M7

Go To Table Of Contents

Place Order

To purchase a printed copy of this manual,

click on the "Place Order" button below.

Service and

-001 thru -010

Self-Contained Steam Sterilizer

Serial Number Prefixes:

RB, CR, CP, CS, FM, FN

NO LONGER IN

Parts Manual

M7

-001

thru

-010

Some service parts may not

PRODUCTION

be available for this product!

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

SF-1418 Part No. 003-0721-00 Rev. P (1/01/07)

Go To Table Of Contents

TABLE OF CONTENTS

Section/Paragraph Page

IMPORTANT INSTRUCTIONS

General Safety Instructions ........................................ ii

Warnings .................................................................. ii

Warranty Instructions.................................................. ii

SECTION I GENERAL INFORMATION

1.1 Scope of Manual......................................... 1-1

1.2 How to Use Manual .................................... 1-1

1.3 Description of M7 Sterilizer ......................... 1-1

1.4 Specifications ............................................. 1-3

1.5 Parts Replacement Ordering ...................... 1-4

1.6 Special Tools .............................................. 1-4

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test ......................................... 2-1

2.2 Troubleshooting Procedures....................... 2-2

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance ............................. 3-1

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Introduction ................................................. 4-1

4.2 Cover Assembly Removal / Installation....... 4-1

4.3 Timer Assembly Removal / Installation (New

Style Timer Assembly) ........................... 4-1

4.4 Timer Assembly Removal / Installation (Old

Style Timer Assembly) ........................... 4-2

4.5 Timer Buzzer Removal / Installation ........... 4-3

4.6 Pilot Light Removal / Installation ................. 4-4

4.7 Heating Element Removal / Installation ...... 4-4

4.8 Overheat Thermostat Removal /

Installation .............................................. 4-6

4.9 Temperature Regulator Relay Removal /

Installation .............................................. 4-8

4.10 Temperature Regulator Relay

Adjustment ........................................... 4-10

4.11 Diaphragm Cup Removal / Installation...... 4-12

4.12 Temperature Gauge Removal /

Installation ............................................ 4-12

4.13 Pressure Relief Valve Removal /

Installation ............................................ 4-13

Section/Paragraph Page

4.14 Bellows Assembly Removal /

Installation (Specify Serial Number) ..... 4-14

4.15 Bellows Assembly Removal /

Installation (Specify Serial Number) ..... 4-15

4.16 Bellows Assembly Removal /

Installation (Specify Serial Number) ..... 4-16

4.17 Fill / Vent Valve Removal / Installation ...... 4-17

4.18 Door Assembly Removal / Installation ...... 4-18

4.19 Door Gasket Removal / Installation .......... 4-19

4.20 Wire Rack And Trays Removal /

Installation ............................................ 4-20

4.21 Condensing Tank Removal /

Installation ............................................ 4-20

4.22 Chamber Assembly Removal /

Installation ............................................ 4-22

SECTION V SCHEMATICS, DIAGRAMS, AND

CHARTS

5.1 Electrical Schematics / Wiring Diagrams .... 5-1

5.2 Flow Diagrams............................................ 5-7

5.3 Suggested Times And Temperatures

Charts................................................... 5-11

SECTION VI PARTS LIST

6.1 Introduction ................................................. 6-1

6.2 Description of Columns................................6-1

M7 Sterilizer................................................ 6-2

Sterilizer Cover ........................................... 6-3

Sterilizer Cover Components ...................... 6-4

Sterilizer Main Components.......................6-5.*

Front Panel Components ...........................6-6.*

Door Assembly ..........................................6-7.*

Base Components .....................................6-8.*

Chamber Components - Side ..................... 6-9

Chamber Components - Lower................6-10.*

Tank Assembly ........................................6-11.*

Valve Assembly ...................................... 6-12.*

Rack And Trays ........................................ 6-13

Packaging................................................. 6-14

COMMENTS ........................................................... 7-1

FAX ORDERING FORM.......................................... 7-2

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark 1994 SF-1418 Rev. 5/95 Page i Printed in U.S.A.

IMPORTANT INSTRUCTIONS

Return To Table Of Contents

General Safety Instructions

Safety First: The primary concern of Midmark Corpo-

ration is that this sterilizer is maintained with the safety

of the staff in mind. To assure that services and repairs

are completed safely and correctly, proceed as follows:

(1) Read this entire manual before performing any

services or repairs on this sterilizer.

(2) Be sure you understand the instructions

contained in this manual before attempting to

service or repair this sterilizer.

Warnings

Throughout this manual are Note, Caution, and Danger

paragraphs that call attention to particular procedures.

These items are used as follows:

NOTE

A note is used to amplify an operating procedure,

practice, or condition.

Warranty Instructions

Refer to the Midmark “Limited Warranty” printed on the

back cover of the Installation and Operation Manual for

warranty information. Failure to follow the guidelines

listed below will void the warranty and/or render the

sterilizer unsafe for operation.

• In the event of a malfunction, do not attempt to

operate the sterilizer until necessary repairs have

been made.

• Do not attempt to disassemble sterilizer, replace

malfunctioning or damaged components, or perform

adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts of another manufacturer

when replacing inoperative or damaged components.

Use only Midmark replacement parts.

CAUTION

!!

not correctly followed, could result in equipment

damage.

A CAUTION is used for an operating

procedure, practice, or condition which, if

DANGER

!!

which, if not correctly followed, could result in

loss of life or serious personal injury.

A DANGER is used for an operating

procedure, practice, or condition

© Midmark 1994 SF-1418 Rev. 2/95 Page ii Printed in U.S.A.

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1 Scope of Manual

This manual contains detailed troubleshooting, scheduled maintenance, maintenance, and service instructions for the M7 SpeedClave ® Sterilizer. This manual

is intended to be used by Midmark’s authorized service

technicians.

1.2 How to Use Manual

A. Manual Use When Performing Scheduled Mainte-

nance.

(1) Perform inspections and services listed in

Scheduled Maintenance Chart (Refer to

para 3.1).

(2) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with Maintenance / Service Instructions (Refer to para 4.1).

B. Manual Use When Sterilizer Is Malfunctioning And

Cause Is Unknown.

(1) Perform an operational test on sterilizer (Refer

to para 2.1).

(2) Perform troubleshooting procedures listed in

Troubleshooting Guide (Refer to para 2.2).

(3) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with Maintenance/Service Instructions (Refer to para 4.1).

C. Manual Use When Damaged Component Is Known.

(1) Replace or adjust component in accordance

with Maintenance/Service Instructions (Refer to

para 4.1).

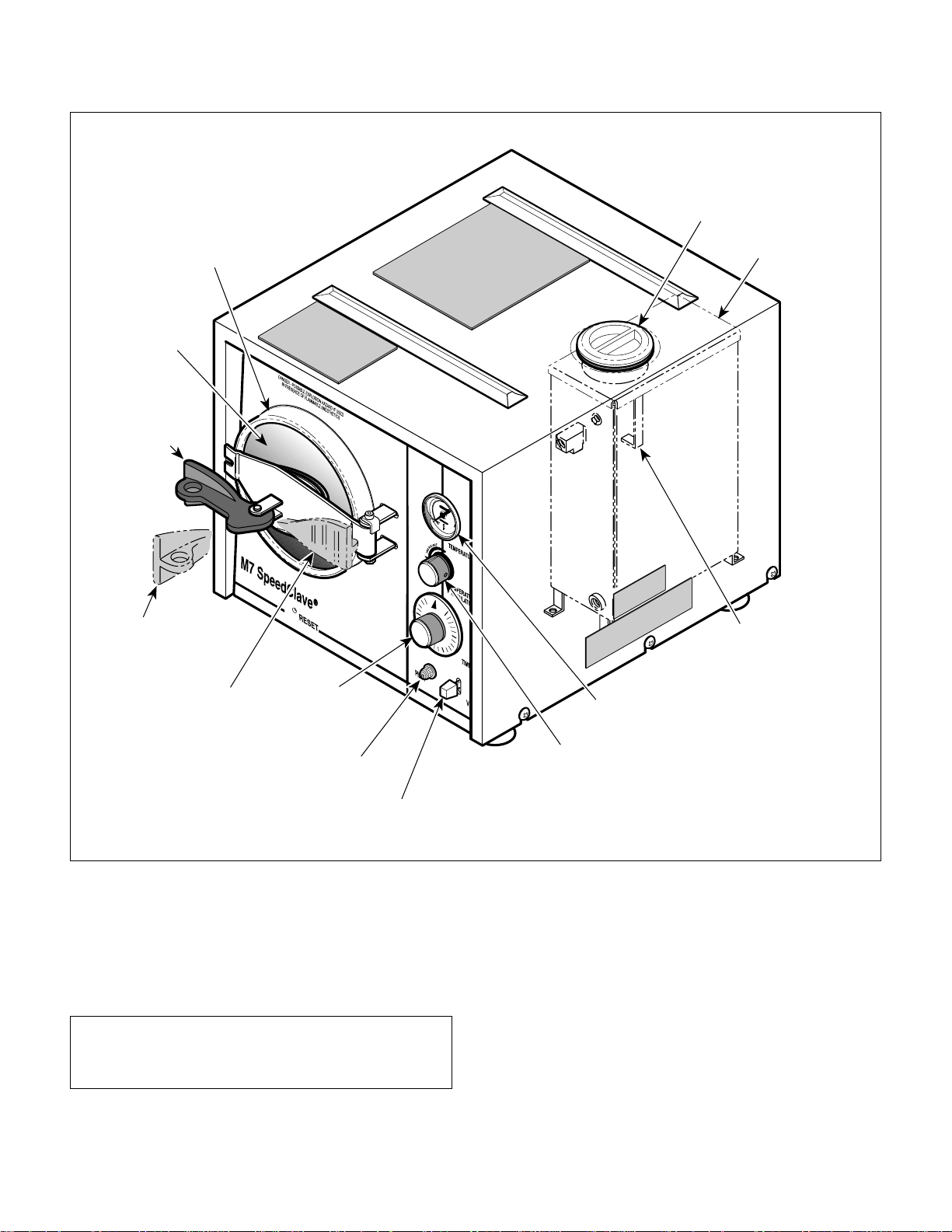

1.3 Description Of M7 Sterilizer

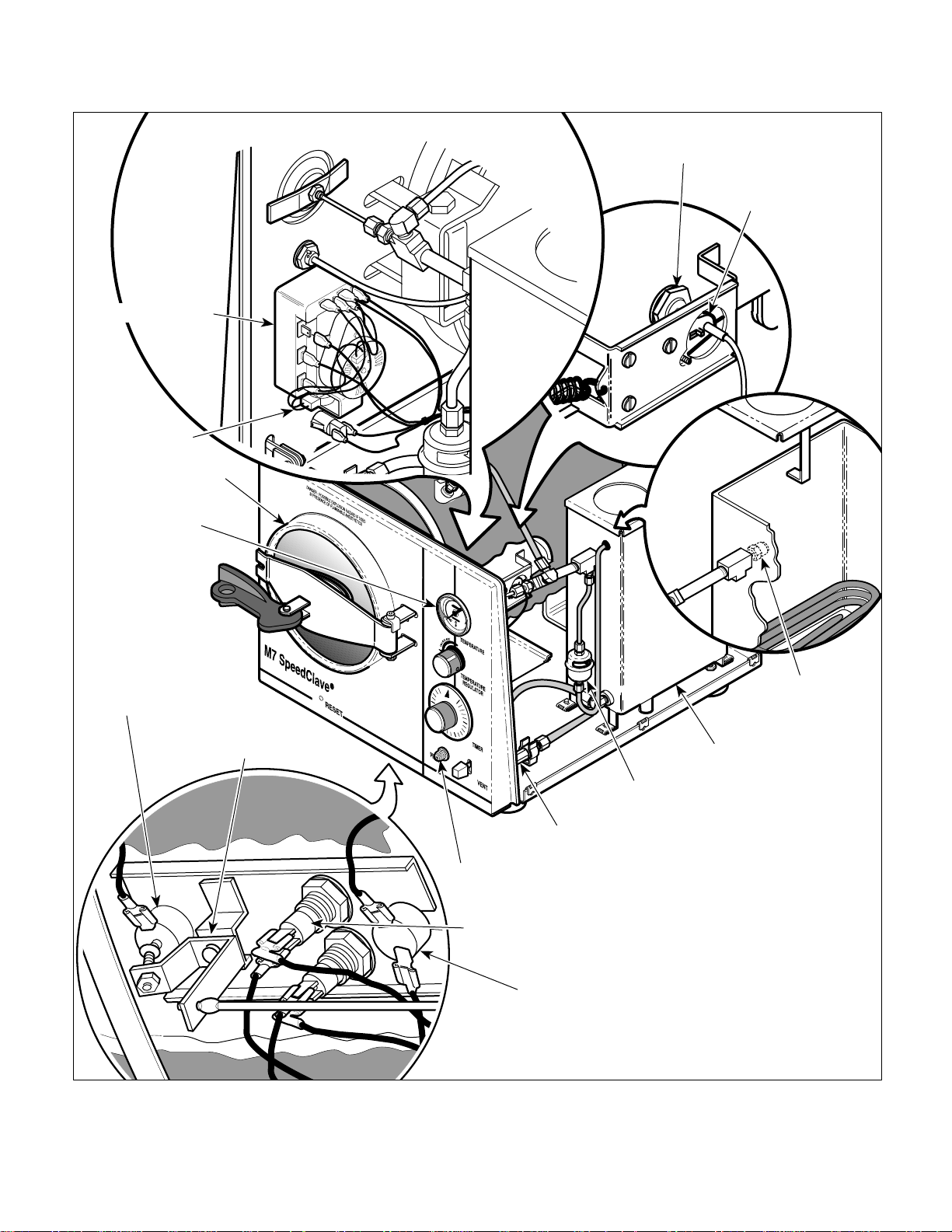

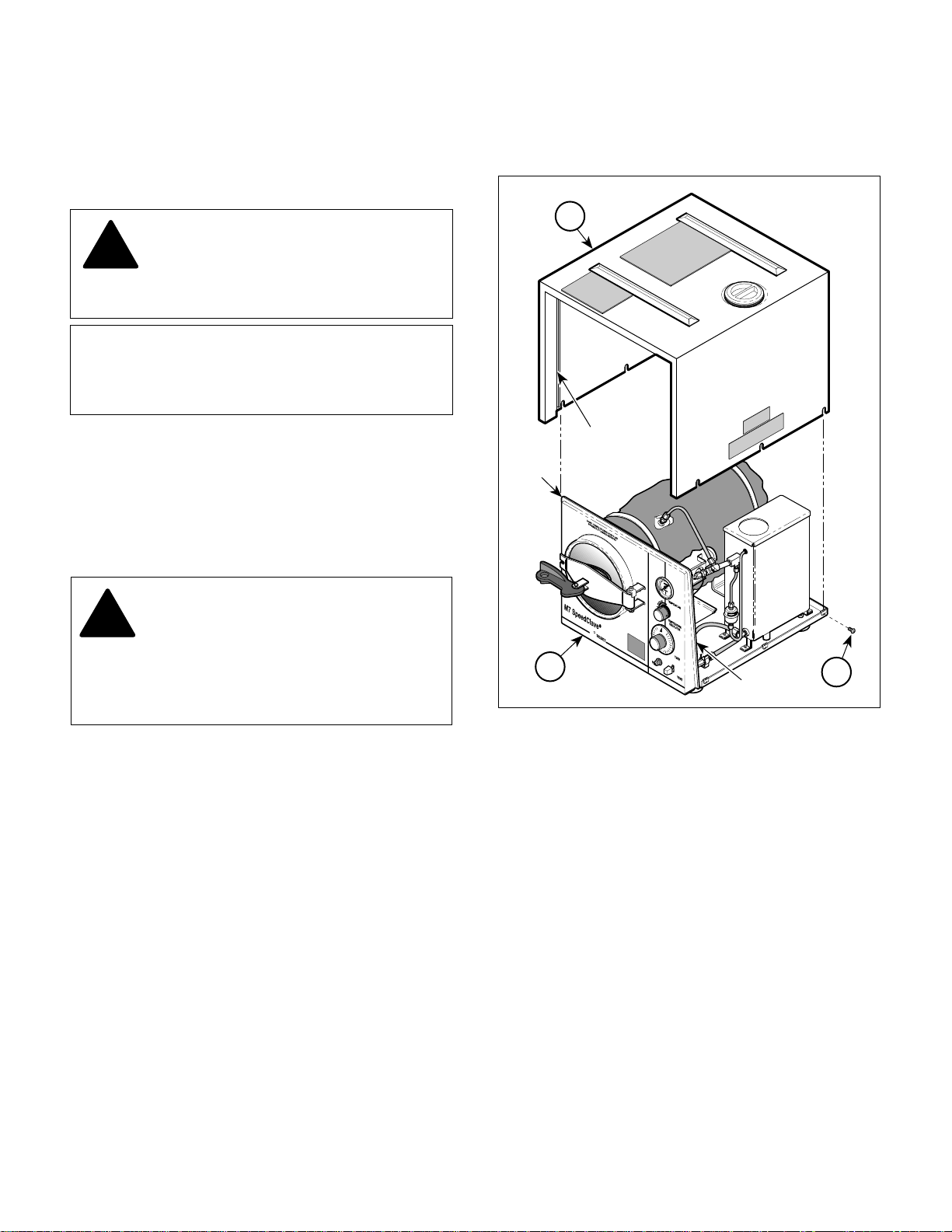

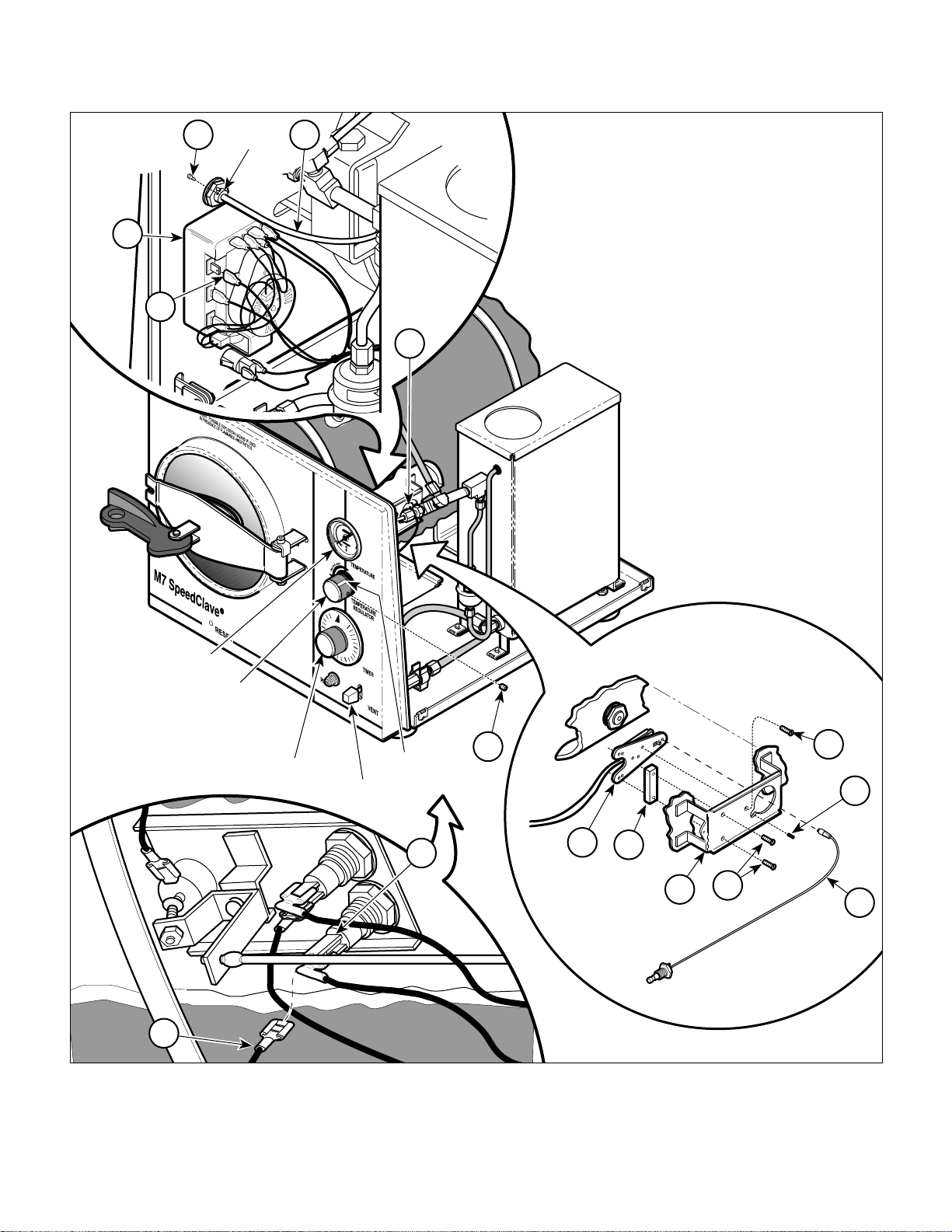

A. General Description (See Figure 1-1).

The M7 SpeedClave ® Sterilizer is a self generating

steam sterilizer designed to sterilize instruments and

other sterilizable goods. The major components of the

sterilizer consist of a chamber, condensing tank assembly, heating element, temperature regulator relay,

diaphragm cup, timer assembly, timer buzzer, manual

reset overheat thermostat (low water), auto-reset

overheat thermostat (low water) (auto-reset overheat

thermostat is only on newer units with CS or RB serial

number prefixes), pilot light, fill / vent valve, bellows

assembly, pressure relief valve, temperature gauge,

and reset button linkage assembly.

B. Theory of Operation (See Figures 5-1 thru 5-3).

Electrical Operation

Current flows thru the normally closed contacts of the

overheat thermostat(s) (also known as the low water

thermostat) to one side of the contacts on the timer

switch. When the timer assembly is not set to a time,

the timer switch contacts are not closed and no path to

the heating element is completed. When the operator

sets the timer assembly to any time setting, the timer

switch contacts are closed allowing current to flow

across the normally closed contacts of the temperature

regulator relay and be applied to the heating element,

causing it to heat up. Current is also applied across the

pilot light causing it to illuminate, thus indicating that the

heating element is energized. The diaphragm cup is

pressure sensitive and expands outward as the pressure in the chamber increases. The normally closed

temperature regulator relay is adjusted so the diaphragm cup will push open the contacts of the relay

when the selected temperature / pressure is reached

during a sterilizing cycle, de-energizing the heating

element. When the temperature / pressure lowers

slightly, the diaphragm cup contracts allowing the

temperature regulator relay to close its contacts which

causes current to be applied to the heating element and

pilot light again. The temperature in the chamber is

regulated to within +1° to +2° of the selected temperature during the cycle by the continuous opening and

closing of the temperature regulator relay contacts by

the diaphragm cup. The timer assembly contains a

timer motor which runs the timer assembly. When the

timer is run down to a setting of 0 minutes, the timer

switch contacts move, breaking the circuit to the

heating element and pilot light. A circuit to the timer

buzzer is now completed, causing it to sound. The

timer assembly timer motor continues to run for one

minute. Then the timer switch contacts are opened,

causing the timer buzzer to stop sounding.

© Midmark 1994 SF-1418 Rev. 5/95 Page 1-1 Printed in U.S.A.

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

TIMER ASSEMBL Y

TIMER

BUZZER

CHAMBER

DIAPHRAGM CUP

TEMPERATURE

REGULATOR RELAY

TEMPERATURE

GAUGE

MANUAL-RESET

OVERHEAT

THERMOSTAT

( LOW WATER)

RESET BUTTON

LINKAGE ASSEMBL Y

PRESSURE

RELIEF VALVE

CONDENSING

TANK ASSEMBLY

BELLOWS

ASSEMBLY

FILL / VENT

VALVE

PILOT LIGHT

HEATING

ELEMENT

© Midmark 1994 SF-1418 Rev. 5/95 Page 1-2 Printed in U.S.A.

AUTO-RESET OVERHEAT THERMOSTAT

(ONLY ON UNITS WITH "CS" & "RB"

SERIAL NUMBER PREFIX: AFTER SERIAL

NUMBERS CS-5296 & RB-14564)

MA253801

Figure 1-1. Major Components

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

During the cycle, if the temperature inside the chamber

rises up higher than 285°F (141°C), the normally closed

manual reset overheat thermostat (also known as low

water thermostat) contacts open, breaking the circuit to

the timer switch, heating element, and pilot light. The

most frequent cause of activation of the overheat

thermostat is a low water condition in the chamber. The

N.C. auto-reset overheat thermostat is a safety backup

for the manual reset overheat thermost and opens at

295°F (146°C). The manual reset overheat thermostat

is reset by pressing the RESET button located on front

panel of the sterilizer and the auto-reset overheat thermostat automatically resets after approximately six minutes.

Water / Air / Steam Flow

The M7 sterilization cycle has four phases; filling, heat

up, sterilizing, and venting.

During the fill portion of the cycle, the operator depresses the FILL / VENT lever which opens the fill /

vent valve. Water flows from the condensing tank thru

the fill / vent valve and into the chamber. When the

operator visually observes that the water level in the

chamber is within 1/2 in. to 5/8 in. (13 to 16 mm) from

the front rim of the chamber, the operator releases the

FILL / VENT lever, closing the fill / vent valve. Now the

operator begins the heat up portion of the cycle by

turning on the timer assembly.

During the heat up portion of the cycle, the water is

heated by the heating element. As the water begins to

boil, air is bled off thru the bellows assembly into the

condensing tank. When the bellows assembly senses

pure steam flowing thru it, the valve in the bellows

assembly closes, allowing pressure in the chamber to

build. The sterilizing portion of the cycle begins when

the bellows assembly is completely closed, not allowing

steam to flow thru it, and the desired temperature in the

chamber for the selected cycle is reached. The operator sets the timer assembly for the desired length of the

cycle and the cycle is run.

When the timer assembly counts down to 0 minutes

and shuts off the heating element, the vent portion of

the cycle begins. After the door handle has been

moved to the vent position, the operator depresses the

FILL / VENT lever which opens the fill / vent valve.

Steam and water flow thru the fill / vent valve and into

the condensing tank, venting the chamber. There is

coiled tubing under water in the condensing tank which

serves to turn the steam back into water.

There is a pressure relief valve which opens if the

pressure in the pressure valve reaches 31 PSI (214

kPa) during a cycle. This provides a safety relief for the

chamber so that unsafe pressures cannot build.

There is a temperature gauge on the front control panel

which indicates the temperature inside the chamber

during a cycle.

1.4 SPECIFICATIONS

Factual data for the sterilizer is provided in Table 1-1.

Table 1-1. Specifications

Description Data

Dimensions (overall):

Length ............................................... 19 in (48.3 cm)

Width .................................................. 14 in (35.6 cm)

Height.................................................... 13 in (33 cm)

Shipping Carton.............................. 24 in x 16 in x 16 in

(61 cm x 40.6 cm x 40.6 cm)

Door Opening .................................... 6

Weight:

With Reservoir Empty.......................... 30 lb (13.6 kg)

With Reservoir Full .............................. 39 lb (17.7 kg)

With Shipping Carton........................... 39 lb (17.7 kg)

Water Reservoir Capacity................ Approx. 3/4 gallon

(2.75 Liters) to full mark

Electrical Requirements:

100 VAC Unit (M7-003) .............. 100 VAC 50 - 60 HZ,

115 VAC Unit (M7-001, ..... 110 - 120 VAC 50 - 60 HZ,

M7-004, and M7-005) 10 amp, single phase

230 VAC Unit (M7-002) ..... 220 - 240 VAC 50 - 60 HZ,

Power Consumption:

100 VAC Unit......................................... 1150 WATTS,

115 VAC Unit......................................... 1150 WATTS,

230 VAC Unit......................................... 1150 WATTS,

Recommended Circuit:

A separate (dedicated) circuit is recommended for

this sterilizer. The sterilizer

to an electrical circuit with other appliances or

equipment unless the circuit is rated for the additional load.

should not

5

/8 in. (16.8 cm)

15 amp, single phase

5 amp, single phase

12 amps @ 100 VAC

10 amps @ 120 VAC

5 amps @ 240 VAC

be connected

© Midmark 1994 SF-1418 Rev. 5/95 Page 1-3 Printed in U.S.A.

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

Table 1-1. Specifications - Continued

Description Data

Chamber Pressure:

Operating ......................................... 27 psi (175 kPa)

Maximum Before Pressure Relief

Valve Opens..................................... 31 psi (214 kPa)

Chamber Temperature: .................. See Tables 5-1 and

5-2 for Suggested Times

And Temperatures

1.5 Parts Replacement Ordering

If a part replacement is required, order the part directly

from the factory as follows:

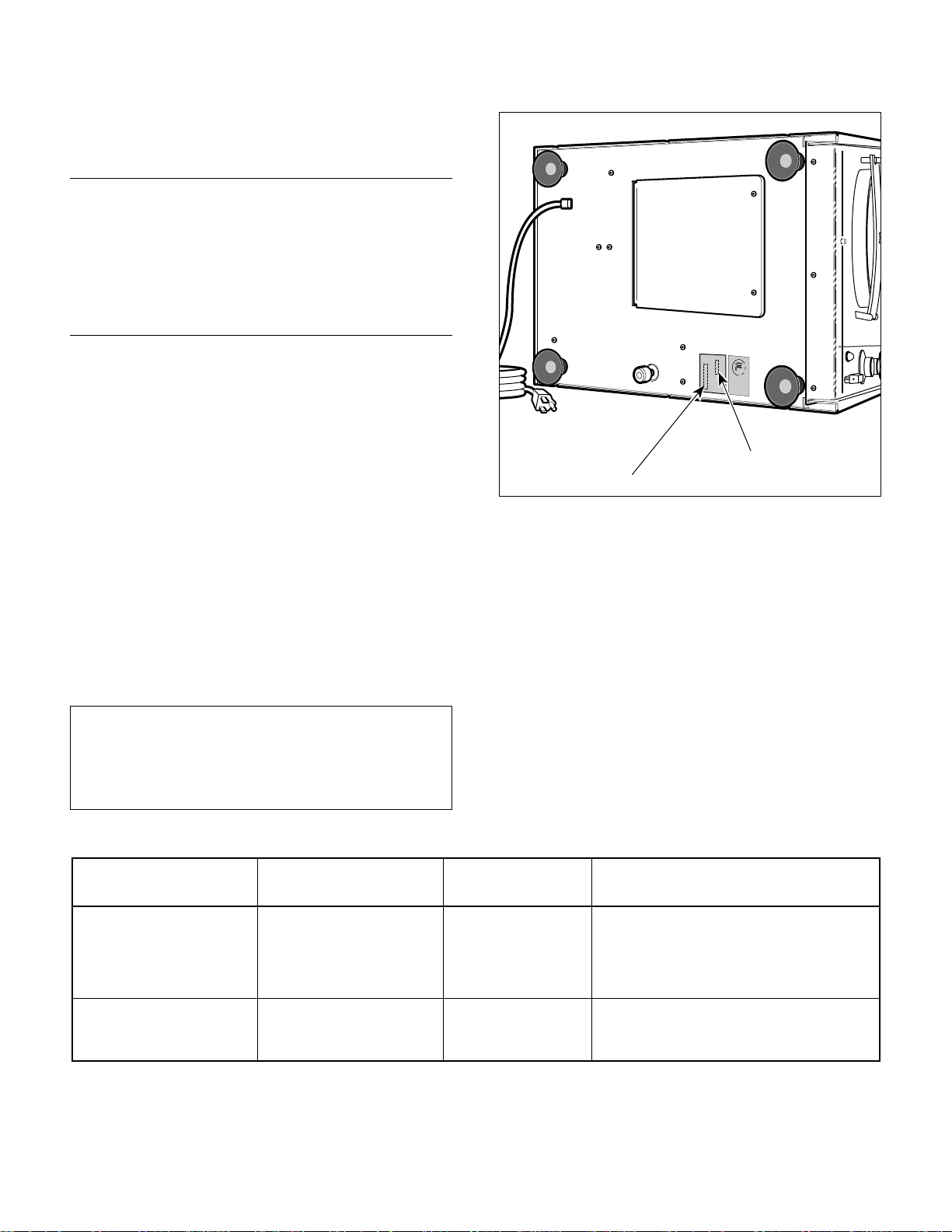

(1) Refer to Figure 1-2 to determine the location of

the model number and serial number of the

sterilizer and record this data. There are

different letter prefixes which proceed the serial

number, depending on the configuration of the

unit. These prefixes are very important and are

needed to order the proper parts.

(2) Refer to the Parts List to determine the item

numbers of the parts, part numbers of the

parts, descriptions of the parts, and quantities

of parts needed and record this data (Refer to

para 6.1).

NOTE

Ask the Purchasing Department of the company that

owns the sterilizer for this information. Otherwise,

this information may be obtained from the dealer that

sold the sterilizer.

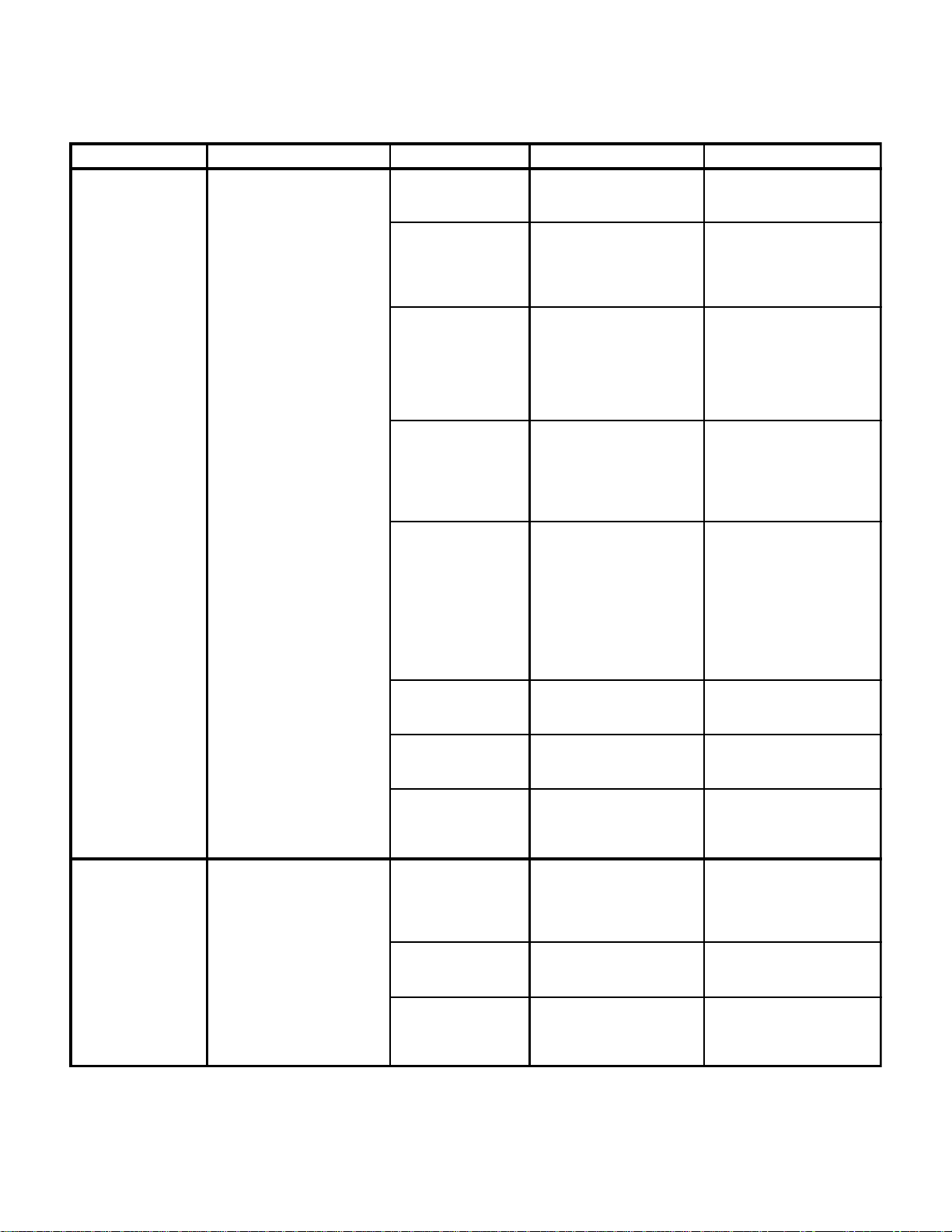

Table 1-2. Special Tool List

looTlaicepSfonoitpircseDs'rerutcafunaM

enohP/sserddA/emaN

MODEL NUMBER

SERIAL NUMBER

MA2535-00

Figure 1-2. Model Number / Serial Number Location

(3) Determine the installation date of the sterilizer

and record this data.

(4) Call Midmark with the recorded information and

ask for the Medical Services Department. See

back cover of this manual for the phone number or use the Fax Order Form (see page 7-2

for Fax Order Form).

1.6 Special Tools

Table 1-2 lists all the special tools needed to repair the

sterilizer, describes how to obtain the special tools, and

describes the purpose of each special tool.

s'rerutcafunaM

rebmuNtraP

looTlaicepSfoesopruP

gniretsigeRmumixaM

retemomrehT

retemitluMelbaliavAyllaicremmoCepyTynA snoitcennocdna,sehctiws,seborpkcehcotdesU

© Midmark 1994 SF-1418 Rev. 5/99 Page 1-4 Printed in U.S.A.

stcudorPnoisicerProlyaT

daoRkeerCenaC082

23782CN,rehctelF

8715-486)828(

1-66412erutarepmetmumixamehtkcehcotdesU

elcycagnirudlesseverusserpehtedisnidehcaer

ehttsujdaro/dnasnoitcnuflamesongaidot

tcerrocaotretemoitnetoperutarepmetmumixam

.gnittes

ytiunitnocgnimrofrepybnoitcnufreporprof

.skcehc

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

SECTION II

TESTING AND TROUBLESHOO TING

SECTION II

2.1 Operational Test

In order to effectively diagnose the malfunction of the

sterilizer, it is necessary to perform an operational test

as follows:

DANGER

!!

the sterilizer. Failure to do so could result in

severe personal injury.

(1) Place the sterilizer on a level surface.

(2) Plug the sterilizer into a properly grounded

(3) Remove the fill cap from the condensing tank.

Refer to the operator manual for

complete instructions on operating

receptacle, capable of supplying correct and

adequate power to operate this sterilizer.

NOTE

Overfilling will cause sterilizer to malfunction.

(4) Fill the condensing tank to the FULL mark

indicator tab with distilled or demineralized

water. Replace filler cap.

(5) Swing the door handle to the unlatched position

and then pull the door out of the chamber.

CAUTION

!!

its lowest setting. Failure to do so could result in an

incorrect reading.

(6) Place a Maximum Registering Thermometer in

(7) Depress the FILL / VENT lever and allow the

(8) Close and latch the door in the chamber as

Ensure that the Maximum Registering

Thermometer has been shaken down to

the middle tray toward the door of the sterilizer

(Refer to Table 1-2 for special tool).

water to fill the chamber until the water level is

within 1/2 to 5/8 in. (13 to 16 mm) from the front

rim of the chamber; then release the FILL /

VENT lever.

follows: Insert the right edge of the door into

the chamber and then push the rest of the door

into the chamber. Latch the door by swinging

the door handle all the way to the latched

position.

(9) Set the TIMER knob to its maximum setting of

30 minutes. Set the TEMPERATURE REGULATOR knob to its maximum setting of 270°F

(132°C) by turning the knob counter-clockwise

as far as possible.

(10) Observe. The PILOT light will illuminate

indicating that the heating element is energized.

Should begin to hear water boiling in the

chamber and steam and air releasing thru the

bellows assembly. Should hear the bellows

assembly close completely - hissing sound

should almost completely stop. The PILOT

light should flash on and off during the cycle

indicating the heating element is being energized and deenergized to regulate the temperature in the chamber.

(11) Record the highest temperature reached during

the cycle from the TEMPERATURE gauge on

the front panel of the sterilizer.

NOTE

Earlier units do not have a timer buzzer.

(12) Observe. Wait for the TIMER knob to run down

to 0 minutes. When 0 minutes is reached, the

sterilization cycle is over and power to the

heating element and pilot light is removed.

Proceed immediately to step 13.

On later units, the timer buzzer will sound when

the timer assembly has run down to 0 minutes.

This is to alert the operator that the sterilization

cycle is completed. After 1 minute the timer

buzzer will stop sounding. Proceed immedi-

ately to step 13.

(13) Swing the door handle to the vent position.

(14) Depress the FILL / VENT lever to vent the

chamber; then release the lever once the

chamber is vented. Allow chamber to cool.

(15) Observe. Water and steam will flow into the

condensing tank, making a bubbling sound.

© Midmark 1994 SF-1418 Page 2-1 Printed in U.S.A.

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

CHAMBER

DOOR

DOOR HANDLE

UNLATCHED

POSITION

FILL CAP

CONDENSING

TANK

DOOR HANDLE

VENT

POSITION

DOOR HANDLE

LATCHED

POSITION

TIMER

KNOB

PILOT LIGHT

FILL / VENT

LEVER

Figure 2-1. Operational Test

When the bubbling sound stops and the door

pops open, the chamber will be vented.

(16) Allow the Maximum Registering Thermometer

to cool and then remove it from the chamber.

NOTE

The Maximum Registering Thermometer has an

accuracy of ± 4 °F (± 2.2 °C).

FILL MARK

INDICATOR TAB

TEMPERATURE

GAUGE

TEMPERATURE

REGULATOR

KNOB

MA2537-00

(17) Read the temperature on the Maximum Regis-

tering Thermometer. The reading should be

270 °F - 272 °F (132.2 - 133.4 °C) and should

match the temperature reading recorded from

the TEMPERATURE gauge during the cycle.

2.2 Troubleshooting Procedures (see next

page)

Table 2-1 is a troubleshooting guide which is used to

determine the cause of the malfunction.

© Midmark 1994 SF-1418 Page 2-2 Printed in U.S.A.

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

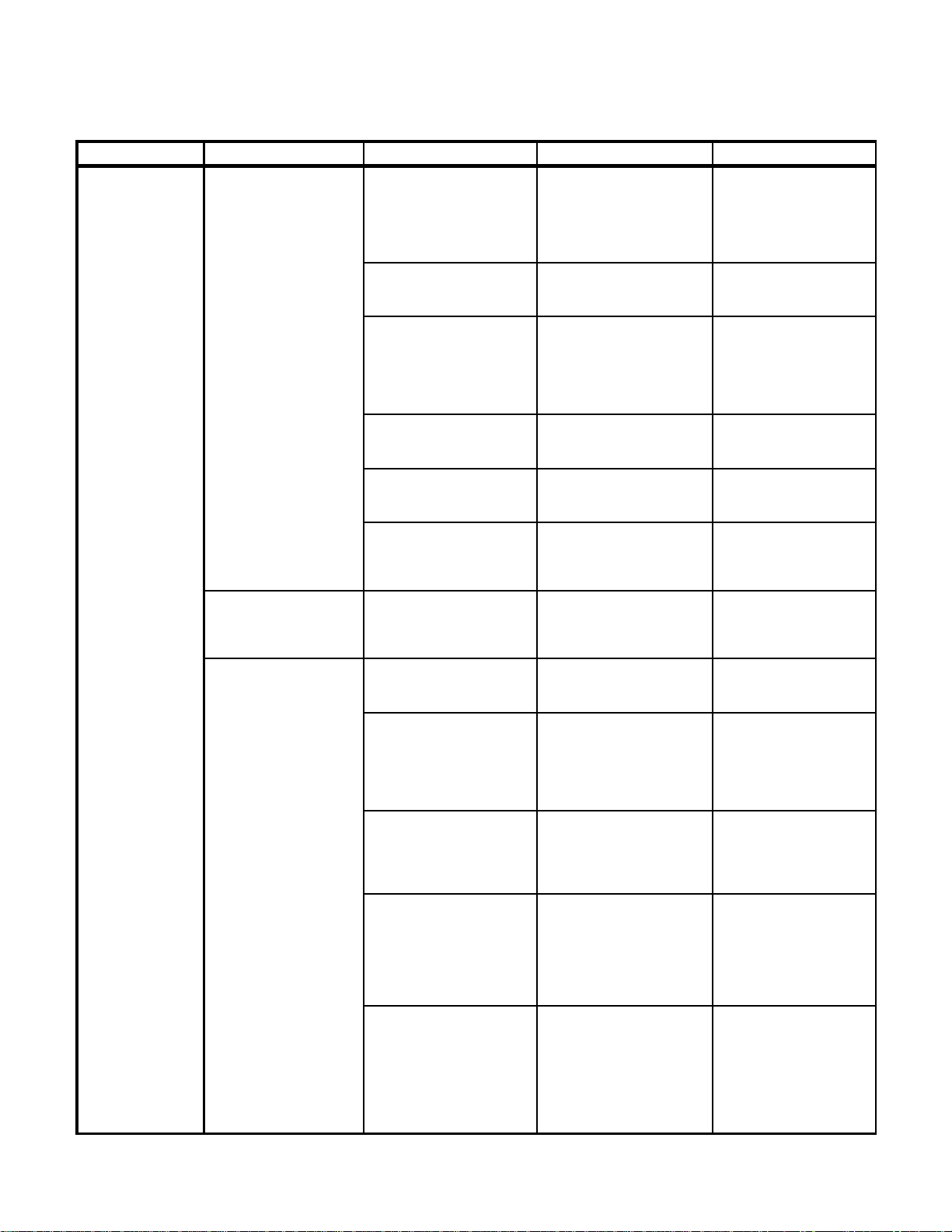

Table 2-1. Troubleshooting Guide

Problem Symptom Probable Cause Check Correction

Unit seems powerless. Pilot light does not illuminate

Unit does not complete

sterilization cycle

properly.

when timer is set and unit does

not start to heat up.

PILOT light does illuminate but

chamber does not reach

required temperature /

pressure during sterilization

cycle.

Power cord is not

plugged in to wall

outlet.

Facility circuit breaker

providing power to unit

is tripped.

Manual reset overheat

thermostat is tripped.

Auto-reset overheat

thermostat is tripped

(Applies only to units

with Serial Numbers

CS5297 and RB14565

Thru Present).

Manual reset or

auto-reset overheat

thermostat is

malfunctioning - stuck

open (Auto-reset

overheat thermostat is

only on units with

Serial Numbers

CS5297 and RB14565

Thru Present).

Timer assembly is

malfunctioning.

Temperature regulator

relay is malfunctioning

- stuck open.

Wiring connections

loose.

Flexible shaft assembly

is malfunctioning.

Temperature regulator

relay is out of

adjustment.

Temperature regulator

relay is malfunctioning.

Check to see if power cord is

plugged in.

Check to see if facility circuit

breaker is tripped. One way

of checking this is to plug a

lamp into wall outlet that unit

was plugged into.

If the unit is hot, allow the

unit to cool for 15 to 20

minutes. Press the RESET

button on the front panel.

Now, the PILOT light should

illuminate when the TIMER

knob is set.

If the unit is hot, allow the

unit to cool for 15 to 20

minutes. Now, the PILOT

light should illuminate when

the TIMER knob is set.

Perform continuity check on

N.C. overheat thermostat

(cool = closed).

Replace suspect timer

assembly with known working

timer assembly.

Perform continuity check on

temperature regulator relay.

Check all wiring connections. Clean any dirty connections.

Check flexible shaft

assembly for wear or

damage.

Check adjustment of

temperature regulator relay.

Check if temperature

regulator relay is stuck open

or contacts not touching

properly.

Plug power cord into facility

wall outlet.

If circuit breaker is tripped,

determine what caused circuit

breaker to trip, correct the

problem, and then

reset/replace circuit breaker.

If necessary, add distilled

water to condensing tank;

then press the RESET button

on the front panel.

Wait 15 to 20 minutes to allow

thermostat to reset itself.

Also, replace manual reset

overheat thermostat. Refer to

para 4.8.

If open, replace overheat

thermostat. Refer to para 4.8.

Replace timer assembly.

Refer to para 4.3 or 4.4.

Replace temperature

regulator relay. Refer to para

4.9.

Tighten any loose

connections. Replace any

damaged connections.

Replace flexible shaft

assembly. Refer to para 4.9.

Adjust temperature regulator

relay. Refer to para 4.10.

Replace temperature

regulator relay. Refer to para

4.9.

SECTION II

© Midmark 1994 SF-1418 Rev. 5/95 Page 2-3 Printed in U.S.A.

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

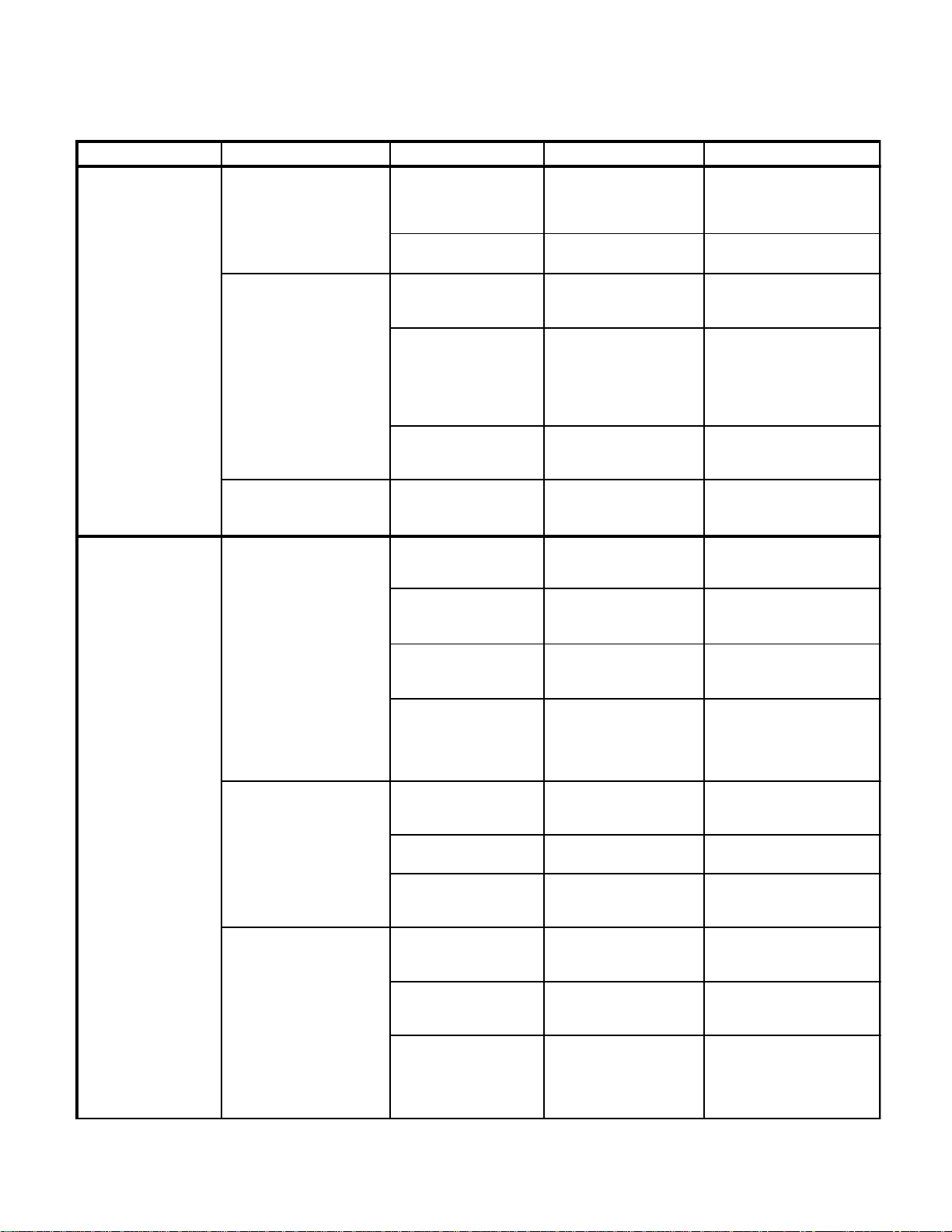

Table 2-1. Troubleshooting Guide - Continued

Problem Symptom Probable Cause Check Correction

Unit does not

complete sterilization

cycle properly Continued.

PILOT light does illuminate

but chamber does not

reach required temperature

/ pressure during

sterilization cycle Continued.

Temperature reaches 210 212 degrees F (98.8 - 100

degrees C) during cycle

and stays there.

Time set on timer

assembly does not expire.

Heating element is

malfunctioning.

Bellows assembly is closing

prematurely or stuck in open

position.

Pressure relief valve is

malfunctioning - stuck open.

Diaphragm cup is

malfunctioning.

Fill / vent valve is

malfunctioning - stuck open

or leaking past o-rings.

Door gasket and / or door

assembly is leaking.

Bellows assembly is stuck in

open position.

Timer motor is

malfunctioning.

Manual reset overheat

thermostat is tripped.

Auto-reset overheat

thermostat is tripped (Applies

only to units with Serial

Numbers CS5297 and

RB14565 Thru Present).

Manual reset or auto-reset

overheat thermostat is

malfunctioning - stuck open

(Auto-reset overheat

thermostat is only on units

with Serial Numbers CS5297

and RB14565 Thru Present).

Diaphragm cup is

malfunctioning - is failing to

open contacts of temperature

regulator relay when

maximum temperature (270

degrees F [132 degrees C]) is

reached resulting in

overheating.

Check resistance of heating

element (in ohms):

100 V, 50 Hz-8.08 to 8.94

115 V, 60 Hz-11.31 to 12.5

230 V, 50 Hz-45.65 to 50.45

Replace suspect bellows

assembly with known working

bellows assembly.

Run cycle and observe

pressure relief valve; it should

not dump pressure until

temperature gauge reads 275

degrees F (135 degrees C) +/2 degrees.

Replace suspect diaphragm

cup with known working

diaphragm cup.

Check fill / vent valve for dirt

and o-rings for wear or

damage.

Run cycle and observe for

leaks around edges of door

assembly.

Replace suspect bellows

assembly with known working

bellows assembly.

Replace suspect timer

assembly with known working

timer assembly.

If the unit is hot, allow the unit

to cool for 15 to 20 minutes.

Press the RESET button on

the front panel. Now, the

PILOT light should illuminate

when the TIMER knob is set.

If the unit is hot, allow the unit

to cool for 15 to 20 minutes.

Now, the PILOT light should

illuminate when the TIMER

knob is set.

Perform continuity check on

N.C. overheat thermostat

(cool = closed).

Replace suspect diaphragm

cup with known working

diaphragm cup.

If heating element

resistance is not within

range, replace heating

element. Refer to para 4.7.

Replace bellows assembly.

Refer to para 4.14, 4.15, or

4.16.

Replace pressure relief

valve. Refer to para 4.13.

Replace diaphragm cup.

Refer to para 4.11.

Clean or replace fill / vent

valve. Refer to para 4.17.

Replace door gasket. Refer

to para 4.19. Replace door

assembly if necessary.

Refer to para 4.18.

Replace bellows assembly.

Refer to para 4.14, 4.15, or

4.16..

Replace timer assembly.

Refer to para 4.3 or 4.4.

If necessary, add distilled

water to condensing tank;

then press the RESET

button on the front panel.

Wait 15 to 20 minutes to

allow thermostat to reset

itself. Also, replace manual

reset overheat thermostat.

Refer to para 4.8.

If open, replace overheat

thermostat. Refer to para

4.8.

Replace diaphragm cup.

Refer to para 4.11.

© Midmark 1994 SF-1418 Rev. 8/97 Page 2-4 Printed in U.S.A.

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

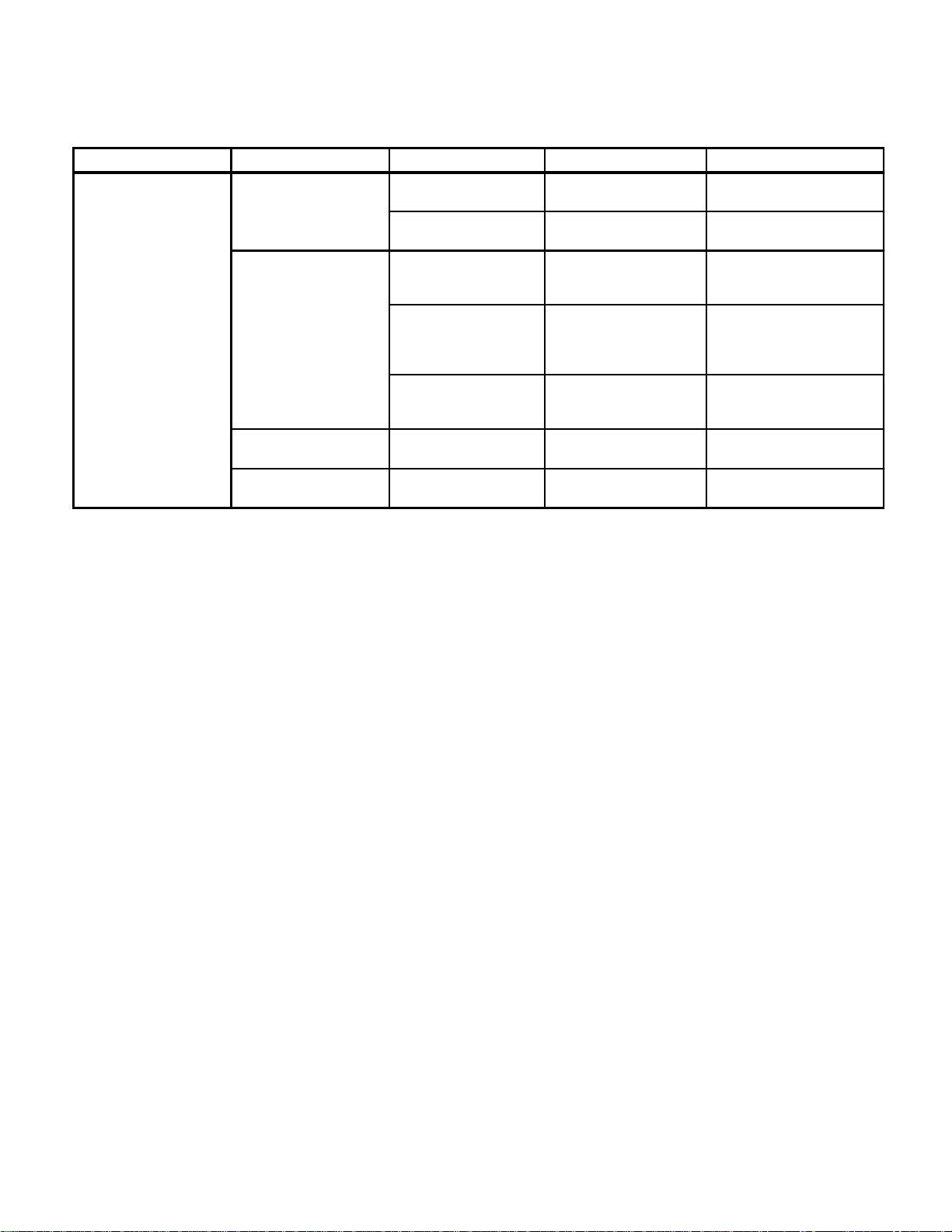

Table 2-1. Troubleshooting Guide - Continued

Problem Symptom Probable Cause Check Correction

Unit does not complete

sterilization cycle

properly - Continued.

FILL / VENT function

does not work properly

Chamber does not vent at

completion of cycle when the

FILL / VENT lever is

depressed.

Sterility Indicators show

sterilization standards were

not met.

Timer does not buzz at end

of cycle.

When FILL / VENT lever is

depressed, water does not

flow into chamber.

When FILL / VENT lever is

released, water continues to

enter the chamber.

When FILL / VENT lever is

depressed, water does not

vent from chamber.

Fill / vent valve is clogged

with foreign matter.

Tubing is clogged. Check tubing for foreign

Improper loading of unit. Check operator's manual

Temperature regulator

relay is out of adjustment.

Bellows assembly is stuck

in open position.

Timer buzzer is

malfunctioning.

Fill / vent valve is clogged

with foreign matter.

Fill / Vent valve is not

adjusted to open and

close properly.

Condensing tank is low on

distilled or demineralized

water.

Tubing is clogged. Check condensing tank

Fill / vent valve is clogged

with foreign matter.

O-rings in Fill / Vent valve

are worn or damaged.

Fill / Vent valve is not

adjusted to open and

close properly.

Fill / vent valve is clogged

with foreign matter.

Fill / Vent valve is not

adjusted to open and

close properly.

Tubing is clogged. Check condensing tank

Check fill / vent valve for

foreign matter.

matter.

for recommended loading

procedures.

Check adjustment of

temperature regulator relay

using a lag thermometer TEMPERATURE gauge on

front panel may be giving

inaccurate reading.

Replace suspect bellows

assembly with known

working bellows assembly.

Replace suspect timer

buzzer with known working

timer buzzer.

Check fill / vent valve for

foreign matter.

Check adjustment of Fill /

Vent valve.

Check water level in

condensing tank.

and tubing for foreign

matter.

Check fill / vent valve for

dirt.

Check o-rings in Fill / Vent

valve for wear or damage.

Check adjustment of Fill /

Vent valve.

Check fill / vent valve for

dirt.

Check adjustment of Fill /

Vent valve.

and tubing for foreign

matter.

Clean or replace fill / vent

valve. Refer to para 4.17.

Clean out tubing.

Load unit properly and repeat

cycle.

Adjust temperature regulator

relay. Refer to para 4.10.

Replace bellows assembly.

Refer to para 4.14, 4.15, or

4.16.

Replace timer buzzer. Refer

to para 4.5.

Clean or replace fill / vent

valve. Refer to para 4.17.

Adjust closing bracket on fill

vent valve. Refer to para

4.17.

Fill condensing tank with

water up to FULL mark.

Clean out condensing tank

and tubing. Replace

condensing tank if necessary.

Refer to para 4.21. Replace

tubing if necessary.

Clean or replace fill / vent

valve. Refer to para 4.17.

Repair Fill / Vent Valve. Refer

to para 4.17.

Adjust closing bracket on fill

vent valve. Refer to para

4.17.

Clean or replace fill / vent

valve. Refer to para 4.17.

Adjust closing bracket on fill

vent valve. Refer to para

4.17.

Clean out condensing tank

and tubing. Replace

condensing tank if necessary.

Refer to para 4.21. Replace

tubing if necessary.

SECTION II

© Midmark 1994 SF-1418 Rev. 5/95 Page 2-5 Printed in U.S.A.

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide - Continued

Problem Symptom Probable Cause Check Correction

Non operational problems

with sterilizer.

Sterilizer slides on counter

top.

Water leaks around

sterilizer.

Door handle is hard to

operate.

Water leaks around door

during cycle.

Film or grease on counter

top.

Damaged "suction" foot. Check if "suction" foot

Loose fittings. Check all fittings for leaks. Remove fitting, coat threads

Compression nut and/ or

compression sleeve is

loose or excessively

deformed.

Tubing is damaged. Check for holes, kinks, or

Handle cam is dry. Check for lubricant on cam

Door gasket is worn or

damaged.

Check for film or grease on

counter top.

works.

Check all compression nuts

for leaks.

other types of damage to

tubing.

of door handle.

Check door gasket for wear

or damage.

Clean counter top.

Replace damaged "suction"

foot.

of fitting with Teflon tape or

sealant, and reinstall fitting.

Loosen compression nut.

Replace compression sleeve

if necessary.

Replace tubing.

Lubricate cam part of handle

with high temperature grease.

Replace door gasket. Refer

to para 4.19.

© Midmark 1994 SF-1418 Page 2-6 Printed in U.S.A.

SCHEDULED MAINTENANCE

Return To Table Of Contents

SECTION III

SCHEDULED MAINTENANCE

SECTION III

3.1 Scheduled Maintenance

periodically on the sterilizer. These inspections and

services should be performed as often as indicated in

Table 3-1 is a Scheduled Maintenance Chart which lists

the chart.

the inspections and services that should be performed

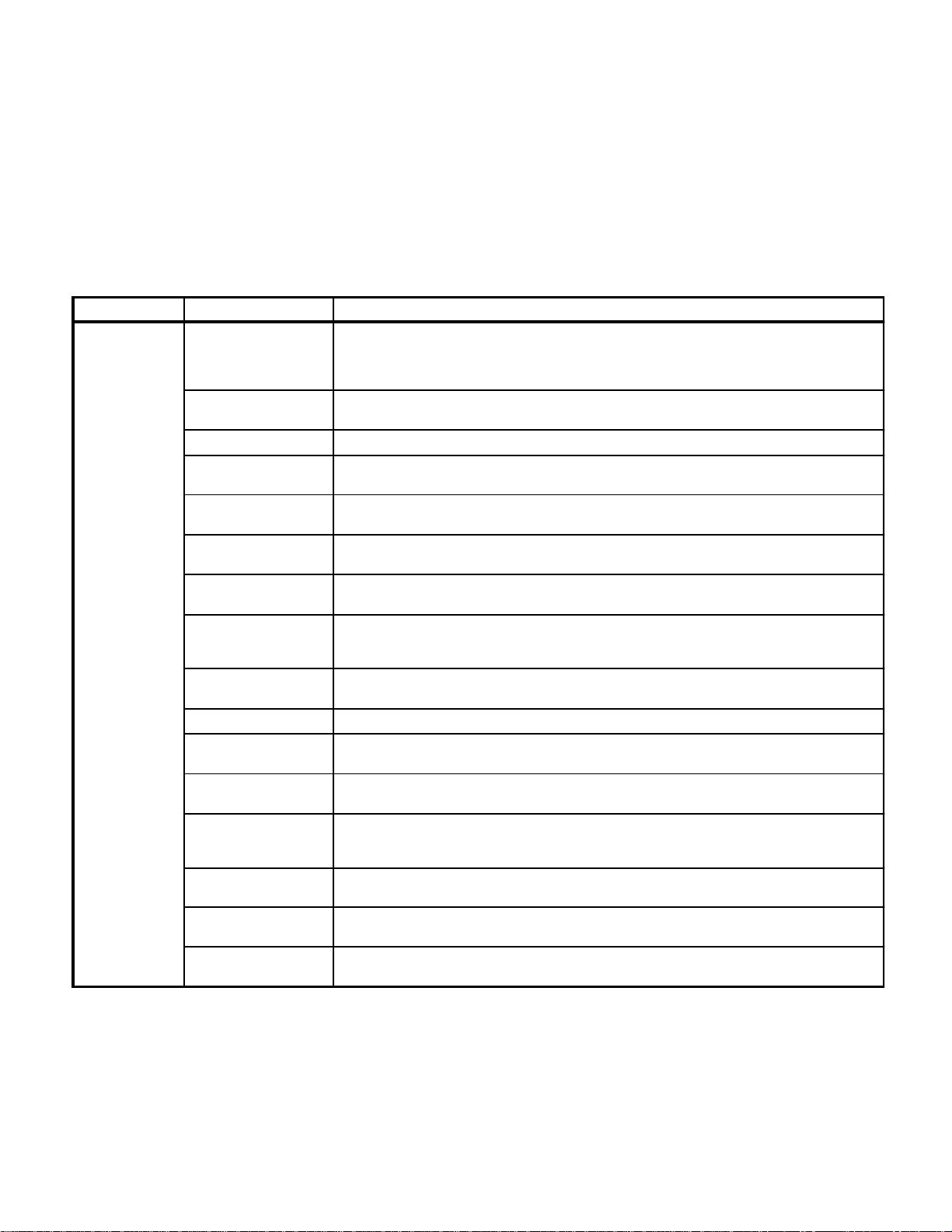

Table 3-1. Scheduled Maintenance Chart

Interval Inspection or Service What to Do

Semi-annually Obvious damage Visually check condition of sterilizer for obvious damage such as: cracks in components, missing

Fasteners/hardware Check sterilizer for missing or loose fasteners/hardware. Replace any missing hardware and

Moving parts All moving parts should be lubricated with high temperature grease.

Warning and

instructional decals

Wiring connections Check the integrity of all wiring connections. Clean all dirty connections. Tighten any loose

Easy movement of door

handle

Door gasket Remove door gasket and check it for dirt, voids, or deterioration. Clean gasket using a mild soap

Door assembly Check door assembly for any damage which would make it unsafe or compromise the

Door assembly hinge

screws.

PILOT light With power to unit, set timer. PILOT light should illuminate.

Condensing tank Remove tank cover and inspect for foreign matter and buildup. Clean out condensing tank and

Tubing Remove tubing and inspect for buildup. Clean, drain, and flush tubing using Speed-Clean

Chamber Check for cracks or other signs of stress or metal fatigue. Clean chamber with Speed-Clean

Wire rack and trays Check wire rack and trays for excessive rust or deterioration. Replace wire rack and trays if

Suction feet Check all four suction feet for wear or deterioration. Make sure suction feet fasten securely to

Operational test Perform an operational test to determine if the sterilizer is operating within its specifications (Refer

components, dents in components, leaks, or any other visible damage which would cause

sterilizer to be unsafe to operate or would compromise the performance of the sterilizer. Repair

sterilizer if necessary.

tighten any loose hardware as necessary using Loctite 242 if necessary.

Check for missing or illegible decals. Replace decals as necessary.

connections. Replace any damaged connections.

Lubricate cam of door assembly with high temperature grease.

and water solution. Replace gasket if necessary. Refer to para 4.19.

performance of the sterilizer. Make sure long and short springs of door assembly have enough

power left to open door. Replace springs or door assembly if necessary. Refer to para 4.18.

Make sure nut on hinge screws are secure. If nut is loose, remove nut, coat threads of nut with

removable threadlocking adhesive (Loctite 242), and reinstall nut.

remove buildup from walls of tank.

(directions for use are on bottle). Replace tubing if necessary. See Operator's manual.

(directions for use are on bottle). Check chamber for excessive rust or deterioration. Replace

chamber if necessary. Refer to para 4.22.

necessary. Refer to para 4.20.

counter top. Clean counter top if necessary. Replace suction feet if necessary.

to para 2.1). Adjust or replace any malfunctioning components

© Midmark 1994 SF-1418 Page 3-1 Printed in U.S.A.

SECTION III

Return To Table Of Contents

SCHEDULED MAINTENANCE

© Midmark 1994 SF-1418 Page 3-2 Printed in U.S.A.

4.1 Introduction

Return To Table Of Contents

SECTION IV

MAINTENANCE / SERVICE

SECTION IV

MAINTENANCE / SER VICE INSTR UCTIONS

DANGER

!!

the sterilizer. Failure to do so could result in

personal injury.

Refer to the Operator Manual for

complete instructions on operating

NOTE

Perform an operational test on the sterilizer after the

repair is completed to confirm the repair was properly

made and that all malfunctions were repaired.

The following paragraphs contain replacement, repair,

and adjustment procedures for the sterilizer.

4.2 Cover Assembly Removal / Installation

A. Removal

DANGER

!!

the sterilizers cover / panels or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

(1) Disconnect power cord from wall outlet.

(2) Loosen six screws (1, Figure 4-1), three on

Always unplug the power cord from

the wall outlet before removing any of

each side, and remove cover assembly (2)

from base assembly (3).

2

CHANNEL

RAIL

3

RAIL

Figure 4-1. Cover Assembly Removal / Installation

1

MA2512-00

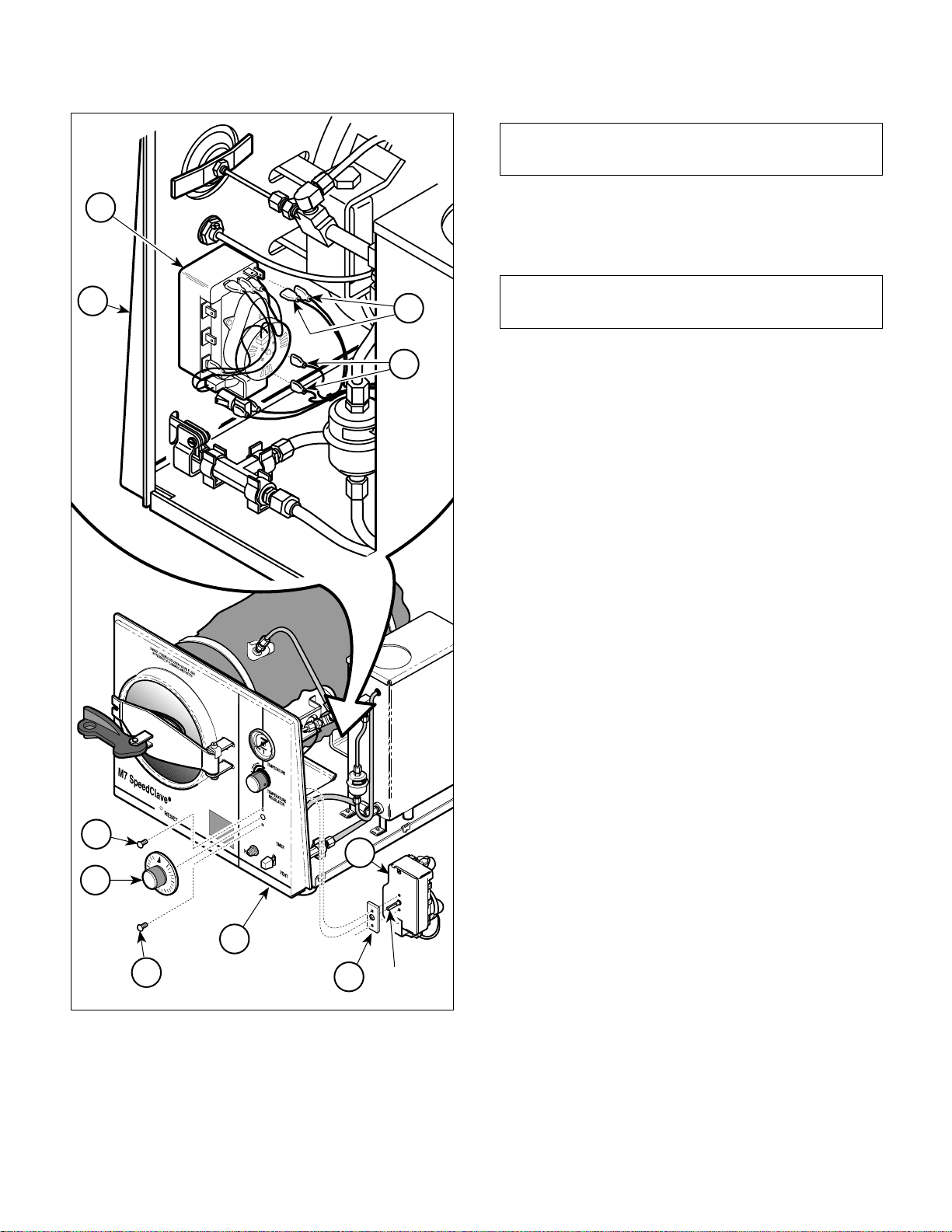

4.3 Timer Assembly Removal / Installation (New Style Timer Assembly)

A. Removal

B. Installation

(1) Align channel of cover assembly (2) with rail of

base assembly (3) and then slide cover assembly onto base assembly. Secure in place by

tightening six screws (1).

(2) Connect power cord to wall outlet.

© Midmark 1994 SF-1418 Page 4-1 Printed in U.S.A.

(1) Remove cover assembly (Refer to para 4.2).

(2) Remove the timer knob (1, Figure 4-2) from

shaft of timer assembly (2) by pulling straight

out on timer knob.

(3) Tag and disconnect four wires (3) from termi-

nals of timer assembly (2).

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

NOTE

Spacer is only used on newer units.

2

6

3

3

(4) Remove two screws (4), timer assembly (2),

and spacer (5) from front panel (6).

B. Installation

NOTE

Spacer is only used on newer units

(1) Install spacer (5) and timer assembly (2) on

front panel (6) and secure with two screws (4).

(2) Connect four wires (3) to terminals of timer

assembly (2).

(3) Install timer knob (1) on shaft of timer assem-

bly (2).

(4) Install cover assembly (Refer to para 4.2).

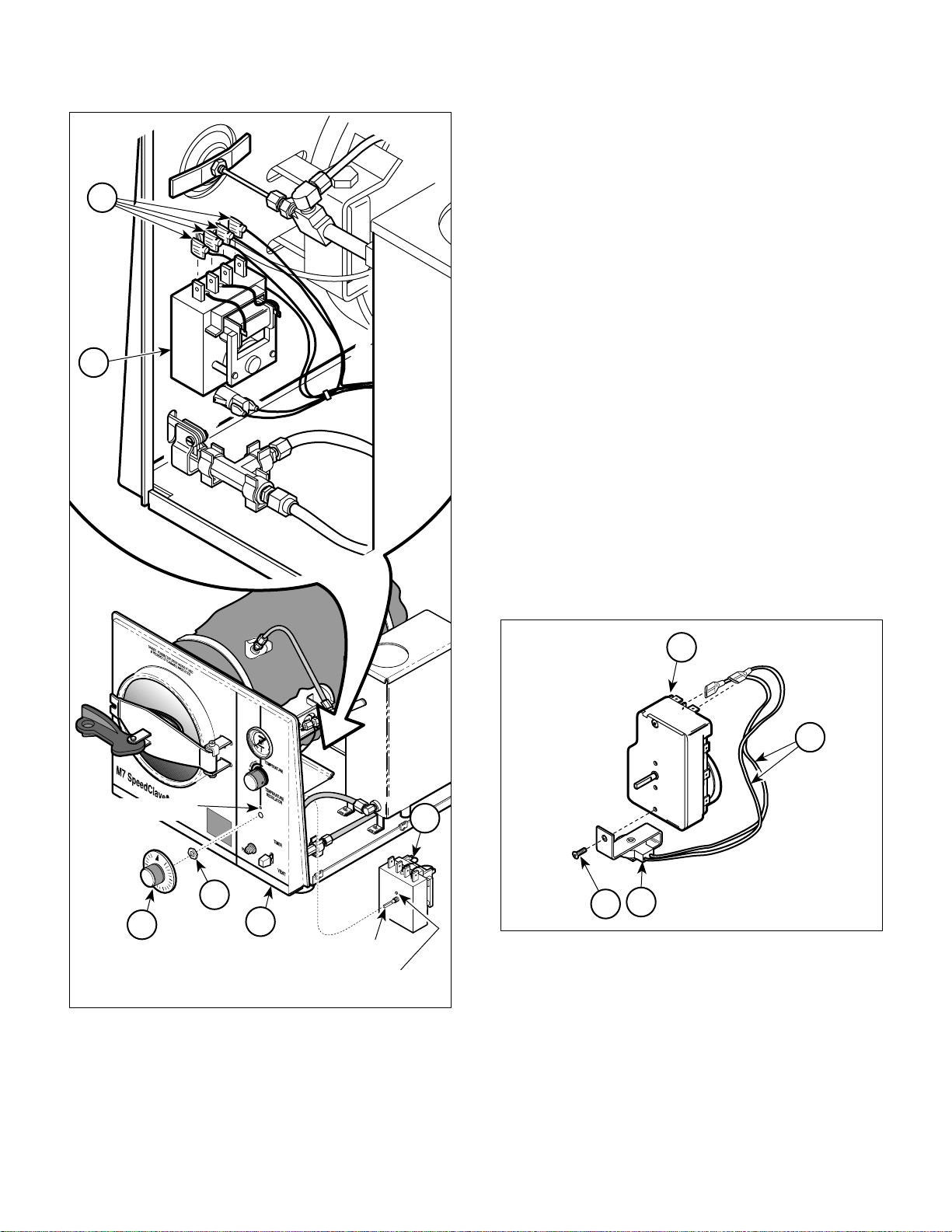

4.4 Timer Assembly Removal / Installation (Old Style Timer Assembly)

A. Removal

4

2

1

6

4

Figure 4-2. Timer Assembly Removal / Installation

SHAFT

5

MA2513-00

(1) Remove cover assembly (Refer to para 4.2).

(2) Remove the timer knob (1, Figure 4-3) from

shaft of timer assembly (2) by pulling straight

out on timer knob.

(3) Tag and disconnect four wires (3) from termi-

nals of timer assembly (2).

(4) Remove nut (4) and timer assembly (2) from

front panel (5).

B. Installation

(1) Align locator pin with locating hole; then install

timer assembly (2) on front panel (5) and

secure with nut (4).

(2) Connect four wires (3) to terminals of timer

assembly (2).

(3) Install timer knob (1) on shaft of timer assem-

bly (2).

(4) Install cover assembly (Refer to para 4.2).

© Midmark 1994 SF-1418 Page 4-2 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

4.5 Timer Buzzer Removal / Installation

(Only On Units With New Style Timer

Assembly)

3

2

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

(2) Remove timer assembly (Refer to para 4.3).

(3) Tag and disconnect two wires (1, Figure 4-4)

from timer assembly (2).

(4) Remove screw (3) and timer buzzer (4) from

timer assembly (2).

B. Installation

(1) Install timer buzzer (4) on timer assembly (2)

and secure with screw (3).

(2) Connect two wires (1) to timer assembly (2).

(3) Install timer assembly (Refer to para 4.3).

(4) Install cover assembly (Refer to para 4.2).

2

1

LOCATING HOLE

4

1

Figure 4-3. Timer Assembly Removal / Installation

© Midmark 1994 SF-1418 Page 4-3 Printed in U.S.A.

5

SHAFT

LOCATOR PIN

2

MA2514-00

4

3

Figure 4-4. Timer Buzzer Removal / Installation

MA2515-00

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

4.6 Pilot Light Removal / Installation

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

(2) Disconnect two wires (1, Figure 4-5) from

terminals of pilot light (2).

NOTE

Pilot lights on older units do not have the four tabs.

These older pilot lights are held in by friction only or

by a retaining ring.

(3) Press in on four tabs of pilot light (2) while

simultaneously removing pilot light from front

panel (3).

3

T ABS

B. Installation

NOTE

Pilot lights on older units do not have the four tabs.

These older pilot lights are held in by friction only or

by a retaining ring.

(1) Push pilot light (2) into front panel (3) until it

pops into place.

(2) Connect two wires (1) to terminals of pilot

light (2).

(3) Install cover assembly (Refer to para 4.2).

4.7 Heating Element Removal / Installation

A. Removal

DANGER

!!

the sterilizers cover / panels or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

Always unplug the power cord from

the wall outlet before removing any of

1

2

3

T ABS

2

T ABS

Figure 4-5. Pilot Light Removal / Installation

MA2516-00

(1) Disconnect power cord from wall outlet.

(2) Unscrew drain (1, Figure 4-6) and drain all

water from condensing tank.

(3) Remove wire rack and trays (Refer to

para 4.20).

© Midmark 1994 SF-1418 Page 4-4 Printed in U.S.A.

(4) Lay unit onto its side.

(5) Remove two screws (2) and inspection cover

(3) from base (4).

(6) Taking care not to kink rod (5), flex rod and

remove it from rocker bracket (6).

8

Return To Table Of Contents

TERMINALS

SECTION IV

MAINTENANCE / SERVICE

(9) Remove two nuts (1, Figure 4-8), lockwashers

(2), and washers (3) from terminal posts of

heating element (4).

(10) Pull bracket (5) off of terminal posts of heating

element (4).

5

6

7

7

4

3

(11) Remove heating element (4) and spacer (6)

from inside of chamber.

(12) Remove one gasket (7) from each terminal post

of heating element (4).

3

4

TERMINAL

POST

4

2

2

1

1

Figure 4-6. Inspection Cover Removal / Installation

(7) Tag and disconnect four wires (7) from termi-

nals of heating element (8).

NOTE

Step 8 applies only to units which have an old style

heating element. Units with a new style heating

element have built in terminals.

(8) If unit has an old style heating element, remove

nut (1, Figure 4-7), two terminals (2), and nut

(3) from each terminal post of heating element

(4). Discard nuts and terminals - will receive

new style heating element.

© Midmark 1994 SF-1418 Page 4-5 Printed in U.S.A.

MA2517-00

MA2518-00

Figure 4-7. Removal Of Terminals From

Old Style Heating Element

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

B. Installation

(1) Install one gasket (7, Figure 4-8) on each

terminal post of heating element (4).

CAUTION

!!

to heating element or improper positioning of heating

element may result. Also, spacer must remain

above gaskets. If spacer is installed under gasket,

leaking will result.

Hold heating element firmly in position

while tightening nuts. Otherwise, damage

NOTE

Flat side of nut should be facing lockwasher.

(2) Install spacer (6) and heating element (4) on

chamber wall and secure with bracket (5), two

washers (3), lockwashers (2), and nuts (1).

(3) Connect four wires (7, Figure 4-6) to terminals

of heating element (8).

(4) Taking care not to kink rod (5), flex rod and

insert it into rocker bracket (6).

(5) Install inspection cover (3) on base (4) and

secure with two screws (2).

4

6

7

5

3

2

1

(6) Turn unit upright.

(7) Install wire rack and trays (Refer to para 4.20).

(8) Tighten drain (1).

(9) Connect power cord to wall outlet.

(10) Fill condensing tank with distilled or demineral-

ized water.

4.8 Overheat Thermostat Removal / Installation

A. Removal

DANGER

!!

the sterilizers cover / panels or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

Always unplug the power cord from

the wall outlet before removing any of

5

TERMINALS

4

MA2519-00

Figure 4-8. Heating Element Removal / Installation

(1) Disconnect power cord from wall outlet.

(2) Unscrew drain (1, Figure 4-9) and drain all

water from condensing tank.

© Midmark 1994 SF-1418 Page 4-6 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

7A

10

MANUAL-RESET

OVERHEAT

THERMOSTAT

8A

11

7A

14

13

9

AUTO-RESET

OVERHEAT

THERMOSTAT

5

7B

8B

14

13

7B

6

4

3

2

1

Figure 4-9. Overheat Thermostat Removal / Installation

(3) Remove wire rack and trays (Refer to

para 4.20).

(4) Lay unit onto its side.

(5) Remove two screws (2) and inspection cover

(3) from base (4).

(6) Taking care not to kink rod (5), flex rod and

remove it from rocker bracket (6).

NOTE

Only units with Serial Numbers CS5297 & RB14565

Thru Present also have auto-reset overheat thermostats.

MA251702

(7) If removing manual reset overheat thermostat

(8A), tag and disconnect two wires (7A) from

terminals of overheat thermostat (8A).

If removing auto-reset overheat thermostat

(8B), tag and disconnect two wires (7B) from

terminals of overheat thermostat (8B).

(8) Loosen two nuts (9) and partially separate

bracket (10) from chamber wall (11).

(9) Remove overheat thermostat (8A or 8B) from

bracket (10).

© Midmark 1994 SF-1418 Rev. 5/95 Page 4-7 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

B. Installation

(1) Install manual reset overheat thermostat (8A)

or auto-reset overheat thermostat (8B) on

bracket (10).

CAUTION

!!

to heating element or improper positioning of heating

element may result. Also, spacer must remain

above gaskets. If spacer is installed under gasket,

leaking will result.

(2) Position bracket (10) on chamber wall (11) and

(3) Connect two wires (7A) to terminals of manual

(4) Taking care not to kink rod (5), flex rod and

Hold heating element firmly in position

while tightening nuts. Otherwise, damage

secure by tightening two nuts (9), making sure

spacer (inside of chamber) is positioned under

heating element properly.

reset overheat thermostat (8A)

wires (7B) to terminals of auto-reset overheat

thermostat (8B).

insert it into rocker bracket (6).

or

connect two

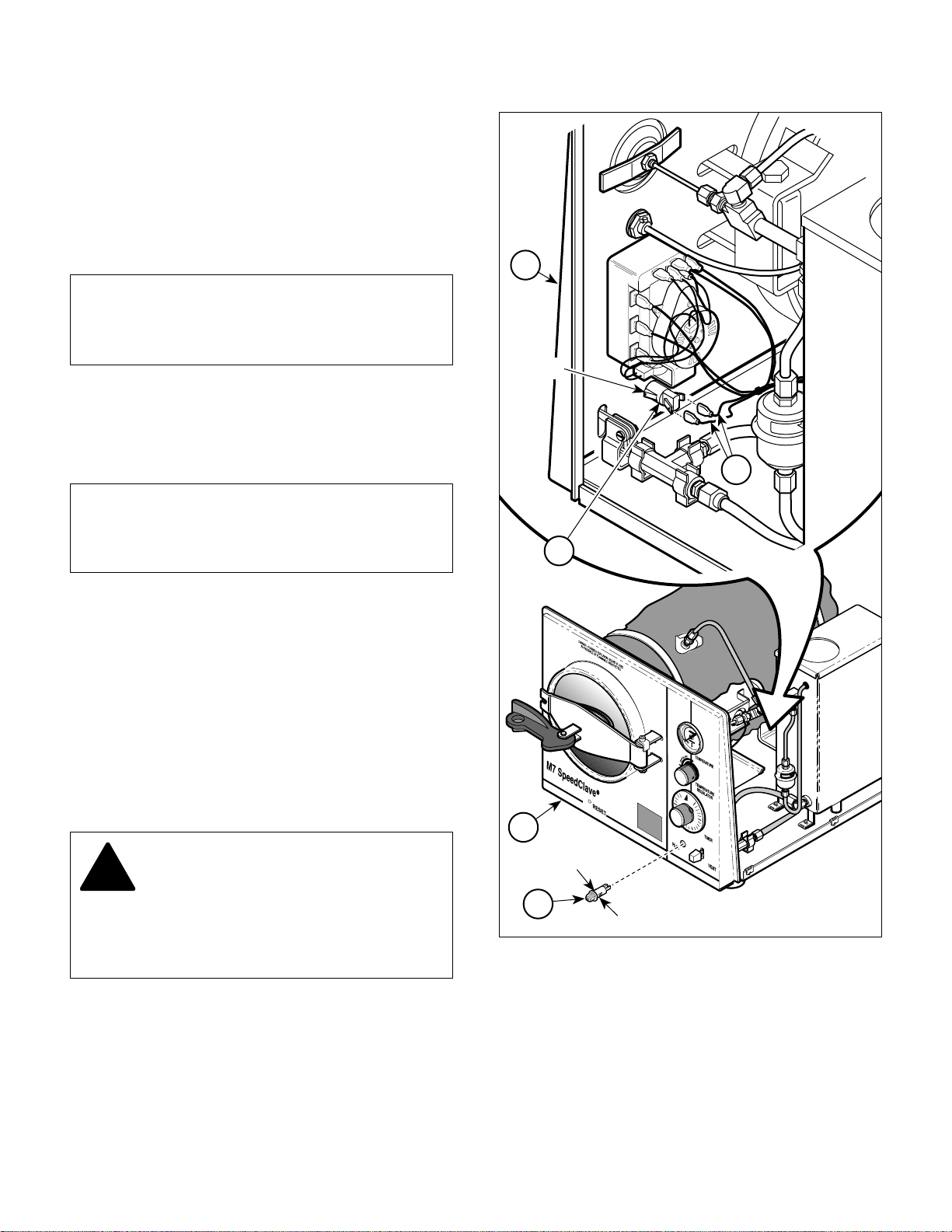

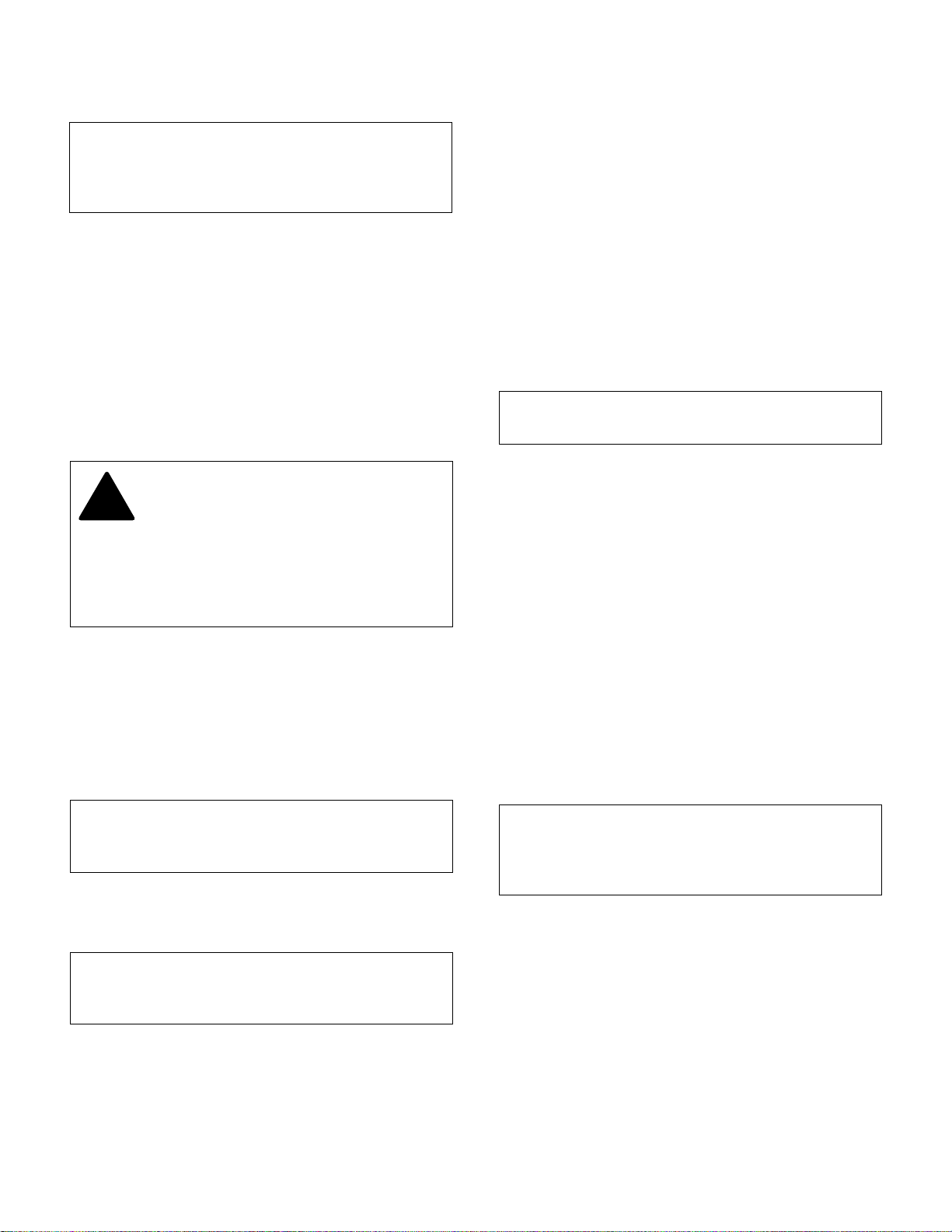

shaft assembly (2) is unscrewed from temperature regulator relay (3).

(4) Tag and disconnect one wire (4) from the timer

assembly (5) and one wire (6) from the heating

element (7).

NOTE

Relay spacer is not used on older 220 VAC units.

(5) Remove two screws (8A), one screw (8B),

temperature regulator relay (3), and relay

spacer (9) from relay bracket (10).

B. Installation

NOTE

Relay spacer is not used on older 220 VAC units.

Screw (8B) is used for adjustment and will be

installed later.

(1) Install relay spacer (9) and temperature regula-

tor relay (3) on relay bracket (10) and secure

with two screws (8A). Do not install screw (8B)

at this time.

(5) Install inspection cover (3) on base (4) and

secure with two screws (2).

(6) Turn unit upright.

(7) Install wire rack and trays (Refer to para 4.20).

(8) Tighten drain (1).

(9) Connect power cord to wall outlet.

(10) Fill condensing tank with distilled or demineral-

ized water.

4.9 Temperature Regulator Relay Removal / Installation

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

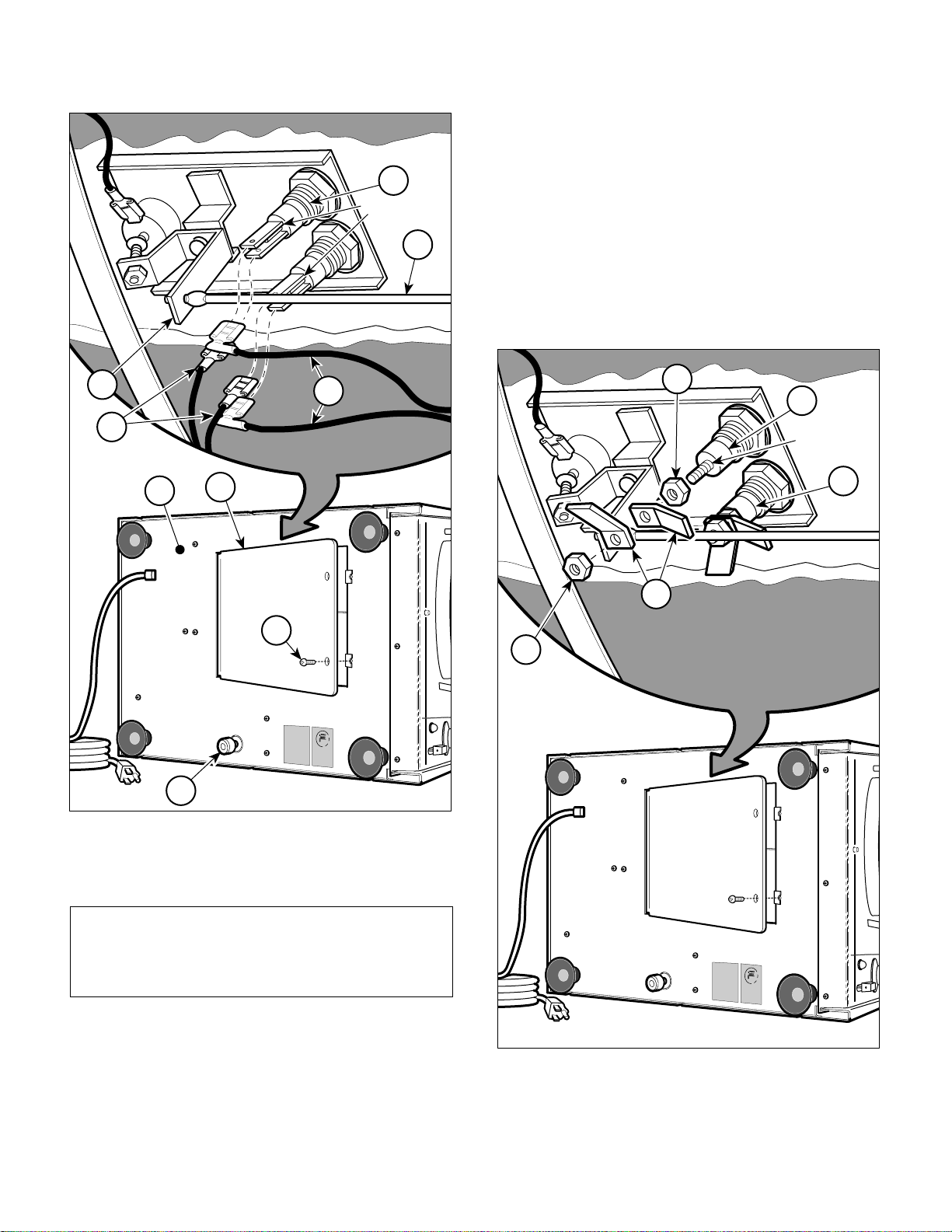

(2) Remove setscrew (1, Figure 4-10) from hub of

flexible shaft assembly (2).

(2) Connect one wire (6) to terminal of heating

element (7) and one wire (4) to terminal of timer

assembly (5).

(3) Adjust setscrew (11) until it is flush with relay

bracket (10).

(4) Coat threaded end of flexible shaft assembly

(2) with high temperature grease.

(5) Screw threaded end of flexible shaft assembly

(2) into temperature regulator relay (3) by

turning TEMPERATURE REGULATOR knob in

clockwise direction. Keep rotating TEMPERATURE REGULATOR knob in clockwise direction until flexible shaft assembly is screwed in

as far as possible.

(6) Rotate TEMPERATURE REGULATOR knob

1

1

/2 turns in a counterclockwise direction.

(7) Install setscrew (1) in hub of flexible shaft

assembly (2).

(3) Rotate TEMPERATURE REGULATOR knob in

a counterclockwise direction until the flexible

© Midmark 1994 SF-1418 Rev. 5/95 Page 4-8 Printed in U.S.A.

(8) Rotate TEMPERATURE REGULATOR knob in

a counterclockwise direction until it hits the

setscrew stop.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

1

HUB

2

5

4

3

TEMPERATURE

GAUGE

TEMPERATURE

REGULATOR

6

KNOB

TIMER

KNOB

WHITE INDEX

FILL / VENT

LEVER

Figure 4-10. Temperature Regulator Relay

MARK

7

Removal / Installation

3

12

8B

11

9

10

8A

2

MA2520-00

© Midmark 1994 SF-1418 Page 4-9 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

NOTE

Earlier units have only one setscrew securing the

TEMPERATURE REGULATOR knob while later

units have two.

(9) Making sure TEMPERATURE REGULATOR

knob is held against setscrew stop, loosen one/

two setscrews (12) in TEMPERATURE REGULATOR knob. Rotate TEMPERATURE REGULATOR knob until white index mark is at the

9:00 o'clock position, then tighten one/two

setscrews (12).

(10) Depress the FILL / VENT lever and allow the

water to fill the chamber until the water level is

within 1/2 - 5/8 in. (13 - 16 mm) from the front

rim of the chamber; then release the lever.

DANGER

!!

bly removed. Use extreme care to prevent

contact with exposed terminals and chamber

components. Failure to do so could result in

electrical shock or burns which could cause

serious personal injury or death.

(11) Plug the power cord into wall outlet.

The following steps require the unit to

be powered up with the cover assem-

(17) After adjustment is satisfactory, turn TIMER

knob to off and vent the chamber.

(18) Install cover assembly (Refer to para 4.2).

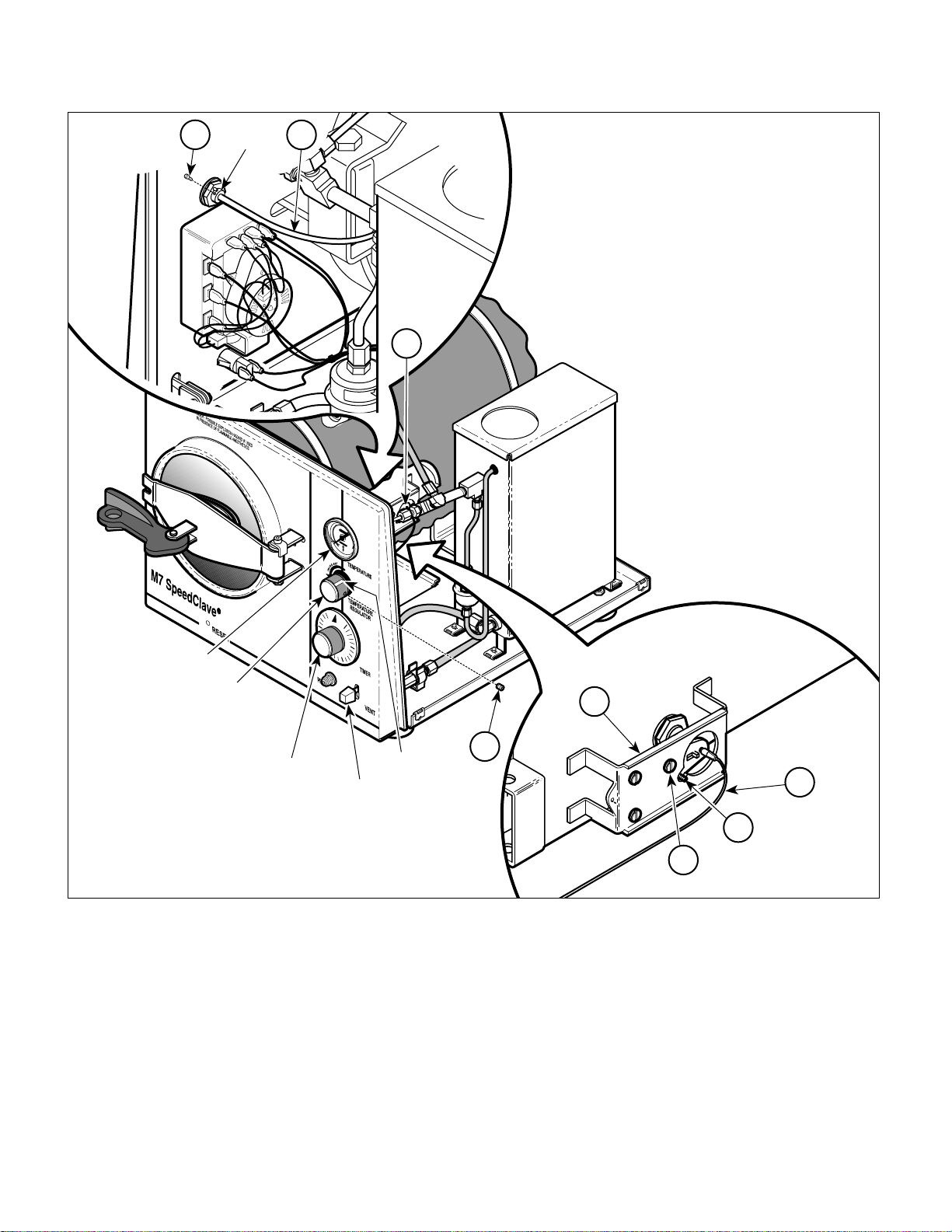

4.10 Temperature Regulator Relay Adjustment

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

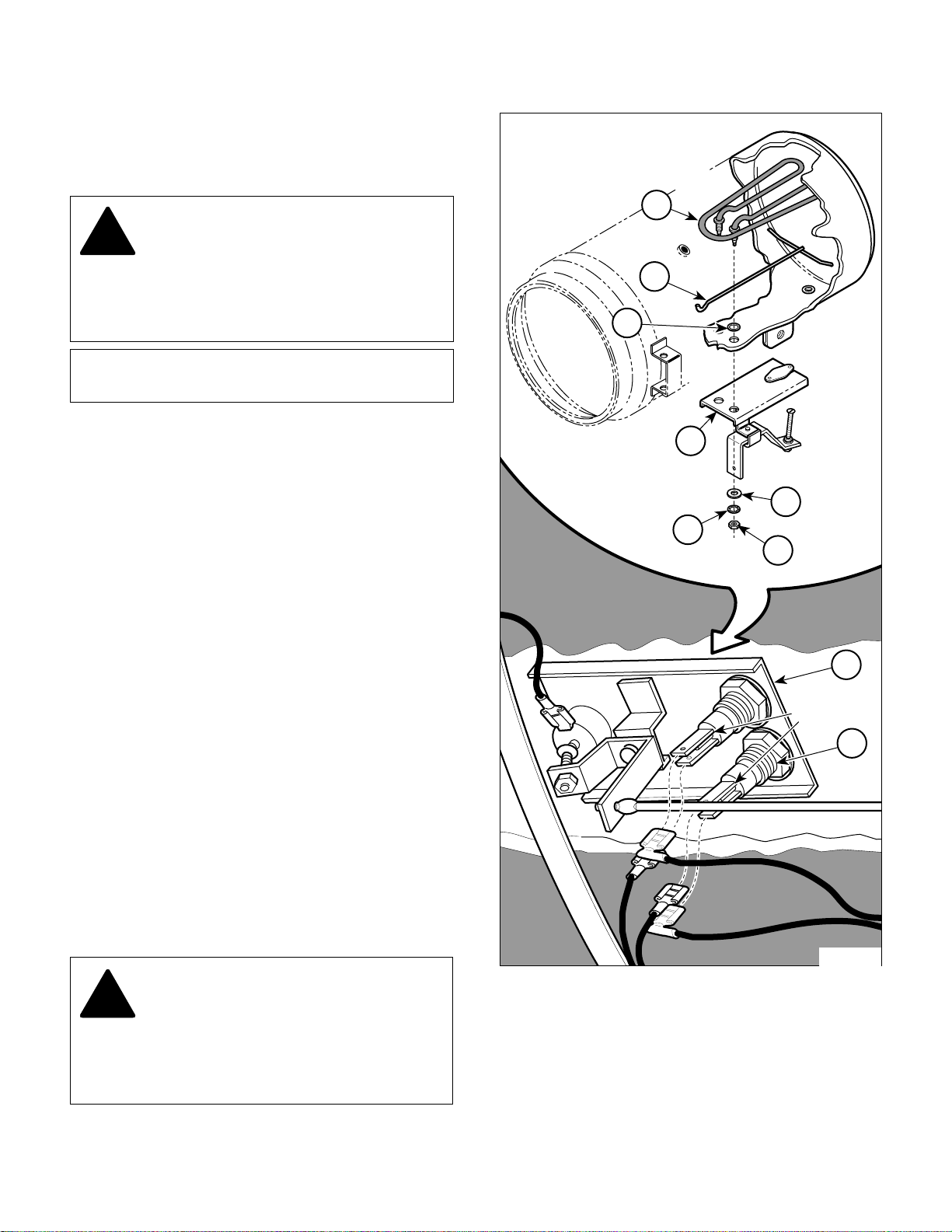

(2) Remove setscrew (1, Figure 4-11) from hub of

flexible shaft assembly (2).

NOTE

Relay spacer is not used on older 220 VAC units.

(3) Remove screw (3).

(4) Adjust setscrew (4) until it is flush with relay

bracket (5).

(5) Rotate TEMPERATURE REGULATOR knob in

clockwise direction until flexible shaft assembly

(2) is screwed in as far as possible.

(6) Rotate TEMPERATURE REGULATOR knob

1

1

/2 turns in a counterclockwise direction.

(12) Close and latch the door of the chamber.

(13) Set the TIMER knob to its maximum setting of

30 minutes.

(14) Unscrew setscrew (11) 2 to 3 turns.

NOTE

Wait until chamber temperature reaches its maximum temperature before attempting to adjust screw.

(15) Install screw (8B). Adjust screw until TEM-

PERATURE gauge reads slightly above 270 °F

(132 °C).

NOTE

Setscrew provides fine tuning of temperature adjustment.

(16) Adjust setscrew (11) until TEMPERATURE

gauge reads 270 - 271 °F (131.6 - 132.8 °C).

(7) Install setscrew (1) in hub of flexible shaft

assembly (2).

(8) Rotate TEMPERATURE REGULATOR knob in

a counterclockwise direction until it hits the

setscrew stop.

NOTE

Earlier units have only one setscrew securing the

TEMPERATURE REGULATOR knob while later

units have two.

(9) Making sure TEMPERATURE REGULATOR

knob is held against stop, loosen one/two

setscrew(s) (6) in TEMPERATURE REGULATOR knob. Rotate TEMPERATURE REGULATOR knob until white index mark is at the 9:00

o'clock position, then tighten one/two

setscrew(s) (6).

© Midmark 1994 SF-1418 Page 4-10 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

1

HUB

2

3

TEMPERATURE

(10) Depress the FILL / VENT lever and allow the

GAUGE

TEMPERATURE

REGULATOR

water to fill the chamber until the water level is

within 1/2 - 5/8 in. (13 - 16 mm) from the front

rim of the chamber; then release the lever.

KNOB

TIMER

KNOB

WHITE INDEX

FILL / VENT

LEVER

Figure 4-11. Temperature Regulator

Relay Adjustment

MARK

5

6

2

4

3

MA2521-01

© Midmark 1994 SF-1418 Page 4-11 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

DANGER

!!

bly removed. Use extreme care to prevent

contact with exposed terminals and chamber

components. Failure to do so could result in

electrical shock or burns which could cause

serious personal injury or death.

(11) Plug the power cord into wall outlet.

(12) Close and latch the door of the chamber.

(13) Set the TIMER knob to its maximum setting of

(14) Unscrew setscrew (4) 2 to 3 turns.

The following steps require the unit to

be powered up with the cover assem-

30 minutes.

NOTE

Wait until chamber temperature reaches as high as it

is going to go before attempting to adjust.

(4) Remove nut (1, Figure 4-12), lockwasher (2),

and diaphragm cup (3) from chamber wall (4).

(5) Remove gasket (5) from diaphragm cup (3).

B. Installation

(1) Install gasket (5) on diaphragm cup (3).

CAUTION

!!

(2) Install diaphragm cup (3) on chamber wall (4)

(3) Install wire rack and trays (Refer to para 4.20).

(4) Install temperature regulator relay (Refer to

(5) Install cover assembly (Refer to para 4.2).

The lip of the nut must face toward the

lockwasher.

and secure with lockwasher (2) and nut (1).

para 4.9).

(15) Install screw (3). Adjust screw until TEMPERA-

TURE gauge reads slightly above 270 °F

(132 °C).

NOTE

Setscrew provides fine tuning of temperature adjustment.

(16) Adjust setscrew (4) until TEMPERATURE

gauge reads 270 - 271 °F (131.6 - 132.8 °C).

(17) After adjustment is satisfactory, turn TIMER

knob to off and vent the chamber.

(18) Install cover assembly (Refer to para 4.2).

4.11 Diaphragm Cup Removal / Installation

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

(2) Remove wire rack and trays (Refer to

para 4.20).

4.12 Temperature Gauge Removal / Installation

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

(2) Loosen nut (1, Figure 4-13) and slide retaining

bar (2) away from front panel (3).

1

LIP

2

4

3

5

MA2522-00

(3) Remove temperature regulator relay (Refer to

para 4.9).

© Midmark 1994 SF-1418 Page 4-12 Printed in U.S.A.

Figure 4-12. Diaphragm Cup Removal / Installation

3

Return To Table Of Contents

5

4

1

7

2

6

Figure 4-13. Temperature Gauge

Removal / Installation

(3) While holding connector (4), loosen compres-

sion nut (5).

MA2523-00

SECTION IV

MAINTENANCE / SERVICE

4.13 Pressure Relief Valve Removal /

Installation

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

NOTE

There may be a strip of tape holding the tank cover

on to prevent the tank cover from vibrating and

making noise.

(2) Remove tank cover (1, Figure 4-14) from tank

assembly (2).

NOTE

The pressure relief valve can be mounted to tee (4)

in two different locations depending if it is an old style

or new style unit.

(3) Remove pressure relief valve (3) from tee (4).

(4) Pull temperature gauge (6) out of connec-

tor (4).

(5) Remove thermometer sleeve (7), compression

nut (5), nut (1), and retaining bar (2) from

temperature gauge (6).

B. Installation

(1) Install retaining bar (2), nut (1), compression

nut (5), and thermometer sleeve (7) on temperature gauge (6).

(2) Making sure temperature gauge is oriented

properly so face of gauge can be read by

operator, position temperature gauge (6) on

front panel (3) and secure with retaining bar (2)

and nut (1).

(3) Slide thermometer sleeve (7) against connec-

tor (4).

(4) Install compression nut (5) on connector (4).

Tighten compression nut until thermometer

sleeve just starts to protrude out back side of

compression nut. Do not tighten any further.

B. Installation

(1) Coat threads of pressure relief valve (3) with

Teflon tape / sealant.

(2) Install pressure relief valve (3) on tee (4).

(3) Install tank cover (1) on tank assembly (2).

(4) Install cover assembly (Refer to para 4.2).

NOTE

The pressure relief valve is designed to open at 31

psi / 275 °F (135 °C).

(5) With the TEMPERATURE REGULATOR knob

set to its maximum setting, run a cycle. The

temperature should reach normal maximum

pressure / temperature of 27 psi / 270 °F (132

°C). If not, it indicates that the pressure relief

valve is opening too early.

(5) Install cover assembly (Refer to para 4.2).

© Midmark 1994 SF-1418 Page 4-13 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

1

4.14 Bellows Assembly Removal Installation (Applies to Units With Serial

Numbers CR-1114, RB-7194, CS1570, And CP-1062 Thru Present)

A. Removal

OLD STYLE

(1) Remove cover assembly (Refer to para 4.2).

DANGER

3

2

!!

Failure to do so could result in serious injury or

burns.

(2) Using a wrench on bellows nuts to hold bellows

Make sure unit is vented and cool

before attempting to make repairs.

assembly (1, Figure 4-15) stationary, loosen

and disconnect compression nuts (2 and 3).

4

(3) Remove bellows assembly (1) from tubes (4).

B. Installation

NEW STYLE

(1) Position bellows assembly (1) on tubes (4),

making sure flow arrow is pointing toward

compression nut (3).

1

4

2

BELLOWS

NUT

2

1

4

ARROW

BELLOWS

NUT

4

3

3

MA2540-00

Figure 4-14. Pressure Relief Valve

Removal / Installation

© Midmark 1994 SF-1418 Page 4-14 Printed in U.S.A.

Figure 4-15. Bellows Assembly

Removal / Installation

MA2524-00

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

(2) Using a wrench on bellows nuts to hold bellows

assembly (1) stationary, screw compression

nuts (2 and 3) onto bellows assembly.

(3) Install cover assembly (Refer to para 4.2).

4.15 Bellows Assembly Removal / Installation (Applies To Units With Serial

Numbers CP-1000 Thru CP-1061,

CR-1000 Thru CR-1113, CS-1000

Thru CS-1569, And RB-1000 Thru

RB-7193)

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

DANGER

!!

Failure to do so could result in serious injury or

burns.

Make sure unit is vented and cool

before attempting to make repairs.

NOTE

There may be a strip of tape holding the tank cover

on to prevent the tank cover from vibrating and

making noise.

(3) Install tank cover (1) on tank assembly (2).

(4) Install cover assembly (Refer to para 4.2).

1

BELLOWS

NUT

FLOW

ARROW

2

4

3

(2) Remove tank cover (1, Figure 4-16) from tank

assembly (2).

(3) Using a wrench on bellows nut to hold bellows

assembly (3) stationary, loosen and disconnect

compression nut (4).

(4) Remove bellows assembly (3) from tube (5).

B. Installation

(1) Position bellows assembly (3) on tube (5),

making sure flow arrow is pointing away from

compression nut (4).

(2) Using a wrench on bellows nut to hold bellows

assembly (3) stationary, screw compression

nut (4) onto bellows assembly.

5

MA2534-01

Figure 4-16. Bellows Assembly

Removal / Installation

© Midmark 1994 SF-1418 Page 4-15 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

4.16 Bellows Assembly Removal / Installation (Sybron Units)

NOTE

Older units which do not have a Serial Number prefix

of CP-xxxx, CR-xxxx, CS-xxxx, or RB-xxxx were

manufactured by Sybron Corp and not by Midmark.

However, a retrofit kit for the bellows assembly is

available. If the unit has already been retrofitted with

a Midmark style bellows, perform para 4.15.

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

DANGER

!!

Failure to do so could result in serious injury or

burns.

(2) Remove tank cover (1, Figure 4-17) from tank

Make sure unit is vented and cool

before attempting to make repairs.

assembly (2).

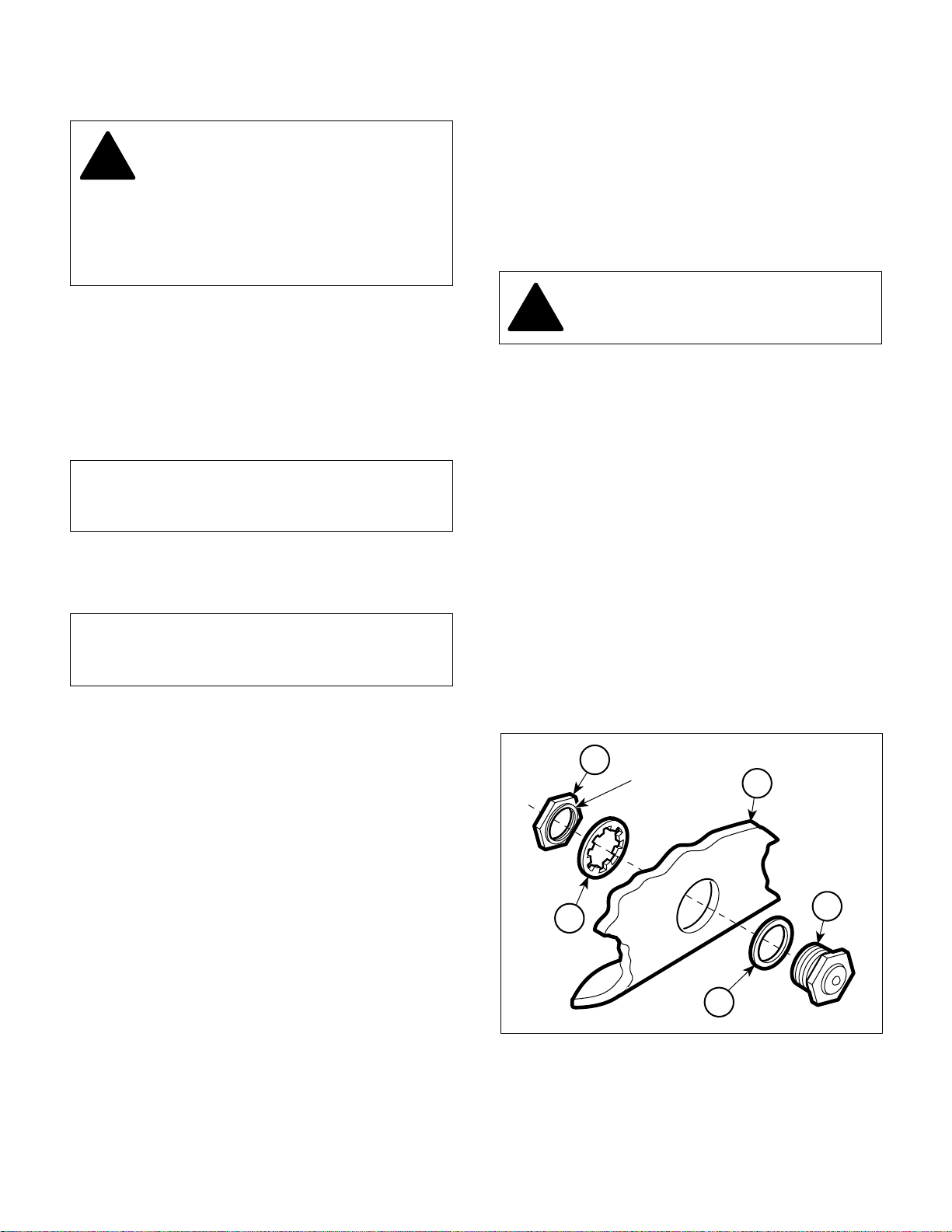

REMOVAL

4

1

3

2

6

5

INSTALLATION

(3) Loosen compression nut (3) and remove

bellows assembly (4) from male connector (5).

(4) Remove male connector (5) from tee (6).

B. Installation

(1) Coat threads of largest elbow in elbow assem-

bly (7) with Teflon tape / sealant.

(2) Install elbow assembly (7) on tee (6).

(3) Install compression nut (8) and compression

sleeve (9) on tube of bellows assembly (10).

(4) Connect tube of bellows assembly (10) to

elbow assembly (7) by screwing compression

nut (9) onto elbow assembly (7).

(5) Install tank cover (1) on tank assembly (2).

(6) Install cover assembly (Refer to para 4.2).

10

1

9

8

TUBE

2

6

© Midmark 1994 SF-1418 Page 4-16 Printed in U.S.A.

7

Figure 4-17. Bellows Assembly

Removal / Installation

MA2539-00

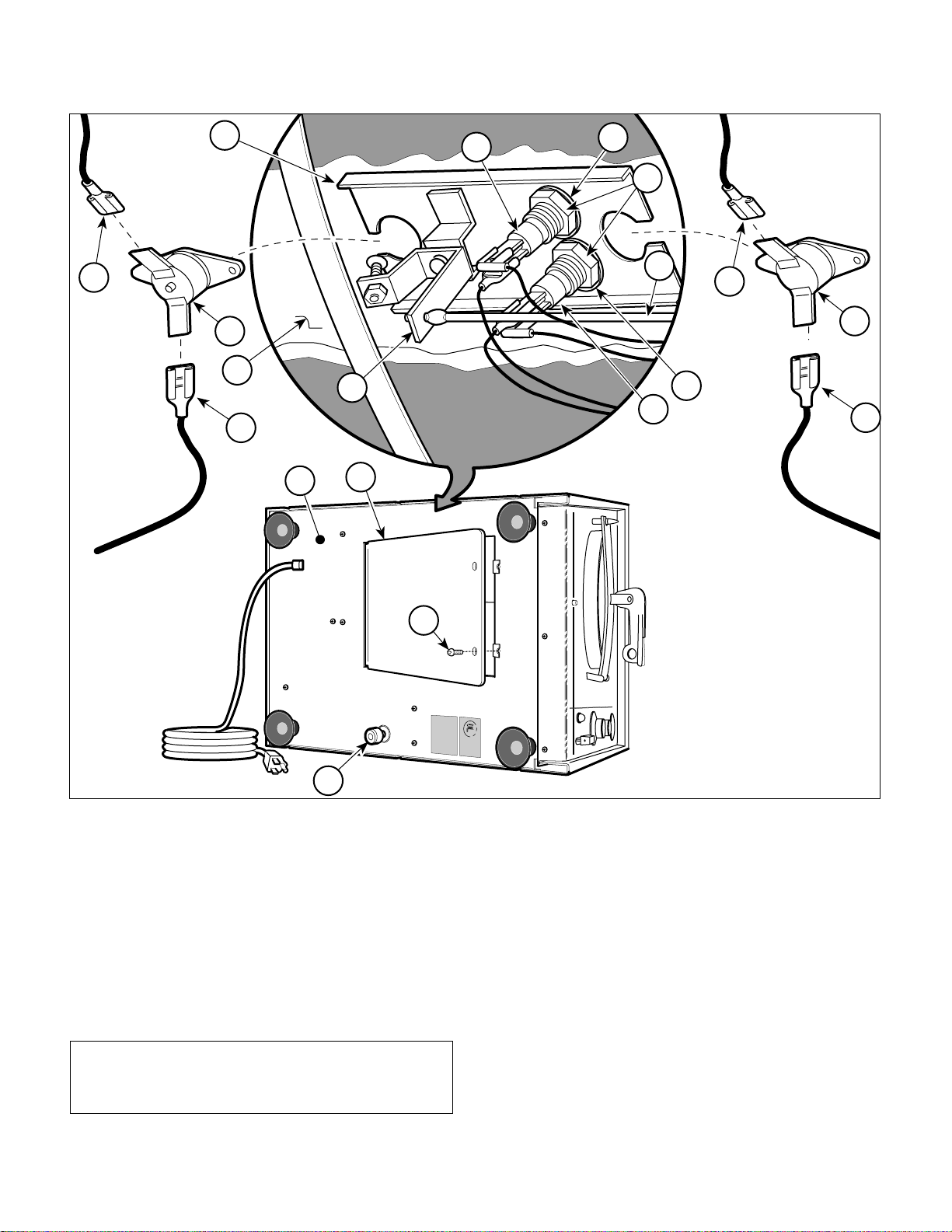

4.17 Fill / Vent Valve Removal /

Return To Table Of Contents

Installation

SECTION IV

MAINTENANCE / SERVICE

DISTANCE "A"

A. Removal

(1) Remove cover assembly (Refer to para 4.2).

DANGER

!!

Failure to do so could result in serious injury or

burns.

(2) Loosen and disconnect two compression nuts

(3) Disengage closing bracket of fill / vent valve

B. Disassembly

(1) Remove fitting (1, Figure 4-19) from valve

Make sure unit is vented and cool

before attempting to make repairs.

(1, Figure 4-18) from fittings of fill / vent valve

assembly (2).

assembly (2) from fill / vent lever (3) by lifting

up on back end of fill / vent valve assembly first

and then pulling it out of brackets (4).

body (2).

1

2

5

4

3

2

8

5

1

6

7

2

3

4

Figure 4-19. Fill / Vent Valve Assembly

Disassembly / Assembly

5

(2) While holding nut (3) stationary, unscrew

closing bracket (4) from plunger (5).

(3) Remove nut (3) and spring (6) from

plunger (5).

MA2526-00

CLOSING

BRACKET

Figure 4-18. Fill / Vent Valve Removal / Installation

© Midmark 1994 SF-1418 Page 4-17 Printed in U.S.A.

(4) Push plunger (5) out of valve body (2).

(5) Remove two o-rings (7 and 8) from plunger (5).

C. Assembly

(1) Flush all foreign matter out of valve body (2)

and off of all components with water.

(2) Coat o-rings (7 and 8) with high temperature

4

lubricant.

(3) Install o-rings (7 and 8) on plunger (5).

3

MA2525-00

(4) Insert plunger (5) into valve body (2).

SECTION IV

!

Return To Table Of Contents

MAINTENANCE / SERVICE

(5) Install spring (6), nut (3), and closing bracket (4)

on plunger (5).

NOTE

The back side of the plunger has a screwdriver slot /

allen wrench to assist in adjusting the closing bracket

and nut.

(6) Adjust closing bracket (4) until Distance A is

approximately 3/16 to 1/4 in. (0.47 to 0.63 cm).

Secure closing bracket in position by tightening

nut (3) against closing bracket.

(7) Coat threads of fitting (1) with Teflon tape /

sealant.

(8) Install fitting (1) on valve body (2).

D. Installation

(1) Install fill / vent valve assembly (2, Figure 4-18)

in brackets (4), making sure fill / vent lever (3)

is inserted in slot of closing bracket.

3

4

6

5

1

2

(2) Position tubes (5) and screw compression nuts

(1) onto fittings of fill / vent valve assembly (2).

(3) Install cover assembly (Refer to para 4.2).

(4) Test operation of fill / vent valve. If water will

not flow or flows very slowly when fill / vent

lever is depressed, lengthen Distance A slightly.

See Figure 4-19.

4.18 Door Assembly Removal /

Installation

A. Removal

DANGER

Make sure unit is vented and cool

before attempting to make repairs.

Failure to do so could result in serious injury or

burns.

(1) Open door handle (1, Figure 4-20) to the un-

latched position.

(2) Remove torque nut (2), screw (3), door stop (4),

and door assembly (5) from hinge (6).

MA2527-00

Figure 4-20. Door Assembly

Removal / Installation

B. Disassembly

NOTE

Washer (2) is held on by removable threadlocking

adhesive (Loctite 242) and may be difficult to remove.

Pull on door to dislodge washer.

(1) Remove cap nut (1, Figure 4-21), washer (2),

and door (3) from T-bolt (4).

(2) Remove short spring (5) and long spring (6) from

T-bolt (4).

(3) Remove retaining ring (7), pin (8), handle (9),

and door cross arm (10) from U-bracket (11).

(4) Remove T-bolt (4) from U-bracket (11).

© Midmark 1994 SF-1418 Rev 10/06 Page 4-18 Printed in U.S.A.

SECTION IV

!

Return To Table Of Contents

MAINTENANCE / SERVICE

5

6

8

4

9

7

Figure 4-21. Door Assembly

Disassembly / Assembly

C. Assembly

(1) Install T-bolt (4) into U-bracket (11).

1

3

2

NOTE

Do not overtighten torque nut or door assembly may

be hard to open and close.

(2) Install door assembly (5) on hinge (6) and

secure with door stop (4), screw (3), and

torque nut (2).

4.19 Door Gasket Removal / Installation

A. Removal

11

10

MA2528-00

Failure to do so could result in serious injury or

burns.

(1) Open the door assembly.

(2) Pry door gasket (1, Figure 4-22) out of gasket

DANGER

Make sure unit is vented and cool

before attempting to make repairs.

channel of chamber (2).

(2) Coat bottom face of washer (2) and threads of

T-bolt (4) with removable threadlocking adhesive.

NOTE

Door must be installed so that bowed portions of door

are on top and bottom; not on the sides.

It may be necessary to place U-bracket in vise in

order to tighten cap nut.

(3) Install long spring (6), short spring (5), and door

(3) on T-bolt (4) and secure with washer (2) and

cap nut (1).

(4) Install door cross arm (10) and handle (9) on U-

bracket (11) and secure with pin (8) and retaining ring (7).

D. Installation

(1) Coat threads of torque nut (2) with removable

threadlocking adhesive (Loctite 242).

2

GASKET

CHANNEL

DOOR

ASSEMBLY

1

MA2529-00

Figure 4-22. Door Gasket Removal / Installation

© Midmark 1994 SF-1418 Page 4-19 Printed in U.S.A.

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

B. Installation

(1) Using a hard bristle brush, clean all foreign

matter from gasket channel of chamber (2).

(2) Lubricate door gasket (1) and gasket channel

of chamber with soapy water or liquid detergent.

(3) Using fingers, push door gasket (1) into gasket

channel of chamber (2).

(4) Run a cycle to seat door gasket. Refer to

Operator Manual if necessary.

4.20 Wire Rack And Trays Removal /

Installation

A. Removal

DANGER

!!

Failure to do so could result in serious injury or

burns.

Make sure unit is vented and cool

before attempting to make repairs.

SLOT

2

3

1

(1) Remove three trays (1, Figure 4-23) from wire

rack (2).

(2) Lift up on left edge of rack base plate (3) until

rack base plate "pops" free of wire rack (2).

(3) While holding rack base plate (3) in a vertical

position, squeeze bottom of wire rack (2)

together and remove it from chamber.

B. Installation

(1) While holding rack base plate (3) in a vertical

position, squeeze the bottom of the wire rack

(2) together and insert it into chamber.

NOTE

There are two slots on the left edge of the rack base