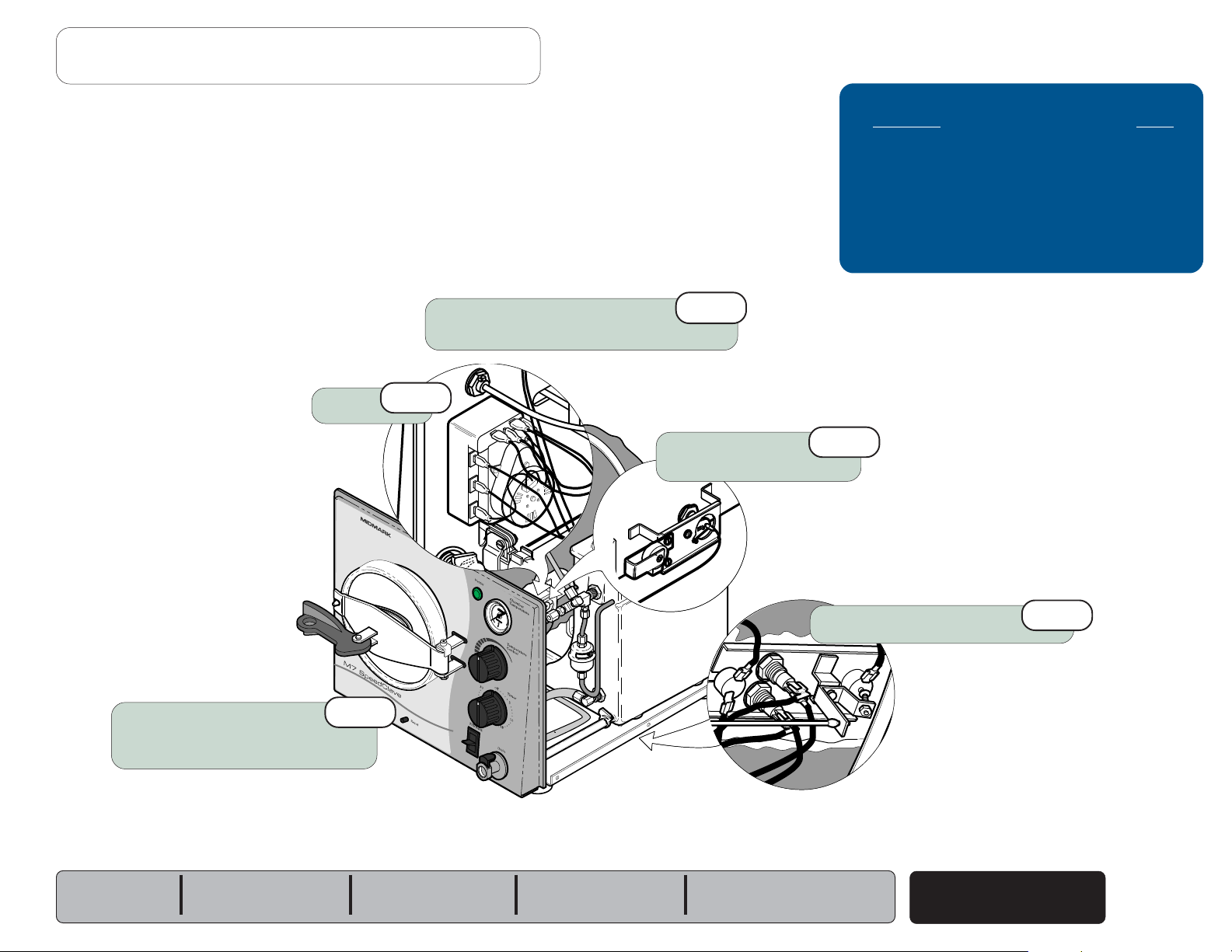

Problem: Heating element does not turn ON.

M7 (-020 thru -022) only

Fuse

[Heater light is OFF]

3rd

Timer

Press RESET button

Allow unit to cool for 15-20 minutes

before pressing RESET button.

1st

7th

R

Temperature

Regulator Assy.

Overheat Thermostats

5th

6th

Check supply voltage

(A dedicated circuit is recommended)

MA670800i

2nd

Electrical System

A-4

© Midmark Corporation 2004 SF-1854

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Problem: Heating element does not turn ON.

Go To Table Of Contents

Next

Back

[Heater light is ON]

Operation & Troubleshooting

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Models:

Serial Numbers:

Heating

1st

Element

M7 (-020 thru -022)

all

R

MA672300i

Electrical System

© Midmark Corporation 2004 SF-1854

A-5

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

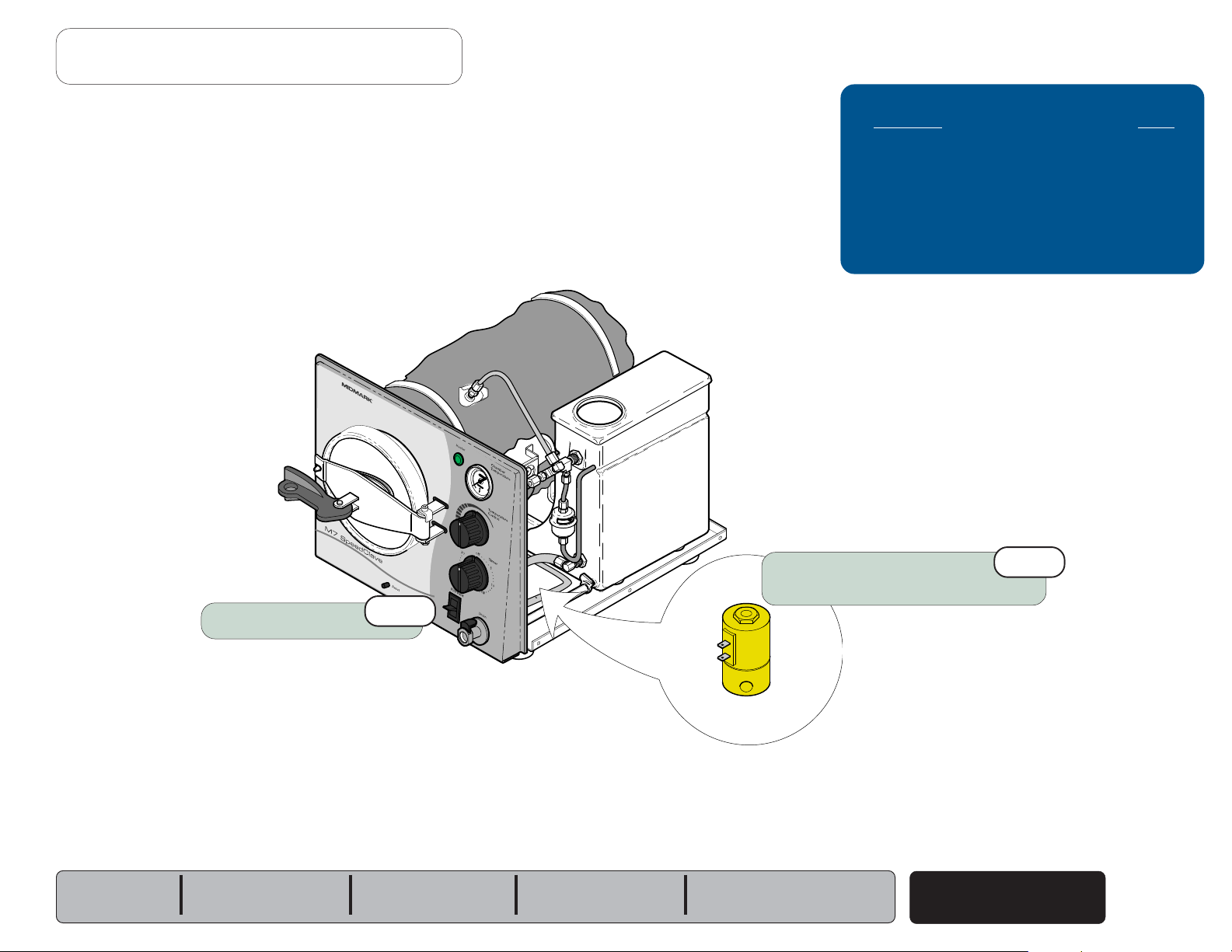

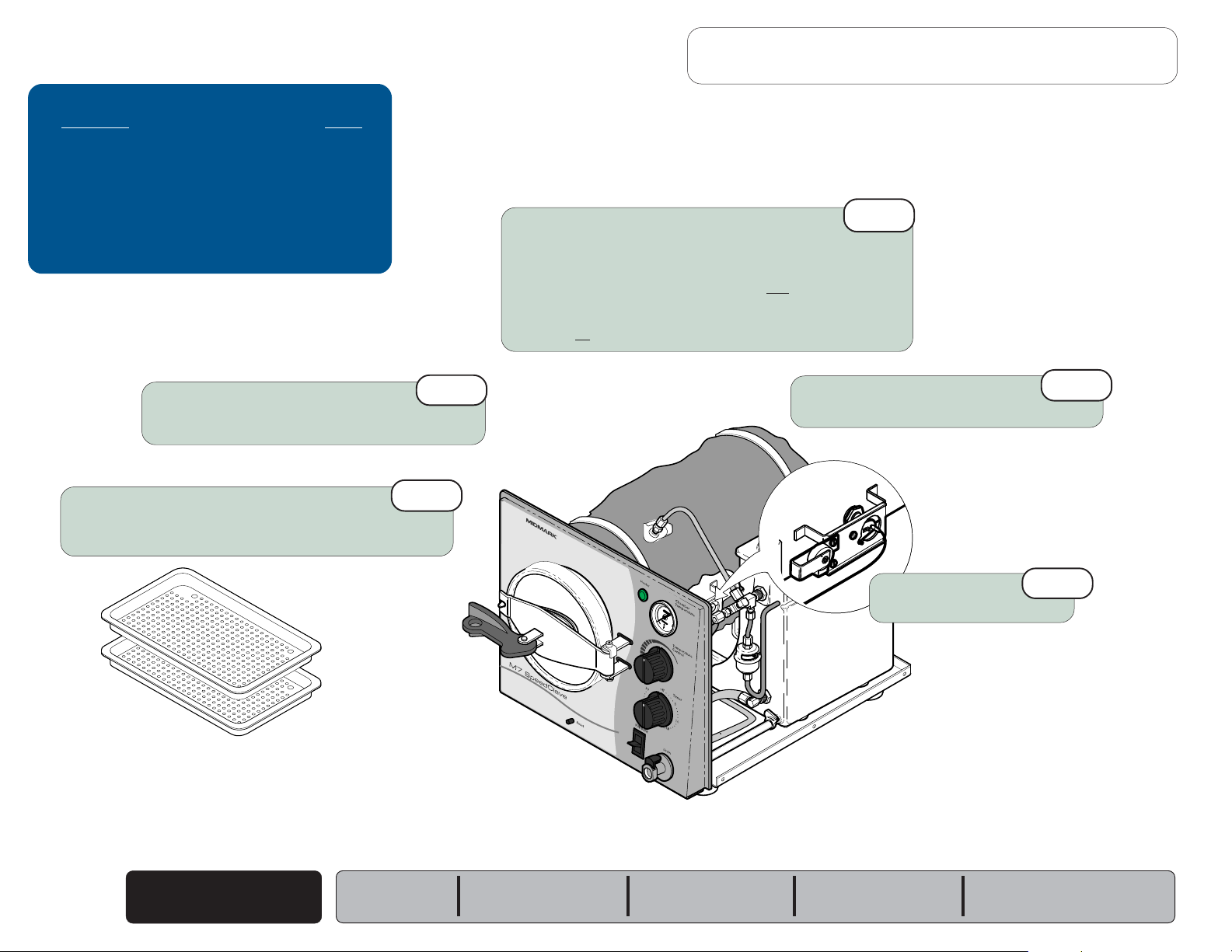

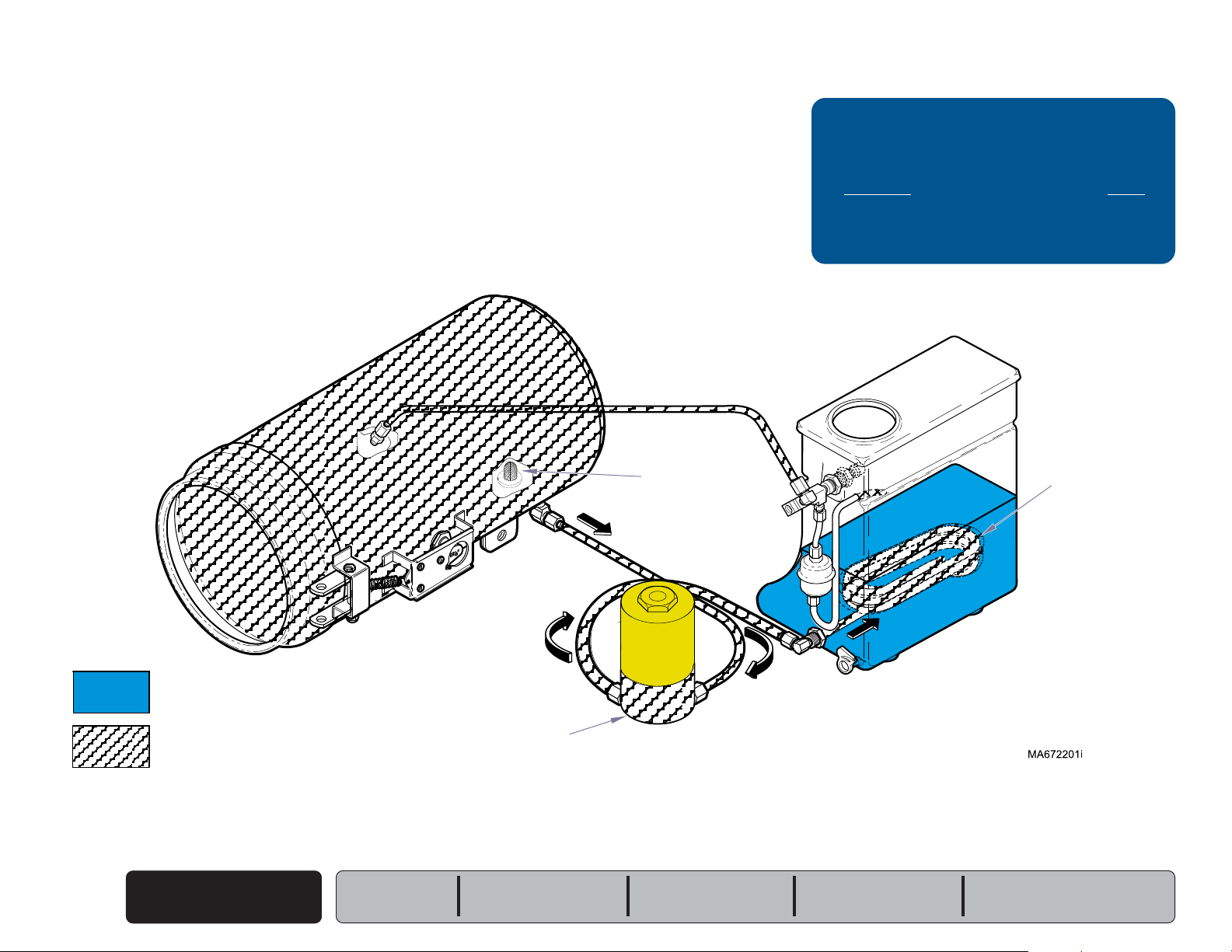

Filling the Chamber

The illustrations show the water flow when filling the chamber.

Refer to the following page for a detailed description of this process.

Filter Screen

Reservoir

Troubleshooting

[Filling the Chamber]

Problem: Page

Chamber does not fill:

- M7 (-020 thru -022) ..............................

Water continuously flows into chamber:

- M7 (-020 thru -022)

...........................

A-8

A-9

Filling the Chamber

A-6

© Midmark Corporation 2004 SF-1854

= Water

Fill / Vent Valve

(open)

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Filling the Chamber

Go To Table Of Contents

Next

Back

When the Fill / Vent Switch is pressed and held...

Fill / Vent Switch & Valve

Current

voltage is applied, the

is open, water from the reservoir flows into the chamber thru the valve and filter

screen.

When the Fill / Vent Switch is released...

Fill / Vent Switch & Valve

The fill/vent switch opens, stopping the current flow to the fill/vent valve.

When voltage is removed, the valve closes. When the valve closes, water

stops flowing into the chamber.

(line voltage)

flows thru the fill/vent switch to the fill/vent valve. When

(normally closed)

fill / vent valve opens. When the valve

Operation & Troubleshooting

R

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Fill / Vent

Switch

MA512903i

Filling the Chamber

© Midmark Corporation 2004 SF-1854

A-7

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Problem: Chamber does not fill.

Filter Screen

Clean / replace as necessary.

2nd

Fill / Vent Switch

R

6th

Fuse

Low water in reservoir?

Add distilled water if necessary.

4th

1st

Check supply voltage

(A dedicated circuit is recommended)

3rd

Filling the Chamber

A-8

© Midmark Corporation 2004 SF-1854

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Fill / Vent Valve & Tubing

Clean / adjust / replace as necessary.

5th

Problem: Water continuously flows into chamber.

Go To Table Of Contents

Next

Back

R

Operation & Troubleshooting

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Models:

Serial Numbers:

Fill / Vent Switch

M7 (-020 thru -022)

all

2nd

Fill / Vent Valve & Tubing

Clean / adjust / replace as necessary.

Filling the Chamber

1st

© Midmark Corporation 2004 SF-1854

A-9

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

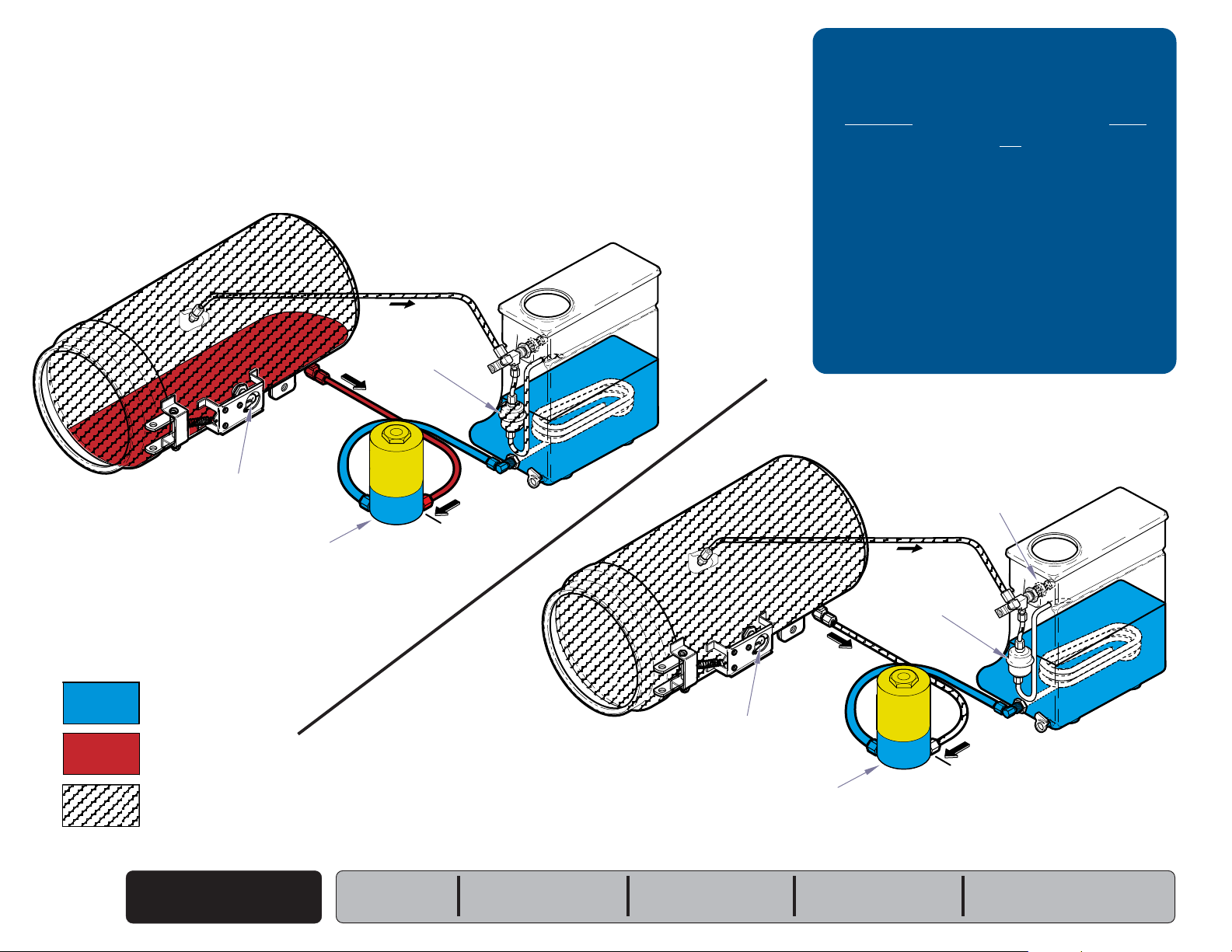

Heat Up / Sterilization

The illustrations show the water / steam flow during heat up & sterilization.

Refer to the following page for a detailed description of this process.

Heat-Up

Bellows

(open)

Temperature

Regulator Relay

(closed)

Troubleshooting

[Heat-Up / Sterilization]

Problem: Page

Heating element does not turn ON:

- Heater light is OFF ...............................

- Heater light is ON

.............................

Heating element turns ON, but does not

reach required temperature ...............

Sterilizer shuts down before

timer setting expires .........................

Biological test strips indicate items

are not sterile ....................................

Timer buzzer does not function ............

Sterilization

Pressure Relief Valve

(closed)

A-4

A-5

A-12

A-13

A-14

A-15

= Water

= Heated Water

= Steam

Heat-Up / Sterilization

A-10

© Midmark Corporation 2004 SF-1854

Fill / Vent Valve

(closed)

Note: Electronic valve is shown.

Manual valve is also closed.

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Temperature

Regulator Relay

(closed / open)

Fill / Vent Valve

(closed)

Note: Electronic valve is shown.

Manual valve is also closed.

Bellows

(closed)

MA672000i

Heat-Up / Sterilization

Go To Table Of Contents

Next

Back

Operation & Troubleshooting

When the timer is turned ON...

Timer

The

(normally open)

timer motor and the temperature regulator relay. The timer motor runs, and

begins to count down the time it was set for.

timer contacts close, and voltage is supplied to the

(The contacts to the timer buzzer remain open).

Temperature Regulator Relay

Current is supplied to the temperature regulator relay thru the timer. If the

chamber temperature is lower than the temperature knob setting*, the relay

contacts are closed. When these contacts are closed, current flows thru the

relay to the heating element and the heater light.

[* The minimum temperature knob setting is approx. 220°F (104°C)]

The diaphragm cup of the relay expands as the temperature & pressure

inside the chamber increase. When the chamber temperature reaches the

temperature knob setting, the relay contacts open, and voltage is removed

from the heating element & heater light.

Heater Light & Heating Element

When the contacts of the temperature regulator relay are closed,

current is supplied to the heater light and the heating element.

As the relay contacts open and close, the heating element cycles ON / OFF.

This continues until the timer setting expires.

When the timer setting expires...

Timer & Timer Buzzer

The contacts to the temperature regulator relay open, stopping the current

flow to the heater light & heating element.

The contacts to the timer buzzer close and current flows to the timer buzzer.

When voltage is applied, the buzzer emits an audible signal.

The contacts to the timer motor remain closed for one minute. After one

minute the contacts to the timer motor & the timer buzzer open, stopping the

current flow to these two components.

R

The heater light is illuminated whenever the heating element is ON.

Bellows & Pressure Relief Valve

Heat-Up:

As the water in the chamber begins to boil, air is forced out of the chamber.

This air passes thru the bellows into the reservoir.

Sterilization:

When pure steam begins to flow thru the bellows, the bellows closes

allowing pressure to build in the chamber. If the pressure in the chamber

exceeds 34 psi (234 kPa), the pressure relief valve opens to prevent unsafe

conditions.

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Temperature Knob

Timer Knob

MA672100i

Heat-Up / Sterilization

© Midmark Corporation 2004 SF-1854

A-11

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Check for pressure leaks.

Refer to Section B for checkpoints.

1st

Problem: Heating element turns ON, but does

not reach required temperature.

[Heater light is ON]

Heating Element

Heat-Up / Sterilization

A-12

© Midmark Corporation 2004 SF-1854

3rd

Models:

Serial Numbers:

R

M7 (-020 thru -022)

all

MA672700i

Temperature

Regulator Assy.

2nd

Problem: Sterilizer shuts down before timer setting expires.

Go To Table Of Contents

Next

Back

Check for pressure leaks.

Refer to Section B for checkpoints.

1st

Operation & Troubleshooting

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Timer

Press RESET button

Allow unit to cool for 15-20 minutes

before pressing RESET button.

2nd

5th

R

Temperature

Regulator Assy.

4th

Overheat Thermostats

MA672800i

3rd

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Heat-Up / Sterilization

© Midmark Corporation 2004 SF-1854

A-13

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Problem: Biological test strips indicate items are not sterile.

Type / condition of indicator strips

This unit requires test strips rated for:

Gravity Displacement Steam Sterilizers

Test strips must be stored in a cool, dry location.

Failure to do so will result in faulty readings.

(Follow all instructions provided with test strips)

1st

Is the sterlizer overloaded?

Large loads or heavy linen packs may

prevent strips from changing.

Are the correct trays being used?

Some trays may prevent proper air flow.

Be sure trays are designed for this sterilizer.

3rd

2nd

4th

Check for pressure leaks.

Refer to Section B for checkpoints.

R

Temperature

Regulator Assy.

MA672900i

5th

Heat-Up / Sterilization

A-14

© Midmark Corporation 2004 SF-1854

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Problem: Timer buzzer does not function.

Go To Table Of Contents

Next

Back

Operation & Troubleshooting

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Timer Buzzer

R

1st

MA672900i

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Heat-Up / Sterilization

© Midmark Corporation 2004 SF-1854

A-15

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Venting the Chamber

The illustrations show the steam / water flow when venting the chamber.

Refer to the following page for a detailed description of this process.

Troubleshooting

[Venting the Chamber]

Problem: Page

Chamber will not vent:

- M7 (-020 thru -022) ..............................

A-18

= Water

= Steam

Venting the Chamber

A-16

© Midmark Corporation 2004 SF-1854

Models:

Serial Numbers:

Fill / Vent Valve

(open)

M7 (-020 thru -022)

all

Filter Screen

Condensing

Coil

MA512903i

R

Venting the Chamber

Go To Table Of Contents

Next

Back

When the Fill / Vent Switch is pressed and held...

Fill / Vent Switch & Valve

Current

voltage is applied, the

water and steam back into the reservoir thru the valve and the condensing coil.

When all of the pressure has been vented, the door will "pop".

Note: Release the lever when the door "pops".

When the Fill / Vent Switch is released...

Fill / Vent Switch & Valve

The fill/vent switch opens, stopping the current flow to the fill/vent valve.

When voltage is removed, the valve closes.

(line voltage)

flows thru the fill/vent switch to the fill/vent valve. When

(normally closed)

fill / vent valve opens. Pressure forces

If the lever is held too long, the chamber will begin to fill.

Operation & Troubleshooting

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Fill / Vent

Switch

Venting the Chamber

© Midmark Corporation 2004 SF-1854

A-17

Operation & Troubleshooting

Go To Table Of Contents

Next

Back

Refer To: Page

Operation & Troubleshooting ................ A-1

Component Testing / Repair ................. B-1

Access Procedures .............................. C-1

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Problem: Chamber will not vent.

Filter Screen

Clean / replace as necessary.

1st

Fill / Vent Switch

R

3rd

Fill / Vent Valve & Tubing

Clean / adjust / replace as necessary.

2nd

Venting the Chamber

A-18

© Midmark Corporation 2004 SF-1854

Models:

Serial Numbers:

M7 (-020 thru -022)

all

Component Testing & Repair

Go To Table Of Contents

Next

Back

Testing & Repair

Component / Procedure Page

Checking For Pressure Leaks .............. B-2

Fuse

[M7 (-020 thru -022) only] ............

Bellows ............................................... B-4

Fill / Vent Valve: ................................... B-6

Temperature Regulator Assy. ................ B-10

Heating Element ................................... B-16

Overheat Thermostats .......................... B-20

Pressure Relief Valve ........................... B-23

Timer Assembly .................................... B-24

Timer Buzzer ........................................ B-28

Temperature Gauge .............................. B-29

Door Assembly ..................................... B-30

Reservoir Tank ...................................... B-32

Chamber Assembly ............................... B-34

B-3

Models:

Serial Numbers:

Section B

© Midmark Corporation 2004 SF-1854

B-1

Component Testing & Repair

Go To Table Of Contents

Next

Back

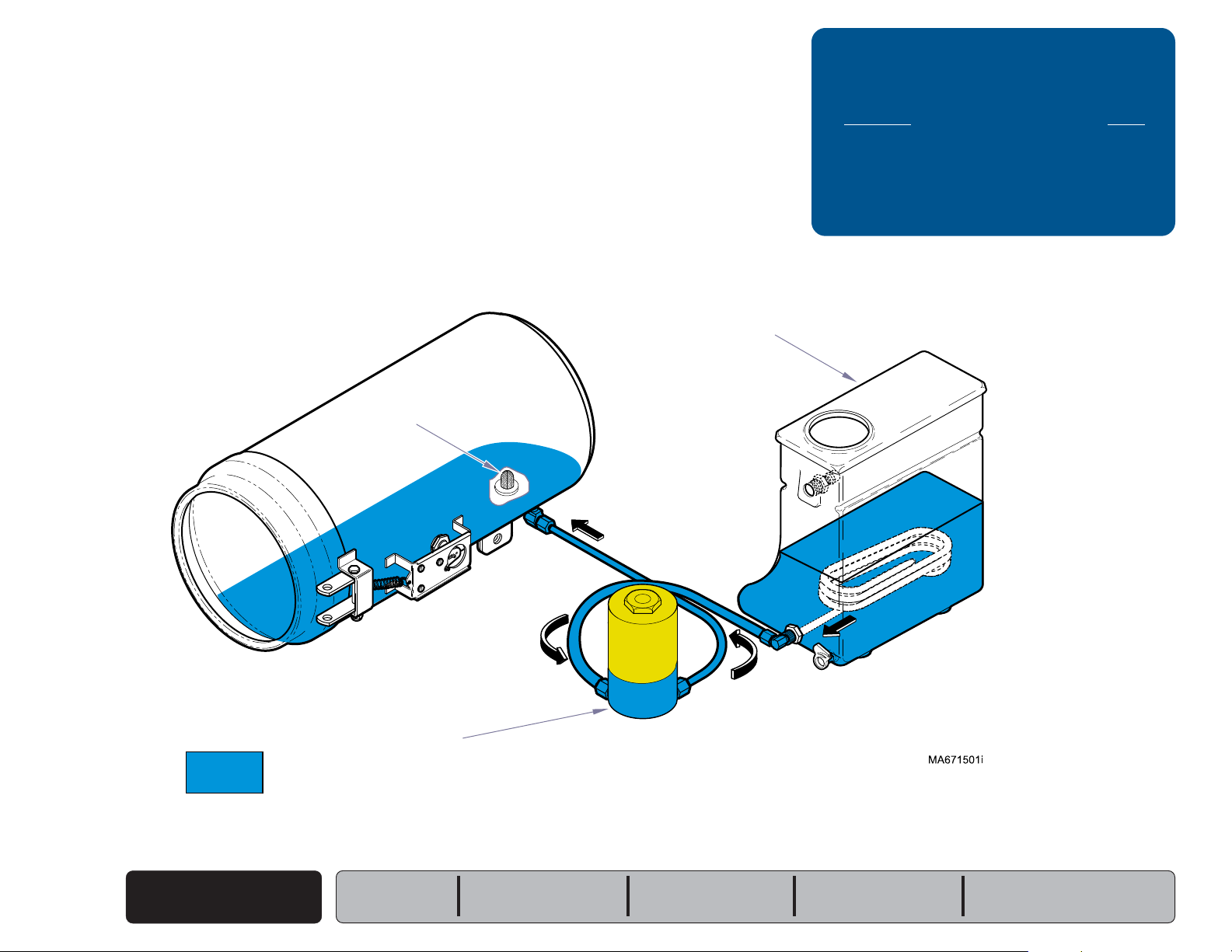

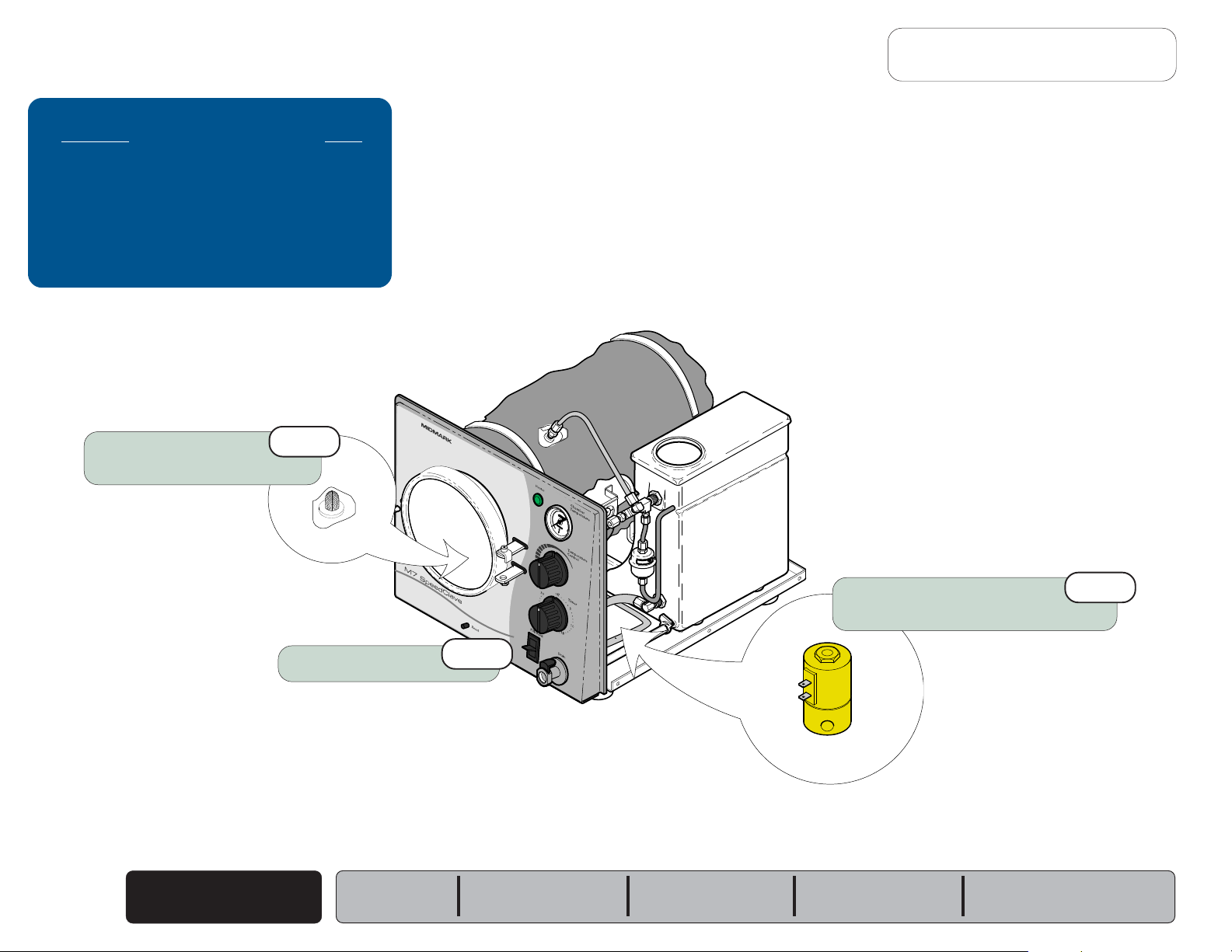

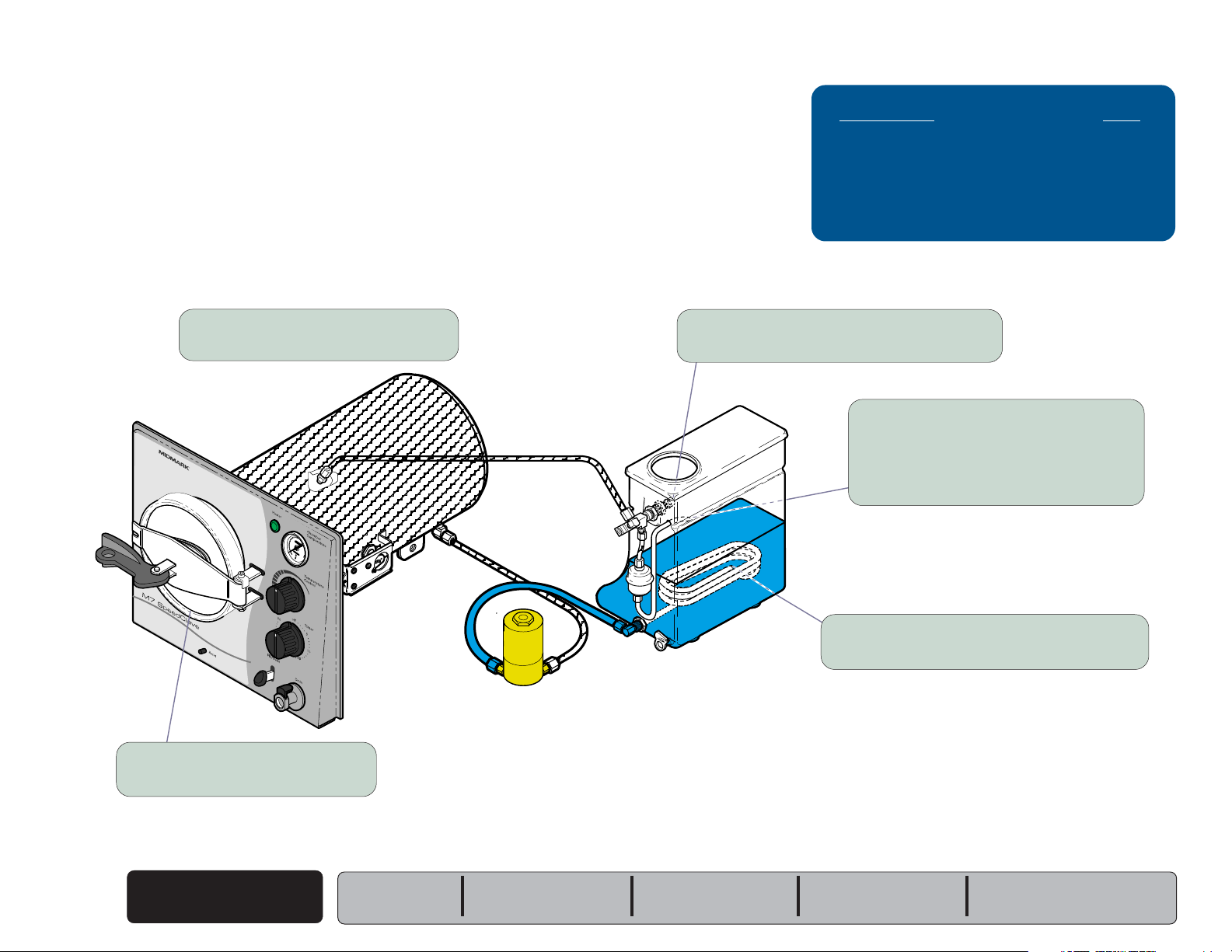

Checking for Pressure Leaks

This illustration shows the areas to check for pressure leaks.

Components Page

Bellows ............................................... B-4

Fill / Vent Valve: ................................... B-6

Pressure Relief Valve ........................... B-23

Door Assembly ..................................... B-30

Water leaking from fitting(s)?

Tighten / replace fittings if necessary.

R

Water leaking from door?

If YES, replace door gasket.

Steam from pressure relief valve?

If YES, replace the pressure relief valve.

Steam from bellows tubing?

If YES, replace the bellows.

Note: The bellows should close at approx. 215°F

(101°C). Periodic "hissing' or "spitting" is

normal.

Bubbles from condensing coil?

If YES, clean or replace the fill / vent valve.

MA673101i

B-2

© Midmark Corporation 2004 SF-1854

Checking for

Pressure Leaks

Models:

Serial Numbers:

M7 (-020 thru -022)

all

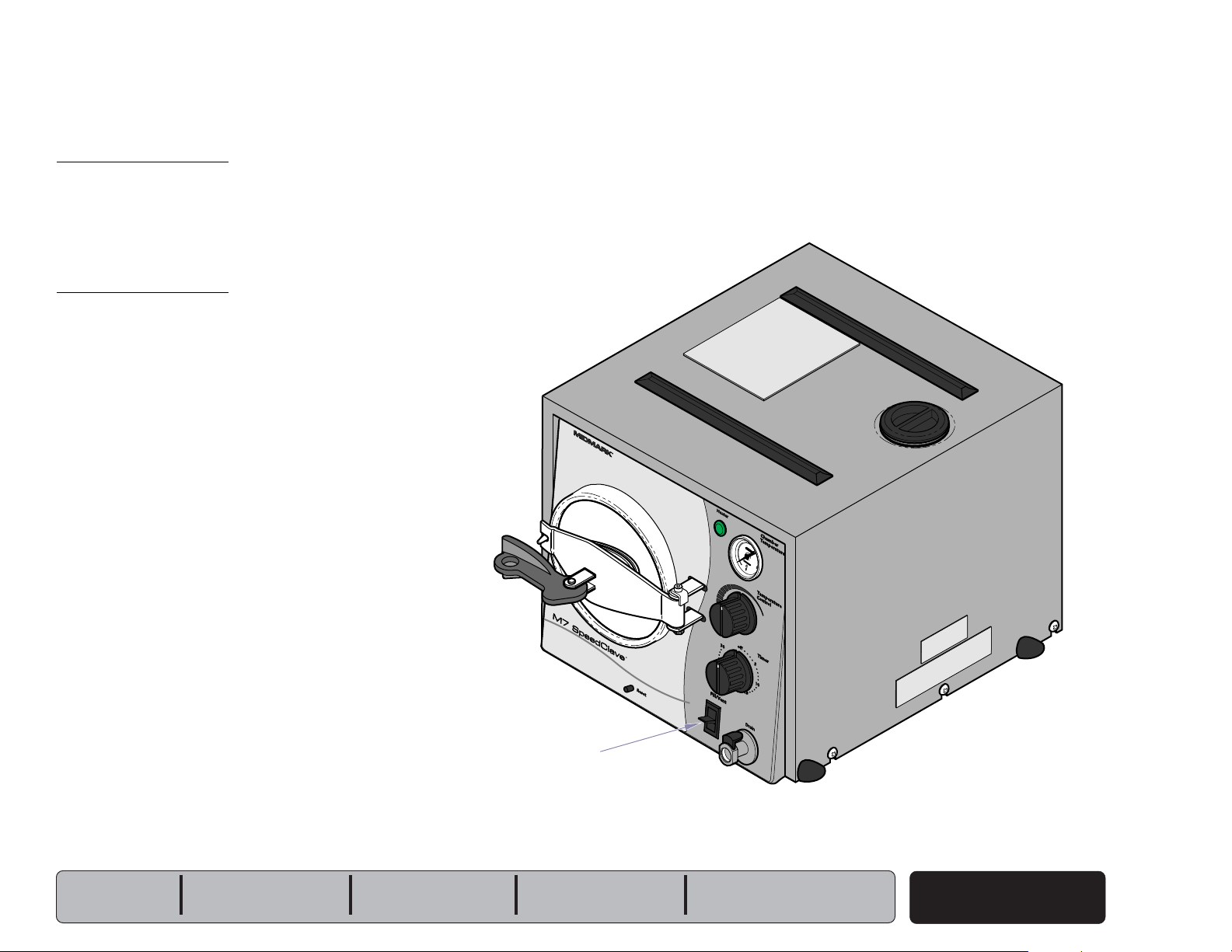

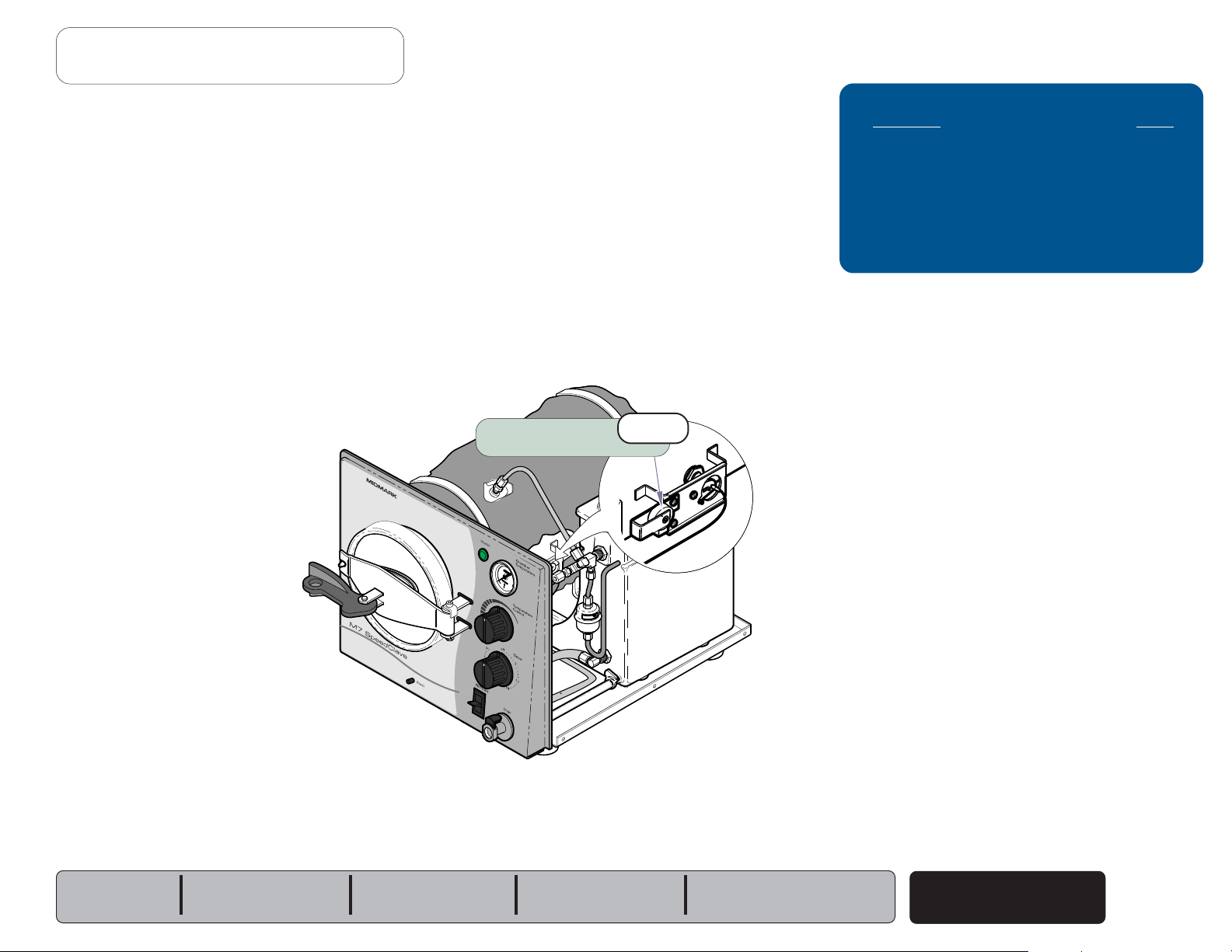

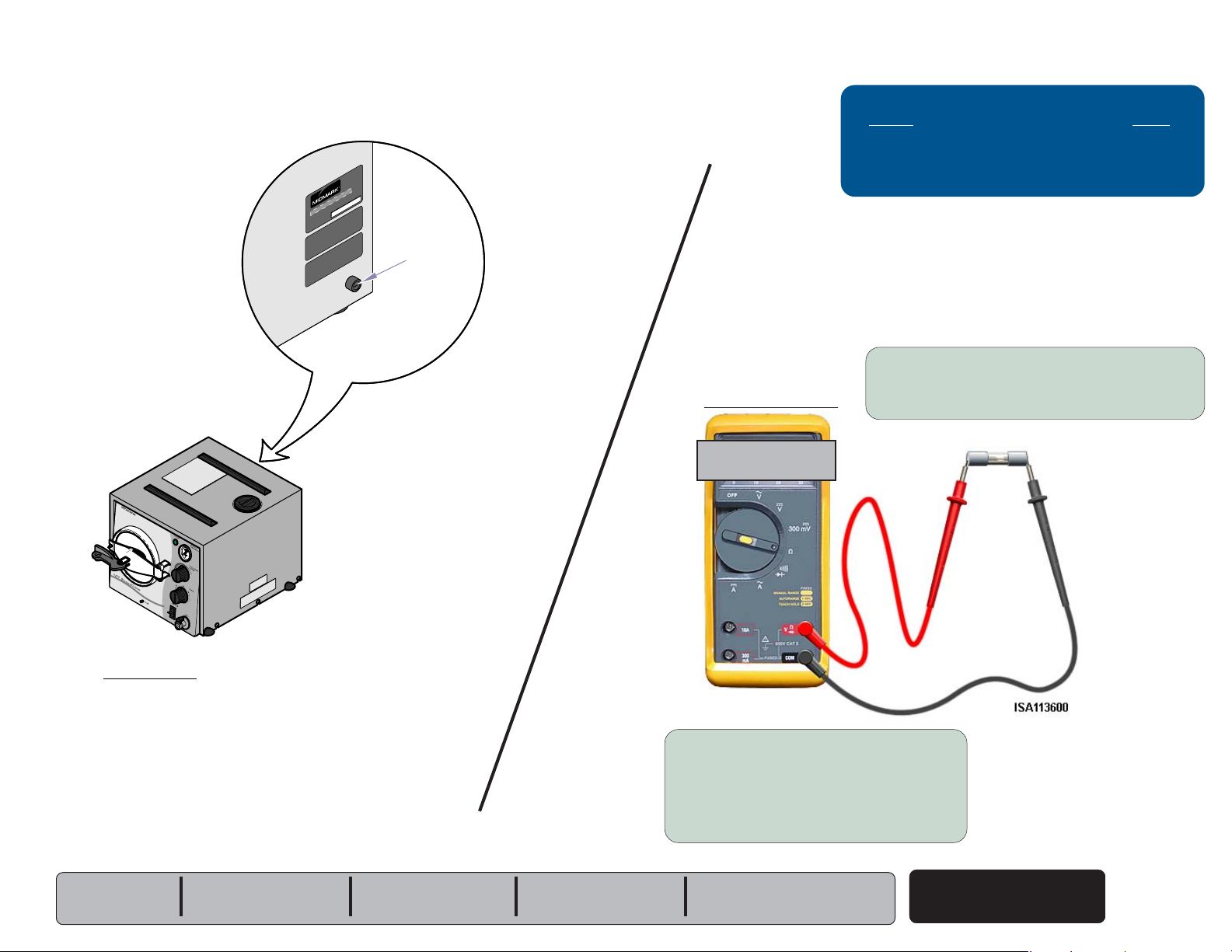

Fuse

Go To Table Of Contents

Next

Back

Location

Fuse

Holder

Component Testing & Repair

Fuse Test

Acceptable Range

Fuses Page

Fuses Page

Wiring Diagrams .................................... D-1

Location ............................................... B-2

Part Numbers ........................................ E-13

Fuse Test ............................................. B-2

Wiring Diagrams ................................... D-1

Fuse Rating ...............................6.3A, 250V

Type T, 5 x 20mm

Part Number ............................ 015-0346-20

Fuse Test

Step 1: Place meter probes on ends of fuse.

[Set meter to 200 ohms (

Ω)]

R

Fuse Ratings:

115V models ......

230V models ......

Models:

Serial Numbers:

12 amp, 250 V, Fast-Acting, 1/4" x 1-1/4"

8 amp, 250 V, Fast-Acting, 5mm x 20mm

M7 (-020 thru -022)

all

less than 5

ΩΩ

Ω

ΩΩ

FuseTest

If reading is OL...

Replace fuse.

If reading is within acceptable range...

Fuse is OK.

Fuse

© Midmark Corporation 2004 SF-1854

B-3

Loading...

Loading...